Developing a Nutrient-Rich Rice Protein Drink for Athletes Using Protease G6 Enzyme †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Rice Paste

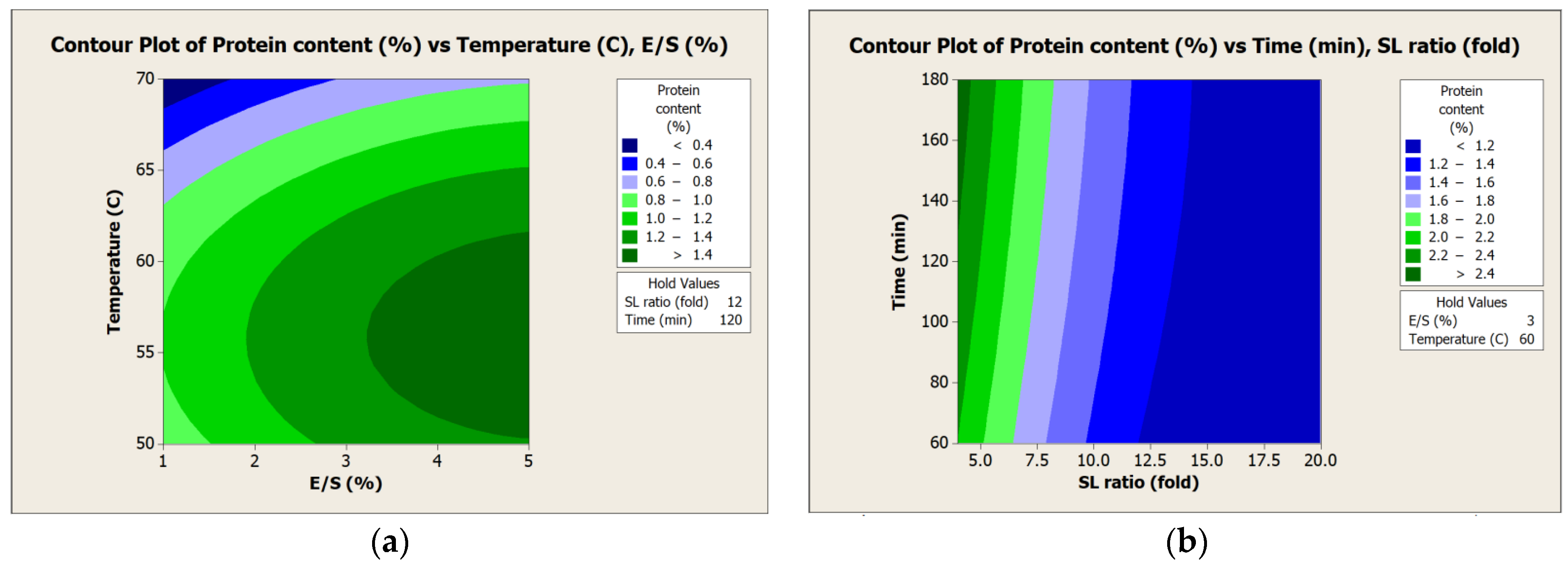

2.2. Experimental Designs

2.3. Extraction of Rice Proteins

2.4. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arenas-Jal, M.; Suñé-Negre, J.M.; Pérez-Lozano, P.; García-Montoya, E. Trends in the food and sports nutrition industry: A review. Crit. Rev. Food Sci. 2020, 60, 2405–2421. [Google Scholar] [CrossRef] [PubMed]

- Ahern, N.; Arendt, E.K.; Sahin, A.W. Protein Soft Drinks: A Retail Market Analysis and Selected Product Characterization. Beverages 2023, 9, 73. [Google Scholar] [CrossRef]

- Magriplis, E.; Michas, G.; Petridi, E.; Chrousos, G.P.; Roma, E.; Benetou, V.; Cholopoulos, N.; Micha, R.; Panagiotakos, D.; Zampelas, A.A. Dietary Sugar Intake and Its Association with Obesity in Children and Adolescents. Children 2021, 8, 676. [Google Scholar] [CrossRef] [PubMed]

- Young, A.; James, K.; Hassan, A. The role of regressive sugar tax in the soft drink industry levy (SDIL): A Marxist analysis. Crit. Perspect. Account 2022, 88, 102326. [Google Scholar] [CrossRef]

- Chen, Y.-J.; Kuo, C.-Y.; Kong, Z.-L.; Lai, C.-Y.; Chen, G.-W.; Yang, A.-J.; Lin, L.-H.; Wang, M.-F. Anti-fatigue effect of a dietary supplement from the fermented by-products of Taiwan tilapia aquatic waste and Monostroma nitidum oligosaccharide complex. Nutrients 2021, 13, 1688. [Google Scholar] [CrossRef] [PubMed]

- Braspaiboon, S.; Osiriphun, S.; Peepathum, P.; Jirarattanarangsri, W. Comparison of the effectiveness of alkaline and enzymatic extraction and the solubility of proteins extracted from carbohydrate-digested rice. Heliyon 2020, 6, 11. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.S.; Oh, H.; Choi, I.; Yoon, C.S.; Han, J. Physico-chemical characteristics of rice protein-based novel textured vegetable proteins as meat analogues produced by low-moisture extrusion cooking technology. LWT 2022, 157, 113056. [Google Scholar] [CrossRef]

- Wang, N.; Cui, X.; Duan, Y.; Yang, S.; Wang, P.; Saleh, A.S.M.; Xiao, Z. Potential health benefits and food applications of rice bran protein: Research advances and challenges. Food Rev. Int. 2023, 39, 3578–3601. [Google Scholar] [CrossRef]

- Gong, X.; Sui, L.; Morton, J.; Brennan, M.A.; Brennan, C.S. Investigation of nutritional and functional effects of rice bran protein hydrolysates by using Preferred Reporting Items for Systematic Reviews and Meta-Analysis (PRISMA) guidelines: A review. Trends Food Sci. Technol. 2021, 110, 798–811. [Google Scholar] [CrossRef]

- Mwaurah, P.W.; Kumar, S.; Kumar, N.; Attkan, A.K.; Panghal, A.; Singh, V.K.; Garg, M.K. Novel oil extraction technologies: Process conditions, quality parameters, and optimization. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3–20. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Qiao, Y.; Wang, X.; Zhang, Y.; Fu, L. Extraction, Structural Characterization, Biological Functions, and Application of Rice Bran Polysaccharides: A Review. Foods. 2023, 12, 639. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Tomar, M.; Potkule, J.; Verma, R.; Punia, S.; Mahapatra, A.; Belwal, T.; Dahuja, A.; Joshi, S.; Berwal, M.K.; et al. Advances in the plant protein extraction: Mechanism and recommendations. Food Hydrocoll. 2021, 115, 106595. [Google Scholar] [CrossRef]

- Kamal, H.; Le, C.F.; Salter, A.M.; Ali, A. Extraction of protein from food waste: An overview of current status and opportunities. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2455–2475. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Fan, G.; Khan, M.A.; Yan, Z.; Beta, T. Ultrasonic-assisted enzymatic extraction and identification of anthocyanin components from mulberry wine residues. Food Chem. 2020, 323, 126714. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, S.; Uppaluri, R.; Das, C. Optimization of ultrasound-assisted extraction (UAE) process for the recovery of bioactive compounds from bitter gourd using response surface methodology (RSM). Food Bioprod. Process. 2020, 120, 114–122. [Google Scholar] [CrossRef]

| Coded Value | −2 | −1 | 0 | 1 | 2 |

|---|---|---|---|---|---|

| E/S (%) | 1 | 2 | 3 | 4 | 5 |

| SL ratio (fold) | 4 | 8 | 12 | 16 | 20 |

| Temperature (°C) | 50 | 55 | 60 | 65 | 70 |

| Time (min) | 60 | 90 | 120 | 150 | 180 |

| 8 | E/S | SL Ratio | Temperature | Time | Protein Concentration (%) | |

|---|---|---|---|---|---|---|

| (%) | (Fold) | (°C) | (min) | Experimental | Predicted | |

| 1 | 2 | 8 | 55 | 90 | 1.38 ± 0.13 | 1.50 |

| 2 | 4 | 8 | 55 | 90 | 1.88 ± 0.03 | 1.87 |

| 3 | 2 | 16 | 55 | 90 | 1.08 ± 0.11 | 0.98 |

| 4 | 4 | 16 | 55 | 90 | 1.17 ± 0.08 | 1.09 |

| 5 | 2 | 8 | 65 | 90 | 1.21 ± 0.03 | 1.21 |

| 6 | 4 | 8 | 65 | 90 | 1.54 ± 0.05 | 1.59 |

| 7 | 2 | 16 | 65 | 90 | 0.83 ± 0.03 | 0.80 |

| 8 | 4 | 16 | 65 | 90 | 0.96 ± 0.04 | 0.92 |

| 9 | 2 | 8 | 55 | 150 | 1.71 ± 0.01 | 1.70 |

| 10 | 4 | 8 | 55 | 150 | 2.04 ± 0.06 | 2.10 |

| 11 | 2 | 16 | 55 | 150 | 1.13 ± 0.03 | 1.10 |

| 12 | 4 | 16 | 55 | 150 | 1.29 ± 0.05 | 1.24 |

| 13 | 2 | 8 | 65 | 150 | 1.13 ± 0.11 | 1.23 |

| 14 | 4 | 8 | 65 | 150 | 1.58 ± 0.06 | 1.64 |

| 15 | 2 | 16 | 65 | 150 | 0.79 ± 0.05 | 0.75 |

| 16 | 4 | 16 | 65 | 150 | 1.00 ± 0.10 | 0.90 |

| 17 | 1 | 12 | 60 | 120 | 0.96 ± 0.02 | 0.94 |

| 18 | 5 | 12 | 60 | 120 | 1.42 ± 0.04 | 1.46 |

| 19 | 3 | 4 | 60 | 120 | 2.58 ± 0.21 | 2.38 |

| 20 | 3 | 20 | 60 | 120 | 0.88 ± 0.23 | 1.11 |

| 21 | 3 | 12 | 50 | 120 | 1.21 ± 0.04 | 1.24 |

| 22 | 3 | 12 | 70 | 120 | 0.63 ± 0.01 | 0.61 |

| 23 | 3 | 12 | 60 | 60 | 1.17 ± 0.03 | 1.20 |

| 24 | 3 | 12 | 60 | 180 | 1.38 ± 0.01 | 1.37 |

| 25 | 3 | 12 | 60 | 120 | 1.21 ± 0.10 | 1.31 |

| 26 | 3 | 12 | 60 | 120 | 1.29 ± 0.02 | 1.31 |

| 27 | 3 | 12 | 60 | 120 | 1.42 ± 0.10 | 1.31 |

| 28 | 3 | 12 | 60 | 120 | 1.33 ± 0.03 | 1.31 |

| 29 | 3 | 12 | 60 | 120 | 1.21 ± 0.11 | 1.31 |

| 30 | 3 | 12 | 60 | 120 | 1.32 ± 0.01 | 1.31 |

| 31 | 3 | 12 | 60 | 120 | 1.43 ± 0.09 | 1.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Braspaiboon, S.; Osiriphun, S.; Peepathum, P.; Mitranun, W.; Jirarattanarangsri, W.; Surawang, S.; Laokuldilok, T.; Koonrungseesomboon, N. Developing a Nutrient-Rich Rice Protein Drink for Athletes Using Protease G6 Enzyme. Biol. Life Sci. Forum 2023, 26, 90. https://doi.org/10.3390/Foods2023-15002

Braspaiboon S, Osiriphun S, Peepathum P, Mitranun W, Jirarattanarangsri W, Surawang S, Laokuldilok T, Koonrungseesomboon N. Developing a Nutrient-Rich Rice Protein Drink for Athletes Using Protease G6 Enzyme. Biology and Life Sciences Forum. 2023; 26(1):90. https://doi.org/10.3390/Foods2023-15002

Chicago/Turabian StyleBraspaiboon, Sukan, Sukhuntha Osiriphun, Prasit Peepathum, Witid Mitranun, Wachira Jirarattanarangsri, Suthat Surawang, Thunnop Laokuldilok, and Nut Koonrungseesomboon. 2023. "Developing a Nutrient-Rich Rice Protein Drink for Athletes Using Protease G6 Enzyme" Biology and Life Sciences Forum 26, no. 1: 90. https://doi.org/10.3390/Foods2023-15002

APA StyleBraspaiboon, S., Osiriphun, S., Peepathum, P., Mitranun, W., Jirarattanarangsri, W., Surawang, S., Laokuldilok, T., & Koonrungseesomboon, N. (2023). Developing a Nutrient-Rich Rice Protein Drink for Athletes Using Protease G6 Enzyme. Biology and Life Sciences Forum, 26(1), 90. https://doi.org/10.3390/Foods2023-15002