Designing Predictive Analytics Frameworks for Supply Chain Quality Management: A Machine Learning Approach to Defect Rate Optimization

Abstract

:1. Introduction

Key Supply Chain Metrics

- Defect rate (DR) presents the percentage of defective products or services within the supply chain output. Its importance comes from high defect rates directly impacting customer satisfaction and operational costs. Predictive analytics reduce DR by identifying and addressing root causes proactively [6].

- Cost Efficiency (CE): the balance between total supply chain expenditure and output quality. It is the reduction in operational inefficiencies, achieved through predictive analytics, that leads to significant cost savings [7].

- Lead Time (LT): the time taken from order placement to product delivery. The importance of reducing lead times indicates improved supply chain agility and responsiveness to demand fluctuations [8].

- Return on Investment (ROI): the financial return generated relative to the costs invested in supply chain improvements. The importance is that ROI serves as a key indicator of the economic feasibility of adopting advanced predictive models [9].

- Customer Satisfaction (CS): a measure of how well supply chain outputs meet customer expectations. The importance is to improve defect rates and lead times, translating directly into higher satisfaction levels [10].

- -

- Suppliers impact lead time and defect rate through raw material quality and delivery consistency [11].

- -

- Manufacturers affect defect rates and cost efficiency through production processes [12].

- -

- Distributors and retailers influence customer satisfaction and lead time via distribution efficiency and service quality [5].

- Leverages predictive analytics to reduce defect rates and enhance operational efficiency in SCM.

- Optimizes resource allocation and strengthens supplier relationships through data-driven insights.

- Quantifies the impact of quality control improvements on ROI and cost reduction.

- To explore the use of historical data and machine learning algorithms for defect rate prediction.

- To design and implement an ensemble model that integrates multiple ML techniques for quality control optimization.

- To assess the effectiveness of the proposed framework in reducing associated costs and enhancing ROI in SCM operations.

- How does the integration of machine learning algorithms, such as random forest, support vector machine, and XGBoost, contribute to reducing defect rates in supply chain management?

- What is the quantifiable impact of machine learning-driven optimization on key performance indicators like ROI and cost reduction within SCM?

2. Related Work

- Quality Management: A comprehensive approach to overseeing all activities and tasks necessary to maintain product and service quality at desired levels. It includes strategic planning, continuous improvement initiatives, and ensuring compliance with quality standards (ISO 9001:2015) [42].

- Quality Control: A subset of quality management that focuses on the operational execution of quality assurance processes. It involves monitoring, inspecting, and testing products to identify and address defects [14].

3. Materials and Methods

3.1. Dataset Selection and Characteristics

- Production Stages: Detailed tracking of different stages in the manufacturing process.

- Defect Types and Frequencies: Data on the occurrence of various defect categories.

- Supply Chain Metrics: Lead times, order fulfillment rates, and delivery delays.

- Cost Analysis: Financial records linking defect rates to associated costs and ROI.

- Utilizing historical defect occurrences to anticipate in reducing rework costs and improving quality control.

- Linking defect rates to financial outcomes, ensuring that quality management interventions yield a positive ROI.

- Applying predictive models to such supply chain disruptions, enabling ML-data-driven risk mitigation.

- Capturing essential supply chain relationships between defect rates, and logistic efficiency, making it relevant for other supply chain applications.

- Facilitating predictive analysis of key performance metrics, allowing businesses to simulate and refine defect reduction and quality improvement strategies.

3.2. Data Preprocessing

- Data Cleaning: Identified and rectified missing values using imputation techniques and normalized feature scales to maintain uniformity. Python libraries such as pandas and scikit-learn were employed.

- Feature Normalization: Min-max scaling was applied to normalize numerical features to a [0, 1] range for improved model convergence.

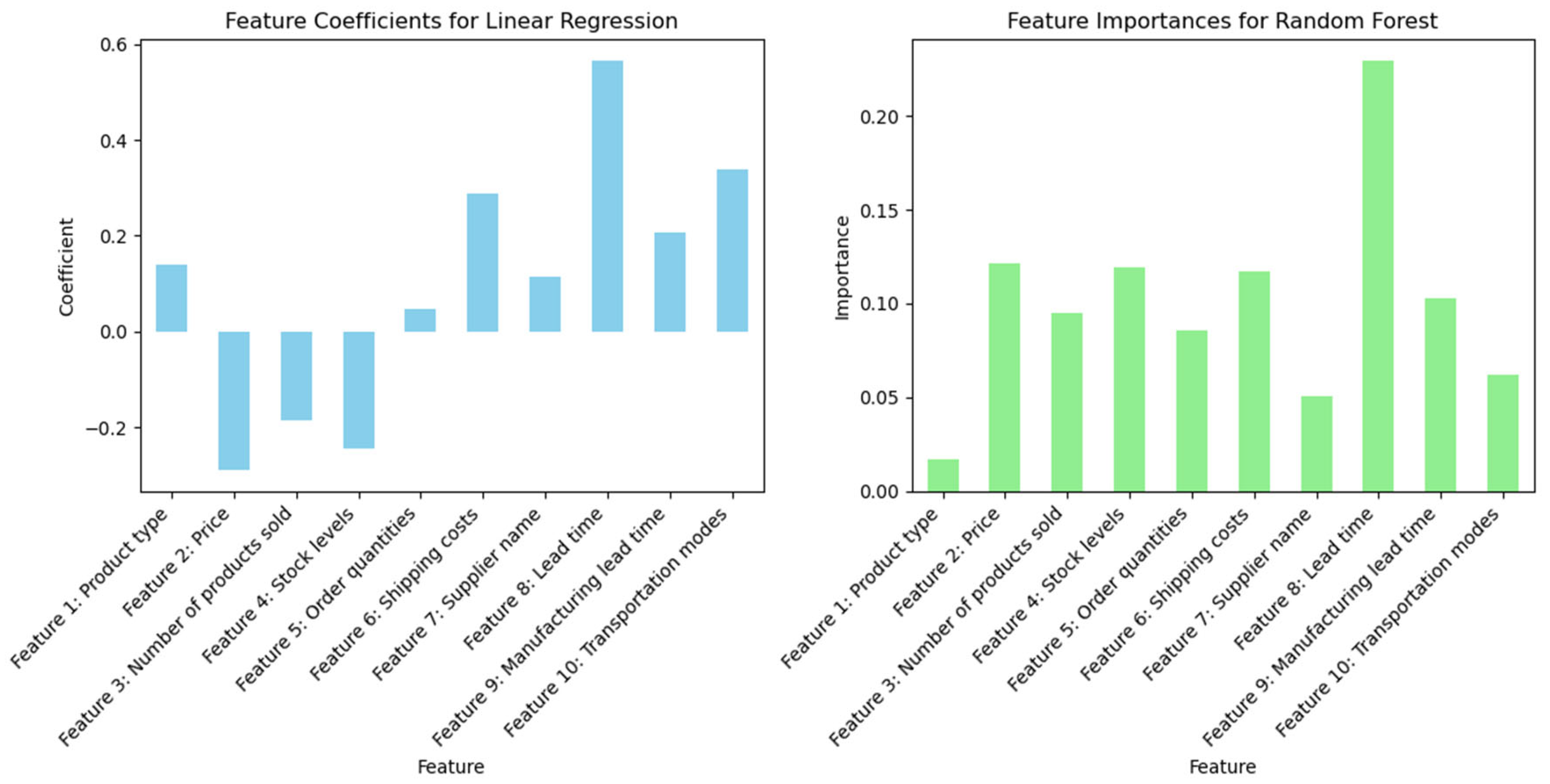

Feature Selection

- -

- Algorithms Compared: Random forest and linear regression were tested, as illustrated in Figure 1.

- -

- Performance Metric: Mean squared error (MSE) was used to evaluate feature selection effectiveness. Random forest outperformed linear regression, achieving an MSE of 2.4028 compared to 2.6781.

- -

- Key Features Identified: Features such as lead time, price, number of products sold, and stock levels were deemed most impactful.

3.3. Prediction Models

- Combined Model: Utilizing RF and SVM predictions using the simple averaging technique.

- Ensemble Model: Integrated RF, SVM, and XGBoost predictions using the VotingRegressor technique, which calculates weighted averages of individual model outputs to enhance accuracy.

3.3.1. Algorithm Design

- ○

- SVM Prediction:

- The decision function of an SVM can be represented as follows:

- is the decision function.

- is the weight vector.

- is the input feature vector.

- is the bias term.

- is the sign function that determines the class label based on the sign of the expression.

- ○

- Random Forest Prediction:

- is the predicted class label.

- is the prediction of the tth decision tree.

- represents the input features.

- Mode is the most frequent prediction among all trees.

| Algorithm 1: The arithmetic pseudo code for the combined model | |

| 1. | Description: Combine the predictions from SVM and RF |

| 2. | Input: SVM_predictions, RF_Predictions |

| 3. | Output: Combined_predictions |

| 4. 5. 6. 7. 8. 9. 10. | Procedure: |

3.3.2. Ensemble Learning

- (n) is the number of samples.

- is the loss function that measures the difference between the predicted and actual values .

- T is the total number of trees in the ensemble.

- Ω (fk) is a regularization term that penalizes complex models to prevent over-fitting.

- i represents each individual sample in the dataset (from 1 to n).

- is the actual target value (ground truth) for the ith sample.

- is the prediction made by the XGBoost model at iteration t for the ith sample.

- k represents each individual tree in the ensemble (from 1 to T).

- fk represents the kth tree in the ensemble.

- Ω(fk) is a regularization term applied to the kth tree to control its complexity.

| Algorithm 2: The pseudo code for the ensemble model | |

| 1. | Description: Pseudocode for Ensemble Prediction Using Majority Voting |

| 2. | Input: SVM_Prediction, RF_Predictions, XGboost_predictions |

| 3. | Output: y’: Final prediction vector using majority voting |

| 4. | Procedure: |

| 5. 6. 7. 8. 9. 10. | |

3.3.3. Validation Technique

- K-Fold Cross-Validation:

- Process: The dataset was split into k = 10k folds. Models were trained on k − 1 folds and validated on the remaining fold.

- Performance Metrics: MSE values were averaged across folds to evaluate generalization.

3.4. ROI Framework for Quality Control Optimization

- Cost Impact Assessment: Using defect rate predictions, the financial impact of defects was quantified under scenarios with and without predictive models.

- ROI Calculation: The return on investment (ROI) was computed as follows:

4. Results

4.1. Predictive Model Performance

- Mean Squared Error (MSE): The ensemble model exhibited a significantly lower MSE compared to the combined model, as shown in Figure 2.

- Accuracy: Both models achieved high accuracy; however, the ensemble model was slightly more precise, affirming its reliability for operational quality predictions.

- Error Distribution: The histograms in Figure 3 illustrate the narrower error range for the ensemble and combined models, in order to indicate the distribution of prediction error and evaluate their performance.

4.2. Quality Control’s Impact on ROI

- Cost Reduction: Historical data analysis revealed inefficiencies and bottlenecks, enabling targeted interventions. Without predictive analytics, total defect-associated costs stood at 19.55. These were reduced to 2.89 when predictive models were applied, achieving a net benefit of 16.66.

- ROI Analysis:

- ○

- Ensemble Model ROI: Achieved 82.21%, reflecting its efficiency in reducing defect rates while optimizing operational costs.

4.3. Interpretation for Business Applications

- Cost Savings: By accurately predicting defect rates, businesses can minimize rework, warranty claims, and returns. For instance, a fashion retailer could reduce inventory waste caused by defective or slow-moving stock.

- Enhanced Decision Making: Predictive insights generated by the framework empower supply chain managers to allocate resources more efficiently, such as prioritizing quality checks for high-risk products or vendors.

4.4. Actionable Insights for Managers

- Supplier Optimization: Insights from the framework help identify underperforming suppliers, enabling businesses to renegotiate contracts, improve supplier relationships, or source from alternative vendors.

- ROI-Driven Investments: The demonstrated cost savings and defect reduction provide a clear case for investing in AI-driven quality control systems. Managers can use these insights to justify budget allocations for machine learning tools and training.

4.5. Long-Term Implications for Business Strategy

- Sustainability: Reducing defects and waste contributes to more sustainable supply chain practices, aligning with global trends toward environmental responsibility.

- Agility: The framework equips businesses with the predictive tools needed to adapt to market fluctuations and unforeseen disruptions, such as supply chain shocks or changes in consumer demand.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mosteanu, N.R.; Faccia, A.; Ansari, A.; Shamout, M.D.; Capitanio, F. Sustainability integration in supply chain management through systematic literature review. Qual.-Access Success 2020, 21, 117–123. [Google Scholar]

- Bhattacharya, S.; Govindan, K.; Dastidar, S.G.; Sharma, P. Applications of artificial intelligence in closed-loop supply chains: Systematic literature review and future research agenda. Transp. Res. Part E Logist. Transp. Rev. 2024, 184, 103455. [Google Scholar]

- Sinha, N.; Garg, A.K.; Dhall, N. Effect of TQM principles on performance of Indian SMEs: The case of automotive supply chain. TQM J. 2016, 28, 338–359. [Google Scholar]

- Jum’a, L.; Alkalha, Z.; Alaraj, M. Towards environmental sustainability: The nexus between green supply chain management, total quality management, and environmental management practices. Int. J. Qual. Reliab. Manag. 2024, 41, 1209–1234. [Google Scholar]

- Jia, F.; Zuluaga-Cardona, L.; Bailey, A.; Rueda, X. Sustainable supply chain management in developing countries: An analysis of the literature. J. Clean. Prod. 2018, 189, 263–278. [Google Scholar]

- Oliveira, R.; Sampaio, P.; Cubo, C.; Carvalho, M.S.; Fernandes, A.C. Defining the supply chain quality management concept. In Handbook of Research Methods for Supply Chain Management; Edward Elgar Publishing: Cheltenham, UK, 2022. [Google Scholar]

- Li, G. Supply Chain Efficiency and Effectiveness Management Using Decision Support Systems. Int. J. Inf. Syst. Supply Chain. Manag. 2022, 15, 1–18. [Google Scholar]

- Tiedemann, F.; Wikner, J.; Johansson, E. Understanding lead-time implications for financial performance: A qualitative study. J. Manuf. Technol. Manag. 2021, 32, 183–207. [Google Scholar] [CrossRef]

- Kouvelis, P.; Qiu, Y. Financing Inventories with an Investment Efficiency Objective: ROI-Maximizing Newsvendor, Bank Loans and Trade Credit Contracts. Soc. Sci. Res. Netw. 2021, 60, 136–161. [Google Scholar] [CrossRef]

- Nagy-Bota, S.; Moldovan, L.; Nagy-Bota, M.C.; Varga, I.E. Mathematical Models Used in the Optimizations of Supply Chains. Acta Marisiensis 2023, 20, 27–31. [Google Scholar]

- Jahin, M.A.; Shovon MS, H.; Shin, J.; Ridoy, I.A.; Mridha, M.F. Big Data—Supply Chain Management Framework for Forecasting: Data Preprocessing and Machine Learning Techniques. Arch. Comput. Methods Eng. 2024, 31, 3619–3645. [Google Scholar]

- Wang, J.; Zheng, R.; Wang, Z. Supply Chain Optimization Strategy Research Based on Deep Learning Algorithm. Mob. Inf. Syst. 2022, 2022, 9058490. [Google Scholar]

- Patil, A.; Dwivedi, A.; Moktadir, M.A. Big data-Industry 4.0 readiness factors for sustainable supply chain management: Towards circularity. Comput. Ind. Eng. 2023, 178, 109109. [Google Scholar]

- Wang, F.; Aviles, J. Enhancing Operational Efficiency: Integrating Machine Learning Predictive Capabilities in Business Intellgence for Informed Decision-Making. Front. Bus. Econ. Manag. 2023, 9, 282–286. [Google Scholar]

- Nguyen, K.; Akbari, M.; Quang, H.T.; McDonald, S.; Hoang, T.H.; Yap, T.L.; George, M. Navigating Environmental Challenges through Supply Chain Quality Management 4.0 in Circular Economy: A Comprehensive Review. Sustainability 2023, 15, 16720. [Google Scholar] [CrossRef]

- Medina-Elizondo, M.; Molina-Morejón, V.M.; Fernández-Contreras, L.; Rodríguez-Figueredo, S. Quality management system in the supply chain of the metal mechanical manufacturing industry. ECORFAN J. Repub. Peru 2022, 8, 24–33. [Google Scholar]

- Rahayu, R.; Purnomo, E.P.; Malawani, A.D. Using The “Return on Investment” Strategy to Sustain Logistic Supply Provider Toward Indonesia’s Logistic Policy. J. Gov. Civ. Soc. 2020, 4, 201–218. [Google Scholar]

- Singh, H. Supply Chain Analysis. 2023. Available online: https://www.kaggle.com/datasets/harshsingh2209/supply-chain-analysis (accessed on 13 March 2024).

- Lada, S.; Chekima, B.; Karim MR, A.; Fabeil, N.F.; Ayub, M.S.; Amirul, S.M.; Ansar, R.; Bouteraa, M.; Fook, L.M.; Zaki, H.O. Determining factors related to artificial intelligence (AI) adoption among Malaysia’s small and medium-sized businesses. J. Open Innov. Technol. Mark. Complex. 2023, 9, 100144. [Google Scholar]

- Sani, S.; Xia, H.; Milisavljevic-Syed, J.; Salonitis, K. Supply Chain 4.0: A Machine Learning-Based Bayesian-Optimized LightGBM Model for Predicting Supply Chain Risk. Machines 2023, 11, 888. [Google Scholar] [CrossRef]

- Alkahtani, M. Supply Chain Management Optimization and Prediction Model Based on Projected Stochastic Gradient. SustainSustainability 2022, 14, 3486. [Google Scholar]

- Hassouna, M.; El-henawy, I.; Haggag, R. A multi-objective optimization for supply chain management using artificial intelligence (AI). Int. J. Adv. Comput. Sci. Appl. 2022, 13, 140–149. [Google Scholar]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial intelligence in supply chain management: A systematic literature review. J. Bus. Res. 2020, 122, 502–517. [Google Scholar]

- Li, B.; Mellou, K.; Zhang, B.; Pathuri, J.; Menache, I. Large Language Models for Supply Chain Optimization. arXiv 2023, arXiv:2307.03875. [Google Scholar]

- Kasturi, K.; Jebathangam, J. Supply Chain Management for Business Process Optimization using Decision Tree Regression Model. Int. J. Adv. Res. Sci. Commun. Technol. 2023, 3, 548–554. [Google Scholar]

- Sodhi, M.S.; Tang, C.S. Supply Chain Management for Extreme Conditions: Research Opportunities. SSRN Electron. J. 2021, 57, 7–16. [Google Scholar]

- Jawad, Z.N.; Balázs, V. Machine learning-driven optimization of enterprise resource planning (ERP) systems: A comprehensive review. Beni-Suef Univ. J. Basic Appl. Sci. 2024, 13, 4. [Google Scholar]

- Zhao, Y.; Jing, S.; Wang, R. Quality Control Decision Research of Two-Level Supply Chain Based on the “ERC” Fairness Preference. In Advances in Intelligent Traffic and Transportation Systems; IOS Press: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Jumoke, A.; Anafeh, A.T.; Ossi, C.S. Breaking Down Silos: Enhancing Supply Chain Efficiency Through Erp Integration and Automation. Int. Res. J. Mod. Eng. Technol. Sci. 2024, 6, 1935. [Google Scholar]

- Nzeako, G.; Akinsanya, M.O.; Popoola, O.A.; Chukwurah, E.G.; Okeke, C.D. The role of AI-Driven predictive analytics in optimizing IT industry supply chains in optimizing IT industry supply chains. Int. J. Manag. Entrep. Res. 2024, 6, 1489–1497. [Google Scholar]

- Olaleye, T.O.; Arogundade, O.T.; Misra, S.; Abayomi-Alli, A.; Kose, U. Predictive Analytics and Software Defect Severity: A Systematic Review and Future Directions. Sci. Program. 2023, 2023, 6221388. [Google Scholar]

- Ross, A.; Neuteboom, W. Implementation of quality management from a historical perspective:the forensic science odyssey. Aust. J. Forensic Sci. 2021, 53, 359–371. [Google Scholar]

- Khedr, A.M. Enhancing supply chain management with deep learning and machine learning techniques: A review. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100379. [Google Scholar]

- Eslamipoor, R.; Sepehriar, A. Enhancing supply chain relationships in the circular economy: Strategies for a green centralized supply chain with deteriorating products. J. Environ. Manag. 2024, 367, 121738. [Google Scholar] [CrossRef] [PubMed]

- Akinbamini, E.; Vargas, A.; Traill, A.; Boza, A.; Cuenca, L. Critical Analysis of Technologies Enhancing Supply Chain Collaboration in the Food Industry: A Nigerian Survey. Logistics 2025, 9, 8. [Google Scholar] [CrossRef]

- Elgalb, A.; Gerges, M. Optimizing Supply Chain Logistics with Big Data and AI: Applications for Reducing Food Waste. J. Curr. Sci. Res. Rev. 2024, 2, 29–39. [Google Scholar]

- Eslamipoor, R. A fuzzy multi-objective model for supplier selection to mitigate the impact of vehicle transportation gases and delivery time. J. Data Inf. Manag. 2022, 4, 231–241. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Critical analysis of the impact of artificial intelligence integration with cutting-edge technologies for production systems. J. Intell. Manuf. 2025, 36, 61–93. [Google Scholar]

- Zahlan, A.; Ranjan, R.P.; Hayes, D. Artificial intelligence innovation in healthcare: Literature review, exploratory analysis, and future research. Technol. Soc. 2023, 74, 102321. [Google Scholar] [CrossRef]

- Alzubaidi, L.; Al-Sabaawi, A.; Bai, J.; Dukhan, A.; Alkenani, A.H.; Al-Asadi, A.; Alwzwazy, H.A.; Manoufali, M.; Fadhel, M.A.; Albahri, A.S.; et al. Towards Risk-Free Trustworthy Artificial Intelligence: Significance and Requirements. Int. J. Intell. Syst. 2023, 2023, 4459198. [Google Scholar]

- Eni, L.N.; Raparthi, M.; LakshmiH; Yennapusa, H.; Balasubramanian, S.; Vodenicharova, M.; Srinu, C. From Data to Decisions Leveraging Machine Learning in Supply- Chain Management. Tuijin Jishu/J. Propuls. Technol. 2023, 44, 4218–4225. [Google Scholar]

- Hrbáčková, L.; Tuček, D. An analysis of two new process approach-related terms in ISO 9001:2015: Risk-based thinking and context of the organization. Sci. Pap. Univ. Pardubic. Ser. D Fac. Econ. Adm. 2019, 45, 65–76. [Google Scholar]

- Woerner, S.; Wagner, S.M.; Chu, Y.; Laumanns, M. Bonus or Penalty? Designing Service-Level Agreements for a Decentralized Supply Chain: The Implication of Return on Investment. IEEE Trans. Eng. Manag. 2024, 71, 837–854. [Google Scholar]

- Nikam, S.; Kolhare, N. Intelligent Quality Control System for Product Manufacturers through ML. In Proceedings of the International Conference on Smart Generation Computing, Communication and Networking (SMART GENCON), Bangalore, India, 23–25 December 2022. [Google Scholar]

- Wisetsri, W.; Syam, E.; Alanya-Beltran, J.; Kulkarni, G.R.; Reddy, R.K.V.; Sheikh, M.F.A. Assessing and comparing the role of machine learning (ml) and supply chain management (scm) towards enhancing e-commerce. In Proceedings of the 2nd International Conference on Advance Computing and Innovative Technologies in Engineering (ICACITE), Greater Noida, India, 28–29 April 2022. [Google Scholar]

- Kuk, E.; Bobek, S.; Nalepa, G.J. ML-Based Proactive Control of Industrial Processes. In Proceedings of the International Conference on Conceptual Structures, Prague, Czech Republic, 3–5 July 2023. [Google Scholar]

- Thayyib, P.V.; Mamilla, R.; Khan, M.; Fatima, H.; Asim, M.; Anwar, I.; Shamsudheen, M.K.; Khan, M.A. State-of-the-Art of Artificial Intelligence and Big Data Analytics Reviews in Five Different Domains: A Bibliometric Summary. Sustainability 2023, 15, 4026. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jawad, Z.N.; Villányi, B. Designing Predictive Analytics Frameworks for Supply Chain Quality Management: A Machine Learning Approach to Defect Rate Optimization. Platforms 2025, 3, 6. https://doi.org/10.3390/platforms3020006

Jawad ZN, Villányi B. Designing Predictive Analytics Frameworks for Supply Chain Quality Management: A Machine Learning Approach to Defect Rate Optimization. Platforms. 2025; 3(2):6. https://doi.org/10.3390/platforms3020006

Chicago/Turabian StyleJawad, Zainab Nadhim, and Balázs Villányi. 2025. "Designing Predictive Analytics Frameworks for Supply Chain Quality Management: A Machine Learning Approach to Defect Rate Optimization" Platforms 3, no. 2: 6. https://doi.org/10.3390/platforms3020006

APA StyleJawad, Z. N., & Villányi, B. (2025). Designing Predictive Analytics Frameworks for Supply Chain Quality Management: A Machine Learning Approach to Defect Rate Optimization. Platforms, 3(2), 6. https://doi.org/10.3390/platforms3020006