Enhancing Methane Yield in Anaerobic Co-Digestion of Primary Sewage Sludge: A Comprehensive Review on Potential Additives and Strategies

Abstract

1. Introduction

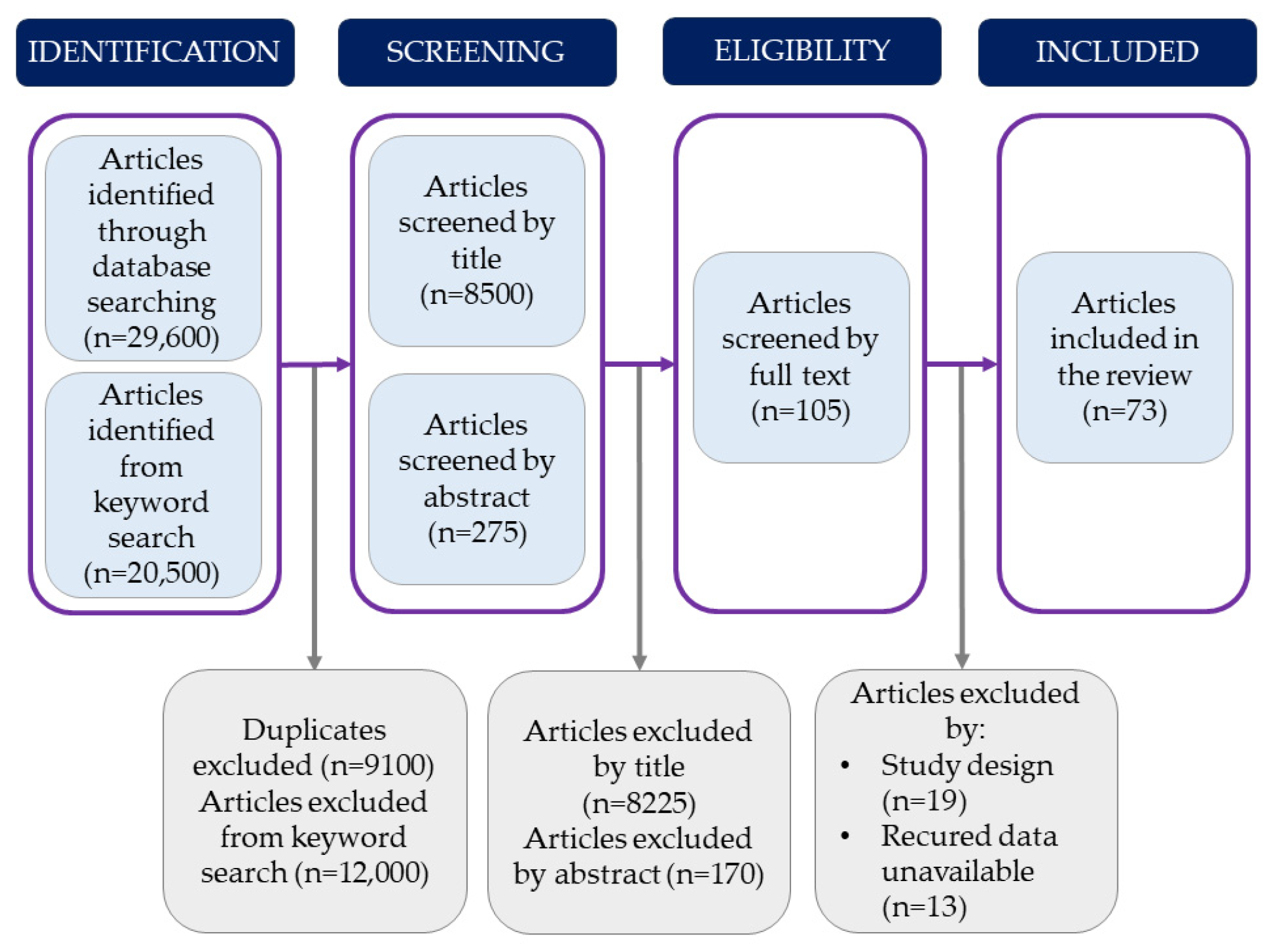

2. Methodology

- Anaerobic co-digestion of primary sludge and biowastes;

- Minerals and nanometal particles in the anaerobic digestion of primary sludge;

- The co-digestion of primary sludge with wastewater and water treatment residues;

- Treatment processes and enhancement of primary sludge anaerobic digestion;

- Microalgae and primary sludge.

3. Anaerobic Co-Digestion of Primary Sludge and Biowastes

3.1. Food Waste (FW), Fruit and Vegetable Waste (FVW), and the Organic Fraction of Municipal Solid Waste (OFMSW)

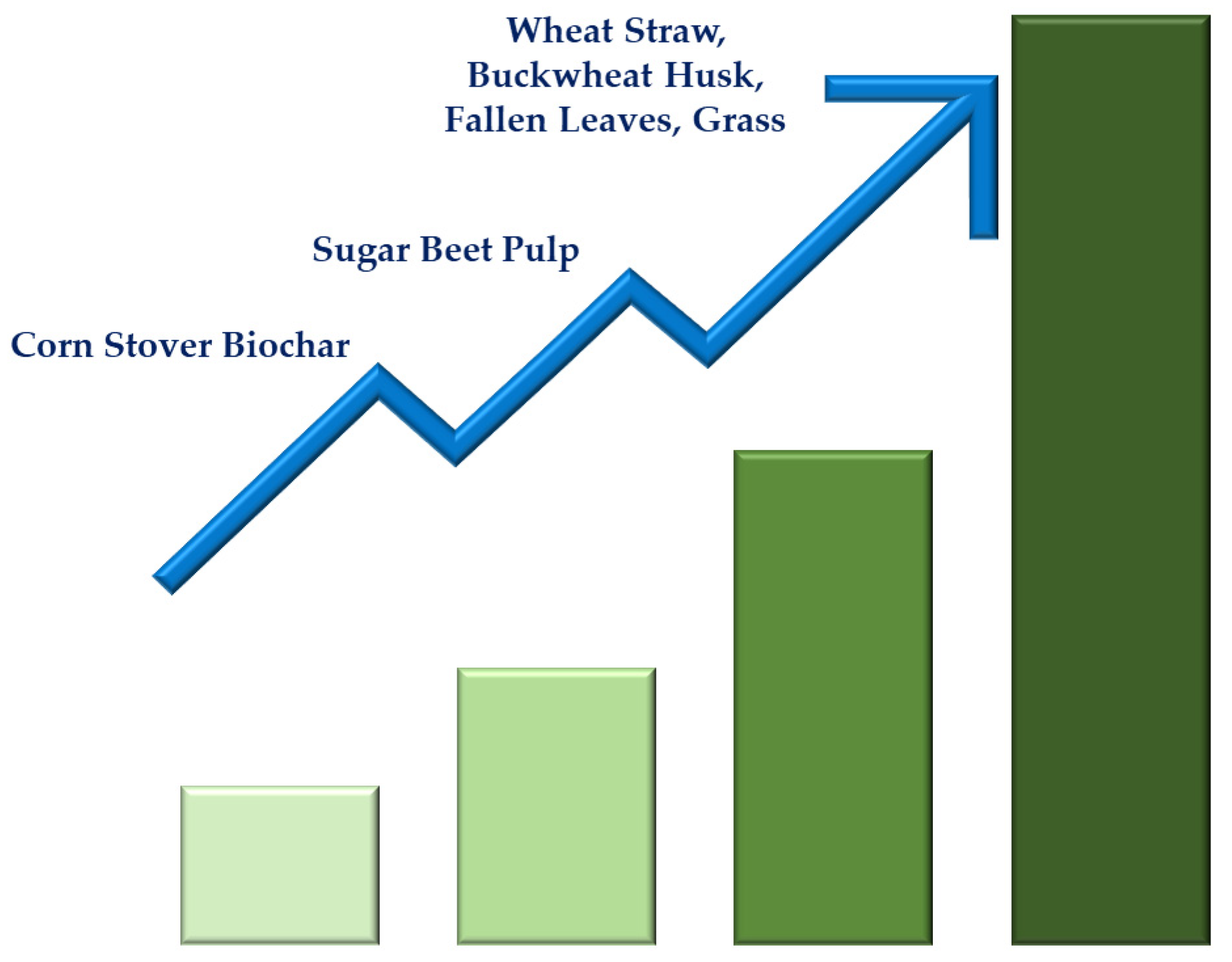

3.2. Agro-Industrial Wastes

| PS Substrate 1 | Co-Substrate 2 | Inoculum 3 | ISR * | OLR + initial | Tested Concentrations | Mode 4 | Scale 5 | T 6 | Efficiency 7 | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | PS | CSB | ADS | 2:1 w/w VS | - | 1.82, 2.55, 3.06 g/g TS− | B | L | TH | + | [6] |

| 1.82 g/g TS + 0.12 g/g TS/d | C | ||||||||||

| 2. | PS | WS BH | CM | 2:1 w/w VS | 3.0, 6.0, 7.5, 8.0, 10.0, 12.0 g VS/L | PS/WS 1:2 w/w VS | B | L | M | +++ | [30] |

| - | PS/WS BH C/N = 10.07, 13.06, 15.01, 20.03, 25.25 | +++ | |||||||||

| 3. | PS | FL GR | ADS + WAS | 2:1 w/w VS | - | PS FL GR C/N = 10, 13, 16, 20, 23 | B | L | M | +++ | [31] |

| 0.5 g VS/L/d | PS FL GR C/N = 13 | SC | |||||||||

| 4. | PS | SBP | ADS | 2:1 w/w VS | - | PS/SBP 7:3, 1:1, 3:7 w/w VS | B | L | M | ++ | [33] |

| 5. | PS | SL CS | CM RC | 2:1 w/w VS | - | PS SL CS C/N = 18, 21, 25, 30, 35 | B | L | M | +++ | [32] |

| - | PS SL CS—CM, C/N = 18 PS SL CS—RC, C/N = 20.70 | B | |||||||||

| 0.5 g VS/L/d | PS SL CS C/N = 18 | SC | |||||||||

| 6. | PS | CM BS | UASB | - | 0.71 g COD/L/d | PS/CM 3:1, 1:1 w/w | C | L | M | + | [47] |

| PS/BW 3:1, 1:1 w/w | +++ | ||||||||||

| PS/CM:BW 2:1:1 w/w | +++ | ||||||||||

| 7. | PS | WH CM | ADS | - | PS/WH 4:1 w/w | SC | L | M | + | [48] | |

| PS/WH 1:1 w/w + Ca(OH) | |||||||||||

| PS/WH/CM (final) 1:0.8:0.2 w/w |

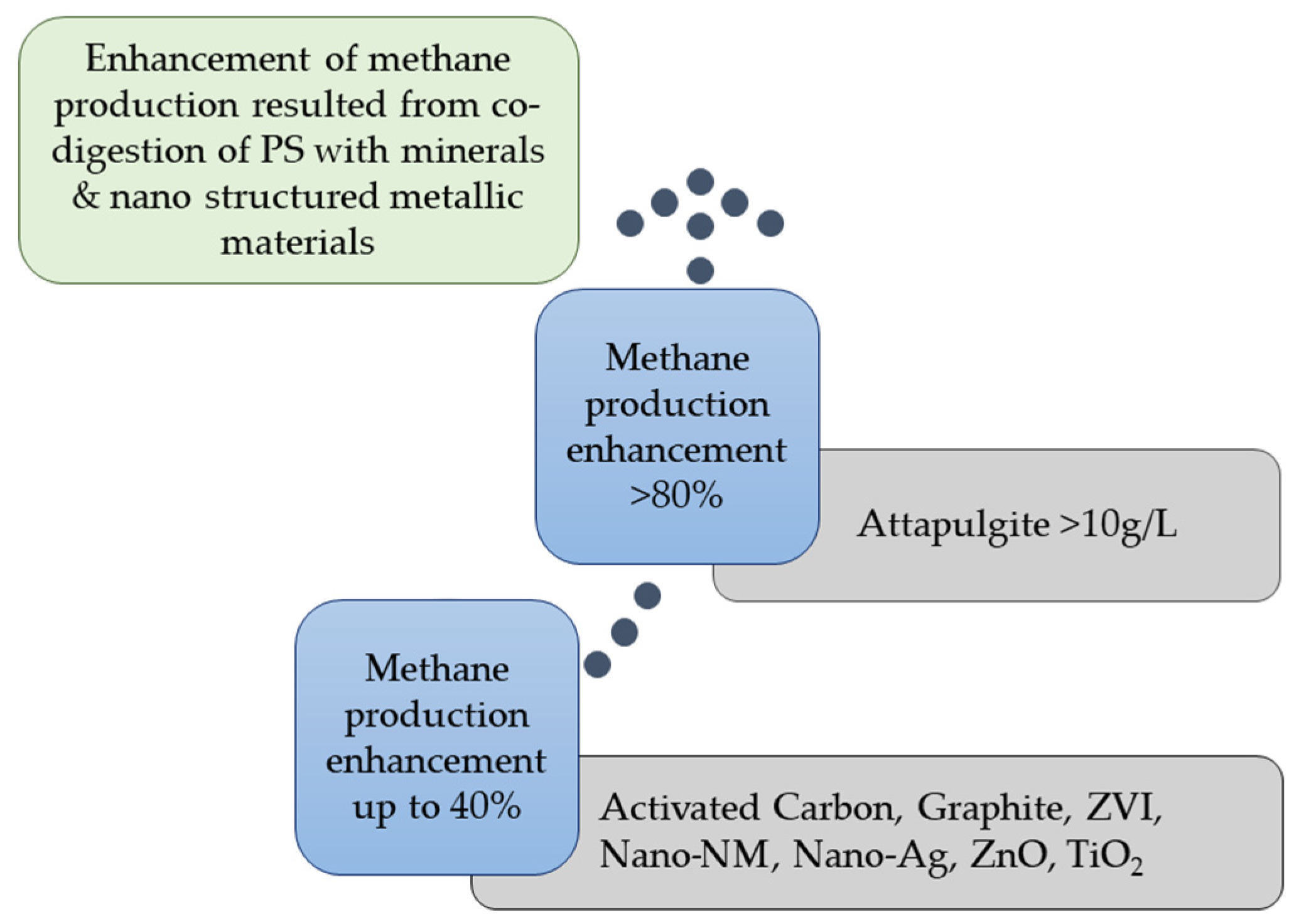

4. Minerals and Nanometal Particles in the Anaerobic Digestion of Primary Sludge

| PS Substrate 1 | Co-Substrate 2 | Inoculum 3 | ISR * | Tested Concentrations | Mode 4 | Scale 5 | T 6 | Efficiency 7 | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. | PS CEPT | AT | ADS | 1:1 w/w VS 2:1 w/w VS | AT 15 g/L | B | L | M | +++ | [5] |

| 2. | PS | AT | ADS | 1:1 w/w VS | AT 10, 20, 40 g/L | B | L | M | +++ | [4] |

| 3. | PS | Nano-TiO2 | ADS | 1:2 w/w VS | Nano-TiO2 1, 10 mg/g TS− | B | L | M | + | [55] |

| Nano-Ag | Nano-Ag 1, 10 mg/g TS | |||||||||

| Nano-ZnO | Nano-ZnO 1, 10 mg/g TS | |||||||||

| 4. | PS | NM NiCl2/CoCl2 GP AC | ADS | 1.5 w/w VS | NM 50, 100, 200 mg/L NiCl2/CoCl2 10:10, 100:100 mg/L GP 250, 500, 1000 mg/L AC 10,000, 15,000, 20,000 mg/L | B | L | M | + | [60] |

| 5. | PS | ZVI | ADS | 2:1 w/w VS | 1, 4, 20 g/L | B | L | M | + | [67] |

5. Co-Digestion of Primary Sludge with Wastewater and Water Treatment Residues

| PS Substrate 1 | Co-Substrate 2 | Inoculum 3 | ISR * | OLR + g COD/L/d | Tested Concentrations | Mode 4 | Scale 5 | T 6 | Efficiency 7 | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | PS | BA | ADS | 2:1 w/w VS | - | 0.60, 0.90, 1.20 w/w TS− | B | L | TH | + | [72] |

| 2. | PS | PW | ADS | - | 1.5, 2.5 | PW/PS 5:95, 10:90 w/w COD | SC | L | M | + | [80] |

| 2.5 | PW/PS 5:95 w/w COD | T | - | ||||||||

| 3. | PS | Fe-DWTS | ADS | 1.5:1 | - | Fe-DWTS 10, 20, 30, 40 % v/v | B | L | M | - | [83] |

| Al-DWTS | Al-DWTS 10, 20, 30, 40 % v/v | - |

6. Treatment Processes and Enhancement of Primary Sludge Anaerobic Digestion

| Substrate 1 | Treatment 2 | Inoculum 3 | ISR * | Tested Conditions | Mode 4 | Scale 5 | T 6 | Efficiency 7 | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. | CEPT | - | ADS | - | OLR 2, 1.5, 2.25, and 3 g VSS/L/d | SC | L | M | - | [90] |

| 2. | PS SS | Advanced primary separation | ADS-LAB | - | SS: 0.5 and 1.5 g/L | - | L | - | - | [95] |

| 3. | PS | FNA (HNO2-N) | ADS | 1.5–2 w/w VS for sludge, w/w TCOD for supernatant | 0.77, 1.54, 2.31, 3.08, and 3.85 mg HNO2-N/L | B | L | M | - | [96] |

| 4. | PS | Enzymatic treatment (P, LP) | ADS-LAB | 1:1 g VSS/g VS | P/LP 3:1, 1:1, 1:3, 0:1 w/w | B | L | M | + | [88] |

| 5. | PS | NaOH | EBS | 4:1 | NaOH 0.1 mol/L to 5, 10, 15% recycled sludge | SC | L | M | + | [97] |

| 6. | PS | MCP | ADS | 0.3:1 v/v | 2, 4, 6, 8, and 10 min of MCP | B | L | M | +++ | [98] |

| 7. | PS | HTT | ADS | 0.3:1 w/w VS | 130, 150, 170, 190, and 210 °C for 30 min | B | L | M | + | [89] |

7. Co-Digestion of Primary Sludge with Crude Glycerol or Microalgae Biomass

7.1. Co-Digestion of Primary Sludge with Crude Glycerol

7.2. Co-Digestion of Primary Sludge with Microalgae Biomass

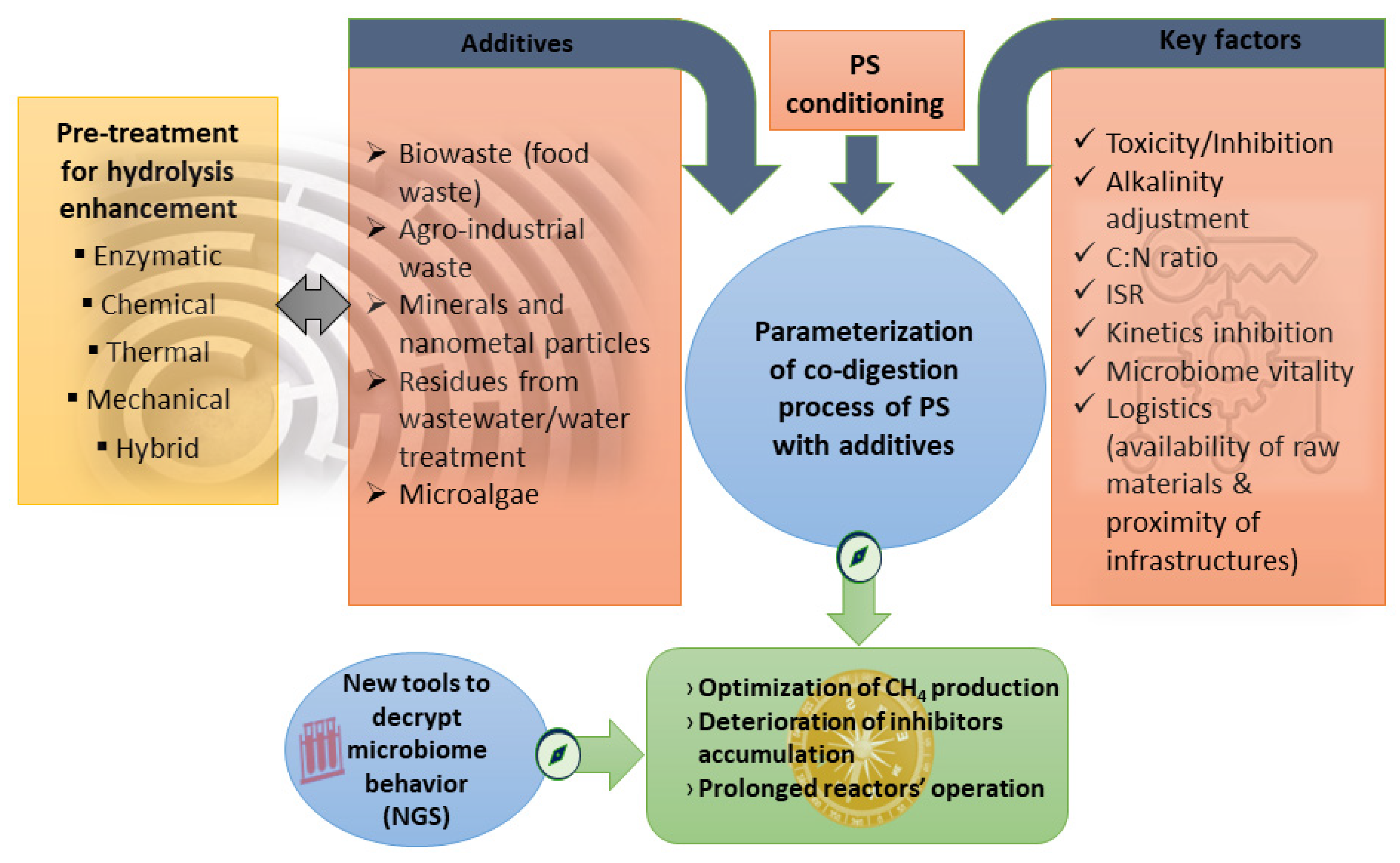

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AC | activated carbon |

| AD | anaerobic digestion |

| ADS | anaerobic digested sludge |

| ADS-LAB | anaerobic digested sludge from lab-scale reactor |

| Al-DWTS | drinking water treatment sludge treated with Al |

| AS | activated sludge |

| HTT | hydrothermal treatment |

| ZVI | zero-valent iron |

| AT | attapulgite |

| B | batch |

| BA | bottom ash |

| BH | buckwheat husk |

| BMP | biochemical methane potential |

| BA | bottom ash |

| BS | brewery sludge |

| C | continuous |

| C/N | carbon-to-nitrogen ratio |

| CEPT | chemically pretreated primary sludge |

| CM | cow manure |

| CS | Corchorus stalks |

| CSB | corn stover biochar |

| DWTS | drinking water treatment sludge |

| EBS | excess biofilm sludge |

| EPS | extracellular polymeric substances |

| ES | excess sludge |

| Fe-DWTS | drinking water treatment sludge treated with Fe |

| FL | fallen leaves |

| FNA | free nitrous acid |

| FVW | fruit and vegetable waste |

| FW | food waste |

| GL | crude glycerol |

| GP | graphite powder |

| GR | grass |

| HTC | hydrothermal carbonization |

| ISR | inoculum-to-substrate ratio |

| k | hydrolysis rate constant |

| L | lab scale |

| LP | lipase |

| M | mesophilic |

| MB | microalgae biomass |

| MCP | mechanical cutting pretreatment |

| NM | nano magnetite |

| NPs | nanoparticles |

| OFMSW | organic fraction of municipal solid waste |

| OLR | organic loading rates |

| P | protease |

| PS | primary sludge |

| PW | process water from hydrothermally treated waste-activated sludge |

| RC | rumen content of cattle |

| SBP | sugar beet pulp |

| SC | semi-continuous |

| SL | sugarcane leaves |

| T | temperature |

| TH | thermophilic |

| UASB | up-flow anaerobic sludge blanket digestion |

| VFAs | volatile fatty acids |

| VS | volatile solids |

| VSS | volatile suspended solids |

| WAS | Waste-activated sludge |

| WH | whey |

| WS | wheat straw |

| λ | lag phase |

References

- European Commission Circular Economy Action Plan. Available online: https://ec.europa.eu/environment/circular-economy/pdf/new_circular_economy_action_plan.pdf (accessed on 25 October 2023).

- European Biogas Association Reaching Net Zero Emissions in the Gas Sector. Available online: https://www.europeanbiogas.eu/reaching-net-zero-emissions-in-the-gas-sector/ (accessed on 16 February 2022).

- Andreoli, C.V.; von Sperling, M.; Fernandes, F. (Eds.) Sludge Treatment and Disposal. In Biological Wastewater Treatment Series; IWA Publishing: London, UK, 2007; Volume 6, ISBN 9781843391661. [Google Scholar]

- Sakaveli, F.; Petala, M.; Tsiridis, V.; Karas, P.A.; Karpouzas, D.G.; Darakas, E. Effect of Attapulgite on Anaerobic Digestion of Primary Sludge and Downstream Valorization of Produced Biosolids. Renew. Energy 2023, 217, 119211. [Google Scholar] [CrossRef]

- Sakaveli, F.; Petala, M.; Tsiridis, V.; Darakas, E. Enhanced Mesophilic Anaerobic Digestion of Primary Sewage Sludge. Water 2021, 13, 348. [Google Scholar] [CrossRef]

- Wei, W.; Guo, W.; Ngo, H.H.; Mannina, G.; Wang, D.; Chen, X.; Liu, Y.; Peng, L.; Ni, B.J. Enhanced High-Quality Biomethane Production from Anaerobic Digestion of Primary Sludge by Corn Stover Biochar. Bioresour. Technol. 2020, 306, 123159. [Google Scholar] [CrossRef] [PubMed]

- Environmental Protection Agency. Waste Water Treatment Manuals—Primary, Secondary and Tertiary Treatment; Environmental Protection Agency: Wexford, Ireland, 1997.

- Metcalf & Eddy Inc. Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; Tchobanoglous, G., Stensel, H., Tsuchihashi, R., Burton, F., Eds.; McGraw-Hill Education: New York, NY, USA, 2013; ISBN 9780073401188. [Google Scholar]

- Obulisamy, P.K.; Chakraborty, D.; Selvam, A.; Wong, J.W.C. Anaerobic Co-Digestion of Food Waste and Chemically Enhanced Primary-Treated Sludge under Mesophilic and Thermophilic Conditions. Environ. Technol. 2016, 37, 3200–3207. [Google Scholar] [CrossRef] [PubMed]

- Khanal, S.K. Anaerobic Biotechnology for Bioenergy Production: Principles and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; ISBN 0813823463. [Google Scholar]

- Gerardi, M.H. The Microbiology of Anaerobic Digesters; Gerardi, M.H., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; ISBN 0-471-20693-8. [Google Scholar]

- Fytili, D.; Zabaniotou, A. Utilization of Sewage Sludge in EU Application of Old and New Methods-A Review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Turovskiy, I.S.; Mathai, P.K. Wastewater Sludge Processing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; ISBN 9780471700548. [Google Scholar]

- Elsayed, M.; Andres, Y.; Blel, W.; Hassan, R.; Ahmed, A. Effect of Inoculum VS, Organic Loads and I/S on the Biochemical Methane Potential of Sludge, Buckwheat Husk and Straw. Desalin. Water Treat. 2019, 157, 69–78. [Google Scholar] [CrossRef]

- Gómez, X.; Cuetos, M.J.; Cara, J.; Morán, A.; García, A.I. Anaerobic Co-Digestion of Primary Sludge and the Fruit and Vegetable Fraction of the Municipal Solid Wastes. Conditions for Mixing and Evaluation of the Organic Loading Rate. Renew. Energy 2006, 31, 2017–2024. [Google Scholar] [CrossRef]

- Miller, J.W.; Swartzbaugh, J.T.; Wiles, C.C. Fuel Production from Organic Residue: Sludge Mixtures. AIChE Symp. Ser. 1978, 74, 117–122. [Google Scholar]

- Al Seadi, T. Biogas Handbook; Syddansk Universitet: Esbjerg, Denmark, 2008; ISBN 978-87-992962-0-0. [Google Scholar]

- Chakraborty, D.; Karthikeyan, O.P.; Selvam, A.; Wong, J.W.C. Co-Digestion of Food Waste and Chemically Enhanced Primary Treated Sludge in a Continuous Stirred Tank Reactor. Biomass Bioenergy 2018, 111, 232–240. [Google Scholar] [CrossRef]

- Kang, X.; Liu, Y. Chemically Enhanced Primary Sludge as an Anaerobic Co-Digestion Additive for Biogas Production from Food Waste. Processes 2019, 7, 709. [Google Scholar] [CrossRef]

- Xie, S.; Wickham, R.; Nghiem, L.D. Synergistic Effect from Anaerobic Co-Digestion of Sewage Sludge and Organic Wastes. Int. Biodeterior. Biodegrad. 2017, 116, 191–197. [Google Scholar] [CrossRef]

- Rakić, N.; Šušteršič, V.; Gordić, D.; Jovičić, N.; Bošković, G.; Bogdanović, I. Characteristics of Biogas Production and Synergistic Effect of Primary Sludge and Food Waste Co-Digestion. Bioenergy Res. 2023, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Lahoz, C.; Fernández-Giménez, B.; Garcia-Herruzo, F.; Rodriguez-Maroto, J.M.; Vereda-Alonso, C. Biomethanization of Mixtures of Fruits and Vegetables Solid Wastes and Sludge from a Municipal Wastewater Treatment Plant. J. Environ. Sci. Health -Part A Toxic/Hazard. Subst. Environ. Eng. 2007, 42, 481–487. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, M.; Diab, A.; Soliman, M. Methane Production from Anaerobic Co-Digestion of Sludge with Fruit and Vegetable Wastes: Effect of Mixing Ratio and Inoculum Type. Biomass Convers. Biorefinery 2021, 11, 989–998. [Google Scholar] [CrossRef]

- Habagil, M.; Keucken, A.; Horváth, I.S. Biogas Production from Food Residues—The Role of Trace Metals and Co-Digestion with Primary Sludge. Environments 2020, 7, 8–10. [Google Scholar] [CrossRef]

- Ahmed, B.; Tyagi, V.K.; Priyanka; Khan, A.A.; Kazmi, A.A. Optimization of Process Parameters for Enhanced Biogas Yield from Anaerobic Co-Digestion of OFMSW and Bio-Solids. Biomass Convers. Biorefinery 2022, 12, 607–618. [Google Scholar] [CrossRef]

- Iacovidou, E.; Ohandja, D.-G.; Voulvoulis, N. Food Waste Co-Digestion with Sewage Sludge—Realising Its Potential in the UK. J. Environ. Manag. 2012, 112, 267–274. [Google Scholar] [CrossRef]

- Solé-Bundó, M.; Salvadó, H.; Passos, F.; Garfí, M.; Ferrer, I. Strategies to Optimize Microalgae Conversion to Biogas: Co-Digestion, Pretreatment and Hydraulic Retention Time. Molecules 2018, 23, 2096. [Google Scholar] [CrossRef]

- Mehariya, S.; Patel, A.K.; Obulisamy, P.K.; Punniyakotti, E.; Wong, J.W.C. Co-Digestion of Food Waste and Sewage Sludge for Methane Production: Current Status and Perspective. Bioresour. Technol. 2018, 265, 519–531. [Google Scholar] [CrossRef]

- Li, Y.; Ni, J.; Cheng, H.; Guo, G.; Zhang, T.; Zhu, A.; Qin, Y.; Li, Y.-Y. Enhanced Digestion of Sludge via Co-Digestion with Food Waste in a High-Solid Anaerobic Membrane Bioreactor: Performance Evaluation and Microbial Response. Sci. Total Environ. 2023, 899, 165701. [Google Scholar] [CrossRef]

- Elsayed, M.; Andres, Y.; Blel, W.; Gad, A.; Ahmed, A. Effect of VS Organic Loads and Buckwheat Husk on Methane Production by Anaerobic Co-Digestion of Primary Sludge and Wheat Straw. Energy Convers. Manag. 2016, 117, 538–547. [Google Scholar] [CrossRef]

- Elsayed, M.; Blel, W.; Soliman, M.; Andres, Y.; Hassan, R. Semi-Continuous Co-Digestion of Sludge, Fallen Leaves, and Grass Performance. Energy 2021, 221, 119888. [Google Scholar] [CrossRef]

- Elsayed, M.; Hassany, R.; Soliman, M. Anaerobic Co-Digestion of Sludge, Sugarcane Leaves, and Corchorus Stalks in Egypt. Biomass Convers. Biorefinery 2021, 13, 2177–2191. [Google Scholar] [CrossRef]

- Elsayed, M.; Andres, Y.; Meky, N.; Hassan, R. Anaerobic Co-Digestion of Sugar Beet Pulp and Sludge: Influence of Periodic Intermittent Stirring and Mixing Ratio. Biomass Convers. Biorefinery 2023, 1–9. [Google Scholar] [CrossRef]

- Rongpipi, S.; Ye, D.; Gomez, E.D.; Gomez, E.W. Progress and Opportunities in the Characterization of Cellulose—An Important Regulator of Cell Wall Growth and Mechanics. Front. Plant Sci. 2019, 9, 1894. [Google Scholar] [CrossRef] [PubMed]

- Xia, T.; Huang, H.; Wu, G.; Sun, E.; Jin, X.; Tang, W. The Characteristic Changes of Rice Straw Fibers in Anaerobic Digestion and Its Effect on Rice Straw-Reinforced Composites. Ind. Crops Prod. 2018, 121, 73–79. [Google Scholar] [CrossRef]

- Horn, S.J.; Vaaje-Kolstad, G.; Westereng, B.; Eijsink, V.G. Novel Enzymes for the Degradation of Cellulose. Biotechnol. Biofuels 2012, 5, 45. [Google Scholar] [CrossRef]

- Xiao, B.; Sun, X.F.; Sun, R. Chemical, Structural, and Thermal Characterizations of Alkali-Soluble Lignins and Hemicelluloses, and Cellulose from Maize Stems, Rye Straw, and Rice Straw. Polym. Degrad. Stab. 2001, 74, 307–319. [Google Scholar] [CrossRef]

- Dharmalingam, B.; Tantayotai, P.; Panakkal, E.J.; Cheenkachorn, K.; Kirdponpattara, S.; Gundupalli, M.P.; Cheng, Y.-S.; Sriariyanun, M. Organic Acid Pretreatments and Optimization Techniques for Mixed Vegetable Waste Biomass Conversion into Biofuel Production. BioEnergy Res. 2023, 16, 1667–1682. [Google Scholar] [CrossRef]

- Nakamura, Y.; Ono, Y.; Saito, T.; Isogai, A. Characterization of Cellulose Microfibrils, Cellulose Molecules, and Hemicelluloses in Buckwheat and Rice Husks. Cellulose 2019, 26, 6529–6541. [Google Scholar] [CrossRef]

- Huang, Y.; Li, F.; Meng, J.; Chen, W. Lignin Content of Agro-Forestry Biomass Negatively Affects the Resultant Biochar PH. BioResources 2019, 13, 5153–5163. [Google Scholar] [CrossRef]

- Sarath, G.; Mitchell, R.B.; Sattler, S.E.; Funnell, D.; Pedersen, J.F.; Graybosch, R.A.; Vogel, K.P. Opportunities and Roadblocks in Utilizing Forages and Small Grains for Liquid Fuels. J. Ind. Microbiol. Biotechnol. 2008, 35, 343–354. [Google Scholar] [CrossRef] [PubMed]

- Mann, D.G.J.; Labbé, N.; Sykes, R.W.; Gracom, K.; Kline, L.; Swamidoss, I.M.; Burris, J.N.; Davis, M.; Stewart, C.N. Rapid Assessment of Lignin Content and Structure in Switchgrass (Panicum virgatum L.) Grown under Different Environmental Conditions. Bioenergy Res. 2009, 2, 246–256. [Google Scholar] [CrossRef]

- Ghimire, N.; Bakke, R.; Bergland, W.H. Liquefaction of Lignocellulosic Biomass for Methane Production: A Review. Bioresour. Technol. 2021, 332, 125068. [Google Scholar] [CrossRef]

- Weiland, P. Biomass Digestion in Agriculture: A Successful Pathway for the Energy Production and Waste Treatment in Germany. Eng. Life Sci. 2006, 6, 302–309. [Google Scholar] [CrossRef]

- Murto, M.; Björnsson, L.; Mattiasson, B. Impact of Food Industrial Waste on Anaerobic Co-Digestion of Sewage Sludge and Pig Manure. J. Environ. Manag. 2004, 70, 101–107. [Google Scholar] [CrossRef]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the Anaerobic Digestion of Agricultural Resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef] [PubMed]

- Nansubuga, I.; Banadda, N.; Babu, M.; Devriez, J.; Verstraete, W.; Rabaey, K. Enhancement of Biogas Potential of Primary Sludge by Co-Digestion with Cow Manure and Brewery Sludge. Int. J. Agric. Biol. Eng. 2015, 8, 86–94. [Google Scholar] [CrossRef]

- Shilton, A.; Powell, N.; Broughton, A.; Pratt, C.; Pratt, S.; Pepper, C. Enhanced Biogas Production Using Cow Manure to Stabilize Co-Digestion of Whey and Primary Sludge. Environ. Technol. 2013, 34, 2491–2496. [Google Scholar] [CrossRef]

- Lin, L.; Wan, C.; Liu, X.; Lei, Z.; Lee, D.J.; Zhang, Y.; Tay, J.H.; Zhang, Z. Anaerobic Digestion of Swine Manure under Natural Zeolite Addition: VFA Evolution, Cation Variation, and Related Microbial Diversity. Appl. Microbiol. Biotechnol. 2013, 97, 10575–10583. [Google Scholar] [CrossRef]

- Fernández, N.; Montalvo, S.; Fernández-Polanco, F.; Guerrero, L.; Cortés, I.; Borja, R.; Sánchez, E.; Travieso, L. Real Evidence about Zeolite as Microorganisms Immobilizer in Anaerobic Fluidized Bed Reactors. Process Biochem. 2007, 42, 721–728. [Google Scholar] [CrossRef]

- Liang, Y.; Xu, L.; Bao, J.; Firmin, K.A.; Zong, W. Attapulgite Enhances Methane Production from Anaerobic Digestion of Pig Slurry by Changing Enzyme Activities and Microbial Community. Renew. Energy 2020, 145, 222–232. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Liu, C.; Liu, X.; Wang, J.; Li, S.; Fan, G.; Zhang, L. Alkaline Pretreatment for Enhancement of Biogas Production from Banana Stem and Swine Manure by Anaerobic Codigestion. Bioresour. Technol. 2013, 149, 353–358. [Google Scholar] [CrossRef] [PubMed]

- Nobu, M.K.; Narihiro, T.; Kuroda, K.; Mei, R.; Liu, W.-T. Chasing the Elusive Euryarchaeota Class WSA2: Genomes Reveal a Uniquely Fastidious Methyl-Reducing Methanogen. ISME J. 2016, 10, 2478–2487. [Google Scholar] [CrossRef]

- Oren, A. The Family Methanocorpusculaceae BT. In The Prokaryotes: Other Major Lineages of Bacteria and The Archaea; Rosenberg, E., DeLong, E.F., Lory, S., Stackebrandt, E., Thompson, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 225–230. ISBN 978-3-642-38954-2. [Google Scholar]

- Sakarya, K.; Akyol, Ç.; Demirel, B. The Effect of Short-Term Exposure of Engineered Nanoparticles on Methane Production during Mesophilic Anaerobic Digestion of Primary Sludge. Water. Air. Soil Pollut. 2015, 226, 100. [Google Scholar] [CrossRef]

- Kaegi, R.; Voegelin, A.; Ort, C.; Sinnet, B.; Thalmann, B.; Krismer, J.; Hagendorfer, H.; Elumelu, M.; Mueller, E. Fate and Transformation of Silver Nanoparticles in Urban Wastewater Systems. Water Res. 2013, 47, 3866–3877. [Google Scholar] [CrossRef]

- Mu, H.; Chen, Y. Long-Term Effect of ZnO Nanoparticles on Waste Activated Sludge Anaerobic Digestion. Water Res. 2011, 45, 5612–5620. [Google Scholar] [CrossRef]

- Kiser, M.A.; Westerhoff, P.; Benn, T.; Wang, Y.; Pérez-Rivera, J.; Hristovski, K. Titanium Nanomaterial Removal and Release from Wastewater Treatment Plants. Environ. Sci. Technol. 2009, 43, 6757–6763. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Guo, R.; Shi, X.; Wang, C.; Wang, L.; Dai, M. Magnetite Nanoparticles Enable a Rapid Conversion of Volatile Fatty Acids to Methane. RSC Adv. 2016, 6, 25662–25668. [Google Scholar] [CrossRef]

- Xie, S.; Li, X.; Wang, C.; Kulandaivelu, J.; Jiang, G. Enhanced Anaerobic Digestion of Primary Sludge with Additives: Performance and Mechanisms. Bioresour. Technol. 2020, 316, 123970. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Samer, M.; Attia, Y.A.; Abdel-Hadi, M.A.; Hassan, H.E.; Badr, Y. Effects of Co and Ni Nanoparticles on Biogas and Methane Production from Anaerobic Digestion of Slurry. Energy Convers. Manag. 2017, 141, 108–119. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, Y.; Ji, D.; Li, X.; Zhang, J.; Zang, L. Synergetic Promotion of Direct Interspecies Electron Transfer for Syntrophic Metabolism of Propionate and Butyrate with Graphite Felt in Anaerobic Digestion. Bioresour. Technol. 2019, 287, 121373. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, L.; Sun, H.; Yuan, Y.; Liu, Y. Granular Activated Carbon Stimulated Microbial Extracellular Secretions in Anaerobic Digesters: An Egalitarian Act and Beyond. Chem. Eng. J. 2023, 456, 140850. [Google Scholar] [CrossRef]

- Guo, Y.; Zheng, Y.; Wang, Y.; Zhao, Y.; Gao, M.; Giesy, J.P.; Guo, L. Enhancing Two-Phase Anaerobic Digestion of Mixture of Primary and Secondary Sludge by Adding Granular Activated Carbon (GAC): Evaluating Acidogenic and Methanogenic Efficiency. Bioresour. Technol. 2022, 363, 127900. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Qi, L.; Chatzisymeon, E.; Yang, P.; Sun, W.; Pang, L. Inorganic Additives to Increase Methane Generation during Anaerobic Digestion of Livestock Manure: A Review. Environ. Chem. Lett. 2021, 19, 4165–4190. [Google Scholar] [CrossRef]

- Boontian, N. Effect of Zero Valent Iron (ZVI) in Wastewater Treatment: A Review. Appl. Mech. Mater. 2015, 775, 180–184. [Google Scholar] [CrossRef]

- Wei, W.; Cai, Z.; Fu, J.; Xie, G.J.; Li, A.; Zhou, X.; Ni, B.J.; Wang, D.; Wang, Q. Zero Valent Iron Enhances Methane Production from Primary Sludge in Anaerobic Digestion. Chem. Eng. J. 2018, 351, 1159–1165. [Google Scholar] [CrossRef]

- Romero-Güiza, M.S.; Vila, J.; Mata-Alvarez, J.; Chimenos, J.M.; Astals, S. The Role of Additives on Anaerobic Digestion: A Review. Renew. Sustain. Energy Rev. 2016, 58, 1486–1499. [Google Scholar] [CrossRef]

- Yin, C.; Shen, Y.; Zhu, N.; Huang, Q.; Lou, Z.; Yuan, H. Anaerobic Digestion of Waste Activated Sludge with Incineration Bottom Ash: Enhanced Methane Production and CO2 Sequestration. Appl. Energy 2018, 215, 503–511. [Google Scholar] [CrossRef]

- Lo, H.-M. Metals Behaviors of MSWI Bottom Ash Co-Digested Anaerobically with MSW. Resour. Conserv. Recycl. 2005, 43, 263–280. [Google Scholar] [CrossRef]

- Banks, C.J.; Lo, H.-M. Assessing the Effects of Municipal Solid Waste Incinerator Bottom Ash on the Decomposition of Biodegradable Waste Using a Completely Mixed Anaerobic Reactor. Waste Manag. Res. 2003, 21, 225–234. [Google Scholar] [CrossRef]

- Wei, W.; Liu, X.; Wu, L.; Wang, D.; Bao, T.; Ni, B.J. Sludge Incineration Bottom Ash Enhances Anaerobic Digestion of Primary Sludge toward Highly Efficient Sludge Anaerobic Codigestion. ACS Sustain. Chem. Eng. 2020, 8, 3005–3012. [Google Scholar] [CrossRef]

- Funke, A.; Ziegler, F. Hydrothermal Carbonization of Biomass: A Summary and Discussion of Chemical Mechanisms for Process Engineering. Biofuels Bioprod. Biorefining 2010, 4, 160–177. [Google Scholar] [CrossRef]

- Villamil, J.A.; Mohedano, A.F.; Rodriguez, J.J.; de la Rubia, M.A. Valorisation of the Liquid Fraction from Hydrothermal Carbonisation of Sewage Sludge by Anaerobic Digestion. J. Chem. Technol. Biotechnol. 2018, 93, 450–456. [Google Scholar] [CrossRef]

- De la Rubia, M.A.; Villamil, J.A.; Rodriguez, J.J.; Mohedano, A.F. Effect of Inoculum Source and Initial Concentration on the Anaerobic Digestion of the Liquid Fraction from Hydrothermal Carbonisation of Sewage Sludge. Renew. Energy 2018, 127, 697–704. [Google Scholar] [CrossRef]

- Wirth, B.; Reza, T.; Mumme, J. Influence of Digestion Temperature and Organic Loading Rate on the Continuous Anaerobic Treatment of Process Liquor from Hydrothermal Carbonization of Sewage Sludge. Bioresour. Technol. 2015, 198, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Aragón-Briceño, C.; Ross, A.B.; Camargo-Valero, M.A. Evaluation and Comparison of Product Yields and Bio-Methane Potential in Sewage Digestate Following Hydrothermal Treatment. Appl. Energy 2017, 208, 1357–1369. [Google Scholar] [CrossRef]

- Broch, A.; Jena, U.; Hoekman, S.K.; Langford, J. Analysis of Solid and Aqueous Phase Products from Hydrothermal Carbonization of Whole and Lipid-Extracted Algae. Energies 2014, 7, 62–79. [Google Scholar] [CrossRef]

- Danso-Boateng, E.; Shama, G.; Wheatley, A.D.; Martin, S.J.; Holdich, R.G. Hydrothermal Carbonisation of Sewage Sludge: Effect of Process Conditions on Product Characteristics and Methane Production. Bioresour. Technol. 2015, 177, 318–327. [Google Scholar] [CrossRef]

- Villamil, J.A.; Mohedano, A.F.; San Martín, J.; Rodriguez, J.J.; de la Rubia, M.A. Anaerobic Co-Digestion of the Process Water from Waste Activated Sludge Hydrothermally Treated with Primary Sewage Sludge: A New Approach for Sewage Sludge Management. Renew. Energy 2020, 146, 435–443. [Google Scholar] [CrossRef]

- Pikaar, I.; Sharma, K.R.; Hu, S.; Gernjak, W.; Keller, J.; Yuan, Z. Reducing Sewer Corrosion through Integrated Urban Water Management. Science 2014, 345, 812–814. [Google Scholar] [CrossRef]

- White, P.J.; Brown, P.H. Plant Nutrition for Sustainable Development and Global Health. Ann. Bot. 2010, 105, 1073–1080. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Li, X.; Pham, C.U.; Nguyen, H.V.; Song, Y.; Chetty, K.; Kulandaivelu, J.; Wang, C.; Hai, F.; Jiang, G. Co-Digestion of Primary Sewage Sludge with Drinking Water Treatment Sludge: A Comprehensive Evaluation of Benefits. Bioresour. Technol. 2021, 330, 124994. [Google Scholar] [CrossRef] [PubMed]

- Khadem, A.F.; Azman, S.; Plugge, C.M.; Zeeman, G.; van Lier, J.B.; Stams, A.J.M. Effect of Humic Acids on the Activity of Pure and Mixed Methanogenic Cultures. Biomass Bioenergy 2017, 99, 21–30. [Google Scholar] [CrossRef]

- O’Flaherty, V.; Lens, P.; Leahy, B.; Colleran, E. Long-Term Competition between Sulphate-Reducing and Methaneproducing Bacteria during Full-Scale Anaerobic Treatment of Citric Acid Production Wastewater. Water Res. 1998, 32, 815–825. [Google Scholar] [CrossRef]

- Khanh Nguyen, V.; Kumar Chaudhary, D.; Hari Dahal, R.; Hoang Trinh, N.; Kim, J.; Chang, S.W.; Hong, Y.; Duc La, D.; Nguyen, X.C.; Hao Ngo, H.; et al. Review on Pretreatment Techniques to Improve Anaerobic Digestion of Sewage Sludge. Fuel 2021, 285, 119105. [Google Scholar] [CrossRef]

- Bahreini, G.; Nazari, L.; Ho, D.; Flannery, C.C.; Elbeshbishy, E.; Santoro, D.; Nakhla, G. Enzymatic Pre-Treatment for Enhancement of Primary Sludge Fermentation. Bioresour. Technol. 2020, 305, 123071. [Google Scholar] [CrossRef] [PubMed]

- Tongco, J.V.; Kim, S.; Oh, B.R.; Heo, S.Y.; Lee, J.; Hwang, S. Enhancement of Hydrolysis and Biogas Production of Primary Sludge by Use of Mixtures of Protease and Lipase. Biotechnol. Bioprocess Eng. 2020, 25, 132–140. [Google Scholar] [CrossRef]

- Yuan, T.; Cheng, Y.; Zhang, Z.; Lei, Z.; Shimizu, K. Comparative Study on Hydrothermal Treatment as Pre- and Post-Treatment of Anaerobic Digestion of Primary Sludge: Focus on Energy Balance, Resources Transformation and Sludge Dewaterability. Appl. Energy 2019, 239, 171–180. [Google Scholar] [CrossRef]

- Zhuang, H.; Amy Tan, G.Y.; Jing, H.; Lee, P.H.; Lee, D.J.; Leu, S.Y. Enhanced Primary Treatment for Net Energy Production from Sewage—The Genetic Clarification of Substrate-Acetate-Methane Pathway in Anaerobic Digestion. Chem. Eng. J. 2022, 431, 133416. [Google Scholar] [CrossRef]

- Badireddy, A.R.; Chellam, S.; Gassman, P.L.; Engelhard, M.H.; Lea, A.S.; Rosso, K.M. Role of Extracellular Polymeric Substances in Bioflocculation of Activated Sludge Microorganisms under Glucose-Controlled Conditions. Water Res. 2010, 44, 4505–4516. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Ting, Y.P.; Chen, J.P.; Xing, C.H.; Shi, S.Q. Advanced Primary Treatment of Waste Water Using a Bio-Flocculation-Adsorption Sedimentation Process. Acta Biotechnol. 2000, 20, 53–64. [Google Scholar] [CrossRef]

- Görner, T.; de Donato, P.; Ameil, M.-H.; Montarges-Pelletier, E.; Lartiges, B.S. Activated Sludge Exopolymers: Separation and Identification Using Size Exclusion Chromatography and Infrared Micro-Spectroscopy. Water Res. 2003, 37, 2388–2393. [Google Scholar] [CrossRef]

- Sheng, G.-P.; Yu, H.-Q.; Li, X.-Y. Extracellular Polymeric Substances (EPS) of Microbial Aggregates in Biological Wastewater Treatment Systems: A Review. Biotechnol. Adv. 2010, 28, 882–894. [Google Scholar] [CrossRef]

- Araneda, M.; Pavez, J.; Luza, B.; Jeison, D. Use of Activated Sludge Biomass as an Agent for Advanced Primary Separation. J. Environ. Manag. 2017, 192, 156–162. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Q.; Ye, L.; Yuan, Z. Effect of Free Nitrous Acid Pre-Treatment on Primary Sludge Biodegradability and Its Implications. Chem. Eng. J. 2016, 290, 31–36. [Google Scholar] [CrossRef]

- Li, H.; Zou, S.; Li, C.; Jin, Y. Alkaline Post-Treatment for Improved Sludge Anaerobic Digestion. Bioresour. Technol. 2013, 140, 187–191. [Google Scholar] [CrossRef]

- Wang, X.; Xie, Y.; Qi, X.; Chen, T.; Zhang, Y.; Gao, C.; Zhang, A.; Ren, W. A New Mechanical Cutting Pretreatment Approach towards the Improvement of Primary Sludge Fermentation and Anaerobic Digestion. J. Environ. Chem. Eng. 2022, 10, 107163. [Google Scholar] [CrossRef]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic Co-Digestion of Wastewater Sludge: A Review of Potential Co-Substrates and Operating Factors for Improved Methane Yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef]

- Attarbachi, T.; Kingsley, M.D.; Spallina, V. New Trends on Crude Glycerol Purification: A Review. Fuel 2023, 340, 127485. [Google Scholar] [CrossRef]

- Paulista, L.O.; Boaventura, R.A.R.; Vilar, V.J.P.; Pinheiro, A.L.N.; Martins, R.J.E. Enhancing Methane Yield from Crude Glycerol Anaerobic Digestion by Coupling with Ultrasound or A. Niger/E. Coli Biodegradation. Environ. Sci. Pollut. Res. 2020, 27, 1461–1474. [Google Scholar] [CrossRef]

- Alves, I.R.F.S.; Mahler, C.F.; Oliveira, L.B.; Reis, M.M.; Bassin, J.P. Assessing the Use of Crude Glycerol from Biodiesel Production as an Alternative to Boost Methane Generation by Anaerobic Co-Digestion of Sewage Sludge. Biomass Bioenergy 2020, 143, 105831. [Google Scholar] [CrossRef]

- Alves, I.R.F.S.; Mahler, C.F.; Oliveira, L.B.; Reis, M.M.; Bassin, J.P. Investigating the Effect of Crude Glycerol from Biodiesel Industry on the Anaerobic Co-Digestion of Sewage Sludge and Food Waste in Ternary Mixtures. Energy 2022, 241, 122818. [Google Scholar] [CrossRef]

- Nartker, S.; Ammerman, M.; Aurandt, J.; Stogsdil, M.; Hayden, O.; Antle, C. Increasing Biogas Production from Sewage Sludge Anaerobic Co-Digestion Process by Adding Crude Glycerol from Biodiesel Industry. Waste Manag. 2014, 34, 2567–2571. [Google Scholar] [CrossRef]

- Li, X.; Shimizu, N. Biochar-Promoted Methane Production and Mitigation of Acidification during Thermophilic Anaerobic Co-Digestion of Food Waste with Crude Glycerol: Comparison with Re-Inoculation. Sustain. Environ. Res. 2023, 33, 4. [Google Scholar] [CrossRef]

- Oswald, W.J.; Gotaas, H.B.; Golueke, C.G.; Kellen, W.R.; Gloyna, E.F.; Hermann, E.R. Algae in Waste Treatment [with Discussion]. Sew. Ind. Waste. 1957, 29, 437–457. [Google Scholar]

- Cai, T.; Park, S.Y.; Li, Y. Nutrient Recovery from Wastewater Streams by Microalgae: Status and Prospects. Renew. Sustain. Energy Rev. 2013, 19, 360–369. [Google Scholar] [CrossRef]

- Ehimen, E.A.; Sun, Z.F.; Carrington, C.G.; Birch, E.J.; Eaton-Rye, J.J. Anaerobic Digestion of Microalgae Residues Resulting from the Biodiesel Production Process. Appl. Energy 2011, 88, 3454–3463. [Google Scholar] [CrossRef]

- Herrmann, C.; Kalita, N.; Wall, D.; Xia, A.; Murphy, J.D. Optimised Biogas Production from Microalgae through Co-Digestion with Carbon-Rich Co-Substrates. Bioresour. Technol. 2016, 214, 328–337. [Google Scholar] [CrossRef]

- Mahdy, A.; Mendez, L.; Ballesteros, M.; González-Fernández, C. Algaculture Integration in Conventional Wastewater Treatment Plants: Anaerobic Digestion Comparison of Primary and Secondary Sludge with Microalgae Biomass. Bioresour. Technol. 2015, 184, 236–244. [Google Scholar] [CrossRef]

- Mora-Sánchez, J.F.; Serna-García, R.; Bouzas, A.; Seco, A.; Ruano, M.V. Anaerobic Membrane Bioreactor for Microalgae and Primary Sludge Co-Digestion at Pilot Scale: Instrumentation, Control and Automation Implementation, and Performance Assessment. Water 2023, 15, 3225. [Google Scholar] [CrossRef]

| PS Substrate 1 | Co-Substrate 2 | Inoculum 3 | ISR * (w/w) | OLR + initial g VS/L/d | Tested Concentrations | Mode 4 | Scale 5 | T 6 | Efficiency 7 | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | CEPT | FW | ADS + UASB | 1:5 | - | FW/CEPT 1:1, 1:2, 3:1, 1:2, 1:3 v/v | B | L | M | - | [9] |

| TH | |||||||||||

| 2. | CEPT | FW | ADS + UASB | 1:5 | - | FW/CEPT 1:7, 1:5, 1:3 w/w | B | L | M | +++ | [18] |

| 3. | CEPT | FW | ADS | 1:1 | - | CEPT/FW 1:4, 2:3, 3:2, 4:1 w/w | B | L | M | ++ | [19] |

| 4. | PS | FW | ADS | 1.5:1 | - | FW/PS 1:1 w/w VS | B | L | M | +++ | [20] |

| 5. | PS | FW | ADS | 2:1 | - | FW/PS 3:1, 1:1, 1:3 | B | L | M | ++ | [21] |

| 6. | PS | FVW | ADS | - | 2.5 | PS/FVW 1:4.5 w/w TS− | C | L | M | + | [15] |

| 7. | PS | FVW | - | - | - | PS/FVW 0–100% w/w NaHCO3 4–16 g/kg NaHCO3+ Ca(OH)2 6 + 4 g/kg | B | L | M | +++ | [22] |

| 8. | PS | FVW | CM AS ES | 2:1 | - | PS/FVW—(CM) 2.3:1, 1:1, 1:2.3, 2:4 w/w VS | B | L | M | + | [23] |

| PS/FVW—(CM, AS, ES) 1:1 w/w VS | +++ | ||||||||||

| 9. | PS | OFMSW | ADS | - | 1.0 | OFMSW/PS 1:1, 3:1, 4:1 w/w VS | SC | L | M | - | [24] |

| 10. | PS | OFMSW | UASB | 1:1 | - | OFMSW/PS 1:1 v/v | B | L | M | [25] |

| PS Substrate 1 | Co-Substrate 2 | Inoculum 3 | ISR * | OLR + initial | Tested Concentrations | Mode 4 | Scale 5 | T 6 | Efficiency 7 | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | PS | GL | ADS | 2:1 w/w VS | - | GL 1, 3% v/v | B | L | M | +++ | [102] |

| 2. | PS | GL FW | ADS | 2:1 w/w VS | - | GL 1, 3% v/v | B | L | M | +++ | [103] |

| 3. | PS | GL | ADS | - | 0.98 kg VS/m3/d | GL 0.8–8% w/w | C | L | M | +++ | [104] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakaveli, F.; Petala, M.; Tsiridis, V.; Darakas, E. Enhancing Methane Yield in Anaerobic Co-Digestion of Primary Sewage Sludge: A Comprehensive Review on Potential Additives and Strategies. Waste 2024, 2, 29-57. https://doi.org/10.3390/waste2010002

Sakaveli F, Petala M, Tsiridis V, Darakas E. Enhancing Methane Yield in Anaerobic Co-Digestion of Primary Sewage Sludge: A Comprehensive Review on Potential Additives and Strategies. Waste. 2024; 2(1):29-57. https://doi.org/10.3390/waste2010002

Chicago/Turabian StyleSakaveli, Foteini, Maria Petala, Vasilios Tsiridis, and Efthymios Darakas. 2024. "Enhancing Methane Yield in Anaerobic Co-Digestion of Primary Sewage Sludge: A Comprehensive Review on Potential Additives and Strategies" Waste 2, no. 1: 29-57. https://doi.org/10.3390/waste2010002

APA StyleSakaveli, F., Petala, M., Tsiridis, V., & Darakas, E. (2024). Enhancing Methane Yield in Anaerobic Co-Digestion of Primary Sewage Sludge: A Comprehensive Review on Potential Additives and Strategies. Waste, 2(1), 29-57. https://doi.org/10.3390/waste2010002