1. Introduction

600 million people in Sub-Saharan Africa (SSA) lack electricity access, which equates to about three-quarters of the unelectrified population worldwide. It has been projected that by 2030, 685 million people will be unelectrified worldwide [

1]. Microgrids are gaining prominence as a suitable option for electricity access in unserved and underserved communities. They, along with solar home systems, were identified by the International Energy Agency (IEA) as the best method of bridging the energy gap for 55% of Africa’s mostly rural unelectrified population by 2030 [

2]. Microgrids are also popular in more developed economies due to their resilience, cost reduction, and emissions-lowering benefits. Therefore, they are an important contributor to the achievement of the Sustainable Development Goal 7 (SDG7) targets.

Renewable-based systems using solar technology have maximum production during the day, and thus, increasing daytime demand would ensure optimal use of the solar generation resources and help lower reliance on battery storage or gensets during evening peak periods.

Electric mobility is gaining prominence due to the global focus on renewable energy uptake, emissions and pollution reduction, and the diminishing costs of battery storage. Both developed and developing countries are increasingly promoting sustainable e-mobility and clean transportation solutions. In East Africa, Rwanda has made significant strides in the e-mobility space, and the Ugandan, Kenyan, and Tanzanian governments in 2023 added policy provisions, such as tax incentives and VAT exemptions, to support the e-mobility sector [

3]. Uganda also has an e-bus manufacturing company [

4]. The Global North, particularly China, Europe, and the USA have registered significant strides in the electrification of transport due to factors such as incentives, favourable national policies, energy security considerations, and increases in oil costs due to geopolitical and market forces [

5,

6]. However, in emerging and developing economies, e-mobility is still in its nascent stages, with electric vehicles comprising under 1% of car sales in 2023 in Eurasia, the Middle East, and Africa [

7]. Challenges to the widespread adoption of e-mobility in emerging and developing economies include distance limitations, lack of charging infrastructure, weak grids, relatively high upfront costs, limited battery life, lengthy charging times compared to petrol/diesel top-up, and limited maximum speeds [

5,

8].

The majority of rural inhabitants in Africa, exceeding 650 million people, predominantly utilise walking, cycling, or public transportation that is typically in the form of imported two- and three-wheeler vehicles [

9]. Two- and three-wheelers are also major sources of employment in the East African region [

10,

11]. Thus, electric two- and three-wheelers (E2&3Ws) present a relatively low-hanging entry point for emerging and developing economies in Africa to electrify transport. Africa has about 20% of the registered motorcycles worldwide, but only 0.2% of them are electric [

8]. The proportions of two- and three-wheelers in the national fleet(s) of some African countries are 70% in Uganda, 53% in Rwanda [

8], 37% in Kenya, 34% in Tanzania, and 23% in Ghana [

12].

Several companies are introducing e-mobility on the continent and in the East African region, but the limited availability of charging infrastructure is a big challenge, so they largely remain restricted to urban areas.

The microgrid distribution network is often confined to about a 1 km radius [

13] and, thus, even when there is surplus electricity production, unconnected households, businesses or institutions in the area that desire an electric connection, and potential customers outside that radius, are unable to access the microgrid electricity services.

On the other hand, there are companies that provide portable batteries in addition to swappable batteries for their e-motorbikes but are challenged by the cost of setting up off-grid charging infrastructure which is usually solar-based. There is thus an untapped opportunity for microgrids to supply charging stations and unconnected potential customers using what would otherwise be curtailed PV energy.

Demand side management (DSM) aims to align electricity supply with demand to avoid problems such as system overloading, over discharge of battery storage, brown-outs, unplanned outages, and reduced equipment lifetime. The common DSM approaches [

14,

15,

16,

17,

18,

19,

20] are load shifting, peak shaving, strategic load conservation, valley filling, flexible load shape, which enables customers to modify their consumption patterns by purchasing power at reduced reliability or quality of service levels, and strategic load growth.

The curtailment of renewable energy production and demand response through load shifting and load shedding have been critiqued for lowering economic viability and system reliability [

21] and impacting user comfort [

22,

23]. In contrast to valley filling which has as its main goal increasing energy consumption during off-peak periods without increasing the maximum power, strategic load growth aims at raising energy consumption and peak demand over a given extended period, such as a year or season.

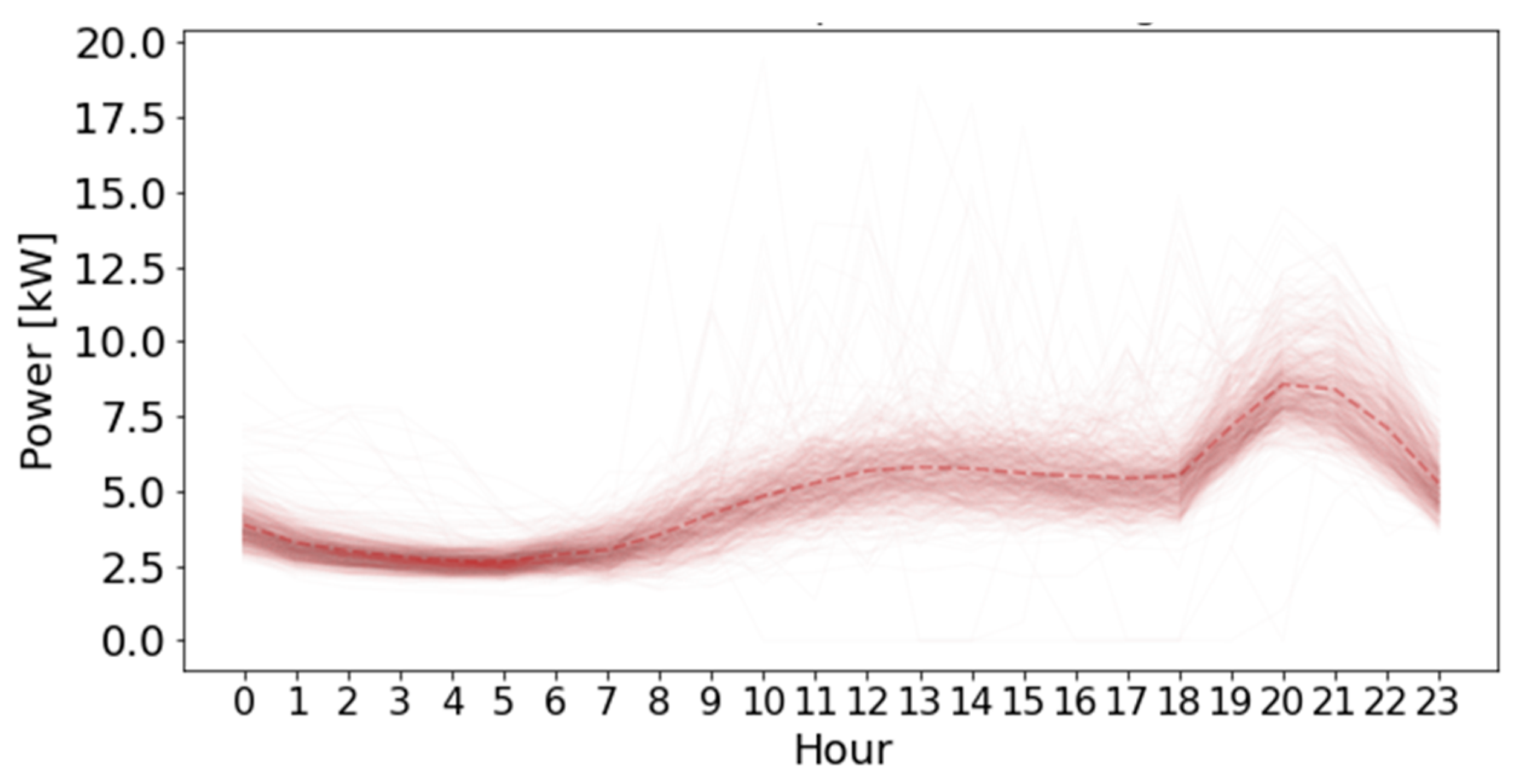

Rural microgrids are typically characterised by low daytime consumption and a poor load factor, which is the average to peak demand ratio, resulting in a high levelized cost of energy and sustainability challenges due to insufficient income generation for financial viability [

18].

To overcome the microgrid sustainability, electricity access, and e-mobility rollout challenges highlighted above, this work proposes strategic load growth as a DSM strategy for rural East African microgrids through integrating electric mobility and portable storage loads and limiting PV energy curtailment. Strategic load growth aims to increase not only valley demand but also peak demand for lengthy periods. It is the method best suited for our approach, as our focus is on driving up demand by supplying e-mobility loads and portable batteries using the excess PV power. The proposed approach can be applied in other countries and regions around the world, particularly in countries with many two- and three-wheelers.

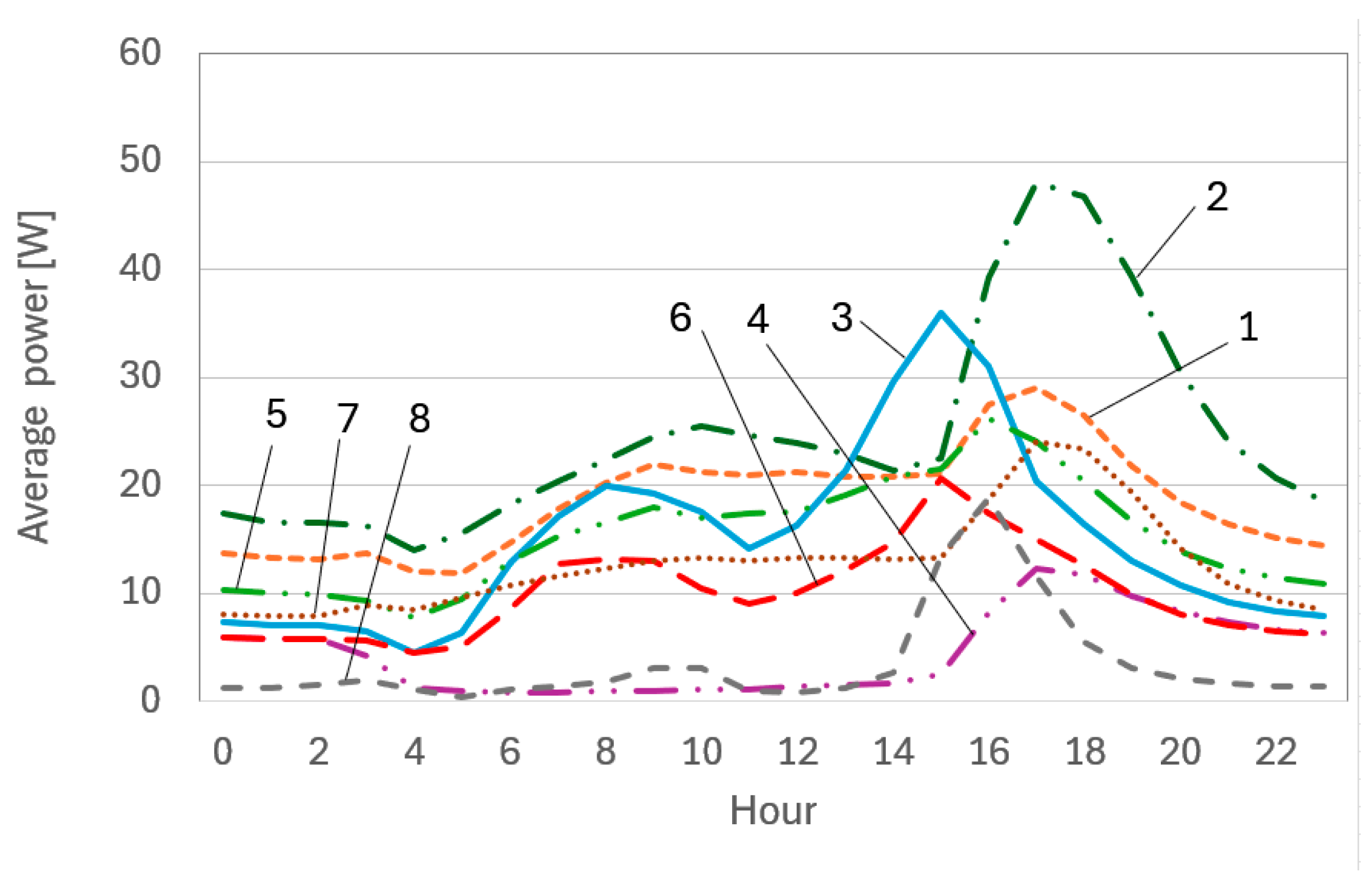

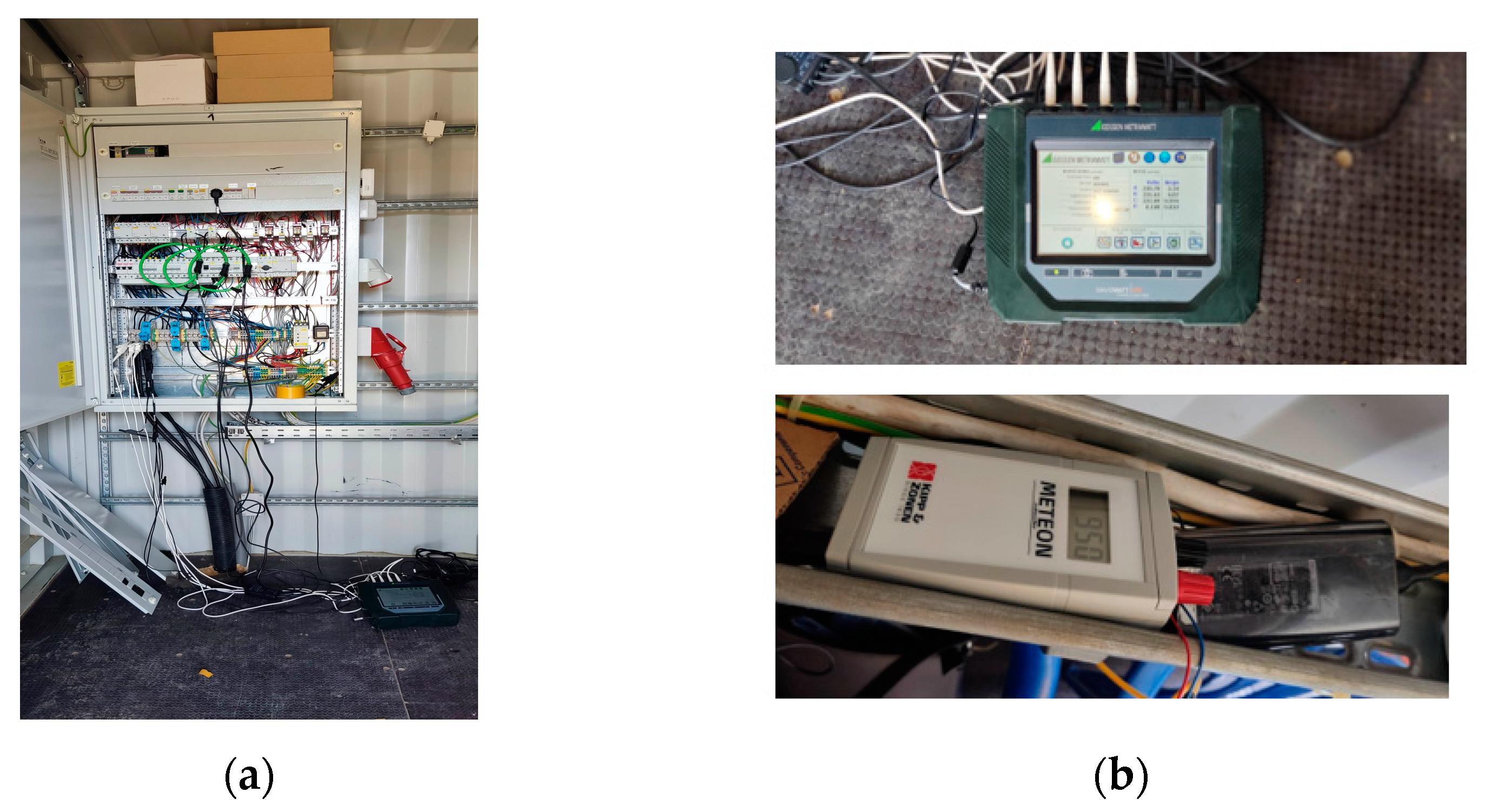

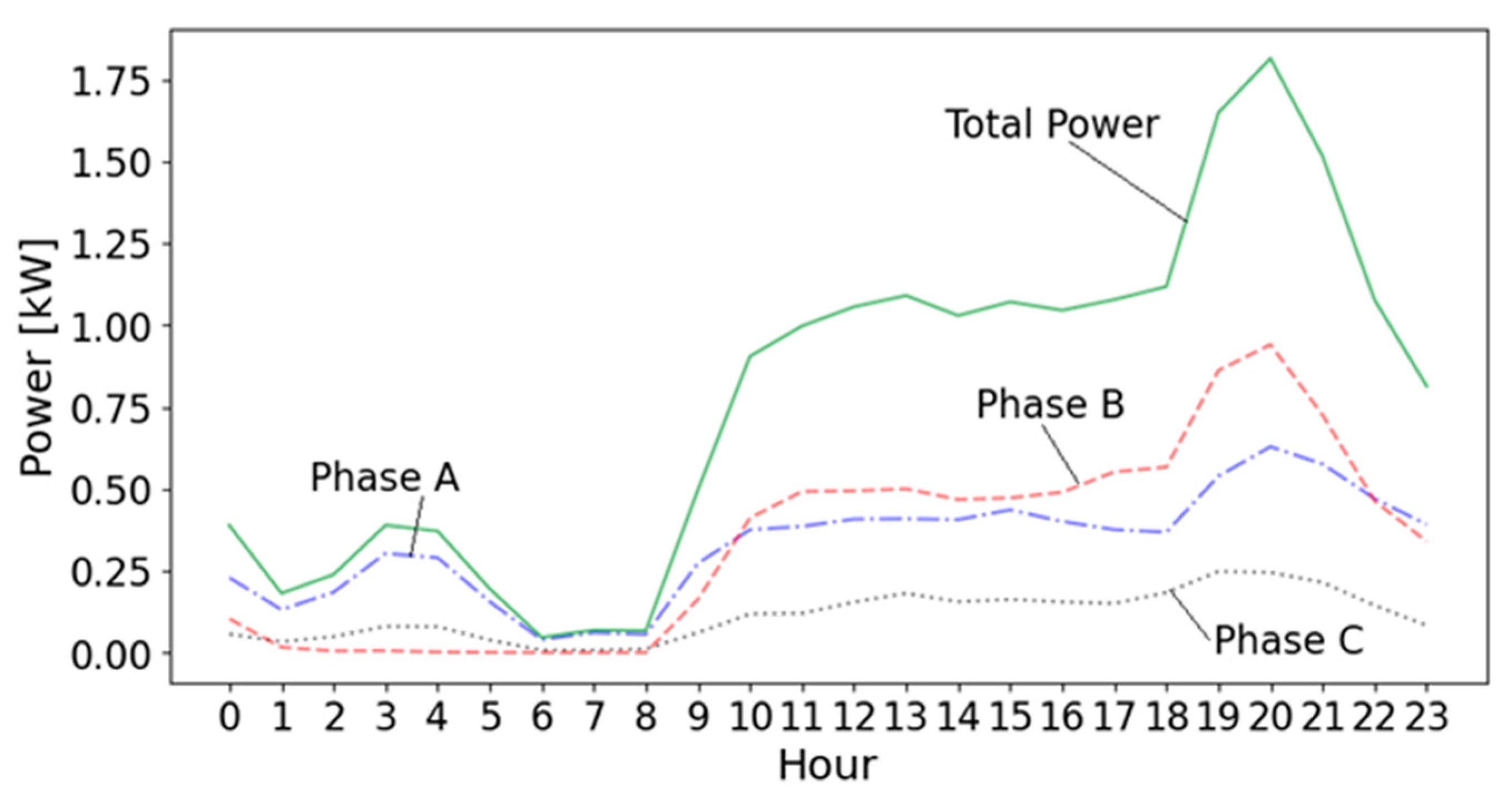

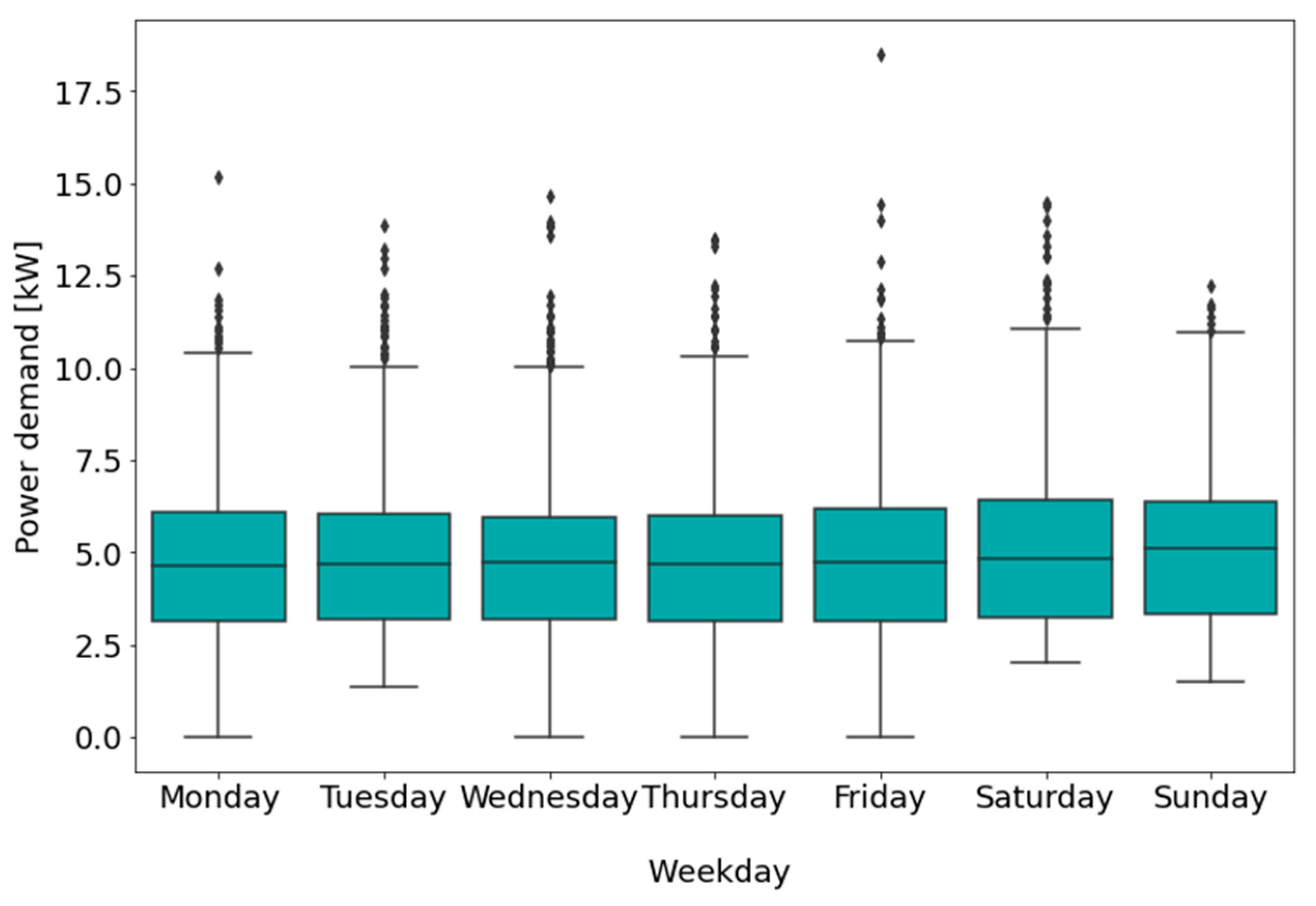

The general outline of the paper is as follows. Data from operational microgrids in Uganda and Tanzania is analysed to provide insights into rural microgrid energy consumption and load profiles in the East African context. An overview of electric mobility and the two- and three-wheeler sector is presented next. Then, modelling and simulation of a microgrid in Uganda with e-mobility and portable storage including consideration of the findings from the microgrids’ load profile analysis is described. Finally, the results are discussed, and some recommendations are given.

4. Optimisation Approach

Microgrid modelling has been investigated with objectives such as minimising lifecycle costs [

61], minimising levelized cost of energy [

14,

50,

90], maximising reliability, minimising renewable generation curtailment [

86,

91], minimising fuel costs and emissions [

92], maximising renewable fraction [

87], and combinations thereof [

93]. Our focus is on minimising generation curtailment.

The microgrid will only charge the battery storage when the base load is completely supplied. The surplus energy from the PV generation after meeting the base load and the battery charging requirements is used to charge the electro-mobility loads and the portable storage. The flow chart in

Figure 13 depicts the basic control strategy.

MATLAB 2023 was used for the system modelling and simulation of the technical and economic aspects of the microgrids. MILP optimisation was used for the control and dispatch of the e-mobility and portable storage loads. The goal of the chosen approach was the minimisation of PV curtailment by charging of the additional loads. The additional loads act as curtailable DSM loads which are supplied depending on the available PV power.

The algorithm is designed to first charge the existing loads with solar energy and then charge the batteries. Excess PV power is used to charge the mobile loads and portable storage, and any unused PV energy thereafter is dumped. It is assumed that the e-mobility and portable loads are supplied by an AC charging station that serves as an additional daytime load for the microgrid. The costs of the charging station and additional loads were not considered in this work as it was assumed that the charging station is operated by third parties.

If there is insufficient PV energy to meet the demand, the battery supplies the required power to the base load until the minimum battery state of charge is reached, after which load shedding occurs. It is assumed that the charging efficiency for the mobility and portable storage loads is 100%.

MILP Optimisation

The MILP solver was used to schedule the e-mobility and portable storage loads depending on the surplus PV generation. This further develops the approach in [

48,

94], with priority weights and power charging requirements determining the number of each additional type of load that can be supplied by the PV in each hour.

The MILP objective function

which was to be maximised is

where

is the number of loads of type

,

refers to the priority weighting of load

,

is the charging power of load

, and

refers to the Bodawerk, Zembo, Africrooze, and portable storage loads, respectively.

The charging priorities assigned were and .

The constraints that were to be observed include the following:

where

denotes the upper bounds of the PV and battery sizes.

The energy balance equation that must be fulfilled at each timestep is given by Equation (25), where battery power is positive if the battery is charging and is negative if the battery is discharging. is the minimum battery energy and is the maximum battery energy. The minimum battery state of charge (SOC) is 50% of the battery capacity.

The e-mobility and portable storage constraints are as follows:

where

is the number of types of e-mobile and portable loads,

is the number of loads of type

charged at time

, and

is the excess PV power at time

after supplying the base load and charging the battery.

Furthermore, the difference between the number of Bodawerk and Zembo batteries charged daily should not exceed 2, as given by Equation (28), to ensure that a comparable number of the e-bikes is charged daily.

Several studies have used estimated charging times to model e-mobility charging patterns and energy profiles. In [

94], peak sun hours and estimated charging times for the e-bikes being studied were used for e-bike load scheduling. In the analysis of e-mobility possibilities for on-land and off-land PV as well as wind installations with battery storage, annual renewable energy and storage supply capacity plus charging time estimates were used to model the e-mobility deployment [

95]. In this work, we adopt a more granular approach by calculating, for each hour of a year, the energy balance for supplying the e-mobile and portable storage loads.

The charging priority weights and targeted daily number of each type of load are shown in

Table 5. We specified the maximum number of batteries of each type to be charged daily (

where

The actual daily number of batteries charged on a given day for each load type () depends on that day’s surplus PV energy.

5. Discussion of Results

Four scenarios were simulated. The results for the scenarios are shown in

Table 6 for the base case (no DSM) (Scenario 1); when the additional DSM loads were introduced (Scenario 2); when the PV, battery, and converter capacities were halved (Scenario 3); and lastly when the PV, battery, and converter capacities, were halved and the additional loads were introduced (Scenario 4).

5.1. Technical Results

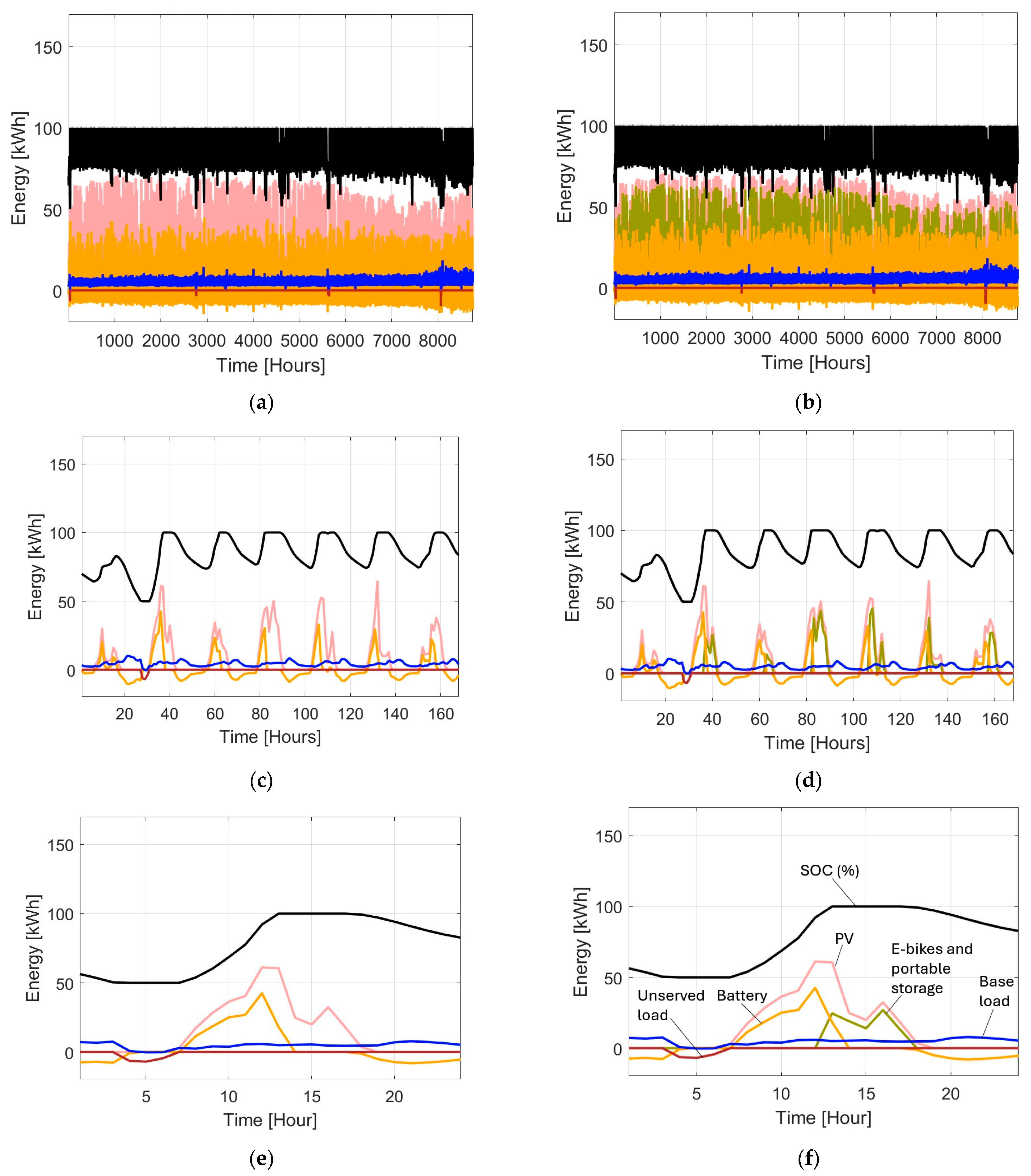

For the business-as-usual case, the energy profiles for when there were no e-bike and portable storage loads are shown in

Figure 14a. Negative battery values indicate battery discharge while positive values correspond to battery charging. The average SOC was 85.4% and dropped to the minimum of SOC of 50% very rarely. There is a perceptible rise in demand after about 8000 h of the yearly duration and thus the battery was discharged to lower levels after that time.

With battery degradation included, the calculated battery lifetime was 14.11 years, as shown in

Table 6.

In general, the PV and battery are sufficient to supply and meet the load demand, with a low LPSP of 0.23%. This is to be expected as the PV capacity sizing outstrips the demand, hence the high reliability. There is a high annual PV curtailment of 60,138.8 kWh, as shown in

Table 6.

The simulated data for the first week of the year is shown in

Figure 14c. The irradiance and, hence, average PV generation fluctuate significantly over the week in question, with day 1, day 3, and day 7 displaying low peak PV energy, indicative of cloudy days and low irradiance. Hence, there is load shedding on day 2 in the early hours due to the battery energy being insufficient to meet overnight and early morning demand. From day 2, there was surplus PV energy that was curtailed once the load demand was met, and the battery energy storage system (ESS) was fully charged. After day 2 of this week, the battery SOC remains relatively high and above 70%.

The load profile for day 2 in

Figure 14e shows the lost load due to the demand exceeding the available supply resources. The dropped load when the morning battery SOC dropped to 50%, as well as the curtailment of PV energy between 1500 h and 1700 h, can also be observed in

Figure 14e.

Scenario 2 corresponds to the introduction of the e-bike and portable storage loads for the base case scenario. The annual curtailed PV energy decreased by 98.5% to only 879.05 kWh, as shown in

Figure 14b and

Table 6. The other energy values other than the additional load energy values remained the same as in Scenario 1 (see

Figure 14). Starting from day 2 of week 1, the additional loads were able to consume most of what would otherwise have been surplus PV energy, as shown in

Figure 14d. On day 1, there was not sufficient irradiance to meet the battery charging and load requirements, and although day 3 also had limited PV production, once the BESS was fully charged, some e-bikes and portable loads could be supplied. Surplus PV generation was able to charge the additional loads from day 2, as

Figure 14f shows.

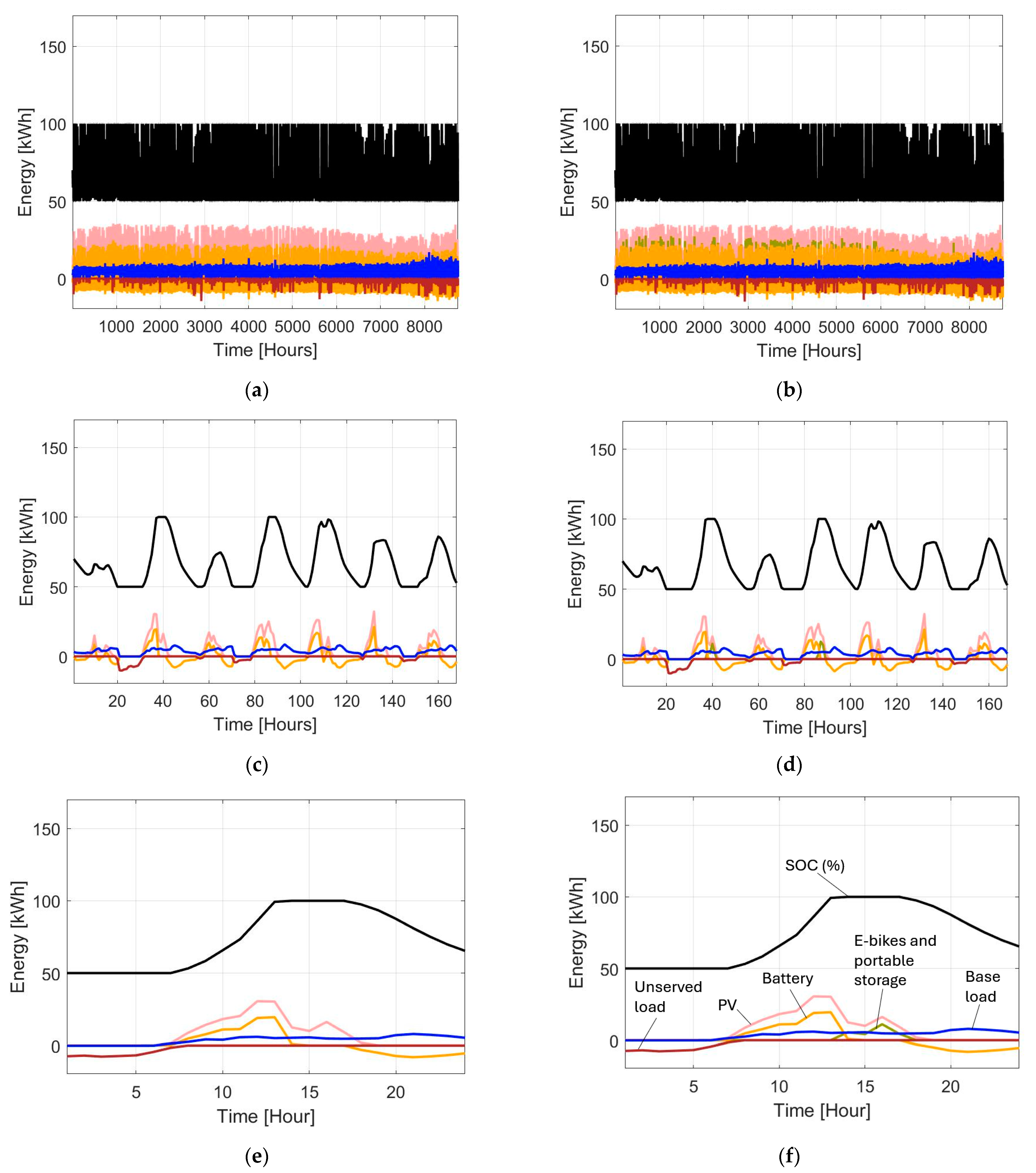

In Scenario 3, the PV capacity, battery size, and converter rating were set to half of the base case sizes (37.92 kW

p, 148.32 kWh, and 40 kW, respectively) and the base load was retained as in the base case (Scenario 1). This was feasible as the peak base load was less than 20 kW. For this case without e-bikes and portable storage, the energy profiles over the year are shown in

Figure 15a.

The 50% battery SOC limit was reached more frequently, with the average SOC reducing to 68.73%, while the LPSP increased to 14.11%, as shown in

Table 6. The curtailed PV energy was 10,669.76 kWh, which is 18% of the initial curtailed energy in Scenario 1. The first week’s energy profile shown in

Figure 15c illustrates the higher depletion rate of the battery storage on the first and third days when there is low irradiance, and hence load-shedding increases compared to the base case shown in

Figure 14c.

On day 2 of the first week, there was a load loss when the battery SOC limit of 50% was reached, until around 7 a.m., when the PV generation commenced, as shown in

Figure 15e.

In Scenario 4, the PV capacity, battery size, and converter rating were set to half of the base case sizes (75.84 kW

p, 148.32 kWh, and 40 kW, respectively) and the base load was retained as is, but with schedulable e-bikes and portable storage loads introduced. The corresponding energy profiles over the year are shown in

Figure 15b.

After the introduction of the e-bike and portable storage loads, there was a 98.6% reduction in annual curtailed PV energy compared to Scenario 3, to only 155.2 kWh. The annual energy supplied to the additional loads was only 10,304.3 kWh, and only 0.5% of this was supplied to the portable batteries, which was insufficient to meet the annual energy needs of even one off-microgrid customer (see

Table 6). This indicates that when the PV generation is more constrained and for the chosen e-bike and portable battery charging priority ratings, it is advisable to only serve e-mobility loads and not include portable storage due to the limited PV surplus. In week 2, on day 2 and day 4, some additional loads were supplied because the base load and battery charging were prioritised first, as seen in

Figure 15d,f.

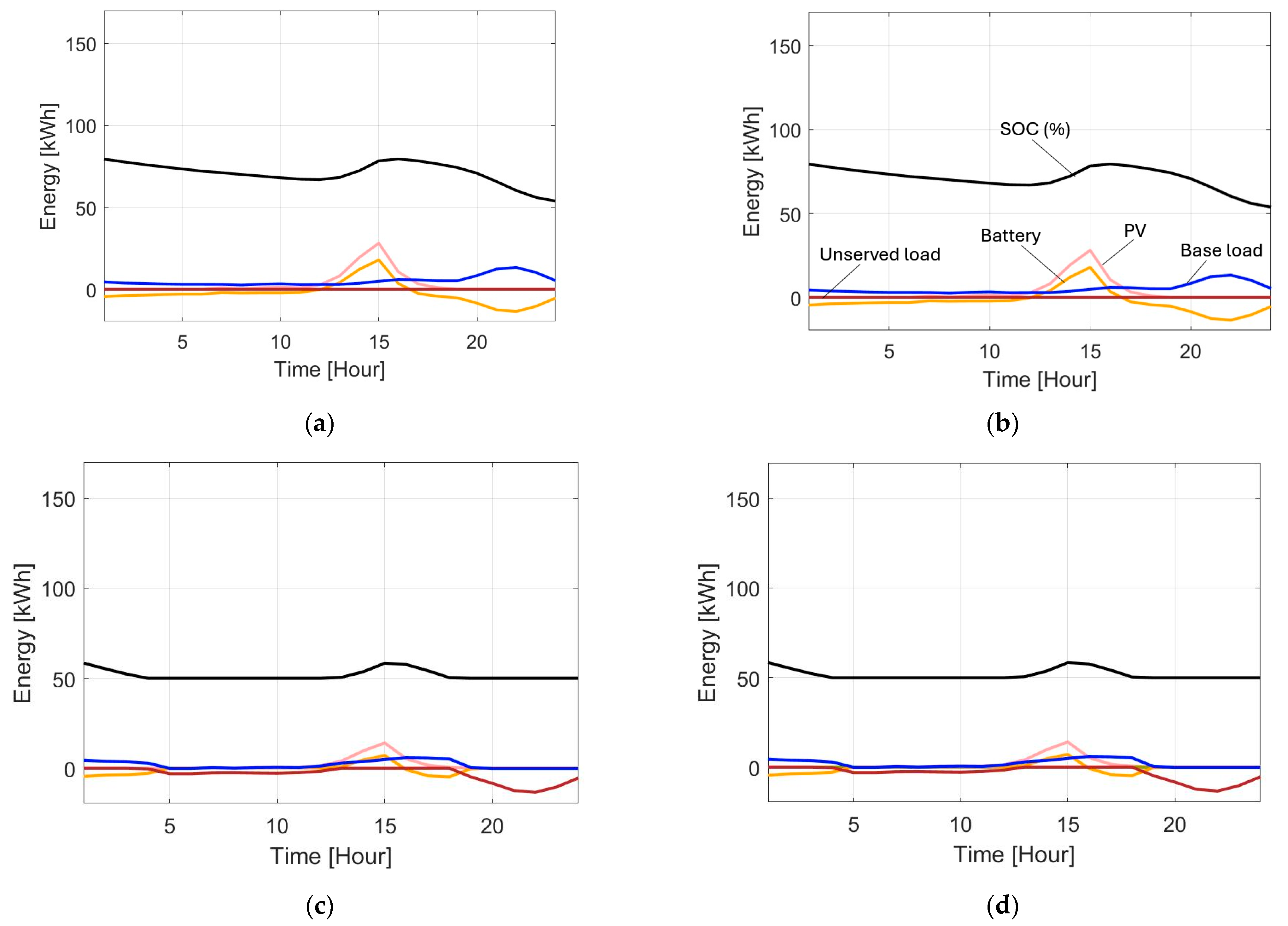

The energy and SOC profiles for Scenarios 1–4 for the day with the lowest total irradiance and hence the lowest PV production over the one-year period are shown in

Figure 16. The base case profiles (i.e., for PV capacity 75.84 kW

p, battery size 296.64 kWh, and converter rating 80 kW) in

Figure 16a for Scenario 1 and

Figure 16b for Scenario 2 show that the battery had sufficient energy on that day to meet the base load requirements but not enough to supply the additional loads due to the low PV production. Battery SOC dropped below 60% on that day.

When the PV capacity, battery size, and converter rating are set to half of the base case sizes (37.92 kW

p, 148.32 kWh and 40 kW, respectively), the energy and SOC profiles for Scenario 3 (

Figure 16c) and Scenario 4 (

Figure 16d) show that there is significant unmet load, especially after 2000 h due to the lower generation and storage capacities. Thus, there was more load curtailment for the smaller energy system, as expected. Furthermore, there was no e-bike or portable battery charging. Thus, it is important for there to be sufficient e-bikes and portable batteries to provide autonomy to meet demand and cater for low PV output days.

5.2. E-Mobility and Portable Storage Results

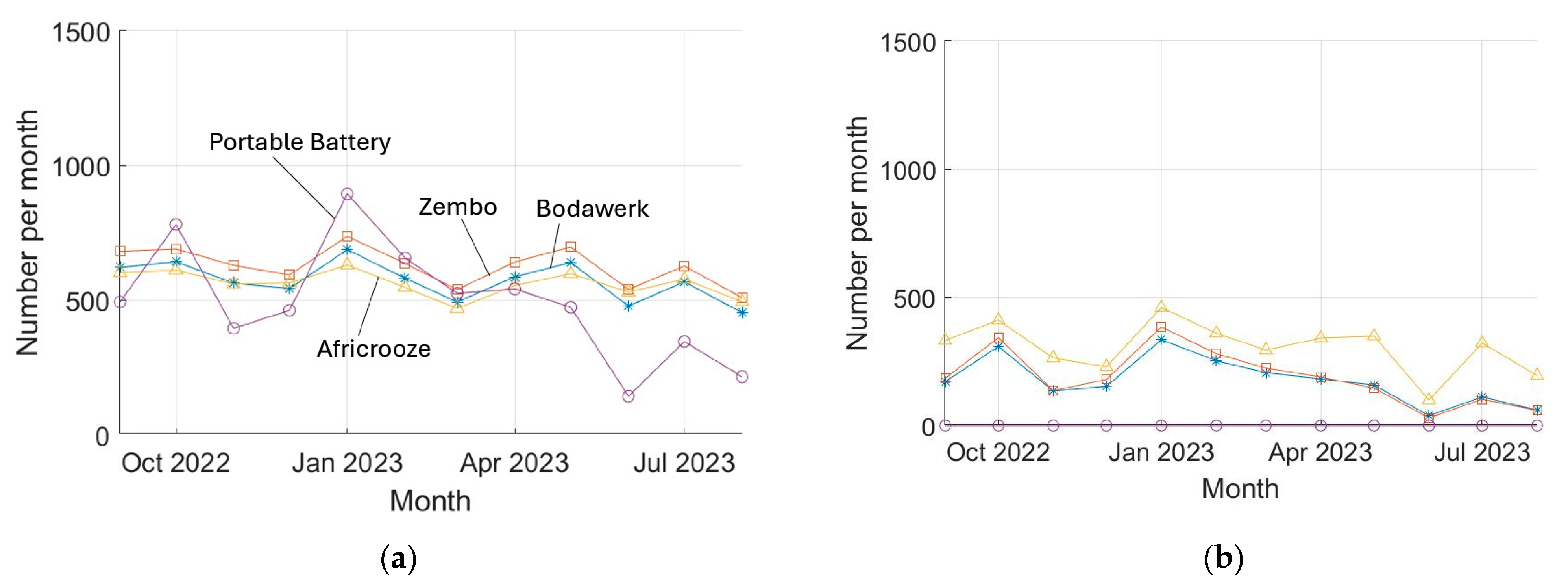

The number of e-bikes and portable batteries charged per month for Scenario 2 and Scenario 4 were plotted in

Figure 17. When the PV, battery, and converter capacities were halved (Scenario 4), there was a significant drop in the e-bikes charged due to the reduction in surplus PV. Notable is that integration of portable storage is not an optimal solution for the given charging priorities and capacities, as evidenced by the drop to 0 of portable batteries charged annually (see

Figure 17b). Therefore, the choice of additional loads and charging priorities should be adjusted to fit the desired DSM objective.

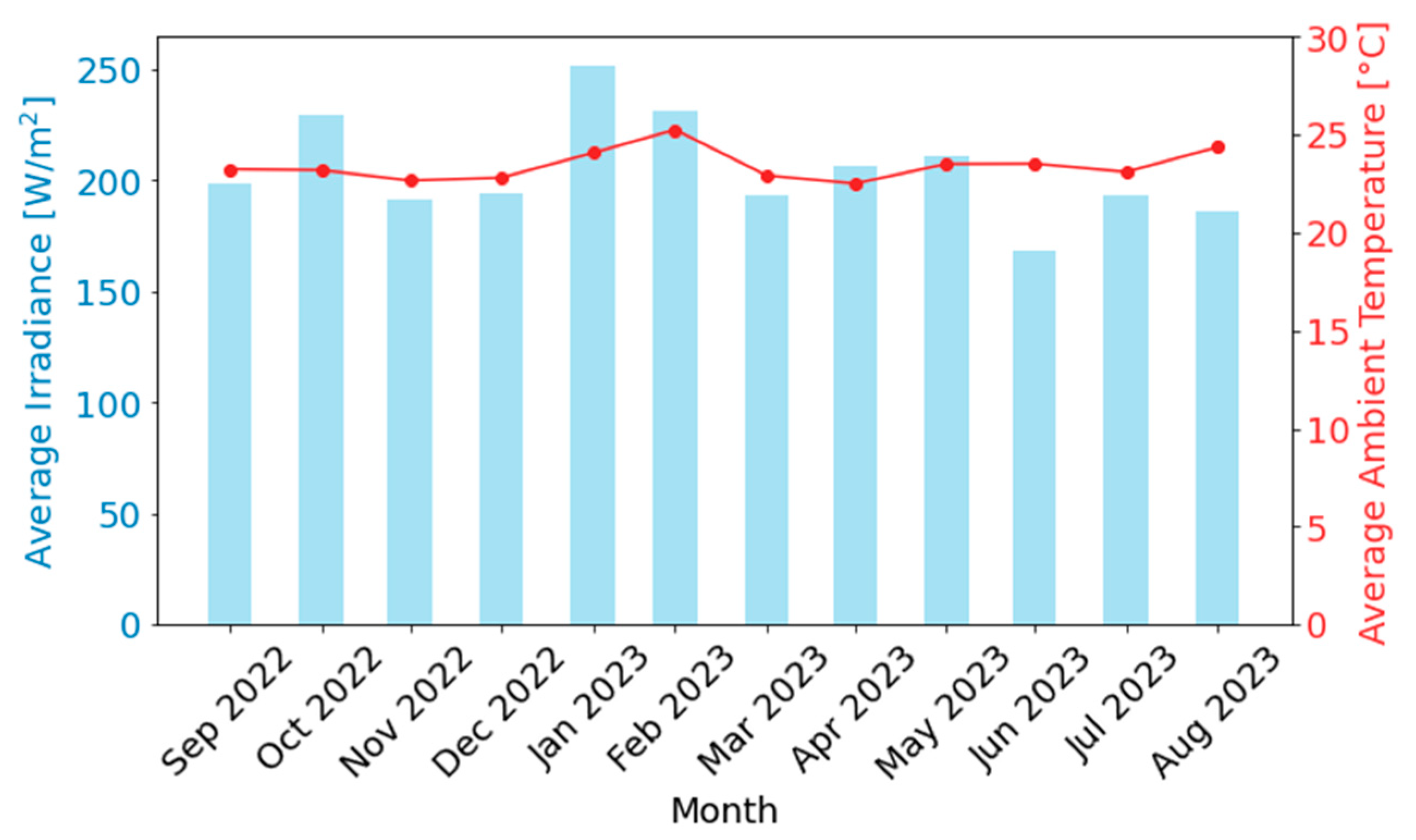

A comparison with

Figure 9 shows that the higher irradiance months of September 2022, October 2022, January 2023, and February 2023 were the months in which there were larger numbers of additional loads charged, as shown in

Figure 17.

The annual emissions avoided by integrating electric mobility in Scenario 2 were 73.27 tons of CO2/year, while the emissions avoided by integrating electric mobility in Scenario 4 were 29.20 tons of CO2/year. This is a 60% reduction in annual CO2 emissions avoided, due to the downscaling of PV capacity by 50% and hence reduction in PV surplus energy.

5.3. Economic Results

Most microgrids described in the literature include various combinations of PV, battery, grid, fuel cell, hydro, biomass, and other energy resources. In this work, we analysed systems with only PV and battery. The LCOE values for varying equipment configurations [

14,

50,

87,

90,

96,

97] range from 0.034 USD/kWh to 1.9 USD/kWh. The extremely wide range is due to various factors, including the types of technologies modelled, capital costs and other economic factors used, off-grid or on-grid status, site-dependent weather conditions, etc.

As per

Table 6, the LCC for Scenarios 3 and 4 (USD 367,053) is only 27% lower than for Scenarios 1 and 2 (USD 499,918), despite Scenarios 3 and 4 having half the PV, converter and battery capacities of Scenarios 1 and 2 and, thus, lower capital costs. This is because the battery lifetime for Scenarios 3 and 4 of 7.62 years is 46% shorter than that of Scenarios 1 and 2; hence, there were higher battery operational costs due to the increased number of battery replacements required over the project lifetime.

There is a 57% reduction in LCOE from 0.808 to 0.350 due to the inclusion of the e-bikes and portable storage in Scenario 2 relative to Scenario 1, which is closer to the USD 0.30/kWh tariff for Ugandan microgrids [

88]. For Scenario 4, there was a 21% reduction in LCOE relative to Scenario 3, from 0.689 to 0.543. All four scenarios gave better LCOE values than that for a stand-alone PV and battery system for Rwanda, which was 1.82 USD/kWh [

96].

5.4. Sensitivity Analysis

The effect of varying the battery cost, converter cost, interest rate, battery lifetime, and charging priority weights for the additional loads as compared to the base case (Scenario 1) were investigated.

Table 7 shows the variation in LCC and LCOE when battery capital costs per kWh (

) were varied as ±10% and ±20% of the base case (Scenario 1) costs.

Even with a 20% increase in battery capital costs, the integration of e-bikes and portable storage decreased the LCOE by over 50%. A 20% decrease in yielded a 11% decrease in LCC and a 61% decrease in LCOE. This highlights the large dependence of LCOE on battery costs, due to their high contribution to operational costs.

The converter costs (

) were varied as ±10% and ±20% of the base case (Scenario 1) costs.

Table 8 shows the negligible impact of (

) on the LCC and LCOE. Without additional loads, a ±20% change in

yielded only a ±3% change in both LCC and LCOE as the LCC values became USD 514,743 and USD 485,093. However, the additional loads generated significant improvements in LCOE with over ≥55% LCOE reductions relative to Scenario 1. This implies that the converter cost has a relatively insignificant impact on LCC and LCOE and thus for PV and battery systems, instead of matching the converter size to the peak load [

77] or 110% of the peak load [

57,

61], we recommend to match the converter size to the PV capacity. This has the additional advantage of catering for load growth without soon requiring a converter upgrade.

The significant contribution of the ESS to the LCC costs is highlighted by the increase by 23% and 64% of the LCC with a 7-year and 5-year battery lifetime, respectively, as illustrated in

Table 9. When the e-mobility and portable storage loads were integrated, the corresponding LCOE values increased to 0.432 USD/kWh and 0.571 USD/kWh.

The interest rate was varied as ±10% and ±20% of the base case (Scenario 1).

Table 10 shows that increasing the interest rate by 20% results in a 16% decrease in LCC to USD 419,602, while decreasing the interest rate by 20% yields an undesirable 24% rise in LCC. Thus, a higher interest rate yields a lower LCC for the model used. The effect of interest rate changes on the LCOE is negligible.

The impact of changing the charging priority of the portable storage loads was investigated by changing the weights from

and

in Scenario 1 to

. The maximum number of each battery type that can be charged daily remain the same as before (see

Table 5), i.e.,

for each of the e-bike types is 20, and

for the portable batteries is 60.

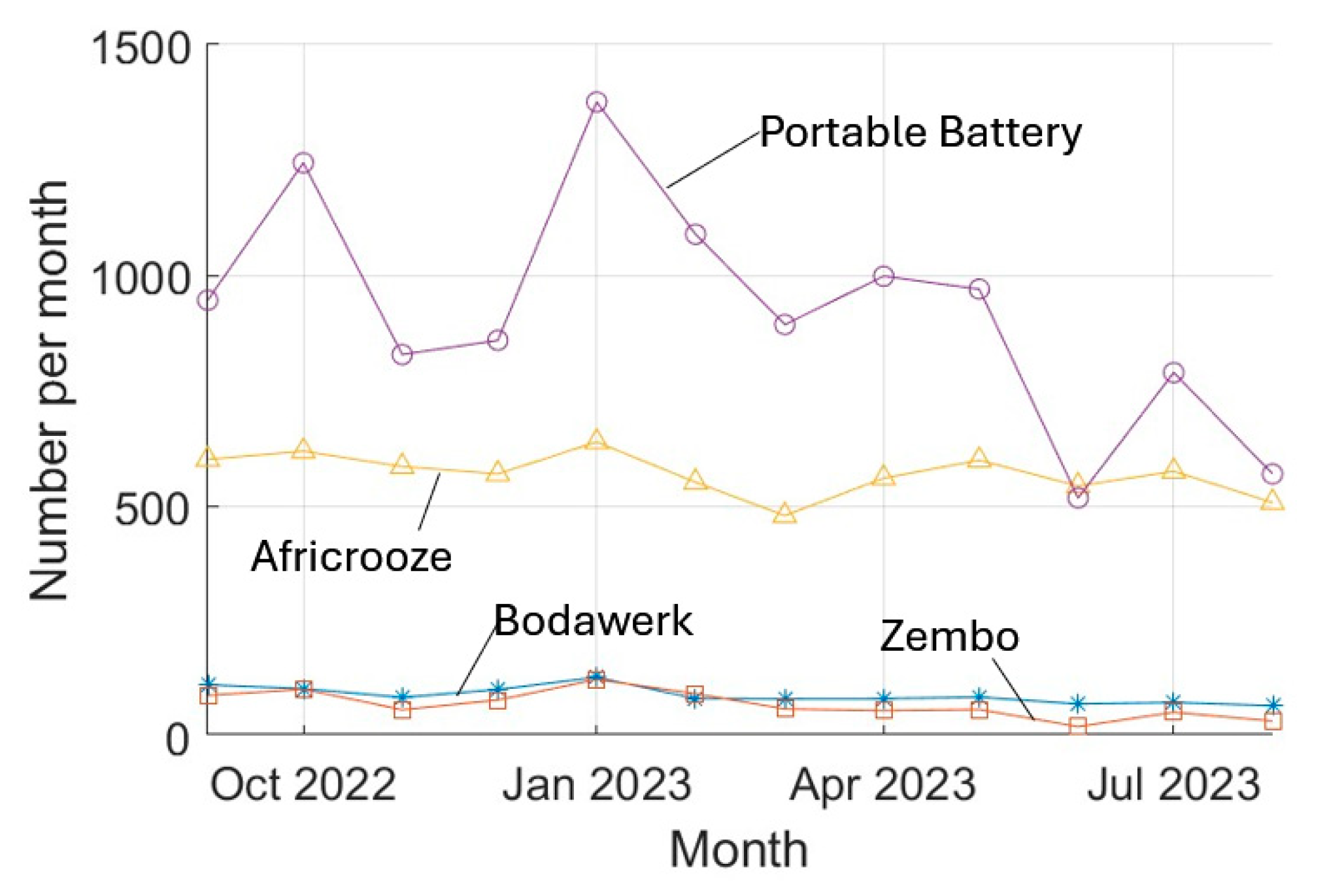

When the weights were made equal, a smaller number of e-bikes were charged (

Figure 18) compared to Scenario 2 (see

Figure 17b) while the portable storage consumed most of the surplus PV energy. Hence, the off-microgrid customers can be prioritised over the e-bikes by increasing

. The annual number of off-microgrid customers who can be served increased by over 90% to 304 annually. As shown in

Table 11, there was a 72% decrease in curtailed PV energy.

When the additional loads are assigned equal weights, the result is equivalent to prioritising off-microgrid customers and de-prioritising emissions reductions from e-mobility. As shown in

Table 11, the annual CO

2 emissions avoided were reduced to 30.34 tons of CO

2/year, and, on average, 30 portable batteries were charged daily.

The constraint on the difference between the number of Zembo and Bodawerk batteries charged daily means only 30% more Bodawerk bikes are charged annually compared to Zembo bikes, while over eight times as many Africrooze bikes compared to Zembo bikes are charged annually. The difference in annual e-bike numbers could be altered by changing the daily targets for each e-bike type as well as the weighting priorities.

To mitigate the challenge of limited charging stations that may be a deterrent to uptake of electric two wheelers, it is recommended that e-mobility and portable storage charging facilities be setup at other off-grid microgrids in the region so as to facilitate ease of battery swapping.

5.5. Benefits of the Proposed Solution

The introduction of e-mobility and portable storage in a microgrid community would elevate energy access in a multi-pronged manner. Portable storage extends electricity to previously unelectrified off-microgrid households and businesses without requiring them to invest in solar home systems or generators. Additionally, cheaper transport for the community and increased earnings of electric two- and three-wheeler riders imply an increased ability to pay for electricity and thus, potentially higher levels of demand. For microgrid developers, increased demand means increased revenue and thus an enhanced ability to maintain and scale up existing microgrids, as well as to setup new microgrids.

This approach can be applied in any microgrid setting where the daytime demand exceeds the solar energy production, and even better where two-and three-wheelers are commonly used, e.g., in India and other African countries.

6. Conclusions

This work analysed load profiles for East African microgrids, and then investigated the integration of electric two-wheelers and portable storage into a solar PV with battery microgrid in Uganda, East Africa. By introducing e-mobility and portable storage, DSM strategic load growth can be achieved, and electricity access can be expanded. This would be an important step toward achieving transport decarbonisation and enhancing microgrid sustainability, as well as augmenting the productive use of energy at rural off-grid microgrids.

Battery degradation was considered. Results showed a 98.5% reduction in PV energy curtailment and a 57% reduction in the LCOE from 0.808 USD/kWh to 0.350 USD/kWh when the electric two-wheeler and portable storage loads were introduced. Avoided emissions of up to 73.27 tons of CO2/year are possible with the proposed e-bikes, and an average of 160 customers could be served annually as off-microgrid consumers without requiring investment in additional distribution infrastructure. Annual revenue could be increased by 135% by incorporating the additional loads, assuming a uniform tariff for all microgrid customers.

Sensitivity analyses were conducted by varying the battery and converter costs, the battery lifetime, the interest rate, and the priority weighting of the additional loads. Battery costs were found to be a major contributor to lifecycle costs and also had a big impact on the LCOE. The interest rate significantly affects the LCC as well.

Most microgrids in Africa use lead–acid battery storage due to the lower upfront costs. However, with a demand surge from e-mobility and portable storage loads, Li-ion batteries would be positioned more favourably as a storage option of choice, given their higher energy density and longer lifetime. An assured, larger demand would mitigate the challenge of higher capital costs that is a deterrent to Li-ion deployment for most rural microgrid developers in emerging economies, due to the uncertainty of anticipated and actual demand levels in rural and off-grid communities.

The introduction of e-mobility and portable storage in a microgrid community can increase energy access in a multi-faceted manner. Portable storage extends electricity to previously unelectrified off-microgrid households and businesses. Cheaper transport for the community, increased earnings of electric two- and three-wheeler riders, and employment opportunities in the e-mobility sector imply an increased ability to pay for electricity and thus, potentially higher levels of demand. Increased demand means increased revenue for the microgrid developers and more funds for maintaining and scaling up existing microgrids as well as for installing new microgrids.

Partnerships and collaboration between microgrid developers and e-mobility and portable storage companies are recommended, as well as a conducive policy and regulatory environment that promotes sustainable e-mobility. It would also be important to have technical personnel available locally to install, maintain, and repair the additional loads and their systems.

Future research could include the modelling of load growth over the project lifetime and the evaluation of other generation sources, storage technologies, different optimisation methods, and incorporation of prediction and forecasting. Flexibility implications of electric two- and three-wheelers and portable storage can also be studied for both isolated and grid-connected microgrids.