Abstract

The global demand for bottled king coconut water has led to a significant accumulation of empty king coconut husks in nut water export industries, posing challenges in managing and disposing of this agricultural waste. To address this issue, the production of king coconut husk ash (KCHA) has emerged as an eco-friendly solution. This product can be applied as a fertilizer, soil amendment, or after mixing with compost to enhance its nutrient value. This study aimed to determine the optimal cut size and moisture level for obtaining a high yield of KCHA with the maximum potassium content. The experiment involved drying full-, half-, quarter-, and chip-sized husks in a dehydrator at 60 °C for 0, 2, 4, 8, 12, 24, and 48 h. The findings revealed that reducing the particle size of the husks accelerated the drying process. The ash produced with chips exhibited the most favorable characteristics, reaching the desired dryness in a relatively shorter time while yielding the highest KCHA content. Moreover, the results indicated that the optimal duration for dehydrating the husks to produce ash was 24 h at 60 °C, resulting in the highest moisture loss. This processing condition facilitated the efficient conversion of king coconut husks into potassium-rich ash. Implementing these findings into the production of KCHA as a nutrient-rich fertilizer or soil amendment offers a sustainable approach to improving agricultural practices while reducing the dependence on synthetic fertilizers and mitigating the environmental challenges associated with their accumulation.

1. Introduction

Sustainable agriculture has emerged as a crucial paradigm in the face of global challenges such as climate change, diminishing natural resources, and food security concerns. In the pursuit of eco-friendly solutions, researchers have turned their attention to agricultural waste valorization, aiming to harness the potential of various byproducts to enhance soil fertility and reduce the dependence on chemical fertilizers [1].

The king coconut (Cocos nucifera var. aurantiaca), indigenous to Sri Lanka, has long been cherished for its sweet and refreshing water [2]. The global demand for bottled king coconut water has led to a significant accumulation of empty king coconut husks in nut water export industries, posing challenges in managing and disposing of this agricultural waste [3]. However, it has drawn interest as a valuable resource with multifaceted applications in the present world. In particular, the conversion of king coconut husk into ash has shown promise as an effective and sustainable soil amendment.

Researchers have reported that coconut husk is a rich reservoir of potassium (K) and other essential nutrients, making it a promising alternative to synthetic fertilizers [4]. Since the king coconut is in the immature stage, the same qualities should be expected. Utilizing king coconut husk ash (KCHA) as a soil amendment not only reduces the dependency on chemical fertilizers, but also presents an eco-friendly solution to the environmental burden posed by agricultural waste. In addition to its agronomic potential, the proper management of agricultural waste is equally significant for sustainable agricultural practices. To fully harness the potential of king coconut husk ash as a sustainable soil amendment, it is essential to investigate the optimal processing parameters that yield high K content. The processing conditions, including temperature, duration, and pre-treatments, significantly influence the final nutrient composition of the ash. An in-depth exploration of these parameters will provide valuable insights into maximizing the K content of KCHA and ensuring its efficacy as a soil enhancer. This study aimed to investigate the optimal cut size and moisture level for obtaining a high yield of KCHA with the maximum K content while simultaneously addressing efficient waste management strategies.

2. Materials and Methods

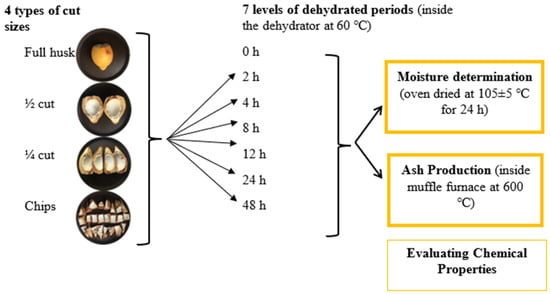

The research was carried out at the Agronomy Division of the Coconut Research Institute in Lunuwila, Sri Lanka. Fresh king coconut husks (KCHs) were collected from the Silvermill Group of the company located at Loluwagoda, Mirigama. The study investigated two factors: the cut size (whole husk, half husk, quarter husk, and chips) and the dehydration time (0, 2, 4, 8, 12, 24, and 48 h) (Figure 1).

Figure 1.

Methodology adapted for KCHA production and evaluation.

All of the data collected were analyzed using IBM SPSS statistical software (Version 26.0). The effect of the cut size and dehydrated time was analyzed using one-way ANOVA. Mean separation was carried out using Duncan’s Multiple Range Test.

3. Results and Discussion

3.1. Moisture Content of Husks Varies with Dehydration Time

Reducing the moisture content of KCHs is essential for producing ash because moisture in the husk interferes with the combustion process. During combustion, the husk is subjected to high temperatures, causing the organic matter to break down and release volatile gases. If the husk contains a high moisture content, a significant portion of the heat energy produced during combustion is used to evaporate this water, leaving less energy available for the combustion of the organic material. The presence of excess moisture can also lead to incomplete combustion, resulting in the production of more smoke, less ash, and a lower quality of the produced ash. In addition to affecting the combustion process, a high moisture content can lead to issues with storing and handling the husk, as it can promote the growth of mold and bacteria. Reducing the moisture content of the husk before combustion ensures better combustion efficiency, higher ash yield, and improved ash quality, making it a more suitable soil amendment and value-added product [5].

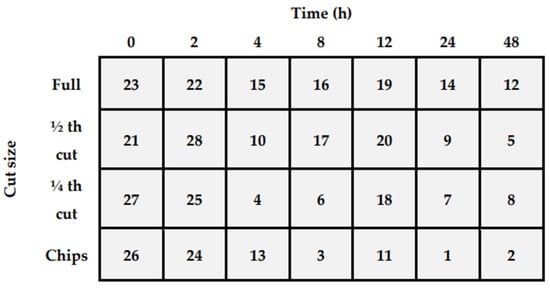

Fresh husks collected from processing factories after the extraction of nut water had a moisture content of 86–87%. As shown in Table 1, by extending the dehydration period as well as reducing the cut size of the KCH, the moisture content can be minimized. There were significant differences in the dehydration time durations of the moisture content of the king coconut husk (p < 0.001). In each dehydration time period, chips showed more moisture losses compared to full husk drying. The greatest amount of moisture is removed when the cut size is smaller. Numerically, 2, 4, 8, 12, 24, and 48 h of dehydration caused 7.1, 28.5, 30.4, 40.5, 71.2, and 47.2% moisture loss compared to full husk, respectively. Except for the whole husk, all cut husk sizes reached < 10% dryness in 48 h of drying. Within 24 h of drying at 60 °C, nearly all of the moisture in the chips evaporated. As a result, while drying king coconut husk, chips may be the most effective drying particle size, reaching dryness in 24 h at 60 °C of continuous drying. If the particle size is larger, it must dry for 48 h before being utilized in the production process.

Table 1.

Retained moisture (%) and ash yield (%) of different cut sizes of husk at different dehydration time periods.

3.2. Ash Yield with Different KCH Cut Sizes and Dehydration Periods

The acquired ash yield from the dehydrated period showed a significant increasing trend as the dehydrated duration increased gradually (Table 1). The husk chips with the lowest moisture (2%) yielded the most significant (p < 0.001) ash yield (7.5%) when dried for 48 h at 60 °C, which was not substantially different from the ash obtained from the chips dried for 24 h. This clearly shows that the lower the moisture content of the husk, the higher the ash output.

The significant increasing trend in ash yield as the dehydrated duration increases can be attributed to the removal of moisture from the KCH during the dehydration process. As the dehydration time increases, more water is eliminated from the husk, resulting in a higher concentration of solid matter. This, in turn, leads to a higher yield of ash when the dehydrated husks are combusted. The authors in [6] also observed a similar relationship between moisture loss and solid gain in various plant materials.

3.3. Total Potassium Content (K) of Different KCH Cut Sizes and Dehydration Periods

K is one of the essential macronutrients required for the growth and development of plants. It plays a crucial role in various physiological processes, including enzyme activation, osmoregulation, and nutrient transport within the plant [7]. Studies have shown that the ash obtained from coconut husk after combustion is rich in K content (6.50% at 300 °C of combustion temperature) [8]. Coconut husk ash has been recognized as a valuable source of K, and it can be used as a natural alternative to synthetic potassium fertilizers in agriculture.

As shown in Table 2, there was no significant difference in the K content of KCHA between the full-sized and half-sized husks according to the dehydration period (p > 0.1). However, there was a significant difference between the quarter-sized and chip-sized husks in terms of the dehydration period (p < 0.01). The K content of KCHA in this study ranged from 18% to 36% on a dry basis.

Table 2.

Total potassium (K) content (%) of different cut sizes of husk at different dehydration time periods.

The best cut size and dehydration time, giving the highest ash yield and K content were determined using a weighted average index. The results of the 28 different treatment combinations (cut size (4) x dehydration time periods (7)) were ranked as shown in Figure 2.

Figure 2.

Ranking of 28 treatment combinations.

3.4. Potential of pH and Electrical Conductivity (EC) Ranges of KCHA as a Nutrient Supplement

The pH and EC of ash are important factors to consider when using it as a fertilizer source because they directly impact soil health, nutrient availability, and plant growth. The pH of ash determines its acidity or alkalinity, playing a critical role in nutrient availability and microbial activity. Ash with a high pH (alkaline) can raise the soil pH, making it less acidic. This can be beneficial for acidic soils, as it helps to neutralize the acidity, making nutrients more accessible to plants. When ash is used as a fertilizer source, its EC can influence soil salinity levels. Excessive salts can negatively affect plant growth by creating osmotic stress, reducing water uptake by plants, and disrupting nutrient uptake. According to the results shown in Table 3, the pH values of KCHA ranged between 9.92 and 11.05. no significant difference in the pH values of KCHA was observed between the treatments (p > 0.05). The electrical conductivity ranged from 10 µS/cm to 40 µS/cm. There were no significant differences between the dehydration time and EC of the produced KCHA, except for chips (p > 0.1). There was a significant difference in the EC of ash that produced chips in different dehydration periods (p < 0.1). By considering the “partial eta squared” values, no significant effect on ash pH or ash EC was identified in relation to the cut size of the KCH. However, the pH and EC of the KCHA were significantly altered due to the dehydration time. The interaction effect of cut size and dehydration time had little or no effect on the pH and EC levels of the KCHA.

Table 3.

pH and EC values of KCHA produced from different cut sizes of husks at different dehydration time periods.

4. Conclusions

Sustainable agriculture has become increasingly important in addressing global challenges such as climate change, depleting natural resources, and food security concerns. The valorization of agricultural waste, particularly king coconut husk, has emerged as a promising eco-friendly solution to enhance soil fertility and reduce the reliance on chemical fertilizers. This study focused on the production of KCHA as a sustainable soil amendment. The findings demonstrated that the moisture content of the husks significantly influenced the ash yield, with lower moisture content leading to higher ash output. Additionally, the K content of KCHA was observed to increase with longer dehydration times. The research also revealed that the cut size of king coconut husks had a limited effect on the pH and EC of the ash. However, the dehydration time had a significant impact on the pH and EC levels of the KCHA. In light of these findings, the use of king coconut husk ash as a nutrient supplement and soil enhancer can contribute to sustainable agriculture practices, mitigate environmental burdens posed by agricultural waste, and promote eco-friendly solutions in the global pursuit of a more sustainable and resilient agricultural system. Further research and field trials are warranted to fully explore the practical applications of KCHA in different soil types and crop systems.

Author Contributions

Conceptualization, A.J.A., S.S.U. and L.D.; methodology, A.J.A. and N.S.D.; software, N.J.; validation, S.D.D., J.P.K. and S.K.I.; formal analysis, S.D.D., N.S.D. and S.S.U.; investigation, S.D.D.; resources, L.D. and S.D.D.; data curation, L.D.; writing—original draft preparation, N.S.D. and L.D.; writing—review and editing, N.J. and N.S.D.; visualization, S.S.U.; supervision, A.J.A. and S.K.I.; project administration, R.J. and P.D.; funding acquisition, S.S. and J.G. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the external research funding program of S.A. Silva & Sons Lanka (Pvt) Ltd., Loluwagoda Mills, Loluwagoda, 11204, Mirigama, Sri Lanka (CRI/AP/2022/2.1.10).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are contained within the article.

Acknowledgments

All authors express their gratitude to the Coconut Research Institute, Sri Lanka, for supporting this research. We would like to express our appreciation to the technical staff of the Agronomy Division of the Coconut Research Institute. We extend our gratitude to the editor and three anonymous reviewers for their valuable comments and critical evaluation.

Conflicts of Interest

Authors S.S., J.G., R.J. and P.D. were employed by the company S.A. Silva & Sons Lanka (Pvt) Ltd., Loluwagoda Mills, Loluwagoda, Mirigama 11204, Sri Lanka. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Kapoor, R.; Ghosh, P.; Kumar, M.; Sengupta, S.; Gupta, A.; Kumar, S.S.; Vijay, V.; Kumar, V.; Kumar Vijay, V.; Pant, D. Valorization of Agricultural Waste for Biogas Based Circular Economy in India: A Research Outlook. Bioresour. Technol. 2020, 304, 123036. [Google Scholar] [CrossRef] [PubMed]

- Jayasinghe, M.D.; Madage, S.S.K.; Hewajulige, I.G.N.; Jayawardana, T.M.D.A.; Halmillawewa, A.P.; Divisekera, D.M.W.D. Identification of Potentially Hazardous Microorganisms and Assessment of Physicochemical Deterioration of Thermally Processed King Coconut (Cocos nucifera var. aurantiaca) Water under Different Processing Conditions in Sri Lanka. J. Food Qual. 2022, 2022, 15. [Google Scholar] [CrossRef]

- Ekanayaka, E.M.G.N.; Dissanayake, D.K.R.P.L.; Herath, H.M.S.K.; Atapattu, A.J. Effect of King Coconut Husk Biochar on Nitrogen Retention in Sandy and Clay Soils Fertilized with Urea and Ammonium Sulphate 2022. In Annual Research Session—2022, Faculty of Technology, EUSL; p. 36. Available online: https://www.researchgate.net/publication/365504541 (accessed on 1 September 2023).

- Herath, H.M.I.K. Potential of Potassium Supply in Locally Available Soil Amendments for Use in Coconut Plantations. J. Food Agric. 2014, 7, 18. [Google Scholar] [CrossRef]

- Saenger, M.; Hartge, E.U.; Werther, J.; Ogada, T.; Siagi, Z. Combustion of Coffee Husks. Renew. Energy 2001, 23. Available online: www.elsevier.nl/locate/renene (accessed on 4 September 2023). [CrossRef]

- Tortoe, C.; Orchard, J.; Beezer, A. Osmotic Dehydration Kinetics of Apple, Banana and Potato. Int. J. Food Sci. Technol. 2007, 42, 312–318. [Google Scholar] [CrossRef]

- Marschner, H. Marschner’s Mineral Nutrition of Higher Plants; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Anwar, A.R.; Ala, A.; Kuswinanti, T.; Syam’un, E. Effect of Ashing Temperature on Potassium Nutrient Content of Various Organic Matter. IOP Conf. Ser. Earth Environ. Sci. 2021, 807, 042044. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).