Aerosol Nanoparticle Control by Electrostatic Precipitation and Filtration Processes—A Review

Abstract

1. Introduction

2. Air Pollution and Ambient Particulate Matter (PM)

3. Ultrafine Particles and Nanoparticles

3.1. Emissions of Nanoparticles and Effects on Human Health

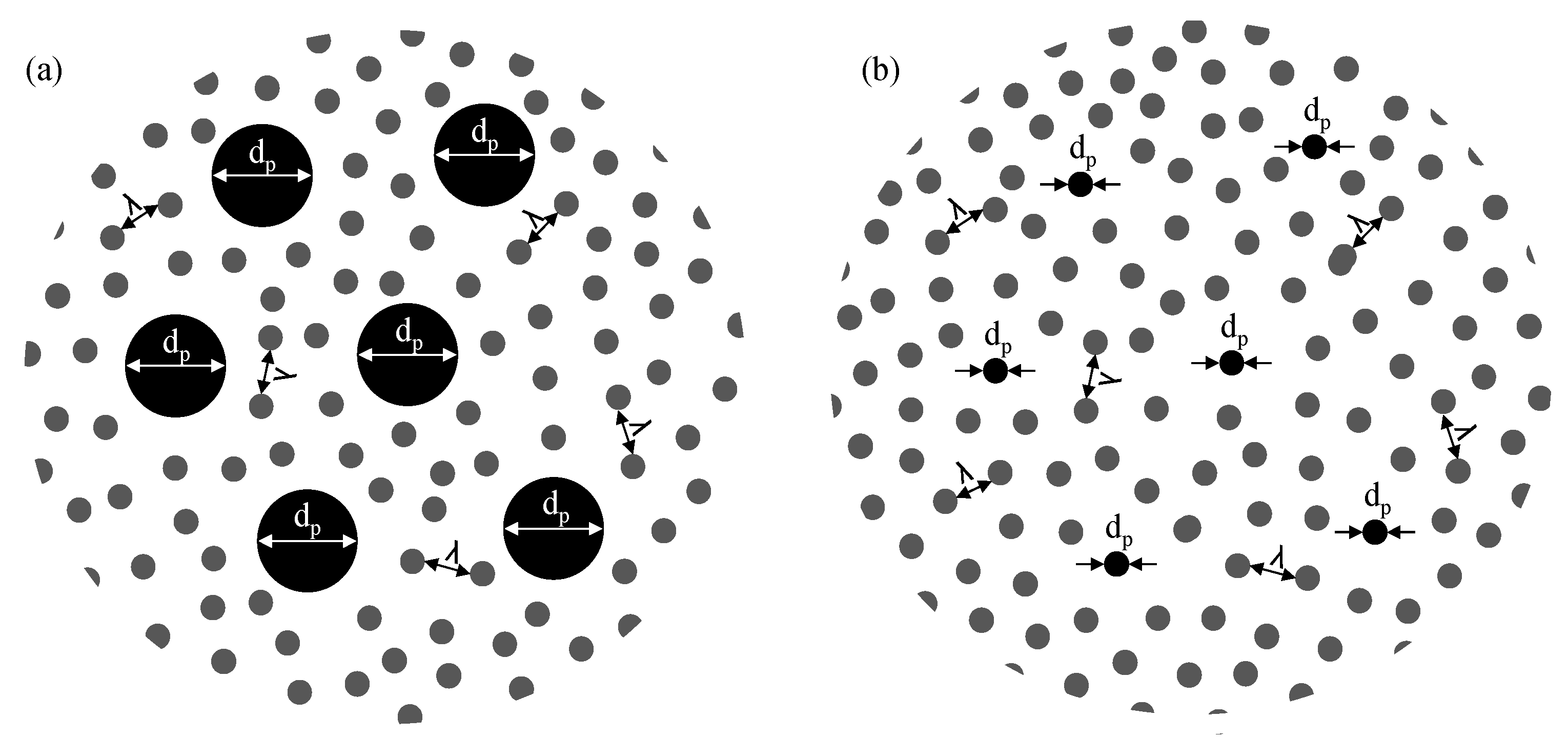

3.2. Characteristics of Nanoparticles

4. Use of Electrostatic Precipitators in the Collection of Nanoparticles

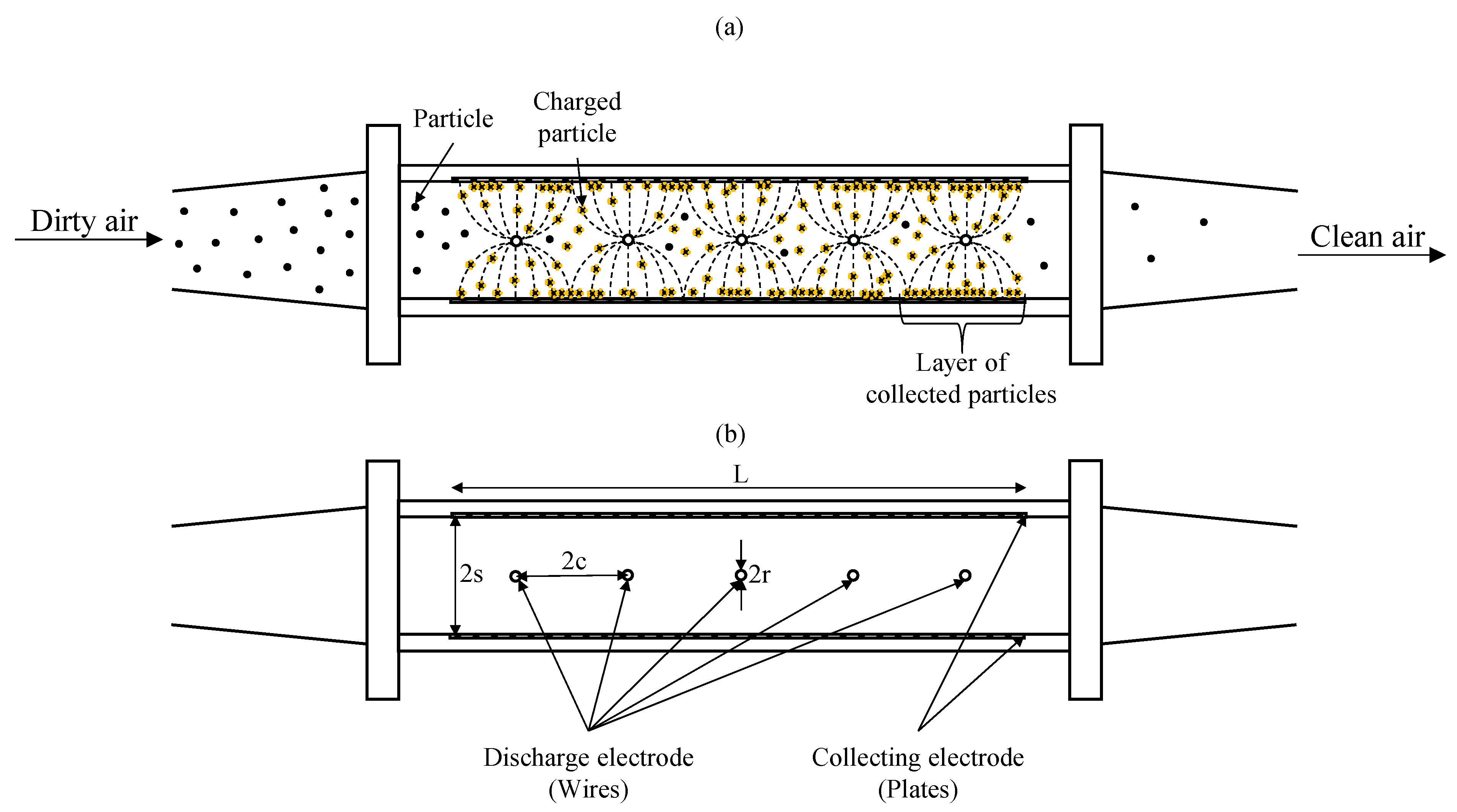

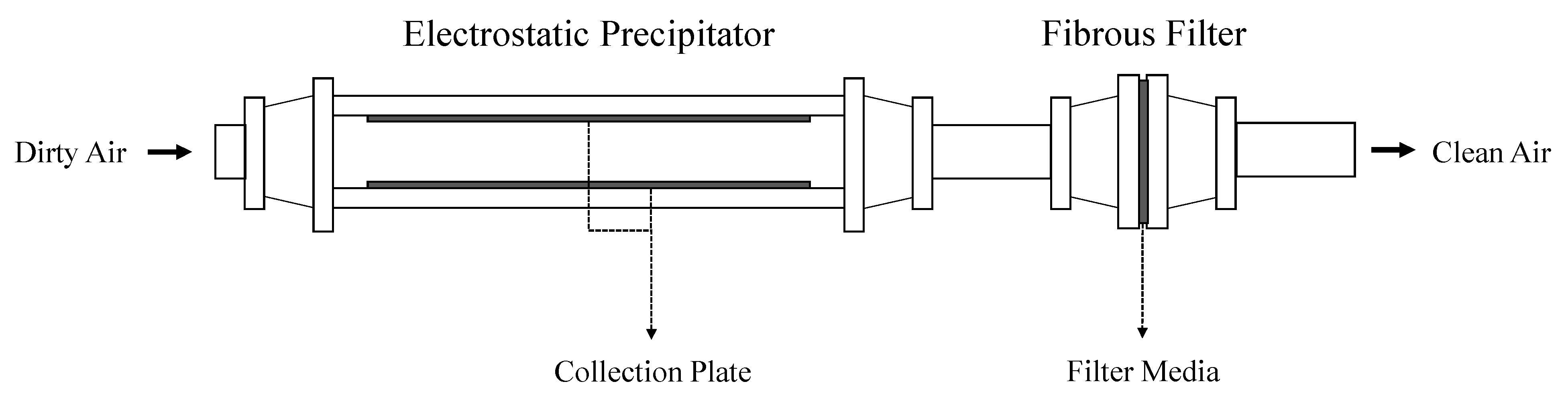

4.1. Electrostatic Precipitation Process

4.2. Studies Involving the Use of Electrostatic Precipitators in Particle Collection

4.2.1. Evaluation of Operating Conditions

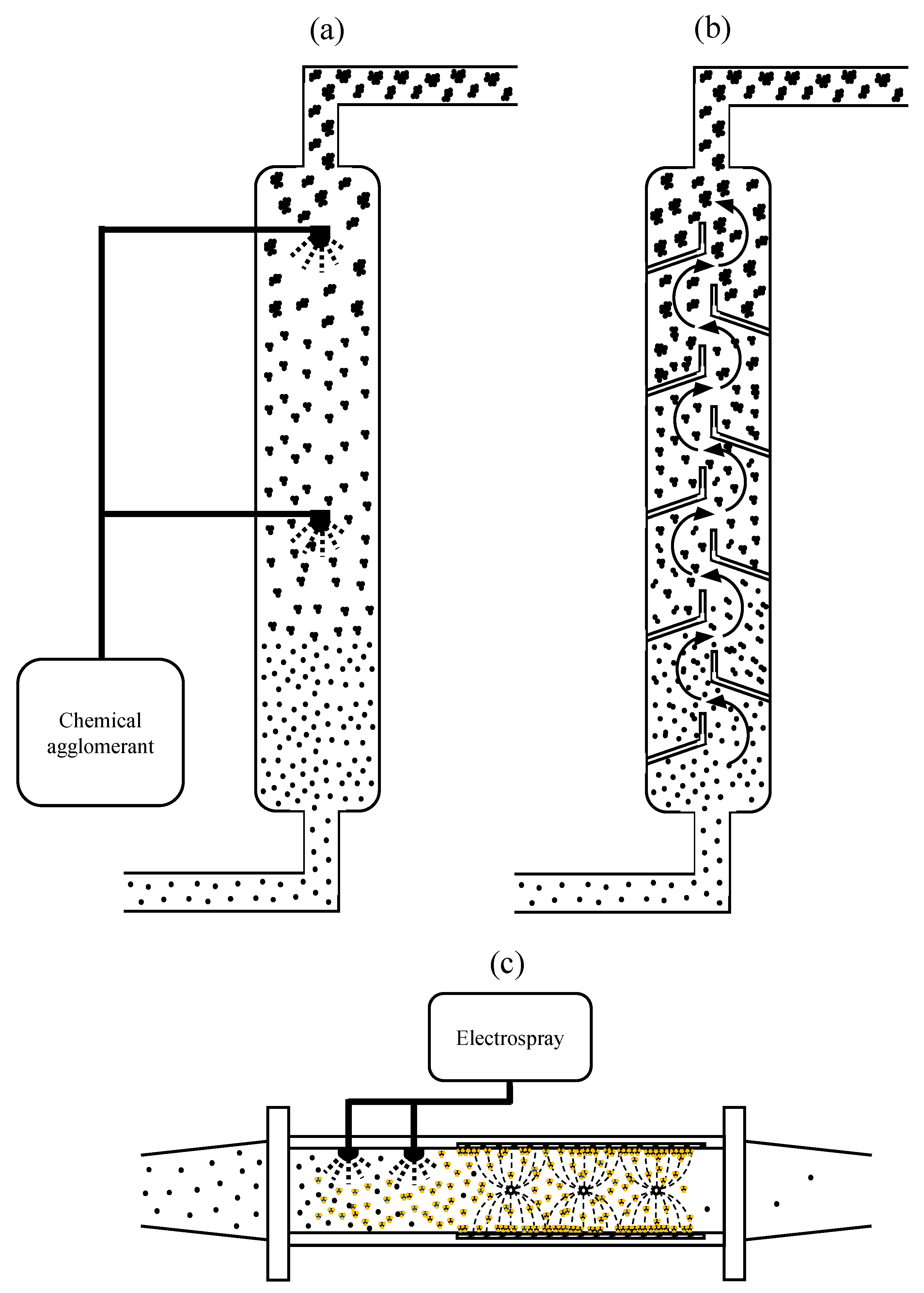

4.2.2. Use of Wet Precipitators and Particle Agglomeration

4.2.3. Evaluation of Geometric Conditions

5. Use of Filters in the Collection of Nanoparticles

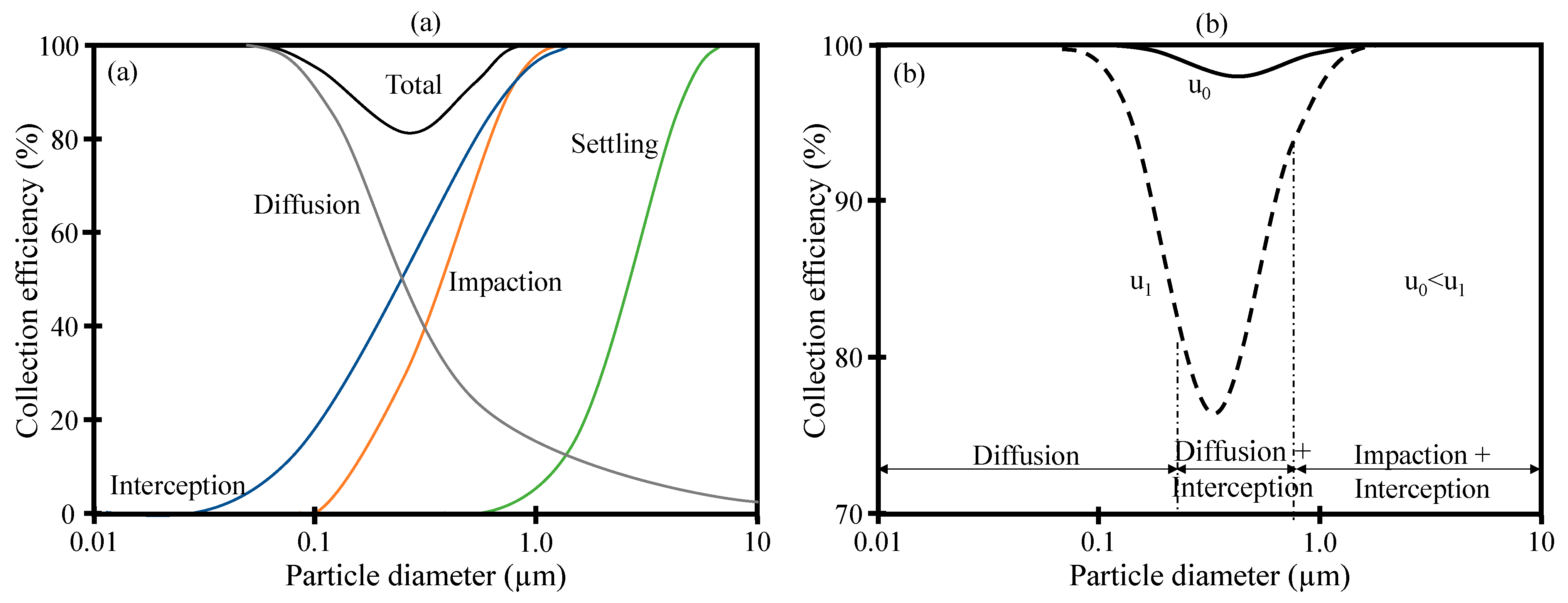

5.1. Filtration Process

5.2. Studies Involving the Use of Filters and Membranes in the Collection of Particles

5.2.1. Evaluations of Different Filter Media and Operating Conditions

5.2.2. Coating, Precoating, and Other Surface Treatments

5.2.3. Development of Filter Media with Nanofibers

5.2.4. Hybrid Filters and Electrostatic Filtration

6. Final Considerations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- DeMello, A.J.; Woolley, A.T. Nanotechnology. Curr. Opin. Chem. Biol. 2010, 14, 545–547. [Google Scholar] [CrossRef] [PubMed]

- Gyles, C. Nanotechnology. Can. Vet. J. La Rev. Vet. Can. 2012, 53, 819–822. [Google Scholar]

- Quina, F.H. Nanotecnologia e o Meio Ambiente: Perspectivas e Riscos. Quim. Nova 2004, 27, 1028–1029. [Google Scholar] [CrossRef]

- Vance, M.E.; Kuiken, T.; Vejerano, E.P.; McGinnis, S.P.; Hochella, M.F.; Hull, D.R. Nanotechnology in the Real World: Redeveloping the Nanomaterial Consumer Products Inventory. Beilstein J. Nanotechnol. 2015, 6, 1769–1780. [Google Scholar] [CrossRef]

- ISO. ISO/TS 12025. Available online: https://www.iso.org/obp/ui/#iso:std:iso:ts:12025:ed-1:v1:en:biblref:5 (accessed on 29 January 2020).

- Hinds, W.C. Aerosol Technology: Properties, Behaviour, and Measurement of Airborne Particles, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1999; ISBN 0-471-19410-7. [Google Scholar]

- Alonso, M.; Alguacil, F.J. Electrostatic Precipitation of Ultrafine Particles Enhanced by Simultaneous Diffusional Deposition on Wire Screens. J. Air Waste Manag. Assoc. 2002, 52, 1342–1347. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, A.E.; Guerra, V.G. Electrostatic Precipitation of Nanoparticles and Submicron Particles: Review of Technological Strategies. Process Saf. Environ. Prot. 2021, 153, 422–438. [Google Scholar] [CrossRef]

- Gauthier, C.; Genet, C. Nanotechnologies and Green Knowledge Creation: Paradox or Enhancer of Sustainable Solutions? J. Bus. Ethics 2014, 124, 571–583. [Google Scholar] [CrossRef]

- Lekamge, S.; Miranda, A.F.; Ball, A.S.; Shukla, R.; Nugegoda, D. The Toxicity of Coated Silver Nanoparticles to Daphnia Carinata and Trophic Transfer from Alga Raphidocelis Subcapitata. PLoS ONE 2019, 14, e0214398. [Google Scholar] [CrossRef]

- Jovanović, B.; Palić, D.Š. Immunotoxicology of Non-Functionalized Engineered Nanoparticles in Aquatic Organisms with Special Emphasis on Fish-Review of Current Knowledge, Gap Identification, and Call for Further Research. Aquat. Toxicol. 2012, 118–119, 141–151. [Google Scholar] [CrossRef]

- Carbone, S.; Vittori Antisari, L.; Gaggia, F.; Baffoni, L.; Di Gioia, D.; Vianello, G.; Nannipieri, P. Bioavailability and Biological Effect of Engineered Silver Nanoparticles in a Forest Soil. J. Hazard. Mater. 2014, 280, 89–96. [Google Scholar] [CrossRef]

- Adams, R.A.; Potter, S.; Bérubé, K.; Higgins, T.P.; Jones, T.P.; Evans, S.A. Prolonged Systemic Inflammation and Damage to the Vascular Endothelium Following Intratracheal Instillation of Air Pollution Nanoparticles in Rats. Clin. Hemorheol. Microcirc. 2019, 72, 1–10. [Google Scholar] [CrossRef]

- Gwinn, M.R.; Vallyathan, V. Nanoparticles: Health Effects-Pros and Cons. Environ. Health Perspect. 2006, 114, 1818–1825. [Google Scholar] [CrossRef]

- Pomatto, L.C.D.; Cline, M.; Woodward, N.; Pakbin, P.; Sioutas, C.; Morgan, T.E.; Finch, C.E.; Forman, H.J.; Davies, K.J.A. Aging Attenuates Redox Adaptive Homeostasis and Proteostasis in Female Mice Exposed to Traffic-Derived Nanoparticles (‘Vehicular Smog’). Free Radic. Biol. Med. 2018, 121, 86–97. [Google Scholar] [CrossRef]

- Semmler-Behnke, M.; Kreyling, W.G.; Lipka, J.; Fertsch, S.; Wenk, A.; Takenaka, S.; Schmid, G.; Brandau, W. Biodistribution of 1.4- and 18-Nm Gold Particles in Rats. Small 2008, 4, 2108–2111. [Google Scholar] [CrossRef] [PubMed]

- Brunekreef, B.; Holgate, S.T. Air Pollution and Health. Lancet 2002, 360, 1233–1242. [Google Scholar] [CrossRef] [PubMed]

- Calderón-Garcidueñas, L.; González-Maciel, A.; Mukherjee, P.S.; Reynoso-Robles, R.; Pérez-Guillé, B.; Gayosso-Chávez, C.; Torres-Jardón, R.; Cross, J.V.; Ahmed, I.A.M.M.; Karloukovski, V.V.; et al. Combustion- and Friction-Derived Magnetic Air Pollution Nanoparticles in Human Hearts. Environ. Res. 2019, 176, 108567. [Google Scholar] [CrossRef]

- Oberdörster, G.; Oberdörster, E.; Oberdörster, J. Nanotoxicology: An Emerging Discipline Evolving from Studies of Ultrafine Particles. Environ. Health Perspect. 2005, 113, 823–839. [Google Scholar] [CrossRef]

- Oberdörster, G.; Sharp, Z.; Atudorei, V.; Elder, A.; Gelein, R.; Kreyling, W.; Cox, C. Translocation of Inhaled Ultrafine Particles to the Brain. Inhal. Toxicol. 2004, 16, 437–445. [Google Scholar] [CrossRef]

- Wu, J.; Ding, T.; Sun, J. Neurotoxic Potential of Iron Oxide Nanoparticles in the Rat Brain Striatum and Hippocampus. Neurotoxicology 2013, 34, 243–253. [Google Scholar] [CrossRef]

- Maher, B.A.; Ahmed, I.A.M.M.; Karloukovski, V.; MacLaren, D.A.; Foulds, P.G.; Allsop, D.; Mann, D.M.A.A.; Torres-Jardón, R.; Calderon-Garciduenas, L. Magnetite Pollution Nanoparticles in the Human Brain. Proc. Natl. Acad. Sci. USA 2016, 113, 10797–10801. [Google Scholar] [CrossRef] [PubMed]

- Win-Shwe, T.T.; Fujimaki, H. Nanoparticles and Neurotoxicity. Int. J. Mol. Sci. 2011, 12, 6267–6280. [Google Scholar] [CrossRef]

- Veronesi, B.; Makwana, O.; Pooler, M.; Chen, L.C. Effects of Subchronic Exposure to Concentrated Ambient Particles: VII. Degeneration of Dopaminergic Neurons in Apo E-/-Mice. Inhal. Toxicol. 2005, 17, 235–241. [Google Scholar] [CrossRef] [PubMed]

- Cupaioli, F.A.; Zucca, F.A.; Boraschi, D.; Zecca, L. Engineered Nanoparticles. How Brain Friendly Is This New Guest? Prog. Neurobiol. 2014, 119–120, 20–38. [Google Scholar] [CrossRef] [PubMed]

- Mohnen, V.; Hidy, G.M. Measurements of Atmospheric Nanoparticles (1875–1980). Bull. Am. Meteorol. Soc. 2010, 91, 1525–1539. [Google Scholar] [CrossRef]

- Calderón-Garcidueñas, L.; Ayala, A. Air Pollution, Ultrafine Particles, and Your Brain: Are Combustion Nanoparticle Emissions and Engineered Nanoparticles Causing Preventable Fatal Neurodegenerative Diseases and Common Neuropsychiatric Outcomes? Environ. Sci. Technol. 2022, 56, 6847–6856. [Google Scholar] [CrossRef]

- Nazarenko, Y.; Zhen, H.; Han, T.; Lioy, P.J.; Mainelis, G. Potential for Inhalation Exposure to Engineered Nanoparticles from Nanotechnology-Based Cosmetic Powders. Environ. Health Perspect. 2012, 120, 885–892. [Google Scholar] [CrossRef] [PubMed]

- Tillett, T. A Compact Exposure: Estimating Inhalation of Engineered Nanoparticles in Cosmetic Powders. Environ. Health Perspect. 2012, 120, a245. [Google Scholar] [CrossRef] [PubMed]

- Hillman, A.L.; Abbott, M.B.; Valero-Garcés, B.L.; Morellon, M.; Barreiro-Lostres, F.; Bain, D.J. Lead Pollution Resulting from Roman Gold Extraction in Northwestern Spain. Holocene 2017, 27, 1465–1474. [Google Scholar] [CrossRef]

- Harra, J.; Mäkitalo, J.; Siikanen, R.; Virkki, M.; Genty, G.; Kobayashi, T.; Kauranen, M.; Mäkelä, J.M. Size-Controlled Aerosol Synthesis of Silver Nanoparticles for Plasmonic Materials. J. Nanoparticle Res. 2012, 14. [Google Scholar] [CrossRef]

- Boddu, S.R.; Gutti, V.R.; Ghosh, T.K.; Tompson, R.V.; Loyalka, S.K. Gold, Silver, and Palladium Nanoparticle/Nano-Agglomerate Generation, Collection, and Characterization. J. Nanoparticle Res. 2011, 13, 6591–6601. [Google Scholar] [CrossRef]

- Souza, J.P.; Mansano, A.S.; Venturini, F.P.; Marangoni, V.S.; Lins, P.M.P.; Silva, B.P.C.; Dressler, B.; Zucolotto, V. Toxicity of Gold Nanorods on Ceriodaphnia Dubia and Danio Rerio after Sub-Lethal Exposure and Recovery. Environ. Sci. Pollut. Res. 2021, 28, 25316–25326. [Google Scholar] [CrossRef]

- Bumajdad, A.; Nazeer, A.A.; Al Sagheer, F.; Nahar, S.; Zaki, M.I. Controlled Synthesis of ZrO2 Nanoparticles with Tailored Size, Morphology and Crystal Phases via Organic/Inorganic Hybrid Films. Sci. Rep. 2018, 8, 3695. [Google Scholar] [CrossRef]

- Sheth, P.; Sandhu, H.; Singhal, D.; Malick, W.; Shah, N.; Serpil Kislalioglu, M. Nanoparticles in the Pharmaceutical Industry and the Use of Supercritical Fluid Technologies for Nanoparticle Production. Curr. Drug Deliv. 2012, 9, 269–284. [Google Scholar] [CrossRef]

- Abdel-Mageed, H.M.; Fouad, S.A.; Teaima, M.H.; Abdel-Aty, A.M.; Fahmy, A.S.; Shaker, D.S.; Mohamed, S.A. Optimization of Nano Spray Drying Parameters for Production of α-Amylase Nanopowder for Biotheraputic Applications Using Factorial Design. Dry. Technol. 2019, 37, 2152–2160. [Google Scholar] [CrossRef]

- Dobrowolski, A.; Strob, R.; Nietfeld, J.; Pieloth, D.; Wiggers, H.; Thommes, M. Preparation of Spray Dried Submicron Particles: Part B—Particle Recovery by Electrostatic Precipitation. Int. J. Pharm. 2018, 548, 237–243. [Google Scholar] [CrossRef] [PubMed]

- Aisida, S.O.; Akpa, P.A.; Ahmad, I.; Zhao, T.; Maaza, M.; Ezema, F.I. Bio-Inspired Encapsulation and Functionalization of Iron Oxide Nanoparticles for Biomedical Applications. Eur. Polym. J. 2020, 122, 109371. [Google Scholar] [CrossRef]

- Aseri, A.; Garg, S.K.; Nayak, A.; Trivedi, S.K.; Ahsan, J. Magnetic Nanoparticles: Magnetic Nano-Technology Using Biomedical Applications and Future Prospects. Int. J. Pharm. Sci. Rev. Res. 2015, 31, 119–131. [Google Scholar]

- Materón, E.M.; Miyazaki, C.M.; Carr, O.; Joshi, N.; Picciani, P.H.S.; Dalmaschio, C.J.; Davis, F.; Shimizu, F.M. Magnetic Nanoparticles in Biomedical Applications: A Review. Appl. Surf. Sci. Adv. 2021, 6, 100163. [Google Scholar] [CrossRef]

- Feitosa, N.d.R. Desempenho de Meios Filtrantes Na Remoção de Partículas Nanométricas de Aerossóis. Dissertação (Mestrado), Universidade Federal de São Carlos, São Carlos, Brazil, 2009. [Google Scholar]

- Cyrs, W.D.; Boysen, D.A.; Casuccio, G.; Lersch, T.; Peters, T.M. Nanoparticle Collection Efficiency of Capillary Pore Membrane Filters. J. Aerosol Sci. 2010, 41, 655–664. [Google Scholar] [CrossRef]

- Wang, C.S.; Otani, Y. Removal of Nanoparticles from Gas Streams by Fibrous Filters: A Review. Ind. Eng. Chem. Res. 2013, 52, 5–17. [Google Scholar] [CrossRef]

- Cadavid-Rodriguez, M.C.; Charvet, A.; Bemer, D.; Thomas, D. Optimization of Bubble Column Performance for Nanoparticle Collection. J. Hazard. Mater. 2014, 271, 24–32. [Google Scholar] [CrossRef] [PubMed]

- Lin, G.Y.; Cuc, L.T.; Lu, W.; Tsai, C.J.; Chein, H.M.; Chang, F.T. High-Efficiency Wet Electrocyclone for Removing Fine and Nanosized Particles. Sep. Purif. Technol. 2013, 114, 99–107. [Google Scholar] [CrossRef]

- de Aquino Lima, F.; Guerra, V.G. Influence of Wire Spacing and Plate Spacing on Electrostatic Precipitation of Nanoparticles: An Approach Involving Electrostatic Shielding and Diffusion Charging. Particuology 2023, 80, 127–139. [Google Scholar] [CrossRef]

- Andrade, R.G.S.A.; Guerra, V.G. Discharge Electrode Influence on Electrostatic Precipitation of Nanoparticles. Powder Technol. 2021, 379, 417–427. [Google Scholar] [CrossRef]

- Knutson, E.O. History of Diffusion Batteries in Aerosol Measurements. Aerosol Sci. Technol. 1999, 31, 83–128. [Google Scholar] [CrossRef]

- Fierz, M.; Scherrer, L.; Burtscher, H. Real-Time Measurement of Aerosol Size Distributions with an Electrical Diffusion Battery. J. Aerosol Sci. 2002, 33, 1049–1060. [Google Scholar] [CrossRef]

- Parker, K.R. Applied Electrostatic Precipitation; Blackie Academic & Professional: London, UK, 1997; ISBN 9789401071932. [Google Scholar]

- Castro, B.J.C.; Lacerda, C.R.; Melo, B.R.; Sartim, R.; Aguiar, M.L. Performance Assessment of a Bench Scale Hybrid Filter in the Collection of Nanoparticles. Process Saf. Environ. Prot. 2021, 154, 32–42. [Google Scholar] [CrossRef]

- Fann, N.; Lamson, A.D.; Anenberg, S.C.; Wesson, K.; Risley, D.; Hubbell, B.J. Estimating the National Public Health Burden Associated with Exposure to Ambient PM2.5 and Ozone. Risk Anal. 2012, 32, 81–95. [Google Scholar] [CrossRef]

- Laumbach, R.J.; Kipen, H.M. Respiratory Health Effects of Air Pollution: Update on Biomass Smoke and Traffic Pollution. J. Allergy Clin. Immunol. 2012, 129, 3–11. [Google Scholar] [CrossRef]

- Fiordelisi, A.; Piscitelli, P.; Trimarco, B.; Coscioni, E.; Iaccarino, G.; Sorriento, D. The Mechanisms of Air Pollution and Particulate Matter in Cardiovascular Diseases. Heart Fail. Rev. 2017, 22, 337–347. [Google Scholar] [CrossRef]

- Miller, M.R.; Newby, D.E. Air Pollution and Cardiovascular Disease: Car Sick. Cardiovasc. Res. 2020, 116, 279–294. [Google Scholar] [CrossRef] [PubMed]

- Oberdörster, G. Pulmonary Effects of Inhaled Ultrafine Particles. Int. Arch. Occup. Environ. Health 2000, 74, 1–8. [Google Scholar] [CrossRef]

- Warheit, D.B. Nanoparticles: Health Impacts? Mater. Today 2004, 7, 32–35. [Google Scholar] [CrossRef]

- Phairuang, W.; Piriyakarnsakul, S.; Inerb, M.; Hongtieab, S.; Thongyen, T.; Chomanee, J.; Boongla, Y.; Suriyawong, P.; Samae, H.; Chanonmuang, P.; et al. Ambient Nanoparticles (PM0.1) Mapping in Thailand. Atmosphere 2022, 14, 66. [Google Scholar] [CrossRef]

- Schraufnagel, D.E. The Health Effects of Ultrafine Particles. Exp. Mol. Med. 2020, 52, 311–317. [Google Scholar] [CrossRef] [PubMed]

- Kwon, H.-S.; Ryu, M.H.; Carlsten, C. Ultrafine Particles: Unique Physicochemical Properties Relevant to Health and Disease. Exp. Mol. Med. 2020, 52, 318–328. [Google Scholar] [CrossRef]

- Li, N.; Georas, S.; Alexis, N.; Fritz, P.; Xia, T.; Williams, M.A.; Horner, E.; Nel, A. A Work Group Report on Ultrafine Particles (American Academy of Allergy, Asthma & Immunology): Why Ambient Ultrafine and Engineered Nanoparticles Should Receive Special Attention for Possible Adverse Health Outcomes in Human Subjects. J. Allergy Clin. Immunol. 2016, 138, 386–396. [Google Scholar] [CrossRef]

- Nel, A. Toxic Potential of Materials at the Nanolevel. Science 2006, 311, 622–627. [Google Scholar] [CrossRef]

- Yang, M.; Jalava, P.; Hakkarainen, H.; Roponen, M.; Leskinen, A.; Komppula, M.; Dong, G.-P.; Lao, X.-Q.; Wu, Q.-Z.; Xu, S.-L.; et al. Fine and Ultrafine Airborne PM Influence Inflammation Response of Young Adults and Toxicological Responses in Vitro. Sci. Total Environ. 2022, 836, 155618. [Google Scholar] [CrossRef]

- Nóbrega, S.W.; Falaguasta, M.C.R.; Coury, J.R. A Study of a Wire-Plate Eletrostatic Precipitator Operating in the Removal of Polydispersed Particles. Braz. J. Chem. Eng. 2004, 21, 275–284. [Google Scholar] [CrossRef]

- Pui, D.Y.H.; Chen, D.-R. Nanometer Particles: A New Frontier for Multidisciplinary Research. J. Aerosol Sci. 1997, 28, 539–544. [Google Scholar] [CrossRef]

- Oliveira, A.E.; Guerra, V.G. Effect of Low Gas Velocity on the Nanoparticle Collection Performance of an Electrostatic Precipitator. Sep. Sci. Technol. 2019, 54, 1211–1220. [Google Scholar] [CrossRef]

- Oliveira, A.E.; Guerra, V.G. Influence of Particle Concentration and Residence Time on the Efficiency of Nanoparticulate Collection by Electrostatic Precipitation. J. Electrostat. 2018, 96, 1–9. [Google Scholar] [CrossRef]

- Joodatnia, P.; Kumar, P.; Robins, A. Fast Response Sequential Measurements and Modelling of Nanoparticles inside and Outside a Car Cabin. Atmos. Environ. 2013, 71, 364–375. [Google Scholar] [CrossRef]

- Bencs, L.; Horemans, B.; Buczyńska, A.J.; Van Grieken, R. Uneven Distribution of Inorganic Pollutants in Marine Air Originating from Ocean-Going Ships. Environ. Pollut. 2017, 222, 226–233. [Google Scholar] [CrossRef] [PubMed]

- The Nanodatabase Search Database. Available online: http://nanodb.dk/en/ (accessed on 10 February 2020).

- Project on Emerging Nanotechnologies Consumer Products Inventory. Available online: https://www.nanotechproject.tech/cpi/products/ (accessed on 10 February 2020).

- Weichenthal, S.; Dufresne, A.; Infante-Rivard, C.; Joseph, L. Determinants of Ultrafine Particle Exposures in Transportation Environments: Findings of an 8-Month Survey Conducted in Montréal, Canada. J. Expo. Sci. Environ. Epidemiol. 2008, 18, 551–563. [Google Scholar] [CrossRef]

- Matson, U. Indoor and Outdoor Concentrations of Ultrafine Particles in Some Scandinavian Rural and Urban Areas. Sci. Total Environ. 2005, 343, 169–176. [Google Scholar] [CrossRef]

- Nevshupa, R.; Jimenez-Relinque, E.; Grande, M.; Martinez, E.; Castellote, M. Assessment of Urban Air Pollution Related to Potential Nanoparticle Emission from Photocatalytic Pavements. J. Environ. Manag. 2020, 272, 111059. [Google Scholar] [CrossRef] [PubMed]

- Heitbrink, W.A.; Evans, D.E.; Peters, T.M.; Slavin, T.J. Characterization and Mapping of Very Fine Particles in an Engine Machining and Assembly Facility. J. Occup. Environ. Hyg. 2007, 4, 341–351. [Google Scholar] [CrossRef]

- Pond, Z.A.; Saha, P.K.; Coleman, C.J.; Presto, A.A.; Robinson, A.L.; Arden Pope, C., III. Mortality Risk and Long-Term Exposure to Ultrafine Particles and Primary Fine Particle Components in a National U.S. Cohort. Environ. Int. 2022, 167, 107439. [Google Scholar] [CrossRef]

- Verma, V.; Ning, Z.; Cho, A.K.; Schauer, J.J.; Shafer, M.M.; Sioutas, C. Redox Activity of Urban Quasi-Ultrafine Particles from Primary and Secondary Sources. Atmos. Environ. 2009, 43, 6360–6368. [Google Scholar] [CrossRef]

- Moore, K.F.; Ning, Z.; Ntziachristos, L.; Schauer, J.J.; Sioutas, C. Daily Variation in the Properties of Urban Ultrafine Aerosol—Part I: Physical Characterization and Volatility. Atmos. Environ. 2007, 41, 8633–8646. [Google Scholar] [CrossRef]

- Ning, Z.; Geller, M.D.; Moore, K.F.; Sheesley, R.; Schauer, J.J.; Sioutas, C. Daily Variation in Chemical Characteristics of Urban Ultrafine Aerosols and Inference of Their Sources. Environ. Sci. Technol. 2007, 41, 6000–6006. [Google Scholar] [CrossRef] [PubMed]

- Saffari, A.; Hasheminassab, S.; Wang, D.; Shafer, M.M.; Schauer, J.J.; Sioutas, C. Impact of Primary and Secondary Organic Sources on the Oxidative Potential of Quasi-Ultrafine Particles (PM0.25) at Three Contrasting Locations in the Los Angeles Basin. Atmos. Environ. 2015, 120, 286–296. [Google Scholar] [CrossRef]

- Hama, S.M.L.; Cordell, R.L.; Monks, P.S. Quantifying Primary and Secondary Source Contributions to Ultrafine Particles in the UK Urban Background. Atmos. Environ. 2017, 166, 62–78. [Google Scholar] [CrossRef]

- Robinson, A.L.; Donahue, N.M.; Shrivastava, M.K.; Weitkamp, E.A.; Sage, A.M.; Grieshop, A.P.; Lane, T.E.; Pierce, J.R.; Pandis, S.N. Rethinking Organic Aerosols: Semivolatile Emissions and Photochemical Aging. Science 2007, 315, 1259–1262. [Google Scholar] [CrossRef]

- Li, Q.; Wyatt, A.; Kamens, R.M. Oxidant Generation and Toxicity Enhancement of Aged-Diesel Exhaust. Atmos. Environ. 2009, 43, 1037–1042. [Google Scholar] [CrossRef]

- Goel, A.; Kumar, P. Vertical and Horizontal Variability in Airborne Nanoparticles and Their Exposure around Signalised Traffic Intersections. Environ. Pollut. 2016, 214, 54–69. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.H.; Huang, C.H.; Huang, H.L.; Tsai, C.J. Concentrations of Ultrafine Particles at a Highway Toll Collection Booth and Exposure Implications for Toll Collectors. Sci. Total Environ. 2010, 409, 364–369. [Google Scholar] [CrossRef]

- Rönkkö, T.; Pirjola, L.; Ntziachristos, L.; Heikkilä, J.; Karjalainen, P.; Hillamo, R.; Keskinen, J. Vehicle Engines Produce Exhaust Nanoparticles Even When Not Fueled. Environ. Sci. Technol. 2014, 48, 2043–2050. [Google Scholar] [CrossRef]

- Holmén, B.A.; Ayala, A. Ultrafine PM Emissions from Natural Gas, Oxidation-Catalyst Diesel, and Particle-Trap Diesel Heavy-Duty Transit Buses. Environ. Sci. Technol. 2002, 36, 5041–5050. [Google Scholar] [CrossRef] [PubMed]

- Mayer, A.; Burtscher, H.; Loretz, S.; Kasper, M.; Czerwinski, J. High Air Pollution in Vehicle Cabins Due to Traffic Nanoparticle Emission Exposure and a Solution for In-Use Vehicles. IOP Conf. Ser. Mater. Sci. Eng. 2018, 421, 032018. [Google Scholar] [CrossRef]

- Al-Dabbous, A.N.; Kumar, P. The Influence of Roadside Vegetation Barriers on Airborne Nanoparticles and Pedestrians Exposure under Varying Wind Conditions. Atmos. Environ. 2014, 90, 113–124. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Chao, Y.C.; Wu, C.H.; Tsai, C.J.; Uang, S.N.; Shih, T.S. Measurements of Ultrafine Particle Concentrations and Size Distribution in an Iron Foundry. J. Hazard. Mater. 2008, 158, 124–130. [Google Scholar] [CrossRef] [PubMed]

- Wheatley, A.D.; Sadhra, S. Occupational Exposure to Diesel Exhaust Fumes. Ann. Occup. Hyg. 2004, 48, 369–376. [Google Scholar] [CrossRef]

- Wu, J.; Tou, F.; Guo, X.; Liu, C.; Sun, Y.; Xu, M.; Liu, M.; Yang, Y. Vast Emission of Fe- and Ti-Containing Nanoparticles from Representative Coal-Fired Power Plants in China and Environmental Implications. Sci. Total Environ. 2022, 838, 156070. [Google Scholar] [CrossRef]

- Elihn, K.; Berg, P. Ultrafine Particlec Characteristics in Seven Industrial Plants. Ann. Occup. Hyg. 2009, 53, 475–484. [Google Scholar] [CrossRef] [PubMed]

- Gonet, T.; Maher, B.A. Airborne, Vehicle-Derived Fe-Bearing Nanoparticles in the Urban Environment: A Review. Environ. Sci. Technol. 2019, 53, 9970–9991. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, M.L.S.; Pinto, D.; Tutikian, B.F.; da Boit, K.; Saikia, B.K.; Silva, L.F.O. Pollution from Uncontrolled Coal Fires: Continuous Gaseous Emissions and Nanoparticles from Coal Mines. J. Clean. Prod. 2019, 215, 1140–1148. [Google Scholar] [CrossRef]

- Natasha; Shahid, M.; Dumat, C.; Khalid, S.; Rabbani, F.; Farooq, A.B.U.; Amjad, M.; Abbas, G.; Niazi, N.K. Foliar Uptake of Arsenic Nanoparticles by Spinach: An Assessment of Physiological and Human Health Risk Implications. Environ. Sci. Pollut. Res. 2019, 26, 20121–20131. [Google Scholar] [CrossRef]

- Zhang, Q.; Lu, D.; Wang, D.; Yang, X.; Zuo, P.; Yang, H.; Fu, Q.; Liu, Q.; Jiang, G. Separation and Tracing of Anthropogenic Magnetite Nanoparticles in the Urban Atmosphere. Environ. Sci. Technol. 2020, 54, 9274–9284. [Google Scholar] [CrossRef]

- Torti, S.V.; Torti, F.M. Winning the War with Iron. Nat. Nanotechnol. 2019, 14, 499–500. [Google Scholar] [CrossRef] [PubMed]

- Yacobi, N.R.; Malmstadt, N.; Fazlollahi, F.; DeMaio, L.; Marchelletta, R.; Hamm-Alvarez, S.F.; Borok, Z.; Kim, K.-J.; Crandall, E.D. Mechanisms of Alveolar Epithelial Translocation of a Defined Population of Nanoparticles. Am. J. Respir. Cell Mol. Biol. 2010, 42, 604–614. [Google Scholar] [CrossRef]

- Monteiller, C.; Tran, L.; MacNee, W.; Faux, S.; Jones, A.; Miller, B.; Donaldson, K. The Pro-Inflammatory Effects of Low-Toxicity Low-Solubility Particles, Nanoparticles and Fine Particles, on Epithelial Cells in Vitro: The Role of Surface Area. Occup. Environ. Med. 2007, 64, 609–615. [Google Scholar] [CrossRef]

- Hesketh, H.E. Air Pollution Control: Tradicional and Hazerdous Pollutants; Technomic Publishing Company: Lancaster, UK, 1996; ISBN 1-56676-413-0. [Google Scholar]

- Dullien, F.A.L. Introduction to Industrial Gas Cleaning; Academic Press: San Diego, CA, USA, 1989. [Google Scholar]

- Afshari, A.; Ekberg, L.; Forejt, L.; Mo, J.; Rahimi, S.; Siegel, J.; Chen, W.; Wargocki, P.; Zurami, S.; Zhang, J. Electrostatic Precipitators as an Indoor Air Cleaner—A Literature Review. Sustainability 2020, 12, 8774. [Google Scholar] [CrossRef]

- Sudrajad, A.; Yusof, A.F. Review of Electrostatic Precipitator Device for Reduce of Diesel Engine Particulate Matter. Energy Procedia 2015, 68, 370–380. [Google Scholar] [CrossRef]

- Riehle, C. Electrostatic Precipitation. In Gas Cleaning in Demanding Applications; Springer: Dordrecht, The Netherlands, 1997; pp. 193–228. [Google Scholar]

- Parker, K.R. Electrical Operation of Electrostatic Precipitators, 1st ed.; Institution of Engineering and Technology: London, UK, 2003; ISBN 9780852961377. [Google Scholar]

- Riehle, C. Basic and Theoretical Operation of ESPs. In Applied Electrostatic Precipitation; Blackie Academic & Professional: London, UK, 1997; pp. 25–87. [Google Scholar]

- Tepper, G.; Kessick, R. A Study of Ionization and Collection Efficiencies in Electrospray-Based Electrostatic Precipitators. J. Aerosol Sci. 2008, 39, 609–617. [Google Scholar] [CrossRef]

- Bai, Y.; Han, C.B.; He, C.; Gu, G.Q.; Nie, J.H.; Shao, J.J.; Xiao, T.X.; Deng, C.R.; Wang, Z.L. Washable Multilayer Triboelectric Air Filter for Efficient Particulate Matter PM 2.5 Removal. Adv. Funct. Mater. 2018, 28, 1706680. [Google Scholar] [CrossRef]

- Zhao, J.; Li, H.; Yang, Z.; Zhu, L.; Zhang, M.; Feng, Y.; Qu, W.; Yang, J.; Shih, K. Dual Roles of Nano-Sulfide in Efficient Removal of Elemental Mercury from Coal Combustion Flue Gas within a Wide Temperature Range. Environ. Sci. Technol. 2018, 52, 12926–12933. [Google Scholar] [CrossRef]

- Jiang, J.; Lee, M.-H.; Biswas, P. Model for Nanoparticle Charging by Diffusion, Direct Photoionization, and Thermionization Mechanisms. J. Electrostat. 2007, 65, 209–220. [Google Scholar] [CrossRef]

- White, H.J. Industrial Electrostatic Precipitation; Addison-Wesley: Reading, UK, 1963. [Google Scholar]

- Wettervik, B.; Johnson, T.; Jakobsson, S.; Mark, A.; Edelvik, F. A Domain Decomposition Method for Three Species Modeling of Multi-Electrode Negative Corona Discharge—With Applications to Electrostatic Precipitators. J. Electrostat. 2015, 77, 139–146. [Google Scholar] [CrossRef]

- Park, J.-H.; Chun, C.-H. An Improved Modelling for Prediction of Grade Efficiency of Electrostatic Precipitators with Negative Corona. J. Aerosol. Sci. 2002, 33, 673–694. [Google Scholar] [CrossRef]

- Yehia, A.; Abdel-Fattah, E.; Mizuno, A. Positive Direct Current Corona Discharges in Single Wire-Duct Electrostatic Precipitators. AIP Adv. 2016, 6, 055213. [Google Scholar] [CrossRef]

- Kawada, Y.; Kaneko, T.; Ito, T.; Chang, J.S. Simultaneous Removal of Aerosol Particles, NOx and SO2 from Incense Smokes by a Dc Wire-Plate Electrostatic Precipitator under Positive Coronas. J. Aerosol. Sci. 2001, 32, 945–946. [Google Scholar] [CrossRef]

- Chen, Q.; Fang, M.; Cen, J.; Lv, M.; Shao, S.; Xia, Z. Comparison of Positive and Negative DC Discharge under Coal Pyrolysis Gas Media at High Temperatures. Powder Technol. 2019, 345, 352–362. [Google Scholar] [CrossRef]

- Liu, C.-Y.; Tseng, C.-H.; Wang, K.-F. The Assessment of Indoor Formaldehyde and Bioaerosol Removal by Using Negative Discharge Electrostatic Air Cleaners. Int. J. Environ. Res. Public Health 2022, 19, 7209. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Davidson, J.H. Ozone Production in the Negative DC Corona: The Dependence of Discharge Polarity. Plasma Chem. Plasma Process. 2003, 23, 501–518. [Google Scholar] [CrossRef]

- Long, Z.; Yao, Q. Evaluation of Various Particle Charging Models for Simulating Particle Dynamics in Electrostatic Precipitators. J. Aerosol Sci. 2010, 41, 702–718. [Google Scholar] [CrossRef]

- Choudhary, K.; Gentry, J. Particle Collection Efficiency of a Bench Scale Electrostatic Precipitator in the Field Charging Region as a Function of Particle Size. J. Colloid Interf. Sci. 1974, 48, 263–280. [Google Scholar] [CrossRef]

- Dunkle, S.G. Electrostatic Precipitators. In Industrial Air Pollution Control Systems; McGraw-Hill: New York, NY, USA, 1997; pp. 471–510. [Google Scholar]

- Zhang, J.-P.; Du, Y.-Y.; Wu, H.; Liu, Y.; Ren, J.-X.; Ji, D.-M. A Numerical Simulation of Diffusion Charging Effect on Collection Efficiency in Wire-Plate Electrostatic Precipitators. IEEE Trans. Plasma Sci. 2011, 39, 1823–1828. [Google Scholar] [CrossRef]

- Lu, Q.; Yang, Z.; Zheng, C.; Li, X.; Zhao, C.; Xu, X.; Gao, X.; Luo, Z.; Ni, M.; Cen, K. Numerical Simulation on the Fine Particle Charging and Transport Behaviors in a Wire-Plate Electrostatic Precipitator. Adv. Powder Technol. 2016, 27, 1905–1911. [Google Scholar] [CrossRef]

- Krinke, T.J.; Deppert, K.; Magnusson, M.H.; Fissan, H. Nanostructured Deposition of Nanoparticles from the Gas Phase. Part. Part. Syst. Charact. 2002, 19, 321–326. [Google Scholar] [CrossRef]

- Dong, M.; Zhou, F.; Zhang, Y.; Shang, Y.; Li, S. Numerical Study on Fine-Particle Charging and Transport Behaviour in Electrostatic Precipitators. Powder Technol. 2018, 330, 210–218. [Google Scholar] [CrossRef]

- Arif, S.; Branken, D.J.; Everson, R.C.; Neomagus, H.W.J.P.; Arif, A. The Influence of Design Parameters on the Occurrence of Shielding in Multi-Electrode ESPs and Its Effect on Performance. J. Electrostat. 2018, 93, 17–30. [Google Scholar] [CrossRef]

- Chang, C.-L.; Bai, H. Effects of Some Geometric Parameters on the Electrostatic Precipitator Efficiency at Different Operation Indexes. Aerosol Sci. Technol. 2000, 33, 228–238. [Google Scholar] [CrossRef]

- Sumorek, A. The Influence of Shape and Dimension of Dust Particle on Electrostatic Precipitator Operation. Przegląd Elektrotech. 2018, 1, 56–59. [Google Scholar] [CrossRef]

- Dong, M.; Zhou, F.; Shang, Y.; Li, S. Numerical Study on Electrohydrodynamic Flow and Fine-Particle Collection Efficiency in a Spike Electrode-Plate Electrostatic Precipitator. Powder Technol. 2019, 351, 71–83. [Google Scholar] [CrossRef]

- Ning, Z.; Podlinski, J.; Shen, X.; Li, S.; Wang, S.; Han, P.; Yan, K. Electrode Geometry Optimization in Wire-Plate Electrostatic Precipitator and Its Impact on Collection Efficiency. J. Electrostat. 2016, 80, 76–84. [Google Scholar] [CrossRef]

- Gao, M.; Zhu, Y.; Yao, X.; Shi, J.; Shangguan, W. Dust Removal Performance of Two-Stage Electrostatic Precipitators and Its Influencing Factors. Powder Technol. 2019, 348, 13–23. [Google Scholar] [CrossRef]

- Kherbouche, F.; Benmimoun, Y.; Tilmatine, A.; Zouaghi, A.; Zouzou, N. Study of a New Electrostatic Precipitator with Asymmetrical Wire-to-Cylinder Configuration for Cement Particles Collection. J. Electrostat. 2016, 83, 7–15. [Google Scholar] [CrossRef]

- Mo, J.; Tian, E.; Pan, J. New Electrostatic Precipitator with Dielectric Coatings to Efficiently and Safely Remove Sub-Micro Particles in the Building Environment. Sustain. Cities Soc. 2020, 55, 102063. [Google Scholar] [CrossRef]

- Yang, D.; Guo, B.; Ye, X.; Yu, A.; Guo, J. Numerical Simulation of Electrostatic Precipitator Considering the Dust Particle Space Charge. Powder Technol. 2019, 354, 552–560. [Google Scholar] [CrossRef]

- Yoo, K.H.; Lee, J.S.; Oh, M. Do Charging and Collection of Submicron Particles in Two-Stage Parallel-Plate Electrostatic Precipitators. Aerosol. Sci. Technol. 1997, 27, 308–323. [Google Scholar] [CrossRef]

- Schmatloch, V.; Rauch, S. Design and Characterisation of an Electrostatic Precipitator for Small Heating Appliances. J. Electrostat. 2005, 63, 85–100. [Google Scholar] [CrossRef]

- Zhuang, Y.; Jin Kim, Y.; Gyu Lee, T.; Biswas, P. Experimental and Theoretical Studies of Ultra-Fine Particle Behavior in Electrostatic Precipitators. J. Electrostat. 2000, 48, 245–260. [Google Scholar] [CrossRef]

- Morawska, L.; Agranovski, V.; Ristovski, Z.; Jamriska, M. Effect of Face Velocity and the Nature of Aerosol on the Collection of Submicrometer Particles by Electrostatic Precipitator. Indoor Air 2002, 12, 129–137. [Google Scholar] [CrossRef] [PubMed]

- Mertens, J.; Lepaumier, H.; Rogiers, P.; Desagher, D.; Goossens, L.; Duterque, A.; Le Cadre, E.; Zarea, M.; Blondeau, J.; Webber, M. Fine and Ultrafine Particle Number and Size Measurements from Industrial Combustion Processes: Primary Emissions Field Data. Atmos. Pollut. Res. 2020, 11, 803–814. [Google Scholar] [CrossRef]

- Oliveira, A.E.; Guerra, V.G. Efficiency of Electrostatic Precipitation of NiO Nanoparticles Dispersed by Atomization. Sep. Sci. Technol. 2020, 55, 2400–2409. [Google Scholar] [CrossRef]

- Oliveira, A.E.; Guerra, V.G. Electrostatic Precipitation of Nickel (II) Oxide and Sodium Chloride Nanoparticles: Operating Conditions Promoting Sputtering with Electro-Fluid Dynamics Analysis. Process Saf. Environ. Prot. 2021, 147, 450–459. [Google Scholar] [CrossRef]

- Miller, A.; Frey, G.; King, G.; Sunderman, C. A Handheld Electrostatic Precipitator for Sampling Airborne Particles and Nanoparticles. Aerosol Sci. Technol. 2010, 44, 417–427. [Google Scholar] [CrossRef]

- Roux, J.M.; Sarda-Estève, R.; Delapierre, G.; Nadal, M.H.; Bossuet, C.; Olmedo, L. Development of a New Portable Air Sampler Based on Electrostatic Precipitation. Environ. Sci. Pollut. Res. 2016, 23, 8175–8183. [Google Scholar] [CrossRef]

- Vaddi, R.S.; Guan, Y.; Novosselov, I. Behavior of Ultrafine Particles in Electro-Hydrodynamic Flow Induced by Corona Discharge. J. Aerosol Sci. 2020, 148, 105587. [Google Scholar] [CrossRef] [PubMed]

- Nouri, H.; Zouzou, N.; Dascalescu, L.; Zebboudj, Y. Investigation of Relative Humidity Effect on the Particles Velocity and Collection Efficiency of Laboratory Scale Electrostatic Precipitator. Process Saf. Environ. Prot. 2016, 104, 225–232. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, B.; Zhou, L.; Jiang, Y.; Yang, L. Improving the Removal of Fine Particles with an Electrostatic Precipitator by Chemical Agglomeration. Energy Fuels 2016, 30, 8441–8447. [Google Scholar] [CrossRef]

- Bin, H.; Yang, Y.; Lei, Z.; Ao, S.; Cai, L.; Linjun, Y.; Roszak, S. Experimental and DFT Studies of PM2.5 Removal by Chemical Agglomeration. Fuel 2018, 212, 27–33. [Google Scholar] [CrossRef]

- Bin, H.; Yang, Y.; Cai, L.; Zhulin, Y.; Roszak, S.; Linjun, Y. Experimental Study on Particles Agglomeration by Chemical and Turbulent Agglomeration before Electrostatic Precipitators. Powder Technol. 2018, 335, 186–194. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, L.; Shen, A.; Zhou, L.; Wu, H. Combined Effect of Chemical and Turbulent Agglomeration on Improving the Removal of Fine Particles by Different Coupling Mode. Powder Technol. 2019, 344, 242–250. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, L.; Wu, H.; Wu, X. Agglomeration and Removal Characteristics of Fine Particles from Coal Combustion under Different Turbulent Flow Fields. J. Environ. Sci. 2020, 89, 113–124. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Lee, H.S.; Kim, H.H.; Ogata, A. Electrospray with Electrostatic Precipitator Enhances Fine Particles Collection Efficiency. J. Electrostat. 2010, 68, 305–310. [Google Scholar] [CrossRef]

- Kim, W.; An, H.; Lee, D.; Lee, W.; Jung, J.H. Development of a Novel Electrostatic Precipitator System Using a Wet-Porous Electrode Array. Aerosol. Sci. Technol. 2015, 49, 1100–1108. [Google Scholar] [CrossRef]

- Son, C.; Lee, W.; Jung, D.; Lee, D.; Byon, C.; Kim, W. Use of an Electrostatic Precipitator with Wet-Porous Electrode Arrays for Removal of Air Pollution at a Precision Manufacturing Facility. J. Aerosol Sci. 2016, 100, 118–128. [Google Scholar] [CrossRef]

- Sung, J.-H.; Kim, M.; Kim, Y.-J.; Han, B.; Hong, K.-J.; Kim, H.-J. Ultrafine Particle Cleaning Performance of an Ion Spray Electrostatic Air Cleaner Emitting Zero Ozone with Diffusion Charging by Carbon Fiber. Build. Environ. 2019, 166, 106422. [Google Scholar] [CrossRef]

- Teng, C.; Fan, X.; Li, J. Effect of Charged Water Drop Atomization on Particle Removal Performance in Plate Type Wet Electrostatic Precipitator. J. Electrostat. 2020, 104, 103426. [Google Scholar] [CrossRef]

- Anderlohr, C.; Schaber, K. Direct Transfer of Gas-Borne Nanoparticles into Liquid Suspensions by Means of a Wet Electrostatic Precipitator. Aerosol Sci. Technol. 2015, 49, 1281–1290. [Google Scholar] [CrossRef]

- Chen, T.M.; Tsai, C.J.; Yan, S.Y.; Li, S.N. An Efficient Wet Electrostatic Precipitator for Removing Nanoparticles, Submicron and Micron-Sized Particles. Sep. Purif. Technol. 2014, 136, 27–35. [Google Scholar] [CrossRef]

- Dey, L.; Venkataraman, C. A Wet Electrostatic Precipitator (WESP) for Soft Nanoparticle Collection. Aerosol. Sci. Technol. 2012, 46, 750–759. [Google Scholar] [CrossRef]

- Saiyasitpanich, P.; Keener, T.C.; Lu, M.; Khang, S.-J.; Evans, D.E. Collection of Ultrafine Diesel Particulate Matter (DPM) in Cylindrical Single-Stage Wet Electrostatic Precipitators. Environ. Sci. Technol. 2006, 40, 7890–7895. [Google Scholar] [CrossRef] [PubMed]

- Halstead, M.; Gray, N.; Gonzalez-Jimenez, N.; Fresquez, M.; Valentin-Blasini, L.; Watson, C.; Pappas, R.S. Analysis of Toxic Metals in Electronic Cigarette Aerosols Using a Novel Trap Design. J. Anal. Toxicol. 2020, 44, 149–155. [Google Scholar] [CrossRef]

- Borgerding, M.F.; Milhous, L.A.; Hicks, R.D.; Giles, J.A. Cigarette Smoke Composition. Part 2. Method for Determining Major Components in Smoke of Cigarettes That Heat Instead of Burn Tobacco. J. AOAC Int. 1990, 73, 610–615. [Google Scholar] [CrossRef]

- Rhoades, C.B.; White, R.T. Mainstream Smoke Collection by Electrostatic Precipitation for Acid Dissolution in a Microwave Digestion System Prior to Trace Metal Determination. J. AOAC Int. 1997, 80, 1320–1331. [Google Scholar] [CrossRef]

- Zukeran, A.; Sawano, H.; Yasumoto, K. Collection Characteristic of Nanoparticles Emitted from a Diesel Engine with Residual Fuel Oil and Light Fuel Oil in an Electrostatic Precipitator. Energies 2019, 12, 3321. [Google Scholar] [CrossRef]

- Flagan, R.C.; Seinfeld, J.H. Fundamentals of Air Pollution Engineering. Courier Corporation: Chelmsford, MA, USA, 2012. [Google Scholar]

- Intra, P.; Tippayawong, N. An Overview of Unipolar Charger Developments for Nanoparticle Charging. Aerosol. Air Qual. Res. 2011, 11, 187–209. [Google Scholar] [CrossRef]

- Li, M.; Christofides, P.D. Collection Efficiency of Nanosize Particles in a Two-Stage Electrostatic Precipitator. Ind. Eng. Chem. Res. 2006, 45, 8484–8491. [Google Scholar] [CrossRef]

- Lin, G.-Y.; Tsai, C.-J. Numerical Modeling of Nanoparticle Collection Efficiency of Single-Stage Wire-in-Plate Electrostatic Precipitators. Aerosol. Sci. Technol. 2010, 44, 1122–1130. [Google Scholar] [CrossRef]

- Pui, D.Y.H.; Fruin, S.; McMurry, P.H. Unipolar Diffusion Charging of Ultrafine Aerosols. Aerosol Sci. Technol. 1988, 8, 173–187. [Google Scholar] [CrossRef]

- Qi, C.; Chen, D.-R.; Greenberg, P. Performance Study of a Unipolar Aerosol Mini-Charger for a Personal Nanoparticle Sizer. J. Aerosol Sci. 2008, 39, 450–459. [Google Scholar] [CrossRef]

- Alshehhi, M.; Shooshtari, A.; Dessiatoun, S.; Ohadi, M.; Goharzadeh, A. Parametric Performance Analysis of an Electrostatic Wire-Cylinder Aerosol Separator in Laminar Flow Using a Numerical Modeling Approach. Sep. Sci. Technol. 2010, 45, 299–309. [Google Scholar] [CrossRef]

- Pirhadi, M.; Mousavi, A.; Sioutas, C. Evaluation of a High Flow Rate Electrostatic Precipitator (ESP) as a Particulate Matter (PM) Collector for Toxicity Studies. Sci. Total Environ. 2020, 739, 140060. [Google Scholar] [CrossRef]

- Kim, H.J.; Han, B.; Kim, Y.J.; Yoa, S.J. Characteristics of an Electrostatic Precipitator for Submicron Particles Using Non-Metallic Electrodes and Collection Plates. J. Aerosol Sci. 2010, 41, 987–997. [Google Scholar] [CrossRef]

- Yang, Z.; Zheng, C.; Liu, S.; Guo, Y.; Liang, C.; Wang, Y.; Hu, D.; Gao, X. A Combined Wet Electrostatic Precipitator for Efficiently Eliminating Fine Particle Penetration. Fuel Process. Technol. 2018, 180, 122–129. [Google Scholar] [CrossRef]

- Li, Z.; Liu, Y.; Xing, Y.; Tran, T.M.P.; Le, T.C.; Tsai, C.J. Novel Wire-on-Plate Electrostatic Precipitator (WOP-EP) for Controlling Fine Particle and Nanoparticle Pollution. Environ. Sci. Technol. 2015, 49, 8683–8690. [Google Scholar] [CrossRef]

- Chen, L.; Gonze, E.; Ondarts, M.; Outin, J.; Gonthier, Y. Electrostatic Precipitator for Fine and Ultrafine Particle Removal from Indoor Air Environments. Sep. Purif. Technol. 2020, 247, 116964. [Google Scholar] [CrossRef]

- Huang, S.H.; Chen, C.C. Ultrafine Aerosol Penetration through Electrostatic Precipitators. Environ. Sci. Technol. 2002, 36, 4625–4632. [Google Scholar] [CrossRef] [PubMed]

- Knuttsen, F.; Parker, K.R. Mechanical Design Considerations for Dry Precipitators. In Applied Electrostatic Precipitation; Blackie Academic & Professional: London, UK, 1997; pp. 89–112. [Google Scholar]

- NEUNDORFER Electrostatic Precipitator. Available online: http://www.neundorfer.com/knowledgebase/ (accessed on 14 May 2020).

- Davidson, J.H.; Mckinney, P.J. EHD Flow Visualization in the Wire-Plate and Barbed Plate Electrostatic Precipitator. IEEE Trans. Ind. Appl. 1991, 27, 154–160. [Google Scholar] [CrossRef]

- El Dein, A.Z.; Usama, K. Experimental and Simulation Study of V–I Characteristics of Wire–Plate Electrostatic Precipitators Under Clean Air Conditions. Arab. J. Sci. Eng. 2014, 39, 4037–4045. [Google Scholar] [CrossRef]

- Andrade, R.G.S.A.; Oliveira, A.E.; Guerra, V.G. Graphical Methodology to Study the Corona Onset Voltage for Electrostatic Precipitation of Nanoparticles. Theor. Found. Chem. Eng. 2022, 56, 504–512. [Google Scholar] [CrossRef]

- Kasdi, A. Computation and Measurement of Corona Current Density and V–I Characteristics in Wires-to-Plates Electrostatic Precipitator. J. Electrostat. 2016, 81, 1–8. [Google Scholar] [CrossRef]

- Bonfim, D.P.F.; Medeiros, G.B.; de Oliveira, A.E.; Guerra, V.G.; Aguiar, M.L. Nanomaterials in the Environment: Definitions, Characterizations, Effects, and Applications. In Environmental, Ethical, and Economical Issues of Nanotechnology; Hussain, C.M., da Costa, G.M., Eds.; Jenny Stanford Publishing Pte. Ltd.: New York, NY, USA, 2022; pp. 1–30. ISBN 978-981-4877-76-3. [Google Scholar]

- Li, P.; Wang, C.; Zhang, Y.; Wei, F. Air Filtration in the Free Molecular Flow Regime: A Review of High-Efficiency Particulate Air Filters Based on Carbon Nanotubes. Small 2014, 10, 4543–4561. [Google Scholar] [CrossRef]

- Bai, H.; Qian, X.; Fan, J.; Shi, Y.; Duo, Y.; Guo, C.; Wang, X. Theoretical Model of Single Fiber Efficiency and the Effect of Microstructure on Fibrous Filtration Performance: A Review. Ind. Eng. Chem. Res. 2021, 60, 3–36. [Google Scholar] [CrossRef]

- Givehchi, R.; Tan, Z. An Overview of Airborne Nanoparticle Filtration and Thermal Rebound Theory. Aerosol. Air Qual. Res. 2014, 14, 46–63. [Google Scholar] [CrossRef]

- Abdolghader, P.; Brochot, C.; Haghighat, F.; Bahloul, A. Airborne Nanoparticles Filtration Performance of Fibrous Media: A Review. Sci. Technol. Built Environ. 2018, 24, 648–672. [Google Scholar] [CrossRef]

- Kanaoka, C. Fine Particle Filtration Technology Using Fiber as Dust Collection Medium. KONA Powder Part. J. 2019, 36, 88–113. [Google Scholar] [CrossRef]

- Yang, C. Aerosol Filtration Application Using Fibrous Media—An Industrial Perspective. Chin. J. Chem. Eng. 2012, 20, 1–9. [Google Scholar] [CrossRef]

- Zhang, S.; Rind, N.A.; Tang, N.; Liu, H.; Yin, X.; Yu, J.; Ding, B. Electrospun Nanofibers for Air Filtration. In Electrospinning: Nanofabrication and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 365–389. ISBN 9780323512701. [Google Scholar]

- Wang, C.-S. Electrostatic Forces in Fibrous Filters—a Review. Powder Technol. 2001, 118, 166–170. [Google Scholar] [CrossRef]

- Chow, J.C.; Watson, J.G.; Wang, X.; Abbasi, B.; Reed, W.R.; Parks, D. Review of Filters for Air Sampling and Chemical Analysis in Mining Workplaces. Minerals 2022, 12, 1314. [Google Scholar] [CrossRef]

- Mouret, G.; Chazelet, S.; Thomas, D.; Bemer, D. Discussion about the Thermal Rebound of Nanoparticles. Sep. Purif. Technol. 2011, 78, 125–131. [Google Scholar] [CrossRef]

- Brummer, V.; Jecha, D.; Lestinsky, P.; Skryja, P.; Gregor, J.; Stehlik, P. The Treatment of Waste Gas from Fertilizer Production - An Industrial Case Study of Long Term Removing Particulate Matter with a Pilot Unit. Powder Technol. 2016, 297, 374–383. [Google Scholar] [CrossRef]

- Findanis, N.; Southam, M. Control and Management of Particulate Emissions Using Improved Reverse Pulse-Jet Cleaning Systems. Procedia Eng. 2012, 49, 228–238. [Google Scholar] [CrossRef]

- Liu, X.; Shen, H.; Nie, X. Study on the Filtration Performance of the Baghouse Filters for Ultra-Low Emission as a Function of Filter Pore Size and Fiber Diameter. Int. J. Environ. Res. Public Health 2019, 16, 247. [Google Scholar] [CrossRef] [PubMed]

- Tcharkhtchi, A.; Abbasnezhad, N.; Zarbini Seydani, M.; Zirak, N.; Farzaneh, S.; Shirinbayan, M. An Overview of Filtration Efficiency through the Masks: Mechanisms of the Aerosols Penetration. Bioact. Mater. 2021, 6, 106–122. [Google Scholar] [CrossRef]

- Brochot, C.; Abdolghader, P.; Haghighat, F.; Bahloul, A. Performance of Mechanical Filters Used in General Ventilation against Nanoparticles. Sci. Technol. Built Environ. 2020, 26, 1387–1396. [Google Scholar] [CrossRef]

- Brochot, C.; Bahloul, A.; Abdolghader, P.; Haghighat, F. Performance of Mechanical Filters Used in General Ventilation against Nanoparticles. IOP Conf. Ser. Mater. Sci. Eng. 2019, 609, 032044. [Google Scholar] [CrossRef]

- Bortolassi, A.C.C.; Guerra, V.G.; Aguiar, M.L. Evaluation of Different HEPA Filter Media for Removing Nickel Oxide Nanoparticles from Air Filtration. Tecnol. em Metal. Mater. e Mineração 2019, 16, 426–431. [Google Scholar] [CrossRef]

- Bortolassi, A.C.C.; Guerra, V.G.; Aguiar, M.L. Characterization and Evaluate the Efficiency of Different Filter Media in Removing Nanoparticles. Sep. Purif. Technol. 2017, 175, 79–86. [Google Scholar] [CrossRef]

- Kim, C.; Kang, S.; Pui, D.Y.H. Removal of Airborne Sub-3 Nm Particles Using Fibrous Filters and Granular Activated Carbons. Carbon N. Y. 2016, 104, 125–132. [Google Scholar] [CrossRef]

- Bonfim, D.P.F.; Cruz, F.G.S.; Bretas, R.E.S.; Guerra, V.G.; Aguiar, M.L. A Sustainable Recycling Alternative: Electrospun Pet-Membranes for Air Nanofiltration. Polymers 2021, 13, 1166. [Google Scholar] [CrossRef]

- Bulejko, P.; Dohnal, M.; Pospíšil, J.; Svěrák, T. Air Filtration Performance of Symmetric Polypropylene Hollow-Fibre Membranes for Nanoparticle Removal. Sep. Purif. Technol. 2018, 197, 122–128. [Google Scholar] [CrossRef]

- Wang, C.; Li, P.; Zong, Y.; Zhang, Y.; Li, S.; Wei, F. A High Efficiency Particulate Air Filter Based on Agglomerated Carbon Nanotube Fluidized Bed. Carbon N. Y. 2014, 79, 424–431. [Google Scholar] [CrossRef]

- Shin, W.G.; Mulholland, G.W.; Kim, S.C.; Pui, D.Y.H. Experimental Study of Filtration Efficiency of Nanoparticles below 20 nm at Elevated Temperatures. J. Aerosol Sci. 2008, 39, 488–499. [Google Scholar] [CrossRef]

- Zhou, Z.-J.; Zhou, B.; Tseng, C.-H.; Hu, S.-C.; Shiue, A.; Leggett, G. Evaluation of Characterization and Filtration Performance of Air Cleaner Materials. Int. J. Environ. Sci. Technol. 2021, 18, 2209–2220. [Google Scholar] [CrossRef]

- Kim, C.S.; Bao, L.; Okuyama, K.; Shimada, M.; Niinuma, H. Filtration Efficiency of a Fibrous Filter for Nanoparticles. J. Nanoparticle Res. 2006, 8, 215–221. [Google Scholar] [CrossRef]

- Golanski, L.; Guiot, A.; Rouillon, F.; Pocachard, J.; Tardif, F. Experimental Evaluation of Personal Protection Devices against Graphite Nanoaerosols: Fibrous Filter Media, Masks, Protective Clothing, and Gloves. Hum. Exp. Toxicol. 2009, 28, 353–359. [Google Scholar] [CrossRef]

- Kwon, O.; Yoon, C.; Ham, S.; Park, J.; Lee, J.; Yoo, D.; Kim, Y. Characterization and Control of Nanoparticle Emission during 3D Printing. Environ. Sci. Technol. 2017, 51, 10357–10368. [Google Scholar] [CrossRef]

- Förster, H.; Thajudeen, T.; Funk, C.; Peukert, W. Separation of Nanoparticles: Filtration and Scavenging from Waste Incineration Plants. Waste Manag. 2016, 52, 346–352. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Riccobono, F.; Vlachos, T.; Mendoza-Villafuerte, P.; Suarez-Bertoa, R.; Fontaras, G.; Bonnel, P.; Weiss, M. Vehicle Emission Factors of Solid Nanoparticles in the Laboratory and on the Road Using Portable Emission Measurement Systems (PEMS). Front. Environ. Sci. 2015, 3, 82. [Google Scholar] [CrossRef]

- Ushakov, S.; Valland, H.; Nielsen, J.B.; Hennie, E. Effects of Dilution Conditions on Diesel Particle Size Distribution and Filter Mass Measurements in Case of Marine Fuels. Fuel Process. Technol. 2014, 118, 244–253. [Google Scholar] [CrossRef]

- Larcombe, A.N.; Janka, M.A.; Mullins, B.J.; Berry, L.J.; Bredin, A.; Franklin, P.J. The Effects of Electronic Cigarette Aerosol Exposure on Inflammation and Lung Function in Mice. Am. J. Physiol. Cell. Mol. Physiol. 2017, 313, L67–L79. [Google Scholar] [CrossRef]

- Aszyk, J.; Kubica, P.; Namieśnik, J.; Kot-Wasik, A.; Wasik, A. New Approach for E-Cigarette Aerosol Collection by an Original Automatic Aerosol Generator Utilizing Melt-Blown Non-Woven Fabric. Anal. Chim. Acta 2018, 1038, 67–78. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Lin, Y.; Zhu, Y. Transport and Mitigation of Exhaled Electronic Cigarette Aerosols in a Multizone Indoor Environment. Aerosol Air Qual. Res. 2020, 20, 2536–2547. [Google Scholar] [CrossRef]

- Werley, M.S.; Miller, J.H.; Kane, D.B.; Tucker, C.S.; McKinney, W.J.; Oldham, M.J. Prototype E-Cigarette and the Capillary Aerosol Generator (CAG) Comparison and Qualification for Use in Subchronic Inhalation Exposure Testing. Aerosol Sci. Technol. 2016, 50, 1284–1293. [Google Scholar] [CrossRef]

- Martuzevicius, D.; Prasauskas, T.; Setyan, A.; O’Connell, G.; Cahours, X.; Julien, R.; Colard, S. Characterization of the Spatial and Temporal Dispersion Differences between Exhaled E-Cigarette Mist and Cigarette Smoke. Nicotine Tob. Res. 2019, 21, 1371–1377. [Google Scholar] [CrossRef] [PubMed]

- Kärkelä, T.; Ebinger, J.-C.; Tapper, U.; Robyr, O.; Jalanti, T. Investigation into the Presence or Absence of Solid Particles Generated from Thermal Processes in the Aerosol from an Electrically Heated Tobacco Product with and without Filter Elements. Aerosol Air Qual. Res. 2021, 21, 200667. [Google Scholar] [CrossRef]

- Lee, H.; Kim, S.; Joo, H.; Cho, H.; Park, K. A Study on Performance and Reusability of Certified and Uncertified Face Masks. Aerosol Air Qual. Res. 2022, 22, 210370. [Google Scholar] [CrossRef]

- Hill, W.C.; Hull, M.S.; MacCuspie, R.I. Testing of Commercial Masks and Respirators and Cotton Mask Insert Materials Using SARS-CoV-2 Virion-Sized Particulates: Comparison of Ideal Aerosol Filtration Efficiency versus Fitted Filtration Efficiency. Nano Lett. 2020, 20, 7642–7647. [Google Scholar] [CrossRef]

- Rengasamy, S.; Eimer, B.C. Nanoparticle Penetration through Filter Media and Leakage through Face Seal Interface of N95 Filtering Facepiece Respirators. Ann. Occup. Hyg. 2012, 56, 568–580. [Google Scholar] [CrossRef] [PubMed]

- Majchrzycka, K.; Okrasa, M.; Jachowicz, A.; Szulc, J.; Gutarowska, B. Microbial Growth on Dust-Loaded Filtering Materials Used for the Protection of Respiratory Tract as a Factor Affecting Filtration Efficiency. Int. J. Environ. Res. Public Health 2018, 15, 1902. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, Y.; Fan, J.-Q.; Chen, L.-P.; Li, F.; Xue, K. Numerical Simulation and Experimental Validation for the Filtration Performance of Fibrous Air Filter Media with LB Method. Aerosol Air Qual. Res. 2017, 17, 2645–2658. [Google Scholar] [CrossRef]

- Tronville, P.; Rivers, R. Properties of Nanoparticles Affecting Simulation of Fibrous Gas Filter Performance. J. Phys. Conf. Ser. 2015, 617, 012010. [Google Scholar] [CrossRef]

- Fotovati, S.; Tafreshi, H.V.; Pourdeyhimi, B. Analytical Expressions for Predicting Performance of Aerosol Filtration Media Made up of Trilobal Fibers. J. Hazard. Mater. 2011, 186, 1503–1512. [Google Scholar] [CrossRef]

- Mouret, G.; Calle-Chazelet, S.; Thomas, D.; Bemer, D.; Appert-Collin, J.-C. Nanoparticles Filtration by Leaked Fibrous Filters. J. Phys. Conf. Ser. 2009, 170, 012028. [Google Scholar] [CrossRef]

- Givehchi, R.; Tan, Z. The Effect of Capillary Force on Airborne Nanoparticle Filtration. J. Aerosol Sci. 2015, 83, 12–24. [Google Scholar] [CrossRef]

- Todea, A.M.; Schmidt, F.; Schuldt, T.; Asbach, C. Development of a Method to Determine the Fractional Deposition Efficiency of Full-Scale HVAC and HEPA Filter Cassettes for Nanoparticles ≥ 3.5 Nm. Atmosphere 2020, 11, 1191. [Google Scholar] [CrossRef]

- Ghoshdastidar, A.J.; Ramamurthy, J.; Morissette, M.; Ariya, P.A. Development of Methodology to Generate, Measure, and Characterize the Chemical Composition of Oxidized Mercury Nanoparticles. Anal. Bioanal. Chem. 2020, 412, 691–702. [Google Scholar] [CrossRef]

- Park, D.H.; Joe, Y.H.; Piri, A.; An, S.; Hwang, J. Determination of Air Filter Anti-Viral Efficiency against an Airborne Infectious Virus. J. Hazard. Mater. 2020, 396, 122640. [Google Scholar] [CrossRef]

- Sachinidou, P.; Bahk, Y.K.; Tang, M.; Zhang, N.; Chen, S.S.C.; Pui, D.Y.H.; Lima, B.A.; Bosco, G.; Tronville, P.; Mosimann, T.; et al. Inter-Laboratory Validation of the Method to Determine the Filtration Efficiency for Airborne Particles in the 3–500 Nm Range and Results Sensitivity Analysis. Aerosol Air Qual. Res. 2017, 17, 2669–2680. [Google Scholar] [CrossRef]

- Yin, N.; Liu, F. Nanofibrous Filters for PM2.5 Filtration: Conception, Mechanism and Progress. Nano 2021, 16, 2130004. [Google Scholar] [CrossRef]

- Liu, J.; Pui, D.Y.H.; Wang, J. Removal of Airborne Nanoparticles by Membrane Coated Filters. Sci. Total Environ. 2011, 409, 4868–4874. [Google Scholar] [CrossRef]

- Chen, F.; Ji, Z.; Qi, Q. Effect of Surface Wettability on Filtration Performance of Gas-Liquid Coalescing Filters. Powder Technol. 2019, 357, 377–386. [Google Scholar] [CrossRef]

- Innocentini, M.D.d.M.; Coury, J.R.; Fukushima, M.; Colombo, P. High-Efficiency Aerosol Filters Based on Silicon Carbide Foams Coated with Ceramic Nanowires. Sep. Purif. Technol. 2015, 152, 180–191. [Google Scholar] [CrossRef]

- Cho, D.; Naydich, A.; Frey, M.W.; Joo, Y.L. Further Improvement of Air Filtration Efficiency of Cellulose Filters Coated with Nanofibers via Inclusion of Electrostatically Active Nanoparticles. Polymer 2013, 54, 2364–2372. [Google Scholar] [CrossRef]

- Zhang, Y.; He, X.; Zhu, Z.; Wang, W.-N.; Chen, S.-C. Simultaneous Removal of VOCs and PM2.5 by Metal-Organic Framework Coated Electret Filter Media. J. Memb. Sci. 2021, 618, 118629. [Google Scholar] [CrossRef]

- Dai, Z.; Zhu, J.; Yan, J.; Su, J.; Gao, Y.; Zhang, X.; Ke, Q.; Parsons, G.N. An Advanced Dual-Function MnO2-Fabric Air Filter Combining Catalytic Oxidation of Formaldehyde and High-Efficiency Fine Particulate Matter Removal. Adv. Funct. Mater. 2020, 30, 2001488. [Google Scholar] [CrossRef]

- Juuti, P.; Nikka, M.; Gunell, M.; Eerola, E.; Saarinen, J.J.; Omori, Y.; Seto, T.; Mäkelä, J.M. Fabrication of Fiber Filters with Antibacterial Properties for VOC and Particle Removal. Aerosol Air Qual. Res. 2019, 19, 1892–1899. [Google Scholar] [CrossRef]

- Chong, E.; Hwang, G.B.; Nho, C.W.; Kwon, B.M.; Lee, J.E.; Seo, S.; Bae, G.-N.; Jung, J.H. Antimicrobial Durability of Air Filters Coated with Airborne Sophora Flavescens Nanoparticles. Sci. Total Environ. 2013, 444, 110–114. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhong, Z.; Low, Z.-X.; Yao, Z. A Multifunctional Multi-Walled Carbon Nanotubes/Ceramic Membrane Composite Filter for Air Purification. RSC Adv. 2015, 5, 91951–91959. [Google Scholar] [CrossRef]

- Balagna, C.; Perero, S.; Bosco, F.; Mollea, C.; Irfan, M.; Ferraris, M. Antipathogen Nanostructured Coating for Air Filters. Appl. Surf. Sci. 2020, 508, 145283. [Google Scholar] [CrossRef]

- Joe, Y.H.; Ju, W.; Park, J.H.; Yoon, Y.H.; Hwang, J. Correlation between the Antibacterial Ability of Silver Nanoparticle Coated Air Filters and the Dust Loading. Aerosol Air Qual. Res. 2013, 13, 1009–1018. [Google Scholar] [CrossRef]

- Zendehdel, R.; Amini, M.M.; Hajibabaei, M.; Nasiri, M.J.; Jafari, M.J.; Alavijeh, M.K. Doping Metal–Organic Framework Composites to Antibacterial Air Filter Development for Quality Control of Indoor Air. Environ. Prog. Sustain. Energy 2022, 41. [Google Scholar] [CrossRef]

- Machry, K.; Souza, C.W.O.; Aguiar, M.L.; Bernardo, A. Prevention of Pathogen Microorganisms at Indoor Air Ventilation System Using Synthesized Copper Nanoparticles. Can. J. Chem. Eng. 2022, 100, 1739–1746. [Google Scholar] [CrossRef]

- Ali, A.; Pan, M.; Tilly, T.B.; Zia, M.; Wu, C.Y. Performance of Silver, Zinc, and Iron Nanoparticles-Doped Cotton Filters against Airborne E. Coli to Minimize Bioaerosol Exposure. Air Qual. Atmos. Heal. 2018, 11, 1233–1242. [Google Scholar] [CrossRef]

- Salama, K.F.; Alnimr, A.; Alamri, A.; Radi, M.; Alshehri, B.; Rabaan, A.A.; Alshahrani, M. Nano-Treatment of HEPA Filters in COVID-19 Isolation Rooms in an Academic Medical Center in Saudi Arabia. J. Infect. Public Health 2022, 15, 937–941. [Google Scholar] [CrossRef]

- Perelshtein, I.; Levi, I.; Perkas, N.; Pollak, A.; Gedanken, A. CuO-Coated Antibacterial and Antiviral Car Air-Conditioning Filters. ACS Appl. Mater. Interf. 2022, 14, 24850–24855. [Google Scholar] [CrossRef]

- Baselga, M.; Uranga-Murillo, I.; de Miguel, D.; Arias, M.; Sebastián, V.; Pardo, J.; Arruebo, M. Silver Nanoparticles–Polyethyleneimine-Based Coatings with Antiviral Activity against SARS-CoV-2: A New Method to Functionalize Filtration Media. Materials 2022, 15, 4742. [Google Scholar] [CrossRef]

- Park, D.H.; Joe, Y.H.; Hwang, J. Dry Aerosol Coating of Anti-Viral Particles on Commercial Air Filters Using a High-Volume Flow Atomizer. Aerosol Air Qual. Res. 2019, 19, 1636–1644. [Google Scholar] [CrossRef]

- Joe, Y.H.; Woo, K.; Hwang, J. Fabrication of an Anti-Viral Air Filter with SiO2–Ag Nanoparticles and Performance Evaluation in a Continuous Airflow Condition. J. Hazard. Mater. 2014, 280, 356–363. [Google Scholar] [CrossRef]

- Andrade, B.K.S.A.; Sartim, R.; Aguiar, M.L. Precoating Effects in Fine Steelmaking Dust Filtration. Atmosphere 2022, 13, 1669. [Google Scholar] [CrossRef]

- Bao, L.; Seki, K.; Niinuma, H.; Otani, Y.; Balgis, R.; Ogi, T.; Gradon, L.; Okuyama, K. Verification of Slip Flow in Nanofiber Filter Media through Pressure Drop Measurement at Low-Pressure Conditions. Sep. Purif. Technol. 2016, 159, 100–107. [Google Scholar] [CrossRef]

- Tang, M.; Hu, J.; Liang, Y.; Pui, D.Y. Pressure Drop, Penetration and Quality Factor of Filter Paper Containing Nanofibers. Text. Res. J. 2017, 87, 498–508. [Google Scholar] [CrossRef]

- da Mata, G.C.; Morais, M.S.; de Oliveira, W.P.; Aguiar, M.L. Composition Effects on the Morphology of PVA/Chitosan Electrospun Nanofibers. Polymers 2022, 14, 4856. [Google Scholar] [CrossRef]

- Li, J.; Zhang, D.; Yang, T.; Yang, S.; Yang, X.; Zhu, H. Nanofibrous Membrane of Graphene Oxide-in-Polyacrylonitrile Composite with Low Filtration Resistance for the Effective Capture of PM2.5. J. Memb. Sci. 2018, 551, 85–92. [Google Scholar] [CrossRef]

- Deshawar, D.; Gupta, K.; Chokshi, P. Electrospinning of Polymer Solutions: An Analysis of Instability in a Thinning Jet with Solvent Evaporation. Polymer 2020, 202, 122656. [Google Scholar] [CrossRef]

- Kim, H.-J.; Park, S.J.; Park, C.S.; Le, T.-H.; Hun Lee, S.; Ha, T.H.; Kim, H.; Kim, J.; Lee, C.-S.; Yoon, H.; et al. Surface-Modified Polymer Nanofiber Membrane for High-Efficiency Microdust Capturing. Chem. Eng. J. 2018, 339, 204–213. [Google Scholar] [CrossRef]

- Choi, H.-J.; Kim, S.B.; Kim, S.H.; Lee, M.-H. Preparation of Electrospun Polyurethane Filter Media and Their Collection Mechanisms for Ultrafine Particles. J. Air Waste Manag. Assoc. 2014, 64, 322–329. [Google Scholar] [CrossRef]

- Almeida, D.S.; Martins, L.D.; Muniz, E.C.; Rudke, A.P.; Squizzato, R.; Beal, A.; de Souza, P.R.; Bonfim, D.P.F.; Aguiar, M.L.; Gimenes, M.L. Biodegradable CA/CPB Electrospun Nanofibers for Efficient Retention of Airborne Nanoparticles. Process Saf. Environ. Prot. 2020, 144, 177–185. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, A.E.; Aguiar, M.L.; Guerra, V.G. Improved Filter Media with PVA/Citric Acid/Triton X-100 Nanofibers for Filtration of Nanoparticles from Air. Polym. Bull. 2021, 78, 6387–6408. [Google Scholar] [CrossRef]

- Bonfim, D.P.F.; Cruz, F.G.S.; Guerra, V.G.; Aguiar, M.L. Development of Filter Media by Electrospinning for Air Filtration of Nanoparticles from PET Bottles. Membranes 2021, 11, 293. [Google Scholar] [CrossRef] [PubMed]

- Greiner, A.; Wendorff, J.H. Electrospinning: A Fascinating Method for the Preparation of Ultrathin Fibers. Angew. Chem. Int. Ed. 2007, 46, 5670–5703. [Google Scholar] [CrossRef]

- Huang, Z.M.; Zhang, Y.Z.; Kotaki, M.; Ramakrishna, S. A Review on Polymer Nanofibers by Electrospinning and Their Applications in Nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Anitha, S.; Brabu, B.; Thiruvadigal, D.J.; Gopalakrishnan, C.; Natarajan, T.S. Optical, Bactericidal and Water Repellent Properties of Electrospun Nano-Composite Membranes of Cellulose Acetate and ZnO. Carbohydr. Polym. 2012, 87, 1065–1072. [Google Scholar] [CrossRef]

- Ismail, N.; Junior Maksoud, F.; Ghaddar, N.; Ghali, K.; Tehrani-Bagha, A. A Mathematical Model to Predict the Effect of Electrospinning Processing Parameters on the Morphological Characteristic of Nano-Fibrous Web and Associated Filtration Efficiency. J. Aerosol Sci. 2017, 113, 227–241. [Google Scholar] [CrossRef]

- Maze, B.; Vahedi Tafreshi, H.; Wang, Q.; Pourdeyhimi, B. A Simulation of Unsteady-State Filtration via Nanofiber Media at Reduced Operating Pressures. J. Aerosol. Sci. 2007, 38, 550–571. [Google Scholar] [CrossRef]

- Robert, B.; Nallathambi, G. Highly Oriented Poly (m-Phenylene Isophthalamide)/Polyacrylonitrile Based Coaxial Nanofibers Integrated with Electrospun Polyacrylonitrile-Silver Nanoparticle: Application in Air Filtration of Particulate and Microbial Contaminants. J. Appl. Polym. Sci. 2022, 139, 52294. [Google Scholar] [CrossRef]

- Orlando, R.; Polat, M.; Afshari, A.; Johnson, M.S.; Fojan, P. Electrospun Nanofibre Air Filters for Particles and Gaseous Pollutants. Sustainability 2021, 13, 6553. [Google Scholar] [CrossRef]

- Blosi, M.; Costa, A.L.; Ortelli, S.; Belosi, F.; Ravegnani, F.; Varesano, A.; Tonetti, C.; Zanoni, I.; Vineis, C. Polyvinyl Alcohol/Silver Electrospun Nanofibers: Biocidal Filter Media Capturing Virus-size Particles. J. Appl. Polym. Sci. 2021, 138, 51380. [Google Scholar] [CrossRef] [PubMed]

- Remiro, P.d.F.R.; Sousa, C.P.; Alves, H.C.; Bernardo, A.; Aguiar, M.L. In Situ Evaluation of Filter Media Modified by Biocidal Nanomaterials to Control Bioaerosols in Internal Environments. Water Air Soil Pollut. 2021, 232, 176. [Google Scholar] [CrossRef]

- Li, X.; Wang, N.; Fan, G.; Yu, J.; Gao, J.; Sun, G.; Ding, B. Electreted Polyetherimide–Silica Fibrous Membranes for Enhanced Filtration of Fine Particles. J. Colloid Interf. Sci. 2015, 439, 12–20. [Google Scholar] [CrossRef] [PubMed]

- Gobi, N.; Vijayalakshmi, E.; Robert, B.; Srinivasan, N.R. Development of PAN Nano Fibrous Filter Hybridized by SiO2 Nanoparticles Electret for High Efficiency Air Filtration. J. Polym. Mater. 2019, 35, 317–328. [Google Scholar] [CrossRef]

- Yeom, B.Y.; Shim, E.; Pourdeyhimi, B. Boehmite Nanoparticles Incorporated Electrospun Nylon-6 Nanofiber Web for New Electret Filter Media. Macromol. Res. 2010, 18, 884–890. [Google Scholar] [CrossRef]

- Ding, X.; Li, Y.; Si, Y.; Yin, X.; Yu, J.; Ding, B. Electrospun Polyvinylidene Fluoride/SiO2 Nanofibrous Membranes with Enhanced Electret Property for Efficient Air Filtration. Compos. Commun. 2019, 13, 57–62. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Yin, X.; Yu, J.; Ding, B. Electret Polyvinylidene Fluoride Nanofibers Hybridized by Polytetrafluoroethylene Nanoparticles for High-Efficiency Air Filtration. ACS Appl. Mater. Interf. 2016, 8, 23985–23994. [Google Scholar] [CrossRef]

- Li, Y.; Yin, X.; Si, Y.; Yu, J.; Ding, B. All-Polymer Hybrid Electret Fibers for High-Efficiency and Low-Resistance Filter Media. Chem. Eng. J. 2020, 398, 125626. [Google Scholar] [CrossRef]

- He, R.; Li, J.; Chen, M.; Zhang, S.; Cheng, Y.; Ning, X.; Wang, N. Tailoring Moisture Electroactive Ag/Zn@cotton Coupled with Electrospun PVDF/PS Nanofibers for Antimicrobial Face Masks. J. Hazard. Mater. 2022, 428, 128239. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, H.; Zhu, M.; Lv, D.; Yao, J.; Xiong, R.; Huang, C. Electrospun Soy-Protein-Based Nanofibrous Membranes for Effective Antimicrobial Air Filtration. J. Appl. Polym. Sci. 2018, 135, 45766. [Google Scholar] [CrossRef]

- Sun, Z.; Yue, Y.; He, W.; Jiang, F.; Lin, C.-H.; Pui, D.Y.H.; Liang, Y.; Wang, J. The Antibacterial Performance of Positively Charged and Chitosan Dipped Air Filter Media. Build. Environ. 2020, 180, 107020. [Google Scholar] [CrossRef]

- Kayaci, F.; Uyar, T. Electrospun Polyester/Cyclodextrin Nanofibers for Entrapment of Volatile Organic Compounds. Polym. Eng. Sci. 2014, 54, 2970–2978. [Google Scholar] [CrossRef]

- Liu, K.; Xiao, Z.; Ma, P.; Chen, J.; Li, M.; Liu, Q.; Wang, Y.; Wang, D. Large Scale Poly(Vinyl Alcohol-Co-Ethylene)/TiO2 Hybrid Nanofibrous Filters with Efficient Fine Particle Filtration and Repetitive-Use Performance. RSC Adv. 2015, 5, 87924–87931. [Google Scholar] [CrossRef]

- Yi, Z.; Cheng, P.; Chen, J.; Liu, K.; Liu, Q.; Li, M.; Zhong, W.; Wang, W.; Lu, Z.; Wang, D. PVA-Co-PE Nanofibrous Filter Media with Tailored Three-Dimensional Structure for High Performance and Safe Aerosol Filtration via Suspension-Drying Procedure. Ind. Eng. Chem. Res. 2018, 57, 9269–9280. [Google Scholar] [CrossRef]

- Zhang, S.; Tang, N.; Cao, L.; Yin, X.; Yu, J.; Ding, B. Highly Integrated Polysulfone/Polyacrylonitrile/Polyamide-6 Air Filter for Multilevel Physical Sieving Airborne Particles. ACS Appl. Mater. Interf. 2016, 8, 29062–29072. [Google Scholar] [CrossRef]

- Demirel, O.; Kolgesiz, S.; Yuce, S.; Hayat Soytaş, S.; Koseoglu-Imer, D.Y.; Unal, H. Photothermal Electrospun Nanofibers Containing Polydopamine-Coated Halloysite Nanotubes as Antibacterial Air Filters. ACS Appl. Nano Mater. 2022, 5, 18127–18137. [Google Scholar] [CrossRef]

- Li, D.; Shen, Y.; Wang, L.; Liu, F.; Deng, B.; Liu, Q. Hierarchical Structured Polyimide–Silica Hybrid Nano/Microfiber Filters Welded by Solvent Vapor for Air Filtration. Polymers 2020, 12, 2494. [Google Scholar] [CrossRef]

- Wang, N.; Si, Y.; Wang, N.; Sun, G.; El-Newehy, M.; Al-Deyab, S.S.; Ding, B. Multilevel Structured Polyacrylonitrile/Silica Nanofibrous Membranes for High-Performance Air Filtration. Sep. Purif. Technol. 2014, 126, 44–51. [Google Scholar] [CrossRef]

- Wan, H.; Wang, N.; Yang, J.; Si, Y.; Chen, K.; Ding, B.; Sun, G.; El-Newehy, M.; Al-Deyab, S.S.; Yu, J. Hierarchically Structured Polysulfone/Titania Fibrous Membranes with Enhanced Air Filtration Performance. J. Colloid Interf. Sci. 2014, 417, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Karabulut, F.N.H.; Fomra, D.; Höfler, G.; Chand, N.A.; Beckermann, G.W. Virucidal and Bactericidal Filtration Media from Electrospun Polylactic Acid Nanofibres Capable of Protecting against COVID-19. Membranes 2022, 12, 571. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wang, Z.; Zhang, H.; Pan, Z. Nanoporous PLA/(Chitosan Nanoparticle) Composite Fibrous Membranes with Excellent Air Filtration and Antibacterial Performance. Polymers 2018, 10, 1085. [Google Scholar] [CrossRef]

- Lee, H.; Jeon, S. Polyacrylonitrile Nanofiber Membranes Modified with Ni-Based Conductive Metal Organic Frameworks for Air Filtration and Respiration Monitoring. ACS Appl. Nano Mater. 2020, 3, 8192–8198. [Google Scholar] [CrossRef]

- Mirzaei, F.; Abbasi, A.; Dehghan, S.F.; Pourmand, M.R.; Mortazavi, S.-S.; Masoorian, E.; Mousavi, T.; Golbabaei, F. Removal of Bioaerosols Using Metal-Organic Frameworks Incorporated into Electrospun Nanofibers. Fibers Polym. 2021, 22, 2424–2432. [Google Scholar] [CrossRef]

- Hartati, S.; Zulfi, A.; Maulida, P.Y.D.; Yudhowijoyo, A.; Dioktyanto, M.; Saputro, K.E.; Noviyanto, A.; Rochman, N.T. Synthesis of Electrospun PAN/TiO2/Ag Nanofibers Membrane As Potential Air Filtration Media with Photocatalytic Activity. ACS Omega 2022, 7, 10516–10525. [Google Scholar] [CrossRef]

- Dehghan, S.F.; Golbabaei, F.; Maddah, B.; Latifi, M.; Pezeshk, H.; Hasanzadeh, M.; Akbar-Khanzadeh, F. Optimization of Electrospinning Parameters for Polyacrylonitrile-MgO Nanofibers Applied in Air Filtration. J. Air Waste Manag. Assoc. 2016, 66, 912–921. [Google Scholar] [CrossRef]

- Habibi Mohraz, M.; Je Yu, I.; Beitollahi, A.; Farhang Dehghan, S.; Hoon Shin, J.; Golbabaei, F. Assessment of the Potential Release of Nanomaterials from Electrospun Nanofiber Filter Media. NanoImpact 2020, 19, 100223. [Google Scholar] [CrossRef]

- Wang, N.; Cai, M.; Yang, X.; Yang, Y. Electret Nanofibrous Membrane with Enhanced Filtration Performance and Wearing Comfortability for Face Mask. J. Colloid Interf. Sci. 2018, 530, 695–703. [Google Scholar] [CrossRef]

- Olkhov, A.; Staroverova, O.; Iordanskiy, A.; Zaikov, G. Structure and Parameters of Polyhydroxybutyrate Nanofibres. NBI Technol. 2016, 4, 22–29. [Google Scholar] [CrossRef]

- Li, Y.; Cao, L.; Yin, X.; Si, Y.; Yu, J.; Ding, B. Ultrafine, Self-Crimp, and Electret Nano-Wool for Low-Resistance and High-Efficiency Protective Filter Media against PM0.3. J. Colloid Interf. Sci. 2020, 578, 565–573. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Li, J.; Chen, M.; Zhang, S.; He, R.; Wang, N. Environmentally Friendly and Antimicrobial Bilayer Structured Fabrics with Integrated Interception and Sterilization for Personal Protective Mask. Sep. Purif. Technol. 2022, 294, 121165. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, C.; Gao, F.; Pan, G. Needleless Electrospinning for Scaled-up Production of Ultrafine Chitosan Hybrid Nanofibers Used for Air Filtration. RSC Adv. 2016, 6, 105988–105995. [Google Scholar] [CrossRef]

- Li, J.; Gao, F.; Liu, L.Q.; Zhang, Z. Needleless Electro-Spun Nanofibers Used for Filtration of Small Particles. Express Polym. Lett. 2013, 7, 683–689. [Google Scholar] [CrossRef]

- Jackiewicz, A.; Werner, L. Separation of Nanoparticles from Air Using Melt-Blown Filtering Media. Aerosol Air Qual. Res. 2015, 15, 2422–2435. [Google Scholar] [CrossRef]

- Salussoglia, A.I.P.; Tanabe, E.H.; Aguiar, M.L. Evaluation of a Vacuum Collection System in the Preparation of PAN Fibers by Forcespinning for Application in Ultrafine Particle Filtration. J. Appl. Polym. Sci. 2020, 137, 49334. [Google Scholar] [CrossRef]

- Xu, H.; Chen, X.; Chen, M.; Luo, J.; Jin, W.; Zhu, H.; Guo, Y. Development of Antibacterial PTFE Hollow Fiber Membranes Containing Silver-Carried Zirconium Phosphate as Air Filtration Units for the Removal of Ultrafine Particles. Fibers Polym. 2022, 23, 423–435. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Yin, X.; Yu, J.; Ding, B. Anti-Deformed Polyacrylonitrile/Polysulfone Composite Membrane with Binary Structures for Effective Air Filtration. ACS Appl. Mater. Interf. 2016, 8, 8086–8095. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, X.; Teng, D.; Zhao, T.; Li, Y.; Zeng, Y. Multi-Layered Micro/Nanofibrous Nonwovens for Functional Face Mask Filter. Nano Res. 2022, 15, 7549–7558. [Google Scholar] [CrossRef]

- Sarac, Z.; Kilic, A.; Tasdelen-Yucedag, C. Optimization of Electro-blown Polysulfone Nanofiber Mats for Air Filtration Applications. Polym. Eng. Sci. 2023. [Google Scholar] [CrossRef]

- Su, Q.; Huang, Y.; Wei, Z.; Zhu, C.; Zeng, W.; Wang, S.; Long, S.; Zhang, G.; Yang, J.; Wang, X. A Novel Multi-Gradient PASS Nanofibrous Membranes with Outstanding Particulate Matter Removal Efficiency and Excellent Antimicrobial Property. Sep. Purif. Technol. 2023, 307, 122652. [Google Scholar] [CrossRef]

- Kim, H.-J.; Choi, D.-I.; Sung, S.-K.; Lee, S.-H.; Kim, S.-J.; Kim, J.; Han, B.-S.; Kim, D.-I.; Kim, Y. Eco-Friendly Poly(Vinyl Alcohol) Nanofiber-Based Air Filter for Effectively Capturing Particulate Matter. Appl. Sci. 2021, 11, 3831. [Google Scholar] [CrossRef]

- Kakoria, A.; Sinha-Ray, S. Ultrafine Nanofiber-Based High Efficiency Air Filter from Waste Cigarette Butts. Polymer 2022, 255, 125121. [Google Scholar] [CrossRef]

- Hu, S.; Zheng, Z.; Tian, Y.; Zhang, H.; Wang, M.; Yu, Z.; Zhang, X. Preparation and Characterization of Electrospun PAN-CuCl2 Composite Nanofiber Membranes with a Special Net Structure for High-Performance Air Filters. Polymers 2022, 14, 4387. [Google Scholar] [CrossRef] [PubMed]

- Victor, F.S.; Kugarajah, V.; Bangaru, M.; Ranjan, S.; Dharmalingam, S. Electrospun Nanofibers of Polyvinylidene Fluoride Incorporated with Titanium Nanotubes for Purifying Air with Bacterial Contamination. Environ. Sci. Pollut. Res. 2021, 28, 37520–37533. [Google Scholar] [CrossRef]

- Shao, Z.; Chen, Y.; Jiang, J.; Xiao, Y.; Kang, G.; Wang, X.; Li, W.; Zheng, G. Multistage-Split Ultrafine Fluffy Nanofibrous Membrane for High-Efficiency Antibacterial Air Filtration. ACS Appl. Mater. Interf. 2022, 14, 18989–19001. [Google Scholar] [CrossRef]

- Pardo-Figuerez, M.; Chiva-Flor, A.; Figueroa-Lopez, K.; Prieto, C.; Lagaron, J.M. Antimicrobial Nanofiber Based Filters for High Filtration Efficiency Respirators. Nanomaterials 2021, 11, 900. [Google Scholar] [CrossRef]

- Zhang, H.; Jia, L.; Li, P.; Yu, L.; Liu, Y.; Zhao, W.; Wang, H.; Li, B. Large-Scale Blow Spinning of Nanofiber Membranes for Highly Efficient Air Mechanical Filtration with Antibacterial Activity. ACS Appl. Polym. Mater. 2022, 4, 2081–2090. [Google Scholar] [CrossRef]

- Cheng, X.; Zhao, L.; Zhang, Z.; Deng, C.; Li, C.; Du, Y.; Shi, J.; Zhu, M. Highly Efficient, Low-Resistant, Well-Ordered PAN Nanofiber Membranes for Air Filtration. Colloids Surfaces Physicochem. Eng. Asp. 2022, 655, 130302. [Google Scholar] [CrossRef]

- Hua, Y.; Li, Y.; Ji, Z.; Cui, W.; Wu, Z.; Fan, J.; Liu, Y. Dual-Bionic, Fluffy, and Flame Resistant Polyamide-Imide Ultrafine Fibers for High-Temperature Air Filtration. Chem. Eng. J. 2023, 452, 139168. [Google Scholar] [CrossRef]

- Huang, J.J.; Tian, Y.; Wang, R.; Tian, M.; Liao, Y. Fabrication of Bead-on-String Polyacrylonitrile Nanofibrous Air Filters with Superior Filtration Efficiency and Ultralow Pressure Drop. Sep. Purif. Technol. 2020, 237, 116377. [Google Scholar] [CrossRef]

- Hu, J.; Xiong, Z.; Liu, Y.; Lin, J. A Biodegradable Composite Filter Made from Electrospun Zein Fibers Underlaid on the Cellulose Paper Towel. Int. J. Biol. Macromol. 2022, 204, 419–428. [Google Scholar] [CrossRef]

- Tian, E.; Mo, J.; Li, X. Electrostatically Assisted Metal Foam Coarse Filter with Small Pressure Drop for Efficient Removal of Fine Particles: Effect of Filter Medium. Build. Environ. 2018, 144, 419–426. [Google Scholar] [CrossRef]

- Feng, Z.; Long, Z.; Mo, J. Experimental and Theoretical Study of a Novel Electrostatic Enhanced Air Filter (EEAF) for Fine Particles. J. Aerosol. Sci. 2016, 102, 41–54. [Google Scholar] [CrossRef]

- Shi, B.; Ekberg, L. Ionizer Assisted Air Filtration for Collection of Submicron and Ultrafine Particles—Evaluation of Long-Term Performance and Influencing Factors. Environ. Sci. Technol. 2015, 49, 6891–6898. [Google Scholar] [CrossRef]

- Tian, E.; Xia, F.; Wu, J.; Zhang, Y.; Li, J.; Wang, H.; Mo, J. Electrostatic Air Filtration by Multifunctional Dielectric Heterocaking Filters with Ultralow Pressure Drop. ACS Appl. Mater. Interf. 2020, 12, 29383–29392. [Google Scholar] [CrossRef]

- Choi, D.Y.; Heo, K.J.; Kang, J.; An, E.J.; Jung, S.-H.; Lee, B.U.; Lee, H.M.; Jung, J.H. Washable Antimicrobial Polyester/Aluminum Air Filter with a High Capture Efficiency and Low Pressure Drop. J. Hazard. Mater. 2018, 351, 29–37. [Google Scholar] [CrossRef]

- Choi, D.Y.; Jung, S.-H.; Song, D.K.; An, E.J.; Park, D.; Kim, T.-O.; Jung, J.H.; Lee, H.M. Al-Coated Conductive Fibrous Filter with Low Pressure Drop for Efficient Electrostatic Capture of Ultrafine Particulate Pollutants. ACS Appl. Mater. Interf. 2017, 9, 16495–16504. [Google Scholar] [CrossRef]

- Kim, S.J.; Raut, P.; Jana, S.C.; Chase, G. Electrostatically Active Polymer Hybrid Aerogels for Airborne Nanoparticle Filtration. ACS Appl. Mater. Interf. 2017, 9, 6401–6410. [Google Scholar] [CrossRef]

- Zhai, C.; Jana, S.C. Tuning Porous Networks in Polyimide Aerogels for Airborne Nanoparticle Filtration. ACS Appl. Mater. Interfaces 2017, 9, 30074–30082. [Google Scholar] [CrossRef]

- Tien, C.-Y.; Chen, J.-P.; Li, S.; Li, Z.; Zheng, Y.-M.; Peng, A.S.; Zhou, F.; Tsai, C.-J.; Chen, S.-C. Experimental and Theoretical Analysis of Loading Characteristics of Different Electret Media with Various Properties toward the Design of Ideal Depth Filtration for Nanoparticles and Fine Particles. Sep. Purif. Technol. 2020, 233, 116002. [Google Scholar] [CrossRef]

- Ardkapan, S.R.; Johnson, M.S.; Yazdi, S.; Afshari, A.; Bergsøe, N.C. Filtration Efficiency of an Electrostatic Fibrous Filter: Studying Filtration Dependency on Ultrafine Particle Exposure and Composition. J. Aerosol Sci. 2014, 72, 14–20. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Wang, D.; Zhang, Y.; Zhang, X.; Liu, J.; Zhao, Y.; Huang, C.; Jin, X. Polytetrafluoroethylene/Polyphenylene Sulfide Needle-Punched Triboelectric Air Filter for Efficient Particulate Matter Removal. ACS Appl. Mater. Interf. 2019, 11, 48437–48449. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Liu, W.; Jin, X. Needle-Punched Electret Air Filters (NEAFs) with High Filtration Efficiency, Low Filtration Resistance, and Superior Dust Holding Capacity. Sep. Purif. Technol. 2022, 282, 120146. [Google Scholar] [CrossRef]

- Kerner, M.; Schmidt, K.; Schumacher, S.; Asbach, C.; Antonyuk, S. Ageing of Electret Filter Media Due to Deposition of Submicron Particles – Experimental and Numerical Investigations. Sep. Purif. Technol. 2020, 251, 117299. [Google Scholar] [CrossRef]

- Kerner, M.; Schmidt, K.; Hellmann, A.; Schumacher, S.; Pitz, M.; Asbach, C.; Ripperger, S.; Antonyuk, S. Numerical and Experimental Study of Submicron Aerosol Deposition in Electret Microfiber Nonwovens. J. Aerosol. Sci. 2018, 122, 32–44. [Google Scholar] [CrossRef]

- Givehchi, R.; Li, Q.; Tan, Z. The Effect of Electrostatic Forces on Filtration Efficiency of Granular Filters. Powder Technol. 2015, 277, 135–140. [Google Scholar] [CrossRef]