1. Introduction

Materials are exposed to severe damaging conditions in nuclear energy production devices: the fission reactors and the fusion tokamaks (as ITER). During nuclear reactions, neutrons are produced; they penetrate and stop in the facing materials, creating defects (vacancies and self interstitial atoms (SIA)) in the microstructure that can diffuse and agglomerate, deteriorating the material properties. In fusion tokamaks in particular, nanocavities increase the retention of tritium and reduce the thermal conductivity of the material. To guarantee the safety of the reactors, dedicated experimental campaigns and multiscale modeling projects have been performed for decades to understand and model the microstructure evolution. Still, few data exist on the diffusion properties of the nanocavities. The main reasons are, on the one hand, that a significant part of the defects are not visible with any microscope and on the other hand that the pertinent simulations have to handle a large range of temperature-dependent processes that drive to the microstructure evolution and recovery.

In the 1960s, the pores motion and coalescence in metals were intensively studied to understand the material microstructure damage in nuclear devices [

1,

2,

3]. The investigations were limited by the computation capacities and the size resolution of the experimental techniques. For these reasons, the diffusion of small nanocavities is still poorly characterized. Apart from the classical surface diffusion model [

3], in recent years, new theoretical data using atomic scale approaches have been reported. In 2017, Mason et al. calculated the migration energies of small vacancy clusters with density functional theory [

4], Castin et al. characterized the diffusion properties of vacancy clusters using machine learning with the drawback of relying on an empirical potential [

5] and D. Perez et al. investigated the diffusion properties of very small vacancy-helium complexes with accelerated methods and thanks to a supercomputer [

6] but also using empirical potentials. We finally spot, in iron, the results of Jansson et al. [

7] and Pannier et al. [

8] where they show that increasing the cluster size by adding one point defect at a time, change the cluster symmetry for some specific size, modifying strongly the migration energy. This causes rapid fluctuations of the migration energy as a function of the cluster size. On the experimental side, nowadays, electron microscopes allow the analysis of nanometric defects.

We propose to bridge the gap between the smallest defects and the several nanometer size cavities by combining a series of new microscopy results detailed in [

9], an improved object kinetic Monte Carlo (OKMC) model that simulates the nanocavities creation, diffusion and coalescence in irradiated tungsten [

10] and a multiobjective optimization. In this paper, we describe the optimization method whose complexity comes from the large dimension of the inputs and outputs of the model, the computing time of a single simulation and the interdependencies of the data. Indeed, the optimized parameters are the diffusion temperature of the nanocavities which are expected to be set into motion one after the other by ascending size order, when the sample temperature is increased during the annealing stages. On the other hand, however, at the end of each temperature, we do not observe these diffusing nanocavities but the result of their interaction with the whole microstructure.

Section 2 of this paper describes the multiobjective optimization problem.

Section 3, we describe briefly the experimental data and the numerical model.

Section 4, we detail the result of the Pareto front search and our proposition of projection of the objectives in the space of parameters. This manuscript ends with the discussion and conclusion.

2. Problem Formulation

One subtlety of the problem is that two series of temperatures are considered. The first ones are the annealing temperatures, , the real temperatures at which the samples are put during the experiment. The others are the diffusion temperatures, , inputs of the model and hypothetical temperatures at which nanocavities of various sizes start their diffusion. The link between these two series of temperatures is that if one diffusion temperature is close to one annealing temperature, it is likely that the related nanocavity family diffuses and modifies the sample microstructure. However, there is no established method to define the diffusion temperature.

The aim of this work is to determine the diffusion temperature by

values on a discretization of the size (diameter) range from 0.3 to 4 nm. We consider an increasing function,

Experimental data are described in [

9]. We consider the

size and

densities of nanocavities as a function of time and temperature,

where

,

are time and temperature.

and

are related because the observations are realized at the end of the irradiation and annealing stages only. One has

Few experimental data are available, and the scattering is significantly larger that the fluctuations of the simulated results (

Section 3.2). We design a likelihood for

observed and

, fitted by regression on the experimental data by minimizing the sum of squared differences

The numerical OKMC model mimics the experiment. The temperature

of (

1) is the input of the model (

Section 3.3). The outputs give the simulated total nanocavity density and mean sizes

where

is the associated stochastic process and where the temperature function of time is fixed as for the experiment.

The components of the objective function are the functions of the distance between

and

values:

Remember that the indexes are

, where

is the length of

, and

is the number of pairs of

data. One has the density and size objectives, hence

terms:

where

represents the mean on OKMC simulations for one

and where a density of probability of the error is assumed to be proportional to

. Notice the logarithm introduced in Equation (

6) and

S equal to 1 (respectively, 5) for

(respectively,

) in Equation (

7), to strengthen the attachment to the data

compared to

(see also

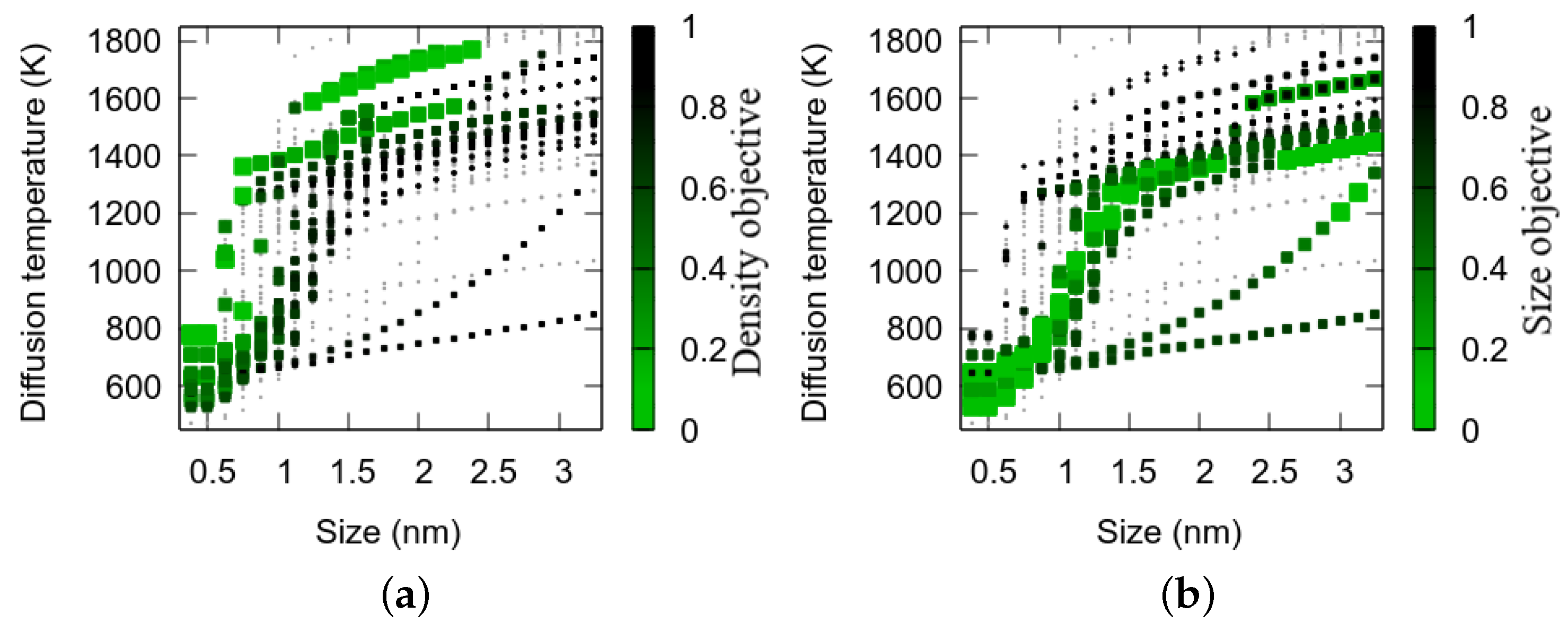

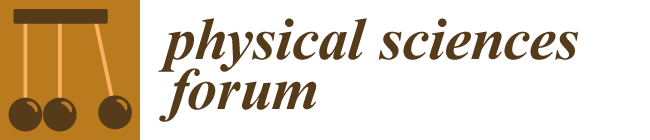

Figure 1b).

A weighted loss function and the steepest descent methods were particularly unsatisfying because of the following:

The dependence of the objectives from one temperature to the next one: depends on . If the simulation is far from the observation at , there is little chance to get it correct at .

An unexpected interdependence of and objectives. At each temperature stage, we observed that the optimization of , tends to disfavor , .

The search of the Pareto front in the

dimensions appeared to be meaningful as we will describe in

Section 4. Finally, to determine the optimum parameters, we tested a

of the objectives in the space of parameters based on the physics of the OKMC. The

matrix is the function of the parameter

:

where

j are the objective indexes,

i are the parameter indexes and

is a function which is equal to 1 if

is true and 0 on the contrary case. Projected objectives are

With this projection, the performance given by the objective j is associated to the class sizes i which did not diffuse at temperature but will start to diffuse at temperature . is to make an average if necessary.

3. Experimental Data and Numerical Model

A detailed description of the experimental results and the improved numerical model are given resp. in [

9,

10]. We will describe the aspects related to the optimization problem, starting with a short description of the irradiation process at the atomistic scale named

collision cascade.

3.1. Collision Cascade

Irradiation of the sample is obtained by bombardment with high energy ions. We know that the ions lose their kinetic energy in the crystal by a series of collisions with the metal atoms which, when the energy they received is high enough, are kicked out of their position in the crystal lattice and initiate a chain reaction named collision cascade. The expansion stage of the collision cascades is shorter than 0.5 ps and is followed by a quick process of defect recombination during a few ps. At the end, defect debris remain and form what is named the primary damage, made of self-interstitial atoms (SIAs) and vacancies. After the collision cascade cooling, the crystal lattice recovery continues more slowly, provided that the defects diffuse, which is the case, for example, at 773 K for SIA, single vacancy and small vacancy clusters.

In this work, the cumulative level of damage is 0.02 dpa, which means that, on average, 2% of the atoms were kicked out of their lattice site during the expansion of the collision cascades. The real fraction of defect is clearly smaller, thanks to the crystal lattice recovery, driven by thermodynamic forces. However, the kinetic of this process is mainly controlled by the defect diffusion. Defects can recomb ine but also agglomerate, forming larger and larger clusters, mainly dislocation loops and nanocavities.

3.2. Experimental Data

The experiment requires the preparation, irradiation and annealing of tungsten samples and the defect characterization. The preparation consists mainly in cutting and polishing 99.95% pure commercialized polycrystalline tungsten samples and preliminary annealing (heating) at 1873 K to remove native defects. Thin zones are obtained with a twin-jet electropolisher with a thickness as small as 33 nm. This makes the sample locally transparent as required by the transmission electron microscope (TEM). The second step is the irradiation stage: bombardment of the sample surface to a fluence of m high energy ions (1.2 MeV W) at 773 K. The third step is a succession of annealings made of plateaus of 1 h each, at increasing setpoint temperature.

At the end of the irradiation and each annealing stage, the sample microstructure is observed by TEM, and several micrographs are saved.

Figure 2a shows, for example, the large concentration of very small nanocavities visible at the end of the irradiation stage.

The nanocavity total density and their mean size as a function of temperature are plotted in

Figure 1a. The large scattering is mainly due to the small number of samples (and micrographs per temperature), local composition variations, variation of the transparency (variation of the sample thickness) and differences in the counting methods (human or automatic) [

11,

12]. On the same figure, lines represent a likelihood function introduced by Equation (

4) and adjusted on experimental points. This function has eight parameters to be equal to 1 for:

with

and

.

Figure 1 illustrate the data attach function of the objectives of Equation (

7). The 0–0.5 objective range corresponds roughly to the 1–0.5 area of the likelihood.

We can see in

Figure 1a that when the temperature increases, the

decreases and the

increases. This is due to the progressive setting into motion of the nanocavities by ascending size order. Some are eliminated at the sample surface or by recombination with SIA defects. Others agglomerate and form larger nanocavities participating in the

coalescence process.

3.3. Numerical Model

The OKMC simulates the creation, diffusion and reactions of defects in a 3D box (∼250 nm). Two types of defects exist: SIA and vacancy. Because of their diffusion, they can find each other and annihilate (defects of opposite type) or form clusters (defects of the same type). The diffusion is function of the jump probability that depends on the defect type and size as well as temperature, using an Arrhenius formula. For vacancy defects, the jump probability is usually

where

is the attempt frequency,

is the migration energy, and

k is the Boltzmann constant. For this work, we simplify the diffusion parameters and use the diffusion temperatures,

, introduced in (

1). The relation with the probability of jump is obtained using [

3] to fix

,

During the simulation of the irradiation stage, defects are introduced as pockets of vacancy and SIA clusters, randomly picked in a database of displacement cascade debris described in [

13]. The microstructure evolution in an OKMC consists in applying events picked randomly according to their probabilities, for instance, one defect jump (diffusion). Reactions such as defect recombinations or agglomerations are realized by checking the vicinity of all the defects. An illustration of the defects present in the simulation box at the end of the irradiation stage is given in

Figure 2b, next to the experimental TEM picture.

5. Discussion

The Pareto optimal solution is the ensemble of parameters where no improvement of the objective can be achieved without losing on another one. Thanks to the projection, we can visualize the objective function in the parameter space, and there remain only two objective components which correspond to the two curves plotted in

Figure 5a. They limit three domains, labeled

A,

B and

C as in

Section 4.1 for the implantation. In set

B, the nanocavities are set into motion too rapidly when the temperature increases, then

drops too quickly and

grows too quickly, and vice versa for set

C. Set

A, the region between those “valleys”, corresponds to compromises between

and

objectives. It contains the Pareto optimal solutions, as moving closer to the

optimum means going further away from the

optimum and vice versa.

For each size class, drawing a vertical line from the lower limit to the higher limit can be seen as an uncertainty on the diffusion temperature, i.e., the limit of knowledge that can be extracted from our experimental data and our model in their current form. In

Figure 5b, our results are compared with literature. They agree with Mason’s calculations of very small vacancy clusters as well as with the classical surface diffusion model for large nanocavities. In the intermediate range, we improve the formula we proposed in [

14] and Castin’s calculations.

A detailed discussion of the limitation of our OKMC model is in [

10] and of the experimental results in [

9]. The discussion remains opened about an automatic optimization algorithm and the projection method. One puzzling question raised by the optimization is the origin of the two branches of the Pareto front in the space parameter. It points that it is not possible to reproduce simultaneously

and

objectives. One explanation is a source of vacancies during the annealing that is considered neither in the experimental interpretation nor in our model, so far.