Using Molecular Dynamic Simulation to Understand the Deformation Mechanism in Cu, Ni, and Equimolar Cu-Ni Polycrystalline Alloys

Abstract

1. Introduction

2. Simulation Method and Conditions

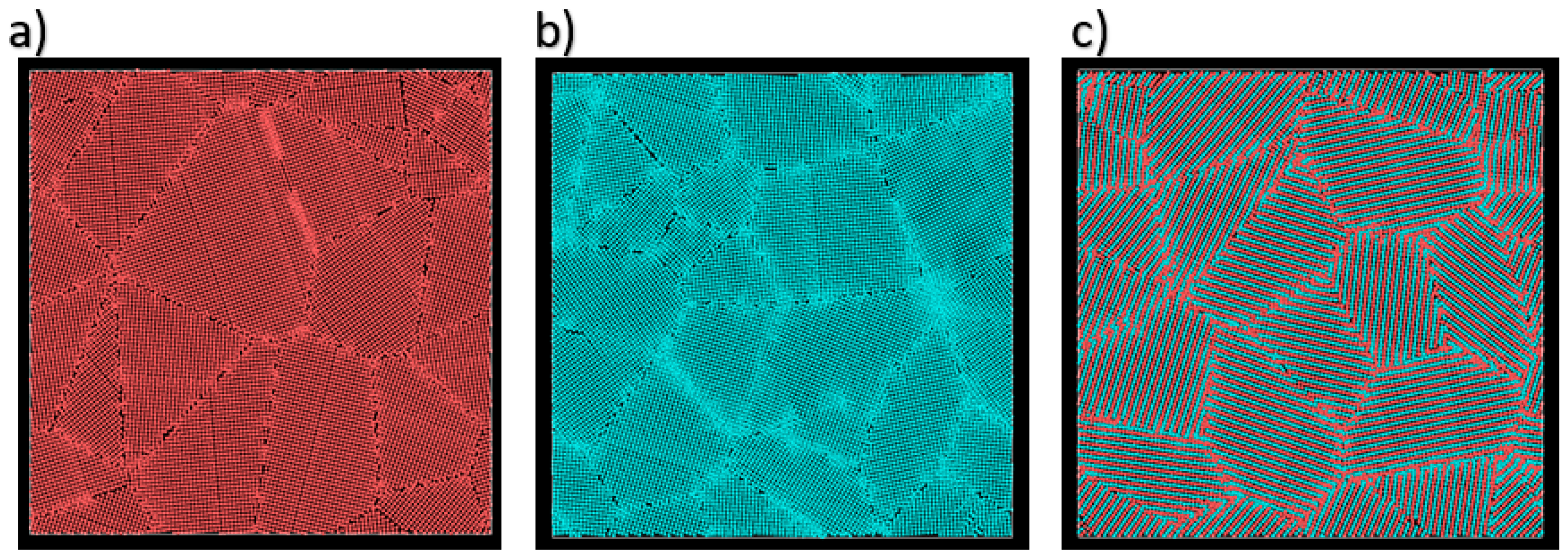

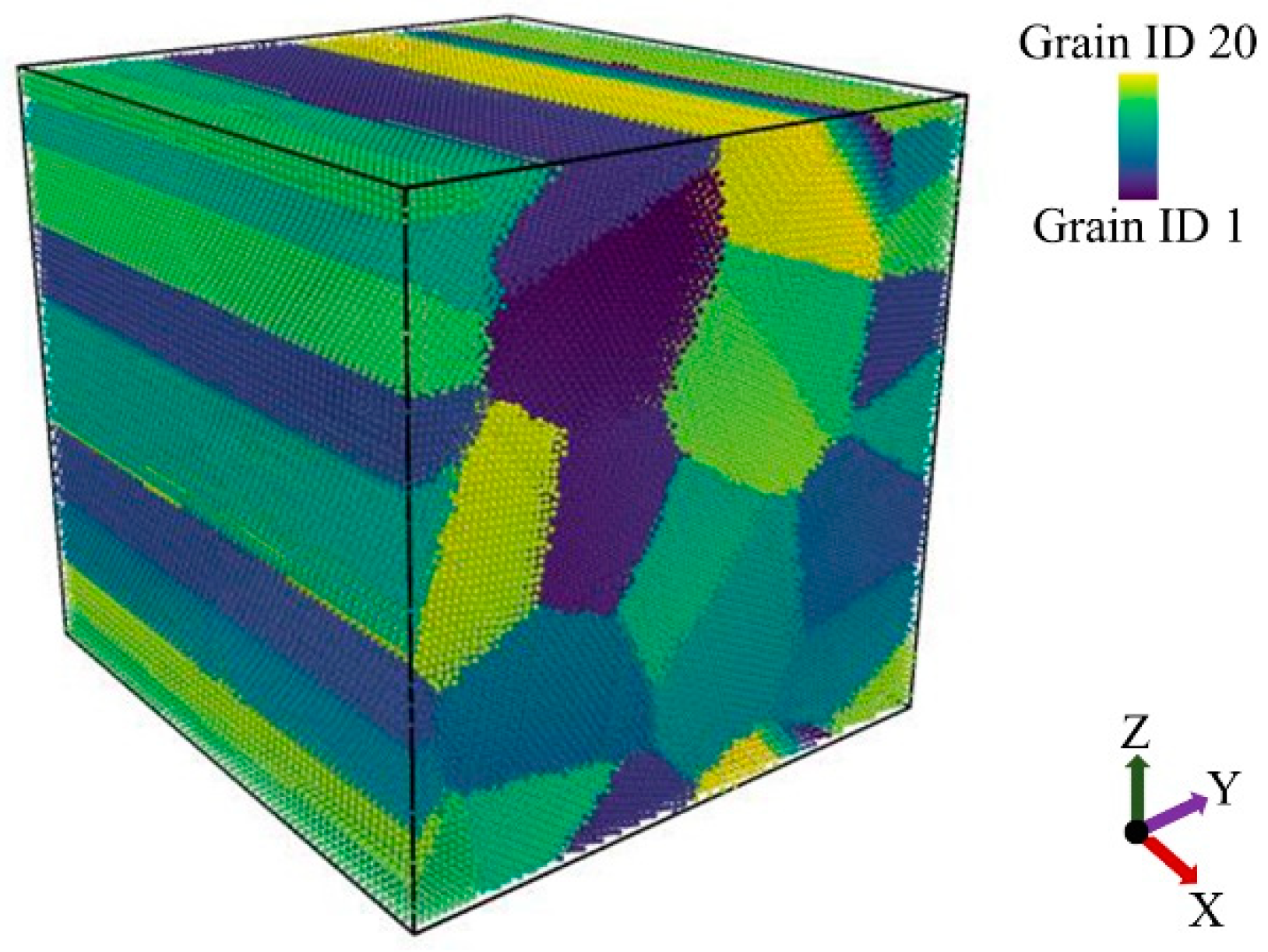

2.1. Building Polycrystals Structure

2.2. Simulation of the Deformation

3. Results and Discussion

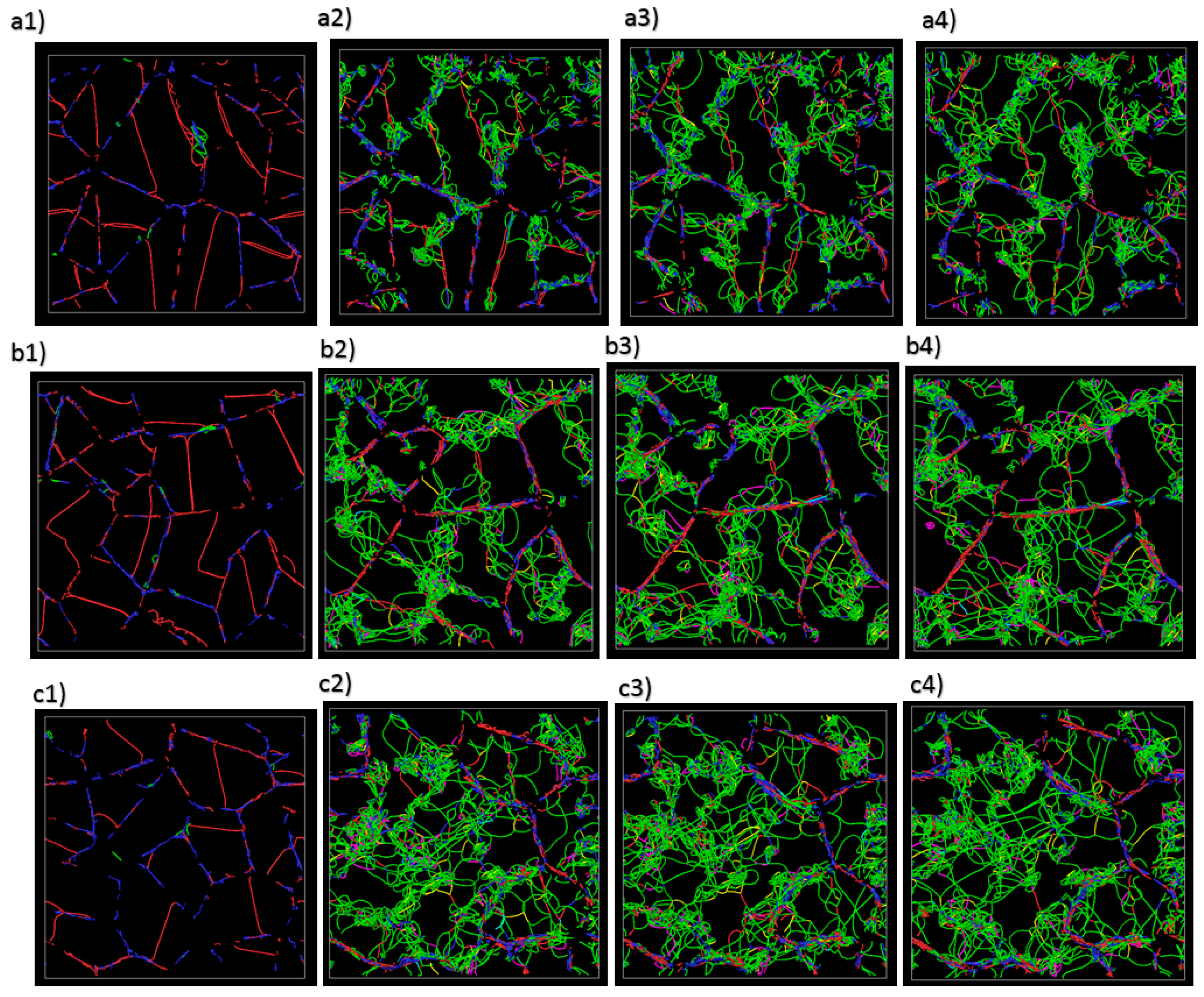

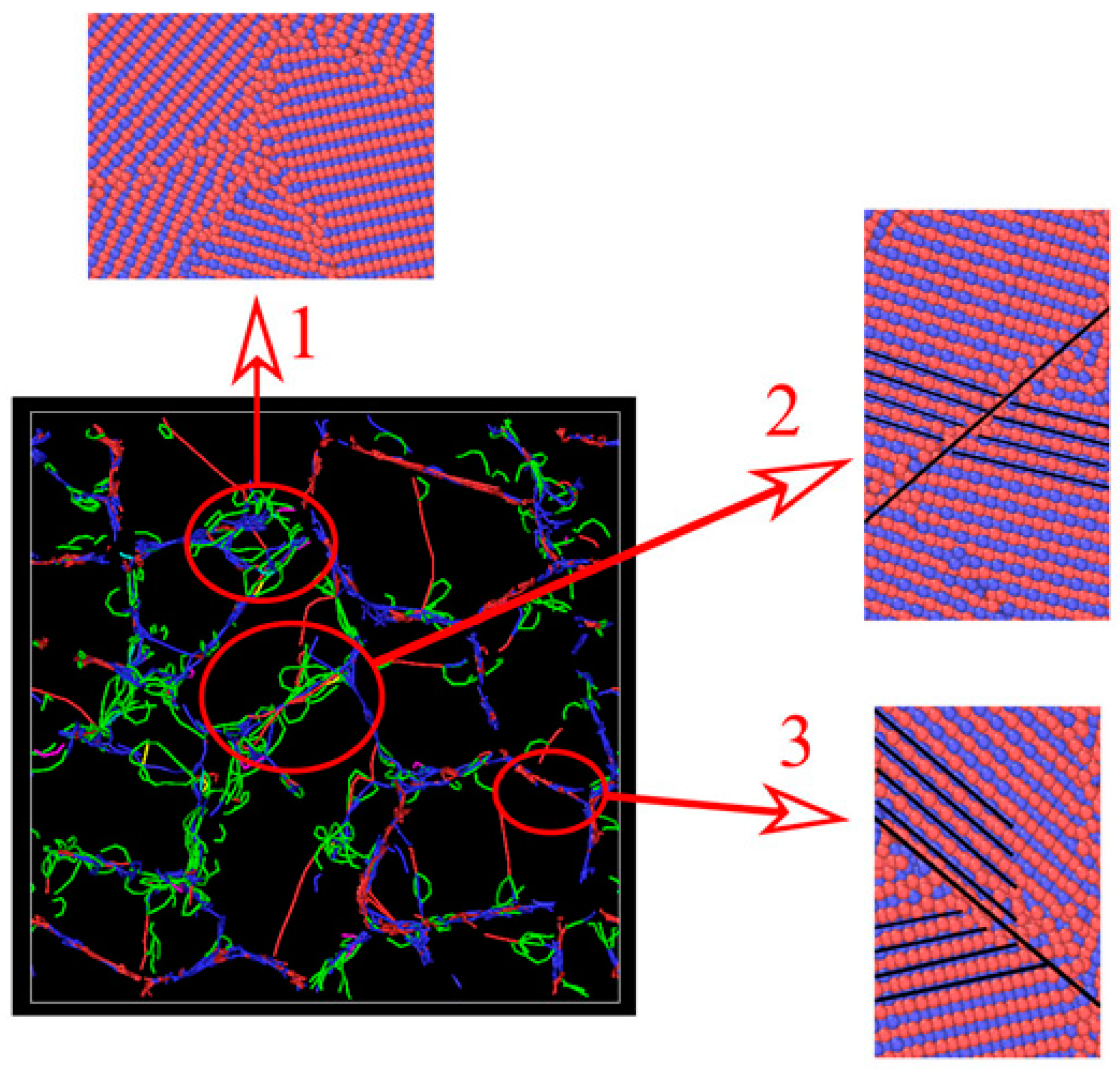

3.1. Nucleation and Growth of Dislocations

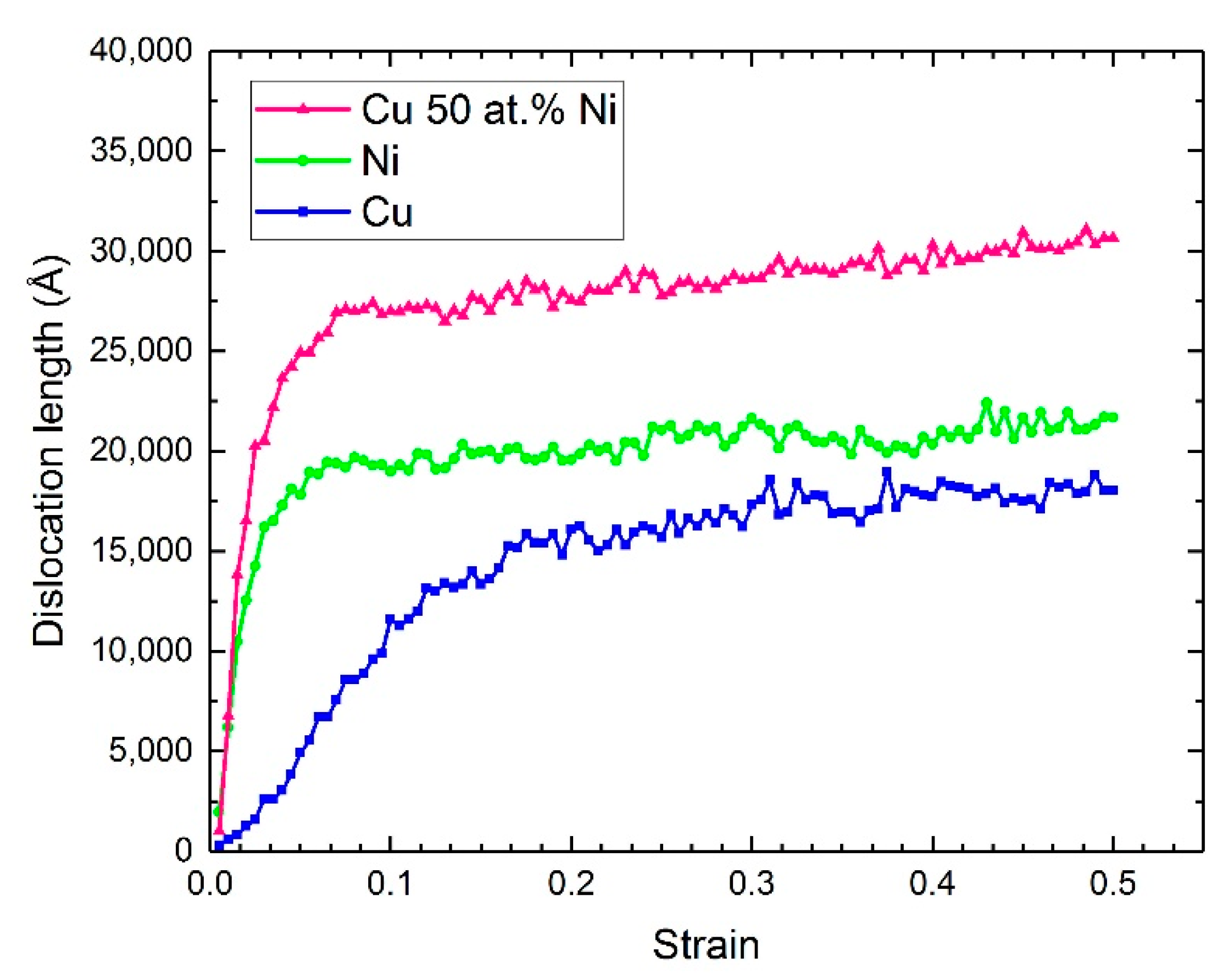

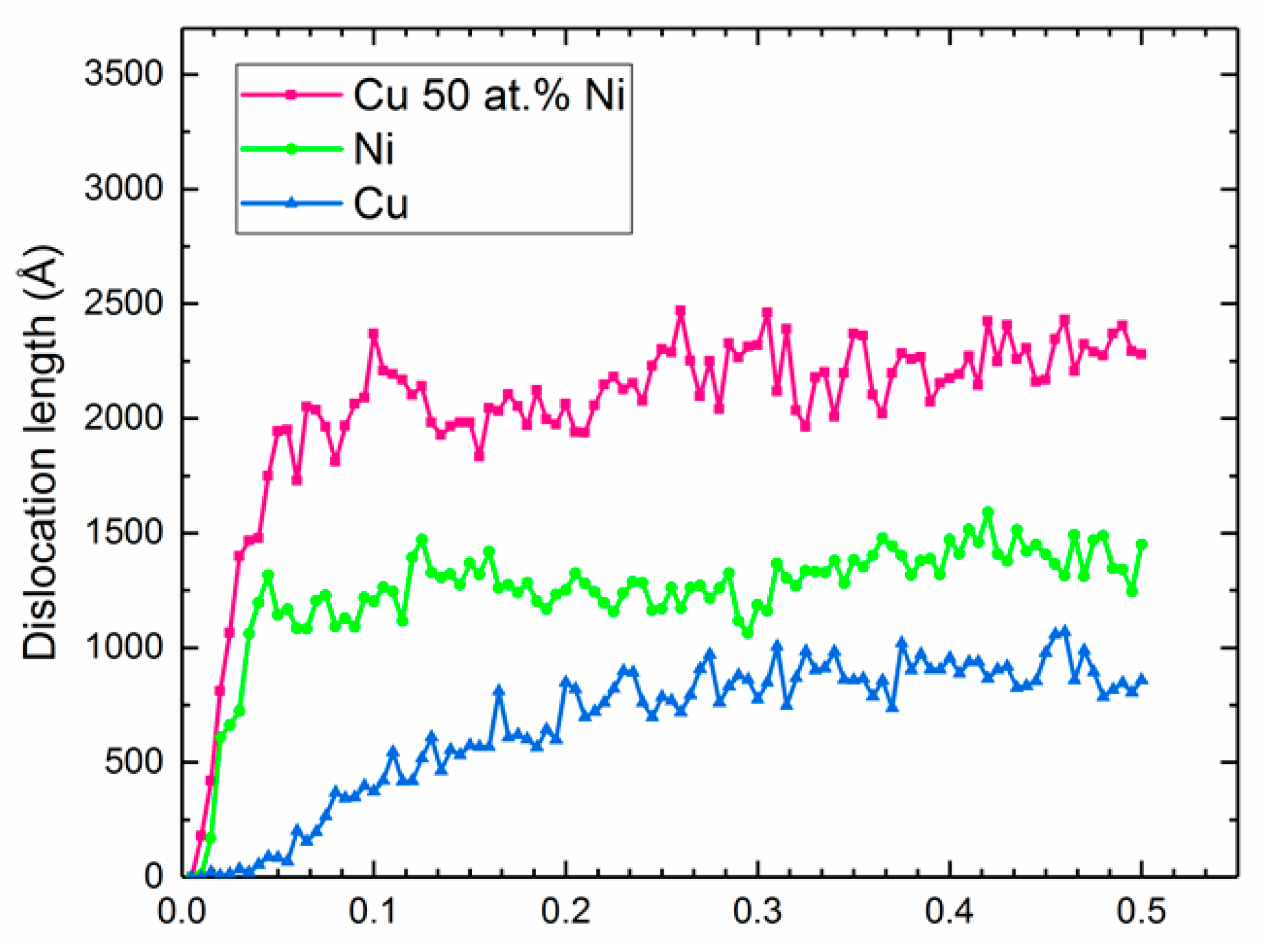

3.2. Dislocation Length

3.3. Stress–Stain Curve

3.4. Stacking Faults

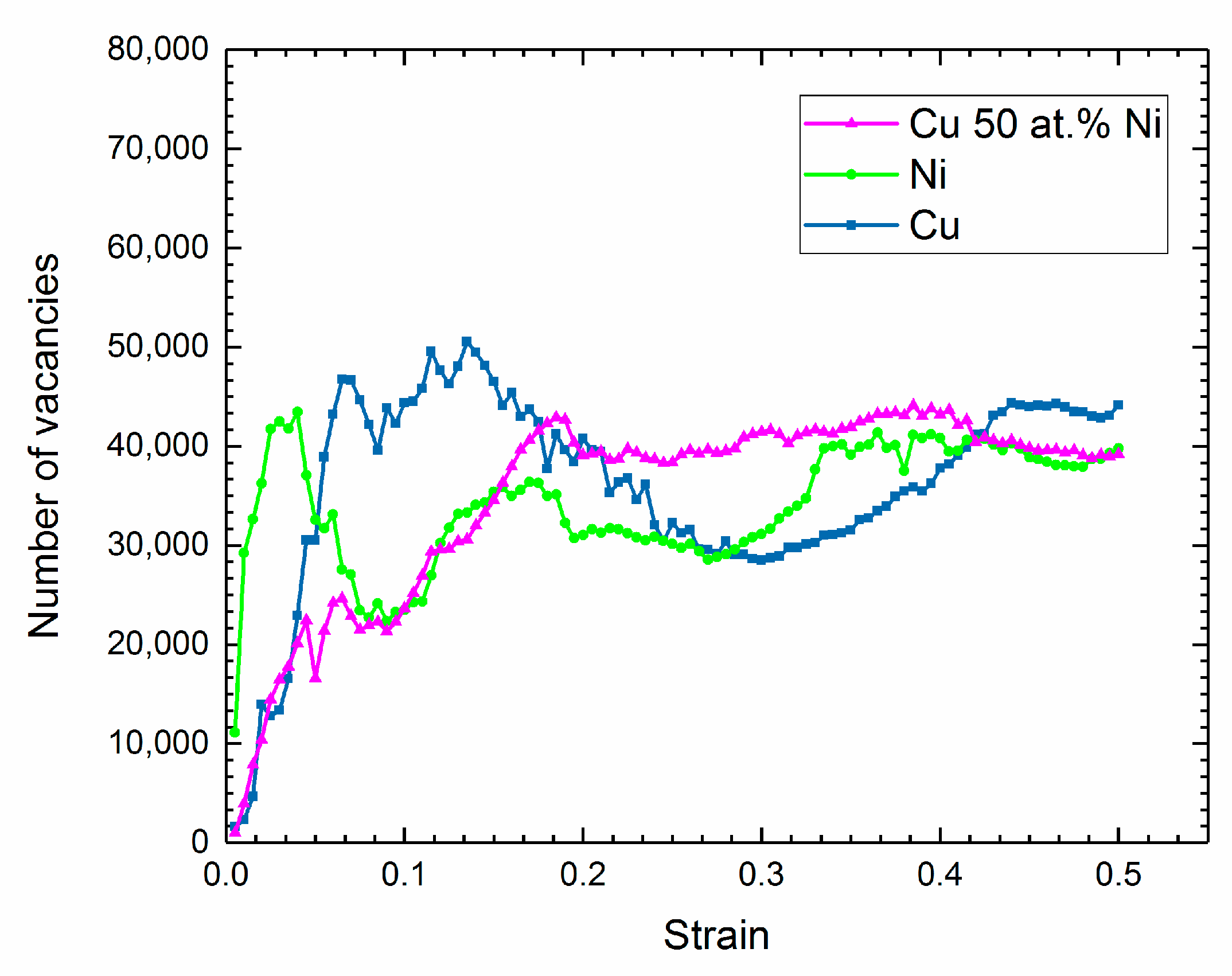

3.5. Vacancy Formation

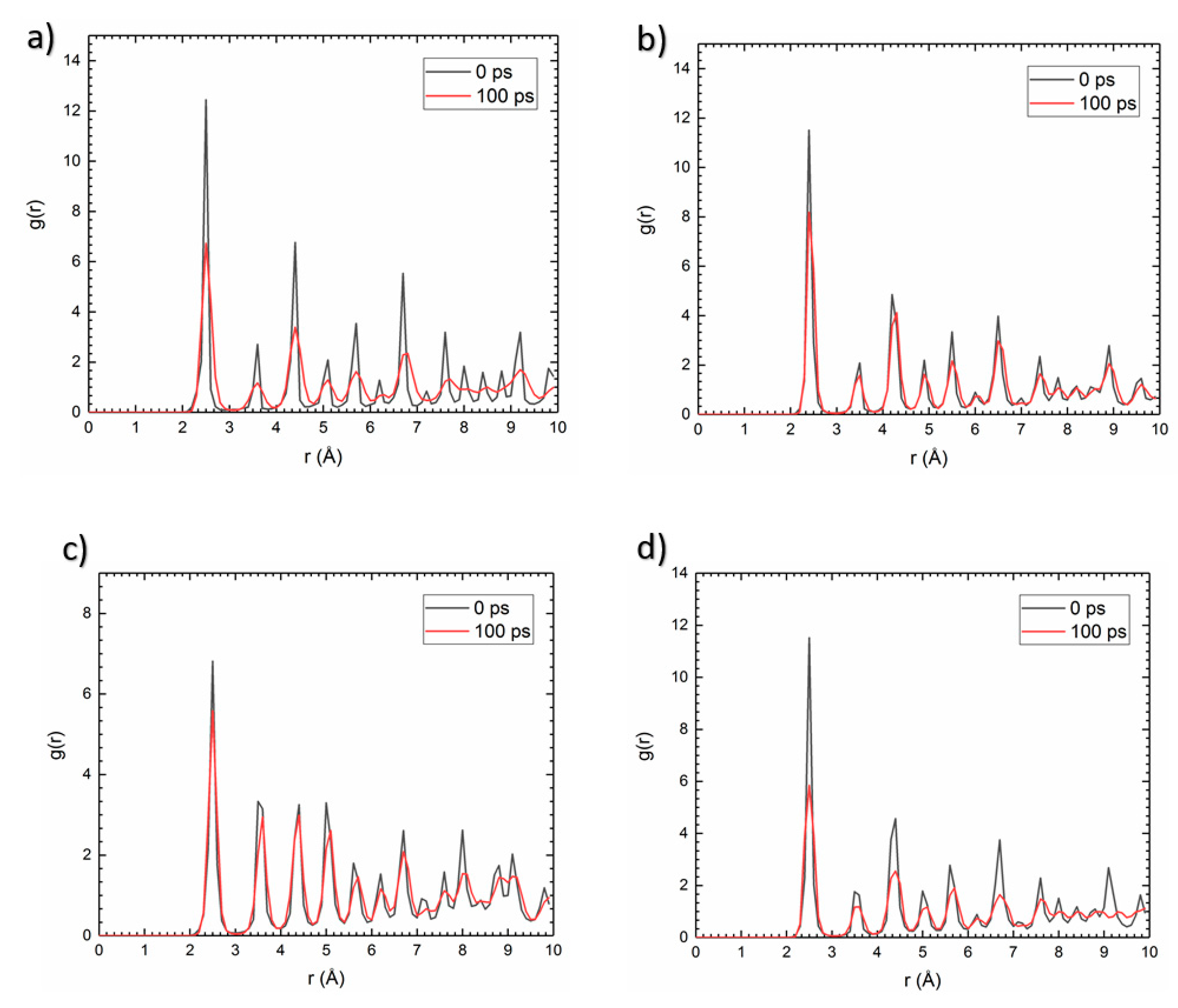

3.6. Radial Distribution Function

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Molaei, F.; Nojabaei, B. Atomistic Simulation of Temperature and Defects Effects on Mechanical Properties of Selected Single and Bicrystalline Geomaterials. J. Mol. Graph. Model. 2022, 117, 108320. [Google Scholar] [CrossRef]

- Zhang, F.; Li, G.; Zhu, D.; Zhou, J. Grain Size Effect on the Mechanical Behaviors in Nanocrystalline Cu-Ag Alloy with Grain Boundary Affect Zone Segregation. Mater. Lett. 2020, 278, 128406. [Google Scholar] [CrossRef]

- Qi, Y.; Xu, H.; He, T.; Feng, M. Effect of Crystallographic Orientation on Mechanical Properties of Single-Crystal CoCrFeMnNi High-Entropy Alloy. Mater. Sci. Eng. A 2021, 814, 141196. [Google Scholar] [CrossRef]

- Rao, S.I.; Antillon, E.; Woodward, C.; Akdim, B.; Parthasarathy, T.A.; Senkov, O.N. Solution Hardening in Body-Centered Cubic Quaternary Alloys Interpreted Using Suzuki’s Kink-Solute Interaction Model. Scr. Mater. 2019, 165, 103–106. [Google Scholar] [CrossRef]

- Antillon, E.; Woodward, C.; Rao, S.I.; Akdim, B.; Parthasarathy, T.A. Chemical Short Range Order Strengthening in a Model FCC High Entropy Alloy. Acta Mater. 2020, 190, 29–42. [Google Scholar] [CrossRef]

- Rupert, T.J. Solid Solution Strengthening and Softening Due to Collective Nanocrystalline Deformation Physics. arXiv 2014, arXiv:1407.5933. [Google Scholar] [CrossRef]

- Pun, S.C.; Wang, W.; Khalajhedayati, A.; Schuler, J.D.; Trelewicz, J.R.; Rupert, T.J. Nanocrystalline Al-Mg with Extreme Strength Due to Grain Boundary Doping. Mater. Sci. Eng. A 2017, 696, 400–406. [Google Scholar] [CrossRef]

- Rajgarhia, R.K.; Spearot, D.E.; Saxena, A. Plastic Deformation of Nanocrystalline Copper-Antimony Alloys. J. Mater. Res. 2010, 25, 411–421. [Google Scholar] [CrossRef]

- Rajgarhia, R.K.; Spearot, D.E.; Saxena, A. Heterogeneous Dislocation Nucleation in Single Crystal Copper–Antimony Solid-Solution Alloys. Model. Simul. Mater. Sci. Eng. 2009, 17, 55001. [Google Scholar] [CrossRef]

- Kamalakshi, G.; Pant, P.; Gururajan, M.P. Deformation Behaviour of Cu and Cu–Al in the Dislocation Starved Regime: A Molecular Dynamics Study. Comput. Mater. Sci. 2022, 203, 111087. [Google Scholar] [CrossRef]

- Mojumder, S.; Thakur, M.S.H.; Islam, M.; Mahboob, M.; Motalab, M. Numerical Investigation of Mechanical Properties of Aluminum-Copper Alloys at Nanoscale. J. Nanoparticle Res. 2021, 23, 1–20. [Google Scholar] [CrossRef]

- Szczerba, M.J.; Szczerba, M.S. Slip versus Twinning in Low and Very Low Stacking-Fault Energy Cu-Al Alloy Single Crystals. Acta Mater. 2017, 133, 109–119. [Google Scholar] [CrossRef]

- Martínez, C.; Briones, F.; Rojas, P.; Aguilar, C.; Guzman, D.; Ordoñez, S. Microstructural and Mechanical Characterization of Copper, Nickel, and Cu-Based Alloys Obtained by Mechanical Alloying and Hot Pressing. Mater. Lett. 2017, 209, 509–512. [Google Scholar] [CrossRef]

- Eder, S.J.; Grützmacher, P.G.; Rodríguez Ripoll, M.; Dini, D.; Gachot, C. Effect of Temperature on the Deformation Behavior of Copper Nickel Alloys under Sliding. Materials 2020, 14, 60. [Google Scholar] [CrossRef] [PubMed]

- Bryukhanov, I.A. Dynamics of Edge Dislocation in Cu–Ni Solid Solution Alloys at Atomic Scale. Int. J. Plast. 2020, 135, 102834. [Google Scholar] [CrossRef]

- Janani, R.D.; Salman, S.A.; Priyadharshini, K.P.; Karthik, V. Effect of Composition on the Stacking Fault Energy of Copper-Nickel Alloys Using Molecular Dynamics Simulations. Mater. Today Proc. 2021, 39, 1796–1800. [Google Scholar] [CrossRef]

- Vu, T.-N.; Pham, V.-T.; Fang, T.-H. Deformation Mechanisms and Mechanical Properties of Nanocrystalline CuxNi100− x Alloys during Indentation Using Molecular Dynamics. Mater. Today Commun. 2022, 33, 104282. [Google Scholar] [CrossRef]

- Doan, D.-Q.; Fang, T.-H.; Chen, T.-H. Influences of Grain Size and Temperature on Tribological Characteristics of CuAlNi Alloys under Nanoindentation and Nanoscratch. Int. J. Mech. Sci. 2020, 185, 105865. [Google Scholar] [CrossRef]

- Shinde, A.B.; Patil, S.; Patil, P.; Salunkhe, R.; Sande, R.; Pawar, S.; Patil, V. Dislocation and Deformation Analysis of Cu-Ni Thin Films during Nano-Indentation Using Molecular Dynamics Simulation Approach. Mater. Today Proc. 2022, 49, 1453–1461. [Google Scholar] [CrossRef]

- Pham, A.-V.; Fang, T.-H.; Tran, A.-S.; Chen, T.-H. Structural and Mechanical Characterization of Sputtered CuxNi100-x Thin Film Using Molecular Dynamics. J. Phys. Chem. Solids 2020, 147, 109663. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A Tool for Manipulating and Converting Atomic Data Files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Srivastava, I.; Kotia, A.; Ghosh, S.K.; Ali, M.K.A. Recent Advances of Molecular Dynamics Simulations in Nanotribology. J. Mol. Liq. 2021, 335, 116154. [Google Scholar] [CrossRef]

- Fischer, F.; Schmitz, G.; Eich, S.M. A Systematic Study of Grain Boundary Segregation and Grain Boundary Formation Energy Using a New Copper–Nickel Embedded-Atom Potential. Acta Mater. 2019, 176, 220–231. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated Identification and Indexing of Dislocations in Crystal Interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 85007. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and Analysis of Atomistic Simulation Data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 15012. [Google Scholar] [CrossRef]

- Kato, M.; Fujii, T.; Onaka, S. Dislocation Bow-out Model for Yield Stress of Ultra-Fine Grained Materials. Mater. Trans. 2008, 49, 1278–1283. [Google Scholar] [CrossRef]

- Wang, J. Atomistic Simulations of Dislocation Pileup: Grain Boundaries Interaction. JOM 2015, 67, 1515–1525. [Google Scholar] [CrossRef]

- Han, X. Investigate the Constrained-Microplasticity of Nano-Polycrystal Silicon in Nanomachining Using Atomic Simulation Method. Appl. Phys. A 2022, 128, 1–14. [Google Scholar] [CrossRef]

- Zhao, P.; Guo, Y. Grain Size Effects on Indentation-Induced Defect Evolution and Plastic Deformation Mechanism of Ploycrystalline Materials. Comput. Mater. Sci. 2018, 155, 431–438. [Google Scholar] [CrossRef]

- Le, K.C.; Sembiring, P.; Tran, T.N. Continuum Dislocation Theory Accounting for Redundant Dislocations and Taylor Hardening. Int. J. Eng. Sci. 2016, 106, 155–167. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and Phenomenology of Strain Hardening: The FCC Case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Tian, Y.Z.; Zhao, L.J.; Chen, S.; Shibata, A.; Zhang, Z.F.; Tsuji, N. Significant Contribution of Stacking Faults to the Strain Hardening Behavior of Cu-15% Al Alloy with Different Grain Sizes. Sci. Rep. 2015, 5, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Sun, P.-L.; Zhao, Y.H.; Cooley, J.C.; Kassner, M.E.; Horita, Z.; Langdon, T.G.; Lavernia, E.J.; Zhu, Y.T. Effect of Stacking Fault Energy on Strength and Ductility of Nanostructured Alloys: An Evaluation with Minimum Solution Hardening. Mater. Sci. Eng. A 2009, 525, 83–86. [Google Scholar] [CrossRef]

- Picard, E.-A.; Sansoz, F. Ni Solute Segregation and Associated Plastic Deformation Mechanisms into Random FCC Ag, BCC Nb and HCP Zr Polycrystals. Acta Mater. 2022, 240, 118367. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yazdani, S.; Vitry, V. Using Molecular Dynamic Simulation to Understand the Deformation Mechanism in Cu, Ni, and Equimolar Cu-Ni Polycrystalline Alloys. Alloys 2023, 2, 77-88. https://doi.org/10.3390/alloys2010005

Yazdani S, Vitry V. Using Molecular Dynamic Simulation to Understand the Deformation Mechanism in Cu, Ni, and Equimolar Cu-Ni Polycrystalline Alloys. Alloys. 2023; 2(1):77-88. https://doi.org/10.3390/alloys2010005

Chicago/Turabian StyleYazdani, Sepehr, and Veronique Vitry. 2023. "Using Molecular Dynamic Simulation to Understand the Deformation Mechanism in Cu, Ni, and Equimolar Cu-Ni Polycrystalline Alloys" Alloys 2, no. 1: 77-88. https://doi.org/10.3390/alloys2010005

APA StyleYazdani, S., & Vitry, V. (2023). Using Molecular Dynamic Simulation to Understand the Deformation Mechanism in Cu, Ni, and Equimolar Cu-Ni Polycrystalline Alloys. Alloys, 2(1), 77-88. https://doi.org/10.3390/alloys2010005