Impact of Rosehip (Rose Canina) Powder Addition and Figure Height on 3D-Printed Gluten-Free Bread †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Rose Hip Powder Obtainment

2.3. Dough Preparation

2.4. Dough 3D Printing

2.5. Determinations

2.5.1. Rheological Characterization

2.5.2. Image Analysis

2.5.3. Color Analysis

2.5.4. Textural Characterization

2.5.5. Statistical Analysis

3. Results and Discussion

3.1. Rheological Characterization

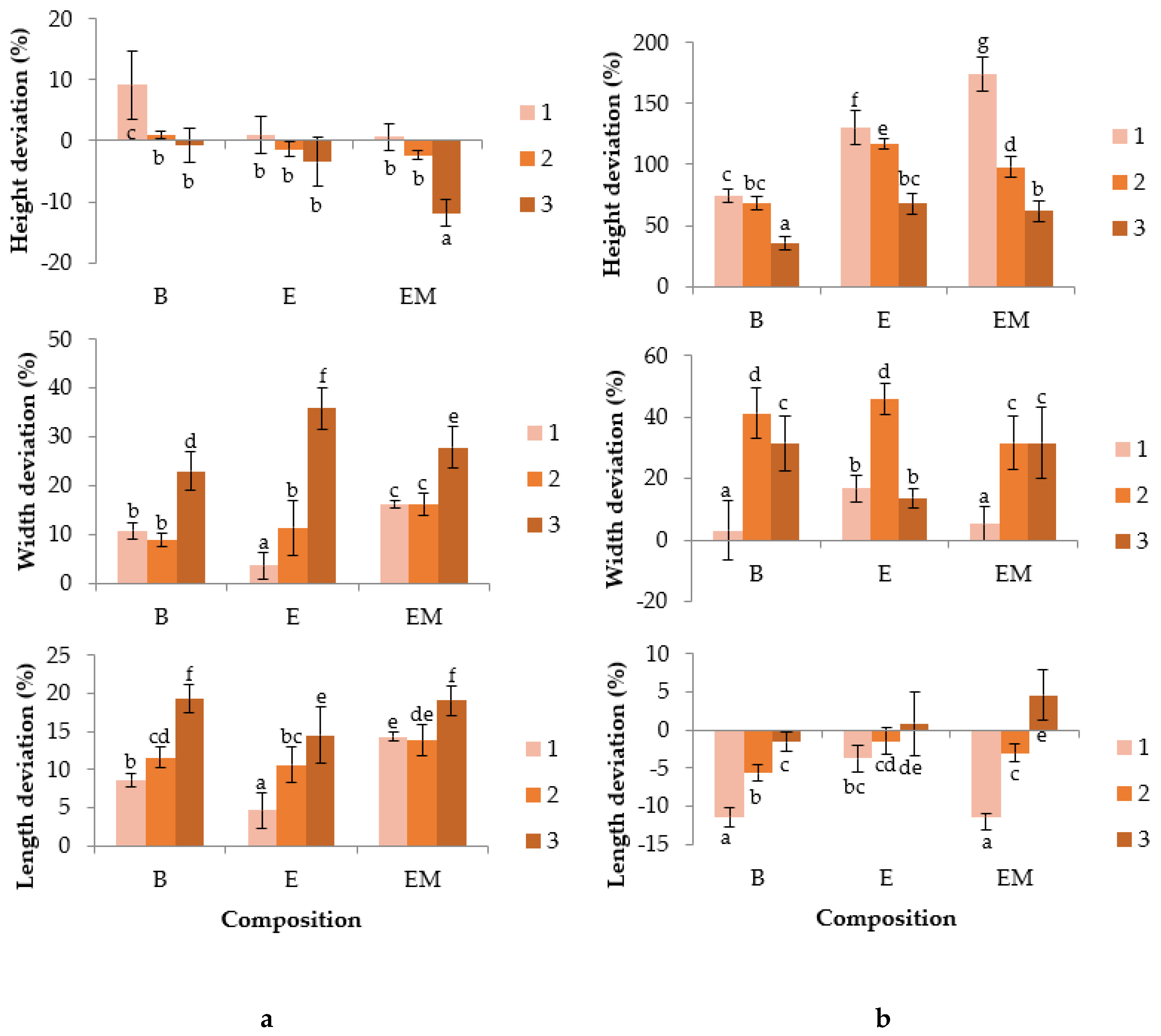

3.2. Image Analysis

3.3. Color Analysis

3.4. Textural Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Godoi, F.C.; Bhandari, B.R.; Prakash, S.; Zhang, M. An introduction to the Principles of 3D Food Printing. In Fundamentals of 3D Food Printing and Applications; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 1; pp. 1–18. [Google Scholar]

- Uribe-Wandurraga, Z.N.; Igual, M.; Reino-Moyón, J.; García-Segovia, P.; Martínez-Monzó, J. Effect of Microalgae (Arthrospira platensis and Chlorella vulgaris) Addition on 3D Printed Cookies. Food Biophys. 2021, 16, 27–39. [Google Scholar] [CrossRef]

- Jagadiswarn, B.; Alagarasan, V.; Palanivelu, P.; Theagarajan, R.; Moses, J.A.; Anandharamakrishnan, C. Valorization of food industry waste and by-products using 3D printing: A study on the development of value-added functional cookies. Future Foods 2021, 4, 100036. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Oral, M.O.; Severini, C. Analyzing the effects of 3D printing process per se on the microstructure and mechanical properties of cereal food products. Innov. Food Sci. Emerg. Technol. 2020, 66, 102531. [Google Scholar] [CrossRef]

- Nijdam, J.J.; Agarwal, D.; Schon, B.S. An experimental assessment of filament-extrusion models used in slicer software for 3D food-printing applications. J. Food Eng. 2021, 317, 110711. [Google Scholar] [CrossRef]

- Valenzuela, B.; Valenzuela, R.; Sanhueza, J.; Morales, G. Functional foods, nutraceuticals and foshu: Are we going to a novel food concept? Rev. Chil. Nutr. 2014, 41, 198–204. [Google Scholar]

- De la Calle, I.; Ros, G.; Peñalver, R.; Nieto, G. Enfermedad celiaca: Causas, patología y valoración nutricional de la dieta sin gluten. Rev. Nutr. Hosp. 2020, 37, 1043–1051. [Google Scholar]

- Patel, S. Rose hip as an underutilized functional food: Evidence-based review. Review. Trends Food Sci. Technol. 2017, 63, 29–38. [Google Scholar] [CrossRef]

- Sharma, Y.; Hedge, R.V.; Venugopal, C.K. Health and nutrition from ornamentals. Int. J. Res. Ayurveda Pharm. 2011, 2, 375–382. [Google Scholar]

- Razungles, A.; Ozszmianski, J.; Sapis, J.-C. Determination of carotenoids infruits of Rosa sp. (Rosa canina andRosa rugosa) and chokeberry (Aronia melanocarpa). J. Food Sci. 1989, 54, 774–775. [Google Scholar] [CrossRef]

- Andersson, S.; Rumpunen, K.; Johansson, E.; Olsson, M.E. Carotenoid content and composition in rose hips (Rosa spp.) during ripening, determination of suitable maturity marker and implications for health promoting food products. Food Chem. 2011, 128, 689–696. [Google Scholar] [CrossRef]

- Gamonpilas, C.; Buathongjan, C.; Kirdsawasd, T.; Rattanaprasert, M.; Klomtun, M.; Phonsatta, N.; Methacanon, P. Pomelo pectin and fiber: Some perspectives and applications in food industry. Food Hydrocoll. 2021, 120, 106981. [Google Scholar] [CrossRef]

| Masa | G* (Pa) | G′ (Pa) | G″ (Pa) | Tanδ (°) | η* (mPa s) |

|---|---|---|---|---|---|

| B | 1444 (65) a | 1408 (64) a | 324 (14) a | 0.2300 (0.0003) a | 230 (10) a |

| E | 1690 (90) b | 1639 (88) b | 410 (19) b | 0.2499 (0.0018) c | 269 (14) b |

| EM | 1450 (95) a | 1409 (92) a | 339 (21) a | 0.2408 (0.0011) b | 231 (15) a |

| Sample | L* | a* | b* | h | C | ΔE |

|---|---|---|---|---|---|---|

| MB | 81.221 (0.019) c | −1.7 (0.2) a | 9 (0.2) a | 100.5 (0.3) c | 9 (0) a | - |

| ME | 64.1 (0.3) a | 14.1 (0.4) c | 29.2 (0.4) c | 64.2 (0.3) a | 32.4 (0.6) c | 30.8 (0.6) b |

| MEM | 66.6 (0.2) b | 10.6 (0.3) b | 24.7 (0.3) b | 66.7 (0.5) b | 26.9 (0.3) b | 24.7 (0.3) a |

| C1B | 59 (8) cd | 7.1 (1.8) b | 25 (6) cd | 73 (7) d | 26 (5) bc | - |

| C1E | 60 (7) cd | 7.7 (0.8) bc | 24 (2) cd | 72 (3) d | 25.5 (1.9) bc | 11 (6) a |

| C1EM | 65 (5) d | 5.3 (1.4) a | 20 (3) abc | 75 (4) d | 21 (3) ab | 11 (8) a |

| C2B | 64 (3) d | 7.4 (0.8) bc | 28 (2) d | 75.3 (1.6) d | 29 (2) c | - |

| C2E | 47 (8) ab | 10.4 (1.5) e | 17 (8) ab | 55 (12) ab | 20 (7) ab | 21 (10) b |

| C2EM | 54 (7) bc | 8.6 (1.5) cd | 22 (5) bcd | 68 (4) cd | 24 (5) abc | 13 (8) a |

| C3B | 62 (5) d | 6.9 (1.2) b | 27 (4) d | 75 (3) d | 28 (4) c | - |

| C3E | 46 (9) a | 10 (2) de | 15 (10) a | 48 (9) a | 19 (9) a | 21 (10) b |

| C3EM | 50 (10) ab | 8.8 (1.6) cd | 19 (9) abc | 59 (19) bc | 22 (8) ab | 16 (14) ab |

| Mi1B | 50 (4) b | 1.4 (0.9) a | 7.5 (0.9) a | 79 (7) d | 7.7 (0.9) a | - |

| Mi1E | 47 (1.3) a | 12.4 (1.2) e | 23.1 (1.6) d | 61.8 (1.3) c | 26.3 (1.8) e | 20 (2) e |

| Mi1EM | 45 (5) a | 8.1 (0.7) b | 14 (3) b | 59 (5) bc | 16 (2) b | 12 (3) a |

| Mi2B | 56 (3) c | 0.6 (0.9) a | 9 (2) a | 86 (4) e | 9 (2) a | - |

| Mi2E | 44 (3) a | 11.7 (1.2) e | 17 (4) c | 54 (4) a | 20 (3) c | 18 (3) de |

| Mi2EM | 47 (3) a | 9 (1.2) bc | 15 (3) bc | 59 (2) bc | 18 (4) bc | 15 (3) bc |

| Mi3B | 55.0 (0.8) c | 1 (2) a | 9 (4) a | 85 (6) e | 9 (4) a | - |

| Mi3E | 44.1 (1.5) a | 10.3 (1.5) d | 16 (2) bc | 57 (3) ab | 19 (3) c | 17 (3) cd |

| Mi3EM | 47 (2) a | 9.6 (0.8) cd | 16 (2) bc | 59 (2) bc | 18 (2) bc | 14 (3) ab |

| Sample | H | A | C | S | Ch | R | P(F máx) |

|---|---|---|---|---|---|---|---|

| 1B | 66 (12) ab | −0.9 (0.9) a | 0.59 (0.06) a | 0.65 (0.12) a | 26 (9) a | 0.32 (0.04) a | 402 (62) f |

| 1E | 43.6 (1.2) a | −6 (5) a | 0.73 (0.16) bc | 0.92 (0.05) bc | 29 (8) a | 0.38 (0.06) b | 303 (133) e |

| 1EM | 122 (21) abc | −1.2 (1.8) a | 0.84 (0.03) d | 0.924 (0.014) c | 94 (17) bc | 0.525 (0.009) c | 248 (57) de |

| 2B | 223 (26) de | −10 (19) a | 0.69 (0.06) ab | 0.88 (0.03) bc | 136 (24) cd | 0.36 (0.04) ab | 247 (62) de |

| 2E | 135 (31) bc | −3.8 (2.9) a | 0.82 (0.04) cd | 0.93 (0.02) c | 103 (23) bc | 0.49 (0.04) c | 226 (80) cd |

| 2EM | 95 (12) ab | 0 (0) a | 0.818 (0.019) cd | 0.93 (0.04) c | 72 (11) b | 0.5 (0.02) c | 180 (76) bc |

| 3B | 277 (92) e | −2 (2) a | 0.71 (0.04) b | 0.85 (0.04) b | 163 (39) d | 0.38 (0.04) b | 160 (21) b |

| 3E | 190 (66) cd | −0.6 (0.9) a | 0.84 (0.03) cd | 0.959 (0.003) c | 153 (58) d | 0.508 (0.013) c | 119 (36) ab |

| 3EM | 141 (14) bcd | −2.3 (3.2) a | 0.88 (0.03) d | 0.9555 (0.0009) c | 118 (8) bcd | 0.5427 (0.0002) c | 76 (18) a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matas, A.; Igual, M.; García-Segovia, P.; Martínez-Monzó, J. Impact of Rosehip (Rose Canina) Powder Addition and Figure Height on 3D-Printed Gluten-Free Bread. Biol. Life Sci. Forum 2021, 6, 75. https://doi.org/10.3390/Foods2021-10979

Matas A, Igual M, García-Segovia P, Martínez-Monzó J. Impact of Rosehip (Rose Canina) Powder Addition and Figure Height on 3D-Printed Gluten-Free Bread. Biology and Life Sciences Forum. 2021; 6(1):75. https://doi.org/10.3390/Foods2021-10979

Chicago/Turabian StyleMatas, Adrián, Marta Igual, Purificación García-Segovia, and Javier Martínez-Monzó. 2021. "Impact of Rosehip (Rose Canina) Powder Addition and Figure Height on 3D-Printed Gluten-Free Bread" Biology and Life Sciences Forum 6, no. 1: 75. https://doi.org/10.3390/Foods2021-10979

APA StyleMatas, A., Igual, M., García-Segovia, P., & Martínez-Monzó, J. (2021). Impact of Rosehip (Rose Canina) Powder Addition and Figure Height on 3D-Printed Gluten-Free Bread. Biology and Life Sciences Forum, 6(1), 75. https://doi.org/10.3390/Foods2021-10979