Wind Energy Potential Ranking of Meteorological Stations of Iran and Its Energy Extraction by Piezoelectric Element

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Collection and Stations Description

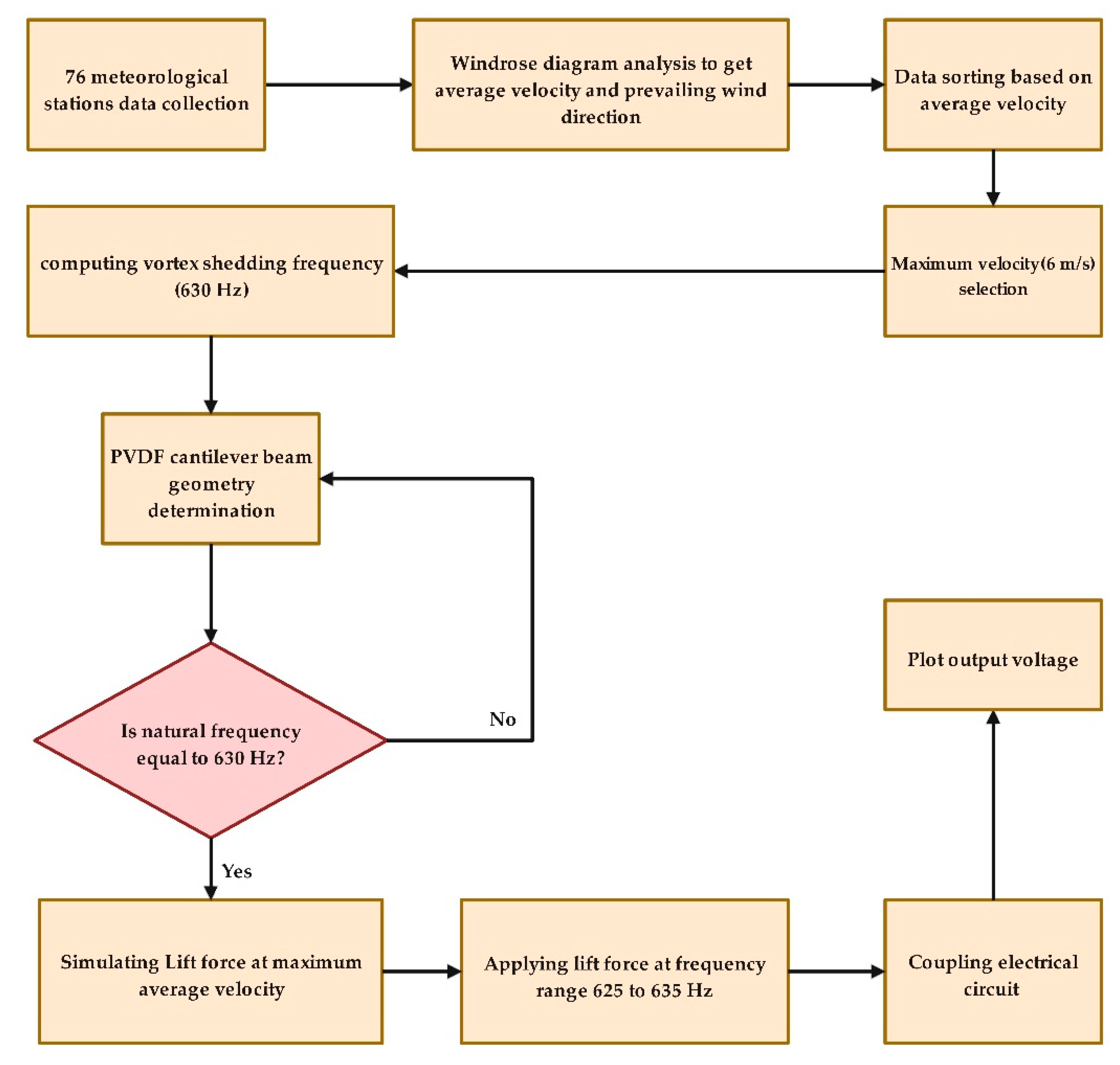

2.2. Simulation Procedure

Energy Harvesting Simulation

3. Results and Discussion

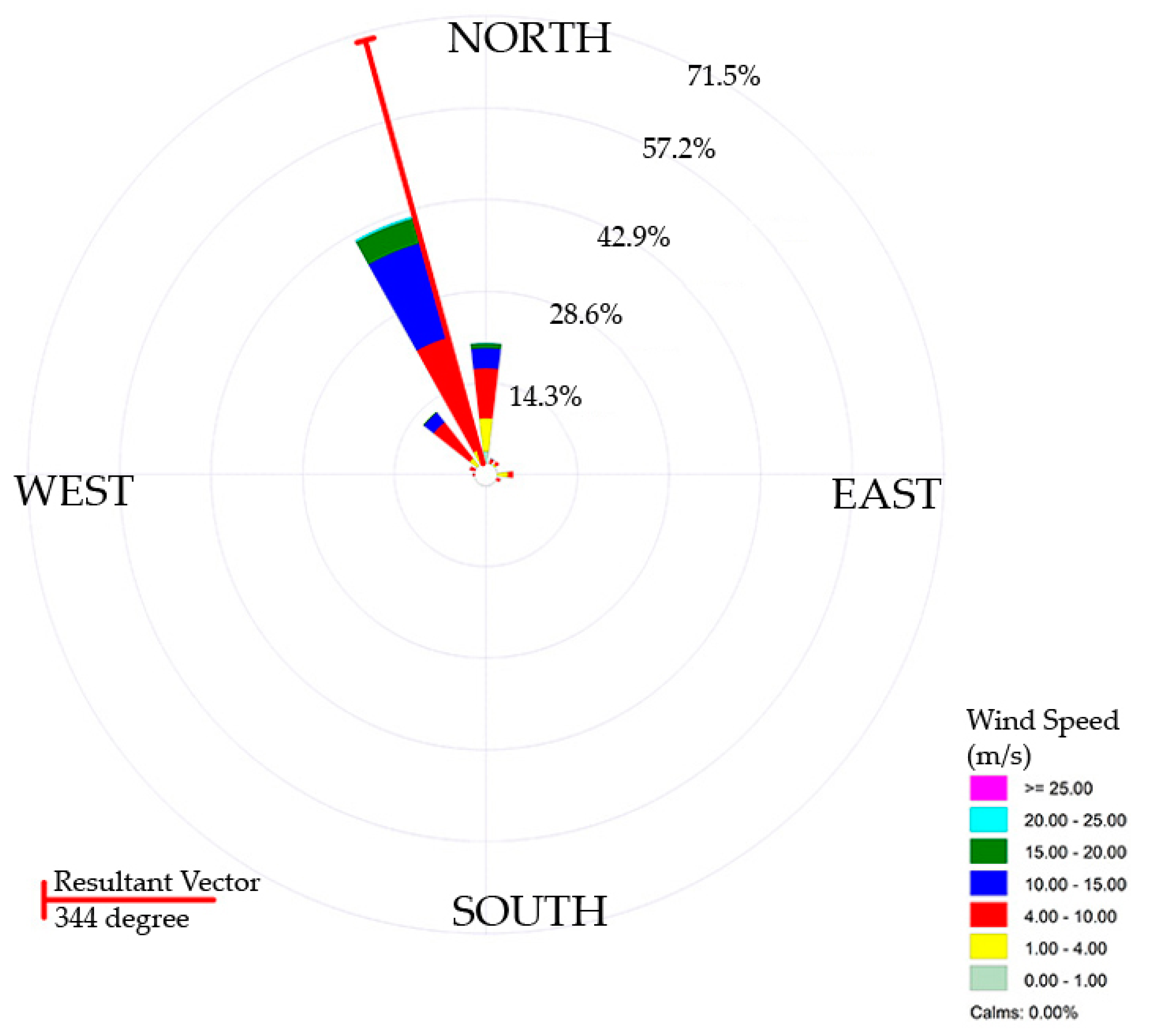

3.1. Zabol

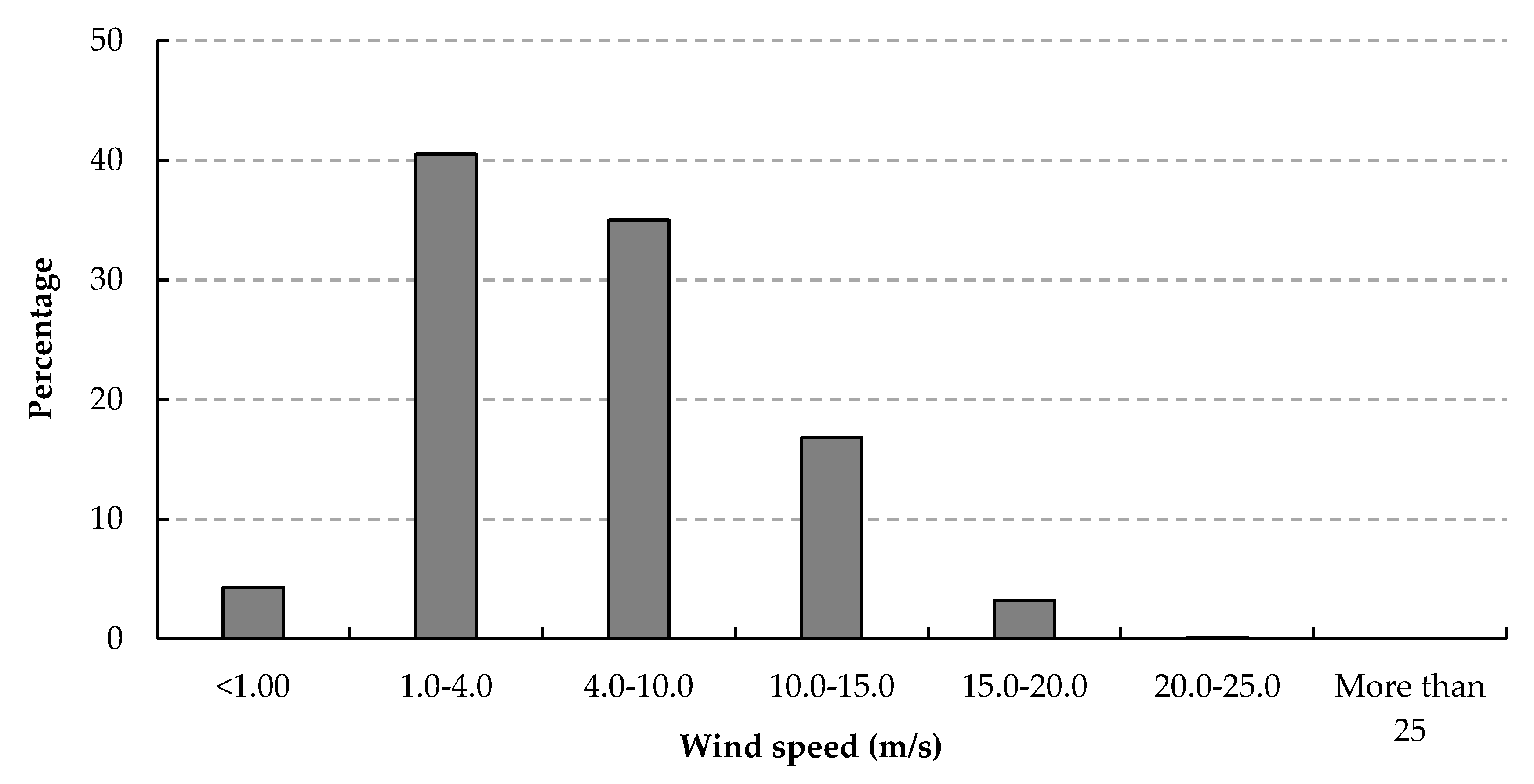

3.2. Siri Island

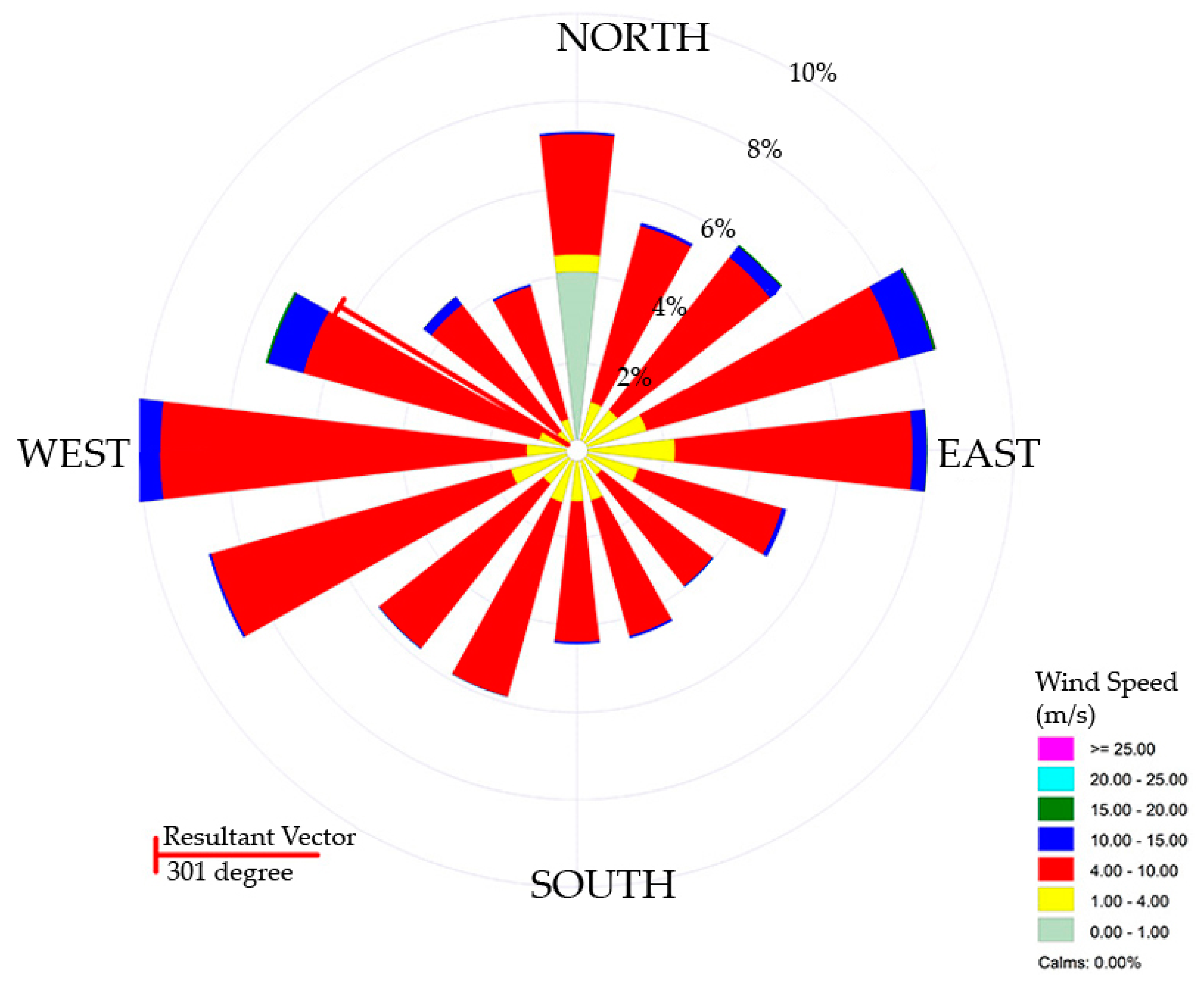

3.3. Aligudarz

3.4. Energy Harvesting Simulation

3.4.1. Lift Force

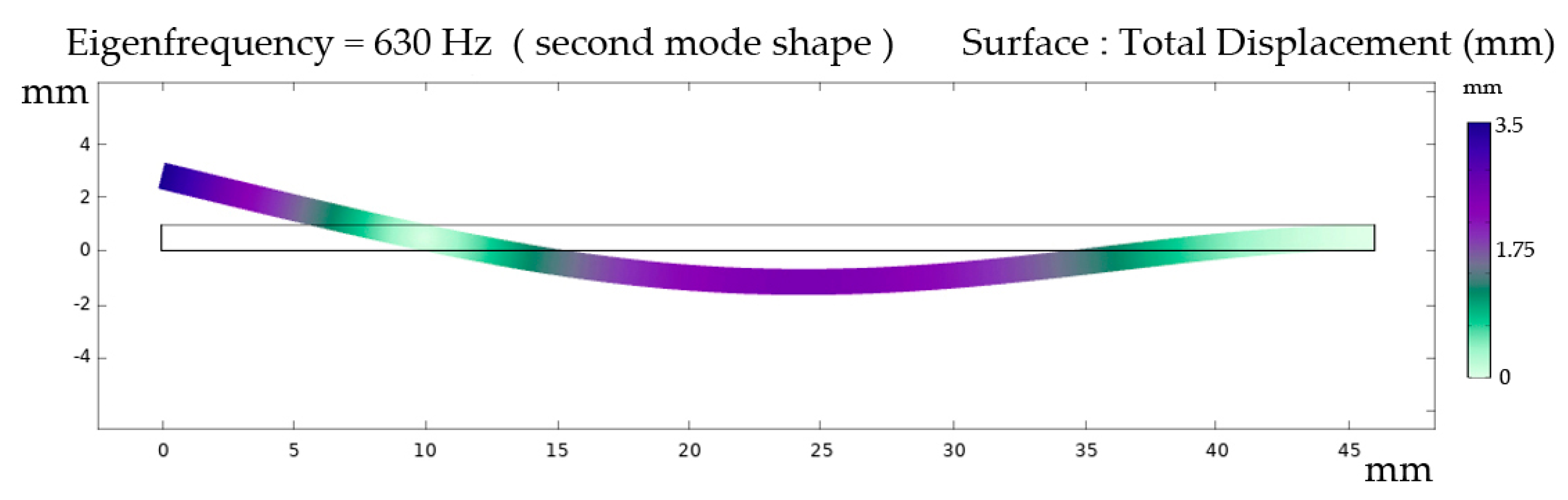

3.4.2. Simulation Based on Piezoelectric Beam I

3.4.3. Simulation Based on Piezoelectric Beam II

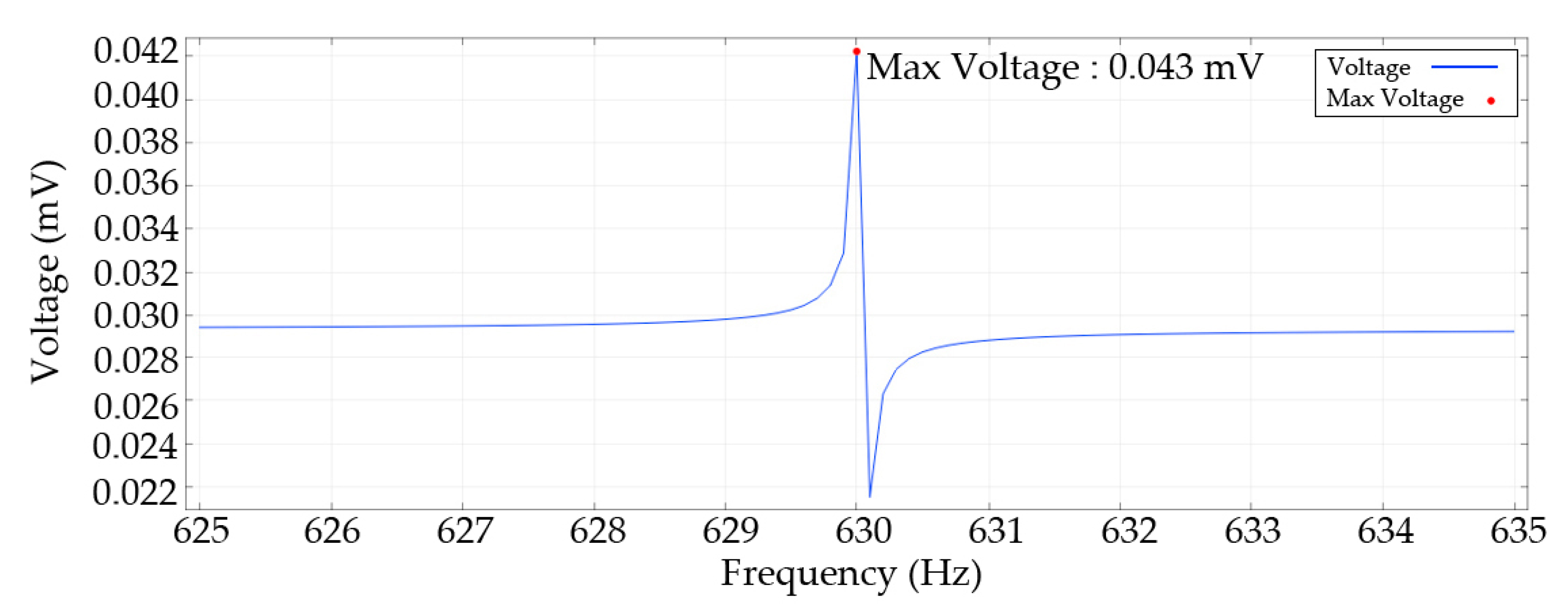

3.4.4. Simulation Based on Piezoelectric Beam III

4. Conclusions

- The maximum voltage of 1.17 mV has been harvested from the piezoelectric element with dimensions of 18.5 × 1.0016 mm.

- From the second piezoelectric element with 46 × 0.99021 mm dimensions, which has a natural frequency of 630 Hz at its second mode, a voltage of 1.52 mV was extracted.

- The third element with dimensions of 55 × 0.5503 mm, which has a natural frequency of 630 Hz in its third shape mode, can also pick up the maximum voltage of 0.043 mV during amplification.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Density | |

| Dynamic Viscosity | |

| V | Wind Speed |

| D | Diameter of the bluff body |

| St | Strouhal number |

| 𝑑 | Piezoelectric Charge constant |

| s | Compliance of Piezoelectric |

| g | Piezoelectric Voltage coefficient |

| Vortex Shedding frequency | |

| Reynolds number | |

| ε | Dielectric Permittivity |

| k | Electromechanical Coupling factor |

References

- Pudasainee, D.; Kurian, V.; Gupta, R. 2-Coal: Past, Present, and Future Sustainable Use; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Mahmoodi, K.; Ghassemi, H.; Razminia, A. Wind Energy Potential Assessment in the Persian Gulf: A Spatial and Temporal Analysis. Ocean Eng. 2020, 216, 107674. [Google Scholar] [CrossRef]

- Potić, I.; Joksimović, T.; Milinčić, U.; Kićović, D.; Milinčić, M. Wind Energy Potential for the Electricity Production—Knjaževac Municipality Case Study (Serbia). Energy Strategy Rev. 2021, 33, 100589. [Google Scholar] [CrossRef]

- Fazelpour, F.; Markarian, E.; Soltani, N. Wind Energy Potential and Economic Assessment of Four Locations in Sistan and Balouchestan Province in Iran. Renew. Energy 2017, 109, 646–667. [Google Scholar] [CrossRef]

- Renewables Consulting Group. Global Offshore Wind: Annual Market Report 2020; Norwegian Energy Partners: Stavanger, Norway, 2020. [Google Scholar]

- Allaei, D.; Andreopoulos, Y. INVELOX: Description of a New Concept in Wind Power and its Performance Evaluation. Energy 2014, 69, 336–344. [Google Scholar] [CrossRef]

- Chizfahm, A.; Yazdi, E.A.; Eghtesad, M. Dynamic Modeling of Vortex Induced Vibration Wind Turbines. Renew. Energy 2018, 121, 632–643. [Google Scholar] [CrossRef]

- Zheng, C.; Liu, Z.; Wu, T.; Wang, H.; Wu, Y.; Shi, X. Experimental Investigation of Vortex-Induced Vibration of a Thousand-Meter-Scale Mega-Tall Building. J. Fluids Struct. 2019, 85, 94–109. [Google Scholar] [CrossRef]

- Lefebure, D.; Dellinger, N.; François, P.; Mosé, R. Analytical and CFD Study of the Influence of Control Parameters on the Maximum Efficiency of a Hydro-Power Conversion System Based on Vortex-Induced Vibrations. Renew. Energy. 2020, 155, 369–377. [Google Scholar] [CrossRef]

- Hamlehdar, M.; Kasaeian, A.; Safaei, M.R. Energy Harvesting from Fluid Flow using Piezoelectrics: A Critical Review. Renew. Energy 2019, 143, 1826–1838. [Google Scholar] [CrossRef]

- Orrego, S.; Shoele, K.; Ruas, A.; Doran, K.; Caggiano, B.; Mittal, R.; Kang, S.H. Harvesting Ambient Wind Energy with an Inverted Piezoelectric Flag. Appl. Energy 2017, 194, 212–222. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, L.; Luo, G.; Zhao, Y.; Yang, P.; Jiang, Z.; Maeda, R. System Level Design of Wireless Sensor Node Powered by Piezoelectric Vibration Energy Harvesting. Sens. Actuators A Phys. 2020, 310, 112039. [Google Scholar] [CrossRef]

- Asthana, P.; Khanna, G. A Broadband Piezoelectric Energy Harvester for IoT Based Applications. Microelectron. J. 2019, 93, 104635. [Google Scholar] [CrossRef]

- Surmenev, R.A.; Orlova, T.; Chernozem, R.V.; Ivanova, A.A.; Bartasyte, A.; Mathur, S.; Surmeneva, M.A. Hybrid Lead-Free Polymer-Based Nanocomposites with Improved Piezoelectric Response for Biomedical Energy-Harvesting Applications: A Review. Nano Energy 2019, 62, 475–506. [Google Scholar] [CrossRef]

- Petrini, F.; Gkoumas, K. Piezoelectric Energy Harvesting from Vortex Shedding and Galloping Induced Vibrations Inside HVAC Ducts. Energy Build. 2018, 158, 371–383. [Google Scholar] [CrossRef]

- Hosseinalizadeh, R.; Sadat Rafiei, E.; Alavijeh, A.S.; Ghaderi, S.F. Economic Analysis of Small Wind Turbines in Residential Energy Sector in Iran. Sustain. Energy Technol. Assess. 2017, 20, 58–71. [Google Scholar] [CrossRef]

- Tizpar, A.; Satkin, M.; Roshan, M.B.; Armoudli, Y. Wind Resource Assessment and Wind Power Potential of Mil-E Nader Region in Sistan and Baluchestan Province, Iran—Part 1: Annual Energy Estimation. Energy Convers. Manag. 2014, 79, 273–280. [Google Scholar] [CrossRef]

- Zheng, M.; Han, D.; Gao, S.; Wang, J. Numerical Investigation of Bluff Body for Vortex Induced Vibration Energy Harvesting. Ocean Eng. 2020, 213, 107624. [Google Scholar] [CrossRef]

- Kan, J.; Fan, C.; Wang, S.; Zhang, Z.; Wen, J.; Huang, L. Study on a Piezo-Windmill for Energy Harvesting. Renew. Energy 2016, 97, 210–217. [Google Scholar] [CrossRef]

- Arionfard, H.; Nishi, Y. Experimental Investigation on the Performance of a Double-Cylinder Flow-Induced Vibration (FIV) Energy Converter. Renew. Energy 2019, 134, 267–275. [Google Scholar] [CrossRef]

- Gu, M.; Song, B.; Zhang, B.; Mao, Z.; Tian, W. The Effects of Submergence Depth on Vortex-Induced Vibration (VIV) and Energy Harvesting of a Circular Cylinder. Renew. Energy 2020, 151, 931–945. [Google Scholar] [CrossRef]

- Yayla, S.; Ayça, S.; Oruç, M. A Case Study on Piezoelectric Energy Harvesting with using Vortex Generator Plate Modeling for Fluids. Renew. Energy 2020, 157, 1243–1253. [Google Scholar] [CrossRef]

- Lai, Z.; Wang, S.; Zhu, L.; Zhang, G.; Wang, J.; Yang, K.; Yurchenko, D. A Hybrid Piezo-Dielectric Wind Energy Harvester for High-Performance Vortex-Induced Vibration Energy Harvesting. Mech. Syst. Signal Process. 2021, 150, 107212. [Google Scholar] [CrossRef]

- Li, X.; Bi, C.; Li, Z.; Liu, B.; Wang, T.; Zhang, S. A Piezoelectric and Electromagnetic Hybrid Galloping Energy Harvester with the Magnet Embedded in the Bluff Body. Micromachines 2021, 12, 626. [Google Scholar] [CrossRef] [PubMed]

- Song, R.; Hou, C.; Yang, C.; Yang, X.; Guo, Q.; Shan, X. Modeling, Validation, and Performance of Two Tandem Cylinder Piezoelectric Energy Harvesters in Water Flow. Micromachines 2021, 12, 872. [Google Scholar] [CrossRef]

- Zhao, L.; Tang, L.; Yang, Y. Comparison of Modeling Methods and Parametric Study for a Piezoelectric Wind Energy Harvester. Smart Mater. Struct. 2013, 22, 125003. [Google Scholar] [CrossRef]

- Su, W.-J.; Wang, Z.-S. Development of a Non-Linear Bi-Directional Vortex-Induced Piezoelectric Energy Harvester with Magnetic Interaction. Sensors 2021, 21, 2299. [Google Scholar] [CrossRef]

- Koçak, K. Practical Ways of Evaluating Wind Speed Persistence. Energy 2008, 33, 65–70. [Google Scholar] [CrossRef]

- Esfandeh, S.; Danehkar, A.; Salmanmahiny, A.; Sadeghi, S.M.M.; Marcu, M.V. Climate Change Risk of Urban Growth and Land Use/Land Cover Conversion: An In-Depth Review of the Recent Research in Iran. Sustainability 2022, 14, 338. [Google Scholar] [CrossRef]

- Abdi, E.; Samdaliry, H.; Ghalandarayeshi, S.H.; Khoramizadeh, A.; Sohrabi, H.; Deljouei, A.; Kvist Johannsen, V.; Etemad, V. Modeling wind-driven tree mortality: The effects of forest roads. Austrian J. For. Sci. 2020, 137, 1–21. [Google Scholar]

- Nazari, M.; Chaichi, M.R.; Kamel, H.; Grismer, M.; Sadeghi, S.M.M. Evaluation of Estimation Methods for Monthly Reference Evapotranspiration in Arid Climates. Arid. Ecosyst. 2020, 10, 329–336. [Google Scholar] [CrossRef]

- White, F.M. Viscous Fluid Flow, 3rd ed.; McGraw–Hill: New York, NY, USA, 2006. [Google Scholar]

- Jokar, H.; Mahzoon, M.; Vatankhah, R. Nonlinear Dynamic Characteristics of Horizontal-Axis Wind Turbine Blades Including Pre-Twist. Ocean Eng. 2022, 256, 111441. [Google Scholar] [CrossRef]

- Aravindhan, N.; Natarajan, M.P.; Ponnuvel, S.; Devan, P.K. Performance Analysis of Shrouded Invelox Wind Collector in the Built Environment. Sci. Technol. Built Environ. 2022, 28, 677–689. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| 25 × 10−12 (C/N) | |

| 1.5 × 108 (unitless) | |

| Ε | 12 (C/Vm) |

| 8.85 × 10−12 (C/Vm) | |

| 0.00088277 (CV/Nm) | |

| 0.235 (Vm/N) |

| # | Beam Thickness (mm) | Beam Length (mm) | Moment of Inertia (mm4) | Mode Shape | Natural Frequency (Hz) |

|---|---|---|---|---|---|

| I | 1.0016 | 18.5000 | 0.0837 | First | 630 |

| II | 0.9902 | 46.0000 | 0.0809 | Second | 630 |

| III | 0.5053 | 55.0000 | 0.0107 | Third | 630 |

| Velocity (m/s) | 1 | 2 | 3 | 4 | 5 | 6 |

| Lift Force (N/m) | 0.003 | 0.018 | 0.055 | 0.099 | 1.666 | 0.240 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agah, M.; Sajadian, K.A.; Khanali, M.; Sadeghi, S.M.M.; Khanbazi, M.; Marcu, M.V. Wind Energy Potential Ranking of Meteorological Stations of Iran and Its Energy Extraction by Piezoelectric Element. Knowledge 2022, 2, 508-524. https://doi.org/10.3390/knowledge2030030

Agah M, Sajadian KA, Khanali M, Sadeghi SMM, Khanbazi M, Marcu MV. Wind Energy Potential Ranking of Meteorological Stations of Iran and Its Energy Extraction by Piezoelectric Element. Knowledge. 2022; 2(3):508-524. https://doi.org/10.3390/knowledge2030030

Chicago/Turabian StyleAgah, Mohammad, Khalil Allah Sajadian, Majid Khanali, Seyed Mohammad Moein Sadeghi, Mehdi Khanbazi, and Marina Viorela Marcu. 2022. "Wind Energy Potential Ranking of Meteorological Stations of Iran and Its Energy Extraction by Piezoelectric Element" Knowledge 2, no. 3: 508-524. https://doi.org/10.3390/knowledge2030030

APA StyleAgah, M., Sajadian, K. A., Khanali, M., Sadeghi, S. M. M., Khanbazi, M., & Marcu, M. V. (2022). Wind Energy Potential Ranking of Meteorological Stations of Iran and Its Energy Extraction by Piezoelectric Element. Knowledge, 2(3), 508-524. https://doi.org/10.3390/knowledge2030030