Quantification of Yield Gain from Bifacial PV Modules in Multi-Megawatt Plants with Sun-Tracking Systems

Abstract

1. Introduction

2. Bifacial Technology: State of the Art

- IEC 61215-2:2021 extends conventional qualification testing to bifacial modules by including specific procedures that account for rear-side irradiance response. For instance, in thermal cycling, hot-spot, and mechanical stress tests, a reflective background or controlled rear-side irradiance is introduced to simulate realistic bifacial operating conditions. Typical rear-side irradiance levels used in testing are around 20% of the front-side irradiance (e.g., 200 W/m2 rear on 1000 W/m2 front) [18].

- IEC TS 60904-1-2:2019 outlines procedures for I–V curve measurements on bifacial PV modules, requiring separate and controlled illumination of both the front and rear surfaces. The standard recommends uniform rear-side irradiance within a representative range—typically between 10% and 30% of the front irradiance—depending on the intended application. The use of bifacial reference cells or dedicated rear irradiance sensors is advised to ensure accurate characterization [19].

- IEC 61724-1:2021 provides monitoring guidelines for PV systems, including the use of bifacial reference cells and the Bifacial Nameplate Irradiance (BNPI) which is a reference cumulative irradiance defined as the sum of front and rear irradiance under standard test conditions (STC). BNPI is used to predict the rated power of bifacial modules under predefined lighting conditions, generally assuming a 20% rear-to-front irradiance ratio (i.e., 200 W/m2 rear, 1000 W/m2 front) [20].

- IEC 62804-1:2015 and IEC 62804-2:2019 address potential-induced degradation (PID) under different voltage levels and polarities. For bifacial modules, both sides are exposed to stress conditions that could trigger PID, including elevated system voltages (up to ±1000 V or ±1500 V) in humid and high-temperature environments [21,22].

- IEC 61853 series (parts 1–4) provides a framework for PV energy rating and performance modeling. For bifacial modules, the standard allows testing under realistic climate conditions, accounting for temperature, solar spectrum, and angle of incidence. Rear-side exposure is ensured by using high-albedo surfaces (typically ≥ 0.3) or mounting configurations that allow unobstructed rear irradiance. The evaluation may include measurement of the bifacial gain and simulation using tools such as PVsyst [23].

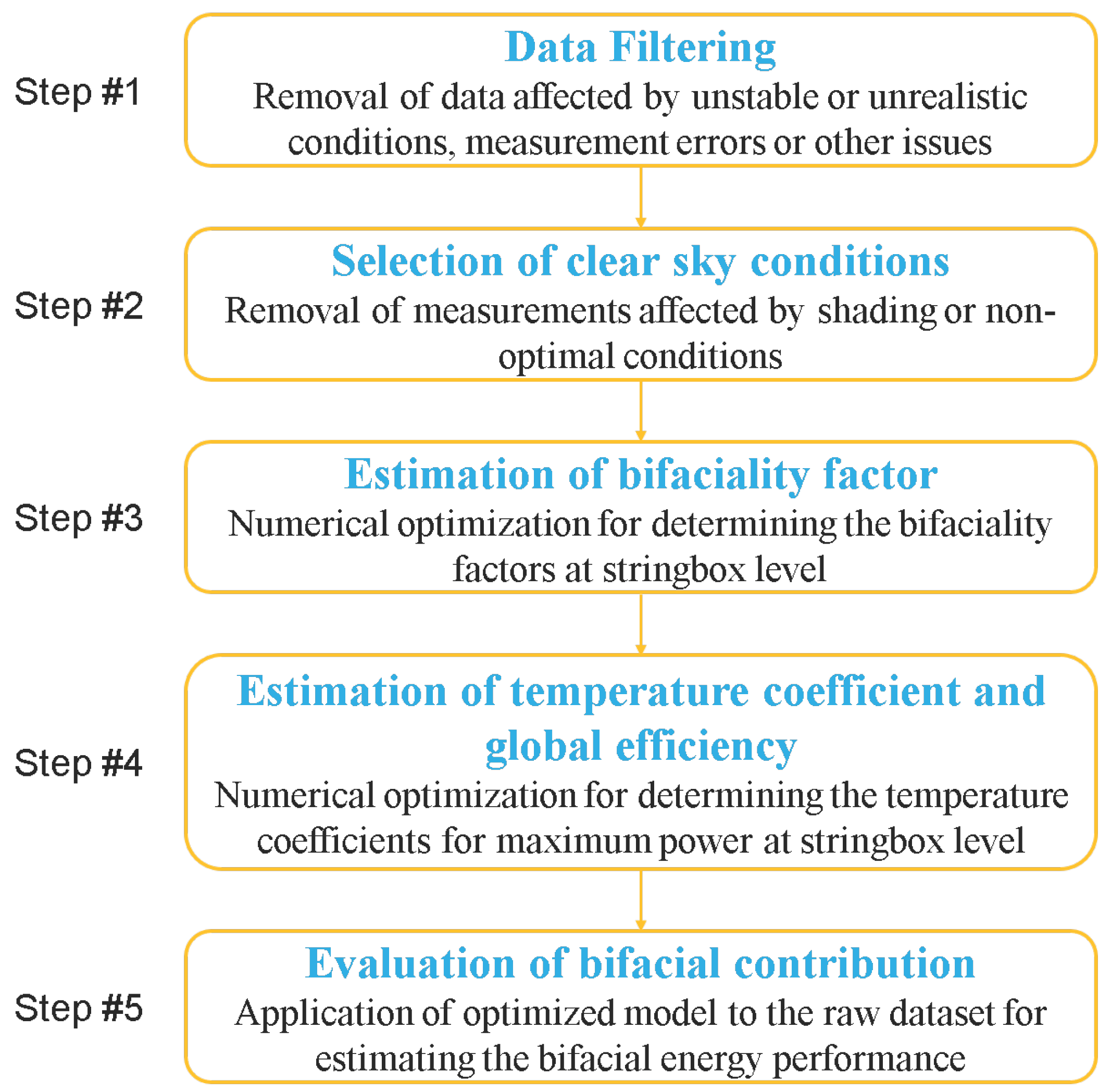

3. Proposed Methodology

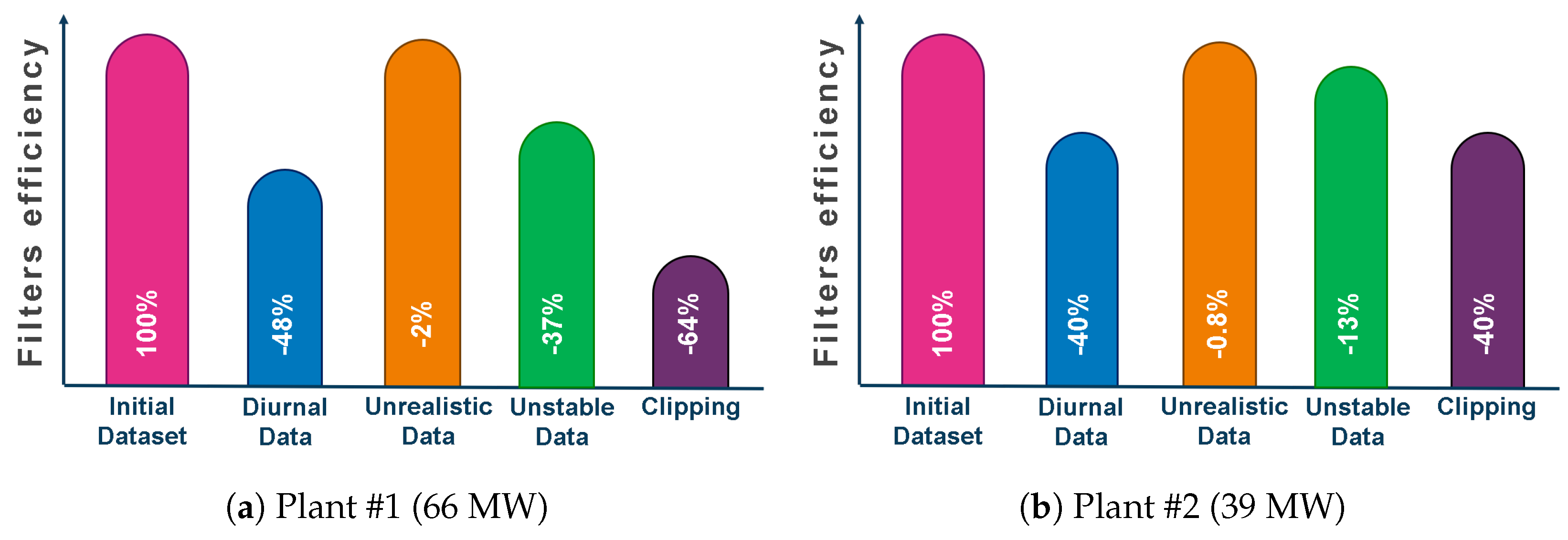

3.1. Step #1: Data Filtering

- Selection of diurnal data: The scope of this filter is excluding nightly data or diurnal data with low irradiance, measured by front pyranometers (). The choice of can vary, but this procedure suggests assuming = 15 W/m2 to remove data with a PV voltage lower than the startup voltage of the inverters.

- Removal of unrealistic data: This filter aims to exclude measurements affected by unrealistic DC/AC conversion efficiency at the inverter level. In particular, the DC/AC efficiency is computed for each inverter as the ratio between AC and DC power ( and , respectively), and data with (maximum efficiency from the inverter datasheet) are excluded.

- Removal of unstable conditions: This filter is applied to exclude data affected by abrupt variations of weather conditions in terms of irradiance (G) and ambient temperature (). Indeed, for each weather quantity acquired at the jth time instant (), the variations with respect to the jth − 1 and jth + 1 instants are computed as follows:where is the global variation of the generic quantity x with respect to previous () and next () time instants. The filter excludes data corresponding to and higher than ±20 W/m2 and 3%, respectively.

- Removal of data affected by clipping: Generally, the owner of the PV plant signs a contract with the Distribution System Operator (DSO) reporting the maximum power that can be injected into the electrical grid. In the time slots of clear sky days with high irradiance (central hours), the PV output might exceed the maximum power the DSO allows to be injected into the grid. In this case, an electronic control of the DC/AC converters shifts the operating point of the PV generators to the optimal condition. As a consequence, the AC power output flattens to meet the global maximum power allowed by the DSO.

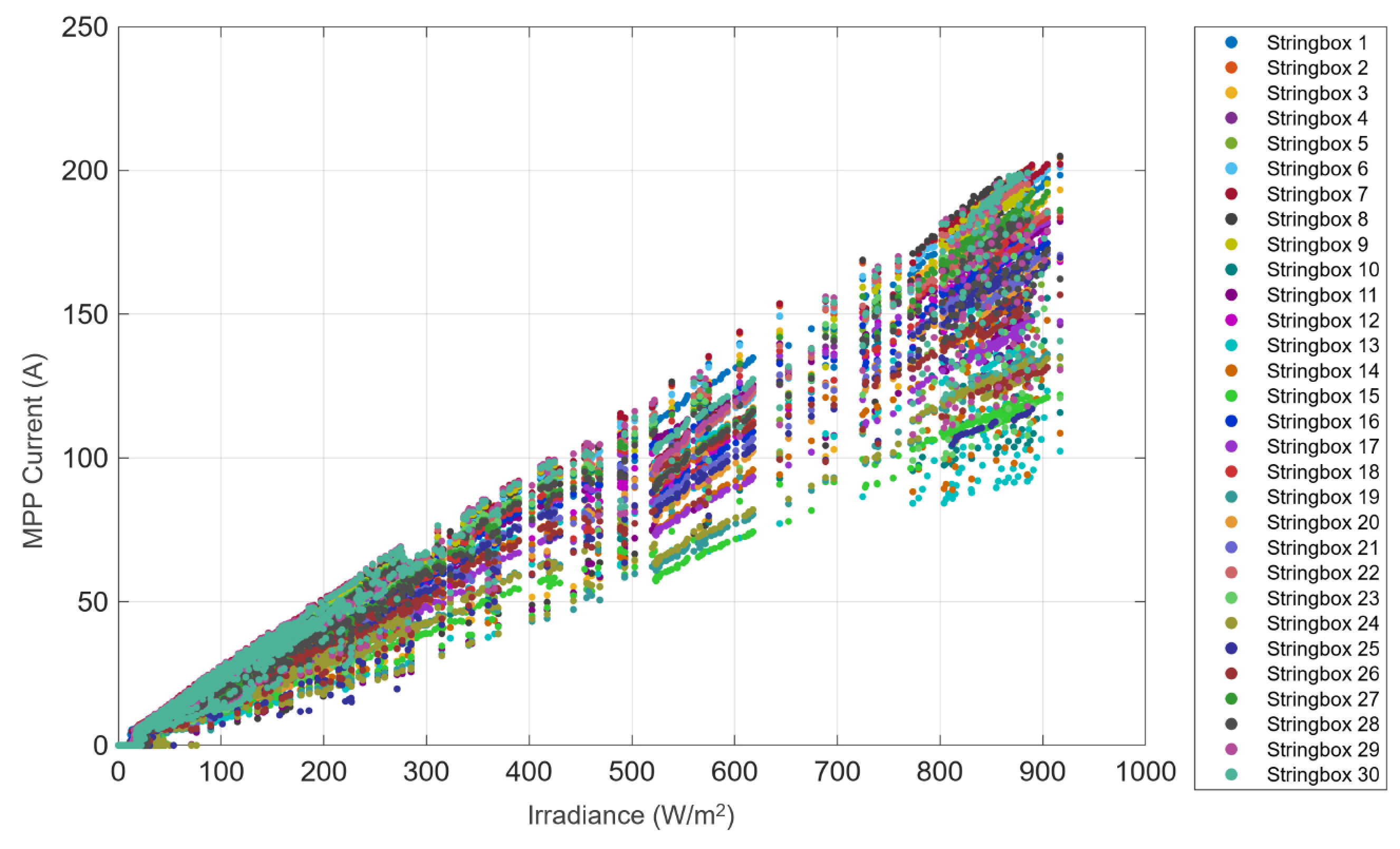

3.2. Step #2: Selection of Clear Sky Conditions

- Evaluation of current at Maximum Power Point (MPP). For any weather condition (irradiance and ambient temperature), the current at the MPP is evaluated according to the following equation:where

- –

- is the MPP current at standard test conditions (STC) for each stringbox;

- –

- is the plane-of-array irradiance acquired by SCADA of front pyranometers;

- –

- is the bifaciality factor;

- –

- is the irradiance acquired by SCADA of rear pyranometers;

- –

- is the irradiance at standard test conditions (STC) (1000 W/m2);

- –

- is the temperature coefficients related to the short-circuit current;

- –

- is the temperature difference between module and STC temperatures (°C).

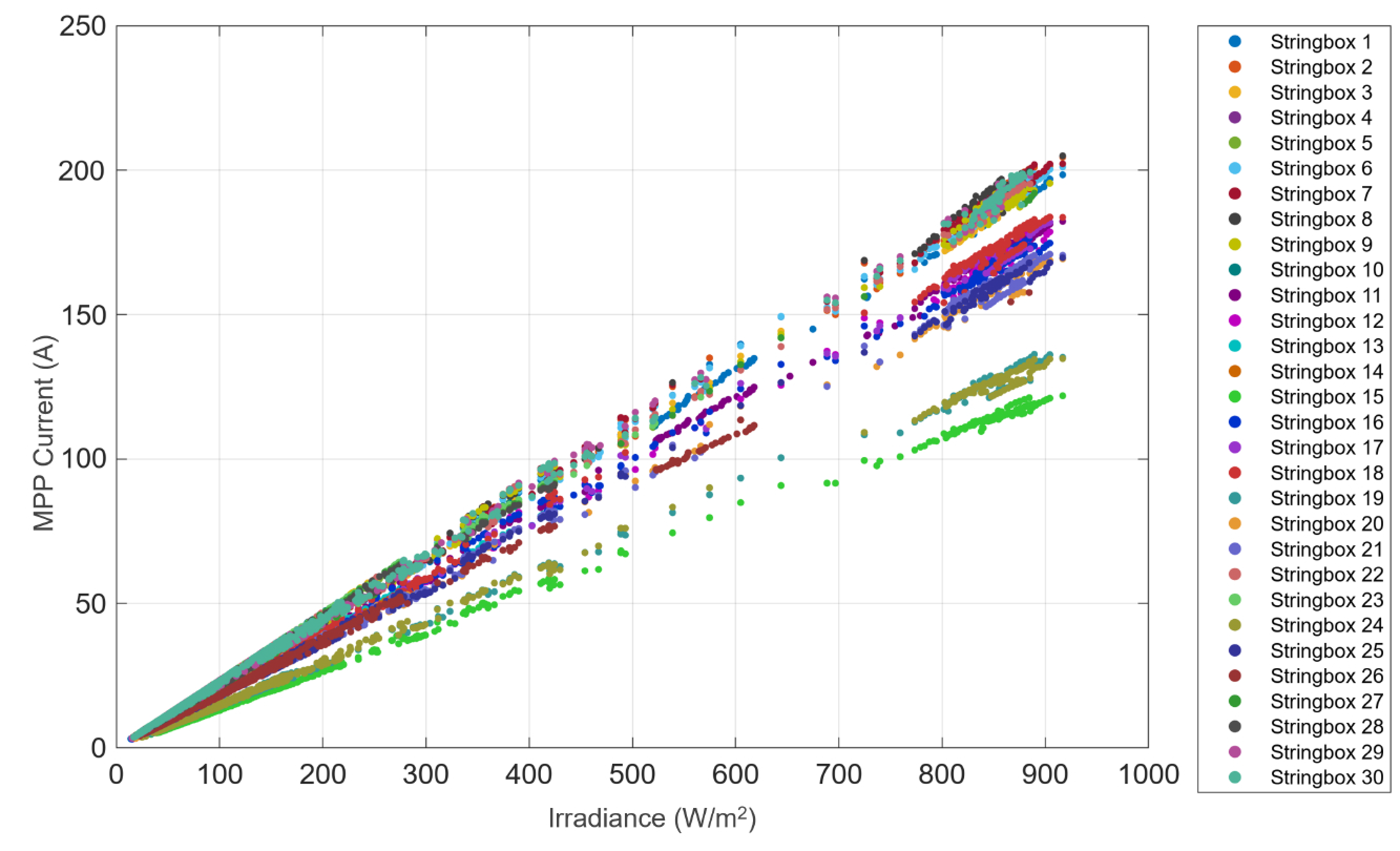

- For each time instant, the comparison between the MPP current and the value stored by the SCADA is performed, and the following condition is investigated:If the relative deviation between the two currents is not in the range 5%, the data are removed. The value 5% is chosen according to the uncertainties of the measuring instrumentation [24,25,26]. Indeed, for large-scale PV plants, a global uncertainty of 5% is reasonable for acquisition systems, taking into account the error contributions due to the measurement of electrical quantities (voltage, current, and power), environmental quantities (front and rear irradiances and ambient temperature), and mechanical quantities (slopes of tracking systems).

- Construction of the final dataset for the optimal training of the model. The following quantities are provided as inputs to the optimization stage of the procedure:

- –

- Irradiance acquired by on-site pyranometers, installed upward and downward with respect to PV modules;

- –

- Air temperature acquired by a weather station;

- –

- DC Current and power at stringbox level.

3.3. Step #3: Estimation of Bifaciality Factor

3.4. Step #4: Estimation of Temperature Coefficient and Global Efficiency

- is the normalized error for the assessment of the generic X quantity;

- is the ith measurement stored by the SCADA system;

- is the ith value calculated with models;

- N is the number of data.

3.5. Step #5: Evaluation of Bifacial Contribution

- is the DC power at STC for the kth stringbox;

- is the plane-of-array irradiance acquired by SCADA of front pyranometers installed in area including the kth stringbox;

- is the irradiance acquired by SCADA of rear pyranometers installed in area including the kth stringbox;

- is the bifaciality factor for the kth stringbox;

- is the irradiance at standard test conditions (STC) (1000 W/m2);

- is the temperature coefficient related to the maximum power for the kth stringbox;

- is the temperature difference between module and STC temperatures for the kth stringbox;

- is the efficiency, taking into account losses due to dirt, reflection, mismatch, and MPP tracking;

- is the efficiency, taking into account Joule losses.

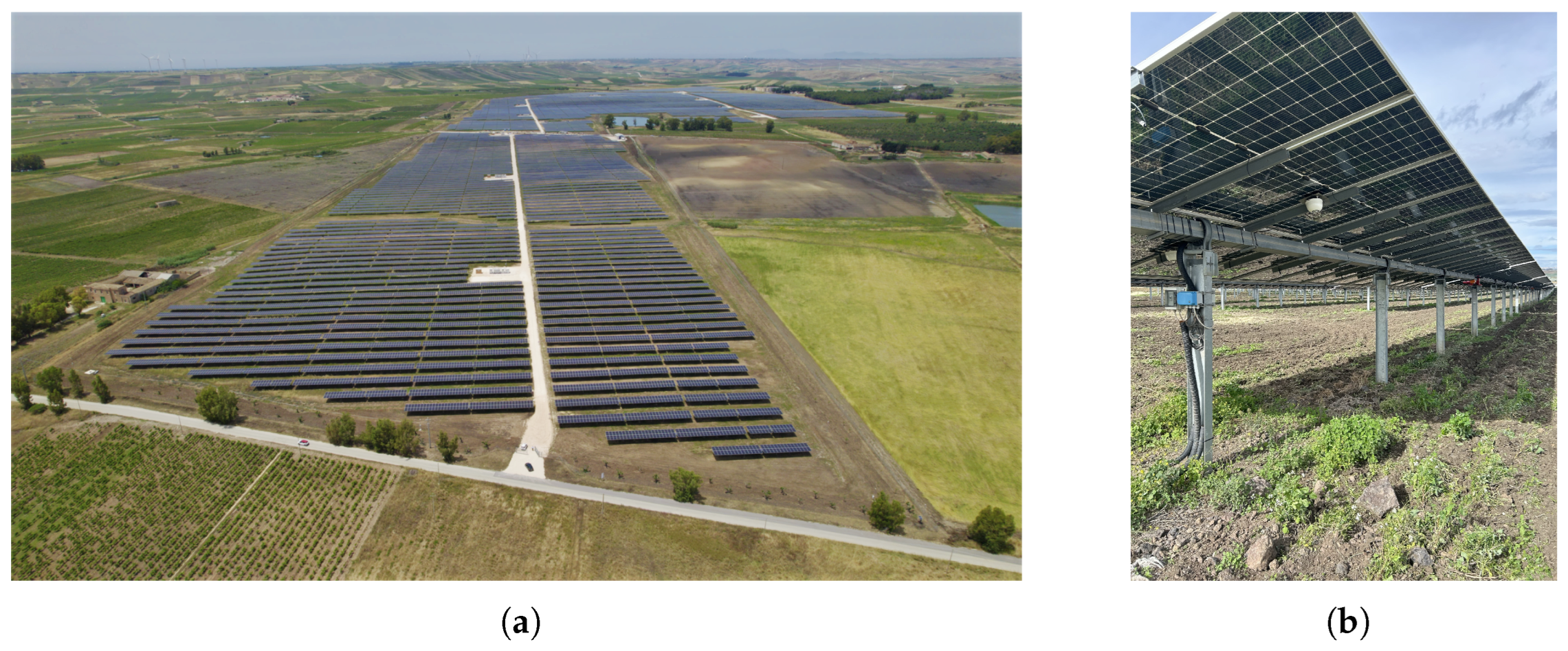

4. PV Plants Under Study

4.1. PV Plant #1

4.2. PV Plant #2

5. Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aime, G.; Ciocia, A.; Malgaroli, G.; Narbey, S.; Saglietti, L.; Spertino, F. Degradation Assessment for Prototypal Perovskite Photovoltaic Modules in Long Term Outdoor Experimental Campaign. In Proceedings of the 2023 IEEE International Conference on Environment and Electrical Engineering and 2023 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I and CPS Europe 2023), Madrid, Spain, 6–9 June 2023. [Google Scholar] [CrossRef]

- Ciocia, A.; Enescu, D.; Amato, A.; Malgaroli, G.; Polacco, R.; Amico, F.; Spertino, F. Agrivoltaic System: A Case Study of PV Production and Olive Cultivation in Southern Italy. In Proceedings of the 2022 57th International Universities Power Engineering Conference: Big Data and Smart Grids (UPEC 2022), Istanbul, Turkey, 30 August–2 September 2022. [Google Scholar] [CrossRef]

- Stein, J.S.; Reise, C.; Bonilla Castro, J.; Friesen, G.; Maugeri, G.; Urrejola, E.; Ranta, S. Bifacial Photovoltaic Modules and Systems: Experience and Results from International Research and Pilot Applications; Technical Report IEA-PVPS T13-14:2021; International Energy Agency Photovoltaic Power Systems Programme (IEA PVPS) Task 13: Paris, France, 2021. [Google Scholar]

- International Technology Roadmap for Photovoltaics (ITRPV). 2023. Available online: https://www.itrpv.org (accessed on 30 May 2025).

- IEA PVPS Task 13. Best Practices for the Optimization of Bifacial Photovoltaic Tracking Systems; Technical Report; International Energy Agency: Paris, France, 2023. [Google Scholar]

- Wikipedia Contributors. Inseguitore Solare. 2025. Available online: https://it.wikipedia.org/wiki/Inseguitore_solare (accessed on 30 June 2025).

- Rodríguez-Gallegos, C.D.; Liu, H.; Gandhi, O.; Singh, J.P.; Krishnamurthy, V.; Kumar, A.; Stein, J.S.; Wang, S.; Li, L.; Reindl, T.; et al. Global Techno-Economic Performance of Bifacial and Tracking Photovoltaic Systems. Joule 2020, 4, 1514–1541. [Google Scholar] [CrossRef]

- IEA PVPS Task 13. Best Practices for the Optimization of Bifacial Photovoltaic Tracking Systems; Technical Report IEA-PVPS T13-22:2024; International Energy Agency Photovoltaic Power Systems Programme (IEA PVPS): Paris, France, 2024; Available online: https://iea-pvps.org (accessed on 8 June 2025).

- Nygård, M.M.; Wiig, M.S.; Roosloot, N.; Otnes, G.; Øgaard, M.B.; Riise, H.N.; Marstein, E.S. Elucidating Uncertainty in Bifacial Photovoltaic Gain Estimation. Sol. Energy 2025, 292, 113469. [Google Scholar] [CrossRef]

- Ayala Peláez, S.; Deline, C.; MacAlpine, S.; Olalla, C. Estimating and Parameterizing Mismatch Power Loss in Bifacial Photovoltaic Systems. Prog. Photovolt. Res. Appl. 2020, 28, 691–703. Available online: https://www.osti.gov/servlets/purl/1606308 (accessed on 13 October 2025).

- PVMet Wiki. 2025. Available online: https://wiki.pvmet.org (accessed on 30 May 2025).

- Gu, W.; Ma, T.; Ahmed, S.; Zhang, Y.; Peng, J. A comprehensive review and outlook of bifacial photovoltaic (bPV) technology. Energy Convers. Manag. 2020, 223, 113283. Available online: https://www.sciencedirect.com/science/article/pii/S0196890420308220 (accessed on 9 July 2025). [CrossRef]

- Zhang, X.; Liu, Y.; Chen, J.; Li, Q. Enabling 95% bifaciality of efficient TOPCon solar cells by rear-side selective sunken pyramid structure and zebra-crossing passivation contact. Sol. Energy Mater. Sol. Cells 2025, 292, 113809. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0927024825004106 (accessed on 9 July 2025). [CrossRef]

- Spertino, F.; Malgaroli, G.; Amato, A.; Qureshi, M.A.E.; Ciocia, A.; Siddiqi, H. An Innovative Technique for Energy Assessment of a Highly Efficient Photovoltaic Module. Solar 2022, 2, 321–333. [Google Scholar] [CrossRef]

- Jinko Solar. Tiger Neo N-Type TOPCon Series Datasheet. 2024. Available online: https://jinkosolarcdn.shwebspace.com/uploads/JKM565-585N-72HL4-(V)-F3-EN.pdf (accessed on 5 June 2025).

- Meyer Burger. HJT Technology Overview, Technical Brief. 2023. Available online: https://www.meyerburger.com/fileadmin/user_upload/Investors/Meyer-Burger-Corporate-Presentation-April-2024.pdf (accessed on 5 June 2025).

- National Renewable Energy Laboratory (NREL). Best Research-Cell Efficiency Chart. 2024. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 8 June 2025).

- IEC 61215-2:2021; Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval—Part 2: Test Procedures. IEC: Geneva, Switzerland, 2021. Available online: https://webstore.iec.ch/en/publication/61350 (accessed on 7 June 2025).

- IEC TS 60904-1-2:2019; Photovoltaic Devices—Part 1–2: Measurement of Current-Voltage Characteristics of Bifacial Photovoltaic Devices. IEC: Geneva, Switzerland, 2019. Available online: https://webstore.iec.ch/en/publication/34357 (accessed on 5 June 2025).

- IEC 61724-1:2021; Photovoltaic System Performance—Part 1: Monitoring. IEC: Geneva, Switzerland, 2021. Available online: https://webstore.iec.ch/en/publication/65561 (accessed on 5 June 2025).

- IEC 62804-1:2015; Photovoltaic (PV) Modules—Test Methods for the Detection of Potential-Induced Degradation—Part 1: Crystalline Silicon. IEC: Geneva, Switzerland, 2015. Available online: https://cdn.standards.iteh.ai/samples/19927/18b6fe079c364496b423791b0284280c/IEC-TS-62804-1-2015.pdf (accessed on 5 June 2025).

- IEC TS 62804-2:2022; Photovoltaic (PV) Modules—Test Methods for the Detection of Potential-Induced Degradation—Part 2: Thin-Film. IEC: Geneva, Switzerland, 2022. Available online: https://webstore.iec.ch/en/publication/33260 (accessed on 7 June 2025).

- IEC 61853-1:2011; Photovoltaic (PV) Module Performance Testing and Energy Rating—Part 1: Irradiance and Temperature Performance Measurements and Power Rating. IEC: Geneva, Switzerland, 2011. Available online: https://webstore.iec.ch/publication/6035 (accessed on 7 June 2025).

- Carstens, H.; Xia, X.; Yadavalli, S. Measurement uncertainty in energy monitoring: Present state of the art. Renew. Sustain. Energy Rev. 2018, 82, 2791–2805. [Google Scholar] [CrossRef]

- Habte, A.; Sengupta, M.; Andreas, A.; Dooraghi, M.; Reda, I.; Kutchenreiter, M. Evaluating the Sources of Uncertainties in the Measurements from Multiple Pyranometers and Pyrheliometers; Technical Report NREL/PO-5D00-68065; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2017. Available online: https://www.nrel.gov/docs/fy17osti/68065.pdf (accessed on 13 October 2025).

- Mihaylov, B.; Betts, T.R.; Pozza, A.; Mullejans, H.; Gottschalg, R. Uncertainty Estimation of Temperature Coefficient Measurements of PV Modules. IEEE J. Photovoltaics 2016, 6, 1554–1563. [Google Scholar] [CrossRef]

- Valdivia, C.E.; Tuli, C.; Russell, A.; Haysom, J.E.; Li, R.; Lekx, D.; Sepehr, M.M.; Hennessy, D.; Hinzer, K.; Schriemer, H.P. Bifacial Photovoltaic Module Energy Yield Calculation and Analysis. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 1094–1099. Available online: https://ieeexplore.ieee.org/document/8366206 (accessed on 9 July 2025).

- Keiner, D.; Walter, L.; Bogdanov, D.; Peters, I.M.; Breyer, C. Assessing the impact of bifacial solar photovoltaics on future power systems based on capacity-density-optimised power plant yield modelling. Sol. Energy 2025, 295, 113543. [Google Scholar] [CrossRef]

- Sohani, A.; Pierro, M.; Moser, D.; Cornaro, C. Comparison of physical models for bifacial PV power estimation. Energy Convers. Manag. 2025, 327, 119515. [Google Scholar] [CrossRef]

| PV Plant | #1 | #2 |

|---|---|---|

| PV module specifications | ||

| Rated power | 535 W and 540 W | |

| Efficiency | 21.5% | |

| −0.35%/°C | ||

| Inverter specifications | ||

| Rated power | 3.437 MW | |

| DC/AC Efficiency | 99.0% | |

| PV layout | ||

| # of modules per string | 28 | |

| # of strings per stringbox | 15–19 | 12–20 |

| # of stringboxes | 272 | 155 |

| Inv. ID | #1 | #2 | #3 | #4 | #5 |

| 75% | 75% | 65% | 75% | 75% | |

| 100% | 100% | 100% | 99% | 98% | |

| −0.35%/°C | −0.35%/°C | −0.35%/°C | −0.35%/°C | −0.35%/°C | |

| Inv. ID | #6 | #7 | #8 | #9 | #10 |

| 73% | 65% | 75% | 73% | 70% | |

| 99% | 100% | 100% | 100% | 99% | |

| −0.35%/°C | −0.35%/°C | −0.35%/°C | −0.35%/°C | −0.35%/°C |

| Inv. ID | #1 | #2 | #3 | #4 | #5 | #6 |

|---|---|---|---|---|---|---|

| 75% | 75% | 75% | 65% | 65% | 75% | |

| 100% | 100% | 98% | 98% | 100% | 100% | |

| −0.35%/°C | −0.35%/°C | −0.35%/°C | −0.35%/°C | −0.35%/°C | −0.35%/°C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malgaroli, G.; Matturro, F.; Cagnetti, A.; Vivino, A.; Terzi, L.; Ciocia, A.; Spertino, F. Quantification of Yield Gain from Bifacial PV Modules in Multi-Megawatt Plants with Sun-Tracking Systems. Solar 2025, 5, 49. https://doi.org/10.3390/solar5040049

Malgaroli G, Matturro F, Cagnetti A, Vivino A, Terzi L, Ciocia A, Spertino F. Quantification of Yield Gain from Bifacial PV Modules in Multi-Megawatt Plants with Sun-Tracking Systems. Solar. 2025; 5(4):49. https://doi.org/10.3390/solar5040049

Chicago/Turabian StyleMalgaroli, Gabriele, Fabiana Matturro, Andrea Cagnetti, Aleandro Vivino, Ludovico Terzi, Alessandro Ciocia, and Filippo Spertino. 2025. "Quantification of Yield Gain from Bifacial PV Modules in Multi-Megawatt Plants with Sun-Tracking Systems" Solar 5, no. 4: 49. https://doi.org/10.3390/solar5040049

APA StyleMalgaroli, G., Matturro, F., Cagnetti, A., Vivino, A., Terzi, L., Ciocia, A., & Spertino, F. (2025). Quantification of Yield Gain from Bifacial PV Modules in Multi-Megawatt Plants with Sun-Tracking Systems. Solar, 5(4), 49. https://doi.org/10.3390/solar5040049