An Attempt to Understand Stainless 316 Powders for Cold-Spray Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Cold-Spray Deposition

2.2. Characterization

3. Results

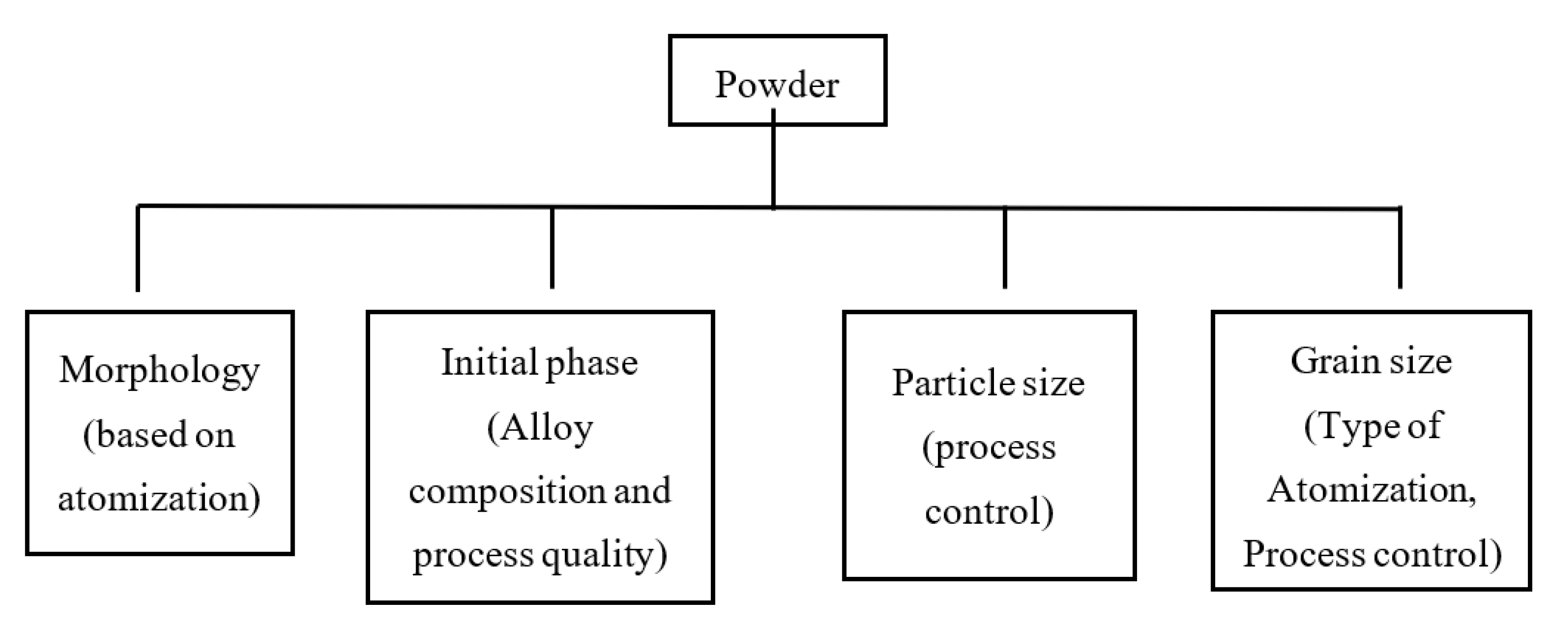

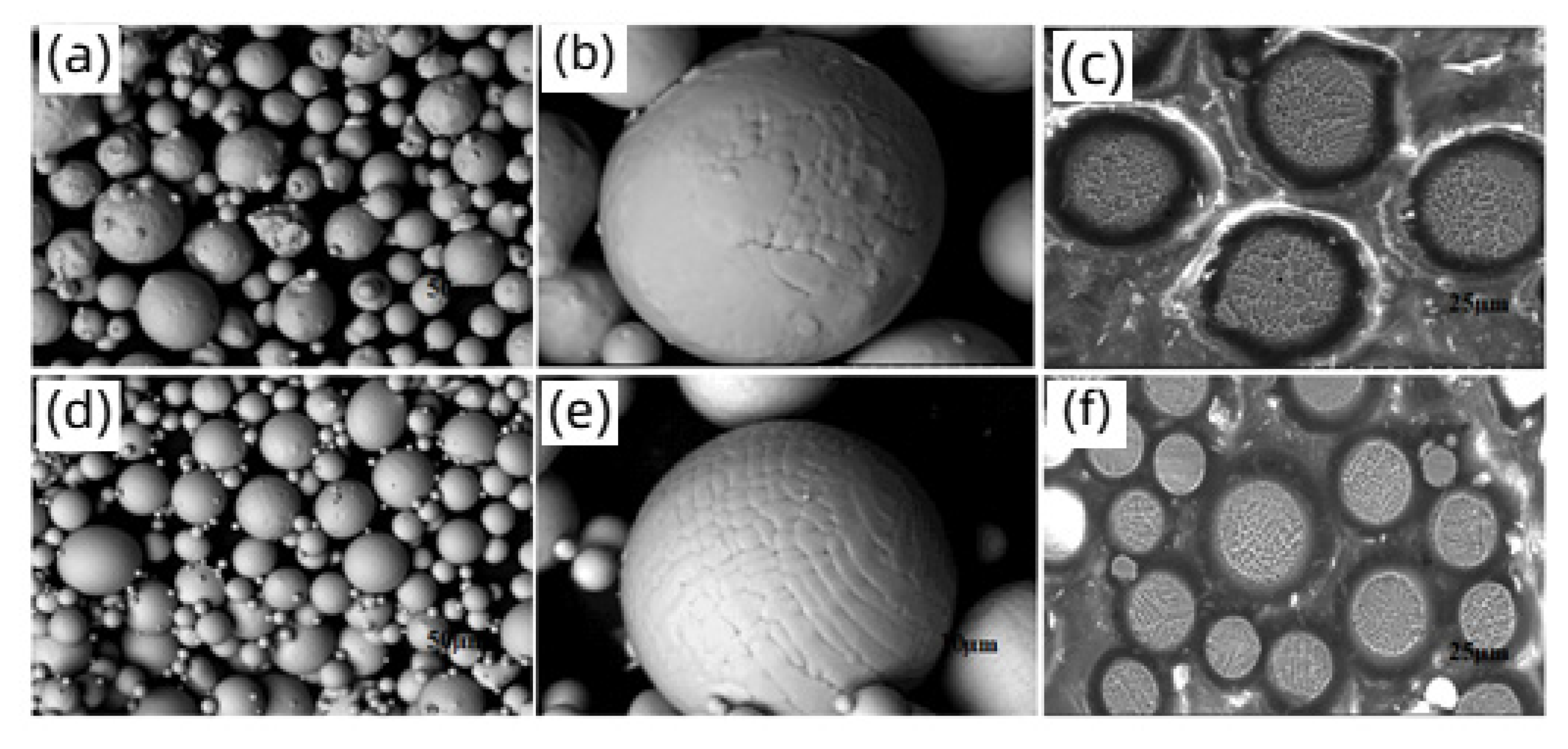

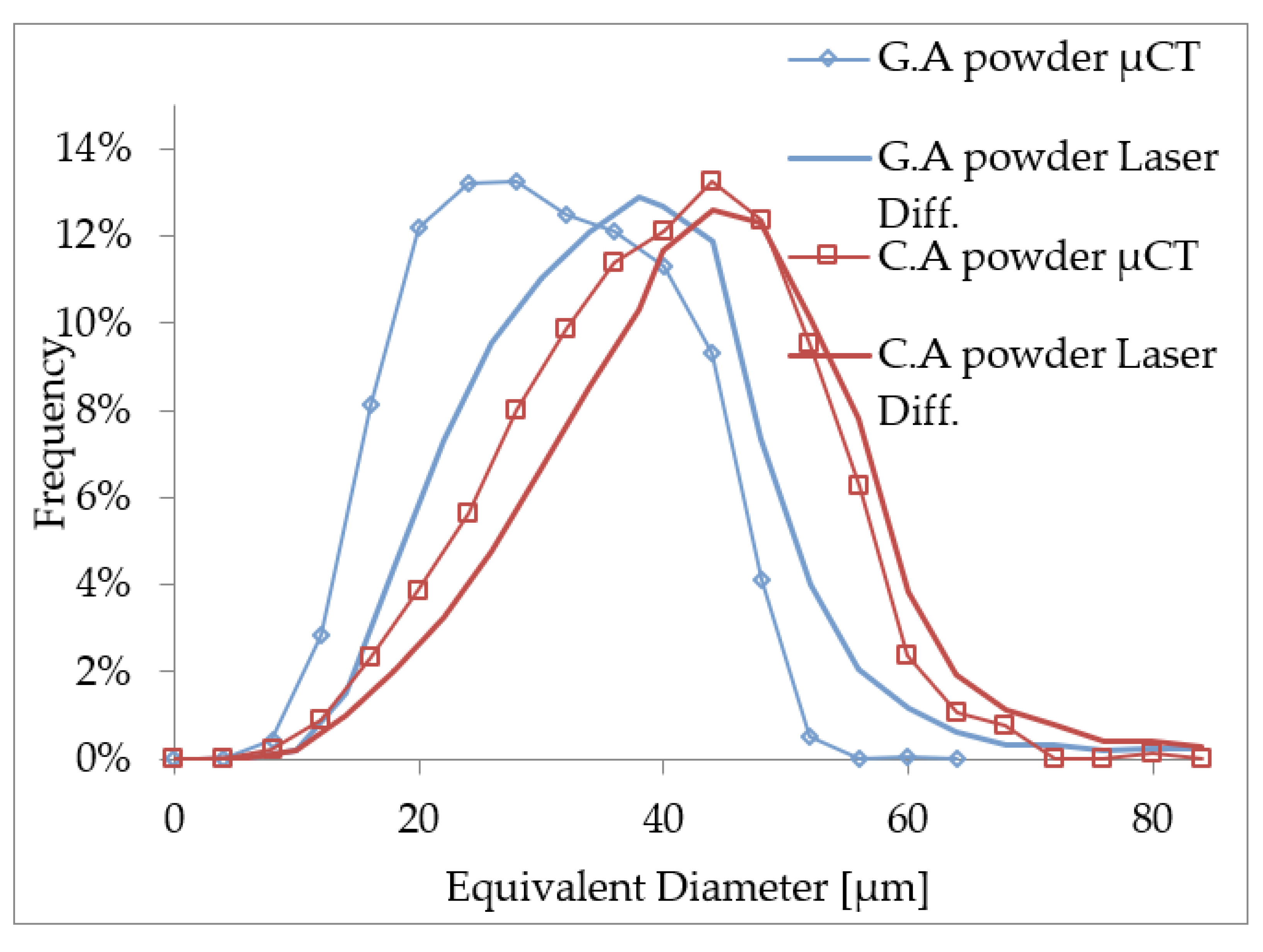

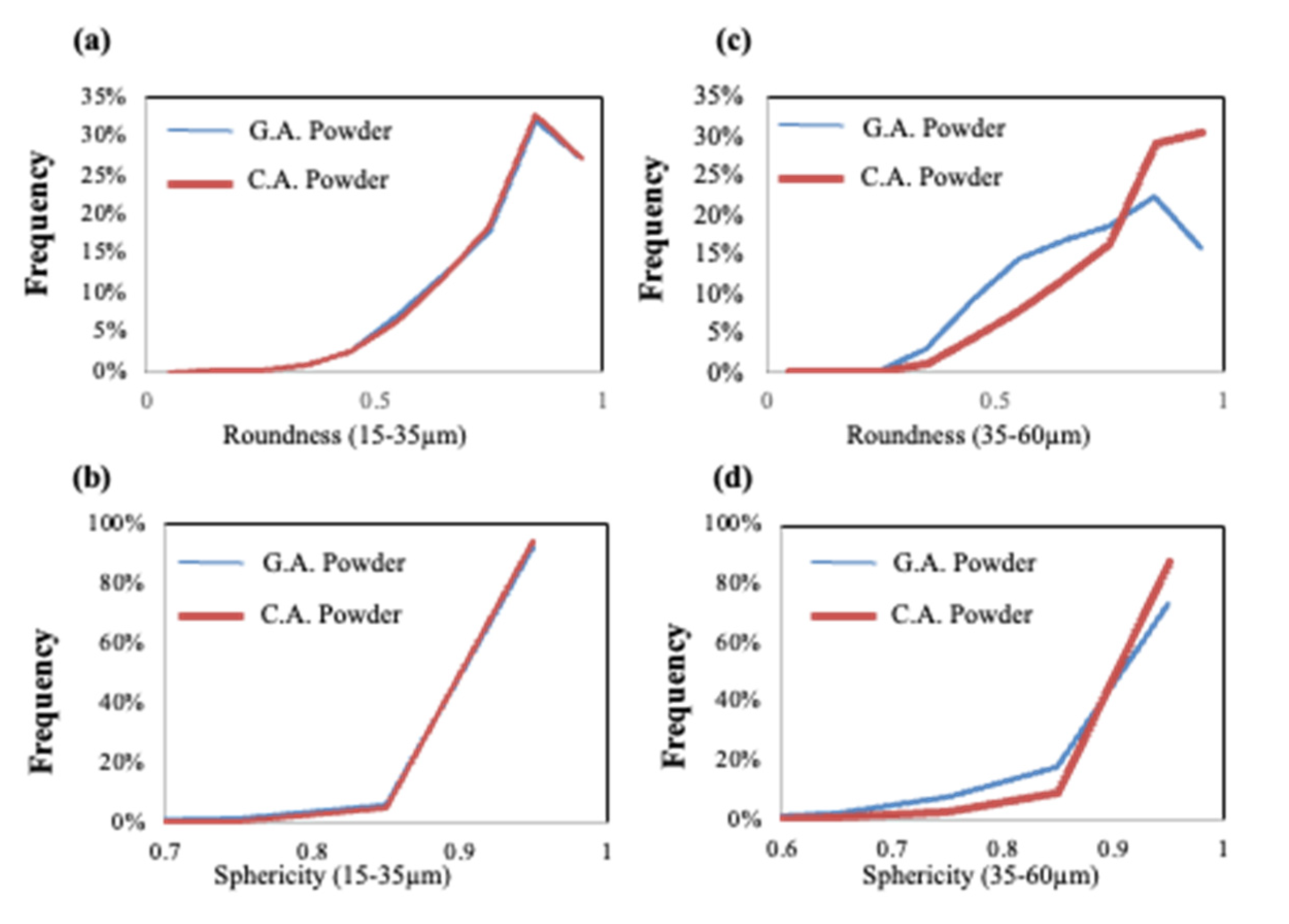

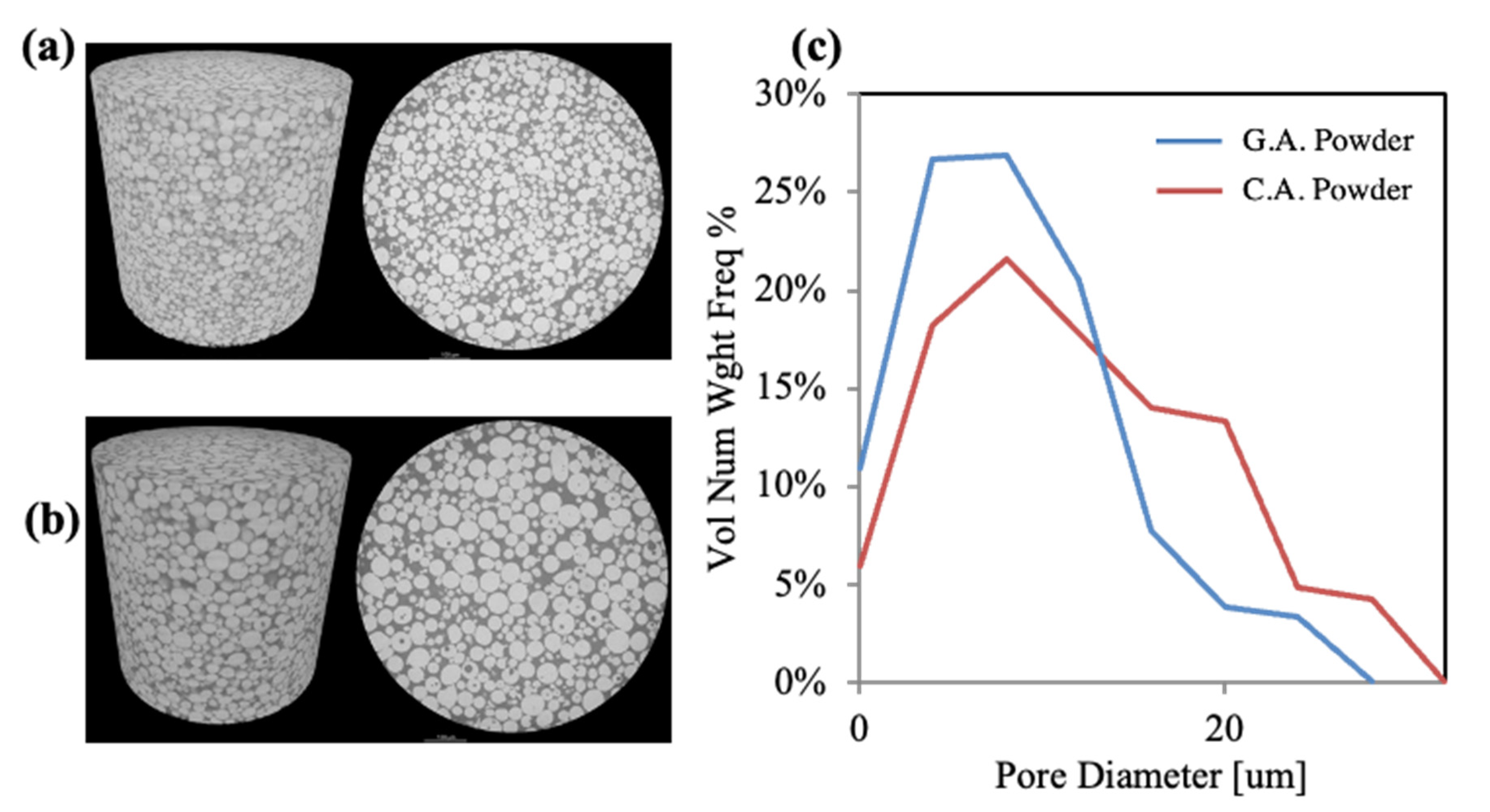

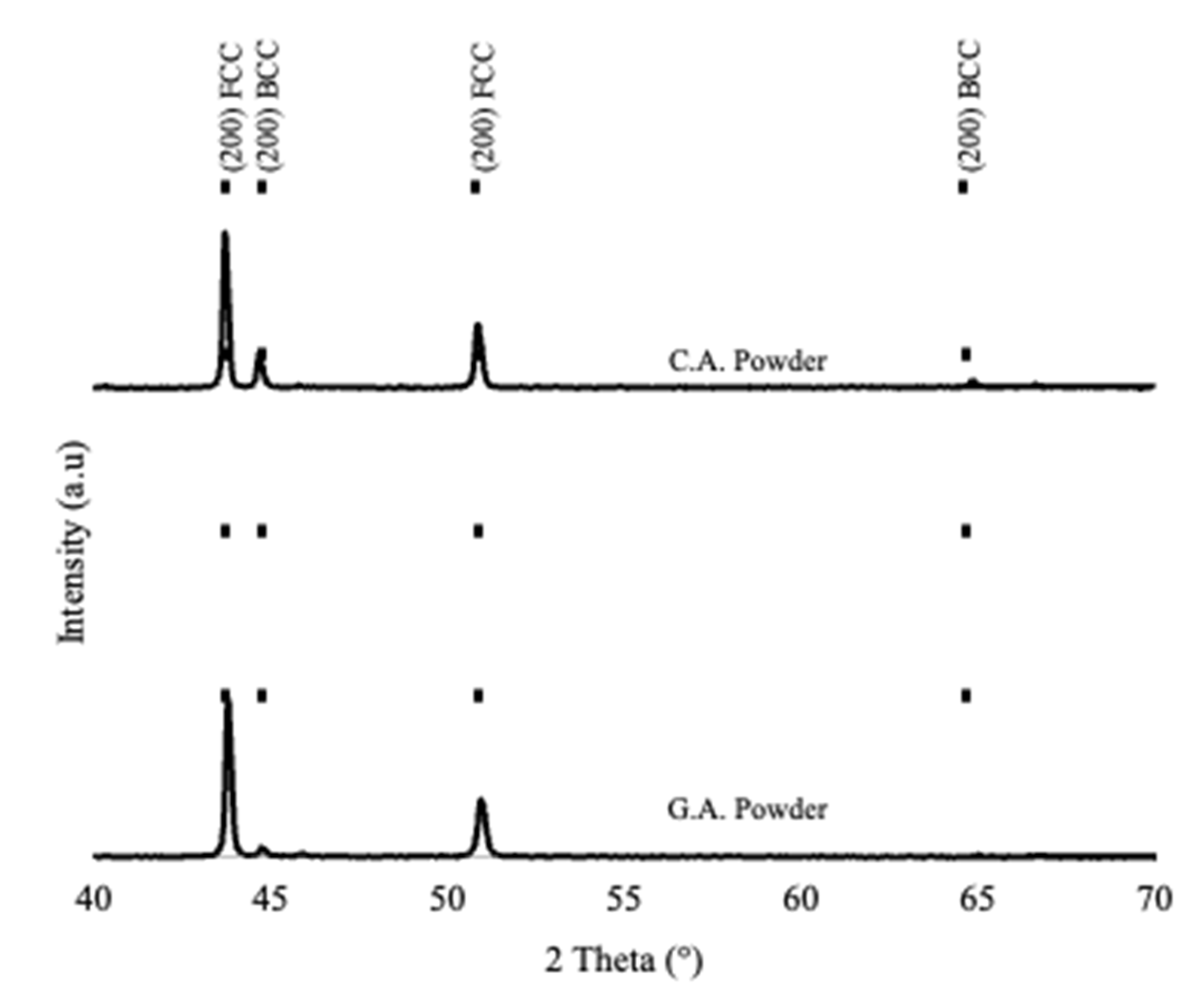

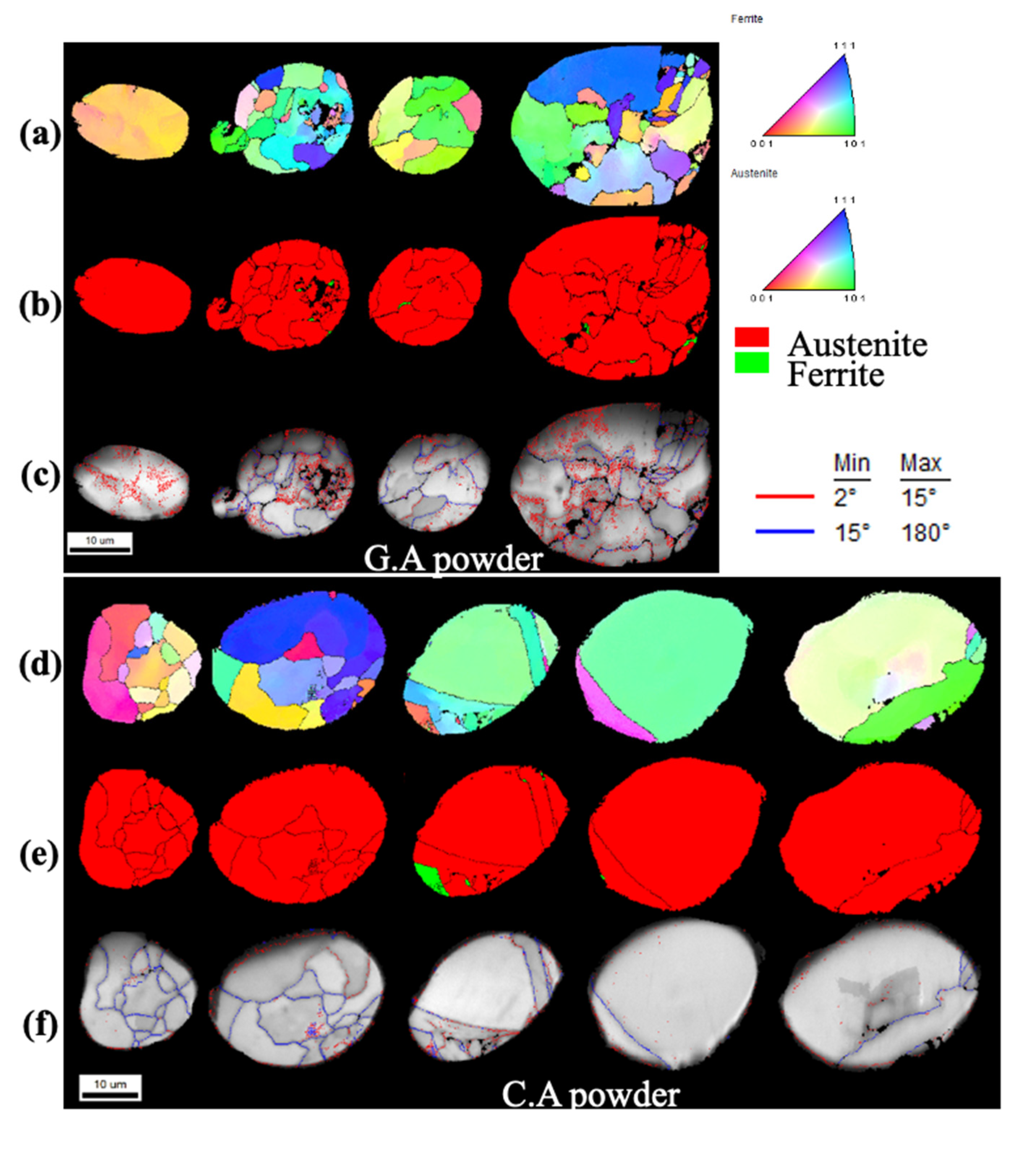

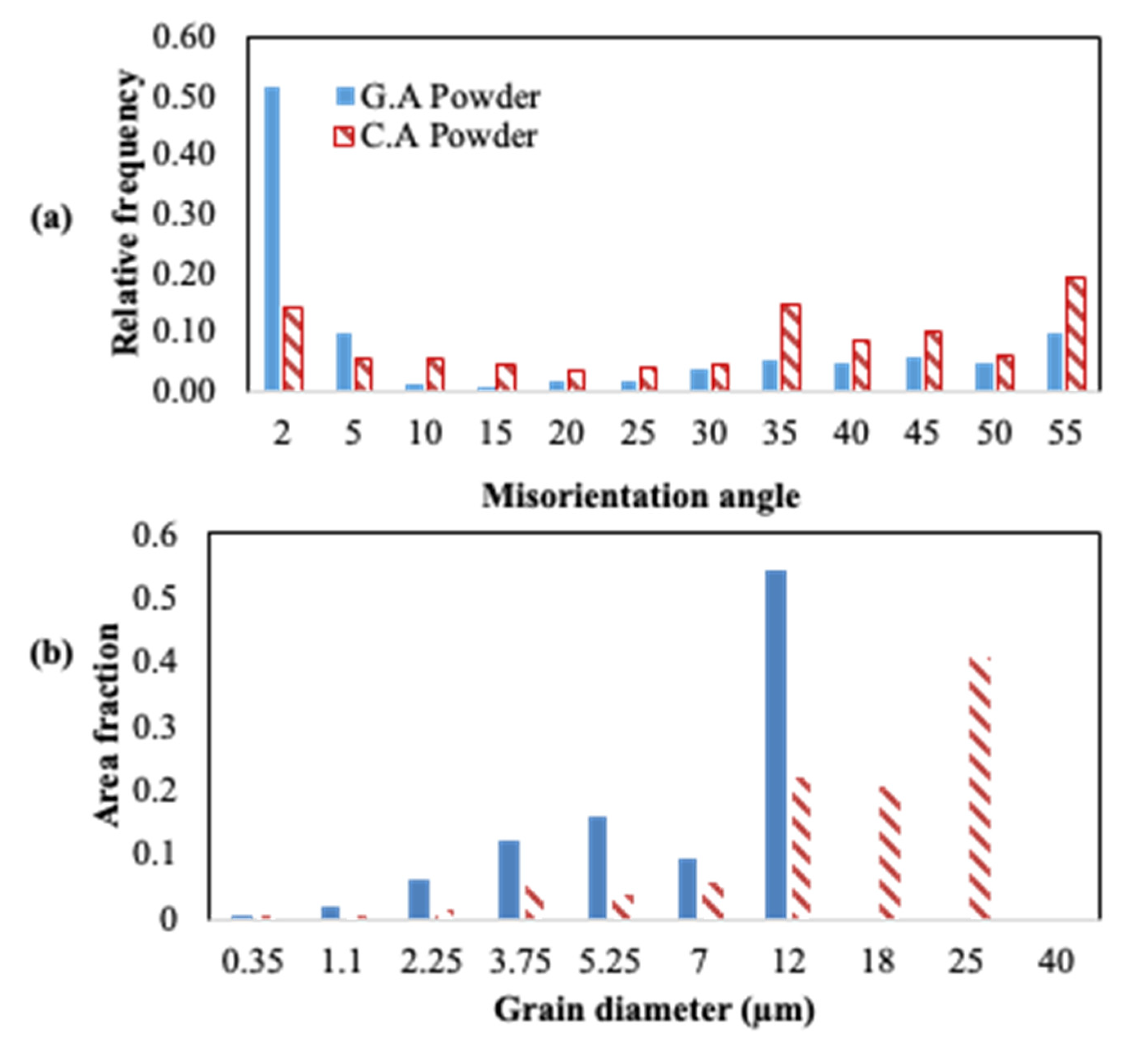

3.1. Powder Characterization

3.2. Coating Characterization

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Champagne, V.K. Introduction. In Practical Cold Spray; Champagne, V.K., Jr., Ozdemir, O.C., Nardi, A., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–25. ISBN 978-3-030-70056-0. [Google Scholar]

- Champagne, V.K.; Papyrin, A.; Smith, M.F.; Karthikeyan, J.; Celotto, S.; Pattison, J.; Ho, J.S.; Johnson, A.N.; O’Neill, W.; Brodmann, F.J.; et al. The Cold Spray Materials Deposition Process; Woodhead Publishing: Cambridge, UK, 2007. [Google Scholar]

- Papyrin, A.; Kosarev, V.; Klinkov, S.; Alkimov, A.; Fomin, V. Cold Spray Technoloigy; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Hassani-Gangaraj, M.; Veysset, D.; Champagne, V.K.; Nelson, K.A.; Schuh, C.A. Adiabatic Shear Instability Is Not Necessary for Adhesion in Cold Spray. Acta Mater. 2018, 158, 430–439. [Google Scholar] [CrossRef]

- Nikbakht, R.; Saadati, M.; Kim, T.-S.; Jahazi, M.; Kim, H.S.; Jodoin, B. Cold Spray Deposition Characteristic and Bonding of CrMnCoFeNi High Entropy Alloy. Surf. Coat. Technol. 2021, 425, 127748. [Google Scholar] [CrossRef]

- Hussain, T.; McCartney, D.G.; Shipway, P.H.; Zhang, D. Bonding Mechanisms in Cold Spraying: The Contributions of Metallurgical and Mechanical Components. J. Therm. Spray Technol. 2009, 18, 364–379. [Google Scholar] [CrossRef]

- Rahmati, S.; Ghaei, A. The Use of Particle/Substrate Material Models in Simulation of Cold-Gas Dynamic-Spray Process. J. Therm. Spray Technol. 2014, 23, 530–540. [Google Scholar] [CrossRef]

- Rahmati, S.; Veiga, R.G.A.; Zúñiga, A.; Jodoin, B. A Numerical Approach to Study the Oxide Layer Effect on Adhesion in Cold Spray. J. Therm. Spray Technol. 2021, 30, 1777–1791. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, Y. Investigation of Oxidation Behavior and Evolvement of Grain Morphology of Fe-Cr-AI Alloy at 1200 °C and 1300 °C. Proc. Int. Therm. Spray Conf. 2015, 2, 1060–1066. [Google Scholar]

- Li, C.-J.; Li, W.-Y.; Liao, H. Examination of the Critical Velocity for Deposition of Particles in Cold Spraying. J. Therm. Spray Technol. 2006, 15, 212–222. [Google Scholar] [CrossRef]

- Yin, S.; Cizek, J.; Yan, X.; Lupoi, R. Annealing Strategies for Enhancing Mechanical Properties of Additively Manufactured 316L Stainless Steel Deposited by Cold Spray. Surf. Coat. Technol. 2019, 370, 353–361. [Google Scholar] [CrossRef]

- Jodoin, B.; Ajdelsztajn, L.; Sansoucy, E.; Zúñiga, A.; Richer, P.; Lavernia, E.J.J. Effect of Particle Size, Morphology, and Hardness on Cold Gas Dynamic Sprayed Aluminum Alloy Coatings. Surf. Coat. Technol. 2006, 201, 3422–3429. [Google Scholar] [CrossRef]

- Spencer, K.; Zhang, M.-X. Optimisation of Stainless Steel Cold Spray Coatings Using Mixed Particle Size Distributions. Surf. Coat. Technol. 2011, 205, 5135–5140. [Google Scholar] [CrossRef]

- Birt, A.M.; Champagne, V.K.; Sisson, R.D.; Apelian, D. Microstructural Analysis of Ti-6Al-4V Powder for Cold Gas Dynamic Spray Applications. Adv. Powder Technol. 2015, 26, 1335–1347. [Google Scholar] [CrossRef]

- Bhattiprolu, V.S.; Johnson, K.W.; Crawford, G.A. Influence of Powder Microstructure on the Microstructural Evolution of As-Sprayed and Heat Treated Cold-Sprayed Ti-6Al-4V Coatings. J. Therm. Spray Technol. 2019, 28, 174–188. [Google Scholar] [CrossRef]

- Nastic, A.; MacDonald, D.; Jodoin, B. The Influence of Feedstock Powder; Springer Nature: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Brewer, L.N.; Schiel, J.F.; Menon, E.S.K.; Woo, D.J. The Connections between Powder Variability and Coating Microstructures for Cold Spray Deposition of Austenitic Stainless Steel. Surf. Coat. Technol. 2018, 334, 50–60. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F. Particle Compression Test: A Key Step towards Tailoring of Feedstock Powder for Cold Spraying. Coatings 2020, 10, 458. [Google Scholar] [CrossRef]

- Hussain, T.; Yue, S.; Li, C.J. Characteristics of Feedstock Materials. In Modern Cold Spray: Materials, Process, and Applications; Springer: Cham, Switzerland, 2015; ISBN 9783319167725. [Google Scholar]

- Han, T.; Zhao, Z.; Gillispie, B.A.; Smith, J.R. Effects of Spray Conditions on Coating Formation by the Kinetic Spray Process. J. Therm. Spray Technol. 2005, 14, 373–383. [Google Scholar] [CrossRef]

- Jeandin, M.; Rolland, G.; Descurninges, L.L.; Berger, M.H. Which Powders for Cold Spray? Surf. Eng. 2014, 30, 291–298. [Google Scholar] [CrossRef]

- Varadaraajan, V.; Mohanty, P. Design and Optimization of Rectangular Cold Spray Nozzle: Radial Injection Angle, Expansion Ratio and Traverse Speed. Surf. Coat. Technol. 2017, 316, 246–254. [Google Scholar] [CrossRef]

- Chu, X.; Che, H.; Vo, P.; Chakrabarty, R.; Sun, B.; Song, J.; Yue, S. Understanding the Cold Spray Deposition Efficiencies of 316L/Fe Mixed Powders by Performing Splat Tests onto as-Polished Coatings. Surf. Coat. Technol. 2017, 324, 353–360. [Google Scholar] [CrossRef]

- Varadaraajan, V. Coaxial Laser Assisted Cold Spray Technology. In Proceedings of the International Thermal Spray Conference and Exposition (ITSC), Long Beach, CA, USA, 11–14 May 2015. [Google Scholar]

- Fukanuma, H.; Ohno, N.; Sun, B.; Huang, R. 1830 A Study of Stainless Steel Deposits Sprayed by Cold Spray Process. Proc. JSME Annu. Meet. 2005, 2005, 257–258. [Google Scholar] [CrossRef]

- Erwin Industries Centrifugal Atomization Technology. Available online: https://ervinindustries.com/ (accessed on 2 January 2023).

- Valls Anglés ISAAC Centrifugal Atomization of Iron-Based Alloys 2019. Available online: https://patents.google.com/patent/WO2015110668A3/en (accessed on 2 January 2023).

- Totten, G.E. Handbook of Residual Stress and Deformation of Steel; ASM International: Almere, The Netherlands, 2002; ISBN 1615032274. [Google Scholar]

- Allmann, R.; Hinek, R. The Introduction of Structure Types into the Inorganic Crystal Structure Database ICSD. Acta Cryst. A 2007, 63, 412–417. [Google Scholar] [CrossRef]

- Sousa, B.C.; Gleason, M.A.; Haddad, B.; Champagne, V.K.; Nardi, A.T.; Cote, D.L. Nanomechanical Characterization for Cold Spray: From Feedstock to Consolidated Material Properties. Metals 2020, 10, 1195. [Google Scholar] [CrossRef]

- ASTM Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings 2021. Available online: https://www.astm.org/c0633-13r21.html (accessed on 2 January 2023).

- Wu, K.; Liu, G.; Hu, B.; Li, F.; Zhang, Y.; Tao, Y.; Liu, J. Solidification Characterization of a New Rapidly Solidified Ni–Cr–Co Based Superalloy. Mater. Charact. 2012, 73, 68–76. [Google Scholar] [CrossRef]

- Leicht, A. Aspects of Building Geometry and Powder Characteristics in Powder Bed Fusion, Gothenburg. 2018. Available online: https://research.chalmers.se/en/publication/500036 (accessed on 2 January 2023).

- Borchers, C.; Schmidt, T.; Gärtner, F.; Kreye, H. High Strain Rate Deformation Microstructures of Stainless Steel 316L by Cold Spraying and Explosive Powder Compaction. Appl. Phys. A 2008, 90, 517–526. [Google Scholar] [CrossRef]

- Rokni, M.R.; Nutt, S.R.; Widener, C.A.; Champagne, V.K.; Hrabe, R.H. Review of Relationship Between Particle Deformation, Coating Microstructure, and Properties in High-Pressure Cold Spray. J. Therm. Spray Technol. 2017, 26, 1308–1355. [Google Scholar] [CrossRef]

- Das, A.; Sunil, S.; Kapoor, R. Effect of Cooling Rate on the Microstructure of a Pressure Vessel Steel. Metallogr. Microstruct. Anal. 2019, 8, 795–805. [Google Scholar] [CrossRef]

- Dikici Burak; Topuz Mehmet Cold Spray Deposition of SS316L Powders on Al5052 Substrates and Their Potential Using for Biomedical Applications. Int. J. Mater. Metall. Eng. 2016, 10. [CrossRef]

- Adachi, S.; Ueda, N. Effect of Cold-Spray Conditions Using a Nitrogen Propellant Gas on AISI 316L Stainless Steel-Coating Microstructures. Coatings 2017, 7, 87. [Google Scholar] [CrossRef]

- Spencer, K.; Fabijanic, D.M.; Zhang, M.-X. The Influence of Al2O3 Reinforcement on the Properties of Stainless Steel Cold Spray Coatings. Surf. Coat. Technol. 2012, 206, 3275–3282. [Google Scholar] [CrossRef]

- Coddet, P.; Verdy, C.; Coddet, C.; Debray, F.; Lecouturier, F. Mechanical Properties of Thick 304L Stainless Steel Deposits Processed by He Cold Spray. Surf. Coat. Technol. 2015, 277, 74–80. [Google Scholar] [CrossRef]

- Kotoban, D.; Grigoriev, S.; Okunkova, A.; Sova, A. Influence of a Shape of Single Track on Deposition Efficiency of 316L Stainless Steel Powder in Cold Spray. Surf. Coat. Technol. 2017, 309, 951–958. [Google Scholar] [CrossRef]

- Roa, J.J.; Fargas, G.; Mateo, A.; Jiménez-Piqué, E. Dependence of Nanoindentation Hardness with Crystallographic Orientation of Austenite Grains in Metastable Stainless Steels. Mater. Sci. Eng. A 2015, 645, 188–195. [Google Scholar] [CrossRef]

- Dosta, S.; Bolelli, G.; Candeli, A.; Lusvarghi, L.; Cano, I.G.; Guilemany, J.M. Plastic Deformation Phenomena during Cold Spray Impact of WC-Co Particles onto Metal Substrates. Acta Mater. 2017, 124, 173–181. [Google Scholar] [CrossRef]

- Grujicic, M.; Saylor, J.R.; Beasley, D.E.; DeRosset, W.S.; Helfritch, D. Computational Analysis of the Interfacial Bonding between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process. Appl. Surf. Sci. 2003, 219, 211–227. [Google Scholar] [CrossRef]

- Moridi, A. Powder Consolidation Using Cold Spray; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-29961-7. [Google Scholar]

- Jenkins, R.; Snyder, R.L. Introduction to X-ray Powder Diffractometry; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1996; ISBN 9781118520994. [Google Scholar]

- Lima, R.S.; Karthikeyan, J.; Kay, C.M.; Lindemann, J.; Berndt, C.C. Microstructural Characteristics of Cold-Sprayed Nanostructured WC–Co Coatings. Thin Solid Film. 2002, 416, 129–135. [Google Scholar] [CrossRef]

- Dabney, T.; Johnson, G.; Yeom, H.; Maier, B.; Walters, J.; Sridharan, K. Experimental Evaluation of Cold Spray FeCrAl Alloys Coated Zirconium-Alloy for Potential Accident Tolerant Fuel Cladding. Nucl. Mater. Energy 2019, 21, 100715. [Google Scholar] [CrossRef]

- SFC Koenig Hardness Conversion Table. Available online: http://www.sfckoenig.com/wp-content/uploads/2018/08/hardness-conversion-table_EN.pdf (accessed on 6 December 2021).

- Barnes, J.; Champagne, V.; Ballard, D.; Eden, T.J.; Shoffner, B.; Potter, J.K.; Wolfe, D.E. Mechanical and Microstructural Effects of Cold Spray Aluminum on Al 7075 Using Kinetic Metallization and Cold Spray Processes. 2007. Available online: https://apps.dtic.mil/sti/citations/ADA470138 (accessed on 3 January 2023).

- Jing, Z.; Dejun, K. Effect of Laser Remelting on Friction-Wear Behaviors of Cold Sprayed Al Coatings in 3.5% NaCl Solution. Materials 2018, 11, 283. [Google Scholar] [CrossRef]

- Varadaraajan, V.; Mohanty, P.S. Role of Precursor Properties in Cold Spray Coating Process. In Proceedings of the International Thermal Spray Conference and Exposition (ITSC), Long Beach, CA, USA, 11–14 May 2015. [Google Scholar]

- Solomon, S. Additive Manufacturing Technology–3D Printing & Design–The 4th Industrial Revolution: 3D Printing & Design; Independently Published: Chicago, IL, USA, 2020; Volume 1. [Google Scholar]

- Suresh, S.; Lee, S.-W.; Aindow, M.; Brody, H.D.; Champagne, V.K.; Dongare, A.M. Mesoscale Modeling of Jet Initiation Behavior and Microstructural Evolution during Cold Spray Single Particle Impact. Acta Mater. 2020, 182, 197–206. [Google Scholar] [CrossRef]

- Guha, R.D.; Sharma, A.J.; Diwan, P.; Khanikar, P. Effect of Grain Orientation on High Strain-Rate Plastic Deformation. Procedia Eng. 2017, 173, 1048–1055. [Google Scholar] [CrossRef]

- Nguyen, T.; Luscher, D.J.; Wilkerson, J.W. The Role of Elastic and Plastic Anisotropy in Intergranular Spall Failure. Acta Mater. 2019, 168, 1–12. [Google Scholar] [CrossRef]

- Tam, J.; Li, W.; Yu, B.; Poirier, D.; Legoux, J.-G.; Lin, P.; Palumbo, G.; Giallonardo, J.D.; Erb, U. Reducing Complex Microstructural Heterogeneity in Electrodeposited and Cold Sprayed Copper Coating Junctions. Surf. Coat. Technol. 2020, 404, 126479. [Google Scholar] [CrossRef]

| Composition | Fe | Cr | Ni | Mn | C | Mo | Si | P | O | N |

|---|---|---|---|---|---|---|---|---|---|---|

| G.A powder | Bal | 16.9 | 11.59 | 0.46 | 0.02 | 2.39 | 0.7 | 0.04 | 0.03 | 0.01 |

| C.A powder | Bal | 17 | 11.5 | 1.35 | 0.03 | 2.16 | 0.87 | 0.037 | 0.04 | 0.0588 |

| (a) | Temperature (°C) | Pressure (MPa/psi) | Standoff (mm) | Carrier Gas (MPa/psi) | Powder Flow(g/min) |

|---|---|---|---|---|---|

| 600 | 3.447/500 | 10 | 0.47/68 | 20 | |

| (b) | Powder | Layers to achieve ~1.3 mm coating thickness | Deposition time | Deposition Efficiency (%) | |

| G.A | 4 | 32 min 28 s | 70.26 ± 0.3 | ||

| C.A | 6 | 48 min 52 s | 41.33 ± 0.92 | ||

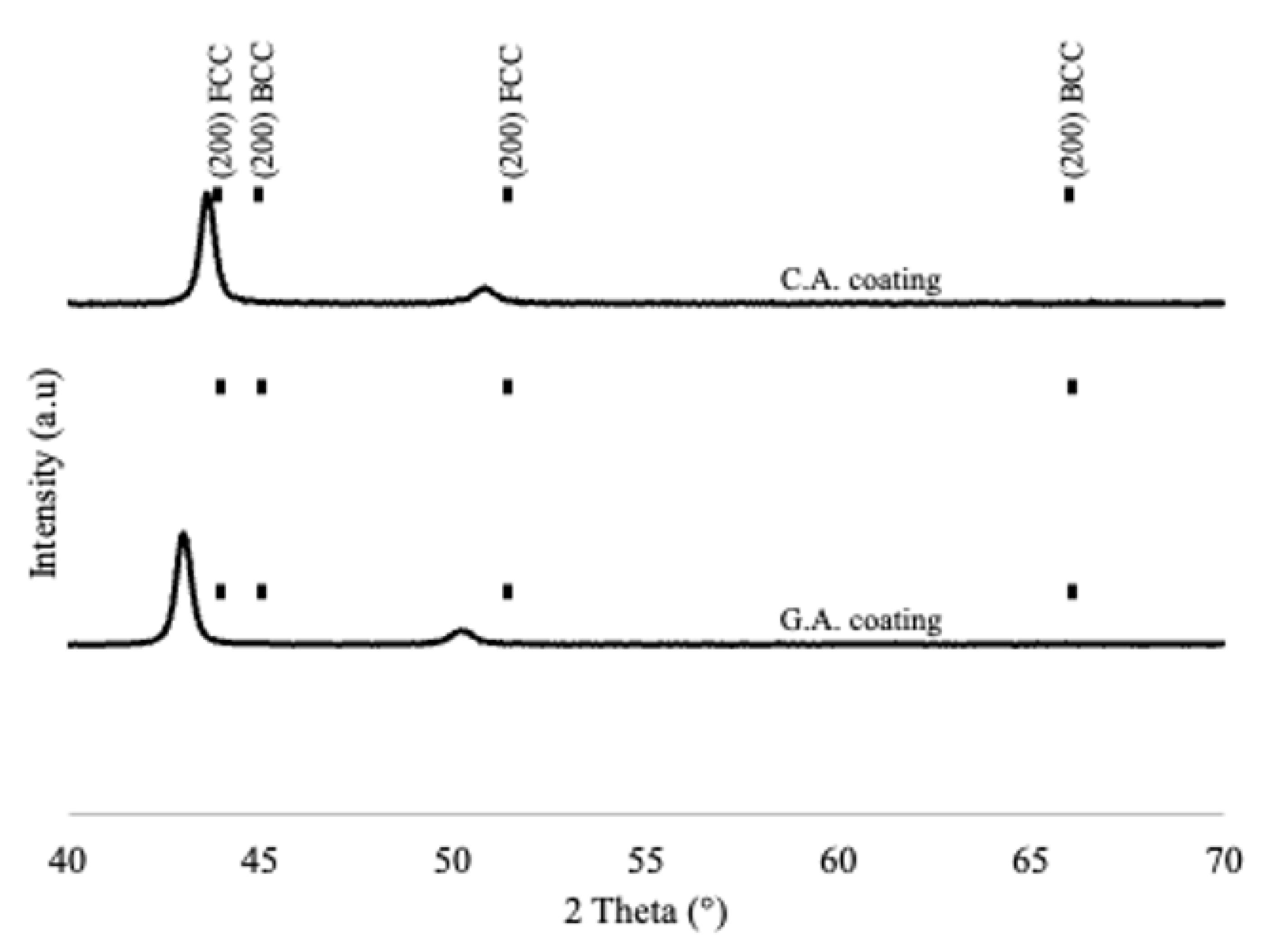

| Phase | a (Å) | b (Å) | c (Å) | α | β | γ | Crystal System | Space Group | ICSD # |

|---|---|---|---|---|---|---|---|---|---|

| Austenite | 3.66 | 3.66 | 3.66 | 90° | 90° | 90° | Cubic | Fm-3 m (225) | 631733 |

| Ferrite | 2.87 | 2.87 | 2.87 | 90° | 90° | 90° | Cubic | Im-3 m (229) | 180969 |

| Powder | D10 (µm) | D50 (µm) | D90 (µm) | Hall Flow (s) | Apparent Density (g/cm3) |

|---|---|---|---|---|---|

| G.A | 20 | 31 | 46.9 | 16 | 4.10 |

| C.A | 18.4 | 30.4 | 48.4 | 13 | 4.29 |

| Crystallite Size (nm) Powder | Crystallite Size (nm) Coating | |

|---|---|---|

| G.A | 50.39 | 16.36 |

| C.A | 61.78 | 18.30 |

| Powder | Micro Hardness (Vickers 10 gF) | Nano Hardness (GPa) | Stiffness (µN/nm) |

|---|---|---|---|

| G.A | 273.14 ± 23.39 | 2.65 ± 0.12 | 215.9 ± 16.1 |

| C.A | 279.4 ± 14.54 | 2.87 ± 0.11 | 248.88 ± 14.08 |

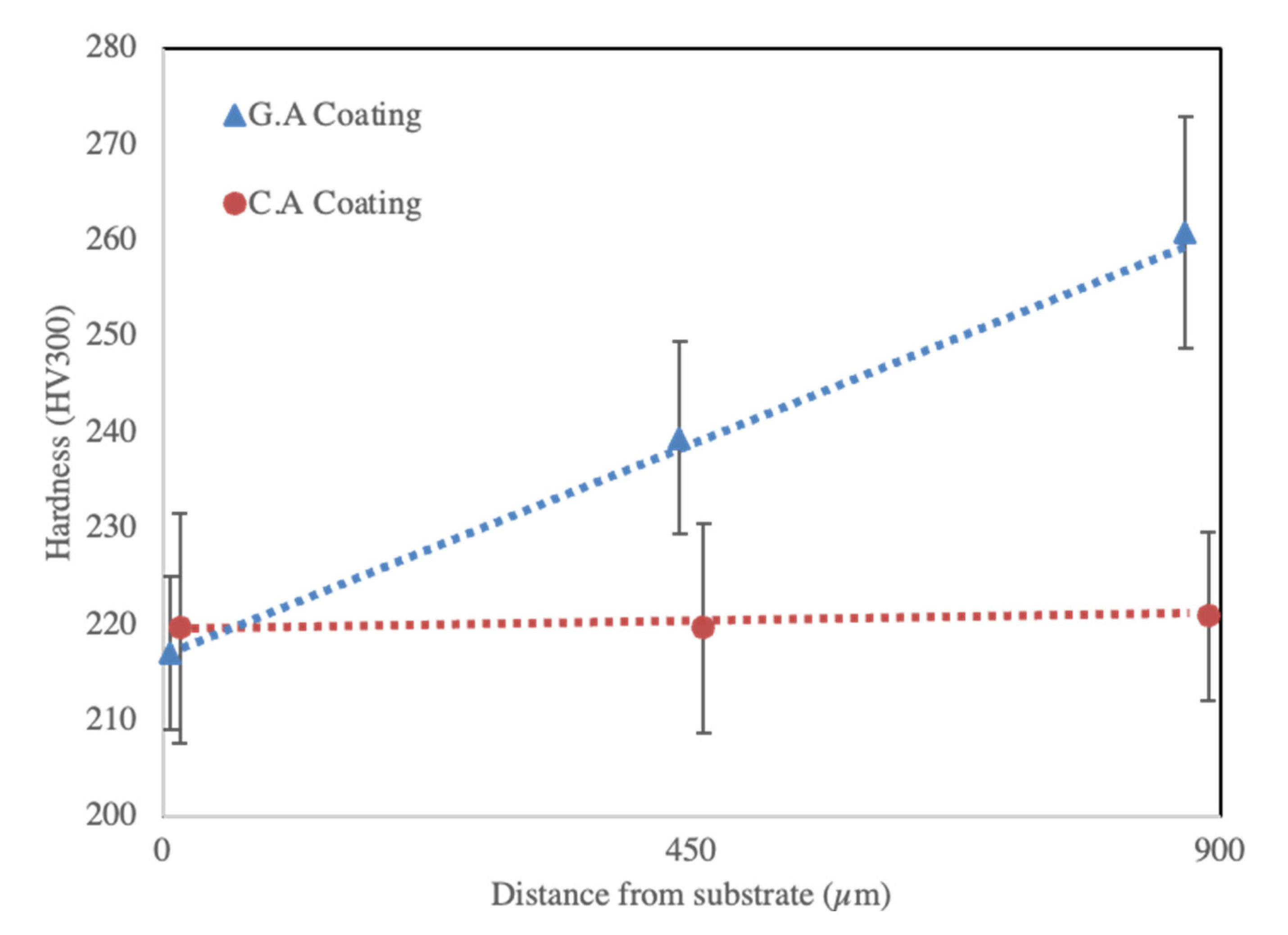

| Bond Strength (MPa) | |

|---|---|

| G.A Coating | 68.125 ± 1.10 |

| C.A Coating | 47.5 ± 0.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karmarkar, N.S.; Varadaraajan, V.V.; Mohanty, P.S.; Nagendiran, S.K. An Attempt to Understand Stainless 316 Powders for Cold-Spray Deposition. Powders 2023, 2, 151-168. https://doi.org/10.3390/powders2010011

Karmarkar NS, Varadaraajan VV, Mohanty PS, Nagendiran SK. An Attempt to Understand Stainless 316 Powders for Cold-Spray Deposition. Powders. 2023; 2(1):151-168. https://doi.org/10.3390/powders2010011

Chicago/Turabian StyleKarmarkar, Neeraj S., Vikram V. Varadaraajan, Pravansu S. Mohanty, and Sharan Kumar Nagendiran. 2023. "An Attempt to Understand Stainless 316 Powders for Cold-Spray Deposition" Powders 2, no. 1: 151-168. https://doi.org/10.3390/powders2010011

APA StyleKarmarkar, N. S., Varadaraajan, V. V., Mohanty, P. S., & Nagendiran, S. K. (2023). An Attempt to Understand Stainless 316 Powders for Cold-Spray Deposition. Powders, 2(1), 151-168. https://doi.org/10.3390/powders2010011