Abstract

Wet milling is a fractionation process widely used in the corn industry, which allows the separation of its main chemical components (starch, proteins, fiber and lipids) with high efficiency and purity compared to dry milling. The first stage of this process consists of maceration; after softening the grain, the actual milling is carried out, and the germ is separated by flotation because of its high lipid content. The chemical composition of pseudocereals is similar to that of cereals, hence their name, so they could be processed in the same way. In this way, the traditional corn wet milling process was adapted to quinoa. The objective of this work is to isolate the germ of red Bolivian Royal quinoa using wet milling, and evaluate its efficiency and physicochemical characteristics due to its large size and nutrient concentration. By cold pressing the red quinoa germ, crude oil was obtained and characterized in terms of: Acid Index, Iodine Index, Saponification Index, K Index, Refractive Index (20 °C) and fatty acid composition, determined by gas chromatography coupled to a mass detector (GC-MS). This profile was compared with the fatty acid profile of the solvent-extracted quinoa oil, and it was observed that there were no significant differences between the two oil samples. In addition, the sample obtained via cold pressing showed similar characteristics to corn oil, except for a higher Saponification Index and proportion of linolenic acid (omega-3).

1. Introduction

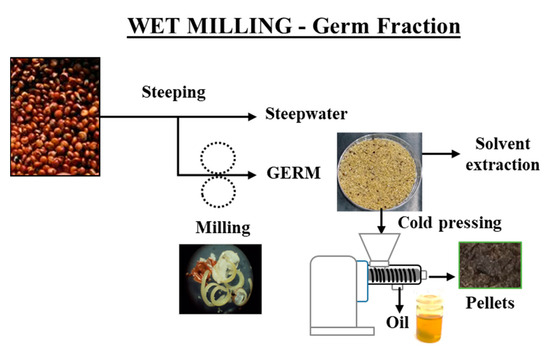

Quinoa grain is a food of high nutritional quality and a source of bioactive compounds, which are concentrated in specific anatomical parts of the grain [1]. The study of quinoa grain fractionation could be approached by adapting the processes currently used in the primary cereal processing industry, specifically dry milling of wheat or wet milling of corn [2] (Figure 1). Wet milling is a fractionation process that allows the high recovery and purity of the chemical components of the grain (starch, proteins, fiber, and lipids) to be obtained compared to dry milling [3].

Figure 1.

Flow sheet of quinoa wet milling and its oil extraction.

The objective of this work is to isolate the germ of red Royal Bolivian quinoa via wet milling, and evaluate its efficiency and physicochemical characteristics. Subsequently, the oil was obtained through cold pressing of the quinoa germ, and its fatty acid profile was compared with the oil obtained through organic solvent extraction.

2. Materials and Methods

The material used in this research was organic red Royal quinoa from Uyuni, Bolivia.

2.1. Obtaining and Characterization of Germ

After quinoa wet milling, the germ was separated through flotation according to Ballester et al. [2]. The efficiency of germ fraction was evaluated according to the following equation:

The proximate composition of the grain and germ of the red Royal quinoa was characterized in terms of moisture, lipids, starch, protein and ash according to Miranda et al. [4].

2.2. Characterization of Quinoa Oil

The extraction procedure was conducted by cold pressing the quinoa germ in an oil Press machine stainless steel (Yameijia A-2288, Zhongshan, China). Subsequently, a liquid–solid extraction with hexane was carried out in a lipid extractor Randall (Velp Scientifica, SER158 Solvent Autoextractor, Usmate, Italy).

The characterization of the oil was carried out using the following parameters: Acidity Index (mg KOH needed to neutralize 1 g of sample), Saponification Index (mg KOH/g oil) and Refractive Index (20 °C) by means of the regulations BOE-A-1977-16116 [5]; Iodine Index (mg I2/100 g) UNE-EN 14111:2022 [6] and K232 Index (Absorbance measured at wavelength 232 nm) UNE-EN-ISO 3656:2011/A1:2017 [7].

In order to obtain the fatty acid profile, the lipids were transesterified to convert them into fatty acid methyl esters [8]. The fatty acid profile was determined by gas chromatography coupled to a mass detector (GC-MS) [9].

2.3. Statistical Analysis

Multiple ANOVA and Fisher’s least significant difference (LDS) tests were applied to establish statistically significant differences. Statistical analyses were performed with the software Statgraphics Centurion XVI and the significance level was established at p < 0.05.

3. Results

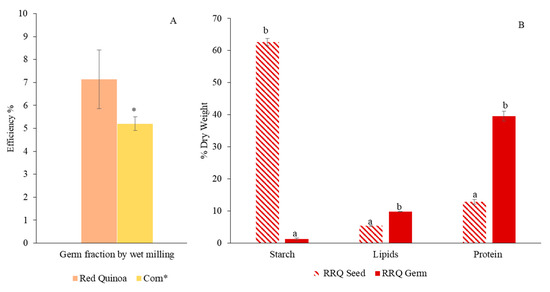

The efficiency of extraction of the red Royal quinoa germ fraction by wet milling was higher than that obtained in corn according to Eckoff et al. [10] (Figure 2A). The fractionation of quinoa resulted in 209% more protein and 84% more lipids compared to the original quinoa grain from which it originated (Figure 2B).

Figure 2.

(A). Extraction efficiency of the red quinoa germ fraction compared to corn germ fraction obtained by wet milling. * Values retrieved from “A 100-g Laboratory Corn Wet-Milling Procedure” by Eckhoff et al. [10]. (B). Red quinoa proximate composition (striped bars) compared to the proximate composition of germ fraction (filled bars). RRQ: Red Royal quinoa; Mean ± SD, n = 3. Bars of the same parameter followed by the same letter indicate that there are no statistically significant differences at a 95% confidence level.

The characterization of red Royal quinoa oil obtained by cold pressing of the germ fraction is shown in Table 1. In addition, the results were compared with corn oil [11]. Both oils showed similar characteristics, except for the Saponification Index, which was higher in quinoa oil than in corn oil, 187–196 mg KOH/g [11].

Table 1.

Chemical and physical characteristics of crude quinoa oil obtained by cold pressing.

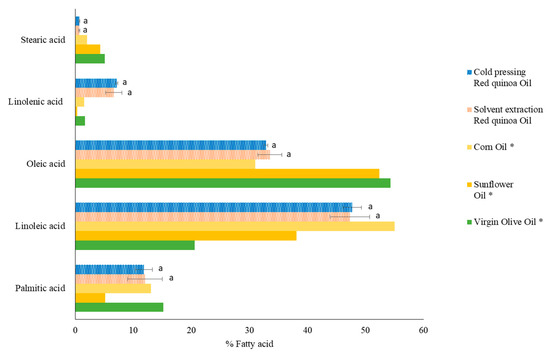

We also obtained quinoa oil using solvent extraction. Comparing the fatty acid profile, no significant differences were observed between the red Royal quinoa oil obtained via cold pressing and solvent extraction (Figure 3). As for essential acids, linoleic acid was present in a similar proportion to corn oil, while linolenic acid was present in a higher proportion (Figure 3) [11].

Figure 3.

Fatty acid profile of quinoa oil of the germ fraction extracted by cold pressing and solvent extraction compared to the fatty acid profile of the most frequently used edible oils. Mean ± SD, n = 3. Bars of the same parameter followed by the same letter indicate that there are no statistically significant differences at a 95% confidence level. * Values retrieved from BOE-A-1983-5543 [11].

4. Conclusions

The wet milling process of quinoa allows the separation of the germ fraction, which leads to the enrichment of fractions rich in protein and food-grade oil, as is the case with cereals such as corn.

The characteristics of quinoa oil are similar regardless of the extraction process (cold pressing or solvent extraction).

Since quinoa oil has a higher concentration of linolenic acid than other edible oils, its use in food could help reverse the nutritional imbalance in terms of the omega-6/omega-3 ratio in Western diets.

Author Contributions

Conceptualization, C.M.H.; Funding acquisition, C.M.H.; Investigation, A.R.-C. and C.M.H.; Methodology, A.R.-C. and C.M.H.; Project administration, C.M.H.; SupervIsion, C.M.H.; Writing-original draft, A.R.-C. and C.M.H.; Writing-review and editing, C.M.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by grant Ia ValSe-Food-CYTED (119RT0567), Food4ImNut Food4ImNut (PID2019-107650RB-C21 funded by MCIN/AEI/10.13039/501100011033.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to their privacy.

Acknowledgments

The contract of Ana Ribera-Castelló from INVESTIGO Program within the framework of the Recovery, Transformation and Resilience Plan of Comunitat Valenciana, Spain.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Reguera, M.; Haros, C.M. Structure and composition of kernels. In Pseudocereals: Chemistry and Technology; Wiley: Chichester, UK, 2017; pp. 28–48. [Google Scholar] [CrossRef]

- Ballester, J.; Gil, J.V.; Fernández, M.T.; Haros, C.M. Quinoa wet-milling: Effect of steeping conditions on starch recovery and quality. Food Hydrocoll. 2019, 89, 837–843. [Google Scholar] [CrossRef]

- Haros, C.M.; Wronkowska, M. Pseudocereal dry and wet milling: Processes, products and applications. In Pseudocereals: Chemistry and Technology; Wiley: Chichester, UK, 2017; pp. 140–162. [Google Scholar] [CrossRef]

- Miranda, K.; Millán, M.C.; Haros, C.M. Effect of Chia as Breadmaking Ingredient on Nutritional Quality, Mineral Availability, and Glycemic Index of Bread. Foods 2020, 9, 663. [Google Scholar] [CrossRef] [PubMed]

- Orden de 31 de Enero de 1977 por la que se Establecen los Métodos Oficiales de Análisis de Aceites y Grasas, Cereales y Derivados, Productos Lácteos y Productos Derivados de la Uva. Boletín Oficial del Estado, 167, de 14 de Julio de 1977. Available online: https://www.boe.es/eli/es/o/1977/01/31/(1)/con (accessed on 10 May 2023).

- UNE-EN 14111:2022; Derivados de Aceites y Grasas. Ésteres metílicos de ácidos grasos (FAME). Determinación del índice de yodo; Asociación Española de Normalización y Certificación: Madrid, Spain, 2022.

- UNE-EN ISO 3656:2011/A1:2017; Aceites y Grasas de Origen Animal y Vegetal. Determinación de la absorbancia ultravioleta expresada como extinción UV específica; Asociación Española de Normalización y Certificación: Madrid, Spain, 2017.

- Zhang, M.; Yang, X.; Zhao, H.T.; Dong, A.J.; Wang, J.; Liu, G.Y.; Zhang, H. A quick method for routine analysis of C18 trans fatty acids in non-hydrogenated edible vegetable oils by gas chromatography–mass spectrometry. Food Control. 2015, 57, 293–301. [Google Scholar] [CrossRef]

- Härtig, C. Rapid identification of fatty acid methyl esters using a multidimensional gas chromatography–mass spectrometry database. J. Chromatogr. A 2008, 1177, 159–169. [Google Scholar] [CrossRef] [PubMed]

- Eckhoff, S.R.; Singh, S.K.; Zehr, B.E.; Rausch, K.D.; Fox, E.J.; Mistry, A.K.; Keeling, P.L. A 100-g laboratory corn wet-milling procedure. Cereal Chem. 1996, 73, 54–57. [Google Scholar]

- Real Decreto 308/1983, de 25 de Enero, por el que se Aprueba la Reglamentación Técnico-Sanitaria de Aceites Vegetales Comestibles. Boletín Oficial del Estado, 44, de 21 February 1983, Spain. Available online: https://www.boe.es/eli/es/rd/1983/01/25/308/con (accessed on 10 March 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).