Preliminary Modeling Study of a Tape Casting System for Thermoplastic Starch Film Forming †

Abstract

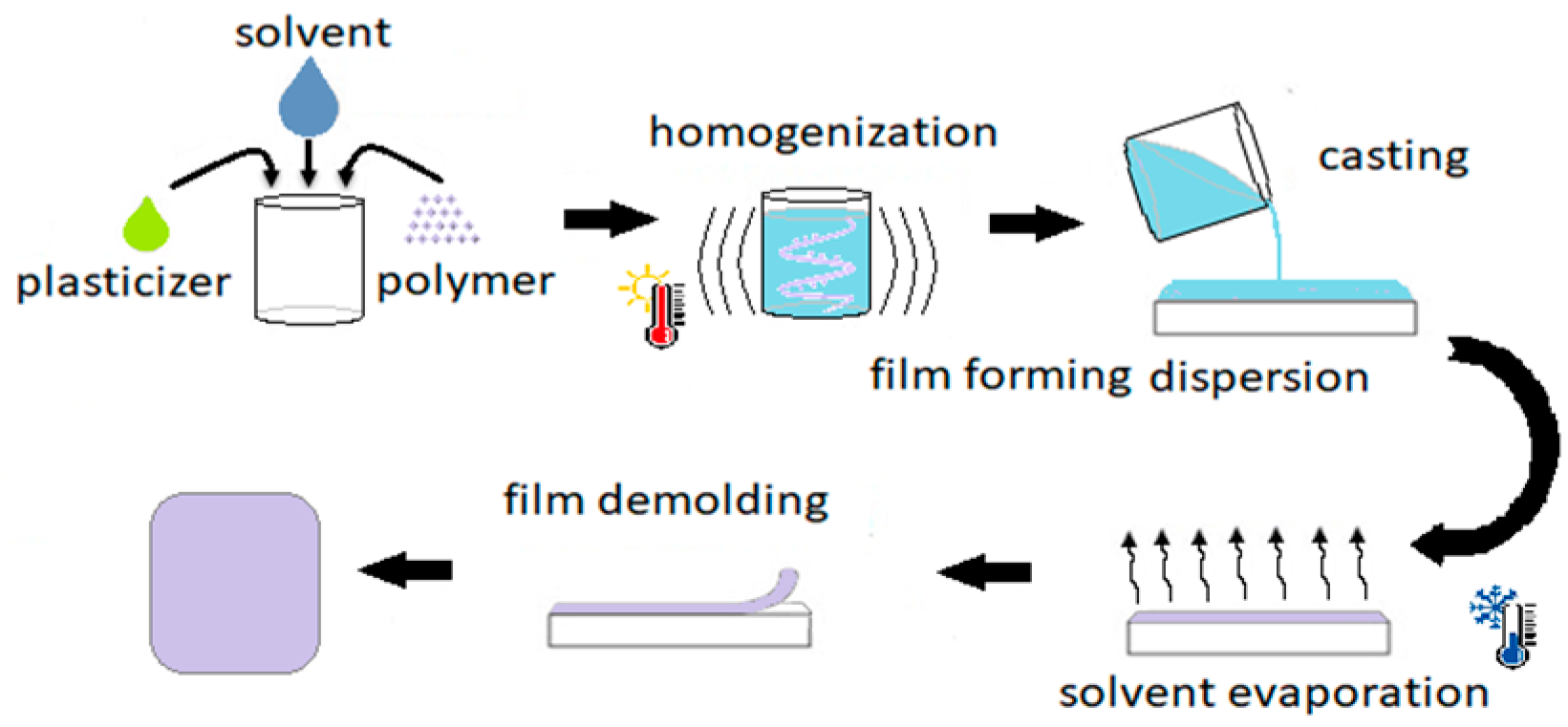

:1. Introduction

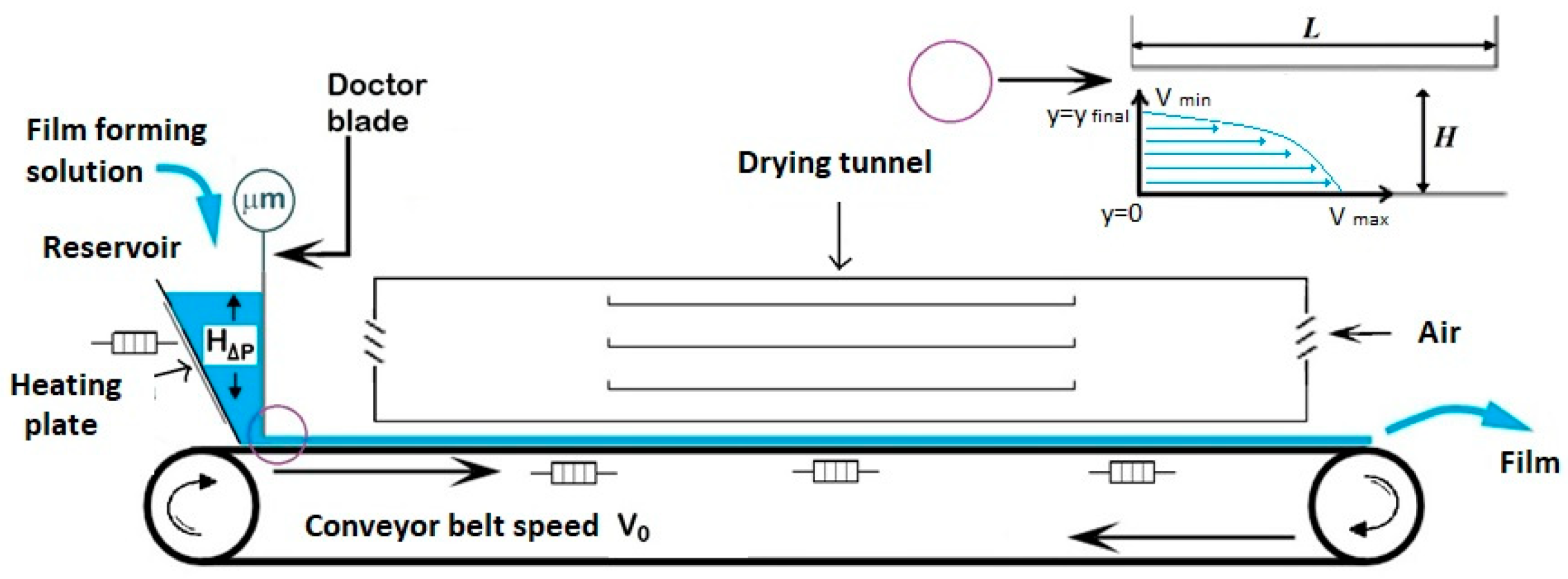

2. Methods

3. Results and Discussion

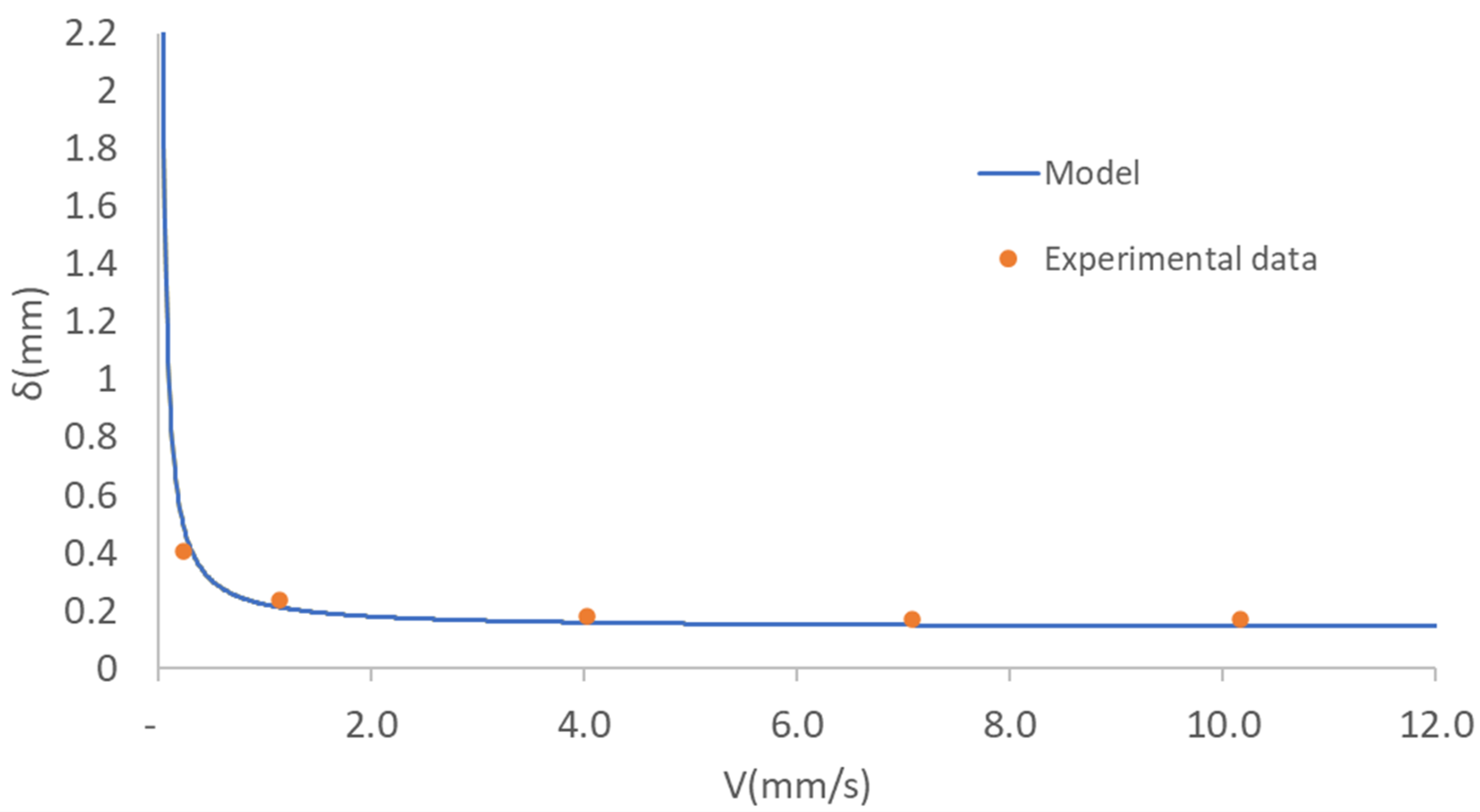

3.1. Validation

3.2. Prediction of Starch Film Conditions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bátori, V.; Åkesson, D.; Zamani, A.; Taherzadeh, M.J.; Sárvári Horváth, I. Anaerobic degradation of bioplastics: A review. Waste Manag. 2018, 80, 406–413. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A review of bioplastics and their adoption in the circular economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef] [PubMed]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agostinis, L.; et al. Bio-based packaging: Materials, modifications, industrial applications and sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef] [PubMed]

- Thomas, J. A Methodological Outlook on Bioplastics from Renewable Resources. Open J. Polym. Chem. 2020, 10, 21–47. [Google Scholar] [CrossRef]

- Elizabeth Gamboni, J.; Verónica Colodro, M.; Marcelo Slavutsky, A.; Alejandra Bertuzzi, M. Selection of the conveyor belt material for edible film production by a continuous casting process. Braz. J. Food Technol. 2021, 24, e2020026. [Google Scholar] [CrossRef]

- Do Val Siqueira, L.; Arias, C.I.; Maniglia, B.C.; Tadini, C.C. Starch-based biodegradable plastics: Methods of production, challenges and future perspectives. Curr. Opin. Food Sci. 2021, 38, 122–130. [Google Scholar] [CrossRef]

- Vogelsang, D.F.; Perilla, J.E.; Buitrago, G.; Algecira, N.A. Preparation of biopolymer films by aqueous tape casting processing. J. Plast. Film Sheeting 2014, 30, 435–448. [Google Scholar] [CrossRef]

- Oliveira de Moraes, J.; Scheibe, A.S.; Augusto, B.; Carciofi, M.; Laurindo, J.B. Conductive drying of starch-fiber films prepared by tape casting: Drying rates and film properties. LWT 2015, 64, 356–366. [Google Scholar] [CrossRef]

- Bertuzzi, M.A.; Slavutsky, A.M. Standard and New Processing Techniques Used in the Preparation of Films and Coatings at the Lab Level and Scale-Up. In Edible Films and Coatings: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2016; pp. 21–42. [Google Scholar]

- De Azeredo, H.M.; Rosa, M.F.; De Sá, M.; Souza Filho, M.; Waldron, K.W. The use of biomass for packaging films and coatings. In Advances in Biorefineries: Biomass and Waste Supply Chain Exploitation; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; pp. 819–874. [Google Scholar]

- Mellinas, C.; Valdés, A.; Ramos, M.; Burgos, N.; del Carmen Garrigós, M.; Jiménez, A. Active edible films: Current state and future trends. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Marcotte, M.; Taherian Hoshahili, A.R.; Ramaswamy, H.S. Rheological properties of selected hydrocolloids as a function of concentration and temperature. Food Res. Int. 2001, 34, 695–703. [Google Scholar] [CrossRef]

- Xie, F.; Yu, L.; Su, B.; Liu, P.; Wang, J.; Liu, H.; Chen, L. Rheological properties of starches with different amylose/amylopectin ratios. J. Cereal Sci. 2009, 49, 371–377. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, X.; Xu, Y.; Xu, Z.; Li, H.; Sui, Z.; Corke, H. Gel texture and rheological properties of normal amylose and waxy potato starch blends with rice starches differing in amylose content. Int. J. Food Sci. Technol. 2021, 56, 1946–1958. [Google Scholar] [CrossRef]

- De Moraes, J.O.; Scheibe, A.S.; Sereno, A.; Laurindo, J.B. Scale-up of the production of cassava starch based films using tape-casting. J. Food Eng. 2013, 119, 800–808. [Google Scholar] [CrossRef]

- Karapantsios, T.D. Conductive drying kinetics of pregelatinized starch thin films. J. Food Eng. 2006, 76, 477–489. [Google Scholar] [CrossRef]

- Li, C.; Xiang, F.; Wu, K.; Jiang, F.; Ni, X. Changes in microstructure and rheological properties of konjac glucomannan/zein blend film-forming solution during drying. Carbohydr. Polym. 2020, 250, 116840. [Google Scholar] [CrossRef] [PubMed]

- Mendes, J.F.; Norcino, L.B.; Martins, H.H.A.; Manrich, A.; Otoni, C.G.; Carvalho, E.E.N.; Piccoli, R.H.; Oliveira, J.E.; Pinheiro, A.C.M.; Mattoso, L.H.C. Correlating emulsion characteristics with the properties of active starch films loaded with lemongrass essential oil. Food Hydrocoll. 2020, 100, 105428. [Google Scholar] [CrossRef]

- De Moraes, J.O.; Laurindo, J.B. Properties of starch–cellulose fiber films produced by tape casting coupled with infrared radiation. Dry. Technol. 2018, 36, 830–840. [Google Scholar] [CrossRef]

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing Second Edition; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Tok, A.I.Y.; Boey, F.Y.C.; Lam, Y.C. Non-Newtonian fluid flow model for ceramic tape casting. Mater. Sci. Eng. A 2000, 280, 282–288. [Google Scholar] [CrossRef]

| Gap (m) | Density (Kg/m3) | Drying Time (min) | Final Thickness (mm) |

|---|---|---|---|

| 0.001 | 498 | 36 | 0.06 |

| 0.002 | 828 | 52 | 0.069 |

| 0.003 | 1025 | 67 | 0.118 |

| 0.004 | 1190 | 100 | 0.148 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ávila-Martín, L.; Guzmán Silva, D.K.; Perilla, J.E.; Villa Zabala, C.C. Preliminary Modeling Study of a Tape Casting System for Thermoplastic Starch Film Forming. Biol. Life Sci. Forum 2023, 28, 4. https://doi.org/10.3390/blsf2023028004

Ávila-Martín L, Guzmán Silva DK, Perilla JE, Villa Zabala CC. Preliminary Modeling Study of a Tape Casting System for Thermoplastic Starch Film Forming. Biology and Life Sciences Forum. 2023; 28(1):4. https://doi.org/10.3390/blsf2023028004

Chicago/Turabian StyleÁvila-Martín, Liliana, Diana Katherine Guzmán Silva, Jairo E. Perilla, and Cristian Camilo Villa Zabala. 2023. "Preliminary Modeling Study of a Tape Casting System for Thermoplastic Starch Film Forming" Biology and Life Sciences Forum 28, no. 1: 4. https://doi.org/10.3390/blsf2023028004

APA StyleÁvila-Martín, L., Guzmán Silva, D. K., Perilla, J. E., & Villa Zabala, C. C. (2023). Preliminary Modeling Study of a Tape Casting System for Thermoplastic Starch Film Forming. Biology and Life Sciences Forum, 28(1), 4. https://doi.org/10.3390/blsf2023028004