Enhancing Industrial Buildings’ Performance through Informed Decision Making: A Generative Design for Building-Integrated Photovoltaic and Shading System Optimization

Abstract

1. Introduction

- -

- Material and Methods (Section 2): detailed descriptions of the main procedural steps and simulation settings.

- -

- Results (Section 3): presentation of the main findings for each topic addressed.

- -

- Discussions (Section 4): analysis and comparison of the research outputs with similar studies in the literature.

- -

- Conclusions (Section 5): summary of the research outcomes, along with an overview of the limitations and potential future developments.

2. Materials and Methods

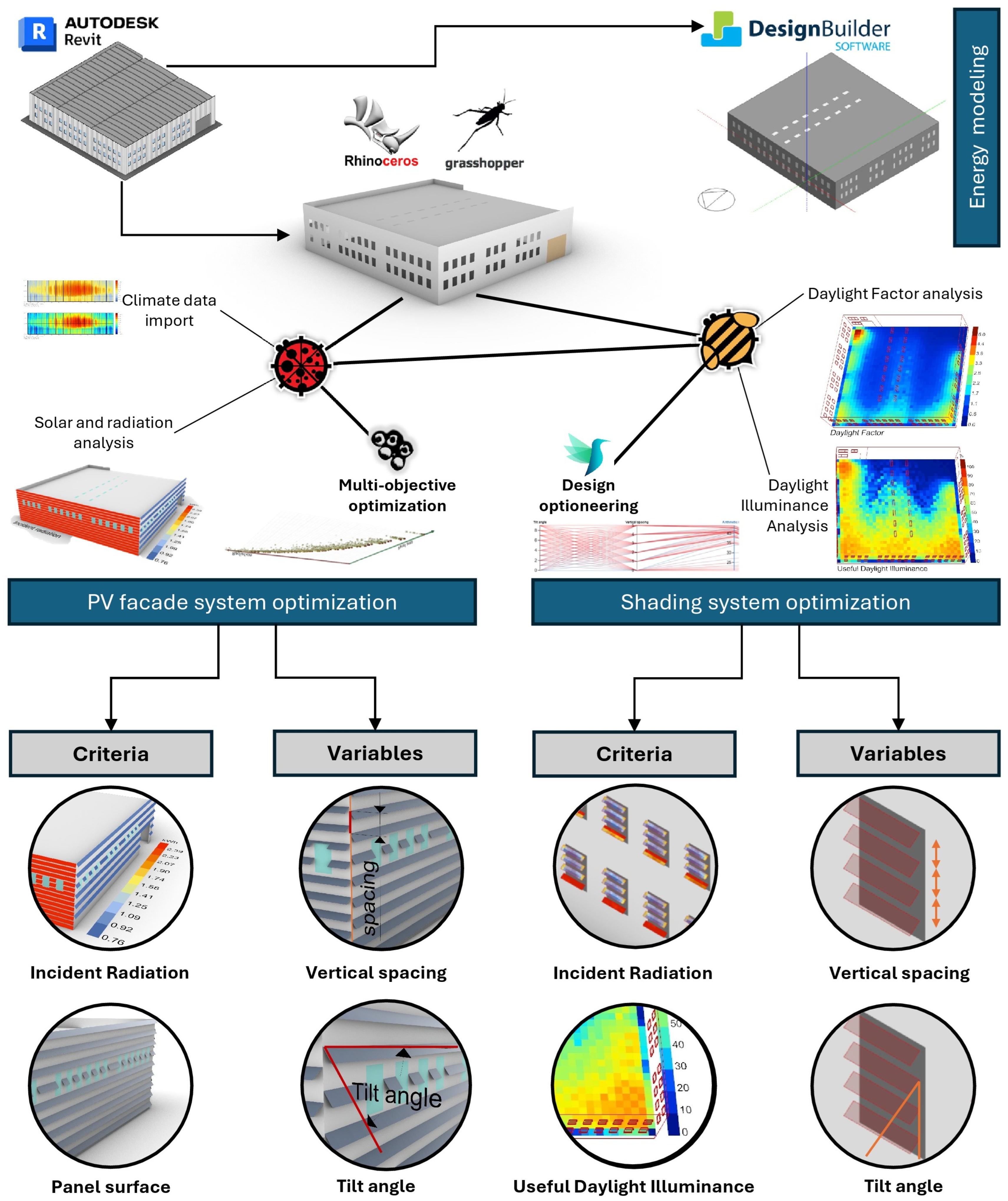

- At first, the building was accurately modeled in a BIM environment using Revit, based on detailed specifications of the geometry and internal layout retrieved from the original design drawings and on-site inspections. This model represented the starting point for all subsequent applications and assessments in the research.

- The interoperability between Revit and Rhinoceros Grasshopper was exploited to directly import the building’s geometry and apply a series of autonomously drafted Visual Programming Language (VPL) algorithms. These were designed to effectively intertwine the input data and outcomes of the different parts of the script leveraging the multidisciplinary simulation tools. Figure 3 shows the script created by the authors.

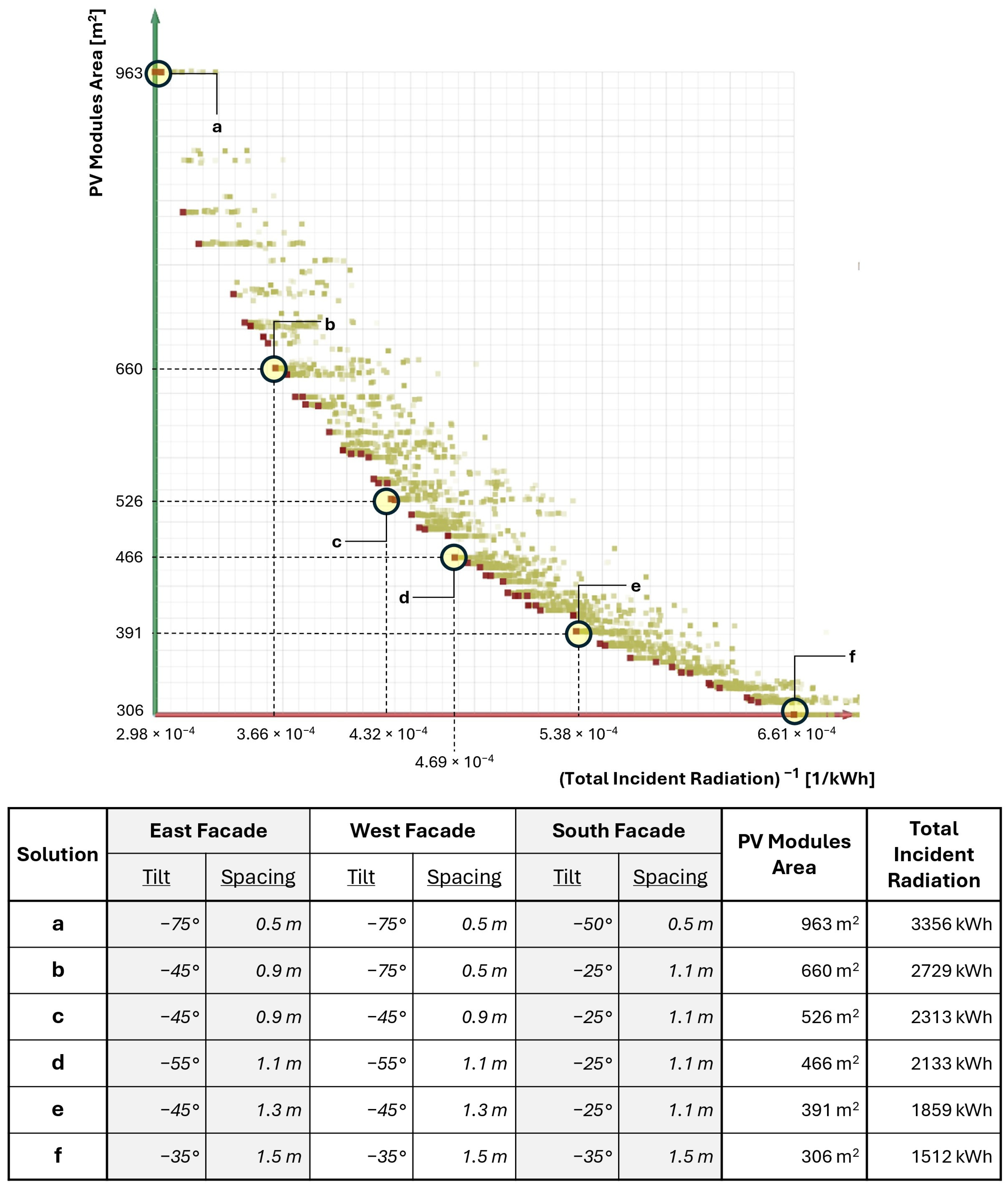

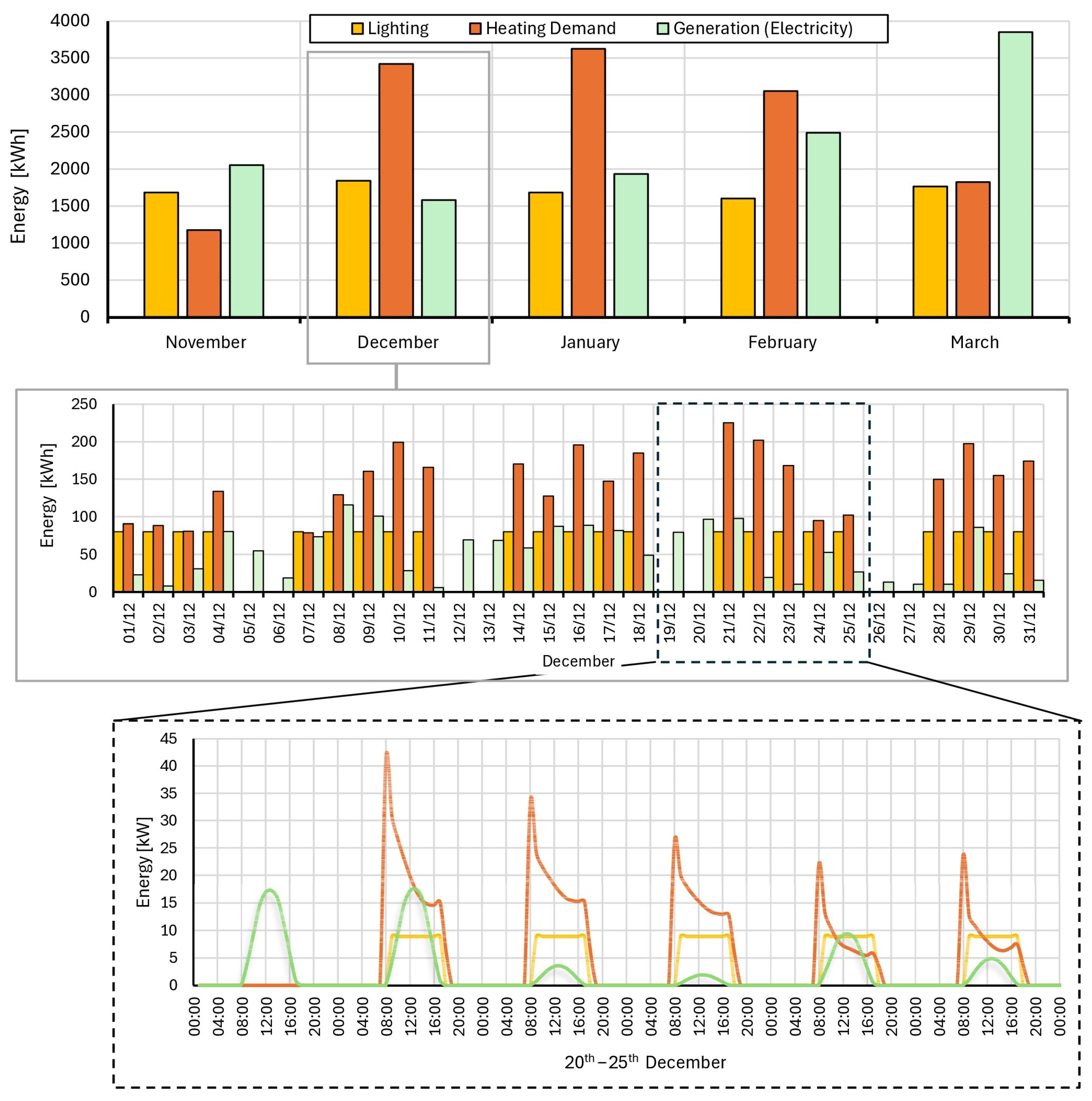

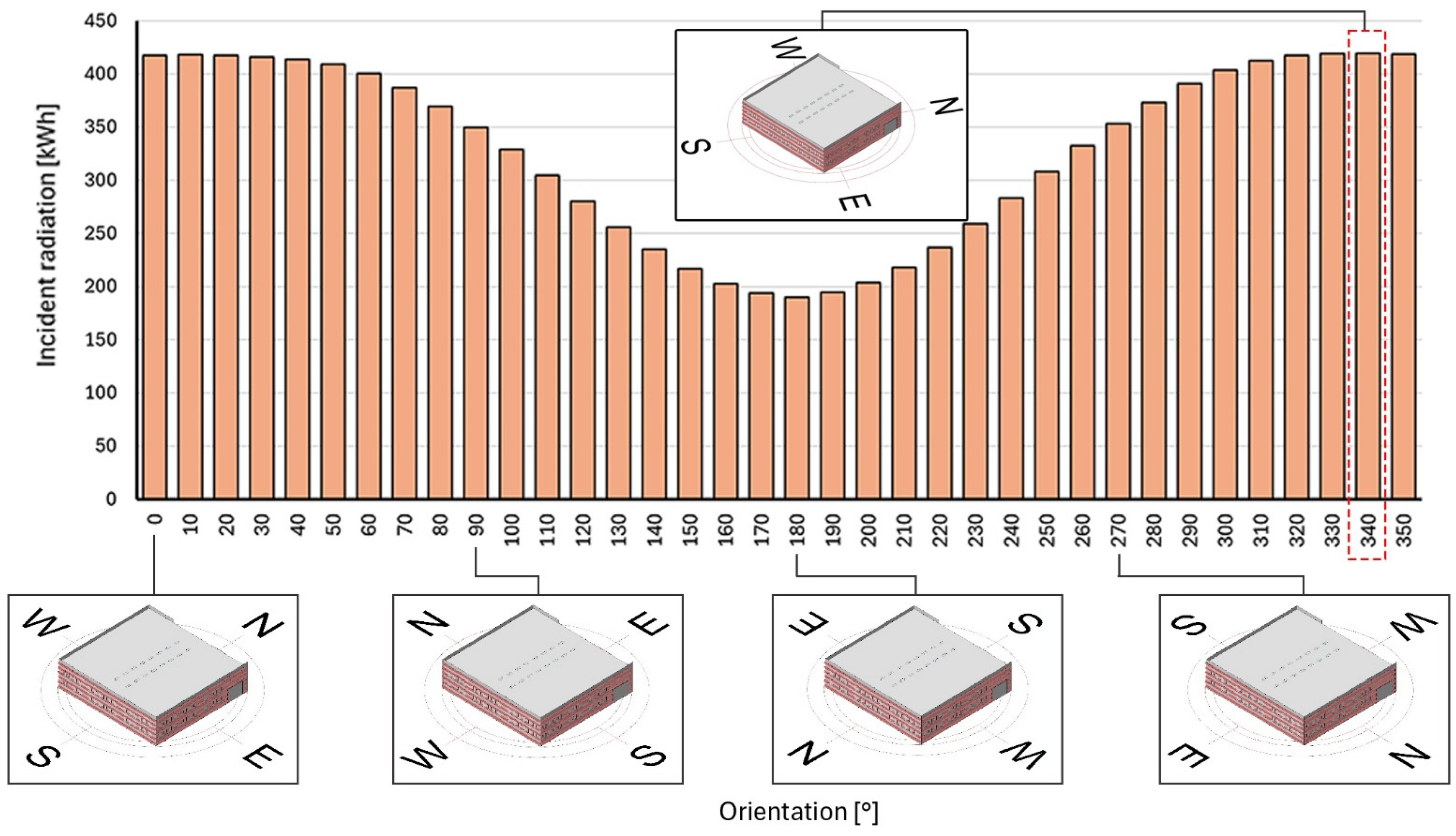

- The Ladybug plugin and its components were used to import and analyze the climatic data referring to the Florence area and to conduct solar and radiation analyses. Simulations were carried out for both the summer and winter solstices (21 June and 21 December) considering a time interval between 7:00 a.m. and 6:00 p.m. to align with the working hours of the company occupying the building. To promote simultaneous energy production and consumption, it is advisable to maximize the yield of the photovoltaic system during the operating hours of the machinery and installed equipment. A multi-objective optimization study was carried out using the Octopus plugin [31] to evaluate different BIPV layouts applied to the different building facades. The energy production and initial investment costs were addressed as evaluation criteria. To express both parameters, the total incident radiation and the total area of the panels installed were used as references. The former is key for assessing the productiveness of the installed PV system, while the area of the PV surface was assumed as representative of the costliness of the different configurations evaluated, as it is directly related to the number of panels installed. Solar incident radiation was calculated through the dedicated simulation engine provided by the Ladybug plugin and included in the Octopus-based optimization. The tilt angle (ranging from 0° to 90° with 10° increments) and the distance (ranging from 0.5 m to 1.5 m in 0.20 steps) between consecutive rows of PV modules on each facade were introduced as the variables for the problem (Table 1). The minimum distance was set to avoid the overlapping of panels when considering their perfectly vertical layout. The research was further developed by applying progressive rotations of 10° with respect to the N-S axis for the entire building, considering the PV modules arranged according to the optimized configuration minimizing the panels’ area in winter conditions. This approach aimed to identify the most promising building orientation ranges for implementing BIPV solutions.

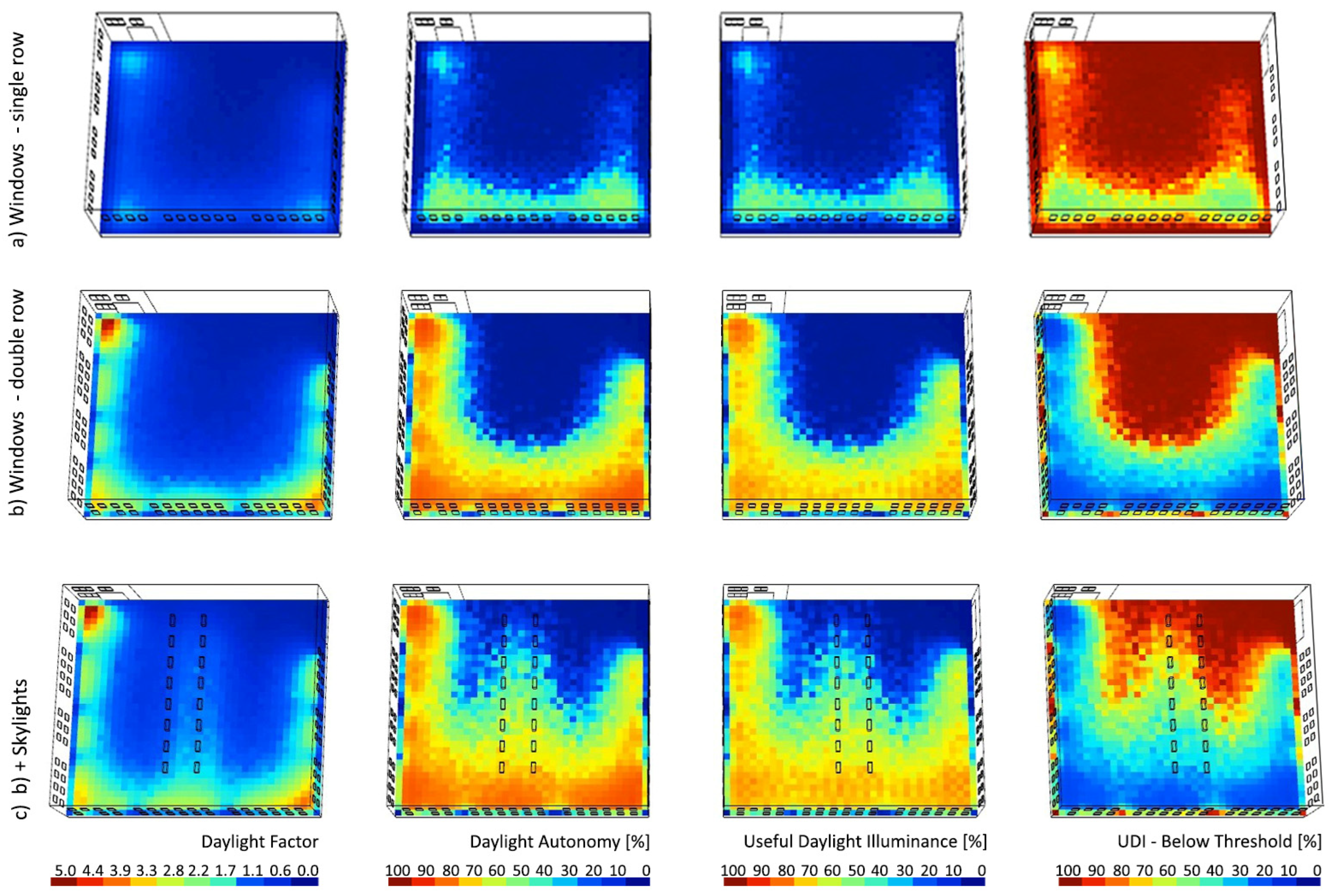

- The Honeybee plugin [32] was used to assess the visual comfort conditions within the working environment, and it was exploited to perform daylight simulations considering the daylight factor (DF), daylight autonomy (DA), and the useful daylight illuminance (UDI) as reference parameters. These parameters respectively represent the amount of daylight that penetrates the building interior, the extent to which a space is naturally lit during occupied hours to satisfy the required illuminance conditions, and the percentage of the annual hours during which the illuminance threshold is met. Solar radiation and climate data were derived from those imported using Ladybug, as previously introduced. To account for the different possible configurations of the building’s apertures commonly retrieved in existing manufacturing facilities, alternative configurations were evaluated: windows on each facade arranged in a single row or two rows, and the presence of roof skylights, including a combination of these scenarios. In this case, the simulations were performed considering the entire year and a minimum illuminance level of 300 lux, as prescribed by UNI EN 12464-1 [33] for generic activities in an industrial environment.

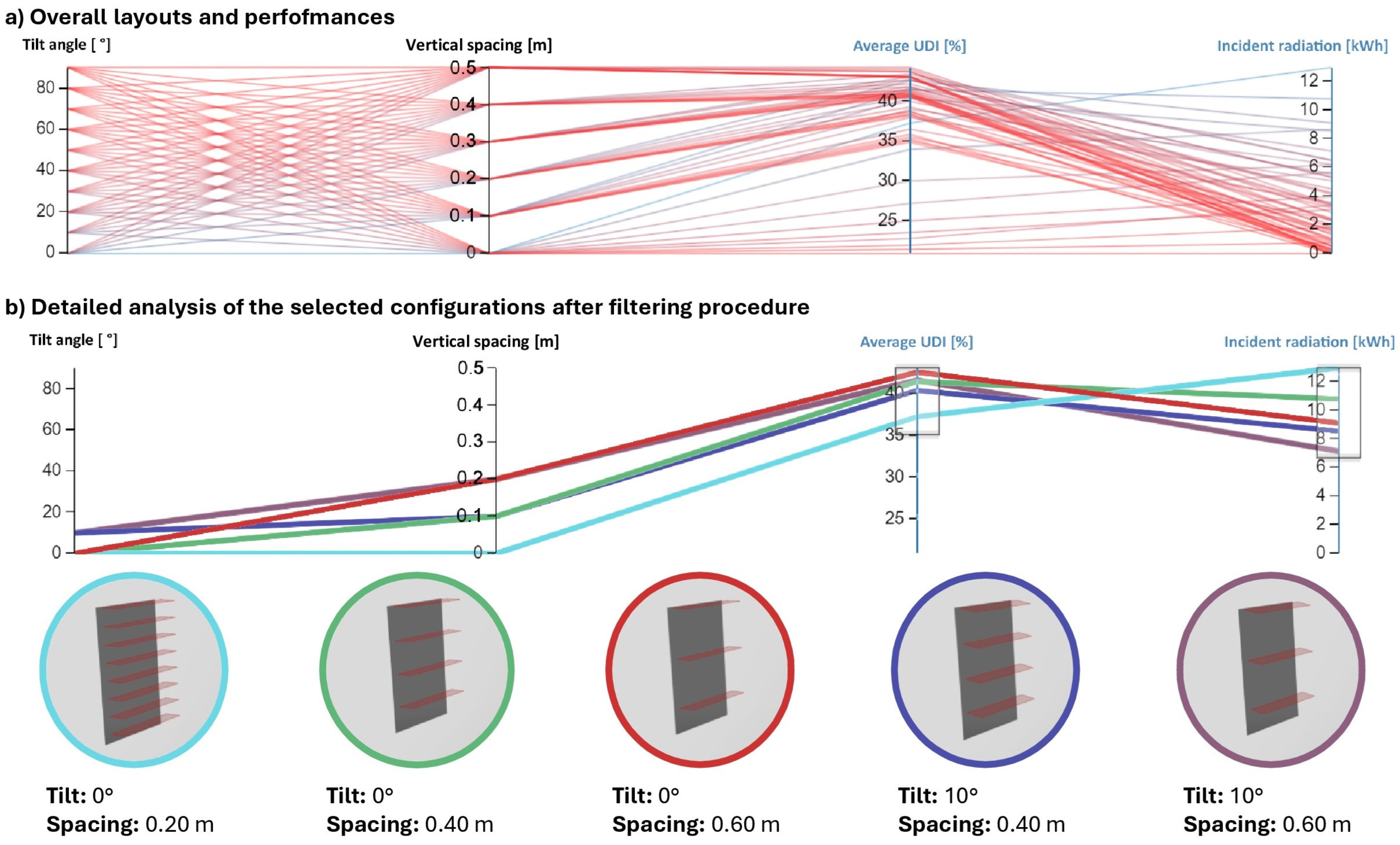

- The outputs of daylight illuminance and incident radiation analyses were also included in defining the optimized solar shading system configurations. In this case, different alternative solutions were evaluated using a design-optioneering approach, iterating a series of simulations through the Colibrì plugin [34] for Grasshopper. For this analysis, 0.20 deep external louvres were designed, considering the tilt angle of each blade ranging from 0° to 90° and vertical spacing between consequent slats from 0.20 m to 1 m. The evaluation focused on 60 distinct options, each resulting from variations in the geometrical arrangements achieved through adjustments of 10° in blade tilt and 0.20 m in vertical spacing. These alternatives were assessed for their performance during the summer solstice throughout the occupancy period. The results were explored through the online viewer Design Explorer by Thornton Tomasetti [35], which allows the comparison and filtering of different configurations tested according to the desired outputs or limitations assigned to the design variables. For the study here presented, the amount of solar incident radiation and the internal UDI average values were considered driving design factors, aiming for an arrangement capable of preventing the influx of excessive solar radiation without compromising adequate natural lighting contribution.

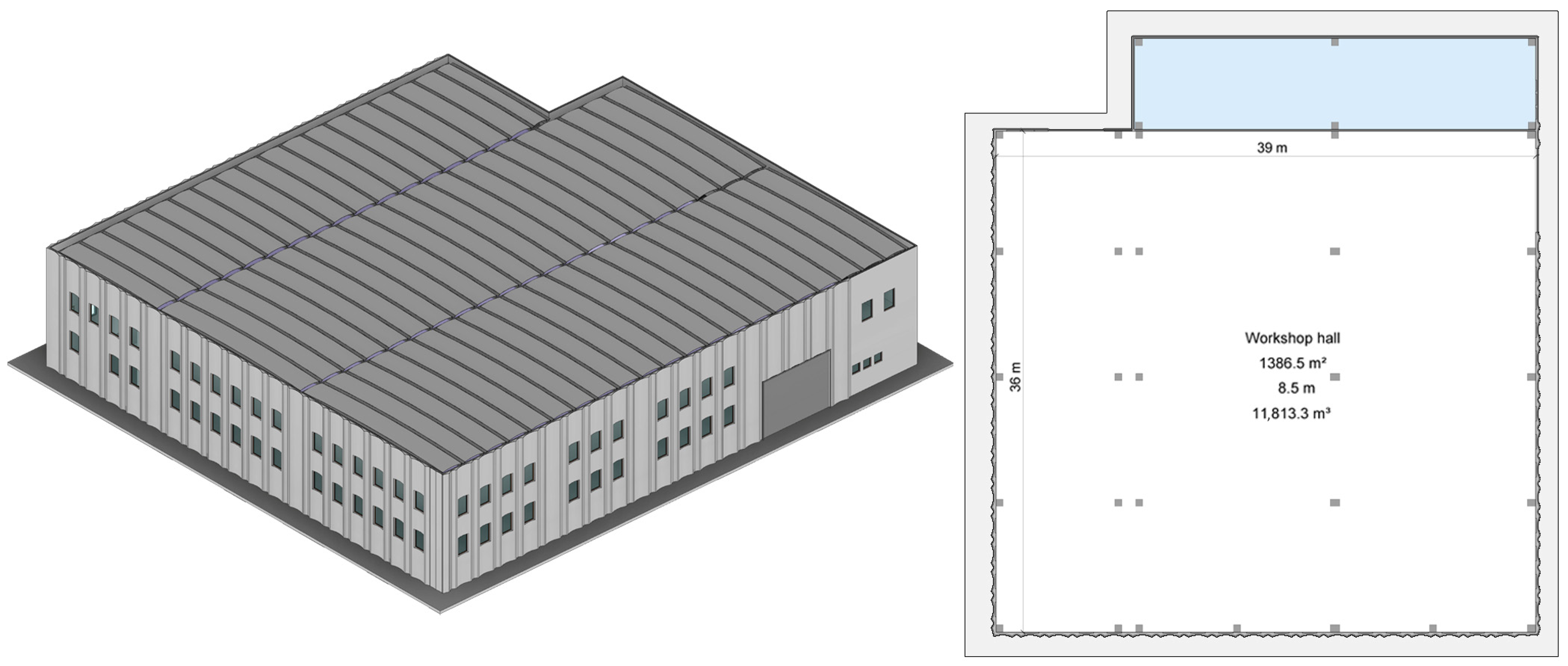

Case Study Building

3. Results

3.1. Optimization of the PV Panels’ Distribution

3.2. Daylight Analysis

3.3. Optimization of Solar Shading Systems

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- REN21. REN21.2023 Renewables 2023 Global Status Report Collection, Global Overview. 2023. Available online: https://www.ren21.net/gsr-2023/modules/global_overview/ (accessed on 27 September 2023).

- United Nations. 2022 Global Status Report for Buildings and Construction. Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector. 2022. Available online: http://globalabc.org/our-work/tracking-progress-global-status-report (accessed on 21 February 2024).

- European Parliament. P9_TA(2023)0068 Prestazione Energetica Nell’edilizia. Emendamenti del Parlamento Europeo, Approvati il 14 Marzo 2023, alla Proposta di Direttiva del Parlamento Europeo e del Consiglio Sulla Prestazione Energetica Nell’edilizia. 2023. Available online: https://eur-lex.europa.eu/legal-content/IT/ALL/?uri=CELEX%3A52021PC0558 (accessed on 26 March 2024).

- European Commission. EU Buiding Stock Observatory. 2017. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/eu-bso_en (accessed on 20 January 2023).

- Banti, N. Existing industrial buildings—A review on multidisciplinary research trends and retrofit solutions. J. Build. Eng. 2024, 84, 108615. [Google Scholar] [CrossRef]

- Minghini, F.; Nerio, T. Seismic Retrofitting Solutions for Precast RC Industrial Buildings Struck by the 2012 Earthquakes in Northern Italy. Built Environ. 2021, 7, 631315. [Google Scholar] [CrossRef]

- Tan, T.; Mills, G.; Papadonikolaki, E.; Liu, Z. Combining multi-criteria decision making (MCDM) methods with building information modelling (BIM): A review. Autom. Constr. 2021, 121, 103451. [Google Scholar] [CrossRef]

- Landim, G.; Digiandomenico, D.; Amaro, J.; Pratschke, A.; Tramontano, M.; Toledo, C. Architectural Optimization and Open Source Development: Nesting and Genetic Algorithms. In Proceedings of the 37th Annual Conference of the Association for Computer Aided Design in Architecture, Cambridge, MA, USA, 2–4 November 2017; pp. 340–349. [Google Scholar]

- Holzer, D. Optioneering in Collaborative Design Practic. J. Archit. Comput. 2018, 8, 165–182. [Google Scholar]

- Bazzocchi, F.; Banti, N.; Biagini, C.; Ciacci, C.; Di Naso, V. Design optioneering for the definition of technological solution of the envelope using BIM. In Proceedings of the 17th IBPSA Conference, Bruges, Belgium, 1–3 September 2022; pp. 1451–1458. [Google Scholar]

- Eltaweel, A.; Su, Y. Parametric design and daylighting: A literature review. Renew. Sustain. Energy Rev. 2017, 73, 1086–1103. [Google Scholar] [CrossRef]

- Stephan, A.; Prideaux, F.; Crawford, R.H. EPiC grasshopper: A bottom-up parametric tool to quantify life cycle embodied environmental flows of buildings and infrastructure assets. Build. Environ. 2024, 248, 111077. [Google Scholar] [CrossRef]

- Liu, Y.; Li, T.; Xu, W.; Wang, Q.; Huang, H.; He, B.J. Building information modelling-enabled multi-objective optimization for energy consumption parametric analysis in green buildings design using hybrid machine learning algorithms. Energy Build. 2023, 300, 113665. [Google Scholar] [CrossRef]

- Bushra, N. A comprehensive analysis of parametric design approaches for solar integration with buildings: A literature review. Renew. Sustain. Energy Rev. 2022, 168, 112849. [Google Scholar] [CrossRef]

- Zhou, Y. Demand response flexibility with synergies on passive PCM walls, BIPVs, and active air-conditioning system in a subtropical climate. Renew. Energy 2022, 199, 204–225. [Google Scholar] [CrossRef]

- Cicelsky, A.; Meir, I.A. Parametric analysis of environmentally responsive strategies for building envelopes specific for hot hyperarid regions. Sustain. Cities Soc. 2014, 13, 279–302. [Google Scholar] [CrossRef]

- Haghighat, S.; Sadeh, H. Parametric design of an automated kinetic building façade using BIM: A case study perspective. J. Build. Eng. 2023, 73, 106800. [Google Scholar] [CrossRef]

- Salimzadeh, N.; Vahdatikhaki, F.; Hammad, A. Parametric modeling and surface-specific sensitivity analysis of PV module layout on building skin using BIM. Energy Build. 2020, 216, 109953. [Google Scholar] [CrossRef]

- Wong, B.C.L.; Wu, Z.; Gan, V.J.L.; Chan, C.M.; Cheng, J.C.P. Parametric building information modelling and optimality criteria methods for automated multi-objective optimisation of structural and energy efficiency. J. Build. Eng. 2023, 75, 107068. [Google Scholar] [CrossRef]

- Espitia-Mesa, G.; Moreno-Villa, A.; Tobón-Echavarría, S.; Rivera, J.C.; Mejía-Gutiérrez, R. Modeling optimal PV surface of BIPVs for maximum energy yield through Genetic Algorithms. Energy Built Environ. 2024, in press. [CrossRef]

- de Sousa Freitas, J.; Cronemberger, J.; Soares, R.M.; Amorim, C.N.D. Modeling and assessing BIPV envelopes using parametric Rhinoceros plugins Grasshopper and Ladybug. Renew. Energy 2020, 160, 1468–1479. [Google Scholar] [CrossRef]

- Fu, Y.; Xu, W.; Wang, Z.; Zhang, S.; Chen, X.; Du, X. Numerical study on comprehensive energy-saving potential of BIPV façade under useful energy utilization for high-rise office buildings in various climatic zones of China. Sol. Energy 2024, 270, 112387. [Google Scholar] [CrossRef]

- Mitsopoulos, G.; Bellos, E.; Tzivanidis, C. Parametric analysis and multi-objective optimization of a solar heating system for various building envelopes. Therm. Sci. Eng. Prog. 2018, 8, 307–317. [Google Scholar] [CrossRef]

- Qingsong, M.; Fukuda, H. Parametric Office Building for Daylight and Energy Analysis in the Early Design Stages. Procedia—Soc. Behav. Sci. 2016, 216, 818–828. [Google Scholar] [CrossRef]

- Alsharif, R.; Arashpour, M.; Golafshani, E.; Rashidi, A.; Li, H. Multi-objective optimization of shading devices using ensemble machine learning and orthogonal design of experiments. Energy Build. 2023, 283, 112840. [Google Scholar] [CrossRef]

- Li, L.; Ma, Q.; Gao, W.; Wei, X. Incorporating users’ adaptive behaviors into multi-objective optimization of shading devices: A case study of an office room in Qingdao. Energy Build. 2023, 301, 113683. [Google Scholar] [CrossRef]

- Reisinger, J.; Zahlbruckner, M.A.; Kovacic, I.; Kán, P.; Wang-Sukalia, X.; Kaufmann, H. Integrated multi-objective evolutionary optimization of production layout scenarios for parametric structural design of flexible industrial buildings. J. Build. Eng. 2022, 46, 103766. [Google Scholar] [CrossRef]

- Dolnikova, E.; Dolnik, B. Comparison of different roof types in terms of lighting conditions in an industrial hall. Adv. Civ. Archit. Eng. 2022, 24, 23–31. [Google Scholar] [CrossRef]

- Mavridou, T.; Doulos, L.T. Evaluation of Different Roof Types Concerning Daylight in Industrial Buildings during the Initial Design Phase: Methodology and Case Study. Buildings 2019, 9, 170. [Google Scholar] [CrossRef]

- Lin, Q.; Kensek, K.; Schiler, M.; Choi, J. Streamlining sustainable design in building information modeling BIM-based PV design and analysis tools. Archit. Sci. Rev. 2021, 64, 467–477. [Google Scholar] [CrossRef]

- Octopus Plugin for Grasshopper. Available online: https://www.food4rhino.com/en/app/octopus (accessed on 17 October 2023).

- Honeybee Plugin for Grasshopper. Available online: https://www.ladybug.tools/honeybee.html (accessed on 17 October 2023).

- UNI EN ISO 12464-1; Illuminazione dei Posti di Lavoro. Ente Nazionale di Normazione: Rome, Italy, 2004.

- Colibri Plugin for Grasshopper. Available online: http://core.thorntontomasetti.com/colibri-release/ (accessed on 17 October 2023).

- DesignExplorer. Available online: https://www.thorntontomasetti.com/capability/design-explorer (accessed on 13 December 2023).

- Governo italiano. Regolamento Recante Norme per la Progettazione, l’installazione, l’esercizio e la Manutenzione degli Impianti Termici degli Edifici ai fini del Contenimento dei Consumi di Energia, in Attuazione dell’art. 4, Comma 4, della legge 9 Gennaio 1991, n. 10; Governo Italiano: Rome, Italy, 1993.

- Nabil, A.; Mardaljevic, J. Useful daylight illuminances: A replacement for daylight factors. Energy Build. 2006, 38, 905–913. [Google Scholar] [CrossRef]

- Katunský, D.; Dolníková, E.; Doroudiani, S. Integrated lighting efficiency analysis in large industrial buildings to enhance indoor environmental quality. Buildings 2017, 7, 47. [Google Scholar] [CrossRef]

- Martín-Chivelet, N.; Gutiérrez, J.C.; Alonso-Abella, M.; Chenlo, F.; Cuenca, J. Building Retrofit with Photovoltaics: Construction and Performance of a BIPV Ventilated Façade. Energies 2018, 11, 1719. [Google Scholar] [CrossRef]

- Reffat, R.M.; Ezzat, R. Impacts of design configurations and movements of PV attached to building facades on increasing generated renewable energy. Sol. Energy 2023, 252, 50–71. [Google Scholar] [CrossRef]

- Paydar, M.A. Optimum design of building integrated PV module as a movable shading device. Sustain. Cities Soc. 2020, 62, 102368. [Google Scholar] [CrossRef]

- Nicoletti, F.; Cucumo, M.A.; Arcuri, N. Building-integrated photovoltaics (BIPV): A mathematical approach to evaluate the electrical production of solar PV blinds. Energy 2023, 263, 126030. [Google Scholar] [CrossRef]

- Menichini, G.; Del Monte, E.; Orlando, M.; Vignoli, A. Out-of-Plane Capacity of Cladding Panel-to-Structure Connections in One-Story R/C Precast Structures; Springer: Dordrecht, The Netherlands, 2020; Volume 18. [Google Scholar]

- Ito, R.; Lee, S. Development of adjustable solar photovoltaic system for integration with solar shading louvers on building façades. Appl. Energy 2024, 359, 122711. [Google Scholar] [CrossRef]

- Nazari, S.; MirzaMohammadi, P.K.; Sajadi, B.; Ha, P.P.; Talatahari, S.; Sareh, P. Designing energy-efficient and visually-thermally comfortable shading systems for office buildings in a cooling-dominant climate. Energy Rep. 2023, 10, 3863–3881. [Google Scholar] [CrossRef]

| Element | Dimensions | |

|---|---|---|

| PV panel | 1.09 m | 0.58 m |

| Louvres blades | 1.10 m | 0.20 m |

| Parameter | Range | Increment |

| PV vertical spacing | 0.5–1.5 m | 0.20 m |

| PV tilt angle | 0–90° | 10° |

| Louvres vertical spacing | 0.20–1 m | 0.20 m |

| Louvres tilt angle | 0–90° | 10° |

| Parameter | Value |

|---|---|

| Heating setpoint | 18 °C |

| Occupancy time | 8:00–17:00 |

| Occupancy | 0.01 people/m2 |

| Metabolic rate | 167 W/person |

| Natural ventilation flow rate | 0.77 m3/s |

| Airtightness | 0.20 ac/h |

| Sheltering coefficient | 0.7 |

| Parameter | Value |

|---|---|

| Maximum power | 110 W |

| Maximum power voltage | 19.6 V |

| Maximum power current | 5.66 A |

| Module efficiency | 17.29% |

| Operating temperature | −40 °C to 85 °C |

| Type of solar cell | Monocrystalline silicon cells |

| Cell size | 166 × 83 mm |

| No. of cells | 36 |

| Temperature coefficient of Voc | −0.28%/°C |

| Temperature coefficient of Isc | 0.02%/°C |

| Latitude | Longitude | Climate Zone | Heating Period | HDD [K/d] | Gh [kWh/m2a] | Dh [kWh/m2a] | Bn [kWh/m2a] | Ta [°C] | Td [°C] | Ws [m/s] |

|---|---|---|---|---|---|---|---|---|---|---|

| 43.34° N | 11.52° E | D | 1/11–15/04 | 2041 | 1447 | 629 | 1496 | 15 | 7.9 | 2.8 |

| Material | Thickness (m) | Conductivity (W/m·K) | Specific Heat (J/kg·K) | Density (kg/m3) |

|---|---|---|---|---|

| Precast concrete | 0.02 | 2.07 | 1000 | 2400 |

| Insulation material (EPS) | 0.045 | 0.04 | 1450 | 15 |

| Precast concrete | 0.02 | 2.07 | 1000 | 2400 |

| Material | Thickness (m) | Conductivity (W/m·K) | Specific Heat (J/kg·K) | Density (kg/m3) |

|---|---|---|---|---|

| Asbestos–cement tiles | 0.01 | 0.6 | 1000 | 1800 |

| Glass wool | 0.06 | 0.04 | 1030 | 12 |

| Air gap | 0.55 | - | - | - |

| Asbestos–cement tiles | 0.01 | 0.6 | 1000 | 1800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banti, N.; Ciacci, C.; Bazzocchi, F.; Di Naso, V. Enhancing Industrial Buildings’ Performance through Informed Decision Making: A Generative Design for Building-Integrated Photovoltaic and Shading System Optimization. Solar 2024, 4, 401-421. https://doi.org/10.3390/solar4030018

Banti N, Ciacci C, Bazzocchi F, Di Naso V. Enhancing Industrial Buildings’ Performance through Informed Decision Making: A Generative Design for Building-Integrated Photovoltaic and Shading System Optimization. Solar. 2024; 4(3):401-421. https://doi.org/10.3390/solar4030018

Chicago/Turabian StyleBanti, Neri, Cecilia Ciacci, Frida Bazzocchi, and Vincenzo Di Naso. 2024. "Enhancing Industrial Buildings’ Performance through Informed Decision Making: A Generative Design for Building-Integrated Photovoltaic and Shading System Optimization" Solar 4, no. 3: 401-421. https://doi.org/10.3390/solar4030018

APA StyleBanti, N., Ciacci, C., Bazzocchi, F., & Di Naso, V. (2024). Enhancing Industrial Buildings’ Performance through Informed Decision Making: A Generative Design for Building-Integrated Photovoltaic and Shading System Optimization. Solar, 4(3), 401-421. https://doi.org/10.3390/solar4030018