Abstract

Gluten-free baked goods (GFBGs) are based mainly on refined flours and starches, being characterized by a poor nutritional profile. The use of alternative flours rich in protein and dietary fibre, and with a good sensorial profile, in the formulation of GFBGs could improve either nutritional or sensorial properties. The objective of the study was to evaluate the global differences/similarities and overall acceptability of gluten-free breads (GFBs) formulated with alternative flours among regular consumers and those with gluten-related disorders. The results showed four well-differentiated groups of GFBs with descriptors related to texture, odour, flavour, colour, and crumb, and most of the samples received a punctuation in a range of 5.9–7.3 in a 9-point hedonic scale. The identification of descriptors in GFBs formulated with flours with a good nutritional profile could be a useful tool in the design of baked goods for the food industry.

1. Introduction

GFBGs have become a growing trend in the food industry, mainly because consumers with gluten-related disorders are looking for healthier options. Over the last years, the supply of gluten-free products has significantly increased. However, these products are often associated with a lower quality compared to their wheat-containing counterparts, which is mainly explained by a lower sensorial acceptability, less flavour, lower nutritional profile, and a shorter shelf-life [1]. They are also notable for being less available and affordable [2]. These challenges in the quality and availability of gluten-free products reinforce the need for continuing research and development in this food segment.

In this context, sensory analysis by regular consumers plays a critical role in GFBs characterization. Scientists and producers strive to find the perfect combination of ingredients that deliver an appealing taste, texture, and aroma while maintaining a high standard of technological and nutritional quality. This involves a comprehensive sensory evaluation process to ensure that GFBGs are as flavourful and attractive as their gluten-containing counterparts. Furthermore, consumers are increasingly interested in local and sustainable food options [3]. This has led to a growing demand for GFBs that not only meet dietary intake needs but are also produced locally and are environmentally friendly. In this work, the use of Napping® in the description of the sensory characteristics of GFBs formulated with novel flours provides the opportunity to identify the descriptors related to the most important attributes commonly recognized by the consumers of these products. The objective of the study was to evaluate the global differences and similarities and the overall acceptability of GFBs formulated with alternative flours in regular consumers with and without gluten-related disorders.

2. Materials and Methods

2.1. Materials

Alternative gluten-free flours were purchased locally: brown rice (Ying Yang, Dietéti-ca Científica S.A.C.I.F.I, Rem. de Escalada, Bs. As., Argentina) rice bran supplied by Coopera-tive Villa Elisa S.A. (Entre Ríos, Argentina), lupine (Épicos, Tecnología Alimentaria Rioplatense S.R.L., C.A.B.A., Bs.As., Argentina), millet (Ying Yang, Dietética Científica S.A.C.I.F.I, Rem. de Escalada, Bs. As., Argentina), carob (native species from Argentina, man-ually collected), quinoa (Aiken, Neofarms S.R.L., Los Charrúas, Entre Ríos, Argentina), sorghum (Celidarina, Agroalimentos PRAGA, Alejo Ledesma, Córdoba, Argentina), teff (Épicos, Tecnología Alimentaria Rioplatense S.R.L., C.A.B.A., Bs.As., Argentina), and buckwheat (Celidarina, Agroalimentos PRAGA, Alejo Ledesma, Córdoba, Argentina). Other ingredients used in breadmaking were rice flour from long-grain rice (Villa Elisa, Entre Ríos, Argentina), corn starch (Maizena, Unilever Argentina S.A., Munro, Bs. As., Ar-gentina), sunflower oil (Natura, Aceitera General Deheza S.A., Gral. Deheza, Cba., Argentina), sugar (Lesdesma, LEDESMA S.A.A.I., Lib. Gral. San Martín, Juj., Argentina), hy-droxypropyl methylcellulose (Methocel K4M, Dow Chemical Company, Midland, MI, USA) and dehydrated yeast (LEVEX, Lasaffre, Virrey del Pino, Bs. As., Argentina).

2.2. GFBs Formulation and Preparation

Nine different GFBs were formulated using a modified recipe reported by Genevois et al. [4], where refined flours and starch were partially replaced with alternative flours (20%; (see Section 2.1)). Briefly, all ingredients, that is, rice flour (22.5%), corn starch (57.5%), al-ternative flour (20%), sunflower oil (6%), sugar (5%), HPMC (2%), and salt 2%, were mixed. Then, the dry yeast (3%) was hydrated in ¼ of the total water volume and mixed with the rest of the ingredients using a professional stand mixer (AEB-105, Alhias, China) equipped with a dough hook for 2 min at speed 1 (on a scale of 1 to 5 of the mixer). The optimal fermentation time of dough (OFTD) and the optimal hydration level were previously determined to achieve the ¾ increase in dough volume during proofing and the maximum specific volume after baking, respectively. Approximately 200 g of dough was placed into disposable aluminium pans (23 × 6 × 4.5 cm) and fermented in a proofing chamber at 30 °C, 90% relative moisture (HPP 108, Memmert GmbH + Co. Kg, Schwabach, Germany) according to the OFTD of each GFBs. The GFBs were baked in an electric convec-tor oven (Beta 21 L, Pauna S.A., Lomas del Mirador, Bs. As., Argentina) at 180 °C for 30 min and cooled at room temperature for 1 h. Finally, loaves were packed in sealed poly-propylene bags and stored at room temperature (25 °C) for 24 h until sensorial analysis was carried out.

2.3. Ultra-Flash Profiling, Projective Mapping (Napping®®), and Affective Test

Nine samples of GFBs (25 g of each formulation) were evaluated by the panellists in accordance with international standards [5]. Samples were coded with three-digit numbers and evaluated at room temperature in individual cabinets. The participants of the study were randomly recruited from social networks with the following inclusion criteria: (1) age > 18 years-old; (2) regular consumers of GFBs, with or without gluten-related-disorders. Consumers were instructed to taste each sample of GFBs from left to right and clean their mouths with water between samples to avoid carryover effects. They were asked to define each sample using words to describe objective attributes, preventing the use of hedonic descriptors. Then, the panellists were instructed to draw the samples on a sheet (dimension map of 40 cm × 60 cm) in a way that the distance between them would be perceived as being similar or different. For each consumer map, the X and Y coordinates of each sample were recorded in cm, considering the left bottom corner of the sheet as the origin of the coordinate system.

At the end of the projective mapping test, all panellists were asked to complete an af-fective test for overall acceptance using a 9-point structured hedonic scale (1: dislike ex-tremely, 2: dislike very much, 3: dislike moderately, 4: dislike a little, 5: neither like nor dislike, 6: like a little, 7: like moderately, 8: like very much, and 9: like extremely) for each sample.

2.4. Statistical Analysis

The words defining objective attributes provided by consumers in the projective mapping were first qualitatively analysed following the ultra-flash profiling methodology described by Ares et al. [6]. Terms with similar meaning were grouped into categories, and frequency of mention was determined by counting the number of consumers that used those words to describe each sample. The categories mentioned by more than 10% of the consumers were considered in the data analysis. The coordinates from the consumer map, considered as active variables, and the absolute frequency of sensory descriptors projected as supplementary variables were analysed using multiple-factor analysis (MFA) to obtain the sensorial profile of each GFBs [7]. Analysis of variance (ANOVA) was used to determine significant differences between means with a level of significance (α) of 0.05 followed by Fisher’s LSD post hoc test. All statistical analyses were performed using XLSTAT system software (V1.5.1409, 2023, Addinsoft™).

3. Results and Discussion

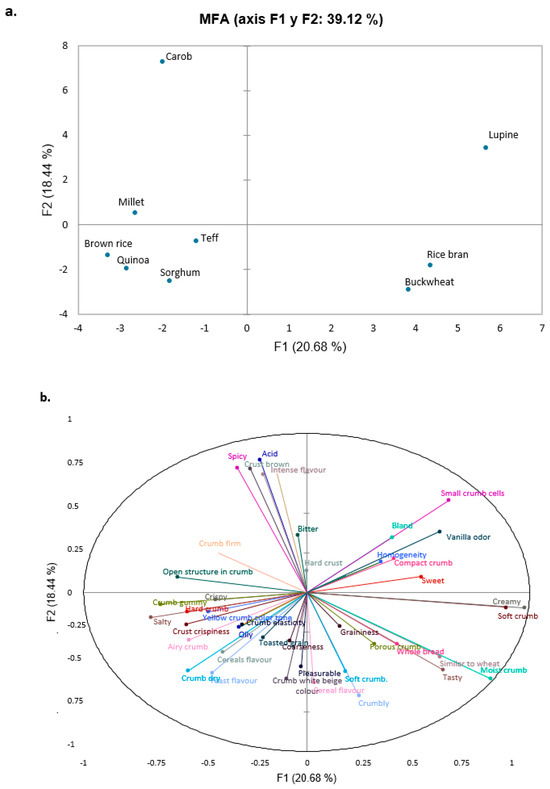

Thirty-four untrained consumers participated in this study, where 56% were females and 44% were males, between 29 and 70 years old, and 29% were regular consumers of GFBs while 71% were consumers with gluten-related disorders. The qualitative analysis of ultra-flash profiling was carried out to unify the criteria in relation to the terms suggested by regular consumers of GFBs with or without gluten-related-disorders. Consumers used between one and five words to describe each sample of GFBs, resulting in 70 descriptors which were grouped into 42 descriptors; the synonyms used by different panellists were combined into one term. The latter were re-grouped into 17 categories to carry out the MFA analysis. In Figure 1a, the first two dimensions of the MFA applied to the projective mapping data for the nine GFBs formulated with alternative flours are depicted. Meanwhile, Figure 1b, illustrates the biplot obtained by MFA, incorporating all descriptors recorded from the sensorial evaluation of the GFBs with alternative flours. The statistical MFA localizes the samples based on the results of the projective mapping, and it relates the dimensions with the attributes in order to describe which are responsible for the differences or similarities between the samples.

Figure 1.

(a) Biplot representation of the GFBs formulated with different alternative flours (n = 9), in the first two dimensions of the MFA of data from projective mapping. F1: first dimension; F2: second dimension. (b) Biplot representation of the nine samples of GFBs formulated with different alternative flours, in the first two dimensions of the MFA of data from projective mapping.

As can be observed in Figure 1a, the sensorial map shows four groups defined according to their inherent characteristics along the vertical and horizontal coordinates, suggesting that the consumers used all the space in a sheet to place the samples: (1) carob and millet; (2) lupine; (3) rice bran and buckwheat; and (4) rice brown, teff, sorghum, and quinoa. The biplot obtained from the MFA explained 39.12% of the total data variability with the two first axis, where F1 represented 20.68% of variability and F2 represented 18.44% of variability. The resulting sensory space map was built as follows: the GFBs formulated with carob flour had a comparatively greater contribution to the observations in F2, than the rest of the samples (59.5%), and it was described with descriptors such as spicy, acid, and intense flavour. In the F1, GFBs containing lupine flour had a contribution of 31.9%, and the main descriptors were moist, creamy, and soft crumb.

Considering the consumers’ descriptions, the sensory profile of the GFBs samples were successfully characterised. GFBs made of carob and millet flour were located at negative values of the F1 and positive values of the F2, characterized mainly for attributes such as acid, spicy, crust brown, crumb firm, open structure in crumb, and intense flavour. The GFBs formulated with lupine flour was located at the positive values of the first and second axes (F1 and F2), being because of its sensory profile characterized by small cells in crumb, vanilla odour, and sweet. The third group of samples made of GFBs with rice bran and buckwheat were localized at the positive values of F1 and negative values of F2. These breads were mainly perceived by consumers as creamy, soft, moist crumb, tasty, crumbly, and similar to wheat. The last defined group of GFBs, which was made of quinoa, brown rice, teff, and sorghum flours, was located at negative values of both axes, being described with sensorial attributes such as salty, crumb dry, crumb gummy, yeast flavour, and crumb with beige colour, showing a clearly different sensory profile.

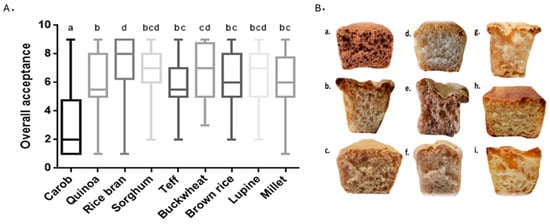

These differences and similarities between samples perceived by the consumers in terms of descriptors could be explained by the physicochemical characteristics of GFBs formulated with different alternative flours, as can be seen in Figure 2B. Although the hy-dration level and optimal fermentation time were optimized to standardize the effect of alternative flour addition and maximize the final quality of the GFBs, it is important to consider that each flour has different chemical composition, colour, odour, and flavour, giving, as result, a unique sensorial profile. For example, a study comparing the sensory attributes of industrially processed and artisanal GFBs revealed that artisanal breads ex-hibited a diverse array of flavours and a dry texture, whereas industrially processed breads were characterized by a bland flavour and a moist texture. Overall, artisanal GFBs displayed more unfavorable characteristics when compared to their industrially pro-cessed counterparts [8]. Another study reported that celiac consumers (n = 205) expected a GBFs characterised by a soft and moist crumb, tasty, similar to a homemade wheat bread, and with a lower price and better availability [9].

Figure 2.

(A) Boxplot of the overall acceptability in regular consumers of GFB. Different letters indicate significant differences (p > 0.05) between mean values of samples. (B) Gluten-free breads formulated with carob (a), quinoa (b), rice bran (c), sorghum (d), teff (e), buckwheat (f), brown rice (g), lupine (h), and millet (i) flours.

In Figure 2A is shown the mean values corresponding to the overall acceptability of the nine GFBs evaluated by the untrained panel (n = 34). Is noteworthy that products that obtain high scores in the Affective Test are more likely to be successful in the market [4].

In the present work, it was observed that the GFBs formulated with alternative flours received a high score in the hedonic test (mean value > 6 ± 2). The overall acceptability showed values between 2.9 and 7.3 in a 9-point hedonic scale. The GFBs formulated with 20% of carob flour was the sample with the lowest (p < 0.05) punctuation (2.9 ± 2.5 in the 9-point hedonic scale) and was mainly assessed as extremely disliked by the consumers (47%). Meanwhile, the breads formulated with rice bran and buckwheat flours received the highest score (7.3 ± 2.0 and 6.9 ± 1.8 in the 9-point hedonic scale, respectively) and were categorized as like moderately by consumers (relative frequency of 34% and 25%, respectively).

4. Conclusions

The GFBs made with alternative flours, as proposed in this study, scored >6 on a 9-point hedonic scale for overall acceptance, except for the GFBs with carob flour. Descriptors for each alternative flour were based on the views and expectations of regular consumers, both with and without gluten-related disorders. These descriptors covered aspects like texture, smell, taste, colour, structure, and crumb moisture. The resulting sensory profile provides useful insights for formulating gluten-free bread that meets technological and nutritional expectations, aligning with consumer preferences. These insights can complement quantitative descriptive analyses conducted by trained sensory panels for GFBGs.

Author Contributions

K.I. and N.E.: Conceptualization, Investigation, Data curation, and Writing—original draft preparation; M.B.P.: Resources and Data curation; M.d.E.P. and C.G.: Project administration, Supervision, and Writing—reviewing and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the National University of Entre Ríos (UNER; PID UNER 9112; PID UNER 9122) and the National Scientific and Technical Research Council of Argentina (CONICET).

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Ethics Committee of the Faculty of Bromatology, UNER, protocol number 2, 13 March 2023.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study prior to the sensorial evaluation.

Data Availability Statement

The data that supports the findings of this study are available if they are requested.

Acknowledgments

The authors would like to express their gratitude to ACELA Entre Ríos, Gualeguaychú, Argentina (Celiac Assistance of Argentina), and Cooperativa Arroceros Villa Elisa LTDA., Entre Ríos, Argentina, for their participation in the project.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Capriles, V.D.; Valéria de Aguiar, E.; Garcia dos Santos, F.; Fernández, M.E.A.; de Melo, B.G.; Tagliapietra, B.L.; Scarton, M.; Clerici, M.T.P.S.; Conti, A.C. Current status and future prospects of sensory and consumer research approaches to gluten-free bakery and pasta products. Food Res. Int. 2023, 173, 113389. [Google Scholar] [CrossRef] [PubMed]

- Arora, K.; Carafa, I.; Fava, F.; Tuohy, K.M.; Nikoloudaki, O.; Gobbetti, M.; Di Cagno, R. Sourdough performances of the golden cereal Tritordeum: Dynamics of microbial ecology, biochemical and nutritional features. Int. J. Food Microbiol. 2022, 374, 109725. [Google Scholar] [CrossRef] [PubMed]

- Da, C.; Machado, R.; Cruz, R.; Thys, S. Cricket powder (Gryllus assimilis) as a new alternative protein source for gluten-free breads. Innov. Food Sci. Emerg. Technol. 2019, 56, 102180. [Google Scholar] [CrossRef]

- Genevois, C.E.; Grenóvero, M.S.; De Escalada Pla, M.F. Use of different proportions of rice milling fractions as strategy for improving quality parameters and nutritional profile of gluten-free bread. J. Food Sci. Technol. 2020, 58, 3913–3923. [Google Scholar] [CrossRef] [PubMed]

- ISO 8589; Sensory Analysis. General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- Ares, G.; Varela, P.; Rado, G.; Giménez, A. Are consumer profiling techniques equivalent for some product categories? The case of orange-flavoured powdered drinks. Int. J. Food Sci. Technol. 2011, 46, 1600–1608. [Google Scholar] [CrossRef]

- Pagès, J. Collection and analysis of perceived product inter-distances using multiple factor analysis: Application to the study of 10 white wines from the Loire Valley. Food Qual. Prefer. 2005, 16, 642–649. [Google Scholar] [CrossRef]

- Muggah, E.M.; Duizer, L.M.; Mcsweeney, M.B. A comparison of sensory properties of artisanal style and industrially processed gluten free breads. Int. J. Gastron. Food Sci. 2016, 3, 38–46. [Google Scholar] [CrossRef]

- Alencar, N.M.M.; de Araújo, V.A.; Faggian, L.; da Silveira Araújo, M.B.; Capriles, V.D. What about gluten-free products? An insight on celiac consumers’ opinions and expectations. J. Sens. Stud. 2021, 36, e12664. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).