Abstract

The consumption of fiber in the human diet is a global recommendation to ensure a healthy diet. Quinoa (Chenopodium quinoa Willd.), a gluten-free grain, and chia (Salvia hispanica), a seed, contain a high fiber content, and both have the potential to be used in the development of nutraceutical and pharmaceutical formulations. An interesting characteristic of chia is its ability to form viscous mucilage when in contact with water, making it a potential binder in solid formulations. However, there are no studies on chia as a binder, and therefore, the objective of the present study was to evaluate the feasibility of using chia as a binder to produce quinoa granules and, subsequently, develop chewable tablet formulations. The quinoa and chia were in a powder form and then transformed into a wet mass with the help of mixer torque rheometer (MTR) equipment. In the wet granulation form, the following parameters were tested: multiple additions, 15 g of material, and 25 timepoints for the addition of 1 mL of water. An experimental design was carried out to evaluate the impact of the variables on the MTR results for subsequent granulation. The granulation point was possible for T1–T9, and most formulations gave satisfactory results, such as an acceptable resistance of the granules. In the end, a formulation was selected for the development of chewable tablets containing quinoa and chia fibers.

1. Introduction

Quinoa (Chenopodium quinoa Willd.) is a gluten-free grain that is widely cultivated in South America, especially in the Andes region, and has been consumed for thousands of years by local populations. Its cultivation has spread to some European countries, as well as Australia and China, and has been increasingly used in diets. It has an incomparable nutritional value [1,2], with outstanding levels of protein, dietary fiber (3–52.0%), vitamins (e.g., vitamin E (tocopherol) and vitamin B2 (riboflavin)), minerals (e.g., calcium, magnesium, and iron), and balanced concentrations of essential amino acids, among many other benefits [3,4].

Furthermore, another interesting food, this one from Central America, is chia (Salvia hispanica), a protein-rich seed that also has a high fiber content (18.0–30.0%). It was widely used by the Aztec and Mayan civilizations as food and contains vitamins (e.g., vitamin E (tocopherol) and vitamin C (ascorbic acid)) and minerals (e.g., calcium, zinc, and iron) [5,6,7].

Fiber plays an important role in nutrition, and its consumption in the human diet is appreciated as a benefit that is supported by scientific studies [8,9,10,11]. The consumption of dietary fiber provides metabolic health benefits [9,12], improves intestinal microflora, may prevent reduced insulin sensitivity [13], has some positive influence on inflammatory pathways (e.g., in the colon), and prevents colorectal diseases and carcinoma [14], among many other benefits [9,10,14].

Both quinoa and chia have great prospects in the food market and are currently part of the effort to develop new fiber-rich food products [15,16,17]. However, the inclusion of quinoa and chia as sources of fiber in nutraceutical and pharmaceutical products is still challenging. For the development of formulations containing quinoa, it is necessary to extract saponins from the grains to prevent the formation of bitter residues in the oral mucosa after consumption [18]. On the other hand, chia has a pleasant sweetness when it is in contact with water or in the presence of any other food, and the high nutritional value of this seed can be complemented if it is incorporated into a formulation containing quinoa [19].

The dietary fiber content in quinoa ranges from 3.0 to 52.0%, and in chia, it ranges from 18.0 to 30.0% [3,5,7,20,21,22]. Therefore, given the growing interest in including more fiber in the diet, a practical form of consumption would be a supplement containing quinoa and chia in the form of chewable tablets.

One aspect explored in the present study is the ability of chia to act as a binder so that large quantities of quinoa can be formed into granules. Chia can form mucilage when it is in contact with water, which has the characteristics of a viscous liquid and could be an excellent binder for formulations that require a wet granulation step, which is necessary for the production of pharmaceutical tablets with a high proportion of active ingredients and an adequate granule flow. Wet granulation is a process of aggregating smaller particles into larger particles, which requires the use of a binding agent [23,24]. When selecting the binding agent, the ideal granulation point should be determined, which is given by the exact volume of liquid to be added to produce granules. Furthermore, after the production of granules, the physical properties need to be measured so that characteristics such as granule flow are in the acceptable range to obtain a good performance of the formulation, mainly in relation to the compressibility and compactability of tablets [23,25].

Wet powder rheometry is used to determine the granulation point of pharmaceutical formulations [24,26]. This method uses a mixer torque rheometer (MTR), and the software can be programmed to perform an analysis of the components of a formulation to obtain the exact amount of binding liquid and subsequently determine whether the flow of the granules is adequate to assess whether it will be difficult to compress in a compression machine.

Furthermore, these components may have small particle sizes, which is an important characteristic of the material, and consequently, wet granulation studies are necessary [27,28].

The physical characterization of solid particles (powders and granules) is essential for the mixing process (system homogenization), especially if the material is an integral part of the formulation [24]. Tests such as those measuring fluidity properties, real density, and mechanical resistance can help predict the behavior and performance of the granules [24,26]. For quinoa supplements, it is necessary to ingest a large amount of this important source of dietary fiber, which would make the tablet too large to ingest. Therefore, in this study, we chose chewable tablets because, even though they are large, they can be easily ingested after chewing. In this way, chewable tablets present themselves as a viable pharmaceutical form for administering quinoa.

Considering the gap in the scientific literature regarding the use of chia as a binder in nutraceutical and pharmaceutical formulations, the objective of the present work was to study, using torque rheometry, whether it is feasible to use chia (in powder form) as a binder to produce quinoa granules, which could then be used to create fiber supplements for consumption.

2. Materials and Methods

2.1. Material

Quinoa grains and chia seeds were purchased as commercial products available on the Brazilian market (Taeq, São Paulo, Brazil) and processed to carry out the characterization study (Section 2.2.3, Section 2.2.4 and Section 2.2.5) and subsequent production of chewable tablets.

In addition, microcrystalline cellulose (Avicel® PH101, DuPont, Wilmington, NC, USA) and purified water were used.

2.2. Methods

2.2.1. Washing, Drying, and Grinding of Quinoa

To eliminate the saponins from the grains, 350 g of quinoa was submerged in a stainless-steel container with purified water in a ratio of 1:7 w/v (quinoa/water) for 48 h at room temperature, with replacement of the water every 12 h. After this treatment, the grains were washed twice (in the same proportion) with purified water at 40 °C. Afterward, the grains were washed with the same proportion of water at room temperature. Subsequently, the grains were dried in an oven (Fabbe-Primar, São Paulo, Brazil) at 50 °C for 6 h, followed by grinding for 3–5 min in an IKA A 11 basic mill (IKA, Staufen, Germany) until a fine powder was obtained. The powder was subjected to further drying in an oven for 3 h. The humidity was monitored using a moisture analyzer (Mettler Toledo, Greifensee, Switzerland), and the powder was dried until the residual water content was between 1 and 3%.

2.2.2. Chia Grinding

The chia seeds were ground for 3–5 min in an IKA A 11 basic mill (IKA, Staufen, Germany) until a fine powder was obtained. The powder was dried in an oven (Fabbe-Primar, São Paulo, Brazil) at 50 °C for 1 h. The humidity was monitored using a moisture analyzer (Mettler Toledo, Greifensee, Switzerland), and the powder was dried until the residual water content was between 1 and 3%.

2.2.3. Particle Size Analysis

The determination of the particle sizes of ground quinoa and chia was carried out using a laser diffraction Particle Size Analyzer 1090 (Cilas, Orleans, France). For both samples, the Fraunhofer method was used [29], operating in dry mode and using the following parameters: ultrasound for 10 s, obscuration of 21%, frequency of 20 Hertz (Hz), pressure of 500 millibars (mb), and measurement and cleaning time of 30 and 15 s for quinoa and chia, respectively. To complement it, the SPAN was calculated, which provides data on sample homogeneity [24]. The results were obtained from the average of six measurements and were calculated using the SizeExpert® software.

2.2.4. Powder Flow Assessment

The flow of the ground quinoa and chia samples was analyzed according to the methodology described by Da Silva et al. [30]. The samples were distributed into a 100 mL graduated cylinder until a volume of 50 mL was reached. The mass was measured using a semi-analytical balance to obtain the apparent density. Next, the sample was measured with a “Tap Density” hydrometer (Ethik, São Paulo, Brazil) to obtain the compacted density. The procedure was carried out in triplicate, and the following properties were determined: apparent density, compacted density, compressibility index (IC), and Hausner ratio (RH), which were calculated using Equations (1)–(4):

where dap = apparent density (g/cm3), Mi = initial mass (g), Vi = initial volume (cm3), dcp = compacted density (g/cm3), and Vf = final volume (cm3).

where CI = Carr Index, HR = Hausner ratio, dcp = compacted density, and dap = apparent density.

2.2.5. True Density

Tests on the quinoa and chia powders and granules were carried out to evaluate the true density of the material, applying the methodology described by Da Silva et al. [24]. The samples were weighed in triplicate on a Marte AUW220D analytical balance (Shimadzu Corporation, Tokyo, Japan), and the quantity did not exceed two-thirds of the volume of the Microcell (4.5 cm3). The equipment used was an Ultrapyc 5000 helium gas ultrapycnometer (Anton Paar, Graz, Austria) under 20 psi of helium gas at room temperature. The results were obtained from five volume and density measurements and are given in g/cm3.

2.3. Design of Experiments

A fractional experimental design was used (Table 1 and Table 2) with the aid of the Statistica 13.0 software (StatSoft, Inc., Tulsa, OK, USA) to evaluate the quantities of the quinoa, diluent (microcrystalline cellulose PH101), and chia binder in the composition of the formulations. The experiments were performed in triplicate.

Table 1.

Variables and respective levels (−1, 0, +1) used in the fractional factorial experimental design. Amounts are described in parts.

Table 2.

Test matrix with fractional factorial of (33-1) with T1–T9 formulations. Amounts in parts with their respective weights in grams and as a percentage.

2.4. Mixer Torque Rheometer Equipment

To obtain granules using chia as the quinoa binder, a wet granulation study was carried out using varying proportions of quinoa, chia, and MCC PH101 powders (Table 2). The equipment used was a mixer torque rheometer (Caleva, Dorset, England), which was also used in the studies by Belem and Ferraz, 2020, and Da Silva et al., 2022 [24,31]. The methodology applied here used multiple additions: 15 g of each component and 25 timepoints where 1 mL of water was added, with a mixing time of 60 s and data collection time of 20 s (Supplementary Materials: Video S1). The MTR generates graphs and is capable of indicating the granulation point using the torque ratio (Nm) versus binder ratio (mg·mL). At the end of the experiment, a curve was generated, indicating the volume of liquid needed to obtain a granulate.

2.5. Granule Production

From the rheometry results, granules of the T1–T9 formulations were produced according to the procedure described by Da Silva et al. (2022) [24]. Approximately 200 g of T1–T9 (mixture of quinoa, chia, and MCC PH101) were weighed on a semi-analytical balance, homogenized for 2 min, and subjected to a low shear granulator (Arno S/A, São Paulo, Brazil) at maximum speed. Ultrapure water was added slowly, and at the end, the mass was passed through a 2.00 mm sieve (Bronzinox, São Paulo, Brazil). The sample was dried for 3 to 4 h at 50 °C until a residual moisture of 1 to 3% was obtained (monitored using a moisture analyzer, Mettler Toledo, Greifense, Switzerland). The dry granulate was calibrated on a 1.18 mm sieve, and then physical characterization was carried out.

Granule Characterization

The granules were characterized by their flow properties (item 2.2.4), true density (item 2.2.5), optical microscopy [24], particle size distribution, and granule resistance [32]. The granules were examined using a microscope (Motic, Zhejiang, China) at 30 and 40× magnification. A sieve shaker (Haver & Boecker, Oelde, Germany) with 1.25–0.71 mm openings was used to evaluate the particle size distribution, and a friabilometer (Logan, NJ, USA) with rotations of 50 rpm for 4 min was used to evaluate the resistance of the granules.

2.6. Production of Chewable Tablets

The tablets were produced using a Lemaq rotary compression machine (LM08D Mini Express, Lemaq, São Paulo, Brazil) in a 16 mm punch. T8 (high amount of quinoa) was selected with approximately 800 mg of quinoa per tablet. During the process, the properties such as the average weight, hardness, thickness, diameter, friability, and disintegration time were monitored according to the specifications required by the American Pharmacopoeia [33].

2.7. Statistical Analysis

The results were statistically analyzed using Statistica 13.0 software (Dell Inc., Round Rock, TX, USA). An analysis of variance (ANOVA) was applied with a significance level of 5% (p ≤ 0.05), and Pareto and response surface graphs were generated.

3. Results and Discussion

3.1. Particle Sizes of Quinoa and Chia

The average particle size of quinoa was 13.50 μm, and the distribution curve demonstrated a possible agglomeration with a bimodal and polydisperse behavior. On the other hand, chia showed a broad particle distribution curve (66.84–377.38 μm) with an average size of 186.50 μm. Both the quinoa and chia samples seemed to be heterogeneous (Figure 1 and Table 3), with a wide range of particle sizes; the chia samples were more homogeneous systems with results closer to the SPAN (=1). This homogeneity measurement is considered appropriate when values are closer to 1 [34]. However, the equipment has scale limitations, and the chia samples may have been harmed due to the reading range during the analysis. Despite this, as our results indicate, 90% of the particles were below 377.38 µm, and more than 80% of the cumulative particles were in the 80–90 µm range, demonstrating that a small fraction must appear after the 500 µm range. This may be due to the characteristic obovoidal-to-ellipsoidal-shaped fibrous material with a rounded base and apex in chia seeds. When processed (milled), the irregular shape became a characteristic of the powder, with many fibrous grooves remaining [19].

Figure 1.

Histogram of the particle size distribution of the quinoa and chia powder samples.

Table 3.

Values of d10, d50, and d90 (mean and ± standard deviation) and the span of the quinoa and chia samples obtained from the dry particle size analysis.

The characteristics of quinoa and chia powders are essential to determining their specifications and ensuring that they are consistent from batch to batch. One of the main aspects is the particle size, especially for the component that makes up the largest proportion of the formulation. In this case, wet granulation is certainly part of the production process, and the influence of small particles in the direct compression step can considerably affect the compressibility and compactability of the powder [35].

3.2. Flow Properties and True Density of Powders

Table 4 shows the powders’ flow properties and true density. According to the specifications of the American Pharmacopoeia [33], the values are not indicative of adequate flow to produce formulations with excellent flow capacity, compactability, and compressibility.

Table 4.

Flow of ground quinoa and chia samples: apparent density (g·mL−1), compressed density (g·mL−1), Carr Index (IC%), Hausner ratio (UR), and true density (g·mL−1) ± range (n = 3).

In addition to determining the particle size characteristics of a material, we must ensure that the formulation has good flow properties. Based on the results presented in Table 4, it is possible to state that the process of producing chewable tablets by direct compression is not viable. Regarding the true density, the quinoa presented higher values than the chia. When a material has a low-density characteristic, especially when present in large amounts in the formulation, it is likely that these properties will affect compactability and compressibility, especially when dealing with fibrous materials such as quinoa [35,36].

3.3. Mixer Torque Rheometry

When observing the rheological profiles of T1–T9, we noticed that the torques differed considerably, as did the amount of water used for each experiment. When using chia as a binder in formulations with a high concentration of fibers (quinoa), a viscous dispersion behavior occurred that was capable of acting as a binder, causing, regardless of the concentration used, the aggregation of the particles in all formulations (Figure 2).

Figure 2.

T1–T9 and calculated mean (duplicate) of multiple additions for different proportions of quinoa, MCC PH101 (diluent), and chia (binder).

In each experiment, as the syringe dispensed water into the powder mixture in the rheometer compartment, a swelling process occurred which, in the case of chia, the powder in contact with the water formed a viscous dispersion (mucilage), helping to aggregate the particles.

In Figure 2, it is notable that the granulation point was obtained in all tests, and we call this point the capillary phase. The wet granulation process is accompanied by phases; at the beginning of the test is the pendular phase, where the binder is wetting the particles, and it is not possible to form a wet mass. Subsequently, the process enters the funicular phase where the particles have more binder, but they still cannot reach the granulation point and form granules. Soon, the capillary phase begins, which is when the amount of binder is adequate to form the granulation point and obtain granules. This is the perfect particle agglomeration mechanism that determines the exact amount of water for the granulation point of each test (Table 5). Finally, at the end of the test is the goticular phase. At this stage, the particles are well aggregated, there is an excess of binding liquid, making it difficult to obtain granules, and the drying time is long [24,25,28].

Table 5.

Average maximum torque (Nm), liquid/solid ratio (mL/g), and water volume (±standard deviation) at the granulation point of T1–T9.

The quinoa particle size differed from that of the chia and MCC PH101 (average 42.52 μm) [24]. For this reason, each rheological profile showed a different behavior in terms of both torque and water volume. A previous study showed that quinoa powder has small particle sizes and a greater swelling capacity [15], which is consistent with our findings. On the other hand, although the quinoa particles were smaller than those of MCC PH101, Formulations T3 and T6 absorbed the highest amount of water, and this is a characteristic of cellulose, which was present in higher concentrations in these two cases.

MCC PH101 is widely applied in wet granulation and is known to increase granule strength [37]. When evaluating the rheological profiles (Figure 2), it was possible to observe that the formulation with the highest torques had a high concentration of MCC PH101 (T3 and T6). However, for formulations with a greater amount of MCC PH101, it is not necessary to add more binder to obtain more resistant granules, as chia fulfilled its role even in a small proportion. Thus, regardless of the concentration of chia used, a minimum amount (approximately 2%) is sufficient to form mucilage and agglutinate the particles to reach the capillary phase.

Statistical Analysis

The model without two-way interactions was used to compare the variables, with values of p > 0.050 for torque Nm (p = 0.885 for quinoa, p = 0.817 for diluent, and p = 0.796 for binder) and water ratio mL/g (p = 0.879 for quinoa, p = 0.765 for diluent, and p = 0.645 for binder). The correlation coefficient (R2) for torque (Nm) was R2 = 0.92304, and for the water ratio (mL·g), R2 = 0.84599. As a result, the model found that there was no influence of the amount of quinoa, diluent, or binder on the torque and water ratio, as demonstrated in the Pareto graphs in Figure 3.

Figure 3.

Pareto graphs for the analysis of variance of torque and water ratio parameters.

However, the response surface graphs demonstrated that the concentration of the MCC PH101 diluent had an impact on the amount of water required to reach the granulation point. Figure 4 shows that increasing the concentration of MCC PH101 in the formulation influences the torque and volume of liquid necessary to reach the granulation point. When analyzing the response to the water variable, it is possible to observe that the diluent (MCC PH101) required a greater volume of liquid to reach the granulation point, and this occurred when the proportion of quinoa was lower. On the other hand, when chia (binder) was tested, we observed a well-distributed water demand (mL), regardless of the proportion of quinoa. Therefore, as the results of chia from T1–T9 did not demonstrate an impact from chia, it is possible to use any proportion of chia as a binder in formulations containing fiber to form mucilage, aggregate the particles to reach the granulation point, produce granules and, subsequently, chewable tablets.

Figure 4.

Response surface graphs indicating the effects on torque (Nm) from diluent and quinoa (A), binder and diluent (B), binder and quinoa (C), and diluent and binder (D). Likewise, the response surface graphs indicate the effect on water demand (mL) from diluent and quinoa (E), binder and diluent (F), quinoa and binder (G), and binder and diluent (H).

The volume of water determined at the granulation point (Table 5) was lower for lower concentrations of the diluent; that is, microcrystalline cellulose seems to affect the amount of water required for granulating the mixtures, as indicated in Figure 4. The use of such an excipient in granules and tablets is interesting since it is a material that can substantially improve the cohesiveness and compactability of formulations [38].

It is important to highlight that for chia, even if higher concentrations of powder are used, the water demand to reach the granulation point was not impacted and remained practically the same (Table 5). This aspect is very interesting because the binder does not require greater amounts of water, which is desirable in wet granulation. It is worth noting that all the water added to the formulation must be later removed by drying; that is, the smaller the amount of water, the shorter the drying time required.

One of the highlights of this work is the fact that the concentration of quinoa in the formulations had no effect on the torque and amount of water needed to reach the granulation point. Furthermore, it should be noted that to increase fiber intake in the diet, it is necessary to use high amounts of fiber; thus, obtaining granules with a large amount of quinoa will enable the large-scale production of tablets with high doses of dietary fiber.

3.4. Granule Production

Next, the formulations were prepared as described in Table 6.

Table 6.

Description of the stages of the T1–T9 granulate production process.

During the process of producing granulates, it was observed that the formulations containing chia in high concentrations (T2, T3, and T4) were more difficult to pass through the sieve after adding water, and this may be due to the formation of excess mucilage. Visually, it seems that it is not necessary to add high concentrations of chia to reach the granulation point.

3.5. Physical Characterization of Granules

3.5.1. Granule Flow and True Density

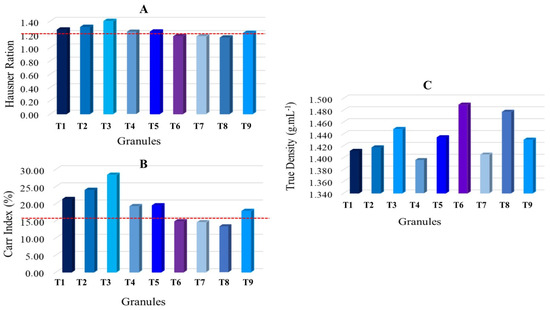

The granule flow and true density results of the formulations are presented in Figure 5.

Figure 5.

Physical characterization results to evaluate the granule flow for T1–T9: (A) Hausner ratio; (B) Carr Index; and (C) true density. The red line in (A,B) represents the specifications of the American Pharmacopoeia [33].

For a tablet formulation to have adequate compressibility and compactability, the flow must not negatively impact the process. In this sense, a critical attribute is the cohesion of the formulation, which is significant in the manufacturing process of any solid pharmaceutical form [36,39]. When the flow of a material is considered suitable for formulation development, it means that in the compressibility stage, the particles will have an affinity to adhere to each other, mainly due to the size and shape of the particles [36,40].

The formulations that exhibited exceptional flow properties, with a value of <15%, were T8, T7, and T6. The other formulations had a reasonable flow rate, or assistance was required, which, in both cases, can be solved with the addition of excipients that help with the fluidity of the powder, for example, a rheology promoter such as silicon dioxide [41]; a diluent to aid filling and compressibility such as microcrystalline cellulose, lactose, or co-processed products [42]; and lubricants such as magnesium stearate [43].

The true densities of the formulations were similar, with T4 having the lowest density, which could be due to the lack of balance in microcrystalline cellulose and the presence of chia in high amounts in the mixture, corroborating that chia has a low density (as shown in Table 4).

3.5.2. Granulometric Distribution and Granule Strength

The granulometric distribution of the formulations is presented in Figure 6, where it is possible to verify that T8, T1, and T9 efficiently produced granulates, presenting a better distribution in the range of 0.8 to 1.18 mm, which represents a suitable size for the granules.

Figure 6.

Resistance of the T1–T9 granules on the sieves before and after the friability testing of the formulations.

Another important characteristic of the granulate is its resistance (shown in Figure 6 and Table 7); it is possible to verify that T2, T3, T9, and T8 had greater resistance. However, it is important to emphasize that T2 did not have a suitable particle size distribution and is thus not considered a promising formulation.

Table 7.

Particle size distribution in the range of 0.80–1.18 mm before and after the friability test.

It is interesting to note that T8 contains 73.17% quinoa with only 2.44% chia as a binder, which makes it a standout among the formulations with the best particle size.

3.5.3. Optical Microscopy

The granule diameter values were heterogeneous and had a wide range at 996.41, 439.77, 766.21, 785.51, 579.56, 966.91, 800.44, 446.30, and 1040.71 µm, respectively (Figure 7). As it is a fibrous material, we can observe that there were no spherical granules but rather irregular ones, indicating that the granules have a variable polydispersity index (various dimensions), which is possibly a characteristic of this type of material [44]. Even with the variation in shape, the granules were mostly resistant, as shown in Table 7, and most formulations had an adequate flow (Figure 6), preventing these physical properties from being a limiting factor to producing chewable tablets.

Figure 7.

The average size of the granules using optical microscopy with 30 and 40× magnification. The sizes of the captured images (in width and height) vary from 1500 to 2500 µm.

Given our results, we noted that it is necessary to work with wet granulation since quinoa is an integral part of the formulation. As a result, the characteristics of the quinoa powder observed in Table 4 and Figure 3 (poor flow and small particle size) in a direct compression process would not enable efficient production since the cohesion of the powder would not be sufficient to form tablets. The investigation into wet powder rheometry using chia as a binder highlighted the significant role chia plays in the granulation of powders. Although some granulated formulations still require assistance with the addition of an excipient to avoid compromising the flow, as a whole, chia seems to be an excellent binder for formulations containing fibers. By using chia as a binder in quinoa formulations, the formulations can achieve a high fiber content, making them suitable for daily consumption as recommended by health authorities.

3.6. Production of Chewable Tablets

Our results showed that the transformation of quinoa and chia powders into granules was able to significantly improve their flow characteristics. We selected the T8 formulation, which contains a greater amount of quinoa and a lower concentration of chia for binding, to produce chewable tablets. By using just 2% chia, we can obtain a granulate with excellent physical properties, making it possible to enable the production of a batch of chewable tablets. During the production process, all parameters were measured and controlled in accordance with the guidelines of the United States Pharmacopeia [27], yielding 1.800 ± 1.25 for average weight, 8.50 ± 0.07 for average thickness, 0.58 ± 1.12 for average friability, 8.70 ± 1.90 for average hardness, and 0.76 ± 2.10 for average disintegration time.

4. Conclusions

Given the results presented in this study, it is possible to state that chia (Salvia hispanica) can efficiently act as a binder in proportions of 2.0–33.0%. This concentration allows the formulation to reach the granulation point of quinoa powders (Chenopodium quinoa Willd.) in proportions of 30.0–73.0%, which guarantees resistant granules and adequate flow for most formulations, enabling the subsequent production of chewable tablets.

The results of the selected model indicated that there is not enough evidence to support the influence of the amount of quinoa, MCC PH101, and chia on the torque and binder/liquid ratio. On the other hand, in the response surface analysis, the water variable had the greatest effect and showed that, for higher concentrations of MCC PH101, a greater volume of liquid is required to reach the granulation point. Furthermore, when using chia as a binder, there is a balance in the distribution of water. The more water that is added to the formulation, the longer the drying time and the higher the processing cost.

Regarding the results of the flow properties and granule resistance, all formulations showed promise for the tablet compression stage (except T1 and T3 due to low resistance and poor flow, respectively), and this is due to chia’s ability to promote the agglutination of a fibrous material, which is at a high concentration in the tablet. The best formulation was T8, as it contained 73.17% quinoa powder and 2.44% chia powder to form a tablet, and, as a result, all the tested properties of these granules were within the specifications.

Based on the concentration of T8 fibers (approximately 75.0%), it is possible to guarantee a sufficient daily dietary fiber content, which enables the appropriate amount of fiber to be consumed, compared to consuming the fiber in the form of quinoa or chia grains themselves.

Finally, using chia as a binder in this study, we produced tablets containing a high concentration of fiber, which can bring a new perspective to chia’s use in other types of formulations since it has health benefits and can replace other excipients or binders.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/powders3020013/s1, Video S1: Wet granulation using chia as a binder to form quinoa granulate.

Author Contributions

Conceptualization: R.P.d.S. and F.J.V.R.; Data curation: R.P.d.S. and F.J.V.R.; Formal Analysis: R.P.d.S.; Investigation: R.P.d.S. and F.J.V.R.; Methodology: R.P.d.S., F.J.V.R. and J.E.d.S.P.; Supervision: H.G.F.; Visualization: R.P.d.S.; Writing—original draft preparation: R.P.d.S.; Writing—review and editing: R.P.d.S., F.J.V.R., J.S.P.D., J.E.d.S.P., S.d.A.P. and H.G.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research did not receive any specific subsidies from funding agencies in the public, commercial, or non-profit sectors.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The processed data required to reproduce these results are included in the Materials and Methods Section (Section 2). Raw data are available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Angeli, V.; Silva, P.M.; Massuela, D.C.; Khan, M.W.; Hamar, A.; Khajehei, F.; Graeff-Hönninger, S.; Piatti, C. Quinoa (Chenopodium quinoa Willd.): An Overview of the Potentials of the “Golden Grain” and Socio-Economic and Environmental Aspects of Its Cultivation and Marketization. Foods 2020, 9, 216. [Google Scholar] [CrossRef] [PubMed]

- Hinojosa, L.; Leguizamo, A.; Carpio, C.; Munoz, D.; Mestanza, C.; Ochoa, J.; Castillo, C.; Murillo, A.; Villacréz, E.; Monar, C.; et al. Quinoa in Ecuador: Recent Advances under Global Expansion. Plants 2021, 10, 298. [Google Scholar] [CrossRef] [PubMed]

- Jancurová, M.; Minarovicová, L.; Dandár, A. Quinoa—A Review. Czech J. Food Sci. 2009, 27, 71–79. [Google Scholar] [CrossRef]

- Alonso-Miravalles, L.; O’Mahony, J.A. Composition, Protein Profile and Rheological Properties of Pseudocereal-Based Protein-Rich Ingredients. Foods 2018, 7, 73. [Google Scholar] [CrossRef] [PubMed]

- Segura-Campos, M.R.; Ciau-Solís, N.; Rosado-Rubio, G.; Chel-Guerrero, L.; Betancur-Ancona, D. Chemical and Functional Properties of Chia Seed (Salvia hispanica L.). Gum. Int. J. Food Sci. 2014, 2014, 241053. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, B.P.; Dias, D.M.; Moreira, M.E.D.; Toledo, R.C.L.; da Matta, S.L.P.; Della Lucia, C.M.; Martino, H.S.D.; Pinheiro-Sant’Ana, H.M. Chia Seed Shows Good Protein Quality, Hypoglycemic Effect and Improves the Lipid Profile and Liver and Intestinal Morphology of Wistar Rats. Plant Foods Hum. Nutr. 2016, 71, 225–230. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Lin, H.W.; Lin, Y.L.; Yang, D.J.; Yu, Y.S.; Chen, J.W.; Wang, S.Y.; Chen, Y.C. Nutritional composition in the chia seed and its processing properties on restructured ham-like products. J. Food Drug Anal. 2018, 26, 124–134. [Google Scholar] [CrossRef]

- Felisberto, M.H.F.; Wahanik, A.L.; Gomes-Ruffi, C.R.; Clerici, M.T.P.S.; Chang, Y.K.; Steel, C.J. Use of chia (Salvia hispanica L.) mucilage gel to reduce fat in pound cakes. LWT Food Sci. Technol. 2015, 63, 1049–1055. [Google Scholar] [CrossRef]

- Barber, T.M.; Kabish, S.; Pfeiffer, A.F.H.; Weickert, M.O. The Health Benefits of Dietary Fibre. Nutrients 2020, 12, 3209. [Google Scholar] [CrossRef] [PubMed]

- Slavin, J. Fiber and Prebiotics: Mechanisms and Health Benefits. Nutrients 2013, 5, 1417–1435. [Google Scholar] [CrossRef]

- Stephen, A.M.; Champ, M.M.; Cloran, S.J.; Fleith, M.; Van Lieshout, L.; Mejborn, H.; Burley, V.J. Dietary fibre in Europe: Current state of knowledge on definitions, sources, recommendations, intakes and relationships to health. Nutr. Res. Rev. 2017, 30, 149–190. [Google Scholar] [CrossRef] [PubMed]

- Hijova, E.; Bertkova, I.; Stofilova, J. Dietary fibre as prebiotics in nutrition. Cent. Eur. J. Public Health 2019, 27, 251–255. [Google Scholar] [CrossRef] [PubMed]

- Weickert, M.O.; Mohlig, M.; Koebnick, C.; Holst, J.J.; Namsolleck, P.; Ristow, M.; Osterhoff, M.; Rochlitz, H.; Rudovich, N.; Spranger, J.; et al. Impact of cereal fibre on glucose-regulating factors. Diabetologia 2005, 48, 2343–2353. [Google Scholar] [CrossRef] [PubMed]

- Gianfredi, V.; Salvatori, T.; Villarini, M.; Moretti, M.; Nucci, D.; Realdon, S. Is dietary fibre truly protective against colon cancer? A systematic review and meta-analysis. Int. J. Food Sci. Nutr. 2018, 69, 904–915. [Google Scholar] [CrossRef] [PubMed]

- Cotovanu, I.; Batariuc, A.; Mironeasa, S. Characterization of Quinoa Seeds Milling Fractions and Their Effect on the Rheological Properties of Wheat Flour Dough. Appl. Sci. 2020, 10, 7225. [Google Scholar] [CrossRef]

- Muñoz-Pabon, K.S.; Roa-Acosta, D.F.; Hoyos-Concha, J.L.; Bravo-Gómez, J.E.; Ortiz-Gómez, V. Quinoa Snack Production at an Industrial Level: Effect of Extrusion and Baking on Digestibility, Bioactive, Rheological, and Physical Properties. Foods 2022, 11, 3383. [Google Scholar] [CrossRef] [PubMed]

- Afzal, I.; Ul Haq, M.Z.; Ahmed, S.; Hirich, A.; Bazile, D. Challenges and Perspectives for Integrating Quinoa into the Agri-Food System. Plants 2023, 12, 3361. [Google Scholar] [CrossRef] [PubMed]

- Graf, B.L.; Rojas-Silva, P.; Rojo, L.E.; Delatorre-Herrera, J.; Baldeon, M.E.; Raskin, I. Innovations in Health Value and Functional Food Development of Quinoa (Chenopodium quinoa Willd.). Compr. Rev. Food Sci. Food Saf. 2015, 14, 431–445. [Google Scholar] [CrossRef] [PubMed]

- Vera-Cespedes, N.; Muñoz, L.A.; Rincón, M.Á.; Haros, C.M. Physico-Chemical and Nutritional Properties of Chia Seeds from Latin American Countries. Foods 2023, 12, 3013. [Google Scholar] [CrossRef]

- Maradini Filho, A.M.; Pirozi, M.R.; Borges, J.T.d.S.; Sant’Ana, H.M.P.; Chaves, J.B.P.; Coimbra, J.S.D.R. Quinoa: Nutritional, functional, and antinutritional aspects. Crit. Rev. Food Sci. Nutr. 2017, 57, 1618–1630. [Google Scholar] [CrossRef]

- Fernandes, S.S.; Salas-Mellado, M.d.l.M. Addition of chia seed mucilage for reduction of fat content in bread and cakes. Food Chem. 2017, 227, 237–244. [Google Scholar] [CrossRef]

- Goyat, J.; Passi, S.J.; Suri, S.; Dutta, H. Development of Chia (Salvia Hispanica, L.) and Quinoa (Chenopodium Quinoa, L.) Seed Flour Substituted Cookies—Physicochemical, Nutritional and Storage Studies. Curr. Res. Nutr. Food. Sci. 2018, 6, 757–769. [Google Scholar] [CrossRef]

- Suresh, P.; Sreedhar, I.; Vaidhiswaran, R.; Venugopal, A. A comprehensive review on process and engineering aspects of pharmaceutical wet granulation. Chem. Eng. J. 2017, 328, 785–815. [Google Scholar] [CrossRef]

- Da Silva, R.P.; Fante, A.S.; Silva, A.R.P.; Pereira, F.L.S.; Gutierrez, Y.L.R.; Ferraz, H.G. Wet powder rheometry: The best conditions for wet granulation using diluent and binder in calcium carbonate samples. Powder Technol. 2022, 397, 117087. [Google Scholar] [CrossRef]

- Otsuka, T.; Kuroiwa, Y.; Sato, K.; Yamashita, K.; Hakomori, T.; Kimura, S.; Iwao, Y.; Itai, S. Use of Mixer Torque Rheometer to Clarify the Relationship between the Kneading States of Wet Mass and the Dissolution of Final Product in High Shear Granulation. Chem. Pharm. Bull. 2018, 66, 554–561. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Zayed, G.M.; Alsharif, F.M.; Abdelhafez, W.A. Utilizing mixer torque rheometer in the prediction of optimal wet massing parameters for pellet formulation by extrusion/spheronization. Saudi Pharm. J. 2019, 27, 182–190. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.Y.; Lamberto, D.J. Development of New Laboratory Tools for Assessment of Granulation Behavior During Bulk Active Pharmaceutical Ingredient Drying. J. Pharm. Sci. 2014, 103, 152–160. [Google Scholar] [CrossRef]

- Kuhs, M.; Moore, J.; Kollamaram, G.; Walker, G.; Croker, D. Predicting optimal wet granulation parameters for extrusion-spheronisation of pharmaceutical pellets using a mixer torque rheometer. Int. J. Pharm. 2017, 517, 19–24. [Google Scholar] [CrossRef]

- Di Stefano, C.; Ferro, V.; Mirabile, S. Comparison between grain-size analyses using laser diffraction and sedimentation methods. Biosyst. Eng. 2010, 106, 205–215. [Google Scholar] [CrossRef]

- Da Silva, R.P.; Kawai, G.S.D.; Andrade, F.R.D.D.; Bezzon, V.D.N.; Ferraz, H.G. Characterisation and traceability of calcium carbonate from the seaweed Lithothamnium calcareum. Solids 2021, 2, 192–211. [Google Scholar] [CrossRef]

- Belem, B.R.; Ferraz, H.G. Rheological profile in mixer torque rheometer of samples containing furazolidone and different binders. Chem. Eng. Res. Des. 2020, 160, 533–539. [Google Scholar] [CrossRef]

- Issa, M.G.; Pessole, L.; Takahashi, A.I.; Andreo, N.; Ferraz, H.C. Physicochemical and dissolution profile characterization of pellets containing different binders obtained by the extrusion-spheronization process. Braz. J. Pharm. Sci. 2012, 48, 379–388. [Google Scholar] [CrossRef]

- United States Pharmacopeia Convention. The United States Pharmacopeia: The National Formulary, 1st ed.; United States Pharmacopeial Convention: Rockville, Maryland, 2022. [Google Scholar]

- Horiba Scientific. A Guidebook to Particle Size Analysis; Horiba Instruments: Irvine, CA, USA, 2017. [Google Scholar]

- Wünsch, I.; Finke, J.H.; John, E.; Juhnke, M.; Kwade, A. The influence of particle size on the application of compression and compaction models for tableting. Int. J. Pharm. 2021, 599, 120424. [Google Scholar] [CrossRef] [PubMed]

- Leung, L.Y.; Mao, C.; Srivastava, I.; Du, P.; Yang, C.Y. Flow Function of Pharmaceutical Powders Is Predominantly Governed by Cohesion, Not by Friction Coefficients. J. Pharm. Sci. 2017, 106, 1865–1873. [Google Scholar] [CrossRef] [PubMed]

- Hiremath, P.; Nuguru, K.; Agrahari, V.; Narang, A.S.; Badawy, S.I.F. Chapter 8—Material Attributes and Their Impact on Wet Granulation Process Performance; Academic Press: Cambridge, MA, USA, 2019; pp. 263–315. [Google Scholar]

- Tank, D.; Karan, K.; Gajera, B.; Dave, R.H. Investigate the effect of solvents on wet granulation of microcrystalline cellulose using hydroxypropyl methylcellulose as a binder and evaluation of rheological and thermal characteristics of granules. Saudi Pharm. J. 2018, 26, 593–602. [Google Scholar] [CrossRef] [PubMed]

- Jones-Salkey, O.; Chu, Z.; Ingram, A.; Windows-Yule, C.R.K. Reviewing the Impact of Powder Cohesion on Continuous Direct Compression (CDC) Performance. Pharmaceutics 2023, 15, 1587. [Google Scholar] [CrossRef]

- Chattoraj, S.; Sun, C.C. Crystal and Particle Engineering Strategies for Improving Powder Compression and Flow Properties to Enable Continuous Tablet Manufacturing by Direct Compression. J. Pharm. Sci. 2018, 107, 968–974. [Google Scholar] [CrossRef]

- Tadauchi, T.; Yamada, D.; Koide, Y.; Yamada, M.; Shimada, Y.; Yamazoe, E.; Ito, T.; Tahara, K. Improving the Powder Properties of an Active Pharmaceutical Ingredient (Ethenzamide) with a Silica Nanoparticle Coating for Direct Compaction into Tablets. Powders 2022, 1, 231–242. [Google Scholar] [CrossRef]

- Schönfeld, B.V.; Westedt, U.; Wagner, K.G. Compression Modulus and Apparent Density of Polymeric Excipients during Compression-Impact on Tabletability. Pharmaceutics 2022, 14, 913. [Google Scholar] [CrossRef]

- Morin, G.; Briens, L. The Effect of Lubricants on Powder Flowability for Pharmaceutical Application. AAPS PharmSciTech 2013, 14, 1158–1168. [Google Scholar] [CrossRef]

- Luo, Y.; Ni, F.T.; Guo, M.Z.; Liu, J.; Chen, H.; Zhang, S.T.; Li, Y.L.; Chen, G.; Wang, G. Quinoa starch microspheres for drug delivery: Preparation and their characteristics. Food Sci. Technol. 2022, 42, e126421. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).