Abstract

This paper investigates a current challenge that enables the hybridization of different materials using a solid-state additive principle. We investigate the suitability of such a principle to easily and efficiently grow a metallic electrically conductive coating on a polymer substrate. The additive principle is obtained using the high-pressure cold spraying (CS) method whose literature does not include an achievement as suggested in this paper, that is, to obtain a good conductive copper coating onto polymer with a very high deposition efficiency by tuning the effect of the stand-off distance, transverse speed of the nozzle, and temperature of the carrier gas on the deposition efficiency (DE) in order to overcome delamination and erosion, and thus to improve the DE. A good coating formation up to 400 µm can be obtained, which implies that a standoff distance higher than 100 mm is needed, since both a high gas temperature (400–500 °C) and high gas pressure (30 bars) are required. A nozzle scanning velocity in the range of 200–300 mm/s gives the highest DE. The results reveal that the Cu coating on PEEK reaches a DE up to 91%, leading to an electrical conductivity up to 60% IACS (International Annealed Copper Standard). Thus, parametric analysis, along with the deposition optimization, promises to be feasible for the future in terms of DE improvement along with a good electrical conductivity in CS.

1. Introduction

Cold gas dynamic spraying [1,2,3,4,5] is a process of spraying metals, ceramics, and polymers in a powder form, where a gas acts as a carrier (typically air, nitrogen, and helium) that accelerates at supersonic velocities thanks to a De Laval nozzle, which in turn accelerates the powders up to supersonic speeds. The bonding occurs once the powder particles reach a critical velocity [6,7,8] upon impact against a surface, where they deform and bond onto it [9]. Since there is a relatively low temperature during the spraying on the substrate, oxidation and substrate heat confinement damage are minimized. Because of the above-mentioned fact, this process has been named as a cold spray process and can be considered as an ideal metallizing technique to fabricate electrically conductive coatings onto polymers.

The cold spray process is receiving worldwide attention due to its numerous benefits and applications on various engineering domains [1,2,3,4,5]. Recent studies related to the metallization of polymers via cold spraying have gained attention due to the low operating temperature, simple principles of operation, and great potential to functionalize polymers [10,11,12,13,14,15,16,17]. The literature of cold spraying encompasses a relevant proof of concept that includes cold sprayed metallic coatings such as aluminum, zinc, and tin on CFRP, carbon/epoxy polymer matrix composites, blend polycarbonates, ABS, polyamide-6, polystyrene, and organic composites reinforced using glass fibres [18,19,20,21,22,23,24]. However, there is a typical issue due to the metallization on polymers by means of the principle of high-speed collision generated by the cold spray method, namely, the coating formation suffers from erosion and/or delamination [14,16,25].

In this paper, we investigate the capability of tuning cold spraying parameters along with operating conditions to achieve a high DE and examine the best electrical conductivity coatings on PEEK. PEEK can be used for diverse applications, including bearings, piston parts, base plates for a conductive coating, or medical orthopedic implants, using the benefits of surface metallic functionalization [1,4]. Previous studies have confirmed the formation of an intermediate layer which weakness the coatings and eventually results in delamination due to spalling [14,16,25,26]. To overcome this main issue, parametric analysis is essential with the CS parameters. The spraying parameters and operating parameters vary in terms of the optimum conditions according to the coating behaviors. From all of them, electrical conductivity is analyzed and compared to the data available in the literature of cold spraying, which mostly suggest the use of low-pressure cold spraying as a suitable CS metallization for polymer substrates.

2. High Pressure Cold Spray Metallization Conditions

2.1. Cold Spray Deposition Data

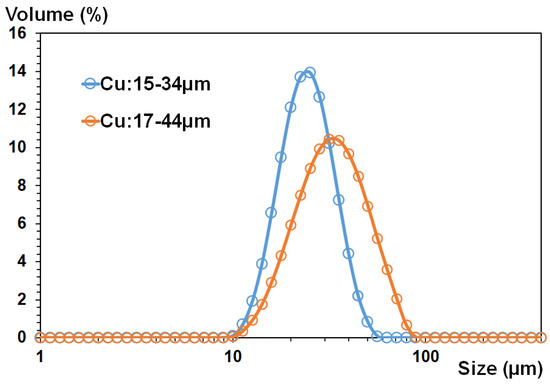

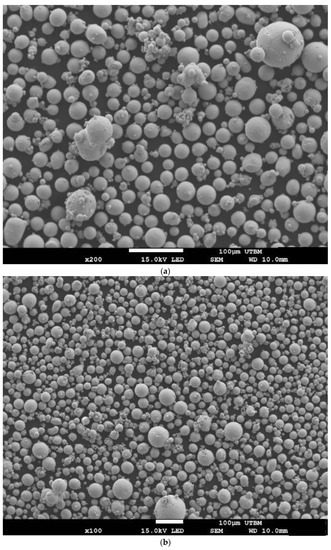

The polymer material (PEEK- polyether ether ketone) used for this study was obtained from RS-PRO, Germany. Sheets of low-density PEEK measuring 5 mm thick were cut into roughly 50 × 50 mm square sections and cleaned with ethanol before spraying. The PEEK polymer is a high performance semi-crystalline thermoplastic that has a high melting point (Tm = 342 °C) and a modulus of elasticity of 4200 MPa (DIN EN ISO 178). It offers excellent rigidity and retains high strength. The powder feedstock consists of spherical copper powders generated in-house (ICB-LERMPS). The copper powder was 99.95% pure by atomic weight and was produced by gas atomization, giving a more regular and spherical shape. Two granulometries, 20–40 µm as large and 15–30 µm as fine, have been used out to optimize the DE. The size distributions were obtained by dry laser measurements using a Malvern Mastersizer 2000 particle size analyzer (Figure 1) and scanning electron microscopy (FESEM JEOL 7800F, FEOL, Japan), and images of the particles are presented in Figure 2.

Figure 1.

Size distributions of the Cu powders: 17–44 µm powders, and 15–33 µm powders.

Figure 2.

Surface morphologies of the Cu powders: 17–44 µm powders (a) and 15–33 µm powders (b).

The high-pressure coating spraying tests were realized using a commercial CS system (Kinetic 3000), implemented at the ICB-LERMPS laboratory. It consisted of a robot ABB with a CS nozzle (MOC 24) that was capable of maneuvering in six axes. Heated and pressurized air was used as the carrier gas, which was drawn from an external compressor that could boost the gas pressure up to 34 bar. The powder feeder was a high-pressure feeding system which was axially connected to the inlet of the nozzle. The nozzle presents a convergent–divergent section with a throat diameter of 2.7 mm and an exit diameter of 6.4 mm. The convergent part had a length of 40 mm, and the divergent part was 119 mm long. To evaluate the optimum parameters to achieve the maximum DE, the temperature of the gas, the velocity of the nozzle (nozzle scan speed) and the standoff distance (SoD) varied. The propellant gas at the nozzle inlet had a pressure of 30 bar. Different propelling gas temperatures (200 °C, 300 °C, 400 °C, and 500 °C) were used to investigate the influence on the metallic coating formation on the PEEK substrate. The standoff distance in between the nozzle exhaust and the substrate was set in between 105–135 mm. The nozzle transverse speeds for depositions of tracks and passes were set from the range of 100–500 mm/s. The incremental displacement (denoted IncD) of the nozzle between two successive tracks is 3 mm until the nozzle completely covers the surface to coat, that gives a cycle or a pass. After completing one set of this cycle, the spraying was repeated over the previous deposited layer, with up to five passes as the maximum pass number.

2.2. Deposition Efficiency Assessment

To evaluate the DE using the spraying strategy, a classical approach has been adopted. DE is defined as the ratio of the weight change of the substrate to the overall weight of powders sprayed out during the time when the gun is in front of the sample. Thanks to the theoretical equation for measuring the mass of particles being sprayed while the nozzle is in front of the substrate is adopted [26], the number of passages of the nozzle in front of the substrate is considered for measuring the DE (2). The theoretical equation for calculating the mass of the particles reaching in front of the substrate is defined as follows:

where Msprayed is the theoretical mass of particle arriving in front of substrate when the nozzle is moving. P is the number of passages of the nozzle in front of the substrate. Mp is the mass flow rate of the particles (g/min). W is the width of the substrate (mm). Vn is the nozzle transverse velocity (mm/s). Then, using this mass of sprayed powder, the DE is assessed as follows:

where Mcoating is the mass of the coating defined as the mass difference in between the mass of the coated substrate and the uncoated substrate.

2.3. Coating Characterization Equipments

To characterize the coating features, a scanning electron microscope (FESEM JEOL 7800F, FEOL, Japan) was used. Top views of cross sections were gathered to perform a global analysis of the coated samples. Coating porosity was evaluated using the image analysis software ImageJ (NIH, Bethesda, Md.) on ten images. The electrical conductivity of the Cu coatings deposited on PEEK substrates was measured using an eddy current tester from Verimet M4900C (Verimation Technology Inc., USA), based on the ASM standard E1004–91.

3. Results and Discussions

3.1. Empirical Approach for Optimizing the Cu Coating Growth onto PEEK

The critical parameters for an efficient CS coating elaboration are the gas parameters, the powder granulometry, and the optimal operating process parameters at the nozzle exit. These parameters, which strongly affect the DE and the coating characteristics, are discussed in the following in detail. The inlet gas pressure of 30 bar was fixed based on the maximum capacity of the high-pressure CS system to make sure that the powders reached higher velocities. The other parameters (gas temperature, transverse speed, standoff distance, and particle size) were taken with respect to their impact on the DE only, as understood during the empirical study of both the coating formation and erosion/delamination issues under a clear chronologically structured variation of these parameters (Table 1). The main purpose of varying the gas temperature is to increase the particle velocity. Different transverse nozzle velocities were adopted to provide different amounts of powders arriving in front of the substrate. At low transverse speeds, the quantity of particles impacting the surface is more, which results in higher compaction and better cohesion, coupled with the generation of thermomechanical softening due to the plastic during the high-speed collision. The standoff distance (SoD) is of greater importance because low values lead to a higher thermal exposure and a pressure force due to the powder collision during the additive growth. A change in particle size modifies the particle collision velocity. So, considering the above, it is possible to optimize the coating formation as well as the DE as a function of the gas temperature, transverse speed, standoff distance, and powder granulometry. The tuning of these parameters can cause a negative or a positive effect. The negative effect consists of erosion or delamination during the continuous collision of the powders, instead of a coating growth. The positive effect is the hammering role that contributes to the strengthening of the copper/copper interface, and thus, to a better coating formation.

Table 1.

Optimization process for reaching the DE of 91% during the HPCS metallization of PEEK, and coating thickness in µm.

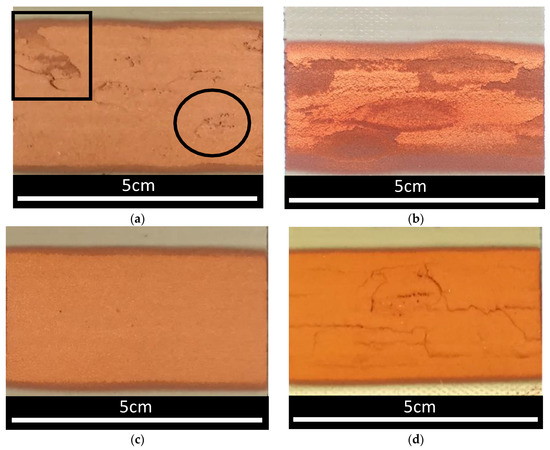

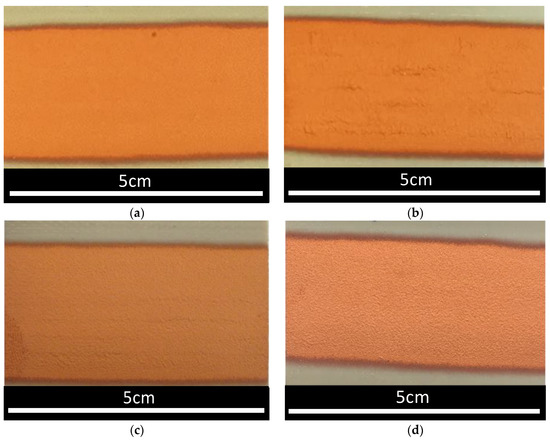

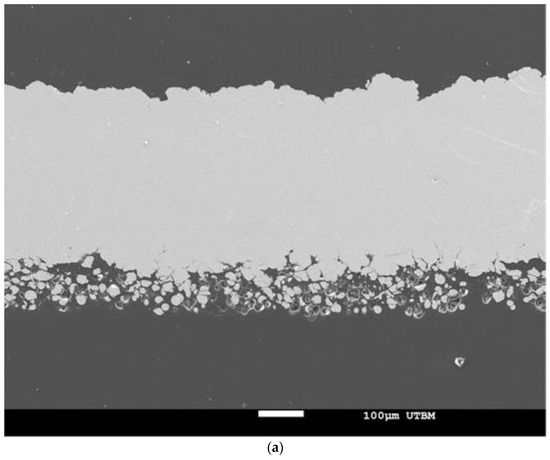

A typical onset of relevant processing conditions consists of the following settings: gas pressure, gas temperature, SoD, and nozzle transverse velocity of 30 bar, 300 °C, 105 mm, 100 mm/s, respectively, denoted as the condition set V1. The DE was found to be 67% and this limited value was due to the cumulative effect of gas temperature and transverse speed. As the gas temperature helps in softening the PEEK substrate properties (Tglass = 150 °C), the powders easily penetrate and later anchor after cooling, but some powders have low impact energy due to their low velocity, resulting in erosion and slight delamination (Figure 3). Since higher powder velocity can be achieved by increasing the gas temperature, condition set V2 (30 bar, 400 °C, 105 mm, 100 mm/s) was deployed but resulted in a limited DE of 30% due to a delamination. The upcoming particles (with much higher velocity) caused a peeling effect. Increasing the SoD from 105 mm to 120 mm (condition set V3: 30 bar, 400 °C, 120 mm, 100 mm/s) enables a DE of 53% with less erosion. The higher SoD reduces the thermal exposure of the substrate, but, at the same time, it also reduces the powder velocity. To avoid such erosion, reducing the sizes of the particles helps in achieving higher powder velocity. A low particle size range (15–33 µm) was used under the condition set V4 (30 bar, 400 °C, 120 mm, 100 mm/s, Cu-15–33 µm), which resulted in higher DE of about 83%. However, because of a delamination followed by a coating re-formation, there was an irregular coating growth (Figure 3c). Such a bad coating can be improved by reducing the amount of powder arriving in front of the substrate, that is, by a slight increase of the nozzle transverse speed to 200 mm/s (set V5: 30 bar, 400 °C, 120 mm, 200 mm/s, Cu-15–33 µm), which produces a better coating (Figure 4a), with a DE of about 87%. Using set V6 (30 bar, 500 °C, 120 mm, 200 mm/s, Cu-15–33 µm), with an aim to further to increase the powder velocity via the high gas temperature of 500 °C, the DE increased slightly to 88% but there was delamination on a few areas of the substrate (Figure 4b). Increasing the SoD to 135 mm (set V7: 30 bar, 500 °C, 200 mm/s, 135 mm, Cu-15–33 µm) improved the DE to 90% but slight erosion was observed (Figure 4c), even though the coating was thick (Figure 5). A final condition set, V8, using a higher nozzle transverse speed of 300 mm/s (30 bar, 500 °C, 135 mm, 300 mm/s, Cu-15–33 µm), enables the optimization of the DE up to 91% with good deposition without any apparent traces of erosion or delamination (Figure 5a), and with the formation of a thick coating (Figure 5b). Compared to various studies reported in the literature [27,28,29], such a DE level of 90% reveals the possibility of reaching an excellent DE by tuning the deposition parameters as revealed in this study. It is impossible to obtain a metallic coating on PEEK with a 100% DE due to the erosion during the first passes.

Figure 3.

Coatings obtained with deposition sets V1 (a), V2 (b), V3 (c), and V4 (d). Typical traces of delamination as illustrated inside the black box and black circle on the figure (a).

Figure 4.

Coatings obtained with deposition sets V5 (a), V6 (b), V7 (c), and V8 (d).

Figure 5.

Typical coating cross section for the deposition set V7 (a) and V8 (b).

3.2. Features of the Cu Coating Obtained at High DE

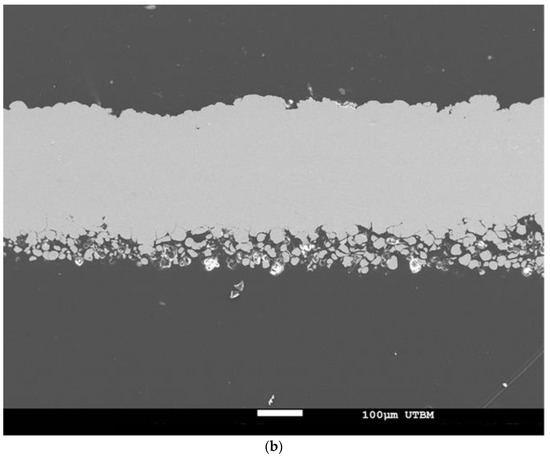

The electrical conductivity values of the cold-sprayed Cu coating on the PEEK substrate were between 43% and 62.3% of those of bulk copper (58 MS/m [26]), which is also comparable to the values of the Cu coating on metal substrates [30]. The set V7 (30 bar, 500 °C, 135 mm, 200 mm/s,) has a higher electrical conductivity compared to other sets because of its optimal operating conditions giving the high DE of 90%. A high electrical conductivity of 62.3% IACS was obtained for V7 due to the low porosity (0.16%) and oxide content (0.92%) values compared to other cases (Figure 6). The oxide content was assessed by SEM EDX analysis. For each coating, five EDX scans across the thickness were performed to provide the content of oxygen (%). Then the mean values were considered to characterize the oxide content of each sample. The V6 case has a lower conductivity value than the V7 case due to the high oxide content (1.69%) in the coatings.

Figure 6.

Electrical conductivity, porosity rate, and oxide content of the Cu coating produced by paths V5, V6, V7, and V8.

A higher oxygen content (1.69%) was noticed in the V6 case compared to its V5 progenitor (1.20%) and this is mainly due to the increased inlet temperature of the gases transferring heat to the substrate surface. The oxidation developed in the coatings is much higher and thus results in high oxide content. The higher oxide content (2.21%) for V8 was mainly attributed to the increase in transverse velocity and standoff distance which reduces the quantity of powders in collision onto the substrate per unit of time. A less particles arriving onto the substrate is conducive to a less compaction, i.e., less plastic deformation of the particles during spraying, and therefore a risk of oxygen entrapment between the particles.

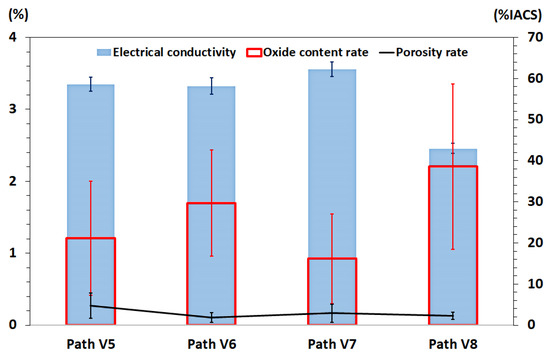

Based on the SEM analysis of the Cu/PEEK interface (Figure 5), the bonding mechanism is a result of the penetration of the Cu powders onto the PEEK, and then Cu-to-Cu bonding once a first layer of embedded Cu powders is produced on the PEEK surface. For assessing the bonding strength, adhesion tests were performed using the ASTM C-633 standard by means of a tensile tester (IC ESCOFFIER, Escotest 50, France) that works with a pull-out speed of 1.26 mm/min. Cold spray depositions onto cylindrical PEEK sample (diameter of 26 mm), for 5 passes, are performed. A good continuous coating (Figure 7) was obtained for the deposition condition of 30 bar, 400 °C, 135 mm, 200 mm/s. Three debonding samples are obtained and respectively showed bonding strengths of 6.92 MPa, 7.19 MPa, and 7.73 MPa, that is, a bonding strength of about 7 MPa. Such a low value occurred due to the bad Cu-to-Cu bonding, because the PEEK absorbs the collision process and then prevents a good plastic deformation of the Cu powders at the Cu/PEEK interface.

Figure 7.

Typical continuous Cu coating onto a cylindrical PEEK substrate (diameter of 26 mm and thickness of 10 mm), obtained with 5 deposition passes with the parameters of 30 bar, 400 °C, 135 mm, and 200 mm/s.

4. Conclusions

Copper coatings have been successfully deposited on PEEK with the perspective to be able to repair aircraft structures using a cold spray technique, and thus to provide good electrical conductivity for protection against lightning strikes. The deposition efficiencies were quantified and found to improve the electrical conductivity of the coating. It was impossible to achieve a good high deposition efficiency DE at shorter distances and high temperatures, suggesting applicability limitations for the process. Various deposition parameters sets were tuned and optimized. Excellent DEs up to 90% were achieved with a high-speed nozzle, with high standoff distances using air as the carrier gas with gas heating. The optimum parameters identified in this study were a standoff distance of 135 mm with a nozzle scan of 300 mm/s and a gas temperature of 500 °C. The features of the coatings exhibit an electrical conductivity up to 60% IACS. These will open a new horizon for the new researchers for better metallization of polymers via cold spraying.

Author Contributions

Conceptualization, L.L.K. and R.N.R.; methodology, L.L.K. and R.N.R.; validation, L.L.K., R.N.R. and S.C.; formal analysis, L.L.K. and R.N.R.; investigation, L.L.K. and R.N.R.; resources, L.L.K. and R.N.R.; data curation, L.L.K. and R.N.R.; writing—original draft preparation, L.L.K. and R.N.R.; writing—review and editing, L.L.K. and R.N.R.; visualization, R.N.R.; supervision, S.C. and R.N.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Raoelison, R.N.; Verdy, C.; Liao, H. Cold gas dynamic spray additive manufacturing today: Deposit possibilities, technological solutions and viable applications. Mater. Des. 2017, 87, 133–266. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold spray coating: Review of material systems and future perspectives. Surface Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Guo, D.; Kazasidis, M.; Hawkins, A.; Fan, N.; Leclerc, Z.; MacDonald, D.; Nastic, A.; Nikbakht, R.; Ortiz-Fernandez, R.; Rahmati, S.; et al. Cold Spray: Over 30 Years of Development Toward a Hot Future. J. Therm. Spray Technol. 2022, 31, 866–907. [Google Scholar] [CrossRef]

- Raoelison, R.N. Coeval Cold Spray Additive Manufacturing Variances and Innovative Contributions. In Cold-Spray Coating: Recent Trends Future Perspect, 1st ed.; Cavaliere, P., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 57–94. [Google Scholar]

- Wu, H.; Raoelison, R.N.; Zhang, Y.; Deng, S.; Hanlin, L. Cold Spraying of 3D Parts—Challenges. In Therm. Spray Coating, 1st ed.; Thakur, L., Vasudev, H., Eds.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Schmidt, T.; Gärtner, F.; Assadi, H.; Kreye, H. Development of a generalized parameter window for cold spray deposition. Acta Mater. 2006, 54, 729–742. [Google Scholar] [CrossRef]

- Assadi, H.; Schmidt, T.; Richter, H.; Kliemann, J.-O.; Binder, K.; Gärtner, F.; Klassen, T.; Kreye, H. On Parameter Selection in Cold Spraying. J. Therm. Spray Technol. 2011, 20, 1161–1176. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, M.; Veysset, D.; Nelson, K.A.; Schuh, C.A. In-situ observations of single micro-particle impact bonding. Scr. Mater. 2018, 145, 9–13. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Bonding mechanism in cold gas spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Della Gatta, R.; Perna, A.S.; Viscusi, A.; Pasquino, G.; Astarita, A. Cold spray deposition of metallic coatings on polymers: A review. J. Mater. Sci. 2021, 57, 27–57. [Google Scholar] [CrossRef]

- Feng, P.; Rokni, M.R.; Nutt, S.R. Depositing Aluminum onto PEKK Composites by Cold Spray. J. Therm. Spray Technol. 2020, 30, 385–393. [Google Scholar] [CrossRef]

- Gillet, V.; Aubignat, E.; Costil, S.; Courant, B.; Langlade, C.; Casari, P.; Knapp, W.; Planche, M.P. Development of low pressure cold sprayed copper coatings on carbon fiber reinforced polymer (CFRP). Surface Coat. Technol. 2019, 364, 306–316. [Google Scholar] [CrossRef]

- Viscusi, A.; Perna, A.S.; Astarita, A.; Boccarusso, L.; Caraviello, A.; Carrino, L.; Della Gatta, R.; Durante, M.; Sansone, R. Experimental Study of Cold Sprayed Metallic Coatings on Thermoplastic Matrix Composites. Key Eng. Mater. 2019, 813, 68–73. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Lalu Koithara, L.; Costil, S. Cold spray coating of PEEK surface by copper deposition: Interfacial adhesion at high deposition efficiency and bonding strength. CIRP J. Manuf. Sci. Technol. 2021, 35, 63–68. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Xie, Y.; Sapanathan, T.; Planche, M.P.; Kromer, R.; Costil, S.; Langlade, C. Cold gas dynamic spray technology: A comprehensive review of processing conditions for various technological developments till to date. Addit. Manuf. 2018, 19, 134–159. [Google Scholar] [CrossRef]

- Lalu Koithara, L.; Raoelison, R.N.; Costil, S.; Xie, X. High deposition efficiency and delamination issues during high-pressure cold spraying metallization of PEEK using spherical copper powders. Int. J. Adv. Manuf. Technol. 2020, 107, 4427–4436. [Google Scholar] [CrossRef]

- Lupoi, R.; O’Neill, W. Deposition of metallic coatings on polymer surfaces using cold spray. Surface Coat. Technol. 2010, 205, 2167–2173. [Google Scholar] [CrossRef]

- Gonzalez, R.; Ashrafizadeh, H.; Lopera, A.; Mertiny, P.; McDonald, A. A Review of Thermal Spray Metallization of Polymer-Based Structures. J. Therm. Spray Technol. 2016, 25, 897–919. [Google Scholar] [CrossRef]

- Akin, S.; Jun, M.B.-G.; Tsai, J.-T.; Park, M.S.; Jeong, Y.H. Fabrication of Electrically Conductive Patterns on ABS Polymer Using Low-Pressure Cold Spray. In Proceedings of the ASME 2020 15th International Manufacturing Science and Engineering Conference, Virtual Online, 15 January 2021. [Google Scholar]

- Rokni, M.R.; Feng, P.; Widener, C.A.; Nutt, S.R. Depositing Al-Based Metallic Coatings onto Polymer Substrates by Cold Spray. J. Therm. Spray Technol. 2019, 28, 1699–1708. [Google Scholar] [CrossRef]

- Tsai, J.-T.; Akin, S.; Zhou, F.; Bahr, D.F.; Jun, M.B.-G. Establishing a Cold Spray Particle Deposition Window on Polymer Substrate. J. Therm. Spray Technol. 2021, 30, 1069–1080. [Google Scholar] [CrossRef]

- Viscusi, A.; Durante, M.; Astarita, A.; Boccarusso, L.; Carrino, L.; Perna, A.S. Experimental Evaluation of Metallic Coating on Polymer by Cold Spray. Procedia Manuf. 2020, 47, 761–765. [Google Scholar] [CrossRef]

- Fallah, P.; Yue, S.; McDonald, A. Hybrid Metallic Coatings on Polymer-Based Composites. In Proceedings of the International Thermal Spraying Conference, Virtual Online, 15 June 2021. [Google Scholar]

- Parmar, H.; Gambardella, A.; Perna, A.S.; Viscusi, A.; Della Gatta, R.; Tucci, F.; Astarita, A.; Carlone, P. Manufacturing and metallization of hybrid thermoplastic-thermoset matrix composites. In Proceedings of the ESAFORM, Virtual Online, 2 April 2021. [Google Scholar]

- Lalu Koithara, L.; Raoelison, R.N.; Costil, S.; Xie, X. Capability of cold spraying to obtain high deposition efficiency for the metallization of PEEK. In Proceedings of the International Thermal Spray Conference, Yokohama, Japan, 26–29 May 2019. [Google Scholar]

- Chen, C.; Xie, X.; Xie, Y.; Yan, X.; Huang, C.; Deng, S.; Ren, Z.; Liao, H. Metallization of polyether ether ketone (PEEK) by copper coating via cold spray. Surface Coat. Technol. 2018, 342, 209–219. [Google Scholar] [CrossRef]

- Che, H.; Vo, P.; Yue, S. Metallization of carbon fibre reinforced polymers by cold spray. Surface Coat. Technol. 2017, 313, 236–247. [Google Scholar] [CrossRef]

- Zhou, X.L.; Chen, A.F.; Liu, J.C.; Wu, X.K.; Zhang, J.S. Preparation of metallic coatings on polymer matrix composites by cold spray. Surface Coat. Technol. 2011, 206, 132–136. [Google Scholar] [CrossRef]

- Che, H.; Chu, X.; Vo, P.; Yue, S. Cold spray of mixed metal powders on carbon fibre reinforced polymers. Surface Coat. Technol. 2017, 329, 232–243. [Google Scholar] [CrossRef]

- Arabgol, Z.; Vidaller, M.V.; Assadi, H.; Gärtner, F.; Klassen, T. Influence of thermal properties and temperature of substrate on the quality of cold-sprayed deposits. Acta Mater. 2017, 127, 287–301. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).