Damage Effect and Injury Range of Shock Waves in Mine Methane Explosion

Abstract

1. Introduction

2. Injury Criteria and Damage Degree of Methane Explosions

2.1. Methane Explosion Condition and Its Effect Factors

2.2. Injury Criteria of Methane Explosion

2.3. Explosion Damage (Injury) Range

- (1)

- Death range: If the person in this range lacks protection, they will be considered to be seriously injured or killed without exception. The starting point is the explosion source point, which is recorded as zero, and the distance of the death disaster is recorded as Lw. It means that the death probability due to pulmonary hemorrhaging caused by the shock wave at the roadway section within the disaster Lw from the explosion source is 50%.

- (2)

- Serious injury range: If the person in this range lacks protection, most of them will suffer serious injuries, and a few of them may die or be slightly injured. Its starting point is the terminal point of the disaster, and its terminal point is Lw. The probability of ear fracturing among the person in the roadway section due to the shock wave is 50% in this range, and the peak overpressure of the shock wave is 44,000 Pa.

- (3)

- Minor injury range: If the person in this range lacks protection, most of them will suffer minor injuries, and a few will be seriously injured or safe; the possibility of death is minor. The starting point of this range is the terminal point of the serious injury range, and the ending point is Lw. The probability of ear fracturing due to shock wave action in the roadway section is 1% in this range, and the peak overpressure of the shock wave is 17,000 Pa.

- (4)

- Safety range: Most persons in this range will not be injured even without protection, and the probability of death is almost zero. The starting point of this range is the end point of the minor injury range, and the end point of this range is infinite.

2.4. Injury Degrees

3. Experimental Study on the Injury Range of Methane Explosion Shock Wave

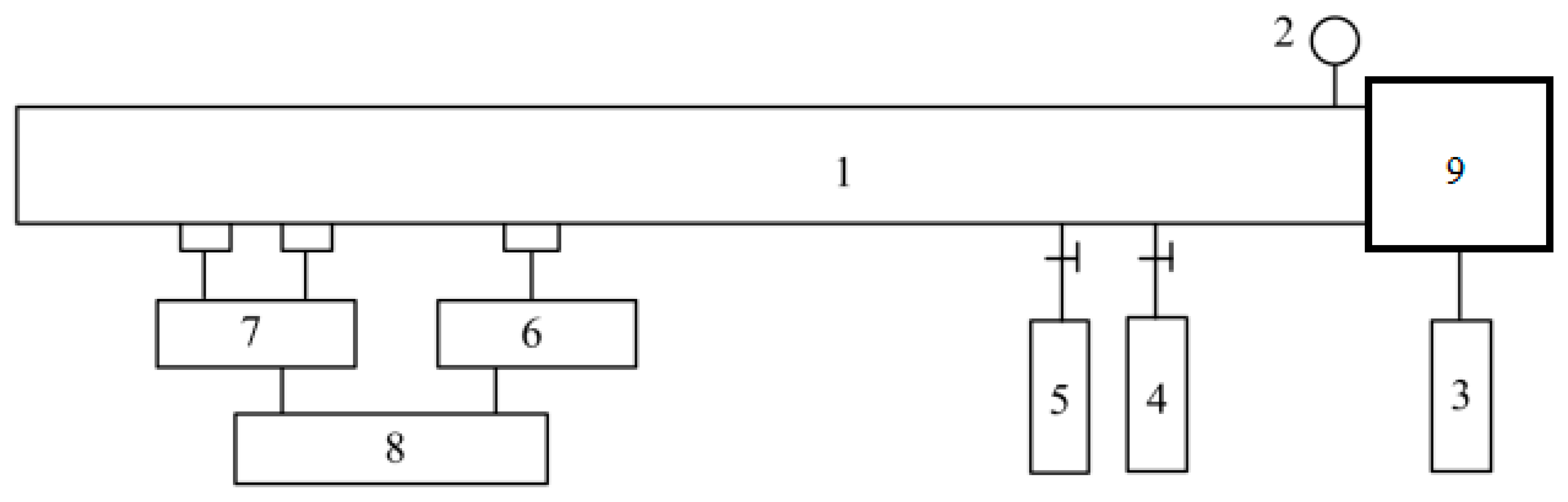

3.1. Experimental System of Methane Explosion

3.2. Analysis on Explosion Propagation Process

- (1)

- Flame propagation

- (2)

- Expansion of explosion products

- (3)

- Propagation of shock wave

3.3. Experimental Results and Analysis

4. Safety Distance of Methane Explosion Overpressure

4.1. Influencing Factors of Overpressure Attenuation of Shock Wave

4.2. Data Processing

5. Conclusions

- (1)

- The injuries of person and the damage to structures caused by a methane explosion in an underground roadway depend on the specific situation of the explosion and the location of the person in the disaster range. The range around the explosion hazard source can be divided into four ranges from the inside to the outside: the death range, serious injury range, minor injury range and safety range.

- (2)

- The safety distance of no injury to person and no damage to structures is 60 m, 240 m, 480 m, 700 m, and 910 m when the methane volume is 15 m3, 25 m3, 50 m3, 100 m3, 200 m3, respectively. Therefore, the larger the amount of methane involved in the explosion, the further the injury distance.

- (3)

- When a shock wave generated by a methane explosion propagates in the roadway, its overpressure attenuation is quite slow. When it decays below the safety threshold value, its propagation distance is quite long. The greater the overpressure of the shock wave, the more rapid the attenuation becomes; in a converse scenario, the attenuation becomes very slow.

- (4)

- The shock wave overpressure at different distances in a straight roadway with a constant cross-sectional area can be obtained as seen in Formula (6).

6. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Zhao, Y.; Addai, E.K. Investigation on propagation mechanism of large scale mine gas explosions. J. Loss Prev. Process Ind. 2017, 49, 342–347. [Google Scholar] [CrossRef]

- Wang, Q.; Jin, S.; Luo, Z.; Dai, A.; Wang, Q.; Li, Z. Flame propagation characteristics of methane explosion under different venting conditions. Fuel 2023, 334, 126721. [Google Scholar] [CrossRef]

- Luo, Z.; Kang, X.; Wang, T.; Su, B.; Cheng, F.; Deng, J. Effects of an obstacle on the deflagration behavior of premixed liquefied petroleum gas-air mixtures in a closed duct. Energy 2021, 234, 121291. [Google Scholar] [CrossRef]

- Yang, W.; Zheng, L.; Wang, C.; Wang, X.; Jin, H.; Fu, Y. Effect of ignition position and inert gas on hydrogen/air explosions. Int. J. Hydrogen Energy 2021, 46, 8820–8833. [Google Scholar] [CrossRef]

- Cui, C.; Shao, H.; Jiang, S.; Zhang, X. Experimental study on gas explosion suppression by coupling CO2 to a vacuum chamber. Powder Technol. 2018, 335, 42–53. [Google Scholar] [CrossRef]

- Gao, K.; Liu, Z.; Wu, C.; Li, J.; Liu, K.; Liu, Y.; Li, S. Effect of low gas concentration in underground return tunnels on characteristics of gas explosions. Process Saf. Environ. Prot. 2021, 152, 679–691. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, X. Analysis of human body injury due to blast wave and protection method. Chin. J. Explos. Propellants 2008, 31, 50–53. [Google Scholar]

- Li, R.; Zhang, Z.; Si, R.; Wang, L.; Li, S.; Wu, W.; Cao, J.; Ren, W. Experimental study on injuries to animals caused by a gas explosion in a large test laneway. Shock. Vib. 2021, 2021, 6632654. [Google Scholar] [CrossRef]

- Yu, M.; Fu, Y.; Zheng, L.; Pan, R.; Wang, X.; Yang, W.; Jin, H. Study on the combined effect of duct scale and SBC concentration on duct-vented methane-air explosion. Process Saf. Environ. Prot. 2021, 148, 939–949. [Google Scholar] [CrossRef]

- Jia, Z.; Ye, Q. Analysis of the response characteristics of a roadway wall under the impact of gas explosion. Energy Sci. Eng. 2023, 11, 2486–2504. [Google Scholar] [CrossRef]

- Li, Z.; Shi, Y.; Shi, X. Damage analysis and assessment of reinforced concrete slab under blast load. J. Build. Struct. 2009, 30, 60–66. [Google Scholar] [CrossRef]

- Pan, J.; Chen, W.; Guo, Z.; Zhou, Z. Evaluation of fire and blast-damaged RPC-FST column based on pressure-impulse diagram. Prot. Eng. 2018, 5, 16–26. [Google Scholar]

- Wei, W. Research on Damage Effect and Evaluation Method of Reinforced Concrete Members under Explosion Load. Ph.D. Dissertation, University of Defense Science and Technology, Changsha, China, 2012. [Google Scholar]

- Cao, X.; Wang, Z.; Lu, Y.; Wang, Y. Numerical simulation of methane explosion suppression by ultrafine water mist in a confined space. Tunn. Undergr. Space Technol. 2021, 109, 103777. [Google Scholar] [CrossRef]

- Li, S.; Jia, Z.; Ye, Q. Study on dynamic response of damper under gas explosion impact. Sustainability 2023, 15, 3356. [Google Scholar] [CrossRef]

- Davies, P.A. A guide to the evaluation of condensed phase explosions. Journal of Hazardous. Materials 1993, 33, 3–9. [Google Scholar]

- Wang, S.; Xie, Z. A discussion on the safety distance in case of gas explosion. J. China Univ. Min. Technol. 1989, 18, 1–7. [Google Scholar] [CrossRef]

- Liu, D. Safety distance calculation of air shock wave in underground explosive material warehouse. Metall. Saf. 1980, 5, 21–26. [Google Scholar]

- Li, Z. Safety distance for persons under blast air shock wave. Explos. Shock. Waves 1990, 10, 135–144. [Google Scholar]

- Qu, Z.; Zhou, X.; Wang, H.; Ma, H. Overpressure attenuation of shock wave during gas explosion. J. China Coal Soc. 2008, 33, 410–414. [Google Scholar]

- Wang, H.; Cao, T.; Zhou, X.Q.; Tan, G.Q.; Xie, J.G.; Jiang, W. Research and application of attenuation law about gas explosion shock wave in coal mine. J. China Coal Soc. 2009, 34, 778–782. [Google Scholar] [CrossRef]

- Lan, C.; Wang, C.; Zhang, C. Realization of safe distance of air shock wave by nomogram in underground blasting. Blasting 2013, 30, 39–42. [Google Scholar]

| Level | Overpressure (KPa) | Injury Degree |

|---|---|---|

| Slight | 19.6–29.4 | Slight contusion of lung and middle ear; local myocardial laceration. |

| Medium | 29.4–49 | Moderate contusion of the middle ear and lung. Sub-capsular hemorrhaging of the liver and spleen. Fusion myocardial tear. |

| Serious injury | 49–98 | Serious contusion of middle ear and lung. Dislocation, myocardial tear, may cause death. |

| Death | >98 | Body cavity, liver and spleen rupture; severe contusion of both lungs. |

| Level | Overpressure (KPa) | Damage Degree |

|---|---|---|

| 1 | 5–10 | House glass damage |

| 2 | 15–20 | Local damage of structures |

| 3 | 20–30 | Structure is slightly damaged and the wall is cracked |

| 4 | 40–50 | Structure is moderately damaged and the wall has large cracks |

| 5 | 60–70 | Structures are seriously damaged, partially collapsed, and reinforced concrete is damaged |

| 6 | 70–100 | Collapse of brick wall |

| 7 | >100 | Damage to reinforced concrete structures and earthquake-proof reinforced concrete |

| Sensors | 1 | 2 | 3 | 4 | 5 | 6 |

| Point position (L/D) | 35 | 50 | 52 | 60 | 62 | 68 |

| Overpressure (KPa) | 60.79 | 78.27 | 81.35 | 98.3 | 97.6 | 78.13 |

| Serial No | Distance from Explosion Point (m) | Peak Overpressure (KPa) | Flame Velocity (m/s) |

|---|---|---|---|

| 1 | 10 | 52.23 | 50.68 |

| 2 | 20 | 63.35 | 67.75 |

| 3 | 30 | 42.67 | 38.70 |

| 4 | 40 | 31.62 | Extinguish |

| 5 | 60 | 19.6 | Extinguish |

| Serial No | Distance from Explosion Point (m) | Peak Overpressure (KPa) | Flame Velocity (m/s) |

|---|---|---|---|

| 1 | 10 | 77.09 | 55.77 |

| 2 | 20 | 92.06 | 71.69 |

| 3 | 40 | 81.61 | 39.94 |

| 4 | 60 | 70.36 | 15.37 |

| 5 | 80 | 59.39 | Extinguish |

| 6 | 100 | 50.28 | Extinguish |

| 7 | 120 | 42.69 | Extinguish |

| 8 | 160 | 26.85 | Extinguish |

| 9 | 240 | 19.6 | Extinguish |

| Serial No | Distance from Explosion Point (m) | Peak Overpressure (KPa) | Flame Velocity (m/s) |

|---|---|---|---|

| 1 | 10 | 89.36 | 59.72 |

| 2 | 20 | 105.19 | 65.63 |

| 3 | 40 | 82.59 | 79.84 |

| 4 | 60 | 69.64 | 58.63 |

| 5 | 80 | 57.19 | 15.36 |

| 6 | 100 | 46.36 | Extinguish |

| 7 | 120 | 36.31 | Extinguish |

| 8 | 390 | 25.3 | Extinguish |

| 9 | 480 | 19.6 | Extinguish |

| Serial No | Distance from Explosion Point (m) | Peak Overpressure (KPa) | Flame Velocity (m/s) |

|---|---|---|---|

| 1 | 10 | 185.19 | 65.78 |

| 2 | 20 | 205.63 | 79.69 |

| 3 | 40 | 181.23 | 98.34 |

| 4 | 60 | 162.61 | 87.39 |

| 5 | 80 | 145.64 | 72.31 |

| 6 | 100 | 129.98 | 47.72 |

| 7 | 120 | 113.35 | 12.36 |

| 8 | 400 | 58.53 | Extinguish |

| 9 | 600 | 29.9 | Extinguish |

| 10 | 700 | 19.6 | Extinguish |

| Serial No | Distance from Explosion Point (m) | Peak Overpressure (KPa) | Flame Velocity (m/s) |

|---|---|---|---|

| 1 | 10 | 251.47 | 69.59 |

| 2 | 20 | 279.54 | 79.46 |

| 3 | 40 | 253.79 | 88.81 |

| 4 | 60 | 238.64 | 96.63 |

| 5 | 80 | 224.31 | 102.35 |

| 6 | 100 | 208.32 | 78.86 |

| 7 | 200 | 155.86 | 28.56 |

| 8 | 400 | 99.69 | Extinguish |

| 9 | 600 | 49.34 | Extinguish |

| 10 | 800 | 29.8 | Extinguish |

| 11 | 910 | 18.4 | Extinguish |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Z.; Ye, Q.; Xiong, W.; Liu, J. Damage Effect and Injury Range of Shock Waves in Mine Methane Explosion. Methane 2024, 3, 584-594. https://doi.org/10.3390/methane3040033

Jia Z, Ye Q, Xiong W, Liu J. Damage Effect and Injury Range of Shock Waves in Mine Methane Explosion. Methane. 2024; 3(4):584-594. https://doi.org/10.3390/methane3040033

Chicago/Turabian StyleJia, Zhenzhen, Qing Ye, Wei Xiong, and Jialin Liu. 2024. "Damage Effect and Injury Range of Shock Waves in Mine Methane Explosion" Methane 3, no. 4: 584-594. https://doi.org/10.3390/methane3040033

APA StyleJia, Z., Ye, Q., Xiong, W., & Liu, J. (2024). Damage Effect and Injury Range of Shock Waves in Mine Methane Explosion. Methane, 3(4), 584-594. https://doi.org/10.3390/methane3040033