Abstract

Post-harvest systems are crucial for fruit conservation, since they minimize the waste of such perishable food and allow its marketability to consumers during the year. This study thus aimed to assess the calcium values in stored fruits, previously sprayed and/or immersed in CaCl2, and the possible implications for quality. Fruits previously sprayed with different concentrations of calcium chloride (0–8 kg·ha−1 CaCl2) during the productive cycle (pre-harvest phase) were separated into two groups at harvest. One group was immediately stored in conservation chambers, while the second group was immersed in 1.3% CaCl2 (for 10 min at room temperature) in the post-harvest stage. After 4 months of storage, the calcium content was evaluated with X-ray fluorescence analysis, and quality parameters, such as total soluble solids, malic acid, hardness and colorimetric parameters of the pulp were also monitored. Overall, the calcium content in stored fruits with post-harvest bath was superior, but the fruits with the exclusive application of CaCl2 during the pre-harvest phase were superior to the respective control. Furthermore, treatment T2 (corresponding to the highest concentration of CaCl2 during pre-harvest, up to 8 kg·ha−1) presented the lowest total soluble solids values. The highest value of malic acid prevailed in fruits with no application of CaCl2, while it also presented the lowest value of hardness. No significant differences were observed for the colorimetric parameters of pulps. In conclusion, the pre-harvest workflow used for this study increased the calcium content in fruits at harvest, but the post-harvest immersion can be used in addition to pre-harvest treatments to avoid fruit quality decay. The calcium applications did not compromise the fruits’ marketability to consumers.

1. Introduction

Agroindustries are investing in ways to increase food productivity to feed the growing global population [1]. However, in the meads of hydric and land resource limitations and climate changes, minimizing food loss and waste, which claims a major part of the agriculture output, could decrease the demand for production increases [1,2]. Furthermore, higher consumption of vegetables and fruits in low- and middle-income countries is expected to occur [1]. In this context, due to its perishability, fruit preservation methods during the post-harvest phase become important to avoid the loss of quality characteristics that often leads to discarded products or reduced consumer acceptability [3].

In plants, calcium (Ca) can either act as an intracellular second messenger or perform structural roles [4], making it one of the most important nutrients for fruit quality and respective post-harvest life [5]. Developing tissues, such as fruits or young leaves, are more prone to Ca deficiencies due to lower transpiration rates and reduced remobilization of Ca from older tissues [4,6], and bitter pit, a typical disorder in apples, has been linked to this mineral‘s deficit [5,6]. Thus, studies with Ca applications and respective impacts on the quality parameters of pears and other fruits during the pre-harvest and post-harvest phases have been performed [7,8,9,10].

Rocha pear (Pyrus communis) is the main pear variety grown in Portugal, and over half of its annual total production is exported, benefiting from its resistance to handling and transport [11]. The storage time of these fruits varies according to the type of storage conditions applied [12]. Under a controlled atmosphere (often used on an industrial scale), Rocha pear fruits can last between 7 and 8 months, since processes such as ripening and senescence are delayed [11,12].

For this study, the Ca content in Rocha pear fruits sprayed with CaCl2 in the pre-harvest phase, and/or immersed in CaCl2 at post-harvest, was assessed after 4 months of storage under a controlled atmosphere. Monitorization of quality parameters, such as total soluble solids, acidity, hardness and color of pulp, was also performed.

2. Materials and Methods

2.1. Pre-Harvest and Post-Harvest Workflow

During the production cycle of 2019, between April and August, pre-harvest foliar sprays were performed in a Rocha pear orchard. For T1, the seven sprays were applied with 4 kg·ha−1 CaCl2, while for T2, the first three sprays were performed with 4 kg·ha−1 CaCl2, followed by an increase in concentration to 8 kg·ha−1 CaCl2 for the remaining sprays. No sprays were performed on the control (Ctr-0 kg·ha−1 CaCl2). In September, the fruits were harvested and transported to the fruticulture center, where each treatment was then divided into two groups. The first group was immediately taken to the storage chambers at temperatures ranging from −0.5 °C to 1 °C and humidity of 95%. The second group was kept in the same storage chamber, but the fruits were first immersed in a solution of 1.3% CaCl2 for 10 min at room temperature. In January, the fruits were collected from the storage chambers for analysis.

2.2. Mineral Content Analysis

The mineral content in fruits was assessed as described in Ref [13], with slight modifications for the fruits. Namely, after a random selection of fruits from the different treatments and brief cleaning with deionized water, the fruits were sliced and put to dry at 50 °C until constant weight, being subsequently grounded for Ca content analysis.

2.3. Quality Parameters Assessment

Total soluble solids (TSS), acidity and hardness, expressed in °Brix, g malic acid/L and kg, respectively, were assessed in randomized fresh fruits from the different treatments. For TSS and acidity, a refractometer (Atago, Tokyo, Japan) and pH meter (Jenway, 350 model, Chelmsford, UK) were used, and samples were prepared as described in the following works [14,15]. For hardness determination, a manual penetrometer (Bellevue type, Paris, France) with an 8 mm (0.5 cm2) tip was used [14].

Using a Minolta CR 400 colorimeter (Minolta corp., Ramsey, NJ, USA) as described in Ref [13], the colorimetric parameters of the pulp from fresh fruits were determined, namely L (brightness), a* (red and green) and b* (yellow and blue).

2.4. Statistics

For statistical analysis of the data, a one-way ANOVA (p ≤ 0.05) and Tukey test (95% confidence level) were executed. Letters a to c indicate significant differences between all treatments.

3. Results

3.1. Calcium in Fruits

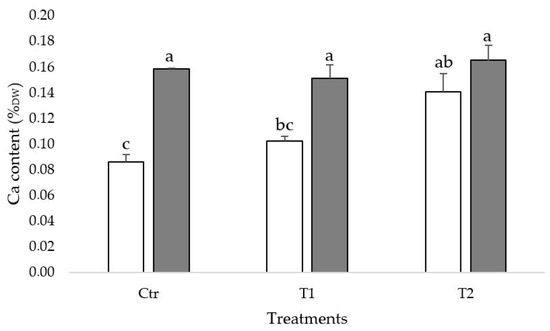

The calcium content (Figure 1) in fruits immersed in CaCl2 was superior to that of fruits with pre-harvest applications. Furthermore, when considering only fruits without post-harvest applications (Figure 1), T2 was significantly different from the control.

Figure 1.

Average values and S.E. of Ca mineral content in pear fruits after 4 months of storage, with (gray) and without (white) post-harvest CaCl2 immersion. For statistical analysis, letters a to c correspond to significant differences between all treatments (single-factor ANOVA test, p ≤ 0.05). Ctr = no foliar sprays, 0 kg·ha−1 CaCl2; T1 = foliar sprays with exclusive use of 4 kg·ha−1 CaCl2; T2 = foliar sprays with 4 kg·ha−1 and 8 kg·ha−1 CaCl2.

3.2. Quality

For quality parameters (Table 1), significant differences were observed for TSS, malic acid and hardness, with values ranging between 10.1 and 11.3 °Brix, 0.80 and 1.09 g/L and 5.44 and 5.81 kg, respectively. Fruits without any CaCl2 applications (Ctr) presented the highest values of TSS and malic acid but the lowest hardness value.

Table 1.

Average values and S.E. of quality parameters of pear fruits stored for 4 months. For statistical analysis, letters a to c correspond to significant differences between all treatments (single-factor ANOVA test, p ≤ 0.05). Ctr = no foliar sprays, 0 kg·ha−1 CaCl2; T1 = foliar sprays with exclusive use of 4 kg·ha−1 CaCl2; T2 = foliar sprays with 4 kg·ha−1 and 8 kg·ha−1 CaCl2; I = Fruits immersed in 1.3% CaCl2 for 10 min at room temperature.

Regarding the colorimetric parameters of the pulp (Table 2), no significant differences were observed for L, a* and b* parameters, with a higher contribution of white, green and yellow predominating, respectively.

Table 2.

Average values and S.E. of colorimetric parameters from pulp of pear fruits stored for 4 months. For statistical analysis, letter a corresponds to the absence of significant differences between all treatments (single-factor ANOVA test, p ≤ 0.05). Ctr = no foliar sprays, 0 kg·ha−1 CaCl2; T1 = foliar sprays with exclusive use of 4 kg·ha−1 CaCl2; T2 = foliar sprays with 4 kg·ha−1 and 8 kg·ha−1 CaCl2; I = Fruits immersed in 1.3% CaCl2 for 10 min at room temperature.

4. Discussion

The storage circumstances were the same for all treatments. The humidity and temperature conditions were accurate for the Rocha pear fruits, and since this fruit is not sensitive to lower temperatures, such as the ones applied, it can be stored without resulting in cold-induced damage [12,16].

The enhancement of Ca content in Rocha pear fruits without post-harvest treatment is related to the pre-harvest applications of CaCl2, and these increases are in accordance with other studies [9,17,18,19,20] where foliar application of CaCl2 increased the Ca content in the edible parts of the sprayed plants. Additionally, Ca applications are already practiced in the horticultural sector not only during the pre-harvest but also during the post-harvest phase [6,10,21], since it helps with the shelf-life and cell wall integrity, ultimately avoiding quality parameters’ decay [22]. Immersion in CaCl2 further increased the Ca in pear fruits, being in accordance with the results in two apple varieties [17].

At harvest, the Rocha pear values of TSS, acidity and hardness should vary between 11 and 13 °Brix, 2 and 3 g/L and 5.5 and 6.5 kg/0.5 cm2, respectively [14,23]. However, pears are climacteric fruits, remaining physiologically active while in storage, and thus, their physico-chemical properties can change during the conservation stage [12].

Fruit flavor is related to TSS and acidity [16], and while in storage, the internal production of ethylene and the respiratory rate can lead to an increase in TSS and a decrease in acidity [12]. Regarding both parameters, only TSS is classified as a fingerprint marker for this variety (stored for 5 months under a controlled atmosphere), with values ranging between 10.0 and 13.8 °Brix [12], a range into which our values fall. Furthermore, a study [9] using Ca pre-harvest applications ranging from 2 to 25 kg·ha−1 in Conference pears reported no differences of soluble solids concentration after 150 days of storage in similar conditions to our study. For acidity, even though there was a slight decrease in values in comparison to Ctr, the general absence of significant differences suggests that Ca does not influence this parameter.

Overall, the hardness values were still within the ideal range set for harvest. For this parameter, higher values are desirable for longer shelf-life and resistance during transport and storage [16]. However, the pre- and post-harvest aspects can influence this parameter, such as fertilization during the production cycle or Ca application during the post-harvest phase [16]. Accordingly, the immersion in CaCl2 (during post-harvest) increased the Ca values of all treatments, namely, for Ctr. Furthermore, when considering the exclusive applications during pre-harvest, the sprayed fruits presented higher values than the respective control. These results confirm that Ca application during pre- or post-harvest phases influence the hardness of Rocha pear fruit due to its structural role in cell wall properties [6].

Color changes in fruits can be related to the different maturity stages, such as the prevalence of green on Rocha pear peel at harvest that later transitions to yellow [11,23]. It is thus considered a quality parameter. However, color changes can also be related to quality decay due to physiological changes during storage, which ultimately result in disorders, such as superficial scald or internal browning [24]. Furthermore, this fruit‘s pulp is white [11], and according to one study [12], parameters L and b* can also be used as fingerprint markers for this variety (for pears stored for 5 months under a controlled atmosphere), with maximum and minimum values ranging between 70.36 and 87.19, and 6.81 and 17.68, respectively. The absence of differences in colorimetric parameters indicates that Ca treatments did not affect the color of the pulps, and our parameters were in accordance with the fingerprint values, with coordinate b* presenting slightly higher values, confirming the absence of damage to the pulp.

5. Conclusions

The application of CaCl2 during pre-harvest led to Ca content increases in fruits, further enhanced by immersion in CaCl2. Additionally, taking into consideration fruit processing (where peeling can be performed) and storage time (with fruits remaining physiologically active), further analysis to assess the calcium distribution in fruit tissues should be considered.

The quality parameters of fruits were not negatively impacted by CaCl2 concentrations, and the storage conditions were adequate, preserving their marketability to consumers or further processing into different food products. Calcium’s structural role was also confirmed by the hardness values of Rocha pear fruits increasing with CaCl2 applications during pre- and post-harvest phases.

Supplementary Materials

The presentation material can be downloaded at: https://www.mdpi.com/article/10.3390/IECHo2022-12481/s1.

Author Contributions

Conceptualization, P.S.C. and F.C.L.; methodology, P.S.C. and F.C.L.; formal analysis, C.C.P., A.C.M., A.R.F.C., D.D., I.C.L., P.S.C., I.P.P. and J.N.S.; resources, J.C.R., P.S.C., M.M.S., P.L., F.H.R., M.S., M.F.P. and F.C.L.; writing—original draft preparation, C.C.P.; writing—review and editing, C.C.P. and F.C.L.; supervision, F.C.L.; project administration, F.C.L.; funding acquisition, F.C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by PDR2020, grant number 101-030734. Funding from Fundação para a Ciência e Tecnologia (FCT) UI/BD/150718/2020 is also greatly acknowledged.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank José Henriques (HBio Lda.) and Eng. Ricardo Mendes (Frutalvor—Central Fruteira CRL) for technical assistance in the orchard and storage chambers. We also give thanks to the Research centers (GeoBioTec) UIDB/04035/2020 and (CEF) UIDB/00239/2020 for support facilities.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- FAO—Food and Agriculture Organization of the United Nations. The Future of Food and Agriculture—Trends and Challenges; FAO: Rome, Italy, 2017; ISBN 978-92-5-109551-5. [Google Scholar]

- FAO—Food and Agriculture Organization of the United Nations. The State of Food and Agriculture—Climate Change, Agriculture and Food Security; FAO: Rome, Italy, 2016; ISBN 978-92-5-109374-0. [Google Scholar]

- Shewfelt, R.L.; Prussia, S.E.; Sparks, A.A. Challenges in handling fresh fruits and vegetables. In Postharvest Handling—A Systems Approach, 3rd ed.; Florkowski, W.J., Shewfelt, R.L., Brueckner, B., Prussia, S.E., Eds.; Elsevier: Oxford, UK, 2014; pp. 11–25. [Google Scholar]

- Thor, K. Calcium—Nutrient and messenger. Front. Plant Sci. 2019, 10, 440. [Google Scholar] [CrossRef] [PubMed]

- Bonomelli, C.; Mogollón, R.; Tonetto de Freitas, S.; Zoffoli, J.P.; Contreras, C. Nutritional relationships in Bitter Pit affected fruit and the feasibility of Vis-NIR Models to determine calcium concentration in ‘Fuji’ Apples. Agronomy 2020, 10, 1476. [Google Scholar] [CrossRef]

- Hocking, B.; Tyerman, S.D.; Burton, R.A.; Gilliham, M. Fruit calcium: Transport and physiology. Front. Plant Sci. 2016, 7, 569. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; Qin, G.; Zhang, H.; Tao, S.; Wu, J.; Wang, S.; Zhang, S. Calcium treatments promote the aroma volatiles emission of pear (Pyrus ussuriensis ‘Nanguoli’) fruit during post-harvest ripening process. Sci. Hortic. 2017, 215, 102–111. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Wang, Y.; Yang, S.; Qu, H. The changes of intracellular calcium concentration and distribution in the hard end pear (Pyrus pyrifolia cv. ‘Whangkeumbae’) fruit. Cell Calcium 2018, 71, 15–23. [Google Scholar] [CrossRef] [PubMed]

- Wójcik, P.; Skorupińska, A.; Filipczak, J. Impacts of preharvest fall sprays of calcium chloride at high rates on quality and ‘Conference’ pear storability. Sci. Hortic. 2014, 168, 51–57. [Google Scholar] [CrossRef]

- Gao, Q.; Tan, Q.; Song, Z.; Chen, W.; Li, X.; Zhu, X. Calcium chloride postharvest treatment delays the ripening and softening of papaya fruit. J. Food Process. Preserv. 2020, 44, e14604. [Google Scholar] [CrossRef]

- ANP—Associação Nacional de Produtores de Pera Rocha. Available online: https://perarocha.pt/anp/ (accessed on 29 September 2021).

- Pedro, S.I.; Coelho, E.; Peres, F.; Machado, A.; Rodrigues, A.M.; Wessel, D.F.; Coimbra, M.A.; Anjos, O. Physicochemical fingerprint of “Pera Rocha do Oeste”. A PDO pear native from Portugal. Foods 2020, 9, 1209. [Google Scholar] [CrossRef] [PubMed]

- Luís, I.C.; Lidon, F.C.; Pessoa, C.C.; Marques, A.C.; Coelho, A.R.F.; Simões, M.; Patanita, M.; Dôres, J.; Ramalho, J.C.; Silva, M.M.; et al. Zinc enrichment in two contrasting genotypes of Triticum aestivum L. grains: Interactions between edaphic conditions and foliar fertilizers. Plants 2021, 10, 204. [Google Scholar] [CrossRef] [PubMed]

- Soares, J.; Silva, A.; Alexandre, J. O Livro da Pera Rocha, 1º Volume—Contributo Para Uma Produção Integrada, 1st ed.; Associação Nacional de Produtores de Pera Rocha: Cadaval, Portugal, 2001; p. 184. [Google Scholar]

- Pessoa, C.C.; Coelho, A.R.F.; Marques, A.C.; Luís, I.C.; Daccak, D.; Silva, M.M.; Ramalho, J.C.; Simões, M.; Reboredo, F.H.; Pessoa, M.F.; et al. Increase of calcium in ‘Rocha’ pear (Pyrus communis L.) for development of functional foods. Biol. Life Sci. Forum 2021, 4, 6. [Google Scholar] [CrossRef]

- Soares, A.C.A. Avaliação da Qualidade Físico-Química e Sensorial de Frutas Durante o Armazenamento e Comercialização. Master’s Thesis, Universidade de Aveiro, Aveiro, Portugal, 2015. [Google Scholar]

- Lidon, F.; Ribeiro, V.; Reboredo, F.; Pessoa, M.; Santos, M.; Ramos, P.; Sánchez, C. Calcium biofortification of apples: Interaction with Macronutrients. In Proceedings of the COST Action Project FA 0905 Mineral-Improved Crop Production for Healthy Food and Feed, Final Conference Agronomic, Molecular Genetics and Human Nutrition Approaches for Improving the Nutricional Quality and Safety of Food Crops, Ela Quality Resort, Antalya-Belek, Turkey, 17–19 March 2014; pp. 102–103. [Google Scholar]

- Coelho, A.R.F.; Lidon, F.C.; Pessoa, C.C.; Marques, A.C.; Luís, I.C.; Caleiro, J.C.; Simões, M.; Kullberg, J.; Legoinha, P.; Brito, G.; et al. Can foliar pulverization with CaCl2 and Ca(NO3)2 trigger Ca enrichment in Solanum tuberosum L. tubers? Plants 2021, 10, 245. [Google Scholar] [CrossRef] [PubMed]

- Madani, B.; Mirshekari, A.; Sofo, A.; Mohamed, M.T.M. Preharvest calcium applications improve postharvest quality of papaya fruits (Carica papaya L. cv. Eksotika II). J. Plant Nutr. 2016, 39, 1483–1492. [Google Scholar] [CrossRef]

- Tzoutzoukou, C.G.; Bouranis, D.L. Effect of preharvest application of calcium on the postharvest physiology of apricot fruit. J. Plant Nutr. 1997, 20, 295–309. [Google Scholar] [CrossRef]

- Picchioni, G.A.; Watada, A.E.; Conway, W.S.; Whitaker, B.D.; Sams, C.E. Postharvest calcium infiltration delays membrane lipid catabolism in apple fruits. J. Agric. Food Chem. 1998, 46, 2452–2457. [Google Scholar] [CrossRef]

- Dayod, M.; Tyerman, S.D.; Leigh, R.A.; Gilliham, M. Calcium storage in plants and the implications for calcium biofortification. Protoplasma 2010, 247, 215–231. [Google Scholar] [CrossRef] [PubMed]

- Caderno de Especificações da Pera Rocha D.OP. Available online: http://primofruta.pt/ficheiros/especificacoes/pera_rocha_caderno_especificacoes.pdf (accessed on 19 October 2021).

- Deuchande, T.; Larrigaudière, C.; Guterres, U.; Carvalho, S.M.P.; Vasconcelos, M.W. Biochemical markers to predict internal browning disorders in ‘Rocha’ pear during storage under high CO2. J. Sci. Food Agric. 2017, 97, 3603–3612. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).