Crack Initiation and Growth Behavior of HVOF Stellite-6 Coatings under Bending Loading

Abstract

1. Introduction

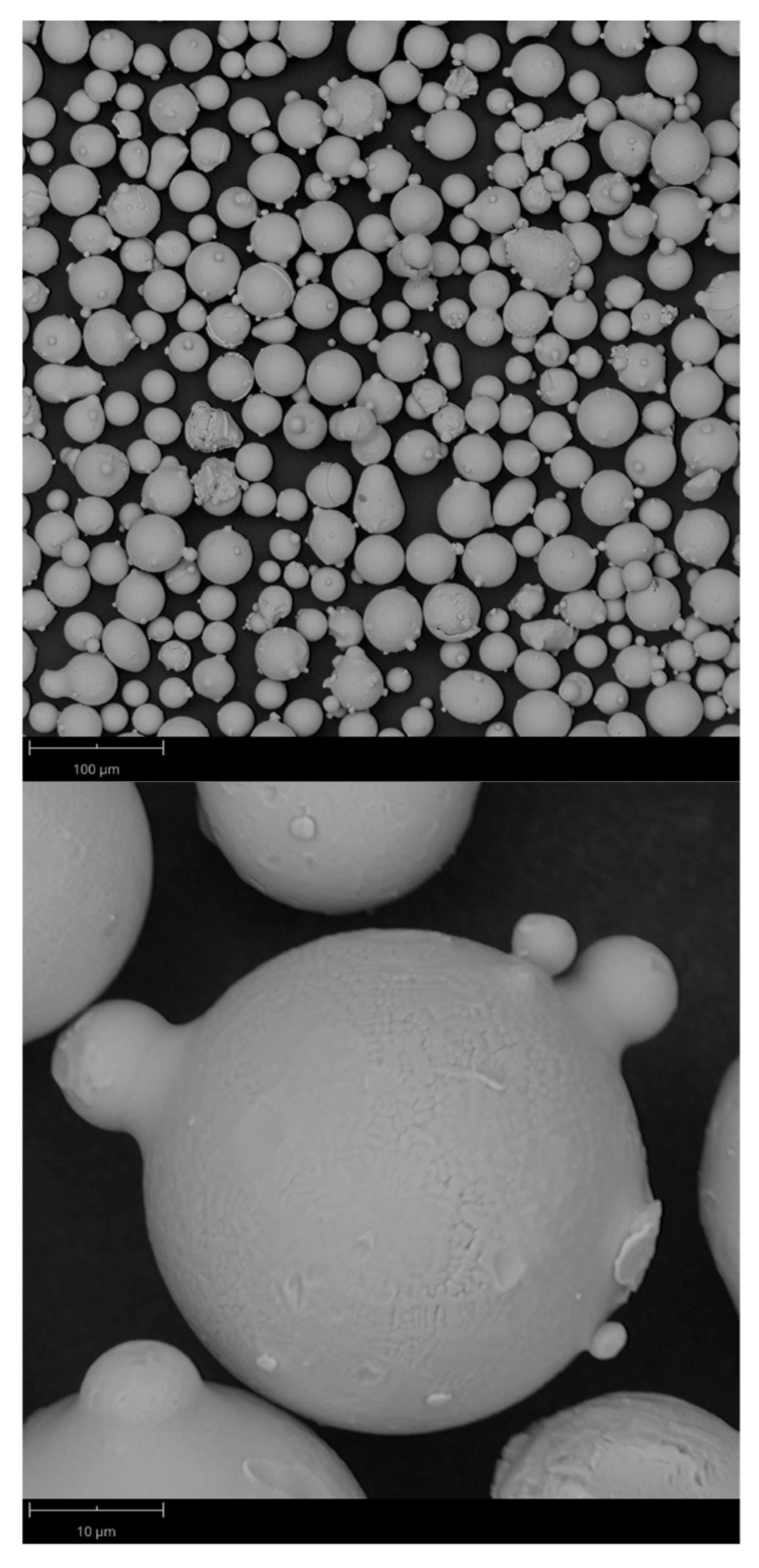

2. Experimental Procedure

3. Results and Discussion

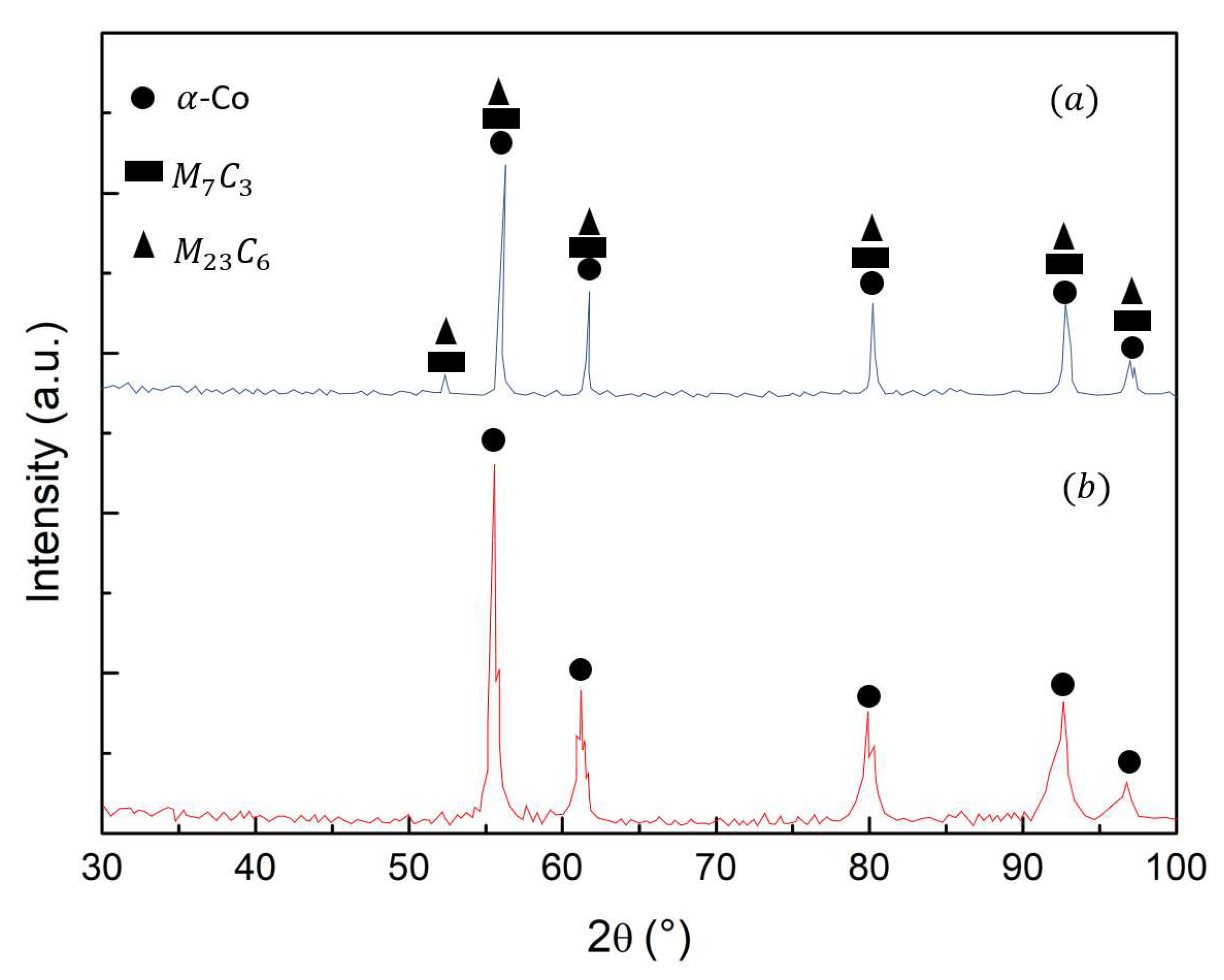

3.1. X-ray Diffraction

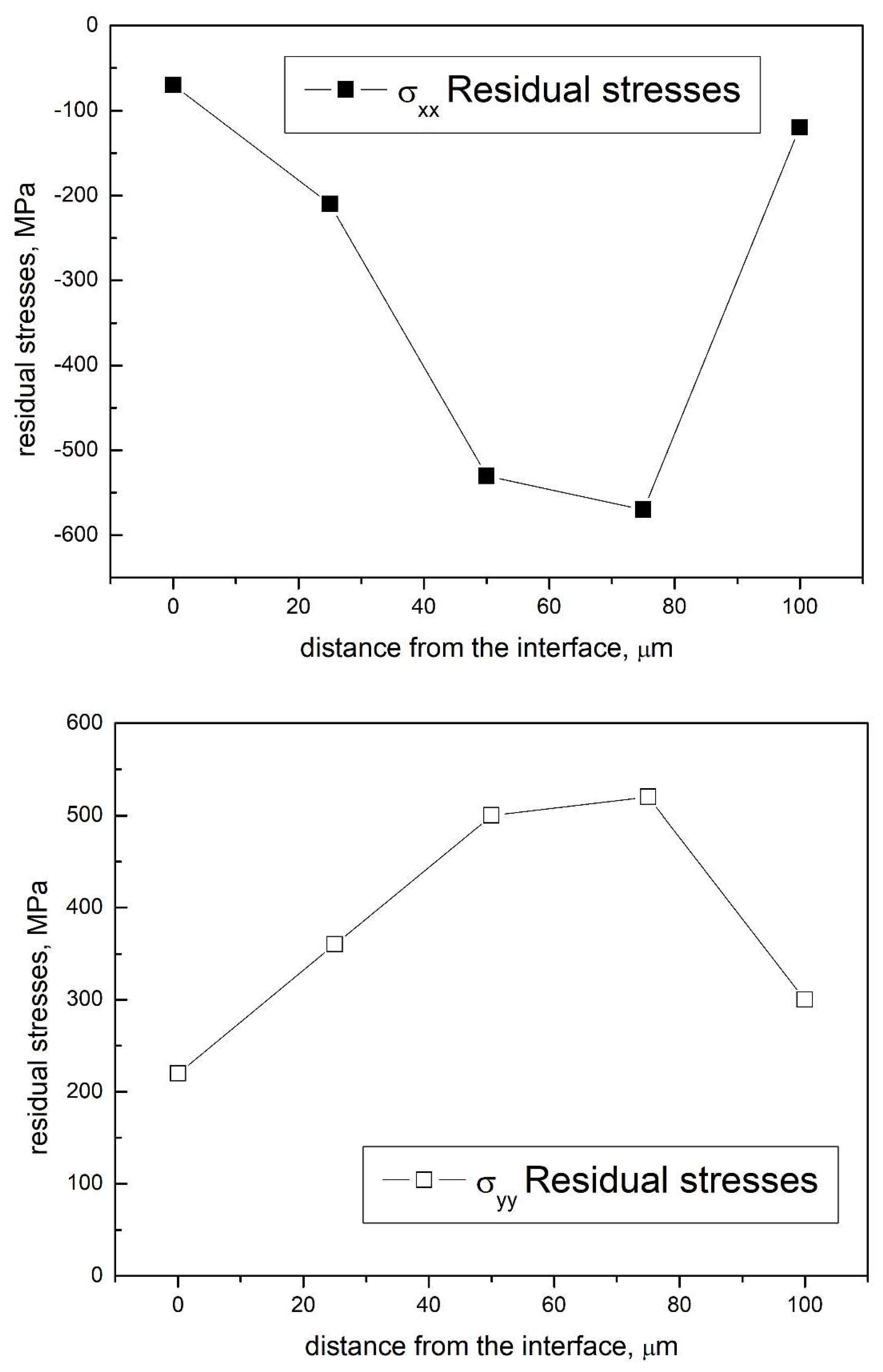

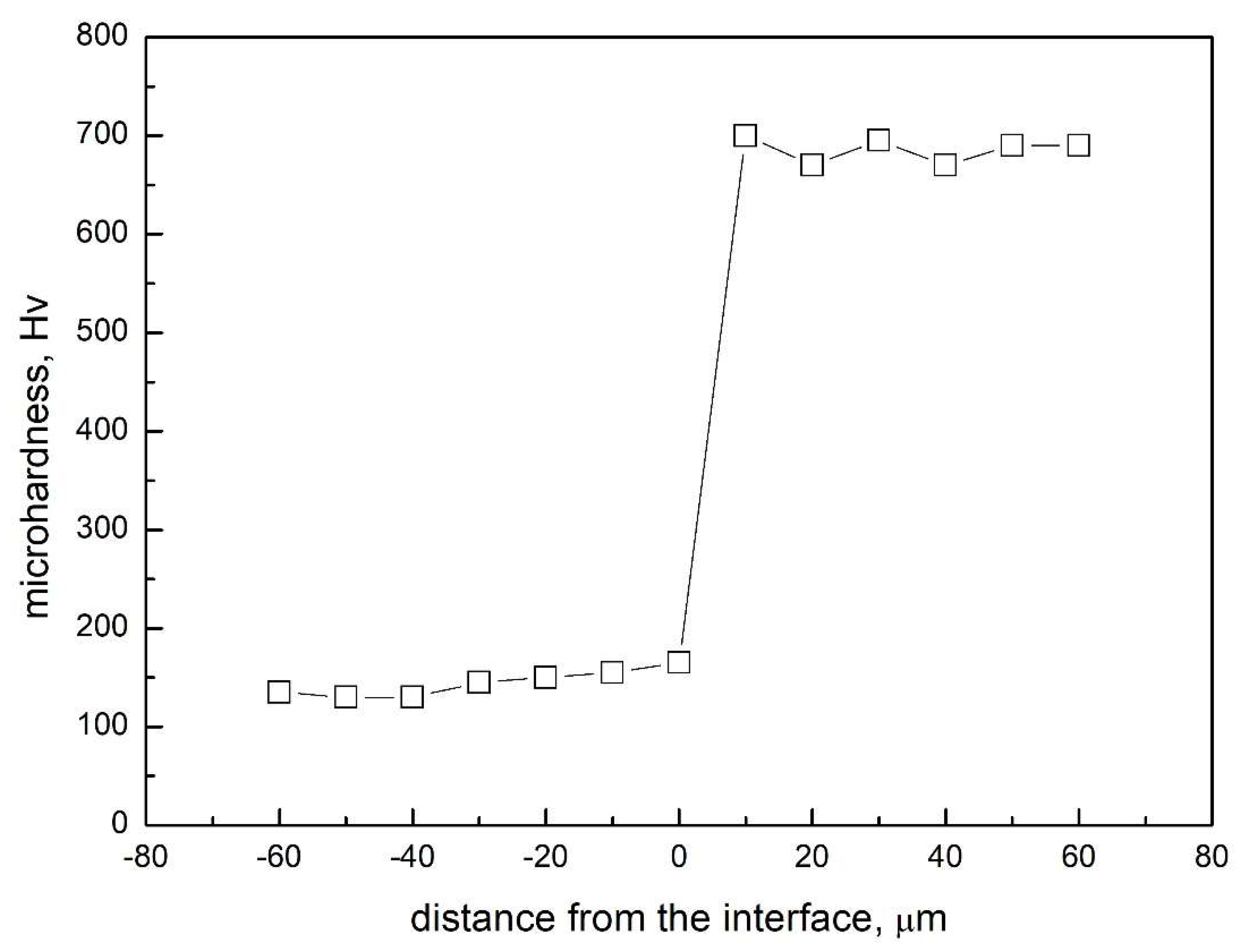

3.2. Microhardness

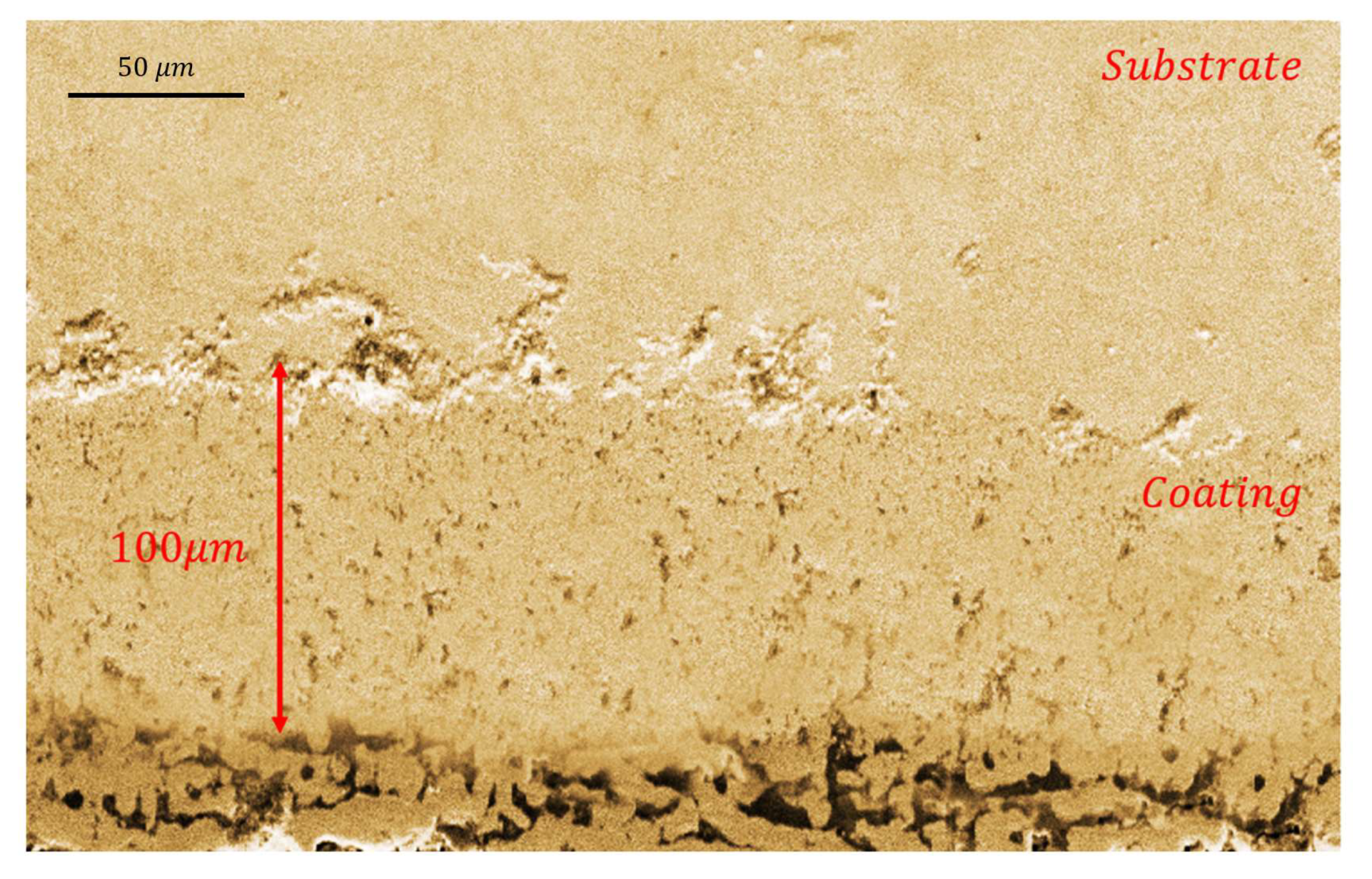

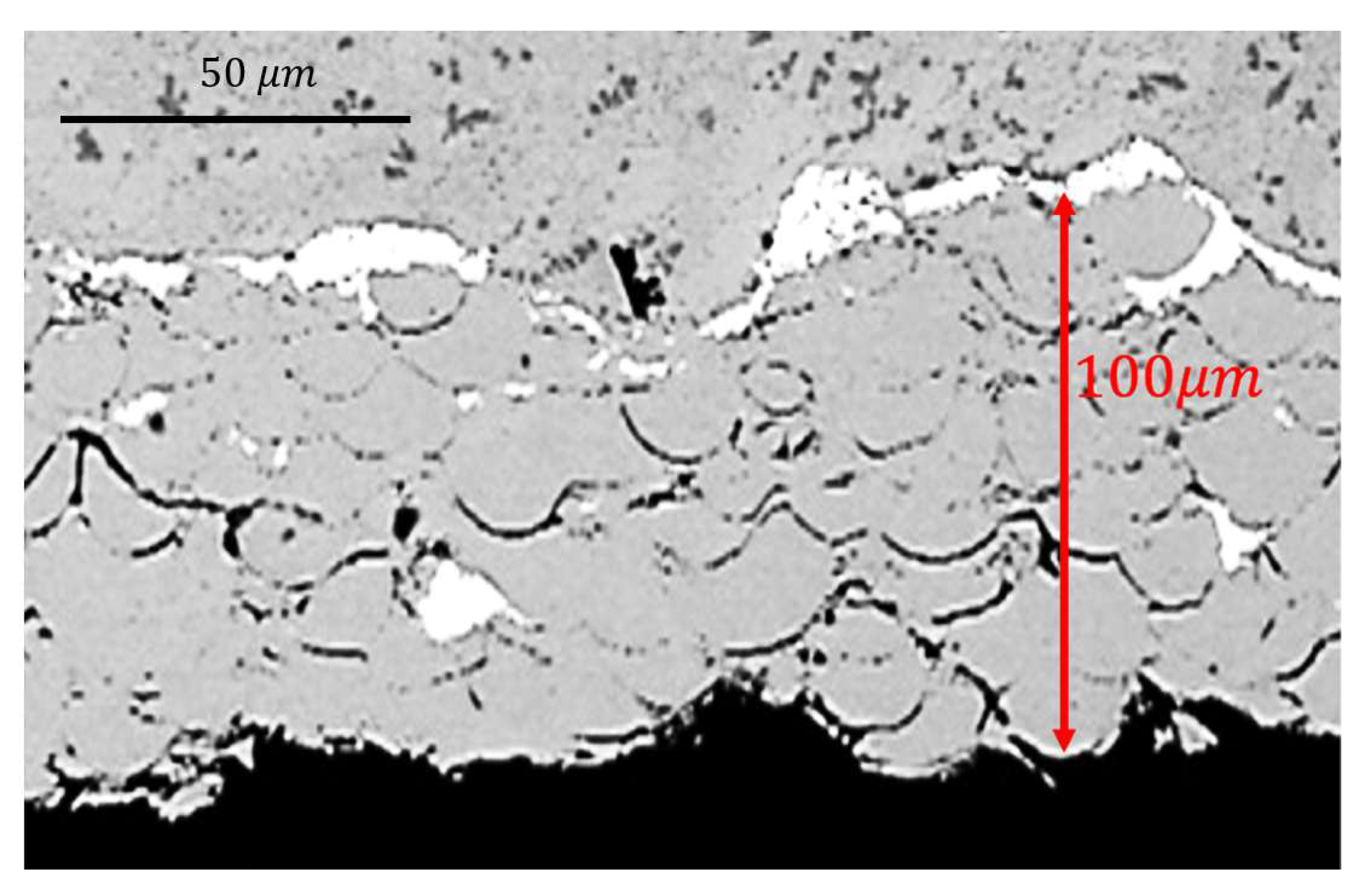

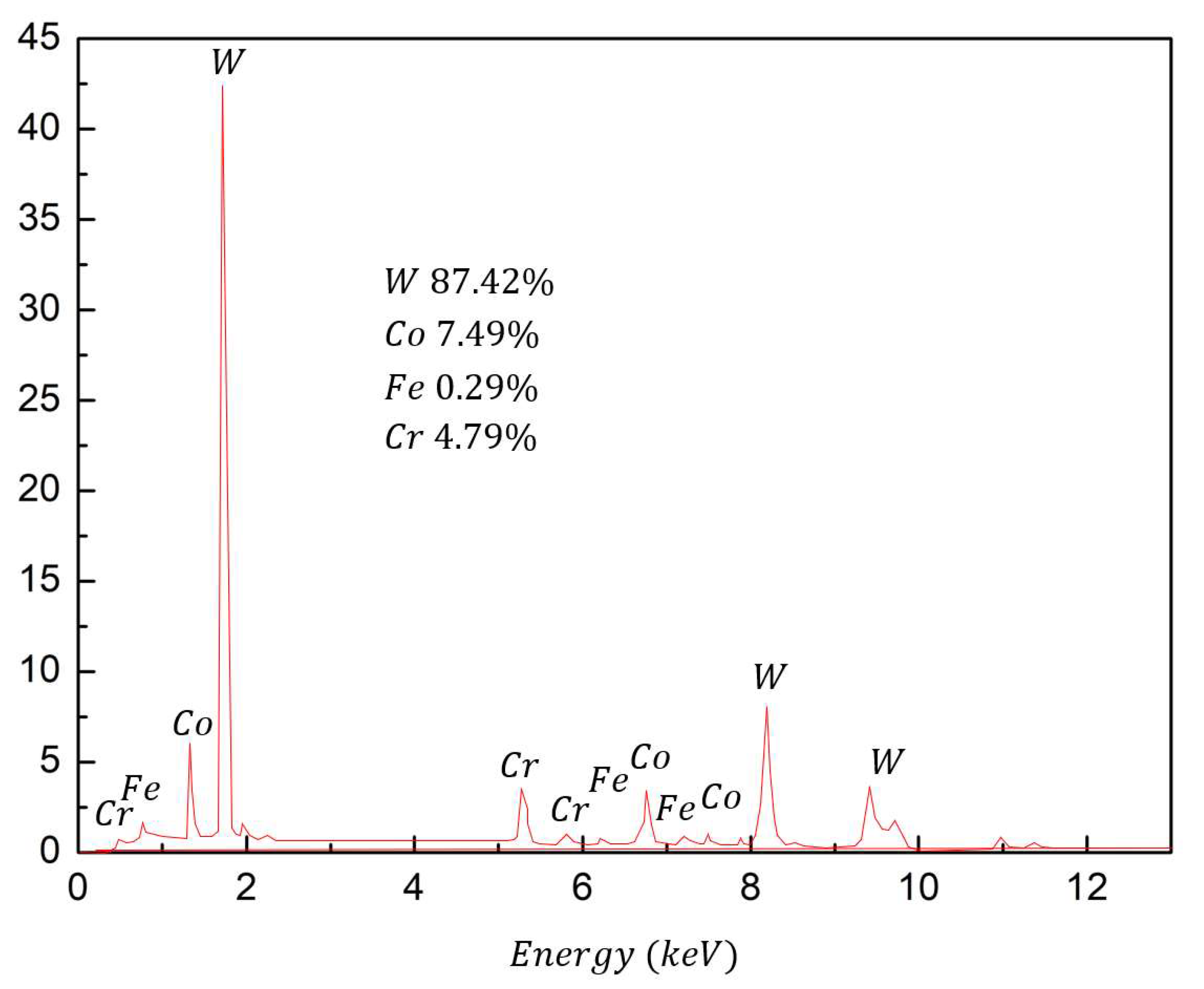

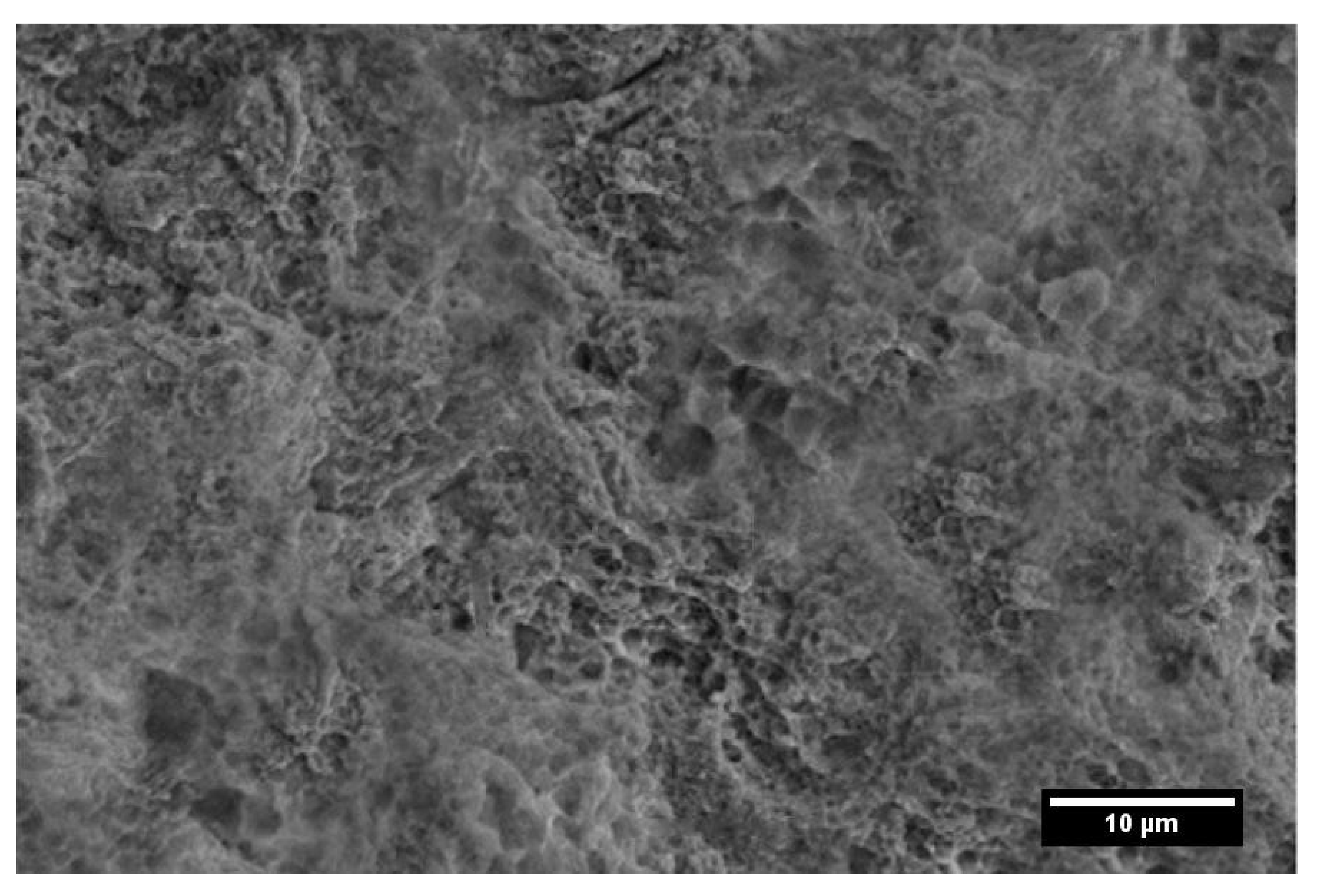

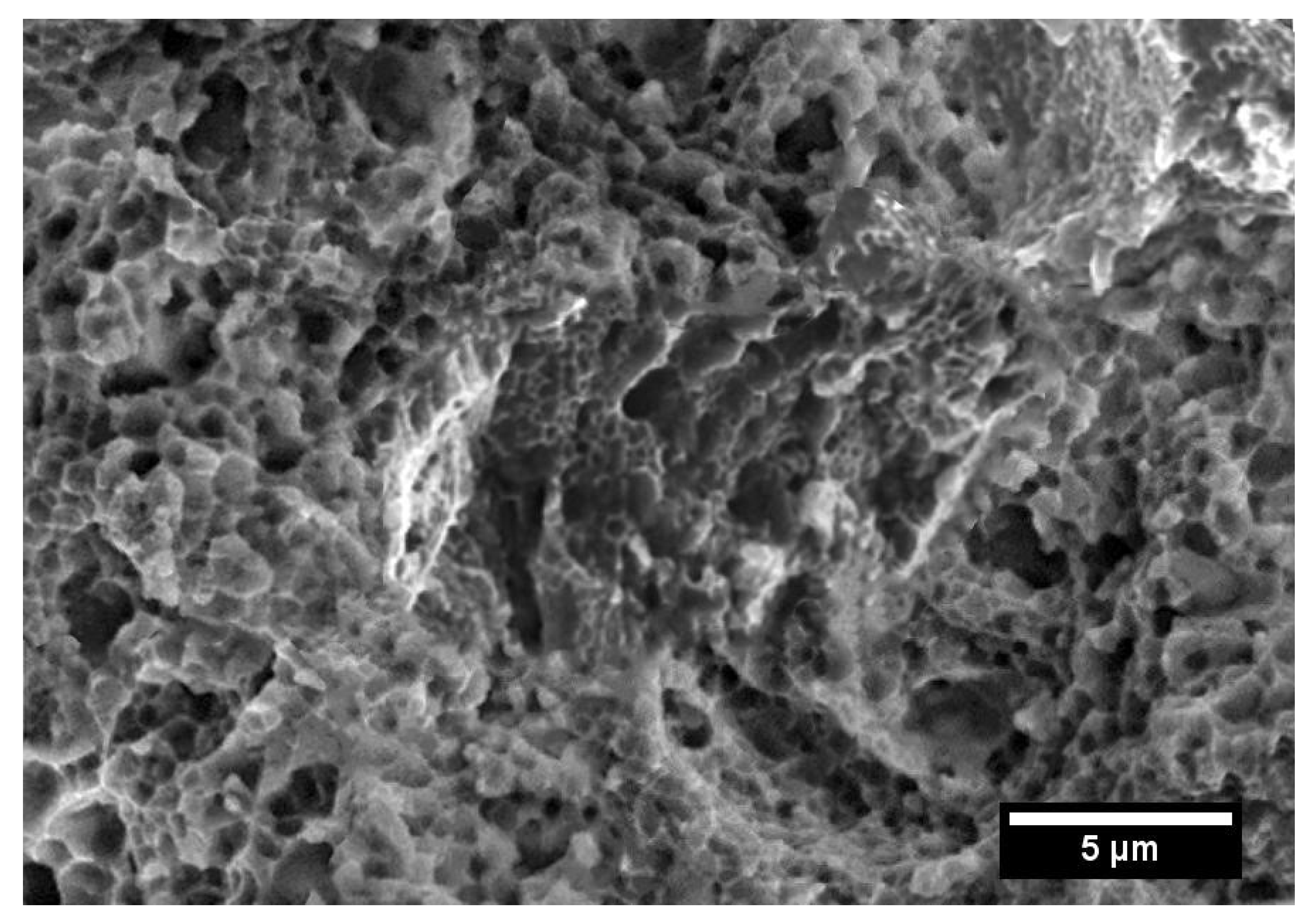

3.3. Microstructure

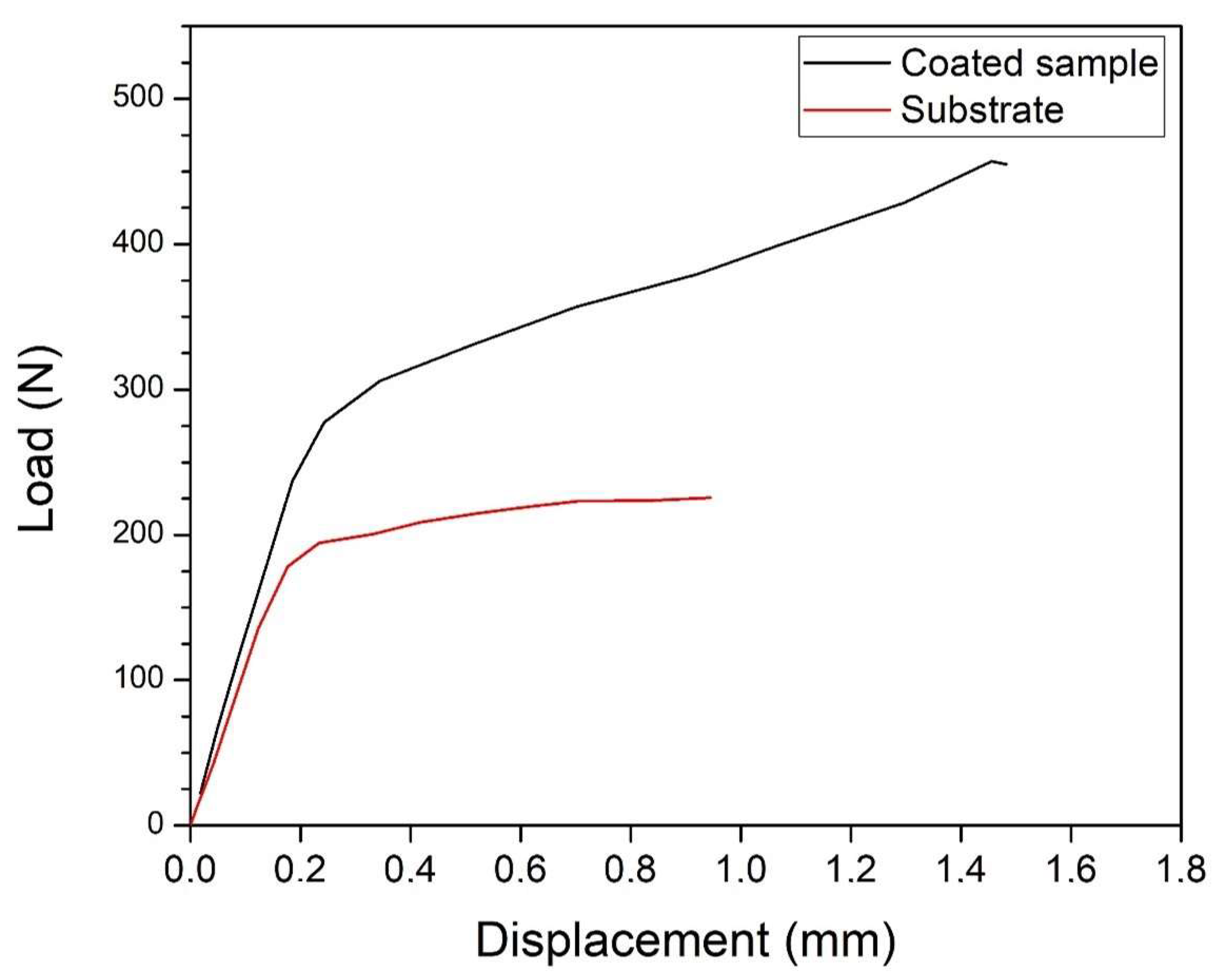

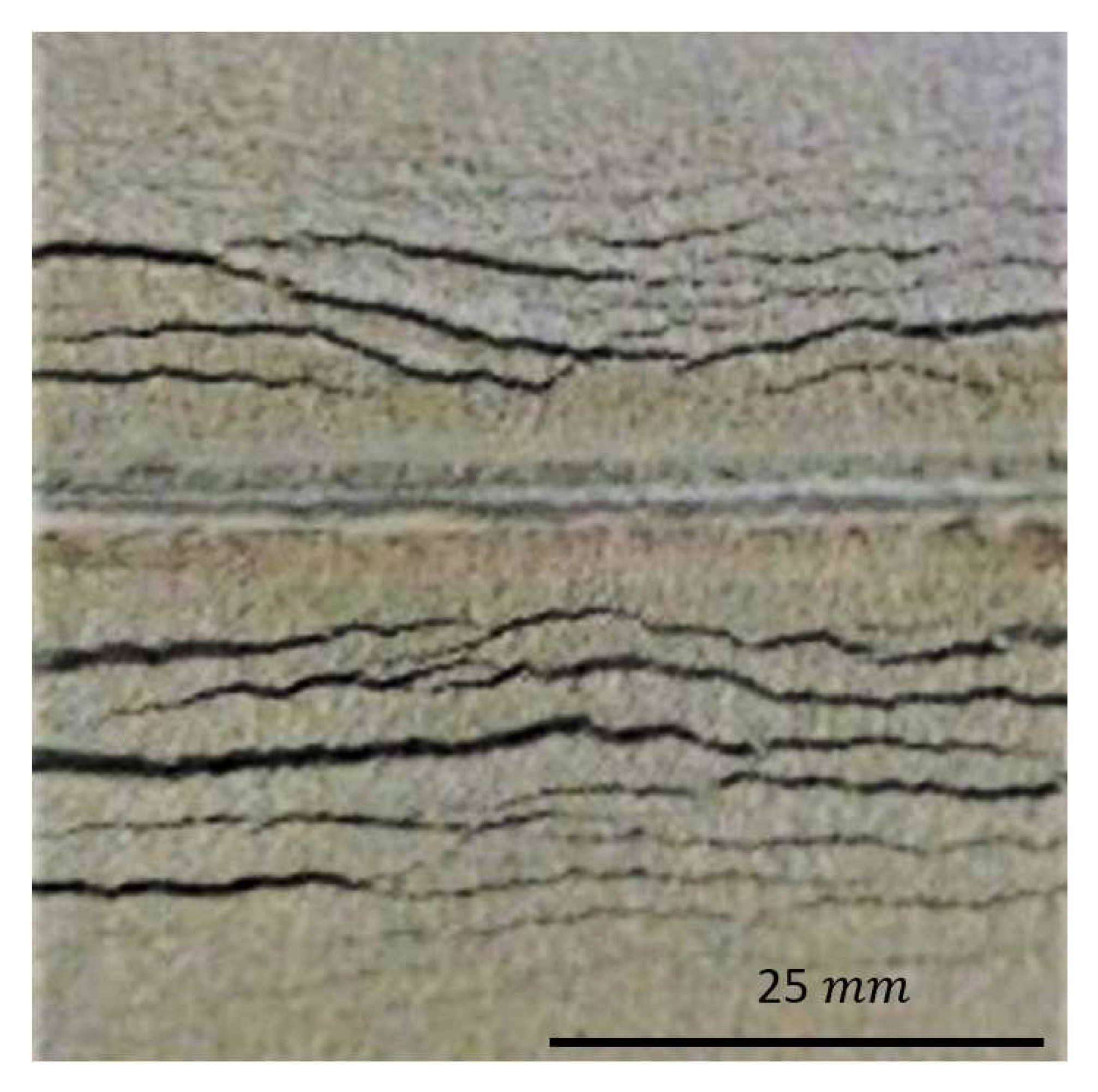

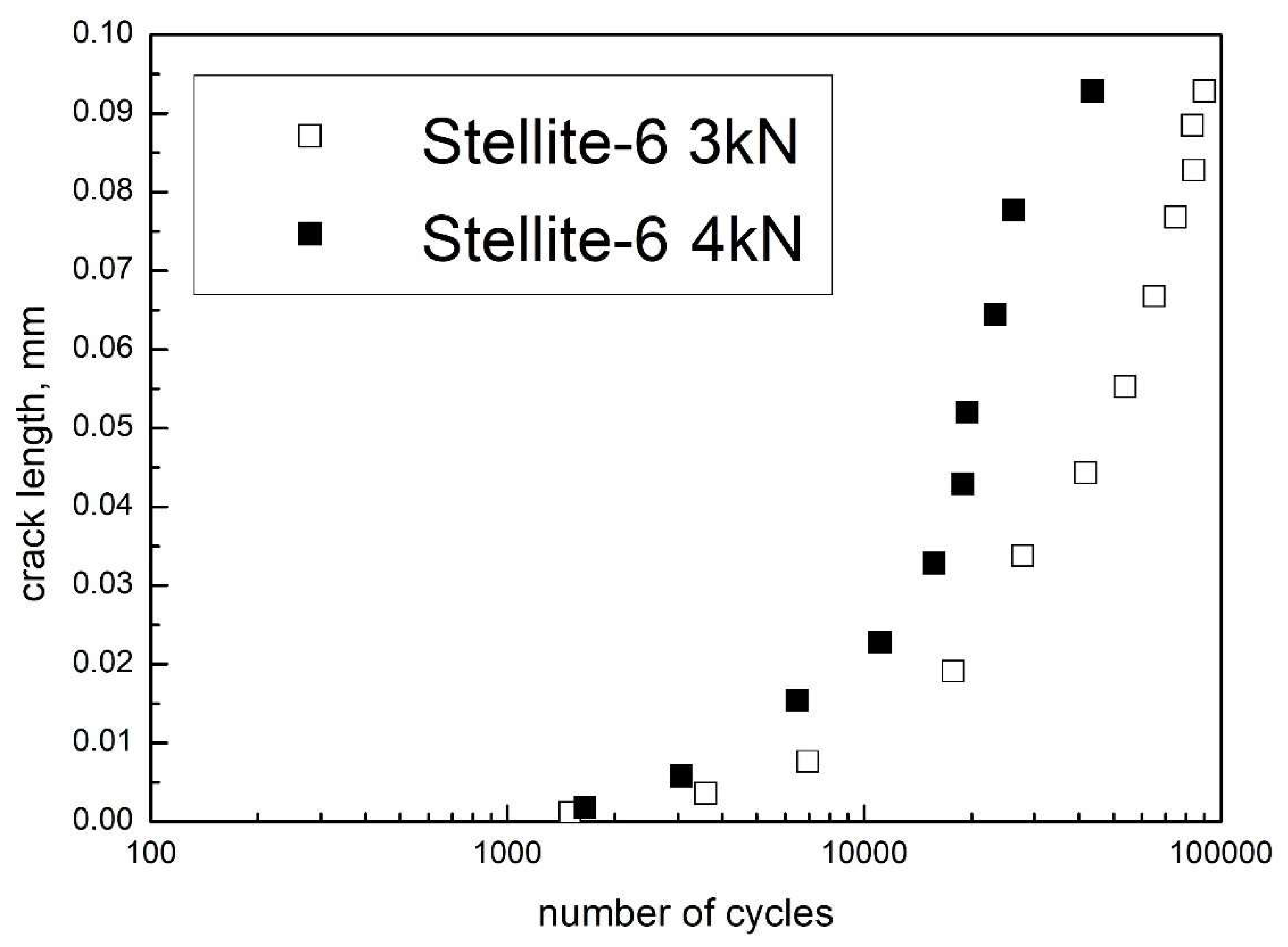

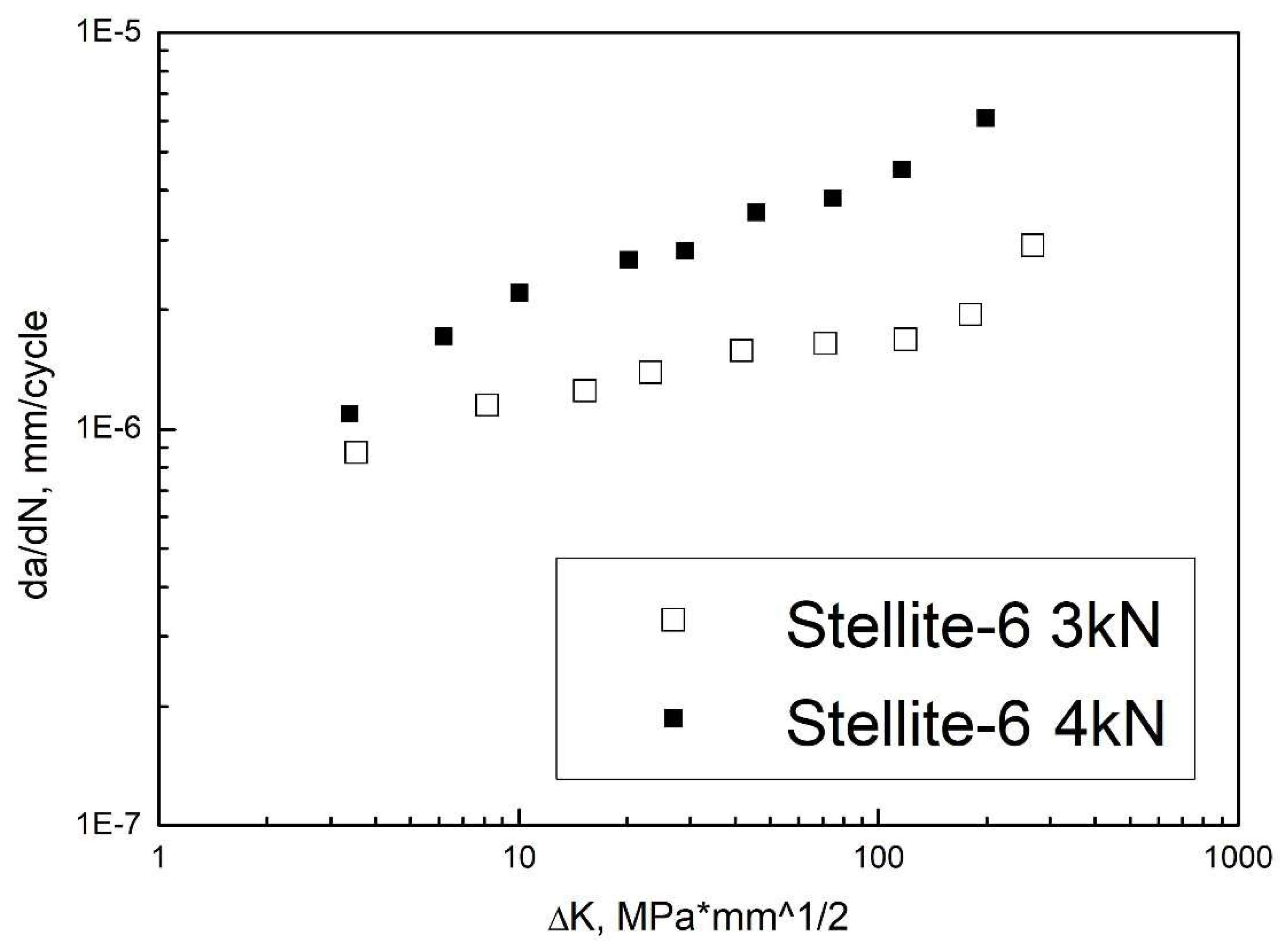

3.4. Bending Behavior

4. Conclusions

- Cobalt-based stellite particles were employed to successfully produce coatings via HVOF on nickel–aluminum–bronze substrates.

- The coating procedure led to a very remarkable increase in the surface hardness.

- The monotonic bending of the coated samples revealed a ductile behavior with the appearance of many superficial distributed cracks on the surface of the coatings. The coating improved the strength.

- The ductility behavior was confirmed by the SEM of the fractured surfaces.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, Y.; Wang, L.; Han, Y.; Xu, X.; Lu, W. Investigation of microstructure and mechanical properties of hot worked NiAl bronze alloy with different deformation degree. Mater. Sci. Eng. A 2015, 643, 17–24. [Google Scholar] [CrossRef]

- Schüssler, A.; Exner, H. The corrosion of nickel-aluminium bronzes in seawater—I. Protective layer formation and the passivation mechanism. Corros. Sci. 1993, 34, 1793–1802. [Google Scholar] [CrossRef]

- Islam, M. Influence of metallurgical structure on the service performance of Ni-Al Bronze process equipment in marine environments. NACE Int. Corros. Conf. Ser. 2017, 3, 1947–1957. [Google Scholar]

- Luo, Q.; Wu, Z.; Qin, Z.; Liu, L.; Hu, W. Surface modification of nickel-aluminum bronze alloy with gradient Ni-Cu solid solution coating via thermal diffusion. Surf. Coat. Technol. 2017, 309, 106–113. [Google Scholar] [CrossRef]

- Islam, M.; Ellor, J. Analysis of Corrosion Damage on Propulsion Shafts of Marine Vessels. In Proceedings of the CORROSION 2015, Dallas, TX, USA, 15–19 March 2015; NACE—International Corrosion Conference Series: Houston, TX, USA, 2015; p. 113704. [Google Scholar]

- Sassatelli, P.; Bolelli, G.; Gualtieri, M.L.; Heinonen, E.; Honkanen, M.; Lusvarghi, L.; Manfredini, T.; Rigon, R.; Vippola, M. Properties of HVOF-sprayed Stellite-6 coatings. Surf. Coat. Technol. 2018, 338, 45–62. [Google Scholar] [CrossRef]

- Kumar, A.; Boy, J.; Zatorski, R.; Stephenson, L.D. Thermal Spray and Weld Repair Alloys for the Repair of Cavitation Damage in Turbines and Pumps: A Technical Note. J. Therm. Spray Technol. 2005, 14, 177–182. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Prakash, S.; Agrawal, R.D. Hot Corrosion Resistance of High-Velocity Oxyfuel Sprayed Coatings on a Nickel-Base Superalloy in Molten Salt Environment. J. Therm. Spray Technol. 2006, 15, 387–399. [Google Scholar] [CrossRef]

- Cavaliere, P.; Perrone, A.; Silvello, A. Fatigue behaviour of Inconel 625 cold spray coatings. Surf. Eng. 2018, 34, 380–391. [Google Scholar] [CrossRef]

- Cavaliere, P.; Silvello, A. Finite element analyses of pure Ni cold spray particles impact related to coating crack behaviour. Surf. Eng. 2017, 34, 361–368. [Google Scholar] [CrossRef]

- Cavaliere, P.; Silvello, A. Crack Repair in Aerospace Aluminum Alloy Panels by Cold Spray. J. Therm. Spray Technol. 2017, 26, 661–670. [Google Scholar] [CrossRef]

- Sebastiani, M.; Mangione, V.; De Felicis, D.; Bemporad, E.; Carassiti, F. Wear mechanisms and in-service surface modifications of a Stellite 6B Co-Cr alloy. Wear 2012, 290, 10–17. [Google Scholar] [CrossRef]

- Yao, M.X.; Wu, J.B.C.; Xie, Y. Wear, corrosion and cracking resistance of some W- or Mo-containing Stellite hardfacing alloys. Mater. Sci. Eng. 2005, 407, 234–244. [Google Scholar] [CrossRef]

- Houdková, Š.; Smazalová, E.; Pala, Z. Effect of Heat Treatment on the Microstructure and Properties of HVOF-Sprayed Co-Cr-W Coating. J. Therm. Spray Technol. 2016, 25, 546–557. [Google Scholar] [CrossRef]

- Houdková, Š.; Smazalová, E. The Influence of High Temperature Exposure on the Wear of Selected HVOF Sprayed Coatings. Defect Diffus. Forum 2016, 368, 55–58. [Google Scholar] [CrossRef]

- Shin, J.-C.; Doh, J.-M.; Yoon, J.-K.; Lee, D.-Y.; Kim, J.-S. Effect of molybdenum on the microstructure and wear resistance of cobalt-base Stellite hardfacing alloys. Surf. Coat. Technol. 2003, 166, 117–126. [Google Scholar] [CrossRef]

- Davis, J.R. ASM Metals Handbook, Weld Clading and Dissimilar Metal Joining; ASM International: Cleveland, OH, USA, 1993; Volume 6, pp. 789–794. [Google Scholar]

- Sidhu, H.S.; Sidhu, B.S.; Prakash, S. Hot Corrosion Behavior of HVOF Sprayed Coatings on ASTM SA213-T11 Steel. J. Therm. Spray Technol. 2007, 16, 349–354. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Prakash, S.; Agrawal, R.D. Hot corrosion studies of HVOF NiCrBSi and Stellite-6 coatings on a Ni-based superalloy in an actual industrial environment of a coal fired boiler. Surf. Coat. Technol. 2006, 201, 1602–1612. [Google Scholar] [CrossRef]

- Mann, B.S.; Arya, V.; Maiti, A.K.; Rao, M.U.B.; Joshi, P. Corrosion and erosion performance of HVOF/TiAlN PVD coatings and candidate materials for high pressure gate valve application. Wear 2006, 260, 75–82. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Prakash, S.; Agrawal, R.D. A comparative study of hot corrosion resistance of HVOF sprayed NiCrBSi and Stellite-6 coated Ni-based superalloy at 900 °C. Mater. Sci. Eng. 2007, 445, 210–218. [Google Scholar] [CrossRef]

- Ciubotariu, C.R.; Frunzăverde, D.; Mărginean, G.; Șerban, V.A.; Bîrdeanu, A.V. Optimization of the laser remelting process for HVOF-sprayed Stellite 6 wear resistant coatings. Opt. Laser Technol. 2016, 77, 98–103. [Google Scholar] [CrossRef]

- Houdkova, S.; Kasparova, M.; Schubert, J. The Spraying Parameters Optimization of the HVOF Stellite 6 Coating. In Proceedings of the 21st International Conference on Metallurgy and Materials, Brno, Czech Republic, 23–25 May 2012. [Google Scholar]

- Shoja-Razavi, R. Laser Surface Treatment of Stellite 6 Coating Deposited by HVOF on 316L Alloy. J. Mater. Eng. Perform. 2016, 25, 2583–2595. [Google Scholar] [CrossRef]

- Sidhu, H.S.; Sidhu, B.S.; Prakash, S. Solid particle erosion of HVOF sprayed NiCr and Stellite-6 coatings. Surf. Coat. Technol. 2007, 202, 232–238. [Google Scholar] [CrossRef]

- Jegadeeswaran, N.; Ramesh, M.R.; Prakrathi, S.; Bhat, K.U. Hot Corrosion Behaviour of HVOF Sprayed Stellite-6 Coatings on Gas Turbine Alloys. Trans. Indian Inst. Met. 2014, 67, 87–93. [Google Scholar] [CrossRef]

- Satya, N.W.; Winarto, W. Microstructure, Hardness, and Surface Cracks Evaluation of HVOF-Sprayed Stellite-1 Coating Applied on Steam Turbine Blade. Key Eng. Mater. 2020, 833, 80–84. [Google Scholar] [CrossRef]

- Seraj, R.A.; Abdollah-Zadeh, A.; Dosta, S.; Assadi, H.; Cano, I.G. Comparison of Stellite coatings on low carbon steel produced by CGS and HVOF spraying. Surf. Coat. Technol. 2019, 372, 299–311. [Google Scholar] [CrossRef]

- Azizpour, M.J.; Tolouei-Rad, M. Evaluation of residual stress in HVOF stellite-6 coatings using non-contact drilling. Mater. Res. Express 2019, 6, 066577. [Google Scholar] [CrossRef]

- Schubert, J.; Česánek, Z. Fracture evaluation of thermally sprayed coatings in dependence on cohesive strength. J. Phys. Conf. Ser. 2017, 843, 12007. [Google Scholar] [CrossRef]

- Matějíček, J.; Šimůnková, Š.H.; Bláhová, O.; Pala, Z. The influence of spraying parameters on stresses and mechanical properties of HVOF-sprayed Co-Cr-W-C coatings. Key Eng. Mater. 2014, 606, 171–174. [Google Scholar] [CrossRef]

- Kasparova, M.; Zahalka, F.; Houdkova, S. The Thermally Sprayed Coatings for Railway Applications. In Proceedings of the 20st International Conference on Metallurgy and Materials, Brno, Czech Republic, 18–20 May 2011. [Google Scholar]

- Brandt, O.C. Mechanical properties of HVOF coatings. J. Therm. Spray Technol. 1995, 4, 147–152. [Google Scholar] [CrossRef]

- Al-Anazi, D.; Hashmi, M.S.J.; Yilbas, B.S. High-velocity oxy-fuel thermally sprayed CoNiCrAlY coatings on Ti-6Al-4V alloy: High cycle fatigue properties of coating. Proc. Inst. Mech. Eng. Part B 2007, 221, 647–654. [Google Scholar] [CrossRef]

- Hernández, L.; Oliveira, F.; Berríos, J.; Villalobos, C.; Pertuz, A.; Cabrera, E.P. Fatigue properties of a 4340 steel coated with a Colmonoy 88 deposit applied by high-velocity oxygen fuel. Surf. Coat. Technol. 2000, 133, 68–77. [Google Scholar] [CrossRef]

- Agüero, A.; Camón, F.; Garcı´a de Blas, J.; del Hoyo, J.C.; Muelas, R.; Santaballa, A.; Ulargui, S.; Vallés, P. HVOF-Deposited WCCoCr as Replacement for Hard Cr in Landing Gear Actuators. J. Therm. Spray Technol. 2011, 20, 1292–1309. [Google Scholar] [CrossRef]

- Puchi-Cabrera, E.S.; Staia, M.H.; Ortiz-Mancilla, M.J.; La Barbera-Sosa, J.G.; Pérez, E.O.; Villalobos-Gutiérrez, C.; Bellayer, S.; Traisnel, M.; Chicot, D.; Lesage, J. Fatigue behavior of a SAE 1045 steel coated with Colmonoy 88 alloy deposited by HVOF thermal spray. Surf. Coat. Technol. 2010, 205, 1119–1126. [Google Scholar] [CrossRef]

- Cavaliere, P. Fatigue properties and crack behavior of ultra-fine and nanocrystalline pure metals. Int. J. Fatigue 2009, 31, 1476–1489. [Google Scholar] [CrossRef]

- Silvello, A.; Cavaliere, P.D.; Albaladejo-Fuentes, V.; Martos, A.; Dosta, S.; Cano, I.G. Powder Properties and Processing Conditions Affecting Cold Spray Deposition. Coatings 2020, 10, 91. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Mosbah, A.Y.; Wexler, D.; Calka, A. Abrasive wear of WC-FeAl composites. Wear 2005, 258, 1337–1341. [Google Scholar] [CrossRef]

- Cavaliere, P.; Silvello, A.; Cinca, N.; Canales, H.; Dosta, S.; Cano, I.G.; Guilemany, J.M. Microstructural and fatigue behavior of cold sprayed Ni-based superalloys coatings. Surf. Coat. Technol. 2017, 324, 390–402. [Google Scholar] [CrossRef]

- Cavaliere, P. Fatigue and Fracture of Nanostructured Materials; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Nairn, J.A. Fracture Mechanics of Composites With Residual Thermal Stresses. J. Appl. Mech. 1997, 64, 804–810. [Google Scholar] [CrossRef]

- La Barbera-Sosa, J.G.; Santana, Y.Y.; Villalobos-Gutiérrez, C.; Chicot, D.; Lesage, J.; Decoopman, X.; Iost, A.; Staia, M.H.; Puchi-Cabrera, E.S. Fatigue behavior of a structural steel coated with a WC–10Co-4Cr/Colmonoy 88 deposit by HVOF thermal spraying. Surf. Coat. Technol. 2013, 220, 248–256. [Google Scholar] [CrossRef][Green Version]

- Kim, S.R.; Nairn, J.A. Fracture mechanics analysis of coating/substrate systems: Part II: Experiments in bending. Eng. Fract. Mech. 2000, 65, 595–607. [Google Scholar] [CrossRef]

- Paris, P.C.; Gomez, R.E.; Anderson, W.E. A rational analytic theory of fatigue. Trend Eng. 1961, 13, 9–14. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeghi, B.; Cavaliere, P.; Perrone, A.; Silvello, A. Crack Initiation and Growth Behavior of HVOF Stellite-6 Coatings under Bending Loading. Powders 2022, 1, 62-74. https://doi.org/10.3390/powders1020006

Sadeghi B, Cavaliere P, Perrone A, Silvello A. Crack Initiation and Growth Behavior of HVOF Stellite-6 Coatings under Bending Loading. Powders. 2022; 1(2):62-74. https://doi.org/10.3390/powders1020006

Chicago/Turabian StyleSadeghi, Behzad, Pasquale Cavaliere, Angelo Perrone, and Alessio Silvello. 2022. "Crack Initiation and Growth Behavior of HVOF Stellite-6 Coatings under Bending Loading" Powders 1, no. 2: 62-74. https://doi.org/10.3390/powders1020006

APA StyleSadeghi, B., Cavaliere, P., Perrone, A., & Silvello, A. (2022). Crack Initiation and Growth Behavior of HVOF Stellite-6 Coatings under Bending Loading. Powders, 1(2), 62-74. https://doi.org/10.3390/powders1020006