Correlation Between Broken Contact Fingers and I–V Characteristics of Partially Shaded Photovoltaic Modules

Abstract

1. Introduction

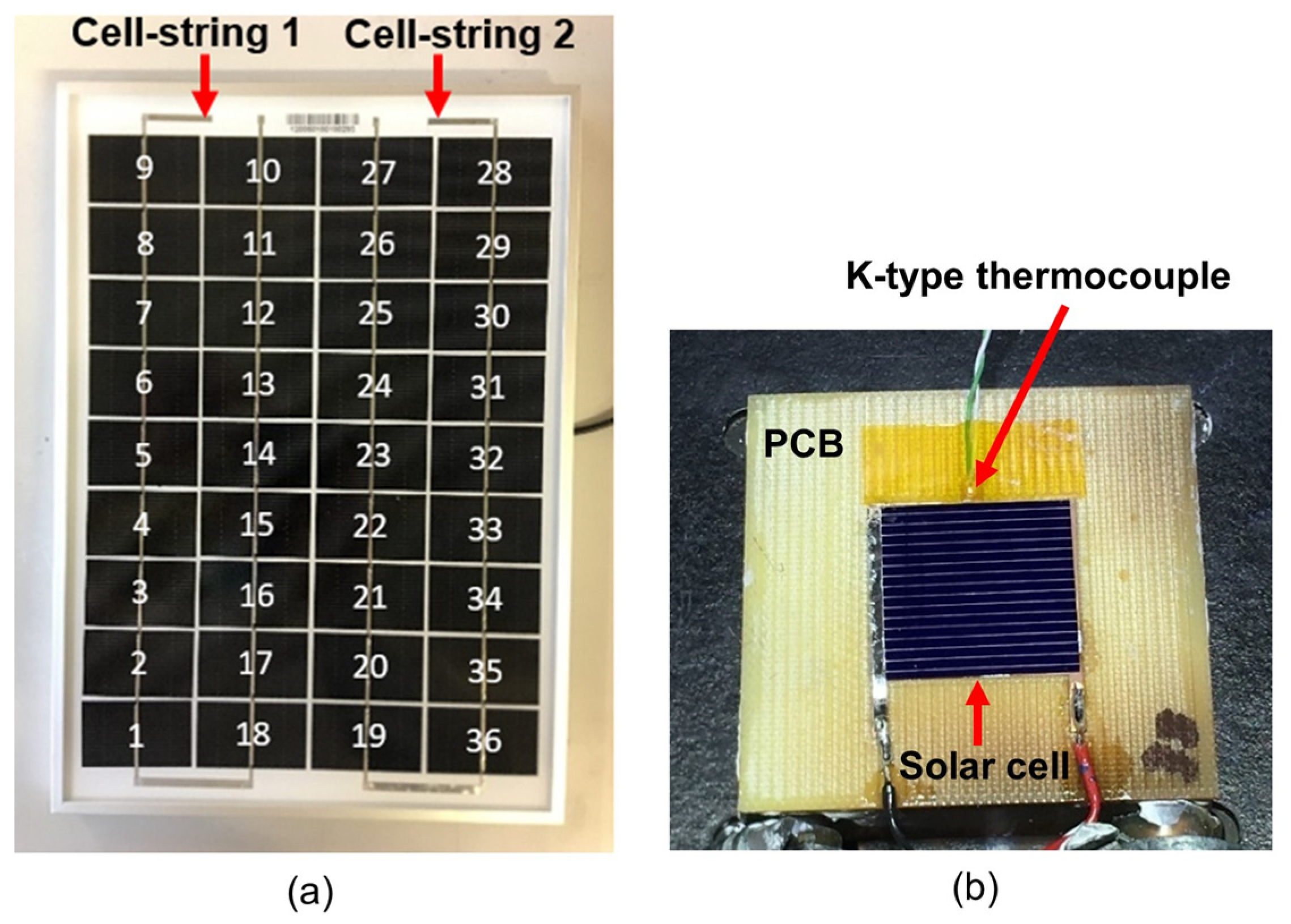

2. Experimental Procedure

2.1. Preparations of PV Devices

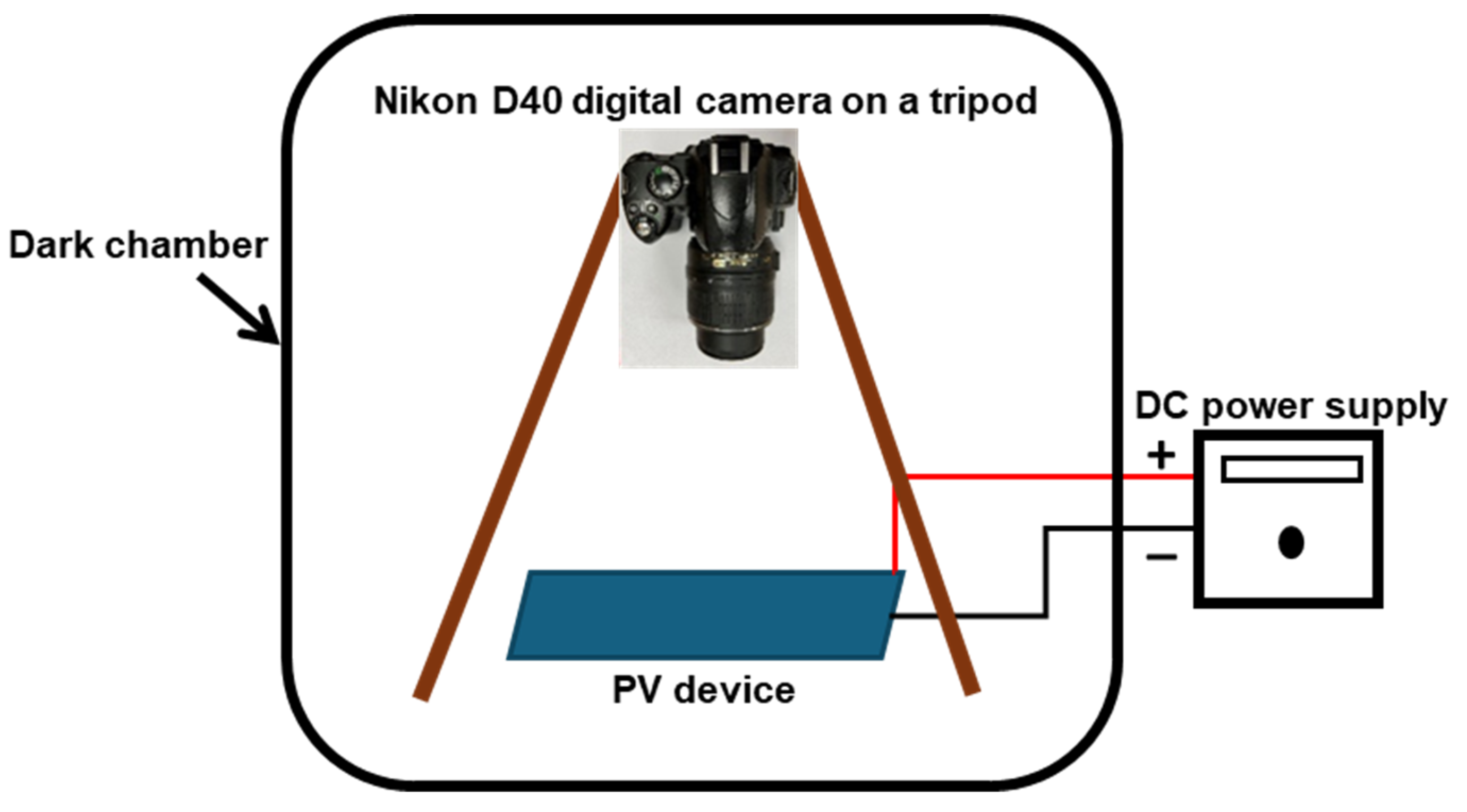

2.2. Setup for I–V Characterization

2.3. EL Imaging Setup

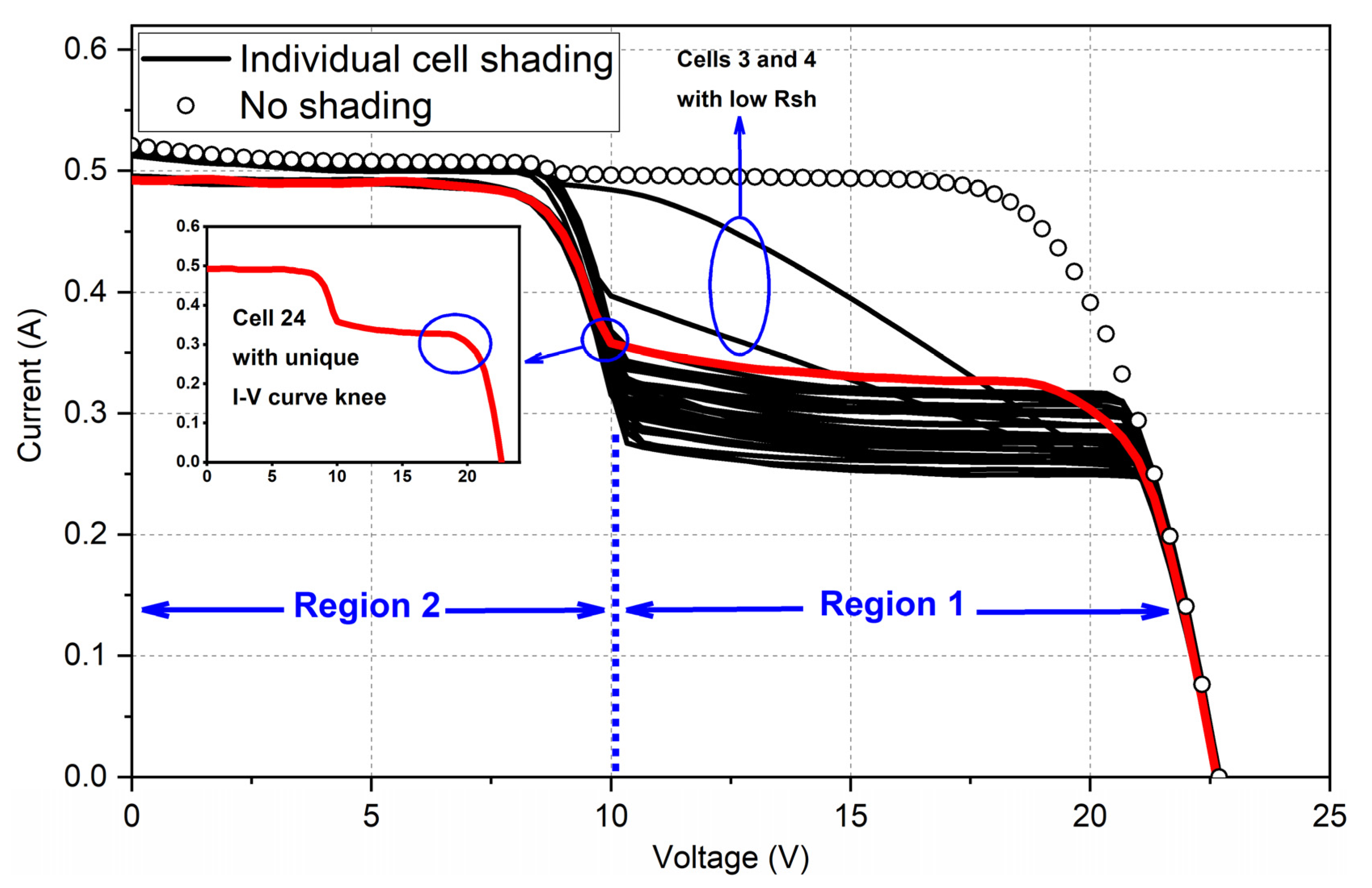

3. I–V Curve Under Individual-Cell Partial Shading

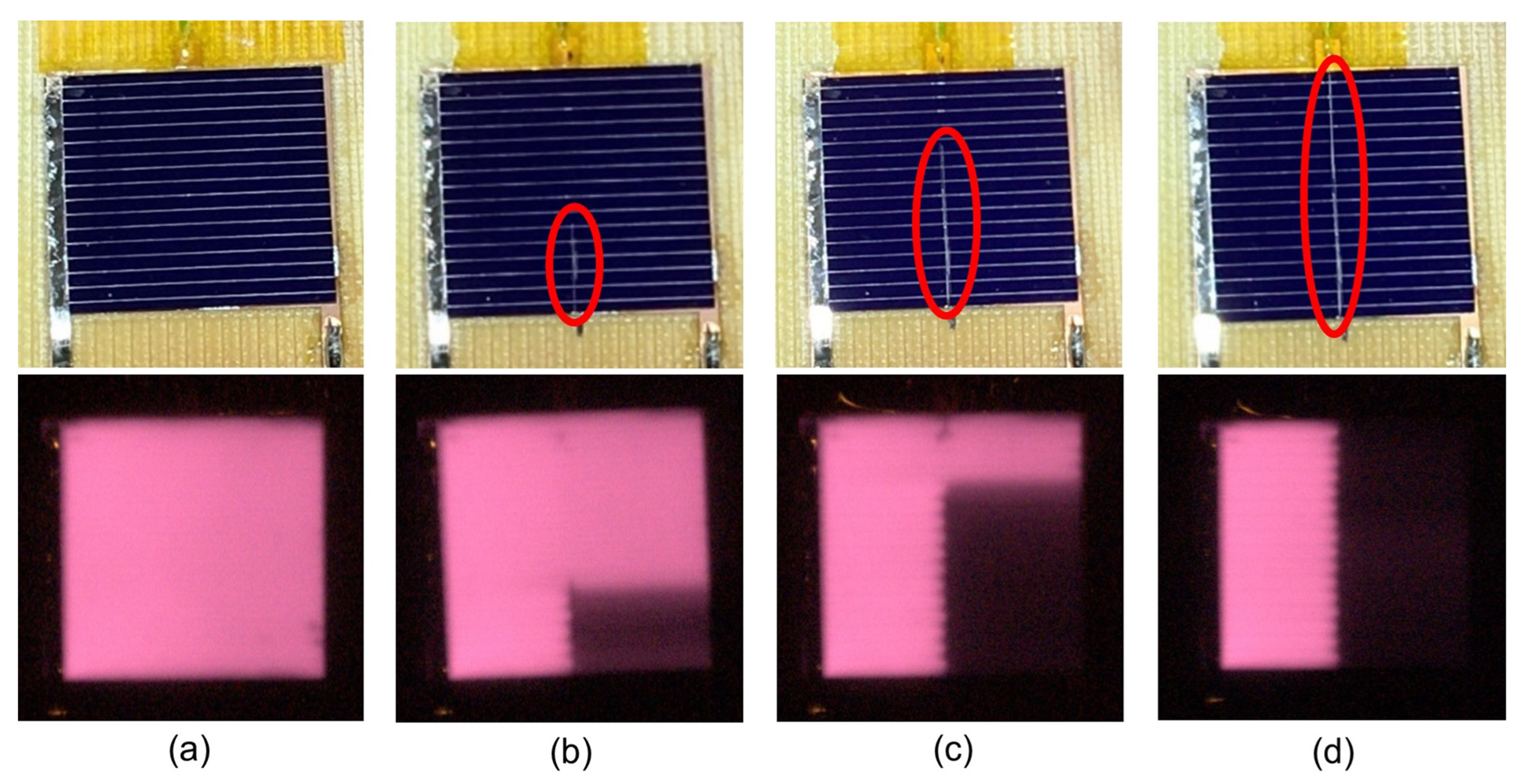

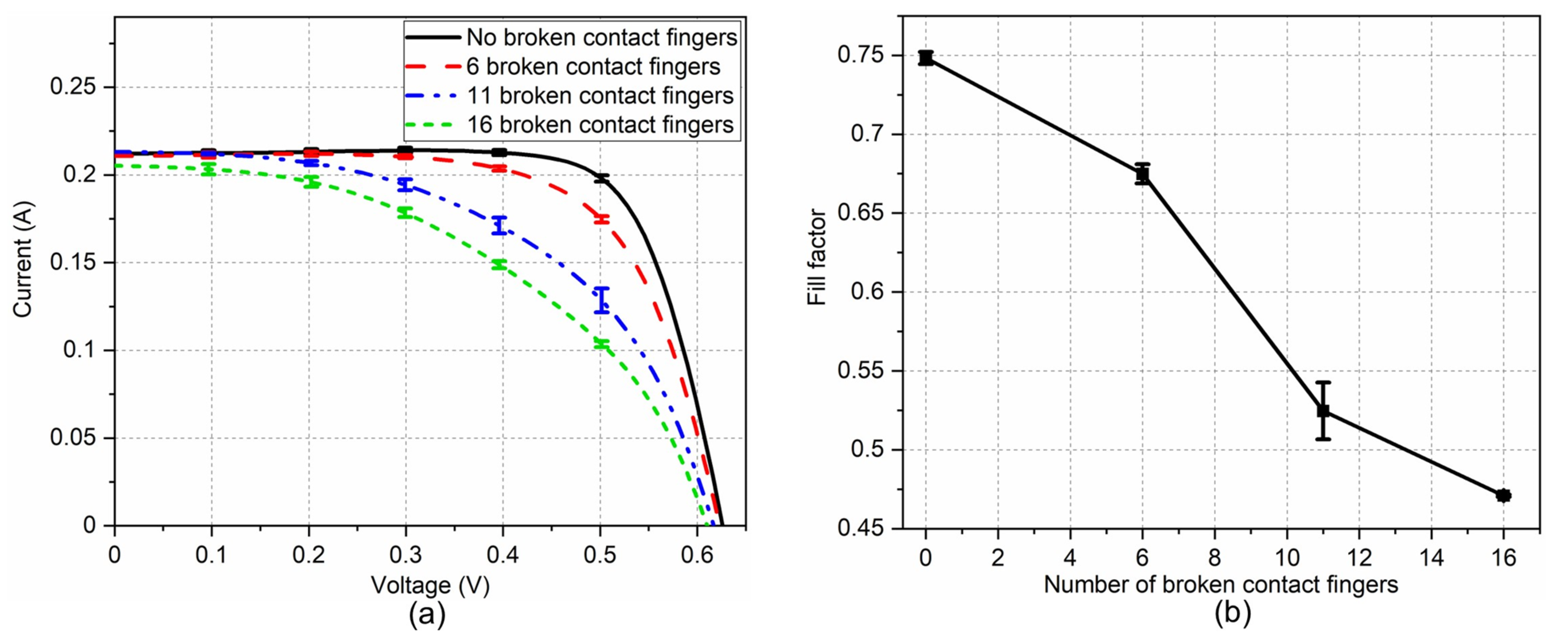

4. Influence of Broken Contact Fingers on a Single Solar Cell

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mertens, K. Photovoltaics Fundamentals, Technology and Practice; Wiley: Chichester, UK, 2014. [Google Scholar]

- Masson, G.; Kaizuka, I. Trends in Photovoltaic Applications 2022. Available online: https://iea-pvps.org/trends_reports/trends-2022/ (accessed on 7 October 2024).

- Wang, P.A. Industrial challenges for Thin Wafer Manufacturing. In Proceedings of theIEEE 4th World Conference on Photovoltaic Energy Conversion, WCPEC-4, IEEE Computer Society, Waikoloa, HI, USA, 7–12 May 2006; IEEE: New York, NY, USA; pp. 1179–1182. [Google Scholar] [CrossRef]

- Papargyri, L.; Theristis, M.; Kubicek, B.; Krametz, T.; Mayr, C.; Papanastasiou, P.; Georghiou, G.E. Modelling and experimental investigations of microcracks in crystalline silicon photovoltaics: A review. Renew. Energy 2020, 145, 2387–2408. [Google Scholar] [CrossRef]

- Kajari-Schröder, S.; Kunze, I.; Eitner, U.; Köntges, M. Spatial and orientational distribution of cracks in crystalline photovoltaic modules generated by mechanical load tests. Sol. Energy Mater. Sol. Cells 2011, 95, 3054–3059. [Google Scholar] [CrossRef]

- Chaturvedi, P.; Hoex, B.; Walsh, T.M. Broken metal fingers in silicon wafer solar cells and PV modules. Sol. Energy Mater. Sol. Cells 2013, 108, 78–81. [Google Scholar] [CrossRef]

- Tippabhotla, S.K.; Radchenko, I.; Song, W.J.R.; Illya, G.; Handara, V.; Kunz, M.; Tamura, N.; Tay, A.A.O.; Budiman, A.S. From cells to laminate: Probing and modeling residual stress evolution in thin silicon photovoltaic modules using synchrotron X-ray micro-diffraction experiments and finite element simulations. Prog. Photovolt. Res. Appl. 2017, 25, 791–809. [Google Scholar] [CrossRef]

- Köntges, M.; Siebert, M.; Morlier, A.; Illing, R.; Bessing, N.; Wegert, F. Impact of transportation on silicon wafer-based photovoltaic modules. Prog. Photovolt. Res. Appl. 2016, 24, 1085–1095. [Google Scholar] [CrossRef]

- Köntges, M.; Kajari-Schröder, S.; Kunze, I. Crack statistic for wafer-based silicon solar cell modules in the field measured by UV fluorescence. IEEE J. Photovolt. 2013, 3, 95–101. [Google Scholar] [CrossRef]

- Khan, F.; Alshahrani, T.; Fareed, I.; Kim, J.H. A comprehensive degradation assessment of the silicon photovoltaic modules installed on concrete base under hot and low-humidity environments: Building applications. Sustain. Energy Technol. Assess. 2022, 52, 102314. Available online: https://www.sciencedirect.com/science/article/pii/S2213138822003666 (accessed on 7 October 2024). [CrossRef]

- Khan, F.; Rezgui, B.D.; Kim, J.H. Reliability study of c-Si PV module mounted on a concrete slab by thermal cycling using electroluminescence scanning: Application in future solar roadway. Materials 2020, 13, 470. [Google Scholar] [CrossRef]

- Köntges, M.; Kunze, I.; Kajari-Schröder, S.; Breitenmoser, X.; Bjørneklett, B. The risk of power loss in crystalline silicon based photovoltaic modules due to micro-cracks. Sol. Energy Mater. Sol. Cells 2011, 95, 1131–1137. [Google Scholar] [CrossRef]

- Morlier, A.; Haase, F.; Köntges, M. Impact of cracks in multicrystalline silicon solar cells on PV module power—A simulation study based on field data. IEEE J. Photovolt. 2015, 5, 1735–1741. [Google Scholar] [CrossRef]

- Dhimish, M. Micro cracks distribution and power degradation of polycrystalline solar cells wafer: Observations constructed from the analysis of 4000 samples. Renew. Energy 2020, 145, 466–477. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mather, P.; Sibley, M. Novel hot spot mitigation technique to enhance photovoltaic solar panels output power performance. Sol. Energy Mater. Sol. Cells 2018, 179, 72–79. [Google Scholar] [CrossRef]

- Abdelhamid, M.; Singh, R.; Omar, M. Review of microcrack detection techniques for silicon solar cells. IEEE J. Photovolt. 2014, 4, 514–524. [Google Scholar] [CrossRef]

- Fuyuki, T.; Kondo, H.; Yamazaki, T.; Takahashi, Y.; Uraoka, Y. Photographic surveying of minority carrier diffusion length in polycrystalline silicon solar cells by electroluminescence. Appl. Phys. Lett. 2005, 86, 262108. [Google Scholar] [CrossRef]

- Muehleisen, W.; Eder, G.C.; Voronko, Y.; Spielberger, M.; Sonnleitner, H.; Knoebl, K.; Ebner, R.; Ujvari, G.; Hirschl, C. Outdoor detection and visualization of hailstorm damages of photovoltaic plants. Renew. Energy 2018, 118, 138–145. [Google Scholar] [CrossRef]

- Fuyuki, T.; Kitiyanan, A. Photographic diagnosis of crystalline silicon solar cells utilizing electroluminescence. Appl. Phys. A Mater. Sci. Process. 2009, 96, 189–196. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M. The impact of cracks on photovoltaic power performance. J. Sci. Adv. Mater. Devices 2017, 2, 199–209. [Google Scholar] [CrossRef]

- Frazão, M.; Silva, J.A.; Lobato, K.; Serra, J.M. Electroluminescence of silicon solar cells using a consumer grade digital camera. Measurement 2017, 99, 7–12. [Google Scholar] [CrossRef]

- Stoicescu, L.; Reuter, M.; Werner, J.H. DaySy: Luminescence imaging of PV modules in daylight. In Proceedings of the 29th European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 23–25 September 2014; pp. 2553–2554. [Google Scholar]

- Alves Dos Reis Benatto, G.; Mantel, C.; Spataru, S.; Santamaria Lancia, A.A.; Riedel, N.; Thorsteinsson, S.; Poulsen, P.B.; Parikh, H.; Forchhammer, S.; Sera, D. Drone-based daylight electroluminescence imaging of PV modules. IEEE J. Photovolt. 2020, 10, 872–877. [Google Scholar] [CrossRef]

- Trupke, T.; Bardos, R.A.; Schubert, M.C.; Warta, W. Photoluminescence imaging of silicon wafers. Appl. Phys. Lett. 2006, 89, 044107. [Google Scholar] [CrossRef]

- Bhoopathy, R.; Kunz, O.; Juhl, M.; Trupke, T.; Hameiri, Z. Outdoor photoluminescence imaging of photovoltaic modules with sunlight excitation. Prog. Photovolt. Res. Appl. 2018, 26, 69–73. [Google Scholar] [CrossRef]

- Zafirovska, I.; Juhl, M.K.; Weber, J.W.; Wong, J.; Trupke, T. Detection of finger interruptions in silicon solar cells using line scan photoluminescence imaging. IEEE J. Photovolt. 2017, 7, 1496–1502. [Google Scholar] [CrossRef]

- Ma, M.; Zhang, Z.; Yun, P.; Xie, Z.; Wang, H.; Ma, W. Photovoltaic module current mismatch fault diagnosis based on I-V data. IEEE J. Photovolt. 2021, 11, 779–788. [Google Scholar] [CrossRef]

- CEI/IEC 61215; Crystalline Silicon Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval. IEC: Geneva, Switzerland, 2005. Available online: https://solargostaran.com/files/standards/IEC/IEC%2061215-2005.pdf (accessed on 7 October 2024).

- Herrmann, W.; Wiesner, W.; Vaassen, W. Hot spot investigations on PV modules—New concepts for a test standard and consequences for module design with respect to bypass diodes. In Conference Record of the Twenty Sixth IEEE Photovoltaic Specialists Conference, Anaheim, CA, USA, 29 Septemebr–3 October 1997; IEEE: Anaheim, CA, USA, 1997; pp. 1129–1132. [Google Scholar] [CrossRef]

- Wang, Y.; Itako, K.; Kudoh, T.; Koh, K.; Ge, Q. Voltage-based hot-spot detection method for photovoltaic string using a projector. Energies 2017, 10, 230. [Google Scholar] [CrossRef]

- Yang, S.; Itako, K.; Kudoh, T.; Koh, K.; Ge, Q. Monitoring and suppression of the typical hot-spot phenomenon resulting from low-resistance defects in a PV string. IEEE J. Photovolt. 2018, 8, 1809–1817. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kang, S.M.; Johnston, B.; Winston, R. A novel method to extract the series resistances of individual cells in a photovoltaic module. Sol. Energy Mater. Sol. Cells 2013, 115, 21–28. [Google Scholar] [CrossRef]

- d’Alessandro, V.; Guerriero, P.; Daliento, S.; Gargiulo, M. A straightforward method to extract the shunt resistance of photovoltaic cells from current-voltage characteristics of mounted arrays. Solid State Electron. 2011, 63, 130–136. [Google Scholar] [CrossRef]

- Alers, G.B.; Zhou, J.; Deline, C.; Hacke, P.; Kurtz, S.R. Degradation of individual cells in a module measured with differential IV analysis. Prog. Photovolt. Res. Appl. 2011, 19, 977–982. [Google Scholar] [CrossRef]

- Atia, A.; Anayi, F.; Gao, M. Influence of shading on solar cell parameters and modelling accuracy improvement of PV modules with reverse biased solar cells. Energies 2022, 15, 9067. [Google Scholar] [CrossRef]

- Al-Shidhani, M.; Al-Najideen, M.; Rocha, V.G.; Min, G. Design and testing of 3D printed cross compound parabolic concentrators for LCPV system. In Proceedings of the 14th International Conference on Concentrator Photovoltaic Systems (CPV-14), Puertollano, Spain, 16–18 April 2018; American Institute of Physics Inc.: College Park, MD, USA, 2018; p. 020001. [Google Scholar] [CrossRef]

- E0927-10; Standard Specification for Solar Simulation for Terrestrial Photovoltaic Testing. ASTM: West Conshohocken, PA, USA, 2010. Available online: https://www.astm.org/e0927-10.html (accessed on 7 October 2024).

- Meyer, E.L.; Van Dyk, E.E. The effect of reduced shunt resistance and shading on photovoltaic module performance. In Conference Record of the Thirty-First IEEE Photovoltaic Specialists Conference, Lake Buena Vista, FL, USA, 3–7 January 2005; IEEE: Lake Buena Vista, FL, USA, 2005; pp. 1331–1334. [Google Scholar] [CrossRef]

- Daliento, S.; Di Napoli, F.; Guerriero, P.; d’Alessandro, V. A modified bypass circuit for improved hot spot reliability of solar panels subject to partial shading. Sol. Energy 2016, 134, 211–218. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atia, A.; Anayi, F.; Bahr, A.; Min, G. Correlation Between Broken Contact Fingers and I–V Characteristics of Partially Shaded Photovoltaic Modules. Solar 2024, 4, 595-605. https://doi.org/10.3390/solar4040028

Atia A, Anayi F, Bahr A, Min G. Correlation Between Broken Contact Fingers and I–V Characteristics of Partially Shaded Photovoltaic Modules. Solar. 2024; 4(4):595-605. https://doi.org/10.3390/solar4040028

Chicago/Turabian StyleAtia, Abdulhamid, Fatih Anayi, Ali Bahr, and Gao Min. 2024. "Correlation Between Broken Contact Fingers and I–V Characteristics of Partially Shaded Photovoltaic Modules" Solar 4, no. 4: 595-605. https://doi.org/10.3390/solar4040028

APA StyleAtia, A., Anayi, F., Bahr, A., & Min, G. (2024). Correlation Between Broken Contact Fingers and I–V Characteristics of Partially Shaded Photovoltaic Modules. Solar, 4(4), 595-605. https://doi.org/10.3390/solar4040028