Abstract

Billions of poultry are slaughtered globally each year to provide protein for a rapidly expanding human population. The large number of birds produced in conventional systems presents animal welfare issues during production, transport, and at the time of slaughter. While we recognise the significance of welfare issues during rearing and transport, this paper highlights the welfare of poultry at the time of slaughter. The impacts of manual handling, inversion and shackling, use of inappropriate electrical stunning parameters, and the use of aversive gas mixtures during controlled atmosphere stunning are some of the evident welfare lapses; if the entrance to the water bath is wet and not isolated, bird welfare can also be compromised during water bath stunning because of pre-stun shocks. We also highlight the use of aversive stunning methods such as carbon dioxide gas at high concentrations, which has been shown to compromise bird welfare. In conclusion, we offer some reflections on ways to improve the welfare of birds during pre-slaughter handling, stunning, and neck cutting.

1. Introduction

The USA, China, and Brazil are the top three global producers of poultry meat, accounting for a combined share of 45% of the total volume produced [1]. In 2021, this figure was estimated to be approximately 140 m tonnes, which was valued at US $322.5 billion with a compound annual growth rate of 3.8% [2]. A recent report [3] on the growth of chicken production worldwide indicated that by 2050, poultry production is expected to reach 180 million tonnes. This would equal a 1200% increase since 1960, which is three times the growth rate of pork and ten times that of beef. The report argues further that chicken is on track to account for more than 40% of all meat eaten globally by 2030.

Poultry appears to be the most consumed animal protein because it is comparatively cheap, convenient (easy to cook), perceived as healthier (low fat) than other types of meat, and more versatile (easy to use in variety of dishes) [4,5,6]. However, despite the economic significance and potential for continued growth of the market, there are concerns over the welfare aspects of poultry rearing, catching, transport, and slaughter [7,8,9]. Poultry production is also a labour-intensive venture, and as more people move out of rural areas, labour shortages [10] pose a threat to effective animal welfare management that could impact growth [11]. The industry is also at risk of disease outbreaks [12] and food safety lapses [13,14]. Furthermore, there are environmental sustainability concerns regarding soil acidification [15], emissions of harmful gases such as ammonia from poultry waste [16], phosphorus pollution [17], the spread of pathogens, and nutrient leaking [18].

There are also issues with inappropriate stocking densities during rearing and transport, lapses in environmental enrichment during husbandry, and challenges related to potential bone breakages during the catching and collection of birds for transport from farms to abattoirs [19,20,21]. The current EU animal welfare legislation is in the process of being revised and several NGOs (e.g., Eurogroup for Animals) argue that this is a critical time for Europe to take a stronger position against cruelty, improve meat chicken welfare standards, and acknowledge the requirements indicated in the European Chicken Commitment: i.e., the use of breeds that demonstrate higher welfare outcomes, lower maximum stocking densities without derogations, and the provision of natural light, perches, and pecking substrates in barns [22].

The incidence of birds being dead on arrival (DoA), described as the number of birds that die in transit between farms and abattoirs, is arguably the biggest animal welfare challenge facing the global poultry industry. Over a 4-year period (2001–2015), Petracci and colleagues [23] conducted a survey involving 70% of Italian abattoirs to estimate the incidence of DoA. During the period of the study, 1266 million broilers, 118 million turkeys, and 54 million spent hens were transported to the abattoirs surveyed. Spent hens are layer birds that have come to the end of their productive life. In total, 0.47% of broilers, 0.38 of turkeys, and 1.22% of spent hens were found to be DoAs. While these figures may seem insignificant, the number of birds involved is high. For instance, the figure of 0.47% of broilers being dead on arrival at abattoirs equates to 5.9 million individual birds out of a total of 1266 million. Park et al. [11] suggested a radical solution for reducing or preventing DoAs. They argued that on-farm poultry slaughter and the use of mobile processing units could potentially minimise handling and transit times. While this approach may be well suited for low-throughput processors, it may not be practical to implement in companies processing millions of birds.

While we recognise the welfare issues associated with events prior to the arrival of birds at abattoirs, this paper focuses on identifying poultry welfare issues that occur after their arrival: that is, pre-slaughter handling, stunning, and bleeding. It must be reiterated that within the UK and EU, there are humane slaughter regulations that stipulate how birds must be handled, stunned, and bled out to protect welfare (see WATOK, 2015; EC 1099/2009). Despite the existence of these regulations, however, welfare lapses still occur [8,24], and it is these lapses that this paper discusses. More specifically, we examine the welfare issues associated with the following procedures: inversion and shackling during water bath stunning and slaughter without stunning, pre-stun shocks during water bath stunning, aversion to gases during controlled atmosphere stunning, and ineffective stunning.

2. Primary Processing of Poultry

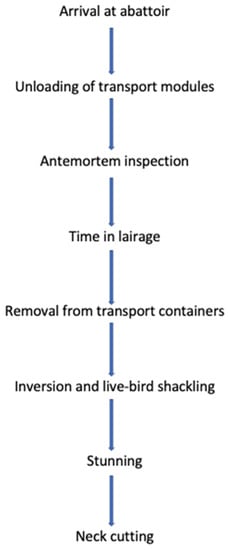

There are some key processes which birds must go through on arrival at abattoirs before they are bled out. These legislated processes are in place to protect the welfare of the birds and ensure that the resulting meat is fit for human consumption. Indeed, it is also worth noting that as well as the potential negative impact on bird welfare, rough pre-slaughter handling can affect the quality of the resulting carcass and meat [25]. For instance, rough handling of birds in the abattoir can impede their welfare by causing acute stress, which then leads to the production of meat of inferior quality known commonly as pale soft exudative (PSE) meat. PSE meats are characterised by an abnormal meat colour with high drip loss, conditions that affect the saleability of meat. Ali and colleagues [25] outlined the main welfare issues before stunning and slaughter as heat stress, feed and water withdrawal, crating and transport, and inversion and live bird shackling. Figure 1 below outlines the mandatory processes for birds (in the UK and within the EU) during primary processing in abattoirs that use water bath stunning [26]. Where animals are stunned using controlled atmosphere (gas) stunning, several steps in Figure 1 are not required, including the removal of birds from transport containers, and inversion and shackling. Non-stun abattoirs follow the same procedures as water bath stunning, except for the stunning stage, which is not performed.

Figure 1.

Primary processing operations during poultry slaughter with water bath stunning (adapted from Fuseini et al. [26], permission obtained).

On arrival at abattoirs using water bath stunning, birds are usually rested in a lairage. They are first unloaded from transport modules and antemortem inspected for notifiable diseases. In addition to inspection for diseased birds, DoAs can also be identified during this antemortem inspection. Jacobs et al. [20] and Caffrey et al. [27] identified the incidence of DoAs as an important indicator of the compromise of birds’ welfare from farm to abattoir. While still in their transport containers or crates, birds may spend some time in the lairage until they are removed from the containers to be inverted and shackled. The shackled birds are then conveyed through an electrified water bath to be stunned before they are bled out; we should note that the removal of individual birds from containers is not needed during controlled atmosphere stunning. The welfare aspects of pre-slaughter handling, water bath stunning, controlled atmosphere stunning, and slaughter without stunning are discussed below. To efficiently assess the welfare consequences of pre-slaughter procedures, the European Food Safety Authority (EFSA) recommends the use of animal-based measures (ABMs), some of which include death, deep breathing, injuries, flight, muscle jerk, panting, vocalisation, and wing flapping [24]. Table 1 is a list of ABMs related to events prior to and following stunning and neck cutting, including their definitions and welfare consequences. The accurate identification of welfare hazards and impending consequences through the use of ABMs can be used to identify the structures, equipment, or personnel responsible for the welfare compromise incident. The EFSA (AHAW Panel) [24] defines a welfare consequence as a change in the welfare of an animal that results from the effect of one or more factors. These factors may be structural (facilities) or related to equipment (transport, shackling, and stunning equipment) or personnel (bird handlers and slaughterers).

Table 1.

List of ABMs, their definitions, and welfare consequences (adapted from EFSA [24]).

3. Animal Welfare Issues Associated with Poultry Slaughter

In this section, we discuss the impact of pre-slaughter handling and slaughter with and without stunning on the welfare of birds. In addition to impacting animal welfare, rough pre-slaughter handling has a significant impact on product quality and profitability [25] (as highlighted above, in relation to meat quality defects and the production of PSE meat).

3.1. Welfare Issues Associated with Pre-Slaughter Operations

To protect the welfare of birds during slaughter, efforts must be made to minimise manual handling. Minimal handling is possible in abattoirs where controlled atmosphere stunning is used because birds are exposed to gases or gaseous mixtures while they are in containers. Conversely, and as already indicated, birds must be removed from transport containers and individually restrained (inverted and shackled) prior to water bath, captive bolt, percussive blow, or cervical dislocation, and during slaughter without stunning [24]. Park and colleagues [11] suggested a combination of artificial intelligence and robotics to automate primary processing of birds with a view to reducing manual handling. There are several issues with the removal of birds from containers and their inversion and shackling. First, it puts birds in an unnatural position which has been shown to be stressful [36,37,38]. Secondly, birds lack a diaphragm, which means that when they are inverted, their viscera (internal organs) move to the thoracic cavity (chest area), thereby causing breathing difficulties that can lead to death if inverted for a long period of time [26]. Shackling has also been shown to cause bone breakages and trauma, particularly in spent hens. To estimate the level of damage caused by shackling, Gregory and Wilkins [39] observed the shackling of spent hens by inspecting them for bone breakages before and after shackling. They found a 44% increase in the proportion of birds showing freshly broken bones, which was concluded to be due to shackling. Kannan [37] noted that inversion and shackling induce fear and pain, resulting in 90% of birds flapping their wings immediately after shackling and 66% flapping when they experienced unevenness along the line. EFSA [24] suggest that wing flapping is likely to result in broken bones or dislocated joints. Wing flapping may be reduced by using breast comforters; one way of achieving this is to use a conveyor beneath the shackle line so that birds can rest on it from the start of shackling until they enter the electrified water bath.

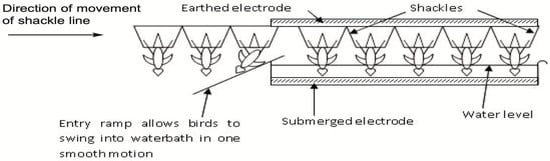

During water bath stunning, birds may experience potentially painful electric shocks at the entrance to the water bath. This occurs when the entry to the water bath is wet and not isolated (live), which results in it being electrified. Rao et al. [40] explained that pre-stun shocks occur when any part of the bird touches the electrified water bath before the bird loses consciousness; wing flapping on entry to the water bath results in pre-stun shocks [24]. It is important to note that pre-stun shocks merely shock birds, but do not stun them. Within the European Union, there is a legislative requirement under Annex 1 of EC 1099/2009 for abattoirs to put in measures aimed at preventing pre-stun shocks to protect bird welfare. Despite this requirement, research has shown that pre-stun shocks are still prevalent in poultry abattoirs [40], although several preventative measures have been suggested [35,41,42]. In a technical note published by the HSA, it was suggested that abattoirs may be able to prevent the incidence of pre-stun shocks by taking the following steps:

- Ensuring that water does not overflow at the entrance to the water bath.

- Ensuring there are sensing devices fitted so that the current is only switched on when birds are in the water bath. This is practical in low-throughput abattoirs where birds are stunned one at a time.

- In high-throughput abattoirs where it is impractical to switch off the current due to multiple birds passing through the water bath at any given time, a steep ramp (extended over the water) should be bolted to the entrance to the water bath to ensure that the head and wings of the bird enters the water first (see Figure 2) [35].

Figure 2. Prevention of pre-stun shocks with an entrance ramp which ensures that birds enter the water bath in a single smooth movement to be stunned immediately (image credit: Humane Slaughter Association (HSA). Reproduced with permission from the HSA from: Electrical Waterbath Stunning of Poultry, HSA 2016 [35]).

Figure 2. Prevention of pre-stun shocks with an entrance ramp which ensures that birds enter the water bath in a single smooth movement to be stunned immediately (image credit: Humane Slaughter Association (HSA). Reproduced with permission from the HSA from: Electrical Waterbath Stunning of Poultry, HSA 2016 [35]).

3.2. Welfare Issues Associated with Ineffective Stunning

Water bath stunning of birds is one of the most problematic methods of stunning from a welfare standpoint. Its effectiveness depends on several factors: bird size, foot resistance/impedance, amount of electrical current, amount of voltage, and frequency. In addition to the welfare issues associated with inversion, shackling, and pre-stun shocks, birds may also be stunned with electrical currents that are not of sufficient magnitude. In the European Council Regulation EC 1099/2009, it is stated that birds must be stunned with a minimum of 100 mA; however, there is sufficient evidence to indicate that millions of birds are currently stunned in UK commercial abattoirs with currents far below the stipulated minimum in EC 1099/2009 and in UK legislation, namely the Welfare of Animals at the Time of Killing (WATOK, 2015) Regulation. A recent report published by the UK’s Food Standards Agency (FSA) suggested that 3% of the 18.4 million birds slaughtered during the period of the survey (7–13 March 2022) were stunned using unapproved electrical parameters [43]. From an animal welfare perspective, the use of electrical parameters outside the regulations are likely to either not stun birds at all or merely immobilise them, thereby compromising the welfare of birds.

EFSA [24] identified poor electric contact as another factor responsible for ineffective stunning during water bath or dry electric head-only stunning of poultry. They explained that in the case of water bath stunning, this occurs between the legs and shackles or between the shackles and earth. In the case of dry electrical stunning of poultry, poor electrical contact may occur between the electrodes and the bird’s head due to dirty electrodes, incorrect electrode placement on the head, or simply the case of an intermittent contact. Table 2 outline some of the welfare hazards associated with water bath stunning.

Table 2.

Animal welfare hazards associated with water bath stunning, and their definitions (definitions adapted from [24]).

Frequency is an important electrical parameter. There are also issues with the use of high-frequency electrical stunning of poultry, which is characterised by a short duration of unconsciousness that presents a danger that many birds may recover consciousness during bleeding. Birds that recover during bleeding will experience the pain associated with the neck cut until death supervenes through sufficient blood loss. Zivotofsky and Strous [44] concluded that the fact that some birds can recover during bleeding defeats the objective of stunning. In multi-bird water bath stunners, birds with high resistance also receive low amount of current in comparison to those with low resistance [26]. Birds receiving low amounts of current are unlikely to be effectively stunned; such birds receive painful electrical shocks [45]. While some of the issues associated with ineffective stunning can be mitigated, others are difficult to overcome. For instance, abattoirs using high frequencies and abnormally low-electrical-current water bath stunning can solve the welfare issues by changing the frequencies and currents, respectively. Hindle et al. [45] noted that it is more difficult to solve the issue of resistance because it is associated with different factors: the presence of multiple birds in the water bath, the condition of shackles (presence of faecal matter and feathers), and the bone structure and thickness of the skull.

3.3. Welfare Issues Associated with Controlled Atmosphere Stunning

Due to the apparent welfare issues associated with water bath stunning of poultry (as discussed above), there has been a decline in the number of abattoirs using this method of stunning in the UK over the last decade or so in favour of controlled atmosphere stunning. In 2011, only 37% of poultry were stunned using controlled atmosphere stunning. This figure had almost doubled to 71% by 2013, and, after a slight drop in 2018 to 70%, it now stands at 80% in 2022 [43,46,47]. While the move away from water bath stunning to controlled atmosphere stunning may have eliminated some welfare issues (including manual handling, inversion and shackling of live birds, pre-stun shocks, and ineffective stunning), controlled atmosphere stunning is not without its own problems and welfare issues. McKeegan and colleagues [34] noted that while controlled atmosphere stunning has the potential to improve bird welfare, there is a lack of consensus as to which gas mixtures are more effective and humane. Different approaches can be employed to stun poultry with gases or gaseous mixtures. In the UK, the most common approaches in commercial abattoirs include the following:

Biphasic approach, which involves exposure to two phases of gaseous mixtures; an anaesthetic phase (involving 40% CO2, 30% N2, or 30% O2) is applied for approximately 60 s to induce brain dysfunction, followed by exposure to a high concentration of CO2 (approximately 80%) in air for approximately 120 s.

Anoxia approach, which involves exposure to inert gases (argon or N2) with less than 3% residual O2.

Hypercapnic anoxia exposure, which involves exposure to inert gases with the addition of up to 30% CO2 in less than 2% residual oxygen.

McKeegan et al. [34] found that birds exposed to hypercapnic anoxic medium showed strong respiratory responses, and this was exacerbated when birds were exposed to biphasic gas mixtures. On the other hand, birds exposed to anoxic conditions showed vigorous wing flapping while they were still conscious. It can be deduced from the findings of [34] that there are welfare issues associated with all three approaches; birds exhibiting strong respiratory responses are likely to be in respiratory discomfort, while those showing vigorous wing flapping are more likely to be injured as a result. Concerns have also been raised regarding the use of high concentrations of carbon dioxide to stun animals, including birds. Anton et al. [48] found that exposure of human subjects to high concentrations of CO2 (between 40 and 55%) elicits pain sensations because it is nociceptive to humans. In birds, several researchers have shown that exposure to high concentrations of the gas is aversive because it activates both central and peripheral chemoreceptors which leads to painful respiratory responses [8,28,49]. It is worth noting that aversion to exposure to high concentrations of CO2 has also been reported in pigs [50,51,52]. Table 3 highlights some welfare hazards associated with exposure of birds to gases.

Table 3.

Animal welfare hazards associated with the use of controlled atmosphere stunning of birds (descriptions adapted from EFSA [24]).

To mitigate the welfare issues associated with the use of some gases or gaseous mixtures, several suggestions have been put forward. Raj [8] suggested a combination of gases that are likely to eliminate aversion, arguing that the use of 30% CO2 and 60% argon in air or 90% argon in air can be humane. McKeegan et al. [34] argued that while some gas mixtures may expose birds to either respiratory discomfort (hypercapnic anoxia and biphasic exposure) or vigorous wing flapping (anoxia), respiratory discomfort is a “price worth paying” when compared with wing flapping. They therefore recommended hypercapnic anoxia and biphasic exposure over anoxia. This view is highly contentious because in all instances, the welfare of birds is compromised. If indeed the objective of humane slaughter is to protect animal welfare during slaughter, animals must not suffer during slaughter. In fact, sections of the Muslim and Jewish communities have long held the belief that stunning is painful [53]; this is a legitimate stance given the fact that some stunning methods are risky in terms of animal welfare. The quest to find truly humane methods for the slaughter of poultry must continue to ensure that birds do not go through potentially painful and aversive procedures during slaughter.

3.4. Welfare Issues Associated with Slaughter without Stunning

European Council Regulation EC 1099/2009 mandates the stunning of all animals prior to slaughter for human consumption. However, EU member states can apply a derogation which allows slaughter without any form of stunning for religious rites. The UK (now outside the EU), Ireland, France, Poland, and others permit slaughter without stunning. From animal welfare standpoint, there are concerns that slaughter without stunning compromises animal welfare [54]. These concerns are related to the stress associated with pre-slaughter restraint (e.g., inversion and shackling in the case of poultry), the pain associated with the neck cut, and the latency of the onset of unconsciousness following neck cutting and during bleeding [24]. Table 4 outlines the main welfare hazards, their consequences, and mitigations during slaughter without stunning. There is evidence to suggest that the neck area is surrounded by high-density nociceptors (pain receptors), which send pain signals to the brain when the skin and tissues are cut during slaughter. EFSA [24] noted that birds may experience increased pain if blunt knives, multiple neck cuts, or changes in cut direction are present during slaughter without stunning because more nociceptors are affected in each case. The pain associated with neck cutting has also been reported in other species. In an experiment involving calves, Gibson et al. [55] used electroencephalograms to measure the electrical activity of the brain and concluded that slaughter without stunning is perceived as a noxious stimulus; in other words, the procedure is painful and compromises animal welfare. Other researchers have made similar conclusions about different species [56,57]. However, it is worth noting that other researchers, albeit a minority, have concluded that when performed correctly, slaughter without stunning can be humane [58,59].

Table 4.

Animal welfare hazards, consequences, and mitigations during slaughter without stunning (EFSA [24]).

Despite these welfare concerns, some halal consumers have indicated a preference for meat processed in this manner; it is regarded as meat of the highest spiritual quality [60] because it guarantees that the animal is alive at the point of exsanguination. Fuseini and Knowles [61] carried out a survey of halal consumers in England and found that the majority of consumers (69.9%) preferred meat from animals slaughtered without stunning. It must be noted that the debate surrounding the acceptability of stunning for halal meat production centres on whether stunning results in death of animals prior to bleeding and whether the procedure obstructs the rate and volume of blood loss [62]. Wotton et al. [63] showed that while some water bath stunning currents/frequency combinations may lead to the death of birds, there are some parameters within Annex 1 of EC 1099/2009 that support the recovery of birds post-stunning. Khalid et al. [60], on the other hand, demonstrated that there is no significant difference in final blood loss between slaughter with stunning, without stunning, or with post-neck-cut stunning. From these findings, it can be concluded that some methods of stunning are non-lethal, and that stunning does not lead to the retention of more blood in the carcass in comparison with slaughter without stunning. It must be noted that the concerns of Muslim consumers around the death of animals due to stunning or the impact of stunning on blood loss are unlikely to be shared by consumers who are not members of this faith community.

4. Quality Assurance Schemes

Quality assurance schemes establish standards, policies, and procedures for the maintenance of animal welfare and product quality. Assurance schemes such as Red Tractor and the Royal Society for the Prevention of Cruelty to Animals (RSPCA) Freedom Food focus on raising animal welfare standards on farms, during transport, and at the point of slaughter. The schemes play a vital role in improving animal welfare by developing standards that require humane handling and slaughter of poultry and other species of animals. The schemes can be either independent or retailers’ own schemes, which usually require farmers and meat processors to meet certain minimum welfare requirements that are usually above those required by legislation. The higher welfare measures are aimed at attracting specific groups of consumers [64]. Nonetheless, these assurance schemes approve stunning methods such as water bath stunning and high-concentration CO2 stunning, which have both been shown to potentially compromise bird welfare. The Better Chicken Commitment (BCC) aims to remove practices that potentially compromise bird welfare. The BCC is a set of welfare standards that has been signed by over 200 leading global food brands with a commitment to eliminate some of the welfare issues highlighted in this paper by the 1 January 2026.

5. Small Poultry Abattoirs and Animal Welfare

Poultry abattoirs are classed as small-, medium-, or large-throughput based on the number of birds they slaughter; this can differ from country to country. The UK’s Ministry of Agriculture, known commonly as the Department for Environment, Food and Rural Affairs (DEFRA) defines small-scale suppliers as those processing fewer than 10,000 birds per year [65]. These operations usually take place on farms and tend to be seasonal processors. Cegar et al. [66], on the other hand, categorised small abattoirs as those slaughtering fewer than 5000 birds per day in commercial facilities in Serbia.

Small-scale abattoirs, in comparison with large-scale abattoirs, may offer some environmental sustainability and welfare improvements. For instance, small-scale abattoirs are local to farms in most cases, thereby eliminating the need for birds to be transported over long distances. A UK All-Party Parliamentary Group for Animal Welfare (APGAW) cited a survey which found that some animals travelled nearly 1000 km to a large-throughput abattoir [67]. Nonetheless, the same report indicated that large abattoirs (poultry and red meat) have the financial means to invest in animal-welfare-friendly infrastructure, such as better lighting in the lairage; good transportation, handling, and restraining devices; and regular in-service training for slaughter operatives and animal handlers. All these investments, when utilised properly by trained operatives, are likely to safeguard bird welfare. One might argue that the lack of improvement in infrastructure in some small abattoirs may be the origin of animal welfare lapses during lairaging, restraint, stunning, and slaughter.

The UK’s Food Standards Agency carried out a survey comparing non-compliance (with animal welfare regulations) in small-, medium-, and large-throughput abattoirs, and they reported that all categories of abattoirs showed good welfare standards. In fact, they reported that 99.9% of animals (all species of animals) that went through UK abattoirs during the period of the survey were treated in accordance with UK welfare regulations [68]. These findings must be interpreted with caution; it should not be assumed that there is 99.9% welfare compliance all year round in the UK, and these results should not be used to suggest the compliance of abattoirs in other countries.

6. Conclusions

In terms of throughput, poultry is the most slaughtered group of animals for human consumption globally. Despite its contribution to the protein needs of the expanding global human population, there are apparent welfare issues associated with pre-slaughter handling, stunning, and bleeding of birds. There are three main slaughter protocols for poultry: slaughter without stunning (mainly for consumption by people of certain faiths), pre-slaughter stunning with controlled atmosphere, and pre-slaughter stunning with water bath. Unfortunately, there are welfare challenges associated with all these methods. Pre-slaughter issues such as inversion and shackling associated with water bath stunning and slaughter without stunning are eliminated during controlled atmosphere stunning; however, controlled atmosphere stunning can also lead to vigorous wing flapping and respiratory distress.

Further research is needed to find more humane methods for poultry slaughter. Modification of the entry to water bath stunners, prevention of overflow of water, and the use of sensing devices to switch on the current when birds are in the water bath may eliminate the issue of pre-stun shocks. Inversion and shackling during slaughter without stunning can be avoided by restraining birds manually by hand; however, this is likely to affect throughput in commercial abattoirs. Further research is needed to identify appropriate gas mixtures to effectively stun birds. It is important that such gases must provide an improvement over current systems that result in respiratory discomfort and vigorous wing flapping. If adopted fully, the Better Chicken Commitment welfare standards will address some of the welfare issues highlighted in this paper, such as inversion and live-bird shackling and the use of carbon dioxide stunning.

Author Contributions

The idea for the manuscript was conceived by A.F., the manuscript was written and reviewed by A.F., M.M. and J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Global Trade Magazine. Global Poultry Production Reach 137 m Tonnes in 2020, Mainly Driven by Growth in China, the EU and the UK. Available online: https://www.globaltrademag.com/global-poultry-production-to-reach-137m-tonnes-in-2020-mainly-driven-by-growth-in-china-the-eu-and-the-uk/ (accessed on 28 November 2022).

- FAO. Statistical Yearbook: World Food and Agriculture; FAO: Rome, Italy, 2021; pp. 1–78.

- Henriksen, J. The Future of Chicken beyond 2050. Poultry World. Available online: https://www.poultryworld.net/the-industrymarkets/market-trends-analysis-the-industrymarkets-2/the-future-of-chicken-poultry-beyond-2050/ (accessed on 22 December 2022).

- Magdelaine, P.; Spiess, M.P.; Valceschini, E. Poultry meat consumption trends in Europe. World’s Poult. Sci. J. 2008, 64, 53–64. [Google Scholar] [CrossRef]

- Kyarisiima, C.C.; Naggujja, F.A.; Magala, H.; Kwizera, H.; Kugonza, D.R.; Bonabana-Wabhi, J. Perceived tasteness and preferences of chicken meat in Uganda. Liv. Res. Rural Dev. 2011, 23, 2–7. [Google Scholar]

- Chatterjee, R.N.; Rajkumar, U. An overview of poultry production in India. Indian J. Anim. Health 2015, 54, 89–108. [Google Scholar]

- Wotton, S.B.; Gregory, N.G. How to prevent pre-stun shocks in water bath stunners. Turkeys 1991, 39, 15–30. [Google Scholar]

- Raj, M. Welfare during stunning and slaughter of poultry. Poult. Sci. 1998, 77, 1815–1819. [Google Scholar] [CrossRef] [PubMed]

- Duncan, I.J. Animal welfare issues in the poultry industry: Is there a lesson to be learnt? J. Appl. Anim. Welf. Sci. 2010, 4, 207–221. [Google Scholar] [CrossRef]

- Zahniser, S.; Taylor, J.E.; Hertz, T.; Charlton, D. Farm Labor Markets in the United States and Mexico Pose Challenges for US Agriculture; Economic Information Bulletin No. EIB-201; U.S. Department of Agriculture: Washington, DC, USA, 2018; pp. 1–40.

- Park, M.; Britton, D.; Daley, W.; McMurray, G.; Navaei, M.; Samoylov, A.; Usher, C.; Xu, J. Artificial intelligence, sensors, robots, and transportation systems drive an innovative future for poultry broiler and breeder management. Anim. Front. 2022, 12, 41–47. [Google Scholar] [CrossRef]

- McLeod, A.; Morgan, N.; Prakash, A.; Hinrichs, J. Economic and social impact of avian influenza. In Proceedings of the Joint FAO/OMS/OIE/World Bank Conference on Avian Influenza and Human Pandemic Influenza, Milan, Italy, 23 September 2005. [Google Scholar]

- Scallan, E.; Griffin, P.M.; Angulo, F.J.; Tauxe, R.V.; Hoekstra, R.M. Foodborne illness acquired in the United States—Unspecified agents. Emerg. Infect. Dis. 2011, 17, 16. [Google Scholar] [CrossRef]

- Nuñez, I.A.; Ross, T.M. A review of H5Nx avian influenza viruses. Ther. Adv. Vaccin. Immunother. 2019, 7, 2515135518821625. [Google Scholar] [CrossRef]

- Beausang, C.; McDonnell, K.; Murphy, F. Anaerobic digestion of poultry litter—A consequential life cycle assessment. Sci. Total Environ. 2020, 735, 139494. [Google Scholar] [CrossRef]

- Joardar, J.C.; Mondal, B.; Sikder, S. Comparative study of poultry litter and poultry litter biochar application in the soil for plant growth. SN Appl. Sci. 2020, 2, 1770. [Google Scholar] [CrossRef]

- Lamm, M.; Markow, L.; Bernhardt, C.; Pelton, T. Blind Eye to Big Chicken: The Environmental Integrity Project. 2021. Available online: https://environmentalintegrity.org/wp-content/uploads/2021/10/MD-Poultry-Report-10-28-21.pdf (accessed on 23 December 2022).

- Reddy, K.C.; Reddy, S.S.; Malik, R.K.; Lemunyon, J.L.; Reeves, D.W. Effect of five-year continuous poultry litter use in cotton produc- tion on major soil nutrients. Agron. J. 2008, 100, 1047–1055. [Google Scholar] [CrossRef]

- Mitchell, M.A.; Kettlewell, P.J. Welfare of poultry during transport—A review. In Poultry Welfare Symposium; Association Proceeding: Cervia, Italy, 2009; pp. 90–100. [Google Scholar]

- Jacobs, L.; Delezie, F.; Duchateau, L.; Goethals, K.; Tuyttens, F.A. Impact of the separate pre-slaughter stages on broiler chicken welfare. Poult. Sci. 2017, 96, 266–273. [Google Scholar] [CrossRef] [PubMed]

- Saraiva, S.; Esteves, A.; Oliveira, I.; Mitchell, M.; Stilwell, G. Impact of pre-slaughter factors on welfare of broilers. Vet. Anim. Sci. 2020, 10, 100146. [Google Scholar] [CrossRef]

- Mcdougal, T. Calls for Stronger Poultry Welfare Rules across Europe. Poultry World. 2022. Available online: https://www.poultryworld.net/poultry/broilers/calls-for-stronger-animal-welfare-rules-across-europe/2022 (accessed on 23 December 2022).

- Petracci, M.; Bianchi, M.; Cavani, C.; Gaspari, P.; Lavazza, A. Preslaughter mortality in broiler chickens, turkeys, and spent hens under commercial slaughtering. Poult. Sci. 2006, 85, 1660–1664. [Google Scholar] [CrossRef]

- European Food Safety Authority (EFSA). Slaughter of animals: Poultry. EFSA J. 2019, 17, 5849. [Google Scholar]

- Ali, M.S.; Kang, G.H.; Joo, S.T. A review: Influences of pre-slaughter stress on poultry meat quality. Asian-Aust. J. Anim. Sci. 2008, 21, 912–916. [Google Scholar] [CrossRef]

- Fuseini, A.; Teye, M.; Wotton, S.B.; Lines, J.A.; Knowles, T.G. Electrical water bath stunning for Halal poultry meat production: Animal welfare issues and compatibility with the Halal rules. CAB Revs. 2018, 13, 1–6. [Google Scholar] [CrossRef]

- Caffrey, N.P.; Dohoo, I.R.; Cockram, M.S. Factors affecting mortality risk during transportation of broiler chickens for slaughter in Atlantic Canada. Prev. Vet. Med. 2017, 147, 199–208. [Google Scholar] [CrossRef]

- Gerritzen, M.A.; Lambooij, E.; Stegeman, J.A.; Spruijt, B.M. Slaughter of poultry during the epidemic of avian influenza in the Netherlands in 2003. Vet. Rec. 2006, 159, 39–42. [Google Scholar] [CrossRef]

- Graml, C.; Niebuhr, K.; Waiblinger, S. Reaction of laying hens to humans in the home or a novel environment. Appl. Anim. Behav. Sci. 2007, 113, 98–109. [Google Scholar] [CrossRef]

- EFSA AHAW Panel. Scientific opinion on the use of animal based measures to assess welfare of broilers. EFSA J. 2012, 2774, 74. [Google Scholar]

- Strawford, M.; Watts, J.M.; Crowe, T.; Classen, H.; Shand, P.J. The effect of stimulated cold weather transport on cold body temperature and behaviour of broilers. Poult. Sci. 2011, 90, 2124–2415. [Google Scholar] [CrossRef] [PubMed]

- Manteuffel, G.; Puppe, B.; Schon, P.C. Vocalisation of farm animals as a measure of welfare. Appl. Anim. Behav. Sci. 2004, 88, 163–182. [Google Scholar] [CrossRef]

- Erasmus, M.A.; Turner, P.V.; Widowski, T.A. Measures of insensibility used to determine effective stunning and killing of poultry. J. Appl. Poult. Res. 2010, 19, 288–298. [Google Scholar] [CrossRef]

- McKeegan, D.E.F.; McIntyre, J.A.; Demmers, T.G.M.; Lowe, J.C.; Wathes, C.M.; van de Broek, P.; Coenen, A.M.L.; Gentle, M.J. Physiological and behavioural responses of broilers to controlled atmosphere stunning: Implications for welfare. Anim. Welf. 2007, 16, 409–426. [Google Scholar] [CrossRef]

- Humane Slaughter Association (HSA). Guidance Notes No. 7 Electrical Waterbath Stunning of Poultry. 2016. Available online: www.hsa.org.uk/shop/publications-1/product/electrical-waterbath-stunning (accessed on 14 February 2023).

- Sparrey, J.M.; Kettlewell, P.J. Shackling of poultry: Is it a welfare problem? World’s Poult. Sci. Assoc. 1994, 50, 167–176. [Google Scholar] [CrossRef]

- Kannan, G.; Heath, J.L.; Wabeck, C.J.; Mench, J.A. Shackling of broilers: Effect on stress responses and breast meat quality. Br. Poult. J. 1997, 38, 323–332. [Google Scholar] [CrossRef]

- Debut, M.; Berri, C.; Arnould, C.; Guemene, D.; Sante-Lhoutellier, V.; Sellier, N. Behavioural and physiological responses of three chicken breeds to pre-slaughter shackling and acute stress. Br. Poult. Sci. 2005, 46, 527–535. [Google Scholar] [CrossRef]

- Gregory, N.G.; Wilkins, L.J. Broken bones in domestic: Handling and processing damage in end-of-lay hens. Br. Poult. Sci. 1989, 30, 555–562. [Google Scholar] [CrossRef]

- Rao, M.A.; Knowles, T.G.; Wotton, S.B. The effect of pre-stun shocks in electrical water-bath stunners on carcase and meat quality in broilers. Anim. Welf. 2013, 22, 79–84. [Google Scholar] [CrossRef]

- Raj, A.B.M.; Tserveni-Gousi, A. Stunning methods for poultry. World’s Poult. Sci. J. 2000, 56, 292–304. [Google Scholar] [CrossRef]

- Humane Slaughter Association (HSA). Prevention of Pre-Stun Shocks in Water Baths; Technical Note; HSA Wheathampstead: Herts, UK, 2006. [Google Scholar]

- Food Standards Agency (FSA). Farm Animals: Slaughter Sector Survey 2022. Available online: https://www.gov.uk/government/publications/farm-animals-slaughter-sector-survey-2022 (accessed on 12 December 2022).

- Zivotofsky, A.Z.; Strous, R.D. A perspective on the electrical stunning of animals: Are there lessons to be learned from human electro-convulsive therapy (ECT)? Meat Sci. 2012, 90, 956–961. [Google Scholar] [CrossRef]

- Hindle, V.A.; Lambooij, E.; Reimert, H.G.M.; Workel, L.D.; Gerritzen, M.A. Animal welfare concerns during the use of the water bath for stunning broilers, hens, and ducks. Poult. Sci. 2010, 89, 401–412. [Google Scholar] [CrossRef]

- Food Standards Agency (FSA). Results of the 2013 Animal Welfare Survey in Great Britain. 2013. Available online: https://www.food.gov.uk/sites/default/files/2013-animalwelfare-survey.pdf (accessed on 12 December 2022).

- Food Standards Agency (FSA). Results of the 2018 FSA Survey into Slaughter Methods in England and Wales; FSA: London, UK, 2019.

- Anton, F.; Euchner, I.; Handwerker, H.O. Psychophysical examination of pain induced by defined CO2 pulses applied to the nasal mucosa. Pain 1992, 49, 53–60. [Google Scholar] [CrossRef]

- Gerritzen, M.A.; Lambooij, B.; Reimert, H.; Stegeman, A.; Spruijt, B. On-farm euthanasia of broiler chickens: Effects of different gas mixtures on behavior and brain activity. Poult. Sci. 2004, 83, 1294–1301. [Google Scholar] [CrossRef]

- Raj, A. Recent developments in stunning and slaughter of poultry. World’s Poult. Sci. J. 2006, 62, 467–484. [Google Scholar] [CrossRef]

- Gent, T.C.; Gebhardt-Henrich, S.; Schild, S.L.A.; Abdel Rahman, A.; Toscano, M.J. Evaluation of poultry stunning with low atmospheric pressure, carbon dioxide or nitrogen using a single aversion testing paradigm. Animals 2020, 10, 1308. [Google Scholar] [CrossRef] [PubMed]

- Raj, A.B.M.; Johnson, S.P.; Wotton, S.B.; McInstry, J.L. Welfare implications of gas stunning pigs: 3. The time to loss of somatosensory evoked potentials and spontaneous electrocorticogram of pigs during exposure to gases. Vet. J. 1997, 153, 329–339. [Google Scholar] [CrossRef] [PubMed]

- Fuseini, A. Halal Slaughter of Livestock: Animal Welfare Science, History and Politics of Religious Slaughter; Springer Nature: Gewerbestrasse, Switzerland, 2023. [Google Scholar]

- FAWC. Report on the welfare of livestock when slaughtered by religious methods. In HMSO Reference Book 262; HMSO: London, UK, 1984; p. 49. [Google Scholar]

- Gibson, T.J.; Johnson, C.B.; Murrell, J.C.; Hulls, C.M.; Mitchinson, S.L.; Stafford, K.J.; Johnstone, A.C.; Mellor, D.J. Electroencephalographic responses of halothane-anaesthetised calves to slaughter by ventral-neck incision without prior stunning. N. Z. Vet. J. 2009, 57, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Daly, C.C.; Kallweit, E.; Ellendorf, F. Cortical function in cattle during slaughter: Conventional captive bolt stunning followed by exsanguination compared with shechita slaughter. Vet. Record. 1988, 122, 325–329. [Google Scholar] [CrossRef]

- Kalweit, E.; Ellendorf, F.; Daly, C.; Smidt, D. Physiological reactions during slaughter of cattle and sheep with and without stunning. Dtsch. Tiearztl Wochenschr. 1989, 96, 89–92. [Google Scholar]

- Grandin, T.; Regenstein, J.M. Religious slaughter and animal welfare: A discussion for meat scientists. Meat Focus Int. 1994, 2, 115–123. [Google Scholar]

- Rosen, S.D. Physiological insights into Shechita. Vet. Record. 2004, 154, 759–765. [Google Scholar] [CrossRef] [PubMed]

- Khalid, R.; Knowles, T.G.; Wotton, S.B. A comparison of blood loss during the Halal slaughter of lambs following traditional religious slaughter without stunning, electric head-only stunning and post-cut electric head-only stunning. Meat Sci. 2015, 110, 15–23. [Google Scholar] [CrossRef]

- Fuseini, A.; Knowles, T.G. The ethics of Halal meat consumption: Preferences of consumers in England according to the method of slaughter. Vet. Record. 2020, 186, 644. [Google Scholar] [CrossRef]

- Fuseini, A.; Wotton, S.B.; Hadley, P.J.; Knowles, T.G. The perception and acceptability of pre-slaughter and post-slaughter stunning for Halal production: The views of UK Islamic scholars and Halal consumers. Meat Sci. 2017, 123, 143–150. [Google Scholar] [CrossRef]

- Wotton, S.B.; Zhang, X.; Mckinstry, J.; Velarde, A.; Knowles, T.G. The effect of the required current/frequency combinations (EC 1099/2009) on the incidence of cardiac arrest in broilers stunned and slaughtered for the Halal market. PeerJ 2014, e255v1. [Google Scholar] [CrossRef]

- Manning, L.; Baines, R.N.; Chadd, S.A. Quality assurance models in food supply chain. Br. Food J. 2006, 108, 91–104. [Google Scholar] [CrossRef]

- DEFRA. Slaughtering Poultry, Rabbits and Hares on Farms for Small-Scale Suppliers. Available online: https://www.gov.uk/guidance/slaughtering-poultry-rabbits-and-hares-on-farms-for-small-scale-suppliers (accessed on 4 February 2022).

- Cegar, S.; Kuruca, L.; Vidovic, B.; Antic, D.; Hauge, S.J.; Alvseike, O.; Blagojevic, B. Risk categorization of poultry abattoirs on the basis of the current process hygiene criteria and indicator microorganisms. Food Control 2022, 132, 108530. [Google Scholar] [CrossRef]

- APGAW. The Future for Small Abattoirs in the UK: Report on an Inquiry into Small Red Meat Abattoir Provision. Available online: https://apgaw.org/wp-content/uploads/2020/06/The-Future-for-Small-Abattoirs-in-the-UK.pdf (accessed on 4 February 2023).

- FSA. Animal Welfare Non-Compliance in Abattoirs. Available online: https://www.food.gov.uk/sites/default/files/media/document/fsa-19-09-20-annex-animal-welfare-final.pdf (accessed on 4 February 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).