Impact of Different Cross-Linking Agents on Functional, Rheological, and Structural Properties of Talipot Palm Starch: A New Source of Stem Starch †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Starch Isolation

2.2. Modification with Epichlorohydrin

2.3. Modification with Phosphoric Acid

2.4. Amylose Content

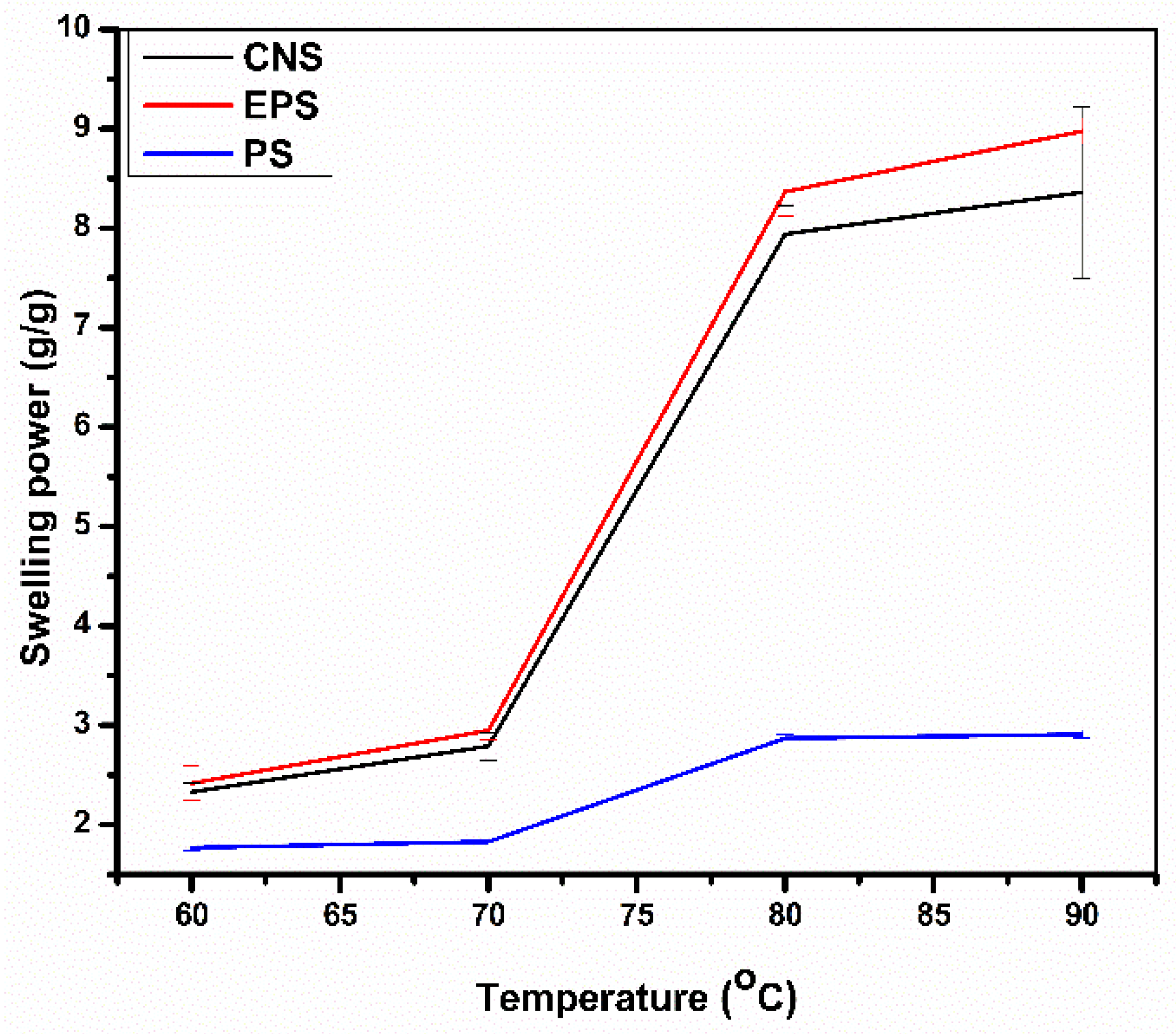

2.5. Swelling Power (SP)

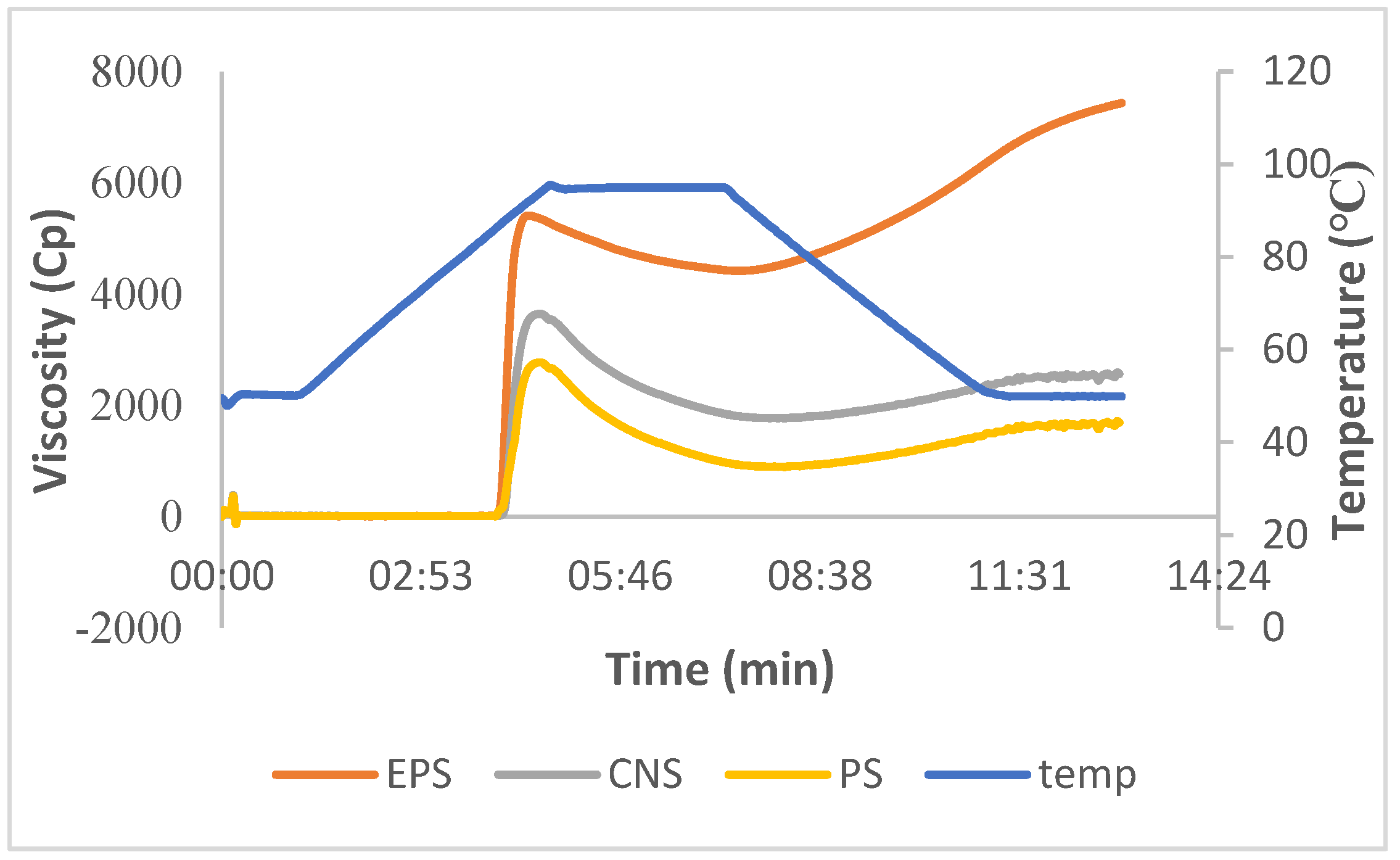

2.6. Pasting Profile

2.7. Gel Textural Properties

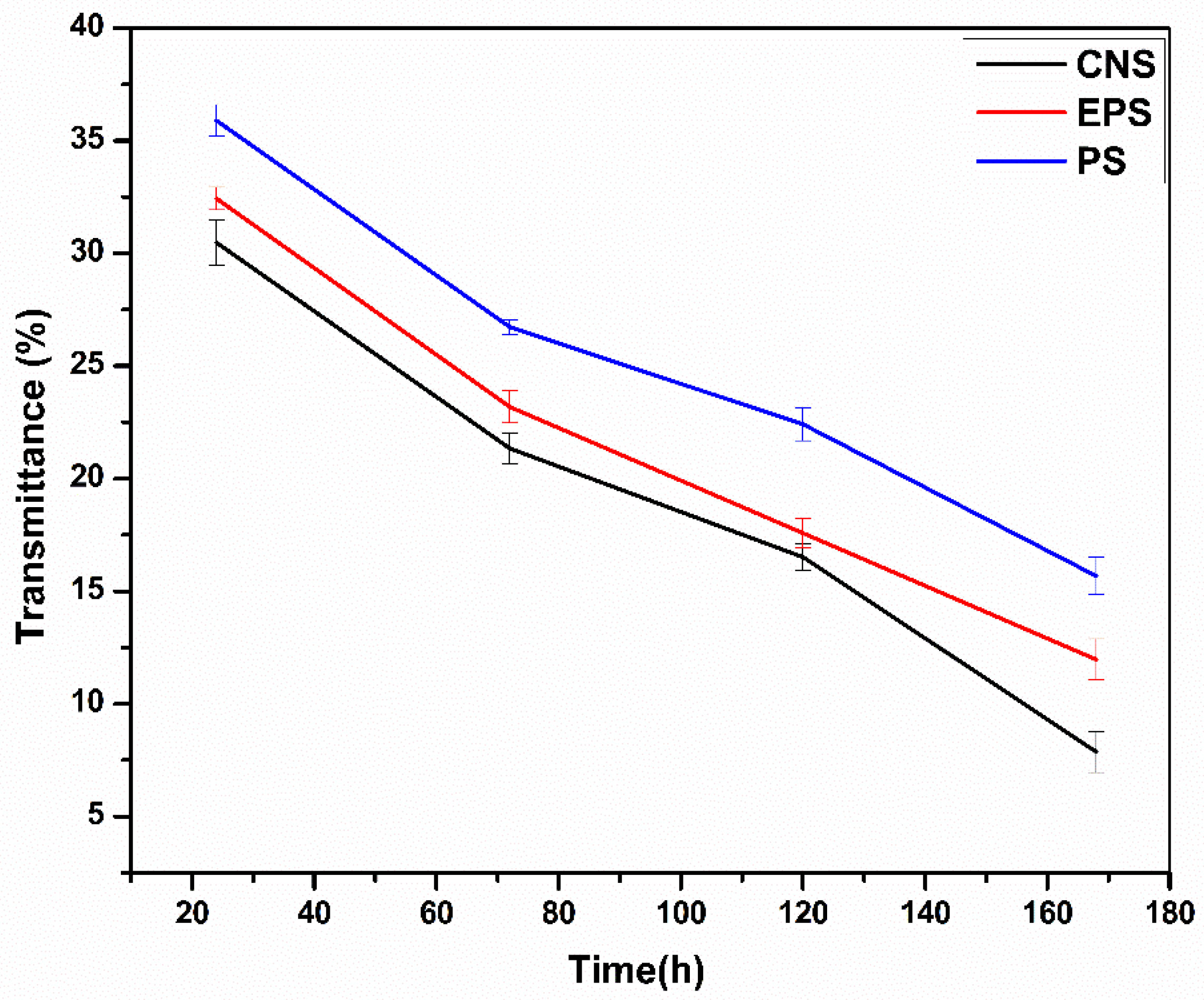

2.8. Light Transmittance

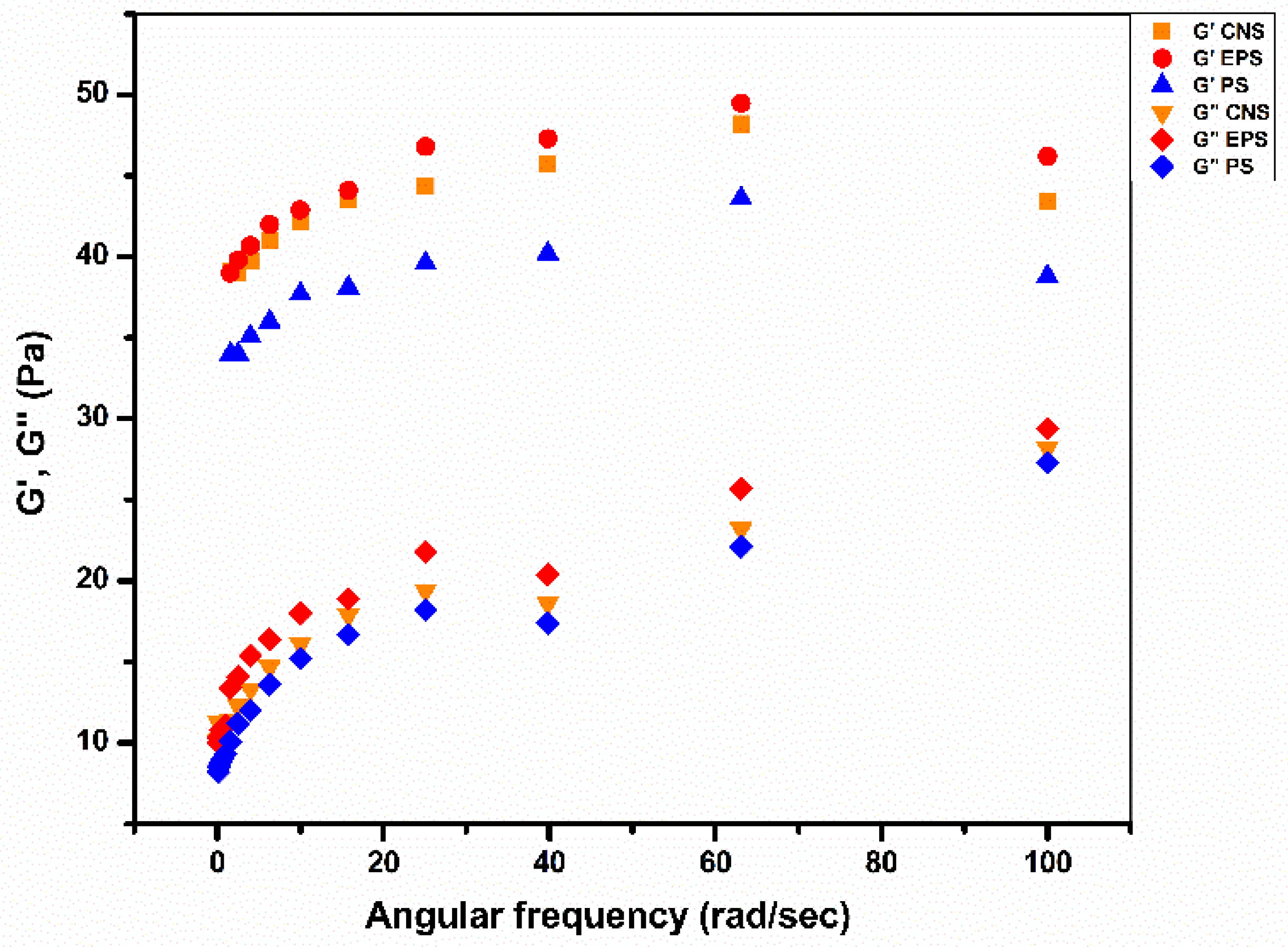

2.9. Rheological Properties

2.10. X-ray Diffractometry (XRD)

2.11. Statistical Analysis

3. Result and Discussion

3.1. Amylose Content

3.2. Swelling Power (SP)

3.3. Pasting Profile

3.4. Gel Texture

3.5. Light Transmittance

3.6. Rheological Properties

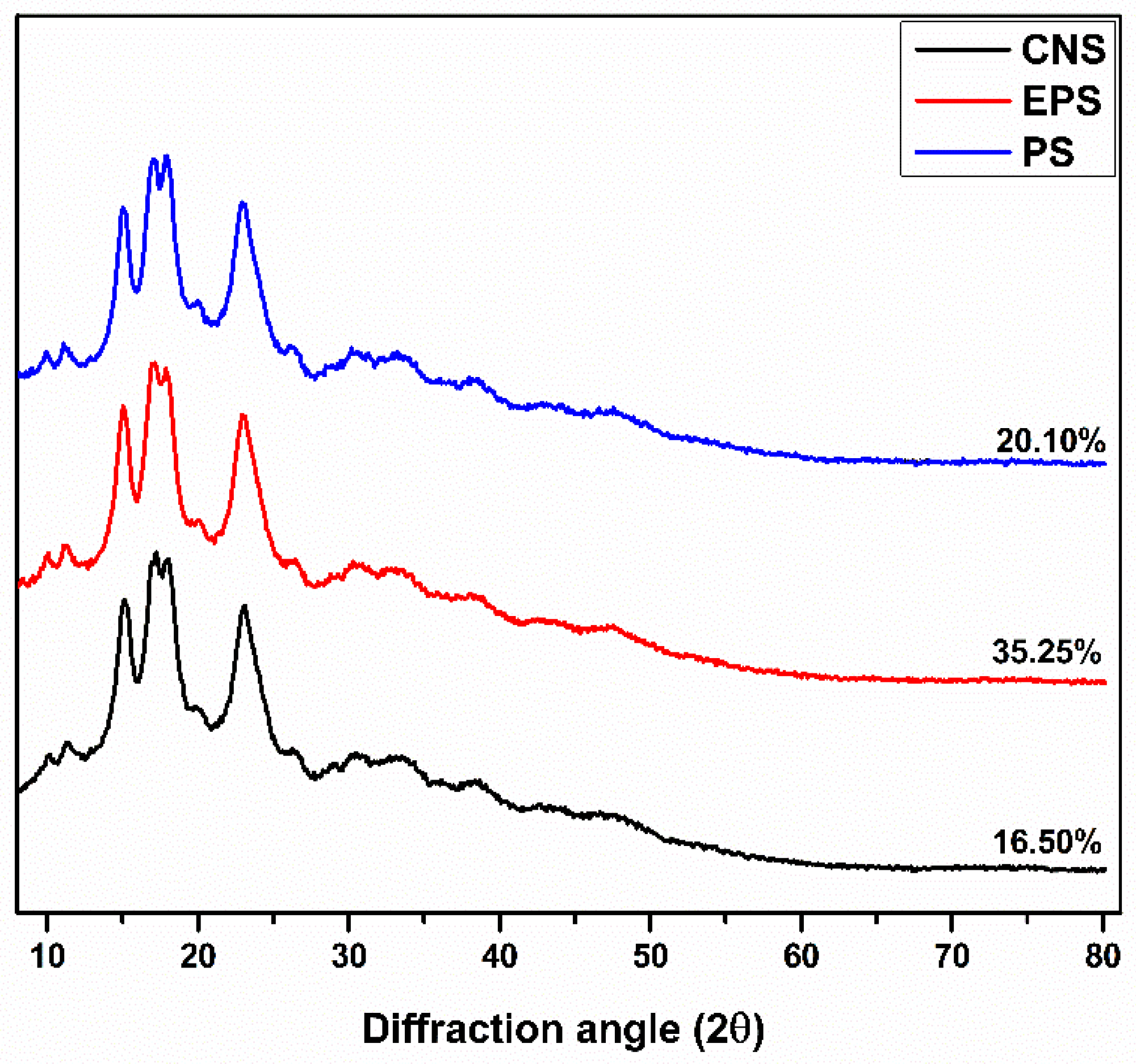

3.7. X-ray Diffractometry (XRD)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chi, C.; Li, X.; Huang, S.; Chen, L.; Zhang, Y.; Li, L.; Miao, S. Basic principles in starch multi-scale structuration to mitigate digestibility: A review. Trends Food Sci. Technol. 2021, 109, 154–168. [Google Scholar] [CrossRef]

- Navaf, M.; Sunooj, K.V.; Aaliya, B.; Sudheesh, C.; Akhila, P.P.; Sabu, S.; Sasidharan, A.; George, J. Talipot palm (Corypha umbraculifera L.) a nonconventional source of starch: Effect of citric acid on structural, rheological, thermal properties and in vitro digestibility. Int. J. Biol. Macromol. 2021, 182, 554–563. [Google Scholar] [CrossRef]

- Navaf, M.; Sunooj, K.V.; Aaliya, B.; Sudheesh, C.; George, J. Physico-chemical, functional, morphological, thermal properties and digestibility of Talipot palm (Corypha umbraculifera L.) flour and starch grown in Malabar region of South India. J. Food Meas. Charact. 2020, 14, 1601–1613. [Google Scholar] [CrossRef]

- Santana, Á.L.; Angela, A.; Meireles, M. New Starches are the Trend for Industry Applications: A Review. Food Public Health 2014, 4, 229–241. [Google Scholar] [CrossRef]

- Ogunmolasuyi, A.M.; Egwim, E.C.; Adewoyin, M.A.; Nkop, J.E. Effect of phosphoric acid treatment on physicochemical, functional, and structural properties of starch extracted from yam (Dioscorea rotundata). Int. J. Food Prop. 2017, 20, 1062–1073. [Google Scholar] [CrossRef] [Green Version]

- Sudheesh, C.; Sunooj, K.V.; Navaf, M.; Bhasha, S.A.; George, J.; Mounir, S.; Kumar, S.; Sajeevkumar, V.A. Hydrothermal modifications of nonconventional kithul (Caryota urens) starch: Physico-chemical, rheological properties and in vitro digestibility. J. Food Sci. Technol. 2020, 57, 2916–2925. [Google Scholar] [CrossRef]

- Jyothi, A.N.; Moorthy, S.N.; Rajasekharan, K.N. Effect of cross-linking with epichlorohydrin on the properties of cassava (Manihot esculenta Crantz) starch. Starch/Staerke 2006, 58, 292–299. [Google Scholar] [CrossRef]

- Heo, H.; Lee, Y.K.; Chang, Y.H. Rheological, pasting, and structural properties of potato starch by cross-linking. Int. J. Food Prop. 2017, 20, 2138–2150. [Google Scholar] [CrossRef]

- Kau, L.; Singh, J.; Singh, N. Effect of cross-linking on some properties of potato (Solanum tuberosum L.) starches. J. Sci. Food Agric. 2006, 86, 1945–1954. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Siroha, A.K.; Punia, S.; Sangwan, L.; Nehra, M.; Purewal, S.S. Effect of degree of cross linking on physicochemical, rheological and morphological properties of Sorghum starch. Carbohydr. Polym. Technol. Appl. 2021, 2, 100073. [Google Scholar] [CrossRef]

- Siroha, A.K.; Sandhu, K.S. Physicochemical, rheological, morphological, and in vitro digestibility properties of cross-linked starch from pearl millet cultivars. Int. J. Food Prop. 2018, 21, 1371–1385. [Google Scholar] [CrossRef] [Green Version]

- Williams, P.C.; Kuzina, F.D.; Hlynka, I. A Rapid colorimetric procedure for estimating the Amylose content of starches and flours. Cereal Chem. 1970, 47, 411–421. [Google Scholar]

- Navaf, M.; Sunooj, K.V.; Krishna, N.U.; Aaliya, B.; Sudheesh, C.; Akhila, P.P.; Sabu, S.; Sasidharan, A.; Mir, S.A.; George, J. Effect of Different Hydrothermal Treatments on Pasting, Textural, and Rheological Properties of Single and Dual Modified Corypha Umbraculifera L. Starch. Starch/Starke 2021, 74, 2100236. [Google Scholar] [CrossRef]

- Aaliya, B.; Sunooj, K.V.; Babu, C.; Rajkumar, S.; Navaf, M.; Akhila, P.P.; Sudheesh, C.; George, J.; Lackner, M. Effect of Thermal Pretreatments on Phosphorylation of Corypha umbraculifera L. Stem Pith Starch: A Comparative Study Using Dry-Heat, Heat-Moisture and Autoclave Treatments. Polymers 2021, 13, 3855. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.; Kaur, M.; Sandhu, K.S.; Godara, S.K. Effect of cross-linking on physico-chemical, thermal, pasting, in vitro digestibility and film forming properties of Faba bean (Vicia faba L.) starch. Int. J. Biol. Macromol. 2020, 159, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Wongsagonsup, R.; Pujchakarn, T.; Jitrakbumrung, S.; Chaiwat, W.; Fuongfuchat, A.; Varavinit, S.; Dangtip, S.; Suphantharika, M. Effect of cross-linking on physicochemical properties of tapioca starch and its application in soup product. Carbohydr. Polym. 2014, 101, 656–665. [Google Scholar] [CrossRef]

- Ali, T.M.; Hasnain, A. Physicochemical, morphological, thermal, pasting, and textural properties of starch acetates. Food Rev. Int. 2016, 32, 161–180. [Google Scholar] [CrossRef]

- Sudheesh, C.; Sunooj, K.V.; George, J.; Kumar, S.; Appukuttan, V. Physico-chemical, morphological, pasting and thermal properties of stem flour and starch isolated from kithul palm (Caryota urens) grown in valley of Western Ghats of India. J. Food Meas. Charact. 2019, 13, 120–130. [Google Scholar] [CrossRef]

- Braşoveanu, M.; Nemţanu, M.R. Pasting properties modeling and comparative analysis of starch exposed to ionizing radiation. Radiat. Phys. Chem. 2020, 168, 108492. [Google Scholar] [CrossRef]

- Kurakake, M.; Akiyama, Y.; Hagiwara, H.; Komaki, T. Effects of cross-linking and low molecular amylose on pasting characteristics of waxy corn starch. Food Chem. 2009, 116, 66–70. [Google Scholar] [CrossRef]

- Liu, H.; Ramsden, L.; Corke, H. Physical properties of cross-linked and acetylated normal and waxy rice starch. Starch/Staerke 1999, 51, 249–252. [Google Scholar] [CrossRef]

- Navaf, M.; Sunooj, K.V.; Aaliya, B.; Sudheesh, C.; Akhila, P.P.; Sabu, S.; Sasidharan, A.; George, J. Impact of gamma irradiation on structural, thermal, and rheological properties of talipot palm (Corypha umbraculifera L.) starch: A stem starch. Radiat. Phys. Chem. 2022, 201, 110459. [Google Scholar] [CrossRef]

- Wani, I.A.; Jabeen, M.; Geelani, H.; Masoodi, F.A.; Saba, I.; Muzaffar, S. Effect of gamma irradiation on physicochemical properties of Indian Horse Chestnut (Aesculus indica Colebr.) starch. Food Hydrocoll. 2014, 35, 253–263. [Google Scholar] [CrossRef]

- Koo, S.H.; Lee, K.Y.; Lee, H.G. Effect of cross-linking on the physicochemical and physiological properties of corn starch. Food Hydrocoll. 2010, 24, 619–625. [Google Scholar] [CrossRef]

- Dong, H.; Vasanthan, T. Effect of phosphorylation techniques on structural, thermal, and pasting properties of pulse starches in comparison with corn starch. Food Hydrocoll. 2020, 109, 106078. [Google Scholar] [CrossRef]

| Sample | Amylose (%) | RC (%) |

|---|---|---|

| CNS | 26.13 ± 0.71 a | 16.50 ± 0.27 c |

| EPS | 19.15 ± 0.34 c | 35.25 ± 0.62 a |

| PS | 21.84 ± 0.51 b | 20.10 ± 0.14 b |

| Sample | Hardness (N) | Springiness (mm) | Gumminess (Nmm) | Chewiness (Nmm) | Cohesiveness |

|---|---|---|---|---|---|

| CNS | 45.54 ± 0.37 b | 0.91 ± 0.02 b | 23.36 ± 0.33 b | 21.22 ± 0.22 b | 0.52 ± 0.01 a |

| EPS | 149.69 ± 1.34 a | 0.97 ± 0.01 a | 66.75 ± 0.63 a | 63.73 ± 0.46 a | 0.43 ± 0.00 b |

| PS | 13.62 ± 0.10 c | 0.87 ± 0.01 b | 5.59 ± 0.48 c | 5.18 ± 0.27 c | 0.43 ± 0.01 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navaf, M.; Sunooj, K.V. Impact of Different Cross-Linking Agents on Functional, Rheological, and Structural Properties of Talipot Palm Starch: A New Source of Stem Starch. Biol. Life Sci. Forum 2022, 20, 16. https://doi.org/10.3390/IECBM2022-13391

Navaf M, Sunooj KV. Impact of Different Cross-Linking Agents on Functional, Rheological, and Structural Properties of Talipot Palm Starch: A New Source of Stem Starch. Biology and Life Sciences Forum. 2022; 20(1):16. https://doi.org/10.3390/IECBM2022-13391

Chicago/Turabian StyleNavaf, Muhammed, and Kappat Valiyapeediyekkal Sunooj. 2022. "Impact of Different Cross-Linking Agents on Functional, Rheological, and Structural Properties of Talipot Palm Starch: A New Source of Stem Starch" Biology and Life Sciences Forum 20, no. 1: 16. https://doi.org/10.3390/IECBM2022-13391

APA StyleNavaf, M., & Sunooj, K. V. (2022). Impact of Different Cross-Linking Agents on Functional, Rheological, and Structural Properties of Talipot Palm Starch: A New Source of Stem Starch. Biology and Life Sciences Forum, 20(1), 16. https://doi.org/10.3390/IECBM2022-13391