Assessing the Likelihood of Staphylococcus aureus Contamination in Bottled Drinking Water Production †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Water Samples

Sample Collection

2.2. Physicochemical Analysis

2.3. Microbiological Analysis

Plating Media Method for S. aureus and Total Coliforms

2.4. Sensitivity Analysis

2.5. Statistical Analysis

3. Results

3.1. Physicochemical and Microbiological Properties of the Water Samples

3.2. Probabilistic Distribution

3.3. Modeling with Multiple Regression Equations

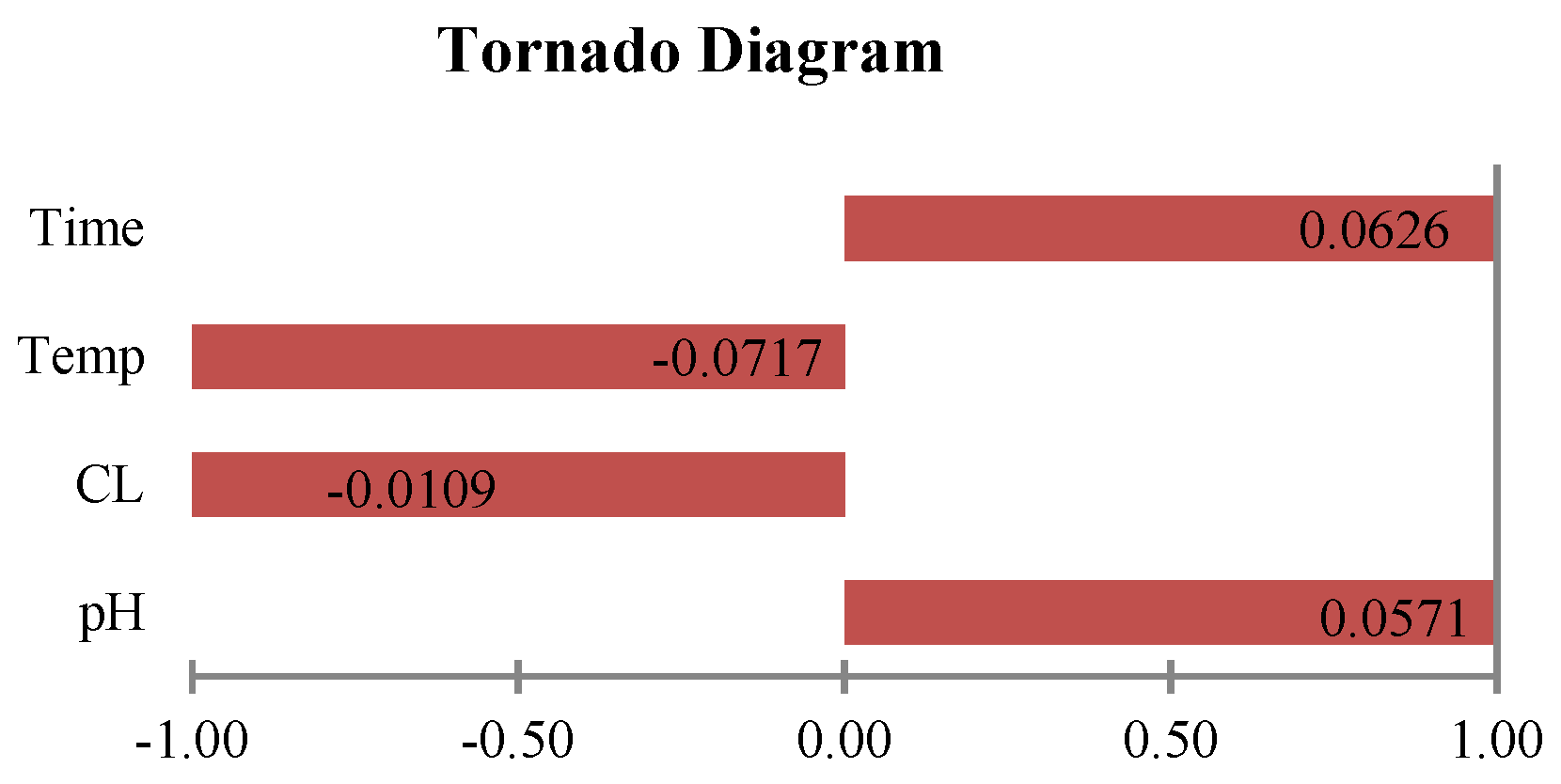

3.4. Sensitivity Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EPA, 2018, Drinking Water Quality. Available online: https://www.epa.gov/report-environment/drinking-water (accessed on 8 September 2023).

- World Health Organization (WHO), 2020, Water and Health. Available online: https://www.who.int/news-room/fact-sheets/detail/drinking-water (accessed on 8 September 2023).

- Lechevallier, M.W.; Seidler, R.J. Staphylococcus aureus in Rural Drinking Water; Department of Microbiology, Oregon State University: Corvallis, OR, USA, 1980. [Google Scholar]

- Wibuloutai, J.; Thanomsangad, P.; Benjawanit, K.; Mahaweerawat, U. Microbial risk assessment of drinking water filtration dispenser toll machines (DFTMs) in Mahasarakham province of Thailand. Water Supply 2019, 19, 1438–1445. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Guidelines for Drinking Water Quality, 4th ed.; World Health Organization: Geneva, Switzerland, 2011; Available online: https://www.who.int/publications/i/item/9789241549950 (accessed on 8 September 2023).

- Ali, S.S.; Anwar, Z.; Zaman, J.; Khattak, K.; Islamic, I. Microbial analysis of drinking water and water distribution system in new urban Peshawar. Curr. Res. J. Biol. Sci. 2012, 4, 731–737. [Google Scholar]

- Codex Alimentarius Commission (2014). Principles and Guidelines for the Conduct of Microbiological Risk Assessment. Available online: https://www.fao.org/3/y1579e/y1579e05.htm (accessed on 8 September 2023).

- Mishra, N.; Mishra, A.K.; Bidija, M. A study on correlation between depression, fear of fall and quality of life in elderly individuals. Int. J. Res. Med. Sci. 2017, 5, 1456–1460. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Analytical Chemists International, 18th ed.; Association of Official Analytical Chemists: Arlington, TX, USA, 2005. [Google Scholar]

- Tallent, S.; Hait, J.; Reginald, W.B.; Gayle, A.L.; Blodgett, R. BAM Appendix 2: Most Probable Number from Serial Dilutions. 2010. Available online: https://www.fda.gov/food/laboratory-methods-food/bam-appendix-2-most-probable-number-serial-dilutions#tab5 (accessed on 8 September 2023).

- Feng, P.; Stephen, D.W.; Michael, A.G.; Burkhardt, W. BAM Chapter 4: Enumeration of Escherichia coli and the Coliform Bacteria. 2020. Available online: https://www.fda.gov/food/laboratory-methods-food/bam-chapter-4-enumeration-escherichia-coli-and-coliform-bacteria (accessed on 8 September 2023).

- Frey, C.H.; Mokhtari, A.; Danish, T. Evaluation of Selected Sensitivity Analysis Methods Based upon Applications to Two Food Safety Process Risk Models; US. Department of Agriculture: Washington, DC, USA, 2003; 460p. [Google Scholar]

- Plant Standard and Certification Division. Thailand Agricultural Regulations and Standards for Plants Certification (TAS. 9001-2013); Department of Agriculture, Ministry of Agriculture and Cooperatives: Bangkok, Thailand, 2013; 345p. [Google Scholar]

- Pratum, C.; Khananthai, N. Assessment of Factors Affecting Drinking water quality from Free Water. Int. J. Environ. Sci. Ed. 2017, 12, 787–797. [Google Scholar]

| Plants | Packing House | Drinking Water Factory A | Drinking Water Factory B | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Samples | Water | Raw | Soft | R.O. | Finished | Raw | Soft | R.O. | Finished |

| Time (min) | 0–20 | - | - | - | - | - | - | - | - |

| Temperature (°C) | 17.3–19.1 | - | - | - | - | - | - | - | - |

| pH | 10.33–10.81 | 7.17 ± 0.25 | 7.24 ± 0.26 | 6.69 ± 0.21 | 5.92 ± 0.32 | 7.60 ± 0.33 | 7.44 ± 0.29 | 6.97 ± 0.22 | 6.80 ± 0.21 |

| Residual chlorine (ppm) | 0.23–1.67 | - | - | - | - | - | - | - | - |

| Total coliform (CFU) | - | 189 ± 8.60 | 316 ± 44.22 | 30 ± 44.40 | 145 ± 7.72 | 26 ± 3.89 | 2 ± 3.13 | 20 ± 1.48 | 13 ± 1.47 |

| S. aureus (CFU) | 3.40 LogCFU | 3 ± 1.00 | 1 ± 0.00 | 1 ± 0.00 | 1 ± 0.00 | 1 ± 0.00 | 1 ± 0.00 | 1 ± 0.00 | 1 ± 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chittaphithakchai, P.; Chomphulao, N.; Kantasap, P.; Wongput, K.; Kaitpoka, P.; Leesurapong, T.; Loakuldilok, T.; Poonlarp, P.; Wangtuei, S.; Jirarattanarangsri, W.; et al. Assessing the Likelihood of Staphylococcus aureus Contamination in Bottled Drinking Water Production. Biol. Life Sci. Forum 2023, 26, 115. https://doi.org/10.3390/Foods2023-15073

Chittaphithakchai P, Chomphulao N, Kantasap P, Wongput K, Kaitpoka P, Leesurapong T, Loakuldilok T, Poonlarp P, Wangtuei S, Jirarattanarangsri W, et al. Assessing the Likelihood of Staphylococcus aureus Contamination in Bottled Drinking Water Production. Biology and Life Sciences Forum. 2023; 26(1):115. https://doi.org/10.3390/Foods2023-15073

Chicago/Turabian StyleChittaphithakchai, Patcharee, Nonlapan Chomphulao, Pasika Kantasap, Kanyapak Wongput, Pawaret Kaitpoka, Thit Leesurapong, Thunnop Loakuldilok, Pichaya Poonlarp, Sutee Wangtuei, Wachira Jirarattanarangsri, and et al. 2023. "Assessing the Likelihood of Staphylococcus aureus Contamination in Bottled Drinking Water Production" Biology and Life Sciences Forum 26, no. 1: 115. https://doi.org/10.3390/Foods2023-15073

APA StyleChittaphithakchai, P., Chomphulao, N., Kantasap, P., Wongput, K., Kaitpoka, P., Leesurapong, T., Loakuldilok, T., Poonlarp, P., Wangtuei, S., Jirarattanarangsri, W., Surawang, S., & Osiriphun, S. (2023). Assessing the Likelihood of Staphylococcus aureus Contamination in Bottled Drinking Water Production. Biology and Life Sciences Forum, 26(1), 115. https://doi.org/10.3390/Foods2023-15073