Abstract

A gelled emulsion (GE) prepared with flax oil and peanut flour was used to replace pork back-fat in Frankfurt-type sausages. Three different formulations were prepared: Control (CS) with 30% pork back fat, and two to achieve 50% and 100% fat substitution by GE (GE50 and GE100, respectively). This study demonstrated that the use of gelled emulsion elaborated with peanut flour and flax oil may be a promising strategy in the reformulation of healthier meat products due to producing a reduction in fat content and improving the fatty acid profile.

1. Introduction

Frankfurter-type sausages are one of the most consumed meat products worldwide. Among the reasons that this product is so popular are its taste, convenience, and low price. On the other hand, this meat product contains a high amount of fat, exceeding 40% in some formulations [1]. This makes the consumer, increasingly aware of the relationship between food and health, begin to reject this type of product. The food industry is aware of this problem and must adapt and offer the consumer products according to their needs and concerns. One of the strategies followed by the food industry to get closer to the products demanded by the consumer is the development of products with low fat content or with a healthier lipid profile compared with traditional formulations [2]. Thus, the aim of this work was to determine the effect of the partial and total replacement of pork backfat with a gelled emulsion elaborated with peanut flour and flaxseed oil on the chemical composition, physic-chemical, and sensorial properties of Frankfurt-type sausages.

2. Material and Methods

2.1. Materials

The ingredients used to make gelled emulsions were: flaxseed oil (53.82% linolenic acid, 15.74% linoleic acid, 19.32 oleic acid, 5.61% palmitic acid, and 4.04% stearic acid) from Laboratorios Almond, S.L. (Murcia, Spain); peanut flour distributed by Buffsupp sport nutrition (Batley, UK); and gelatin of animal origin (pork) with 180 bloom that was supplied from Sosa Ingredients S.L. (Barcelona, Spain).

2.2. Elaboration of Oil-in-Water Gelled Emulsion

Oil-in-water gelled emulsions (GE) were elaborated following the recommendation of Öztürk-Kerimoğlu et al. [3].

2.3. Elaboration of Frankfurt-Type Sausages

Frankfurter-type sausages were elaborated according to the formula described by Botella-Martínez et al. [4]. Three independent replicates of each batch were prepared. The traditional formula was used as a control sample (CS) and the other two batches were formulated replacing the animal fat with the GE previously prepared: in one, 50% of pork backfat was replaced with GE (GE50), and in the other, 100% of pork backfat was replaced with GE (GE100).

2.4. Proximate Composition of Frankfurt-Type Sausages

The chemical composition (moisture, protein, fat, and ash content) of samples was analyzed according to the Association of Official Analytical Chemists analysis [5].

2.5. Fatty Acid Composition

Lipid extraction of Frankfurter was done following the methodology described by Bligh and Dyer. Gas Chromatography (GC) analysis was carried out to determine the fatty acid profile using the methodology described by Pellegrini et al. [6].

2.6. Physic-Chemical Properties

The pH values of samples was assessed directly using a Crison combination electrode probe connected to a pH meter (model 507 Crison, Barcelona, Spain). Texture profile analysis was performed using a texture analyzer TA-XT2 (Stable Micro Systems, Farncombe, UK) following the methods for the objective measurement of meat product texture [7]. The color was studied in the CIEL*a*b* color space using a Minolta CM-700 (Minolta Camera Co., Osaka, Japan). The CIEL*a*b* coordinates determined were: lightness (L*), redness (a*, coordinate red/green), and yellowness (b*, coordinate yellow-blue). Emulsion stability of samples (before heat treatment) was assessed by means of total expressible fluid (TEF) following the recommendations of Pintado et al. [2].

2.7. Lipid Oxidation

Lipid oxidation of samples was determined by the 2-thiobarbituric acid (TBA) method following the recommendations of Rosmini et al. [8]. The lipid oxidation values were expressed as mg malondialdehyde (MDA)/kg sample.

2.8. Sensory Analysis

A 50-member sensory panel with no specific training in the sensory analysis of Frankfurt sausages was recruited from the staff and students of the Miguel Hernández University. Pieces of 2.0 cm (3 pieces, one from each batch) were cut from the Frankfurter and served at room temperature. Unsalted crackers and mineral water were provided to clean the palate between samples. The hedonic scale contained 7 levels (9 = highly acceptable; 1 = highly unacceptable), in which the panelists evaluated the test parameters: color, brightness, salty flavor, fattiness, juiciness, hardness, and general acceptability.

2.9. Statistical Analysis

All assays were undertaken in triplicate and the data were stated as mean ± standard deviation and compared through the statistical program NCSS (2011 version) software. The analysis of the data consisted of one-way analysis of variance (ANOVA), in which the effects of the treatment were considered. Tukey’s post hoc test was applied for comparisons of means, and differences were considered significant at p < 0.05.

3. Results and Discussion

3.1. Chemical Composition

Table 1 shows the chemical composition of Frankfurt-type sausage formulates replacing pork backfat with gelled emulsion elaborated with peanut flour and flaxseed oil. As regards to protein and ash content, no statistical differences (p > 0.05) were found between CS and GE50 and GE100. For moisture, GE100 had the highest (p < 0.05) values whereas no differences (p > 0.05) were obtained for CS and GE50.

Table 1.

Chemical composition of Frankfurt-type sausage formulates replacing pork backfat with gelled emulsion elaborated with peanut flour and flaxseed oil.

In the case of fat content, a substantial reduction (p < 0.05) in total fat content was obtained in Frankfurt sausages as the level of fat replacement by gelled emulsion increased. This reduction is similar to that reported by Botella-Martínez et al. [4] in Frankfurters prepared with gelled emulsion elaborated with vegetable oils and pseudocereal flours. In reference to fatty acid profile (Table 2), the results achieved showed that the fatty acid profile was affected by the fat replacement by gelled emulsion.

Table 2.

Fatty acid profile of Frankfurt-type sausage formulates replacing pork backfat with gelled emulsion elaborated with peanut flour and flaxseed oil.

All of the samples analyzed presented significant differences (p < 0.05) in the content of saturated, monounsaturated, and polyunsaturated fatty acids with respect to the control sample. In the control sample, the monounsaturated and saturated fatty acids were the predominant groups with oleic acid, palmitic acid, and stearic acid as the major compounds. On the other hand, GE50 and GE100 had increased polyunsaturated fatty acids, mainly linoleic (C18:2n-6) and linolenic (C18:3n-3) acids, and this occurred in a manner dependent on the degree of replacement. These results were in agreement with those reported by Nacak et al. [9] who reported a reduction in saturated and monounsaturated fatty acids and an increase in polyunsaturated fatty acids in the fatty acid profile of emulsified sausages elaborated with flaxseed oil.

3.2. Physic-Chemical Properties

Emulsion stability (%TEF), pH, and color parameters are shown in Table 3. In reference to emulsion stability, the higher the %TEF, the lower the emulsion stability. The pork backfat substitution by GE50 and GE100 (at any percentage) caused significant differences (p < 0.05) in emulsion stability. Thus, the GE100 had the lowest (p < 0.05) emulsion stability values. This effect could be explained, as mentioned by de Souza Paglarini et al. [10], due to a reduction in animal fat content in cooked meat products, such as sausages, reducing their stability. All of the Frankfurt-type sausages had pH values in the range considered normal for this type of cooked sausage [11] with statistical differences (p < 0.05) between samples. All color parameters (L*, a*, b*) were significantly (p < 0.05) affected by the use of GE as fat replacer in Frankfurt-type sausages. Thus, EG100 showed the highest (p < 0.05) L*, a*, b* values. These values were, probably, due to the differences in color between pork back fat and the GE used as replacers [12].

Table 3.

Physic-chemical properties of Frankfurt-type sausage formulates replacing pork backfat with gelled emulsion elaborated with peanut flour and flaxseed oil.

Texture (Table 3) is another very important factor for consumers in reference to meat products. The backfat replacement with GE had no effect (p < 0.05) on springiness and cohesiveness. For these parameters, no statistical differences were found between CS and GE50 and GE100. However, the replacement of fat with GE in sausage formulation produced a significant decrease (p < 0.05) in the hardness of the samples which was dependent on the replacement degree. The higher the substitution, the lower the hardness. These results were opposite to those reported by Pintado et al. [2] and Nacak et al. [9], who mentioned that sausages increased in hardness when fat replacement with gelled emulsion was increased, due to lipid–protein interactions.

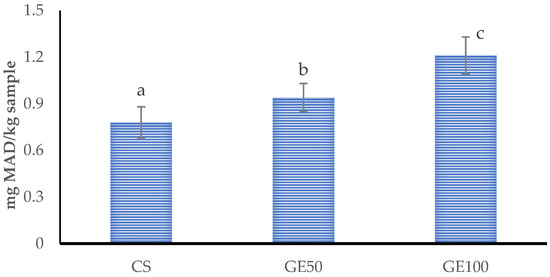

3.3. Lipid Oxidation

The lipid oxidation values of Frankfurt-type sausage formulates replacing pork backfat with gelled emulsion elaborated with peanut flour and flaxseed oil are shown in Figure 1. The control sample had the lowest (p < 0.05) values, with the GE100 showing the highest (p < 0.05) oxidation degree. The results obtained showed that the animal fat replacement with gelled emulsions had an undesirable effect on the oxidative stability of sausages. This phenomenon could be explained by the substitution of saturated fatty acids, present in animal fat and which are more stable against oxidation, with unsaturated fatty acids present in vegetable oils, which are more susceptible to lipid oxidation, as mentioned by Lucas-Gonzalez et al. [13].

Figure 1.

Lipid oxidation values (mg malonaldehyde/kg sample) of Frankfurt-type sausage formulates replacing pork backfat with gelled emulsion elaborated with peanut flour and flaxseed oil. CS: Control sample; GE50: Frankfurt sausage where 50% of the fat was replaced with a gelled emulsion; GE100: Frankfurt sausage where 100% of the fat was replaced with a gelled emulsion. Values with the same letter in the same bars indicate no significant differences according to Tukey’s HSD post-hoc test (p > 0.05).

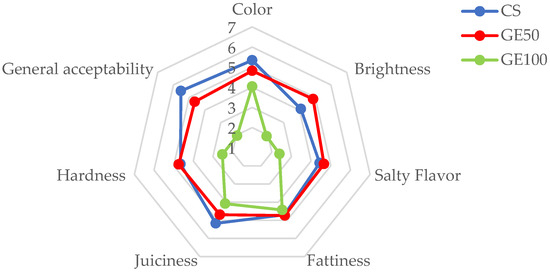

3.4. Sensorial Analysis

Figure 2 shows the results obtained for the sensorial analysis carried out in Frankfurt-type sausage formulates replacing pork backfat with gelled emulsion elaborated with peanut flour and flaxseed oil. According to the results, it was shown that color, salty flavor, fattiness, juiciness, and hardness did not present significant differences (p > 0.05) between GE50 and the control sample. GE100 had the lowest scores (p < 0.05) in all parameters analyzed.

Figure 2.

Sensorial parameters of Frankfurt-type sausage formulates replacing pork backfat with gelled emulsion elaborated with peanut flour and flaxseed oil. CS: Control sample; GE50: Frankfurt sausage where 50% of the fat was replaced with a gelled emulsion; GE100: Frankfurt sausage where 100% of the fat was replaced with a gelled emulsion.

4. Conclusions

This study demonstrated that the use of gelled emulsion elaborated with peanut flour and flax oil may be a promising strategy in the reformulation of healthier meat products as the texture properties and lipid stability, despite being modified, are within the parameters that can be considered normal. On the other hand, the sausages had a better lipid profile with higher content of polyunsaturated fatty acids which increased the amount of omega 3 and reduced saturated fatty acids.

Author Contributions

Conceptualization, M.V.-M.; Methodology and investigation, C.B.-M.; Data curation, E.S.-B. Formal analysis and writing—original draft preparation, J.F.-L. Writing—review and editing, J.Á.P.-A. and M.V.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

All researchers are members of the HealthyMeat network, funded by CYTED (ref: 119RT0568).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jandásek, J. Seasoning in the production of frankfurters and sausages. Maso Int. J. Food Sci. Technol. 2014, 1, 53–62. [Google Scholar]

- Pintado, T.; Ruiz-Capillas, C.; Jiménez-Colmenero, F.; Carmona, P.; Herrero, A.M. Oil-in-water emulsion gels stabilized with chia (Salvia hispanica L.) and cold gelling agents: Technological and infrared spectroscopic characterization. Food Chem. 2015, 185, 470–478. [Google Scholar] [CrossRef] [PubMed]

- Öztürk-Kerimoğlu, B.; Kavuşan, H.S.; Gürel, D.B.; Çağındı, Ö.; Serdaroğlu, M. Cold-set or hot-set emulsion gels consisted of a healthy oil blend to replace beef fat in heat-treated fermented sausages. Meat Sci. 2021, 176, 10846. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Viuda-Martos, M.; Pérez-Álvarez, J.A.; Fernández-López, J. Total and partial fat replacement by gelled emulsion (hemp oil and buckwheat flour) and its impact on the chemical, technological and sensory properties of frankfurters. Foods 2021, 10, 1681. [Google Scholar] [CrossRef] [PubMed]

- Official Methods of Analysis of AOAC International, 18th ed.; Association of Official Analytical Chemistry: Rockville, MD, USA, 2010.

- Pellegrini, M.; Lucas-Gonzales, R.; Ricci, A.; Fontecha, J.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Chemical, fatty acid, polyphenolic profile, techno-functional and antioxidant properties of flours obtained from quinoa (Chenopodium quinoa Willd) seeds. Ind. Crop Prod. 2018, 111, 38–46. [Google Scholar] [CrossRef]

- Bourne, M.C. Texture profile analysis. Food Technol. 1978, 32, 62–72. [Google Scholar]

- Rosmini, M.R.; Perlo, F.; Perez-Alvarez, J.A.; Pagan-Moreno, M.J.; Gago-Gago, M.A.; Lopez-Santoveña, F.; Aranda-Catlá, V. TBA test by extractive method applied to pate. Meat Sci. 1996, 42, 103–110. [Google Scholar] [CrossRef]

- Nacak, B.; Kerimoğlu, B.; Yıldız, D.; Çağındı, Ö.; Serdaroğlu, M. Peanut and linseed oil emulsion gels as potential fat replacer in emulsified sausages. Meat Sci. 2021, 176, 108464. [Google Scholar] [CrossRef] [PubMed]

- de Souza Paglarini, C.; de Figueiredo Furtado, G.; Honório, A.R.; Mokarzel, L.; da Silva Vidal, V.A.; Ribeiro, A.P.B.; Pollonio, M.A.R. Functional emulsion gels as pork back fat replacers in Bologna sausage. Food Struct. 2019, 20, 100–105. [Google Scholar] [CrossRef]

- Fernández-López, J.; Lucas-González, R.; Viuda-Martos, M.; Sayas-Barberá, E.; Navarro, C.; Haros, C.M.; Pérez-Álvarez, J.A. Chia (Salvia hispanica L.) products as ingredients for reformulating frankfurters: Effects on quality properties and shelf-life. Meat Sci. 2019, 156, 139–145. [Google Scholar] [CrossRef] [PubMed]

- de Souza Paglarini, C.; Martini, S.; Pollonio, M.A.R. Using emulsion gels made with sonicated soy protein isolate dispersions to replace fat in frankfurters. LWT-Food Sci. Technol. 2019, 99, 453–459. [Google Scholar] [CrossRef]

- Lucas-Gonzalez, R.; Roldán-Verdu, A.; Sayas-Barberá, E.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Assessment of emulsion gels formulated with chestnut (Castanea sativa M.) flour and chia (Salvia hispanica L.) oil as partial fat replacers in pork burger formulation. J. Sci. Food Agric. 2020, 100, 1265–1273. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).