Relationship between Manufacturing and Properties of Vacuum Sintered Ti and Ti-6Al-7Nb

Abstract

1. Introduction

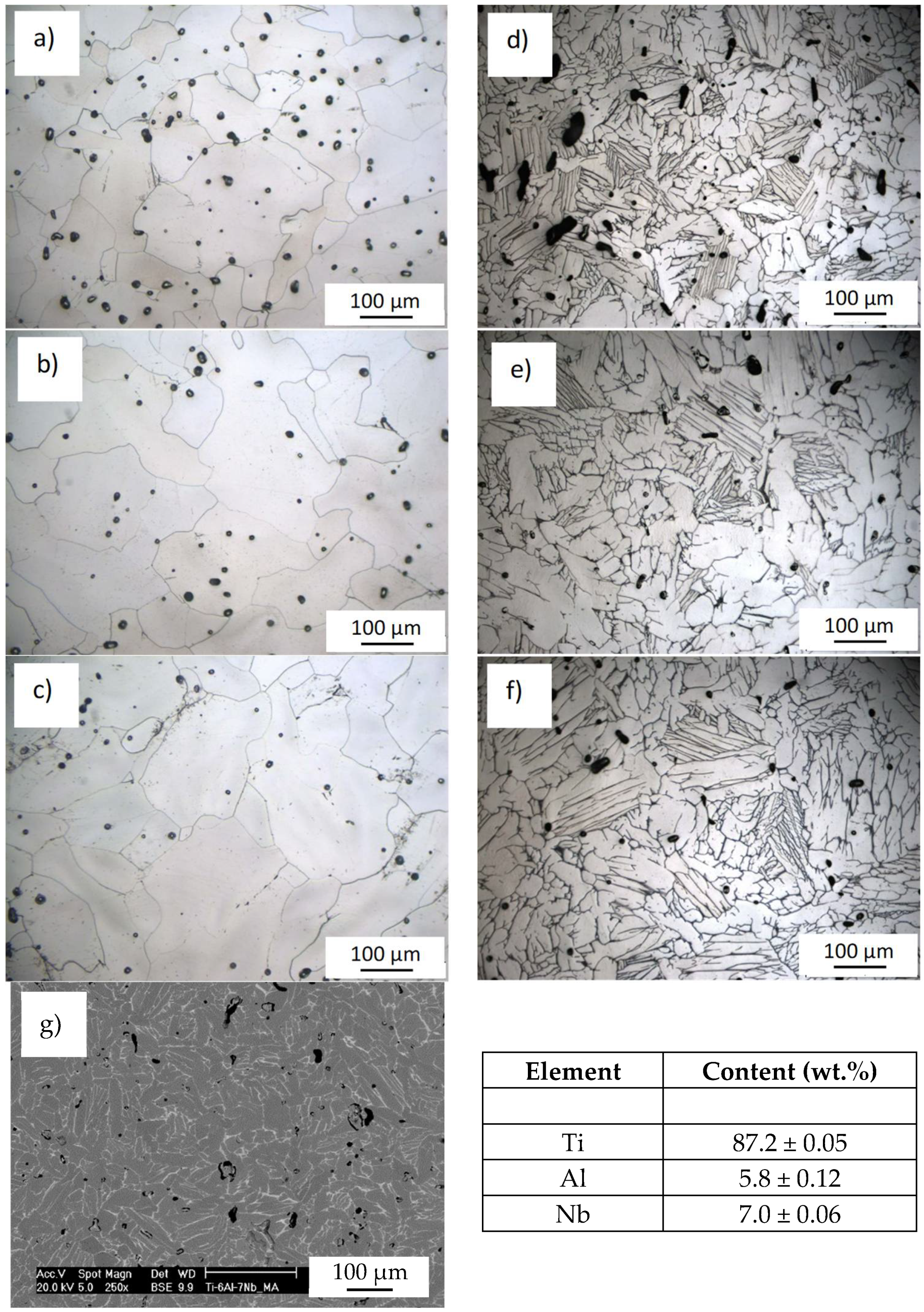

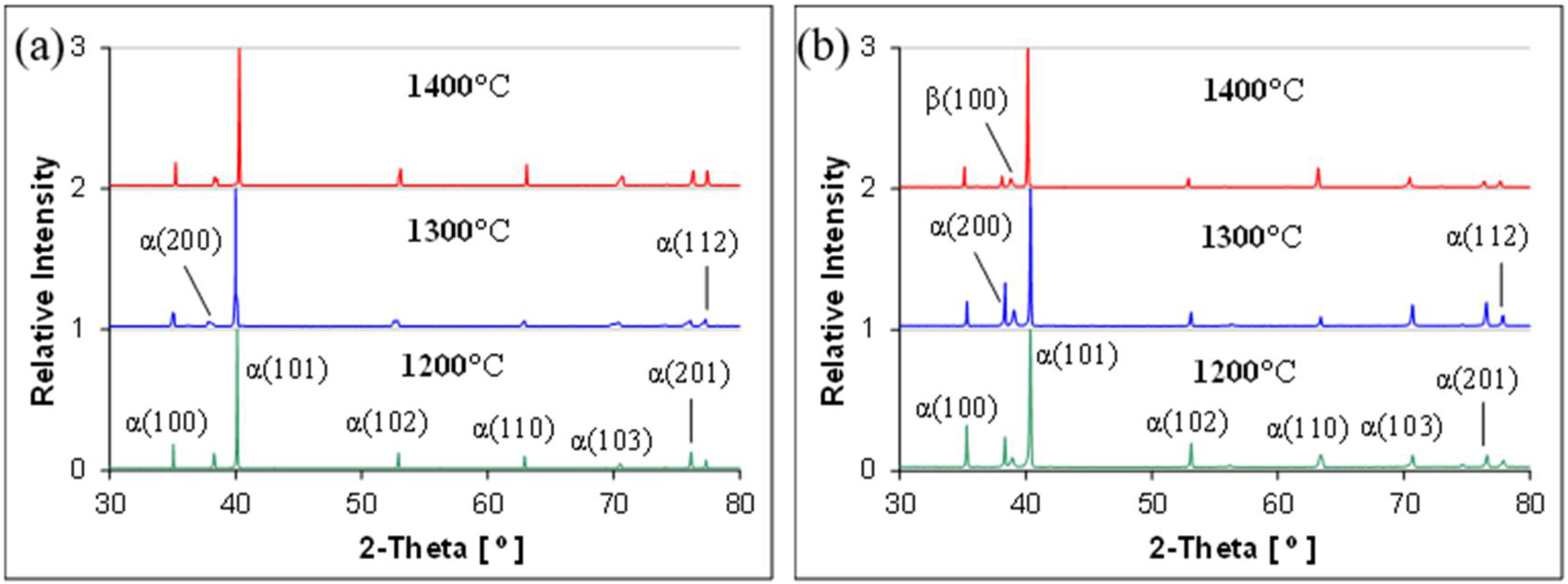

2. Materials and Methods

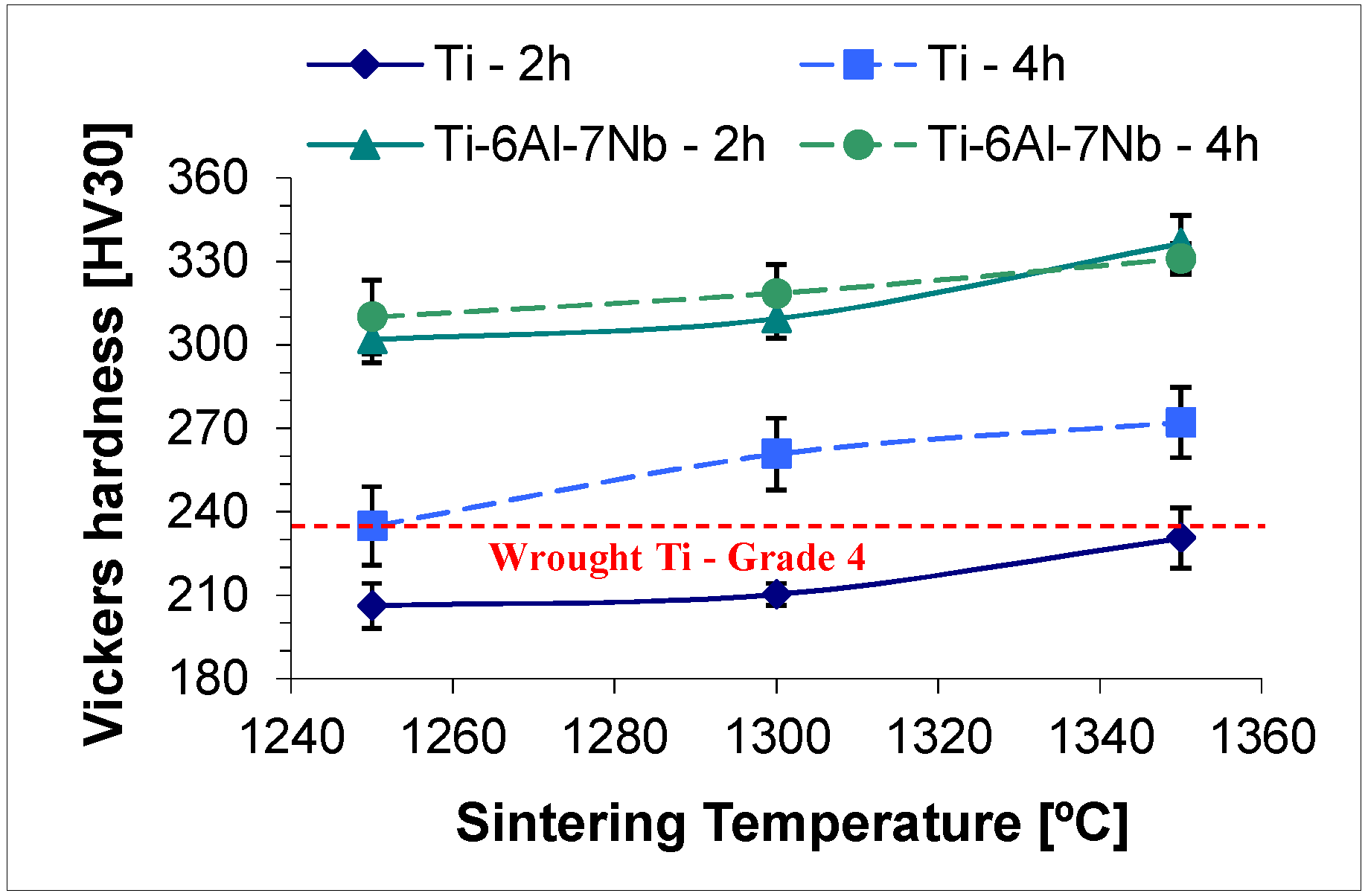

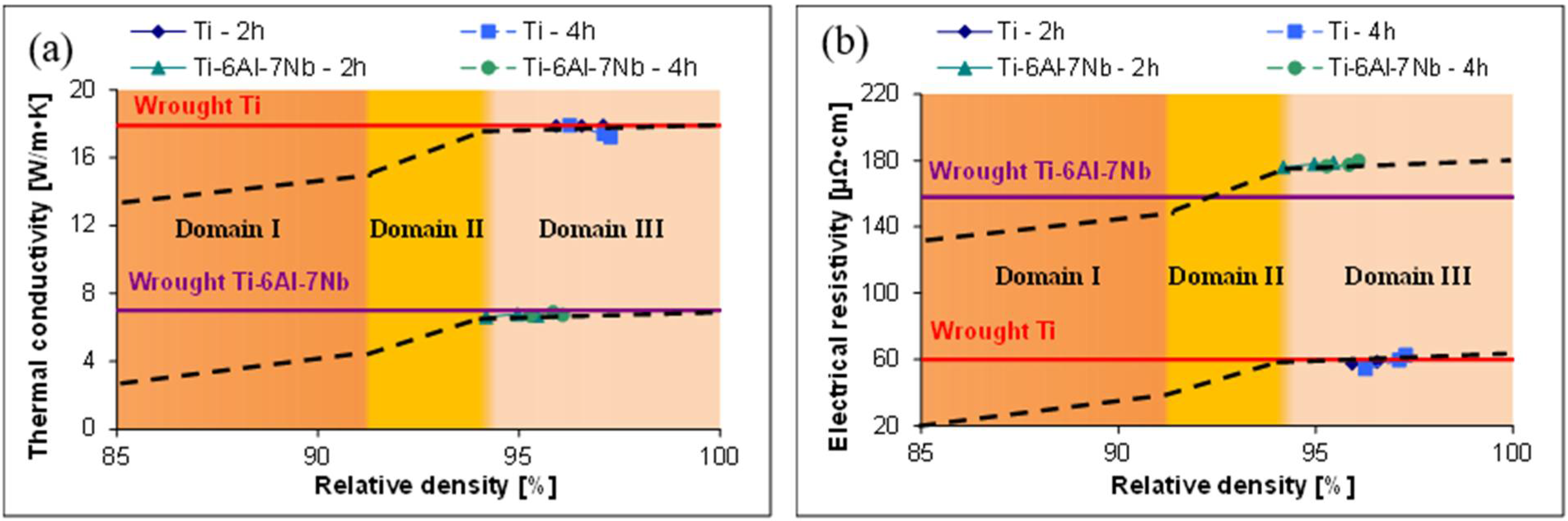

3. Results

4. Discussion

- ▪

- Domain I (between 0 and 6% of porosity, i.e., 94–100% ρr): linear decrease with porosity with low slope;

- ▪

- Domain II (between 6 and 9%, i.e., 91–94% ρr): steep decrease with porosity;

- ▪

- Domain III (over 9%, i.e., below 91% ρr): linear decrease with porosity with a slope larger than in Domain I.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Crowley, G. How to Extract Low-cost Titanium. Adv. Mat. Proc. 2003, 161, 25–27. [Google Scholar]

- Jackson, M.; Dring, K. Materials Perspective—A Review of Advances in Processing and Metallurgy of Titanium Alloys. Mat. Sci. Technol. 2006, 22, 881–887. [Google Scholar] [CrossRef]

- Nowak, M.; Yeoh, W.K.; Bolzoni, L.; Babu, N.H. Development of Al-Nb-B Master Alloys using Nb and KBF4 Powders. Mat. Des. 2015, 75, 40–46. [Google Scholar] [CrossRef]

- Bolzoni, L.; Nowak, M.; Babu, N.H. Assessment of the Influence of Al–2Nb–2B Master Alloy on the Grain Refinement and Properties of LM6 (A413) Alloy. Mater. Sci. Eng. A 2015, 628, 230–237. [Google Scholar] [CrossRef]

- Allen, P. Titanium Alloy Development. Adv. Mat. Proc. 1996, 150, 35–37. [Google Scholar]

- Froes, F.H. Titanium—Is the Time Now? JOM 2004, 56, 30. [Google Scholar] [CrossRef]

- Bolzoni, L.; Ruiz-Navas, E.M.; Gordo, E. Influence of Vacuum Hot-pressing Temperature on the Microstructure and Mechanical Properties of Ti-3Al-2.5V Alloy Obtained by Blended Elemental and Master Alloy Addition Powders. Mat. Chem. Phys. 2012, 137, 608–616. [Google Scholar] [CrossRef]

- Hurless, B.E.; Froes, F.H. Lowering the Cost of Titanium. AMPTIAC Q. 2002, 6, 3–10. [Google Scholar]

- Lapovok, R.; Tomus, D.; Muddle, B. Low-temperature Compaction of Ti–6Al–4V Powder using Equal Channel Angular Extrusion with Back Pressure. Mater. Sci. Eng. A 2008, 490, 171–180. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Zhang, B.; Liao, H.; Coddet, C. Effects of Processing Parameters on Microstructure and Mechanical Property of Selective Laser Melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Kumar, P.; Chandran, K.S.R. Strength–Ductility Property Maps of Powder Metallurgy (PM) Ti-6Al-4V Alloy: A Critical Review of Processing-Structure-Property Relationships. Met. Mater. Trans. A 2017, 48, 2301–2319. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Paramore, J.D.; Sun, P.; Chandran, K.R.; Zhang, Y.; Xia, Y.; Cao, F.; Koopman, M.; Free, M. Powder Metallurgy of Titanium—Past, Present, and Future. Int. Mat. Rev. 2018, 63, 407–459. [Google Scholar] [CrossRef]

- Raynova, S.; Imam, M.; Yang, F.; Bolzoni, L. Hybrid Microwave Sintering of Blended Elemental Ti Alloys. J. Manuf. Process. 2019, 39, 52–57. [Google Scholar] [CrossRef]

- Itoh, Y.; Miura, H.; Uematsu, T.; Sato, K.; Niinomi, M. Improvement of the Properties of Ti-6Al-7Nb Alloy by Metal Injection Molding. In Advances in Powder Metallurgy & Particulate Materials; Metal Powder Industries Federation: Princeton, NJ, USA, 2007; pp. 52–57. [Google Scholar]

- Henriques, V.A.; Bellinati, C.E.; da Silva, C.R. Production of Ti-6%Al-7%Nb Alloy by Powder Metallurgy (P/M). J. Mat. Proc. Technol. 2001, 118, 212–215. [Google Scholar] [CrossRef]

- Itoh, Y.; Miura, H.; Sato, K.; Niinomi, M. Fabrication of Ti-6Al-7Nb Alloys by Metal Injection Molding. Mater. Sci. Forum 2007, 534–536, 357–360. [Google Scholar] [CrossRef]

- Henriques, V.; Sandim, H.; Coelho, G.; da Silva, C. Microstructural Evolution during Hot Pressing of the Blended Elemental Ti–6%Al–7%Nb Alloy. Mater. Sci. Eng. A 2003, 347, 315–324. [Google Scholar] [CrossRef]

- Steedman, G.; Corbin, S.F.; O’Flynn, J. Distinguishing the Influence of Aluminium and Vanadium Additions on Microstructural Evolution and Densification Behaviour during the Sintering of Ti6Al, Ti4V and Ti6Al4V. Powder Metal. 2018, 61, 301–312. [Google Scholar] [CrossRef]

- Bolzoni, L.; Raynova, S.; Yang, F. Strengthening Mechanisms of Ti via Al Addition. J. Alloys Compd. 2020, 820, 153447. [Google Scholar] [CrossRef]

- Zhao, D.; Chang, K.; Ebel, T.; Qian, M.; Willumeit, R.; Yan, M.; Pyczak, F. Microstructure and Mechanical Behavior of Metal Injection Molded Ti–Nb Binary Alloys as Biomedical Material. J. Mech. Behav. Biomed. Mater. 2013, 28, 171–182. [Google Scholar] [CrossRef]

- Yılmaz, E.; Gökçe, A.; Findik, F.; Gulsoy, H. Metallurgical Properties and Biomimetic HA Deposition Performance of Ti-Nb PIM Alloys. J. Alloys Compd. 2018, 746, 301–313. [Google Scholar] [CrossRef]

- Kalita, D.; Rogal, Ł.; Czeppe, T.; Wójcik, A.; Kolano-Burian, A.; Zackiewicz, P.; Kania, B.; Dutkiewicz, J. Microstructure and Mechanical Properties of Ti-Nb Alloys Prepared by Mechanical Alloying and Spark Plasma Sintering. J. Mater. Eng. Perform. 2020, 29, 1445–1452. [Google Scholar] [CrossRef]

- Hein, M.; Kokalj, D.; Dias, N.F.L.; Stangier, D.; Oltmanns, H.; Pramanik, S.; Kietzmann, M.; Hoyer, K.-P.; Meißner, J.; Tillmann, W.; et al. Low Cycle Fatigue Performance of Additively Processed and Heat-Treated Ti-6Al-7Nb Alloy for Biomedical Applications. Metals 2022, 12, 122. [Google Scholar] [CrossRef]

- Cosma, C.; Drstvensek, I.; Berce, P.; Prunean, S.; Legutko, S.; Popa, C.; Balc, N. Physical-Mechanical Characteristics and Microstructure of Ti6Al7Nb Lattice Structures Manufactured by Selective Laser Melting. Materials 2020, 13, 4123. [Google Scholar] [CrossRef]

- Szymczyk, P.; Ziółkowski, G.; Junka, A.; Chlebus, E. Application of Ti6Al7Nb Alloy for the Manufacture of Biomechanical Functional Structures (BFS) for Custom-Made Bone Implants. Materials 2018, 11, 971. [Google Scholar] [CrossRef]

- Yu, Z.; Dong, Y.; Li, X.; Niu, J.; Alexandrov, I.; Chang, H. Study on Corrosion Behavior of Ultrafine-Grained Ti-6Al-7Nb Fabricated by Equal Channel Angular Pressing. Metals 2020, 10, 950. [Google Scholar] [CrossRef]

- Bolzoni, L.; Weissgaerber, T.; Kieback, B.; Ruiz-Navas, E.; Gordo, E. Mechanical Behaviour of Pressed and Sintered CP Ti and Ti–6Al–7Nb Alloy obtained from Master Alloy Addition Powder. J. Mech. Behav. Biomed. Mater. 2013, 20, 149–161. [Google Scholar] [CrossRef] [PubMed]

- Bolzoni, L.; Ruiz-Navas, E.; Neubauer, E.; Gordo, E. Inductive Hot-pressing of Titanium and Titanium Alloy Powders. Mater. Chem. Phys. 2012, 131, 672–679. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Anokhin, V.; Demidik, A.; Savvakin, D.G. Cost-Effective Blended Elemental Powder Metallurgy of Titanium Alloys for Transportation Application. Key Eng. Mater. 2000, 188, 55–62. [Google Scholar] [CrossRef]

- Jia, M.; Gabbitas, B.; Bolzoni, L. Evaluation of Reactive Induction Sintering as a Manufacturing Route for Blended Elemental Ti-5Al-2.5Fe Alloy. J. Mat. Proc. Technol. 2018, 255, 611–620. [Google Scholar] [CrossRef]

- Rock, B.; Imam, M.; Zarah, T. Microwave Assisted Sintering of Cold Iso-Statically Pressed Titanium 6-4 Powder Compacts. In Processing, Properties, and Design of Advanced Ceramics and Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 213–221. [Google Scholar]

- Bolzoni, L.; Ruiz-Navas, E.M.; Gordo, E. Investigation of the Factors Influencing the Tensile Behaviour of PM Ti-3Al-2.5V Alloy. Mat. Sci. Eng. A 2014, 609, 266–272. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.; Lee, B.; Ryu, H.J.; Hong, S.H. Dilatometric Analysis and Microstructural Investigation of the Sintering Mechanisms of Blended Elemental Ti-6Al-4V Powders. Met. Mater. Trans. A 2016, 47, 4616–4624. [Google Scholar] [CrossRef]

- Boyer, R.; Welsch, G.; Collings, E.W. (Eds.) Materials Properties Handbook: Titanium Alloys, 2nd ed.; ASTM International: West Conshohocken, PA, USA, 1998. [Google Scholar]

- Yan, M.; Xu, W.; Dargusch, M.S.; Tang, H.P.; Brandt, M.; Qian, M. Review of Effect of Oxygen on Room Temperature Ductility of Titanium and Titanium Alloys. Powder Metal. 2014, 57, 251–257. [Google Scholar] [CrossRef]

- van der Pauw, L.J. A Method of Measuring Specific Resistivity and Hall Effect of Discs of Arbitrary Shape. Philips Res. Rep. 1958, 13, 1–9. [Google Scholar]

- van der Pauw, L.J. A Method of Measuring Specific Resistivity and Hall Effect on Lamellae of Arbitrary Shape. Philips Technol. Rev. 1958, 20, 220–224. [Google Scholar]

- Luo, S.; Yang, Y.; Schaffer, G.; Qian, M. Warm Die Compaction and Sintering of Titanium and Titanium Alloy Powders. J. Mater. Process. Technol. 2014, 214, 660–666. [Google Scholar] [CrossRef]

- Bolzoni, L.; Alqattan, M.; Peters, L.; Alshammari, Y.; Yang, F. Ternary Ti Alloys Functionalised With Antibacterial Activity. Sci. Rep. 2020, 10, 22201. [Google Scholar] [CrossRef]

- Henry, D. Materials and Coatings for Medical Devices: Cardiovascular; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Semlitsch, M.; Weber, H.; Steger, R. Fifteen Years Experience with Ti-6Al-7Nb Alloy for Joint Replacements. In Titanium ′95: Science and Technology, Proceedings of the Eighth World Conference, Birmingham, UK, 22–26 October 1995; Institute of Materials: Singapore, 1996. [Google Scholar]

- Vincent, C.; Silvain, J.; Heintz, J.; Chandra, N. Effect of porosity on the thermal conductivity of copper processed by powder metallurgy. J. Phys. Chem. Solids 2012, 73, 499–504. [Google Scholar] [CrossRef]

- Raynova, S.; Collas, Y.; Yang, F.; Bolzoni, L. Advancement in the Pressureless Sintering of CP Titanium Using High-Frequency Induction Heating. Met. Mater. Trans. A 2019, 50, 4732–4742. [Google Scholar] [CrossRef]

| Material | Conditions | Oxygen (wt.%) | Δ | Nitrogen (wt.%) | Δ |

|---|---|---|---|---|---|

| Ti | Starting powder | 0.27 ± 0.01 | - | 0.016 ± 0.003 | - |

| 1250 °C, 2 h | 0.32 ± 0.01 | 0.05 | 0.020 ± 0.004 | 0.004 | |

| 1300 °C, 2 h | 0.33 ± 0.04 | 0.06 | 0.025 ± 0.006 | 0.009 | |

| 1350 °C, 2 h | 0.38 ± 0.01 | 0.011 | 0.024 ± 0.004 | 0.008 | |

| 1250 °C, 4 h | 0.36 ± 0.02 | 0.09 | 0.028 ± 0.006 | 0.012 | |

| 1300 °C, 4 h | 0.41 ± 0.04 | 0.014 | 0.044 ± 0.008 | 0.028 | |

| 1350 °C, 4 h | 0.41 ± 0.06 | 0.014 | 0.042 ± 0.004 | 0.026 | |

| Ti-6Al-7Nb | Starting powder | 0.39 ± 0.01 | - | 0.017 ± 0.001 | - |

| 1250 °C, 2 h | 0.41 ± 0.01 | 0.02 | 0.028 ± 0.001 | 0.011 | |

| 1300 °C, 2 h | 0.48 ± 0.02 | 0.09 | 0.033 ± 0.003 | 0.016 | |

| 1350 °C, 2 h | 0.60 ± 0.02 | 0.021 | 0.031 ± 0.001 | 0.014 | |

| 1250 °C, 4 h | 0.50 ± 0.03 | 0.011 | 0.033 ± 0.004 | 0.016 | |

| 1300 °C, 4 h | 0.45 ± 0.01 | 0.06 | 0.032 ± 0.001 | 0.015 | |

| 1350 °C, 4 h | 0.54 ± 0.03 | 0.015 | 0.035 ± 0.004 | 0.018 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolzoni, L.; Ruiz-Navas, E.M.; Gordo, E. Relationship between Manufacturing and Properties of Vacuum Sintered Ti and Ti-6Al-7Nb. Alloys 2022, 1, 232-242. https://doi.org/10.3390/alloys1030014

Bolzoni L, Ruiz-Navas EM, Gordo E. Relationship between Manufacturing and Properties of Vacuum Sintered Ti and Ti-6Al-7Nb. Alloys. 2022; 1(3):232-242. https://doi.org/10.3390/alloys1030014

Chicago/Turabian StyleBolzoni, Leandro, Elisa Maria Ruiz-Navas, and Elena Gordo. 2022. "Relationship between Manufacturing and Properties of Vacuum Sintered Ti and Ti-6Al-7Nb" Alloys 1, no. 3: 232-242. https://doi.org/10.3390/alloys1030014

APA StyleBolzoni, L., Ruiz-Navas, E. M., & Gordo, E. (2022). Relationship between Manufacturing and Properties of Vacuum Sintered Ti and Ti-6Al-7Nb. Alloys, 1(3), 232-242. https://doi.org/10.3390/alloys1030014