Effect of Induction Heating on Surface Properties of Hot-Pressed Ceramics Based on Nanopowders Si3N4 and TiN

Abstract

1. Introduction

2. Materials and Methods

3. Results

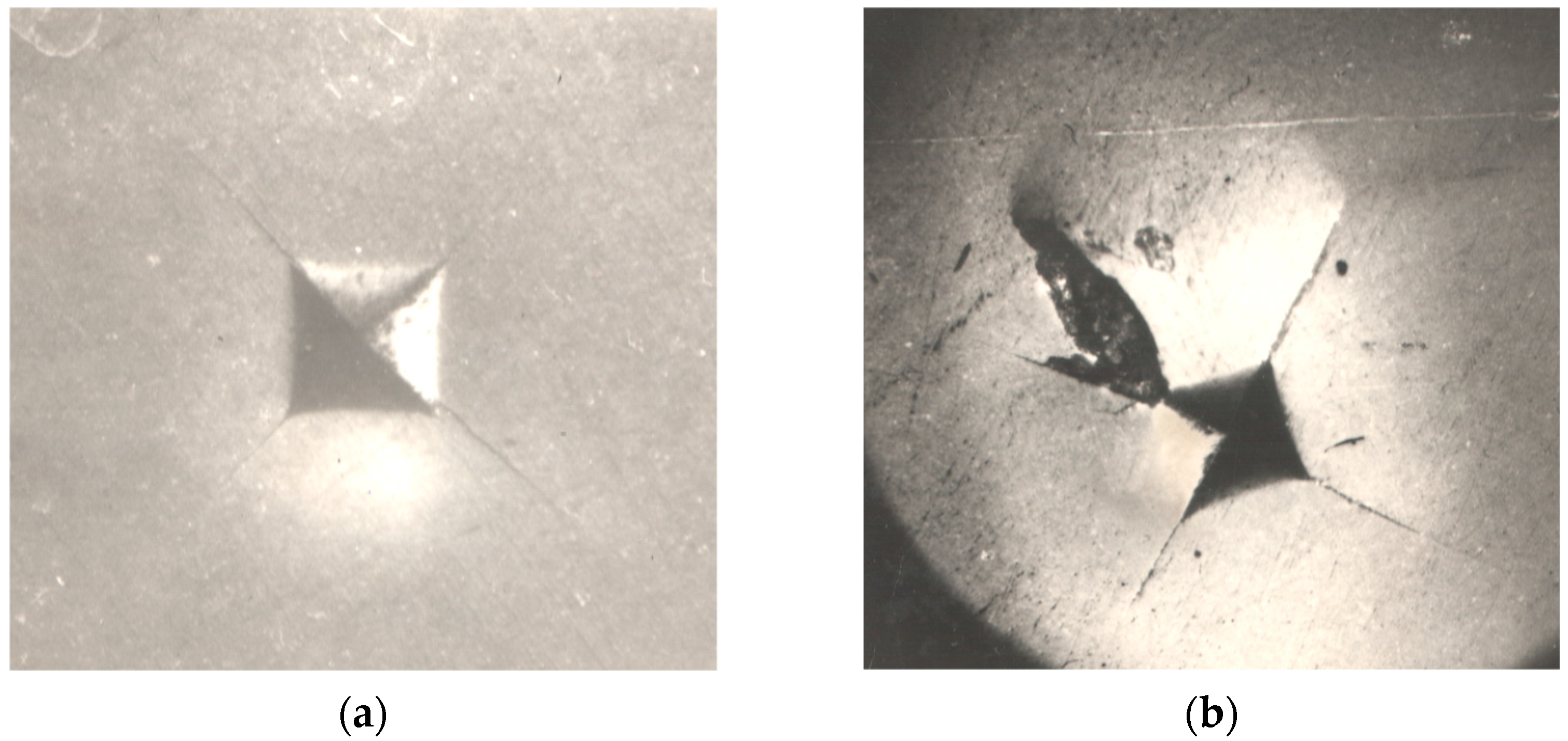

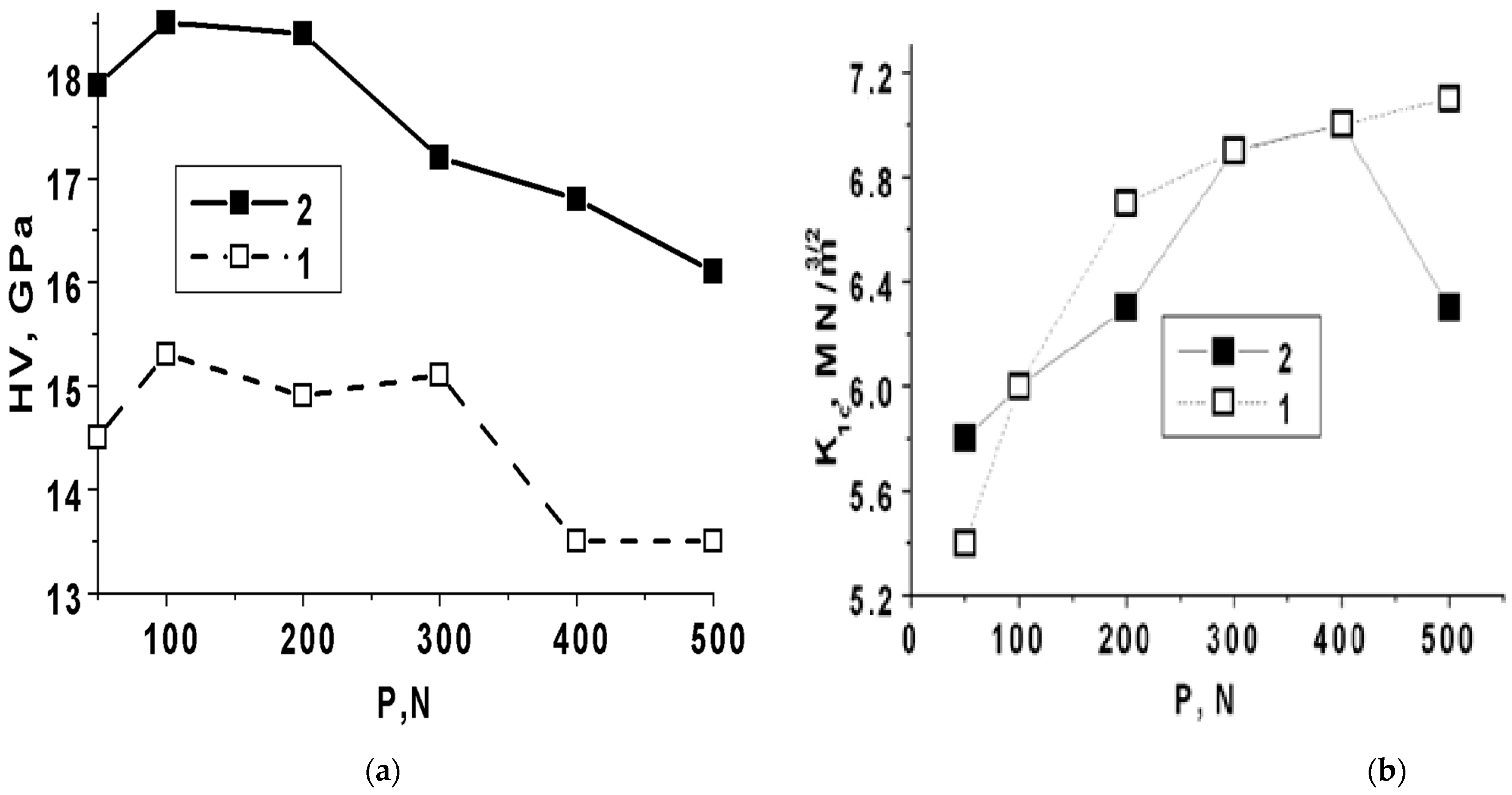

3.1. Density, Hardness, and Fracture Toughness Measurements

3.2. Acoustic Emission Signals Measurements

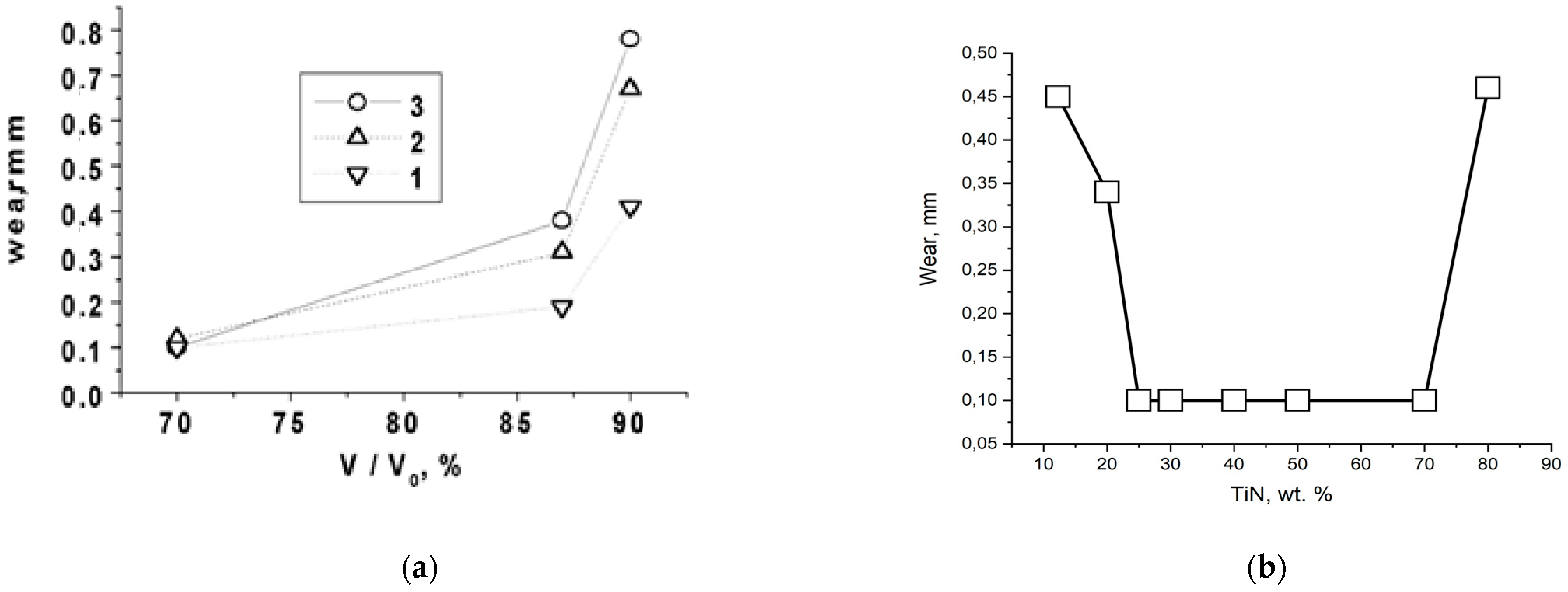

3.3. Wear Measurements

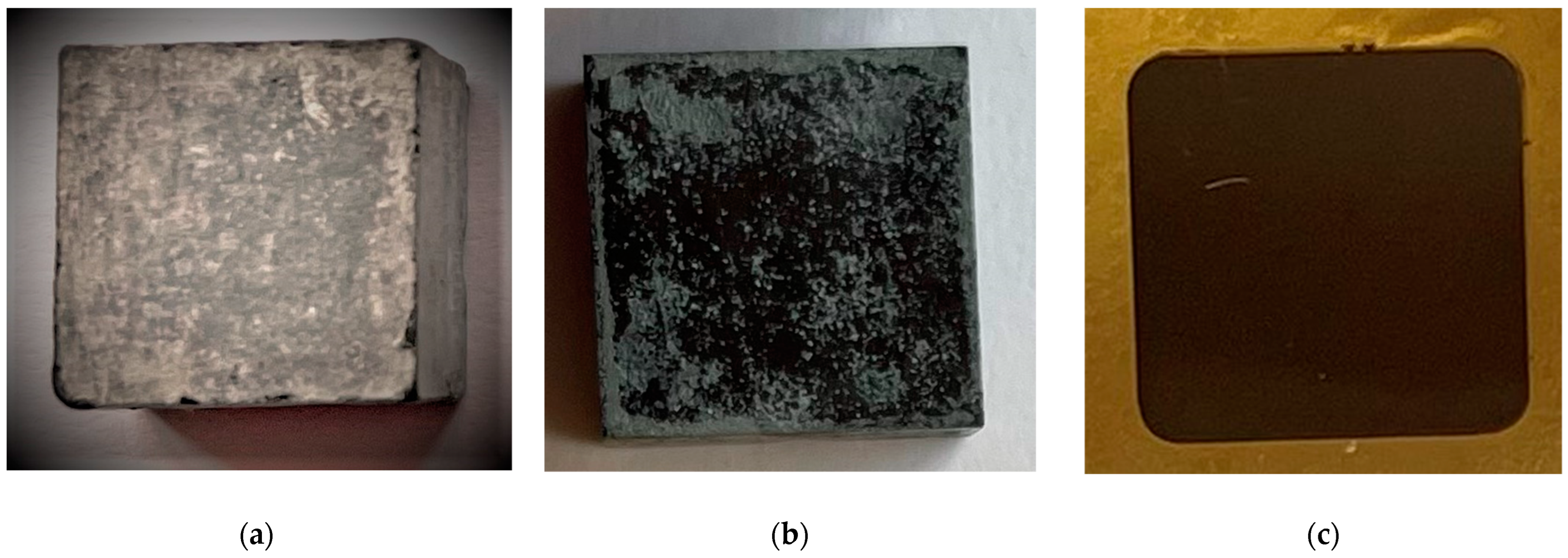

3.4. Darkly Colored Surface Area

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nishimura, T.; Xu, X.; Kimoto, K.; Hirosaki, N.; Tanaka, H. Fabrication of silicon nitride nanoceramics—Powder preparation and sintering: A review. Sci. Technol. Adv. Mater. 2007, 8, 635–643. [Google Scholar] [CrossRef]

- Hu, F.; Xie, Z.P.; Zhang, J.; Hu, Z.L.; An, D. Promising high-thermal-conductivity substrate material for high-power electronic device: Silicon nitride ceramics. Rare Met. 2020, 39, 463–478. [Google Scholar] [CrossRef]

- Klemm, H. Silicon Nitride for High-Temperature Applications. J. Am. Ceram. Soc. 2010, 93, 1501–1522. [Google Scholar] [CrossRef]

- Bocanegra-Bernal, M.H.; Matovic, B. Mechanical properties of silicon nitride-based ceramics and its use in structural applications at high temperatures. Mater. Sci. Eng. A 2010, 527, 1314–1338. [Google Scholar] [CrossRef]

- Krstic, Z.; Krstic, V.D. Silicon nitride: The engineering material of the future. J. Mater. Sci. 2012, 47, 535–552. [Google Scholar] [CrossRef]

- Riley, F. Silicon nitride and related materials. J. Am. Ceram. Soc. 2000, 83, 245. [Google Scholar] [CrossRef]

- Kim, T.H.; Lee, S.; Park, D.W. Synthesis of Silicon Nitride Nanoparticles by Upcycling Silicon Wafer Waste Using Thermal Plasma Jets. Materials 2022, 15, 8796. [Google Scholar] [CrossRef]

- Liu, W.; Tong, W.; He, R.; Wu, H.; Wu, S. Effect of the Y2O3 additive concentration on the properties of a silicon nitride ceramic substrate. Ceram. Int. 2016, 42, 18641–18647. [Google Scholar] [CrossRef]

- Li, S.; Xie, Z.; Xue, W.; Luo, X.; An, L. Sintering of high-performance silicon nitride ceramics under vibratory pressure. J. Am. Ceram. Soc. 2015, 98, 698–701. [Google Scholar] [CrossRef]

- Zhou, Y.; Hyuga, H.; Kusano, D.; Matsunaga, C.; Hirao, K. Effects of yttria and magnesia on densification and thermal conductivity of sintered reaction-bonded silicon nitrides. J. Am. Ceram. Soc. 2019, 102, 1579–1588. [Google Scholar] [CrossRef]

- Hampshire, S. Silicon nitride Ceramics-review of structure, processing and properties. J. Achiev. Mater. Manuf. Eng. 2007, 24, 43. [Google Scholar]

- Zhu, X.; Hayashi, H.; Zhou, Y.; Hirao, K. Influence of additive composition on thermal and mechanical properties of β-Si3N4 ceramics. J. Mater. Res. 2004, 19, 3270–3278. [Google Scholar] [CrossRef]

- Matovic, B.; Rixecker, G.; Aldinger, F. Pressureless sintering of silicon nitride with lithia and yttria. J. Eur. Ceram. Soc. 2004, 24, 3395–3398. [Google Scholar] [CrossRef]

- Kusano, D.; Hyuga, H.; Zhou, Y.; Hirao, K. Effect of Aluminum Content on Mechanical Properties and Thermal Conductivities of Sintered Reaction-Bonded Silicon Nitride. Int. J. Appl. Ceram. Technol. 2014, 11, 534–542. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, G.; Yi, M.; Xu, C. Effect of graphene orientation on microstructure and mechanical properties of silicon nitride ceramics. Process. Appl. Ceram. 2018, 12, 27–35. [Google Scholar] [CrossRef]

- Šajgalik, P.; Dusza, J.; Hoffmann, M.J. Relationship between Microstructure, Toughening Mechanisms, and Fracture Toughness of Reinforced Silicon Nitride Ceramics. J. Am. Ceram. Soc. 1995, 78, 2619–2624. [Google Scholar] [CrossRef]

- Pyzik, A.J.; Beaman, D.R. Microstructure and Properties of Self-Reinforced Silicon Nitride. J. Am. Ceram. Soc. 1993, 76, 2737–2744. [Google Scholar] [CrossRef]

- Švec, P.; Brusilová, A.; Kozánková, J. Effect of microstructure and mechanical properties on wear resistance of silicon nitride ceramics. Mater. Eng. 2008, 16, 34–40. [Google Scholar]

- Li, S.; Wei, C.; Zhou, L.; Wang, P.; Wang, W. Microstructure and fracture strength of silicon nitride ceramics consolidated by oscillatory pressure sintering. Ceram. Int. 2019, 45, 15671–15675. [Google Scholar] [CrossRef]

- Iturriza, I.; Castro, F.; Fuentes, M. Sinter and sinter-HIP of silicon nitride ceramics with yttria and alumina additions. J. Mater. Sci. 1989, 24, 2047–2056. [Google Scholar] [CrossRef]

- Guedes-Silva, C.C.; De Souza Carvalho, F.M.H.; Bressiani, J.C. Effect of rare-earth oxides on properties of silicon nitride obtained by normal sintering and sinter-HIP. J. Rare Earths 2012, 30, 1177–1183. [Google Scholar] [CrossRef]

- Xu, W.; Yin, Z.; Yuan, J.; Wang, Z.; Fang, Y. Effects of sintering additives on mechanical properties and microstructure of Si3N4 ceramics by microwave sintering. Mater. Sci. Eng. A 2017, 684, 127–134. [Google Scholar] [CrossRef]

- Khajelakzay, M.; Bakhshi, S.R.; Borhani, G.H.; Ramazani, M. Synthesis and spark plasma sintering of the α- Si3N4 nanopowder. Ceram. Int. 2016, 42, 14867–14872. [Google Scholar] [CrossRef]

- Golla, B.R.; Ko, J.W.; Kim, H.D. Processing and characterization of sintered reaction bonded Si3N4 ceramics. Int. J. Refract. Met. Hard Mater. 2017, 68, 75–83. [Google Scholar] [CrossRef]

- Han, Y.; Xie, Z.; Li, S.; Zhu, T.; Wu, W.; An, D.; Hu, F.; Zhai, F. Optimum sintering temperature of high quality silicon nitride ceramics under oscillatory pressure. Ceram. Int. 2018, 44, 6949–6952. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Yu, J.B.; Xia, Y.F.; Zuo, K.H.; Yao, D.X.; Zeng, Y.P.; Ren, Z.M. Microstructure and mechanical performance of silicon nitride ceramics with seeds addition. J. Inorg. Mater. 2012, 27, 807–812. [Google Scholar] [CrossRef]

- Hirota, M.; Brito, M.E.; Hirao, K.; Watari, K.; Toriyama, M.; Nagaoka, T. Grain growth behavior during microwave annealing of silicon nitride. Mater. Res. Soc. Symp. Proc. 1996, 430, 441–445. [Google Scholar] [CrossRef]

- Rutkowski, P.; Stobierski, L.; Górny, G. Thermal stability and conductivity of hot-pressed Si3N 4-graphene composites. J. Therm. Anal. Calorim. 2014, 116, 321–328. [Google Scholar] [CrossRef][Green Version]

- Miranzo, P.; García, E.; Ramírez, C.; González-Julián, J.; Belmonte, M.; Osendi, M.I. Anisotropic thermal conductivity of silicon nitride ceramics containing carbon nanostructures. J. Eur. Ceram. Soc. 2012, 32, 1847–1854. [Google Scholar] [CrossRef]

- Hirao, K.; Watari, K.; Brito, M.E.; Toriyama, M.; Kanzaki, S. High Thermal Conductivity in Silicon Nitride with Anisotropie Microstructure. J. Am. Ceram. Soc. 1996, 79, 2485–2488. [Google Scholar] [CrossRef]

- Sun, E.Y.; Becher, P.F.; Plucknett, K.P.; Hsueh, C.; Alexander, K.B.; Waters, S.B. Microstructural Design of Silicon Nitride with Improved Fracture Toughness: II, Effects of Yttria and Alumina Additives. J. Am. Ceram. Soc. 1998, 40, 2821–2830. [Google Scholar] [CrossRef]

- Yu, J.J.; Guo, W.M.; Wei, W.X.; Lin, H.T.; Wang, C.Y. Fabrication and Wear Behaviors of Graded Si3N4 Ceramics by the Combination of Two-Step Sintering and β-Si3N4 Seeds; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; Volume 38, pp. 3457–3462. [Google Scholar]

- Mishima, M.; Sato, Y.; Ueki, M. Relation between microstructure and color tone of skin layer and bulk area of silicon nitride ceramics. Nippon. Seramikkusu Kyokai Gakujutsu Ronbunshi J. Ceram. Soc. Jpn. 1992, 100, 1323–1326. [Google Scholar] [CrossRef][Green Version]

- Terwilliger, G.R.; Lange, F.F. Pressureless sintering of Si3N4. J. Mater. Sci. 1975, 10, 1169. [Google Scholar] [CrossRef]

- Chen, S.C.; Sung, K.Y.; Tzeng, W.Y.; Wu, K.H.; Juang, J.Y.; Uen, T.M.; Luo, C.W.; Lin, J.Y.; Kobayashi, T.; Kuo, H.C. Microstructure and magnetic properties of oxidized titanium nitride thin films in situ grown by pulsed laser deposition. J. Phys. D Appl. Phys. 2013, 46, 075002. [Google Scholar] [CrossRef]

- Gong, C.; Meng, H.; Zhao, X.; Zhang, X.; Yu, L.; Zhang, J.; Zhang, Z. Unique Static Magnetic and Dynamic Electromagnetic Behaviors in Titanium Nitride/Carbon Composites Driven by Defect Engineering. Sci. Rep. 2016, 6, 18927. [Google Scholar] [CrossRef]

- Millers, T.; Grabis, J.; Zālīte, I. Ultrafine Powders of the Refractory Materials in the Composite Development BT. In Proceedings of the MICC 90: Moscow International Composites Conference, Moscow, Russia, 14–16 November 1990; Fridlyander, I.N., Kostikov, V.I., Eds.; Springer: Dordrecht, The Netherlands, 1991; pp. 151–153, ISBN 978-94-011-3676-1. [Google Scholar]

- Zalite, I.; Herrmann, M.; Grabis, J. Materials on the Basis of Finely Dispersed Si3N4 Powders. Key Eng. Mater. 1997, 132–136, 1018–1021. [Google Scholar] [CrossRef]

- Osipova, I.I.; Sartinskaya, L.L. Effect of processing factors on the structural heterogeneity of materials based on ultrafine nitride powders. Powder Metall. Met. Ceram. 1990, 29, 7–9. [Google Scholar] [CrossRef]

- Gnesin, G.G.; Osipova, I.I.; Sartinskaya, L.L.; Grigor’ev, O.N. Properties of materials based on ultradispersed nitride powders. Powder Metall. Met. Ceram. 1990, 29, 668–671. [Google Scholar] [CrossRef]

- Gnesin, G.G.; Osipova, I.I.; Sartinskaya, L.L. Tool Ceramic Materials Based on Ultradispersed Nitride Powders. Poroshkovaya Metall. 1990, 12, 78–82. [Google Scholar]

- Gnesin, G.G.; Osipova, I.I.; Sartinskaya, L.L. Ultradispersed nitride powder-base ceramic tool materials. Powder Metall. Met. Ceram. 1990, 29, 1011–1014. [Google Scholar] [CrossRef]

- Niihara, K.; Morena, R.; Hasselman, D.P.H. Evaluation of KIc of brittle solids by the indentation method with low crack-to-indent ratios. J. Mater. Sci. Lett. 1982, 1, 13–16. [Google Scholar] [CrossRef]

- Boyarskaya, Y.S.; Grabko, D.Z.; Katz, M.S. Physics of Microindentation Processes; Shtiintsa: Kichineu, Moldova, 1986. [Google Scholar]

- Eitzen, D.G.; Wadley, H.N.G. Acoustic Emission: Establishing the Fundamentals. J. Res. Natl. Bur. Stand. 1984, 89, 75–100. [Google Scholar] [CrossRef] [PubMed]

- Sakoman, M.; Ćorić, D.; Vuić, D. Load dependece of hardness and fracture toughness values on hardmetals. In Abstracts Book and Proceedings on USB of International Conference on Materials, Tribology, Recycling, MATRIB 2016/Žmak, Irena; Aleksandrov Fabijanić, Tamara; Ćorić, Danko (ur.); Hrvatsko Društvo za Materijale i Tribologiju: Zagreb, Croatia, 2016; pp. 366–372. [Google Scholar]

- Wang, P.; Kumar, R.; Sankaran, E.M.; Qi, X.; Zhang, X.; Popov, D.; Cornelius, A.L.; Li, B.; Zhao, Y.; Wang, L. Vanadium Diboride (VB2) Synthesized at High Pressure: Elastic, Mechanical, Electronic, and Magnetic Properties and Thermal Stability. Inorg. Chem. 2018, 57, 1096–1105. [Google Scholar] [CrossRef] [PubMed]

- Osipova, I.I.; Sartinskaya, L.L.; Grigor’ev, O.N. Stabilization of properties of tool materials made of ultrafine powders. Phys. Mater. Sci. Phys. Chem. Princ. Dev. New Mater. 1989, 129–133. [Google Scholar]

- Osipova, I.I.; Koval’chenko, A.M.; Sartinskaya, L.L. Optimization of the composition of nitridic ceramic tool material by tribotechnical tests. Powder Metall. Met. Ceram. 1992, 31, 321–324. [Google Scholar] [CrossRef]

- Osipova, I.I.; Kovalchenko, A.M.; Sartinskaya, L.L. Tribotechnical Tests of Tool Nitride Ceramics. Poroshkovaya Metall. 1992, 4, 46–51. [Google Scholar]

- Osipova, I.I.; Koldaev, N.V.; Sartinskaya, L.L. Mechanical properties of materials of ultradispersed nitride and oxide powders. Powder Metall. Met. Ceram. 1996, 34, 573–578. [Google Scholar] [CrossRef]

- Sartinska, L.L.; Gnesin, G.G.; Osipova, I.I. Ceramic composites based on Si3N4-TiN. In Proceedings of the CERAM-2001: International Conference on Advanced Ceramics for the Third Millenium, Tokyo, Japan, 6–8 September 2001; p. 2001. [Google Scholar]

- Alivov, Y.; Grant, T.; Capan, C.; Iwamoto, W.; Pagliuso, P.G.; Molloi, S. Origin of magnetism in undoped TiO2 nanotubes. Nanotechnology 2013, 24, 275704. [Google Scholar] [CrossRef]

| Samples | Composition, wt.% | Porosity, % | |||||

|---|---|---|---|---|---|---|---|

| Si3N4 | Al2O3 | AlN | Y2O3 | TiN | before Grinding | after Additional Grinding | |

| 1 | 95 | 5 | 2.0 | 1.8 | |||

| 2 | 55.4 | 5 | 39.6 | 2.2 | 1.6 | ||

| 3 | 46.5 | 0.5 | 53 | 3.2 | 3.0 | ||

| 4 | 27 | 5 | 68 | 3.9 | 3.7 | ||

| 5 | 27.5 | 2.5 | 70 | 3.1 | 3.0 | ||

| 6 | 61.2 | 22.3 | 16.5 | 1.6 | 1.1 | ||

| 7 | 75 | 2 | 3 | 20 | 2.8 | 2.0 | |

| 8 | 25 | 35 | 40 | 2.3 | 1.2 | ||

| 9 | 14 | 38 | 48 | 2.0 | 1.7 | ||

| 10 | 50 | 50 | 4.1 | 3.9 | |||

| 11 | 50 | 50 | 2.4 | 2.2 | |||

| 12 | 27 | 19 | 24 | 30 | 1.9 | 1.0 | |

| 13 | 56 | 12 | 2 | 30 | 1.0 | 0.1 | |

| 14 | 21 | 26 | 53 | 40 | 0.8 | 0.2 | |

| 15 | 12.6 | 15.6 | 31.7 | 40 | 1.1 | 0.8 | |

| 16 | 36.6 | 15.4 | 6.2 | 41.8 | 0.8 | 0.1 | |

| 17 | 35 | 25 | 10 | 30 | 1.7 | 0.6 | |

| 18 | 87.7 | 12.3 | 12.4 | 12.4 | |||

| 19 | 50 | 50 | 6.1 | 6.0 | |||

| Samples | Composition, % | Total Porosity | Hardness HV | Toughness K1c | Total Number of Acoustic Signals | ||||

|---|---|---|---|---|---|---|---|---|---|

| Si3N4 | Al2O3 | AlN | Y2O3 | TiN | % | GPa | MPa*m1/2 | ||

| Without additional grinding | |||||||||

| 1 | 75 | 2 | 3 | 20 | 2.2 | 18.4 | 7 | 7 | |

| 2 | 61.2 | 22.3 | 16.5 | 3.3 | 14.9 | 5.2 | 40 | ||

| 3 | 55.4 | 5 | 39.6 | 1.4 | 12.4 | 5.4 | 21 | ||

| 4 | 55.4 | 5 | 39.6 | 2.3 | 14.7 | 7 | 170 | ||

| 5 | 87.7 | 12.3 | 12.4 | 1.6 | 2.3 | 14 | |||

| After additional grinding | |||||||||

| 6 | 12.6 | 15.6 | 31.7 | 40 | 0 | 18.2 | 5.8 | 25,000 | |

| 7 | 36.6 | 15.4 | 6.2 | 41.8 | 0 | 19.7 | 7.6 | 130,000 | |

| 8 | 55.4 | 5 | 39.6 | 0.8 | 16 | 7.1 | 2700 | ||

| 9 | 36.6 | 15.4 | 6.2 | 41.8 | 2.9 | 17.8 | 5.4 | 20,000 | |

| 10 | 87.7 | 12.3 | 12.4 | 1.6 | 2.3 | 14 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sartinska, L.L. Effect of Induction Heating on Surface Properties of Hot-Pressed Ceramics Based on Nanopowders Si3N4 and TiN. Powders 2023, 2, 697-708. https://doi.org/10.3390/powders2040043

Sartinska LL. Effect of Induction Heating on Surface Properties of Hot-Pressed Ceramics Based on Nanopowders Si3N4 and TiN. Powders. 2023; 2(4):697-708. https://doi.org/10.3390/powders2040043

Chicago/Turabian StyleSartinska, Lina L. 2023. "Effect of Induction Heating on Surface Properties of Hot-Pressed Ceramics Based on Nanopowders Si3N4 and TiN" Powders 2, no. 4: 697-708. https://doi.org/10.3390/powders2040043

APA StyleSartinska, L. L. (2023). Effect of Induction Heating on Surface Properties of Hot-Pressed Ceramics Based on Nanopowders Si3N4 and TiN. Powders, 2(4), 697-708. https://doi.org/10.3390/powders2040043