1. Introduction

Non-linear control theory research frequently uses Inverted Pendulum Systems (IPSs) [

1] as an example of unstable, underactuated systems [

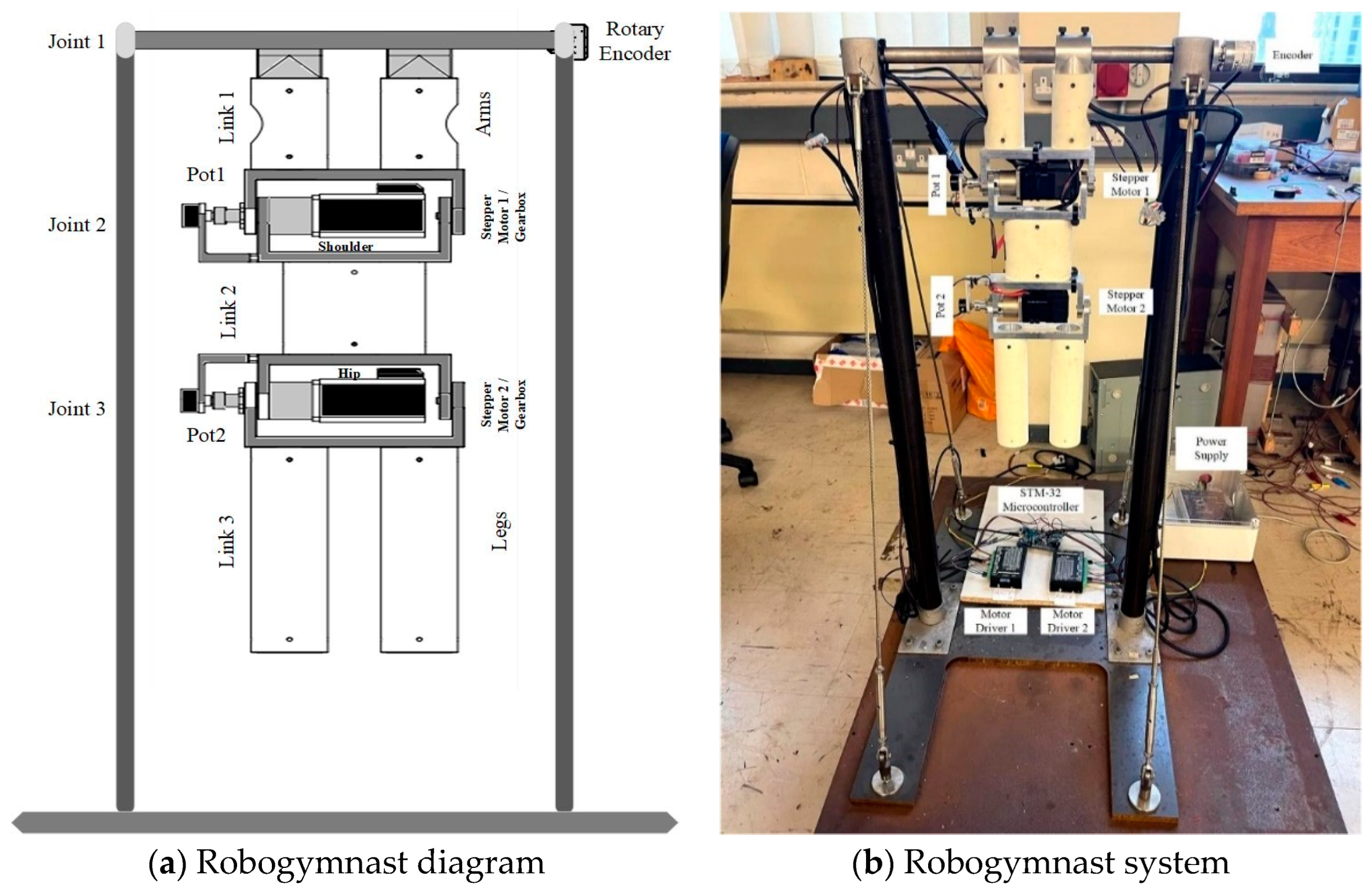

2]. Continuing work to develop novel control technology reflects advances made across a range of areas within the realm of science and technology. Effective measurement of a control system can be achieved through the design and application of a controller with a specific system, to monitor its activities. This paper presents an investigation of swing-up movement in the Robogymnast as a three-link, non-linear robotic system [

3]. The Robogymnast exemplifies complex mechanical systems with more than one link and with underactuation and is therefore a suitable case study for evaluating and comparing different types of control system [

4]. The underactuated system presents control challenges because of the lack of ability to linearise full-state feedback about a specific point of equilibrium in many of these systems, as well as potentially not being small-time local controllable (STLC) [

5]. Various research has been conducted to address this issue in the control engineering and robotics literature [

6]. An inverted pendulum-derived system is a frequent choice with which to demonstrate an underactuated mechanism. This type of system has a component attached to a set point from which it swings freely, and gravity acts upon this component. Motion control investigations frequently employ pendulum systems, which enable hybrid and chaotic systems to be demonstrated [

7,

8,

9].

The triple-inverted pendulum mechanism is of interest to the robotics field because it is analogous to the way in which human bodies are structured and achieve balance. The Acrobat robotic system, named for its similarities to acrobatic movements, is an unstable and underactuated system based on an inverted pendulum, and is therefore an appropriate model for studies of non-linear controls in theory and in implementation [

6,

10]. The Acrobat was used with a designed intelligent control system to allow the robot to balance, with the design combining a conventional controller with fuzzy and adaptive-fuzzy controllers, to achieve swing and catch actions and to balance in inversion [

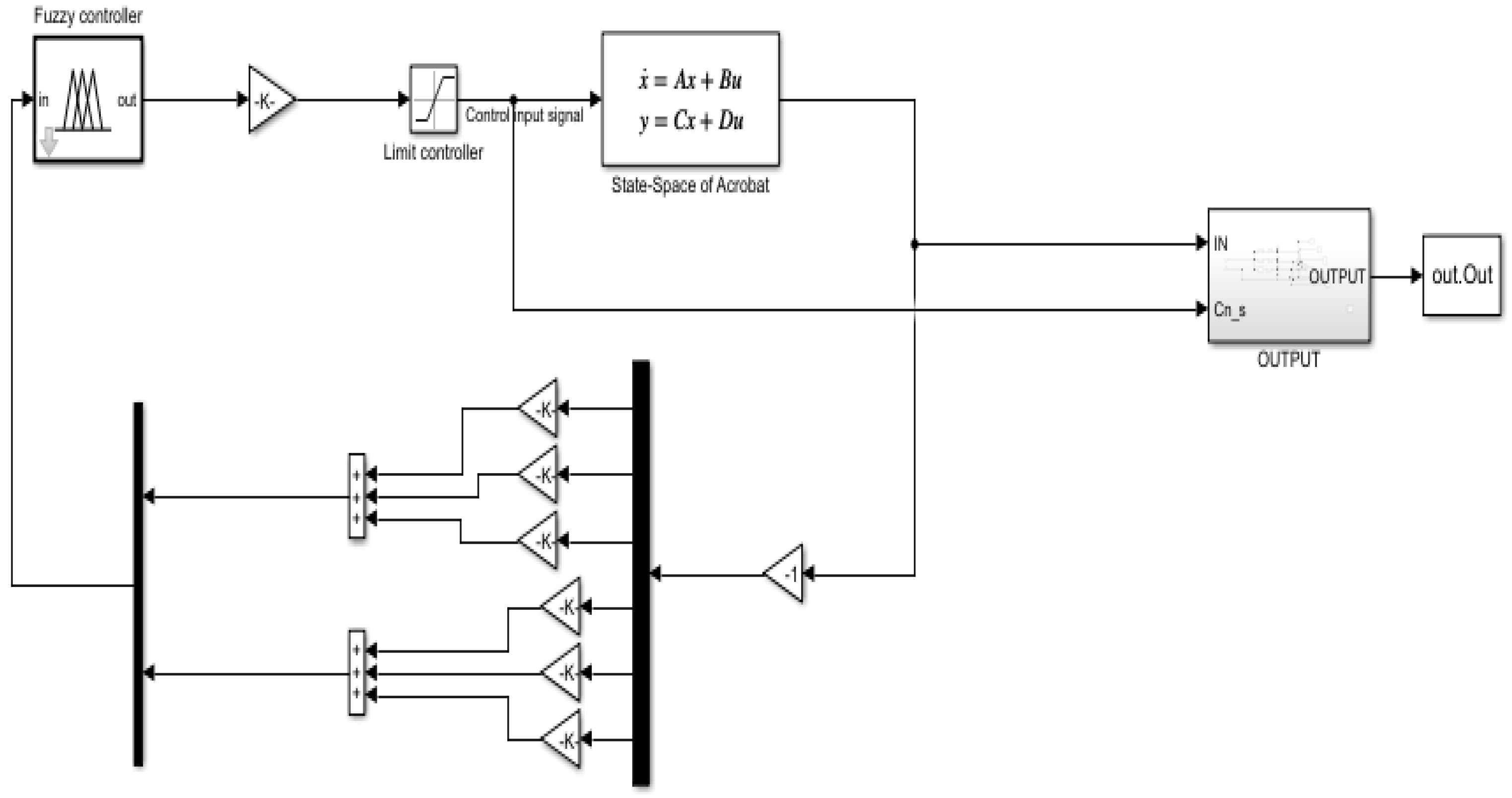

9]. State variable feedback was utilised here, as well as LQR and proportional-integral-derivative.

In brief, the novelty of this work is to apply and compare a different controller on a multi-link robotic system, to analyse and review the stability and robustness of both proposed controllers’ performance, and then investigate the performance of the normal conventional LQR compared with the hybrid fuzzy LQR successfully implemented in various cases by adding and subtracting ±25% and ±50% to the system.

In this work, the paper is organised as follows.

Section 2 describes the relative study and examination of previous research;

Section 3 contains two parts, which are, firstly, an overview of the system, as well as the mathematical model of the Robogymnast analysed; fourthly, the control design of LQR and FLQR are presented. Moreover,

Section 5 presents the robustness investigation for the proposed controller, followed by the results and comparison of all suggested cases. Lastly, we summarize the investigation and future outcomes of the system are mentioned.

2. Literature Review

Various studies [

11,

12,

13,

14,

15,

16] examine autonomous upswing for a three-link robot with a single non-actuated and two actuated joints. The current study’s contribution to this area involves assessing the use of an LQR controller and a fuzzy LQR controller when applied with the Robogymnast: a robot with multiple links and a pendulum action. The robotic system used is described in

Section 2, and a discussion of the system’s mathematical model is also given.

Section 3 considers the upswing control problem, while

Section 4 describes the application of each controller to the Robogymnast and details the responses recorded. Then,

Section 5 discusses the simulation and its findings, while

Section 6 provides the study’s conclusions.

Earlier studies [

17,

18,

19] demonstrate LQR as an active method for designing controllers for the performance of complex systems. In addition, state feedback control (SFC) operates based on where the system’s poles are located, which depends upon state variables and K as the gain matrix. Using SFC, the location of closed-loop system poles can be freely set, while, when using output feedback controls, poles are located at predefined points. The controller used combines LQR as an optimal control method with fuzzy approaches to control [

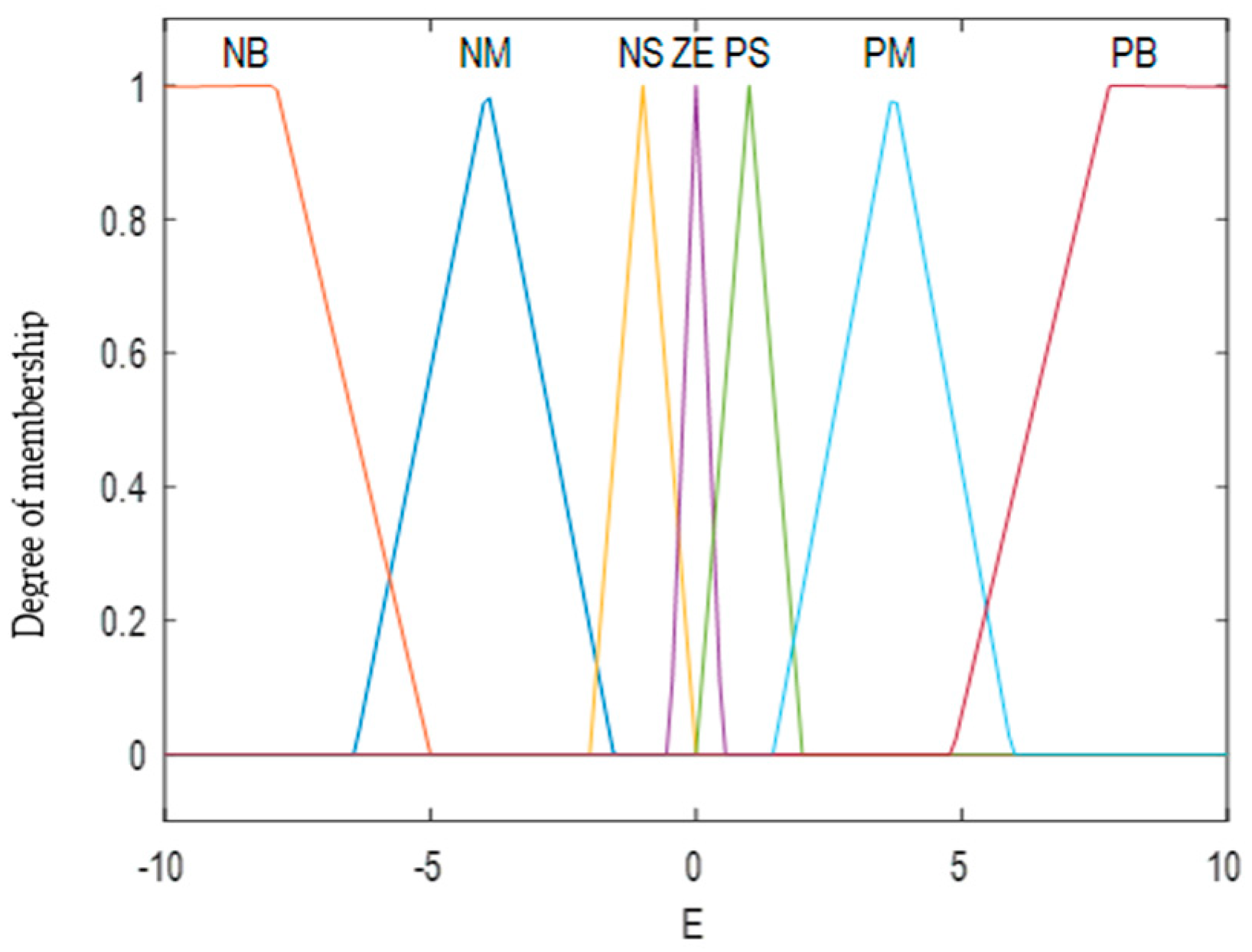

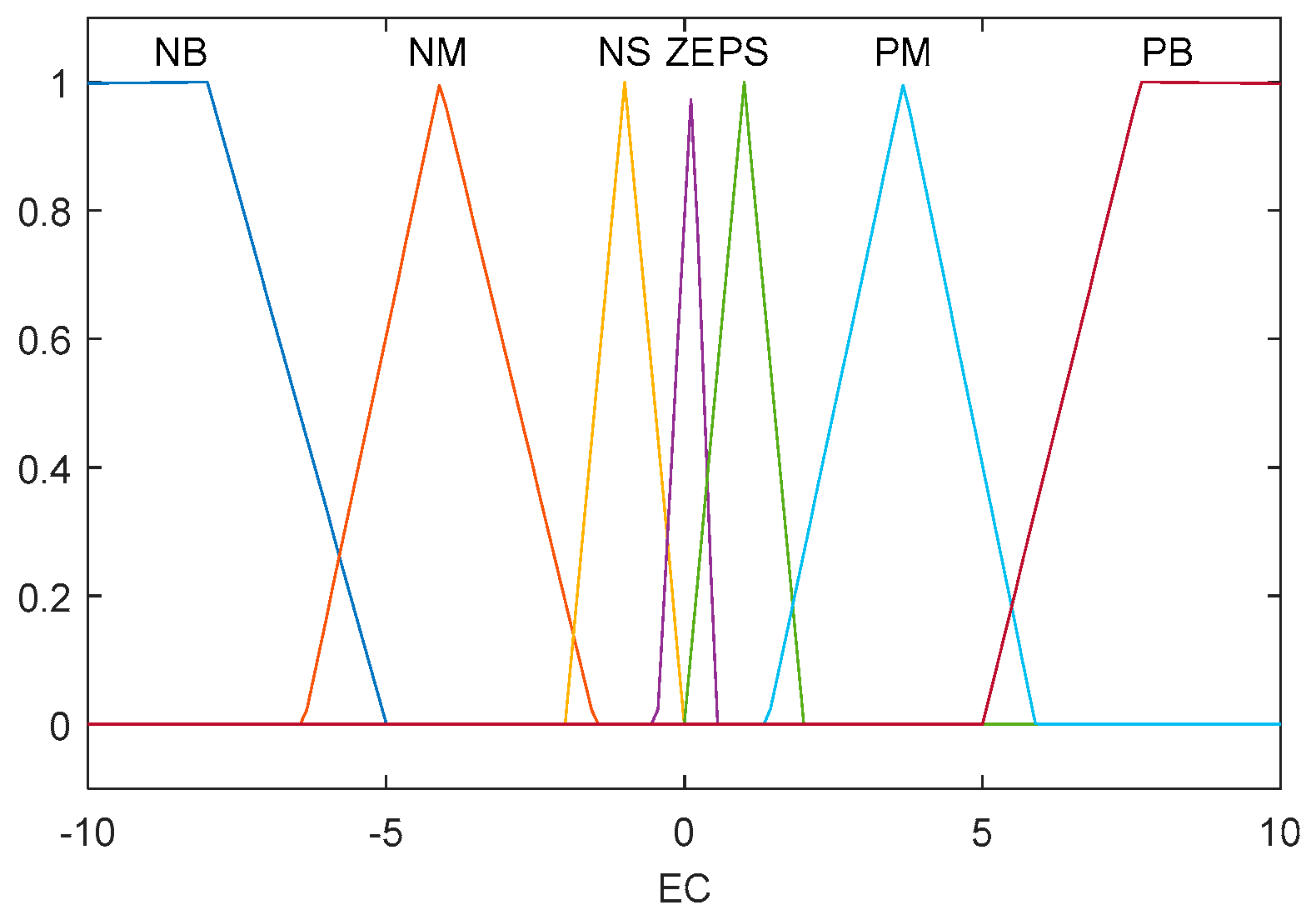

20]. A fuzzy logic control system is rule-based, and depends centrally on a Fuzzy Control Rule (FCR) set connected through fuzzy implication as well as the compositional rule of inference [

21]. FPD controllers use a combination of a PD and fuzzy logic controller [

22], and the choice of this controller type to bring stability to the Robogymnast was made here because the system is non-linearly unstable, and FDP can address this issue and stabilise the robot [

23]. The PD controller is a feedback controller whose output is a control variable, generally derived from error (e) when a comparison is made of a process variable’s (PV’s) reference value as set by the user against the measured value. The error is then used by the different elements within the controller to choose a particular action [

18]. Employed-feedback proportional integral derivative (PID) controllers are widely used for co-ordinating industrial controls, as well as in any context where controls must be modulated on an ongoing basis. A PID controller works by analysing and measuring errors using the difference between the target set-point (SP) and the measured value of the PV, making real-time modifications based on integral (I), derivative (D) and proportional (P) terms. In practice, this results in automated, accurate responses in altering a control function. Through increasing system capabilities, the PID algorithm used by the controller brings the output measured into line with desired inputs while minimising deferral error [

24]. Modelling and simulation of both PID and LQR controllers for use to control the Robogymnast took place in MATLAB/Simulink. Within this, a PID controller was developed and implemented with the robotic pendulum system and its performance compared to that of the conventional LQR controller [

25]. The initial stage involved creating a mathematical model of the robotic system and then modelling a robotics manipulation drive with PI [

19].

6. Discussion

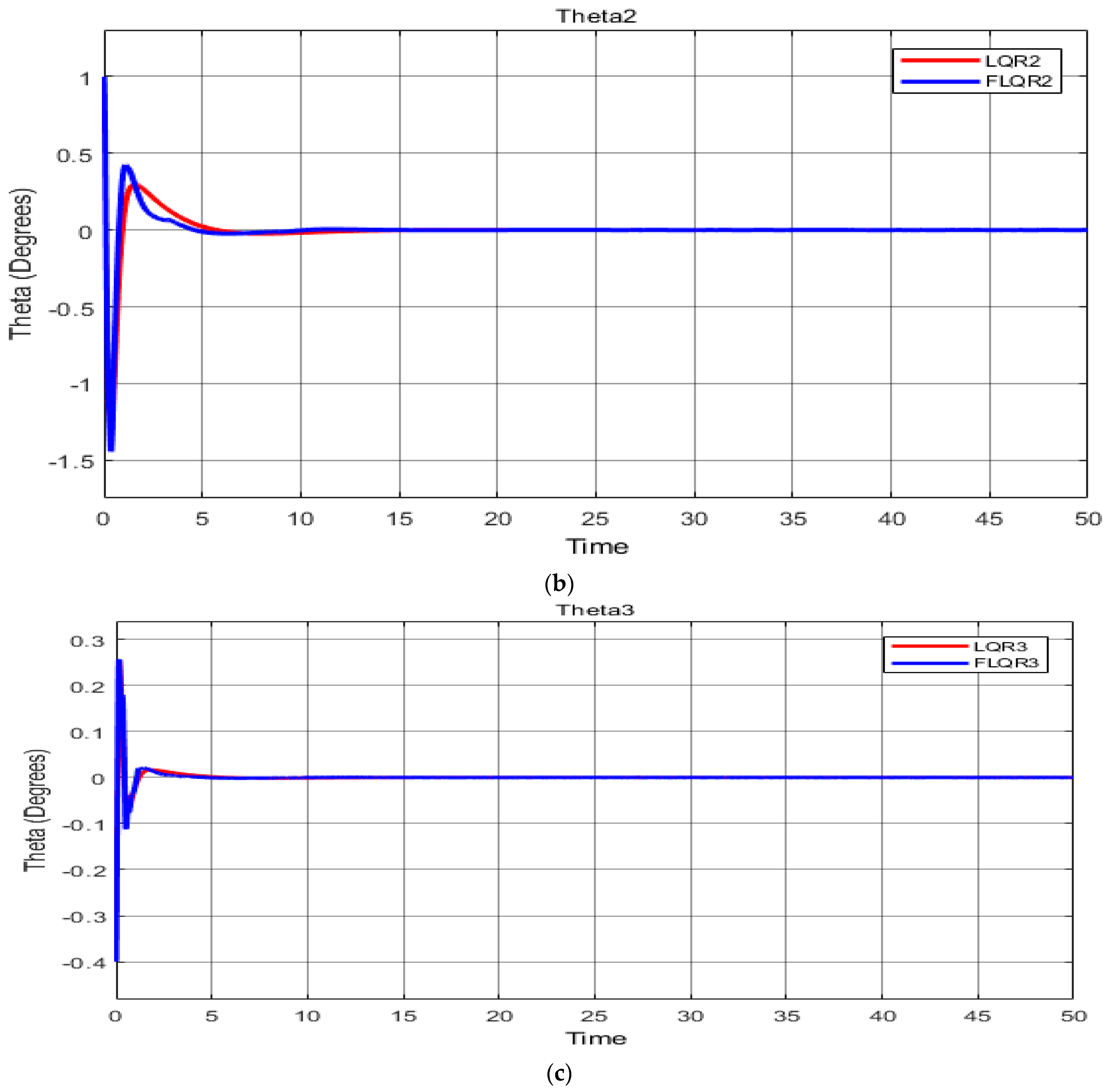

The proposed FLQR controller, as a combined LQR and fuzzy logic control method, performed well for the three-link Robogymnast robotics system, with the examination of the system’s robustness showing that it outperformed the conventional controller across all variables, including time to settle and under- and over-shoot. A more detailed summary of the findings for robustness is provided here.

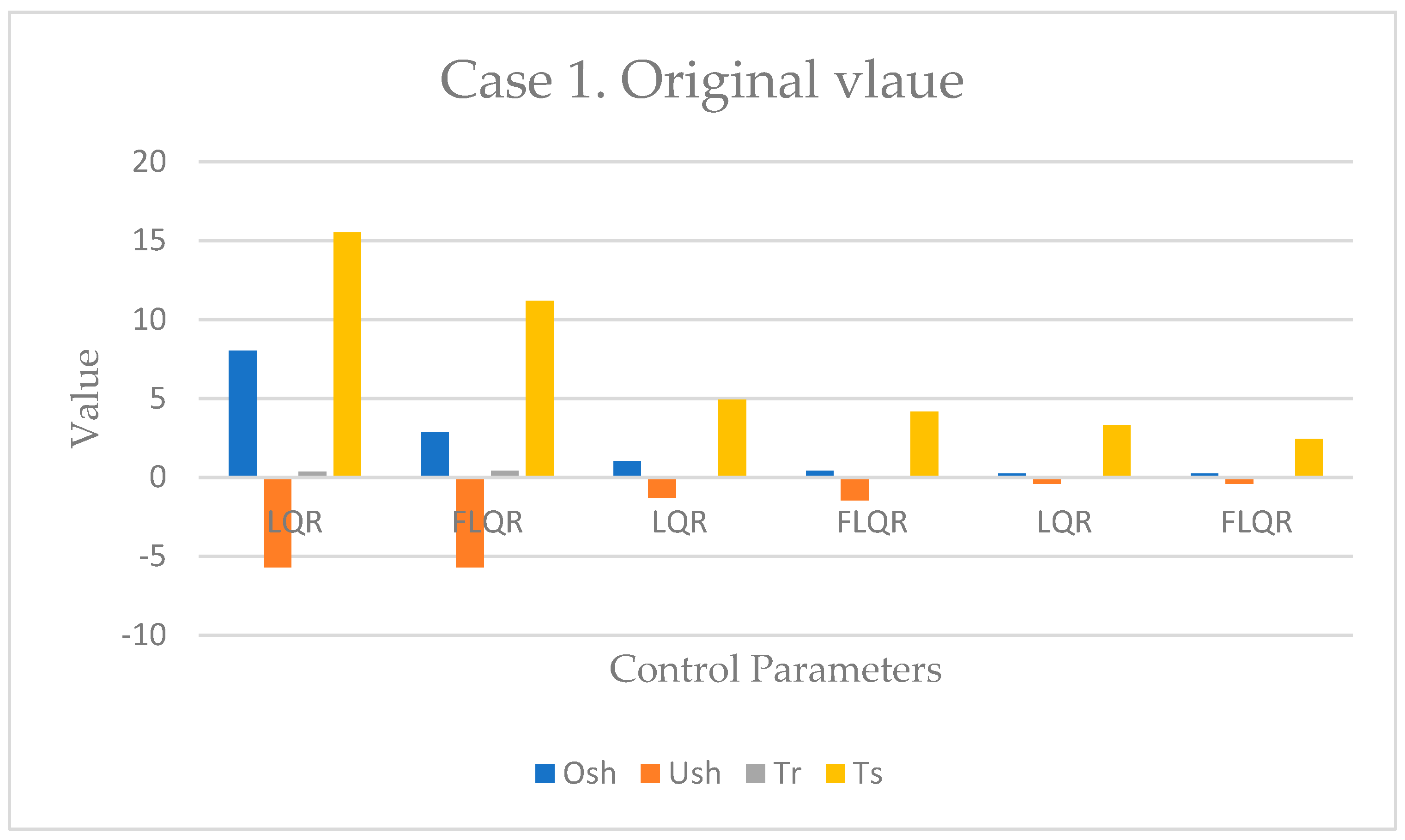

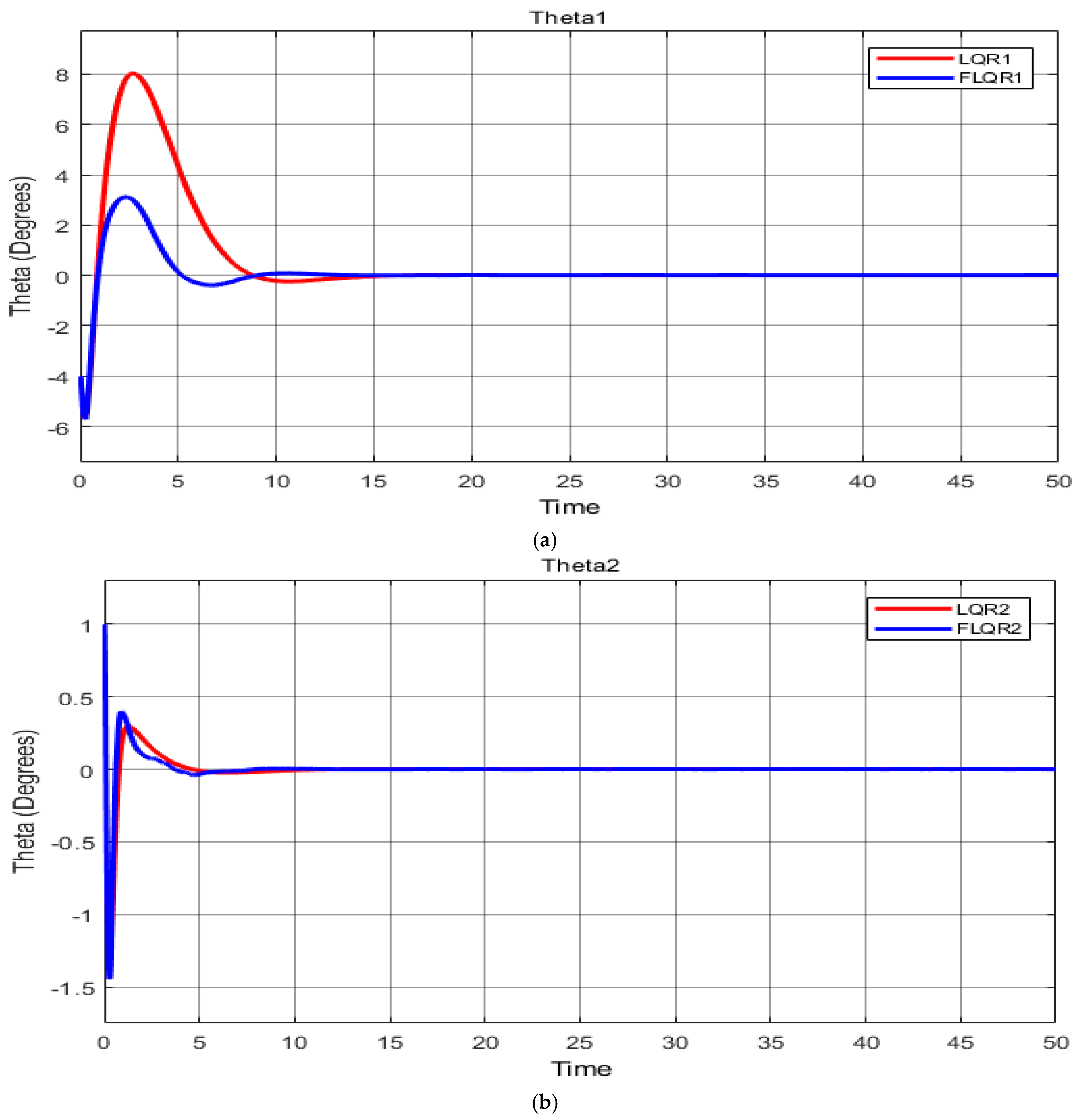

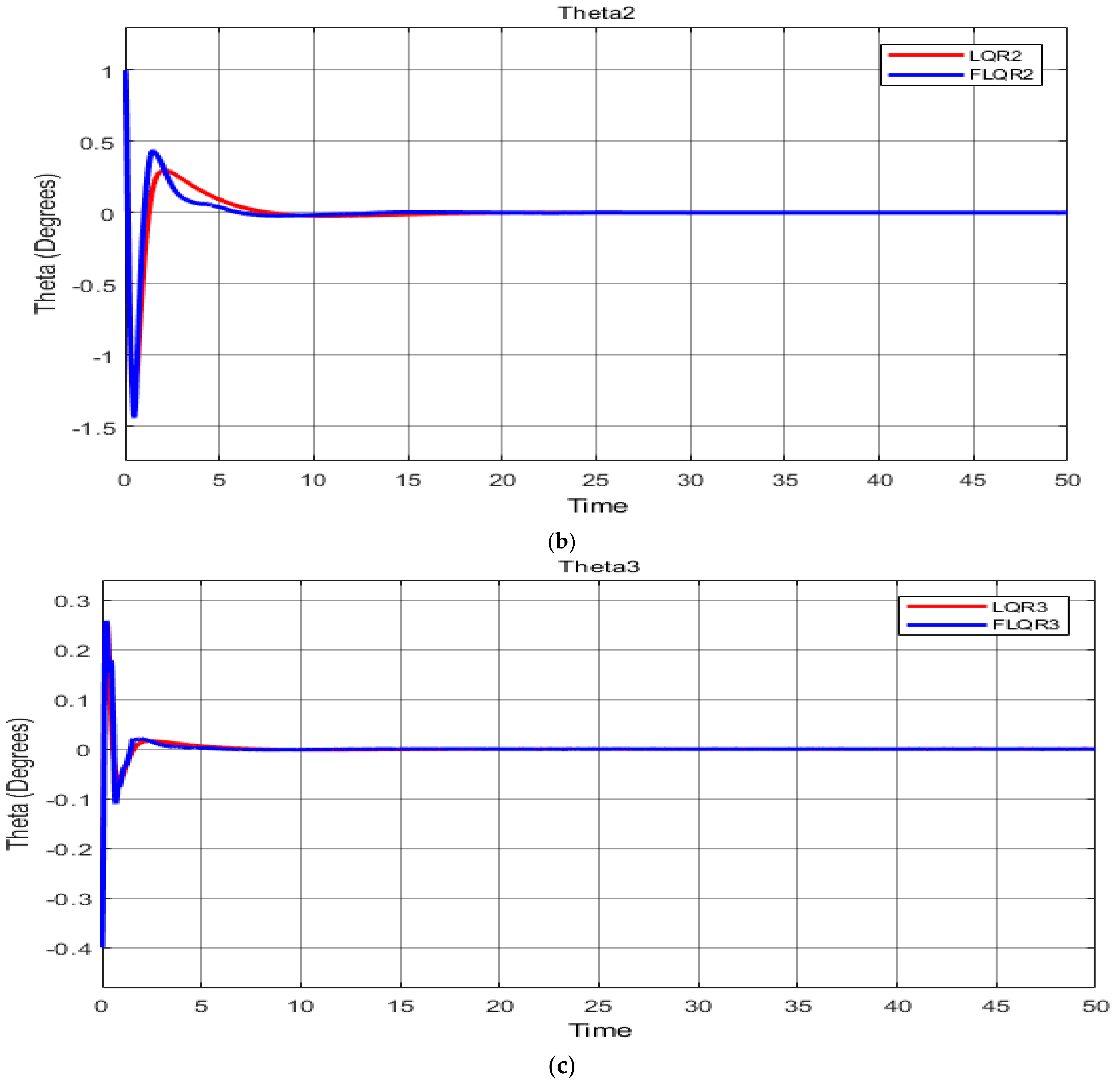

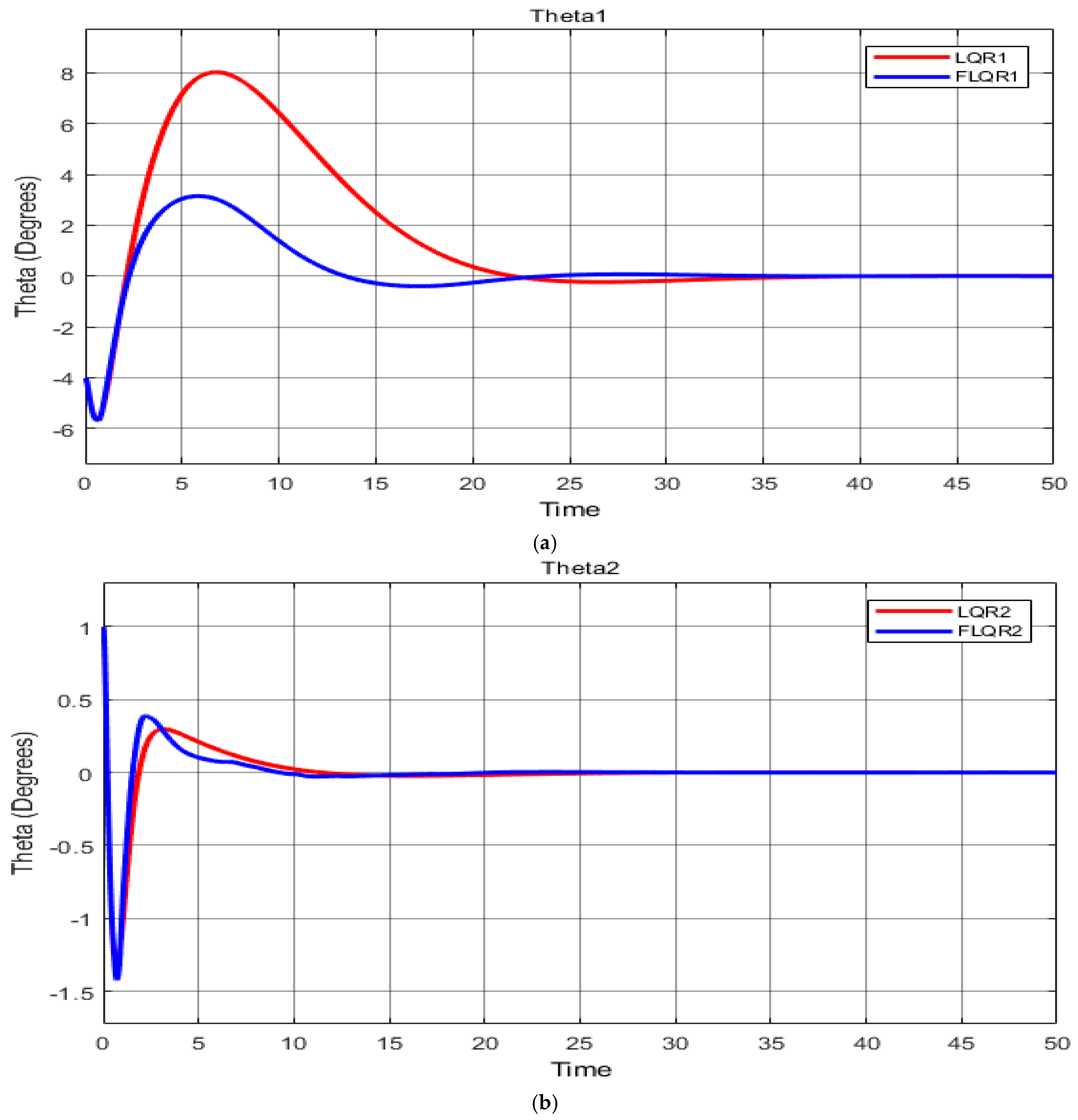

For the first scenario, the measured system response is shown in

Figure 7a–c and

Table 8, giving baseline systems values with no alterations. Comparing the LQR with the FLQR controller, the latter shows decreased overshoot (O

sh) and undershoot (U

sh), with respective overshoot values of 8.02 and 2.88. In addition, while the LQR controller’s rise time was faster (c. 0.35 s), the FLQR showed a faster settling time (11.18 s).

For the second case, in which the mathematical model values are increased by 25%,

Table 5 shows the performance comparison between the two controllers examined for robustness. For the LQR controller, undershoot and overshoot did not differ significantly, but there was a difference of 0.07 s in rise time, and the settling time dropped to 12.41 s from 15.51 s. In contrast, the findings for FLQR demonstrate an increase in overshoot of approximately 0.242 pu, with no alteration in undershoot, and reductions in settling and rising times for the controllers. In addition, for LQR, there was a slight decrease in second angle

overshoot, while undershoot did not change significantly and the times were reduced for each parameter. For FLQR, decreases were found across each parameter. Finally, for

, no change was seen in under- or overshoot for the LQR controller, although reductions occurred in the rising and settling times. For FLQR, time decreases were also found, while the values of the remaining parameters were unchanged from the initial scenario.

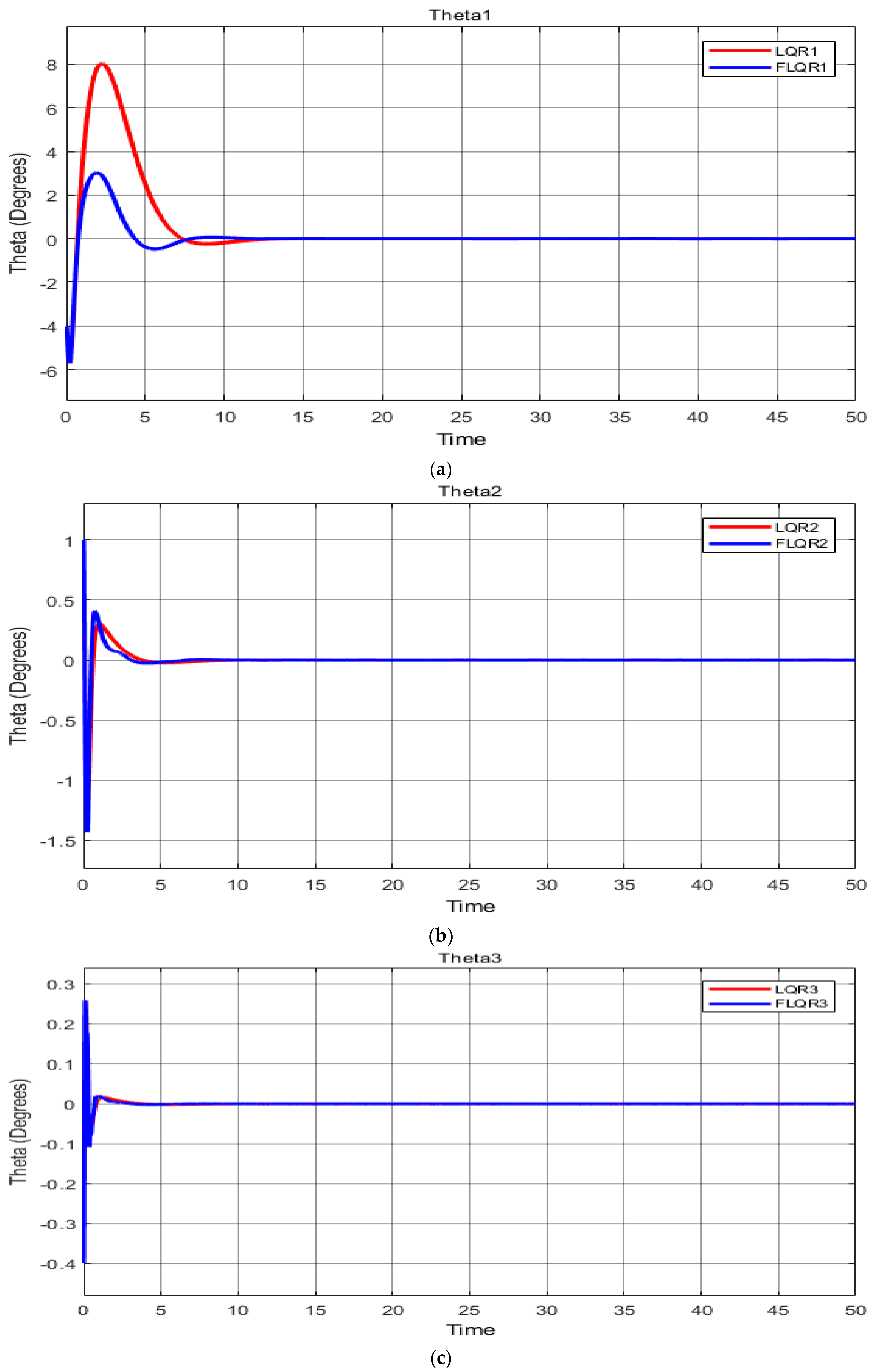

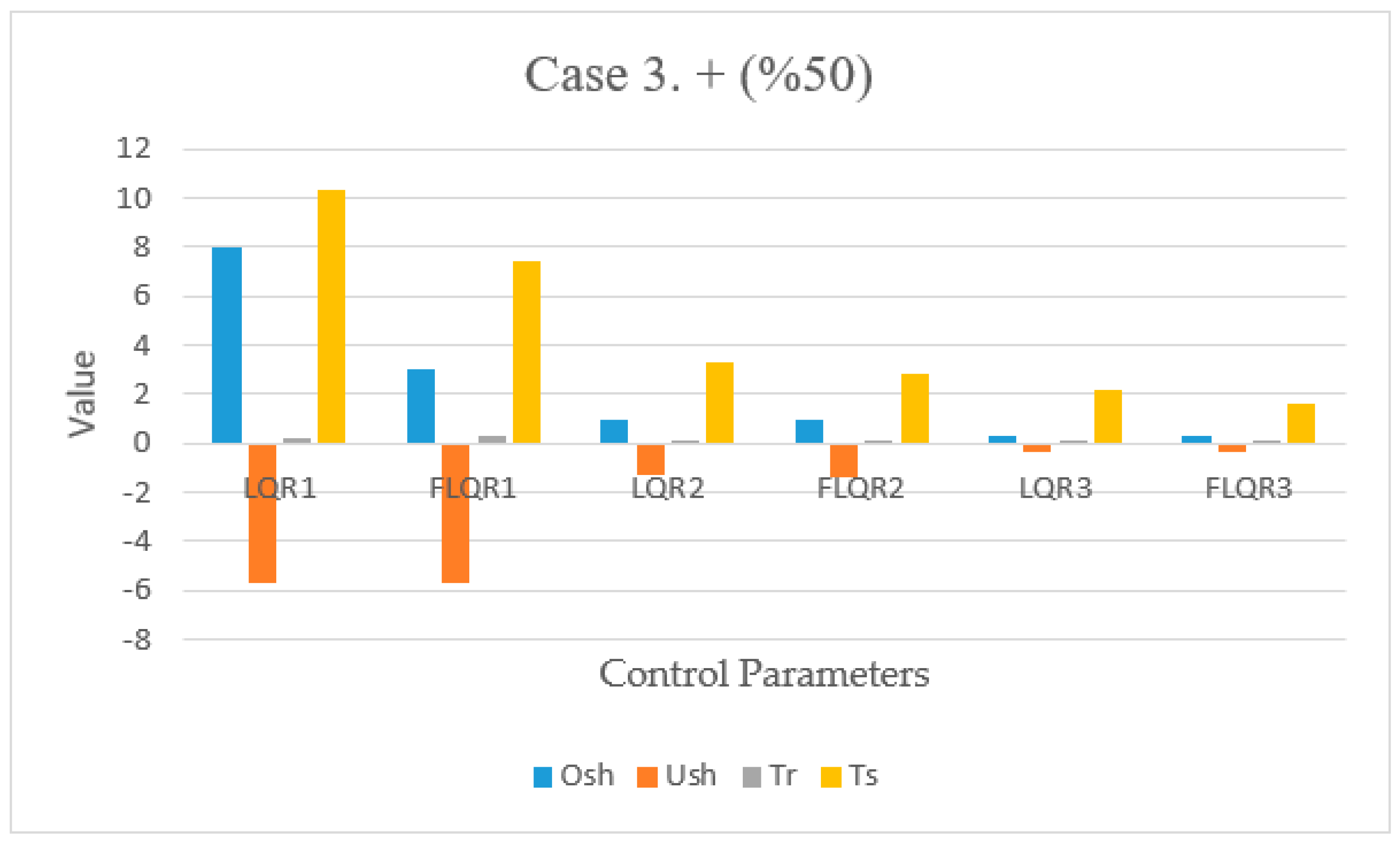

In the third scenario, values were increased by 50% over the system’s baseline. While overshoot remained unchanged for the LQR, undershoot altered only slightly, from −5.69 at baseline to −5.67, but both the rising and settling times were quicker, altering from 0.35 to 0.24 s for rising and a slightly change of 5 s for the settling time. For link with the LQR controller, there was no change in under- or overshoot, but a reduction in the two time variables. Meanwhile, for the FLQR controller, times were also reduced, while no change was seen for under- and overshoot. For the third link , again, under- and overshoot remained the same, while smaller values were found for the time variables.

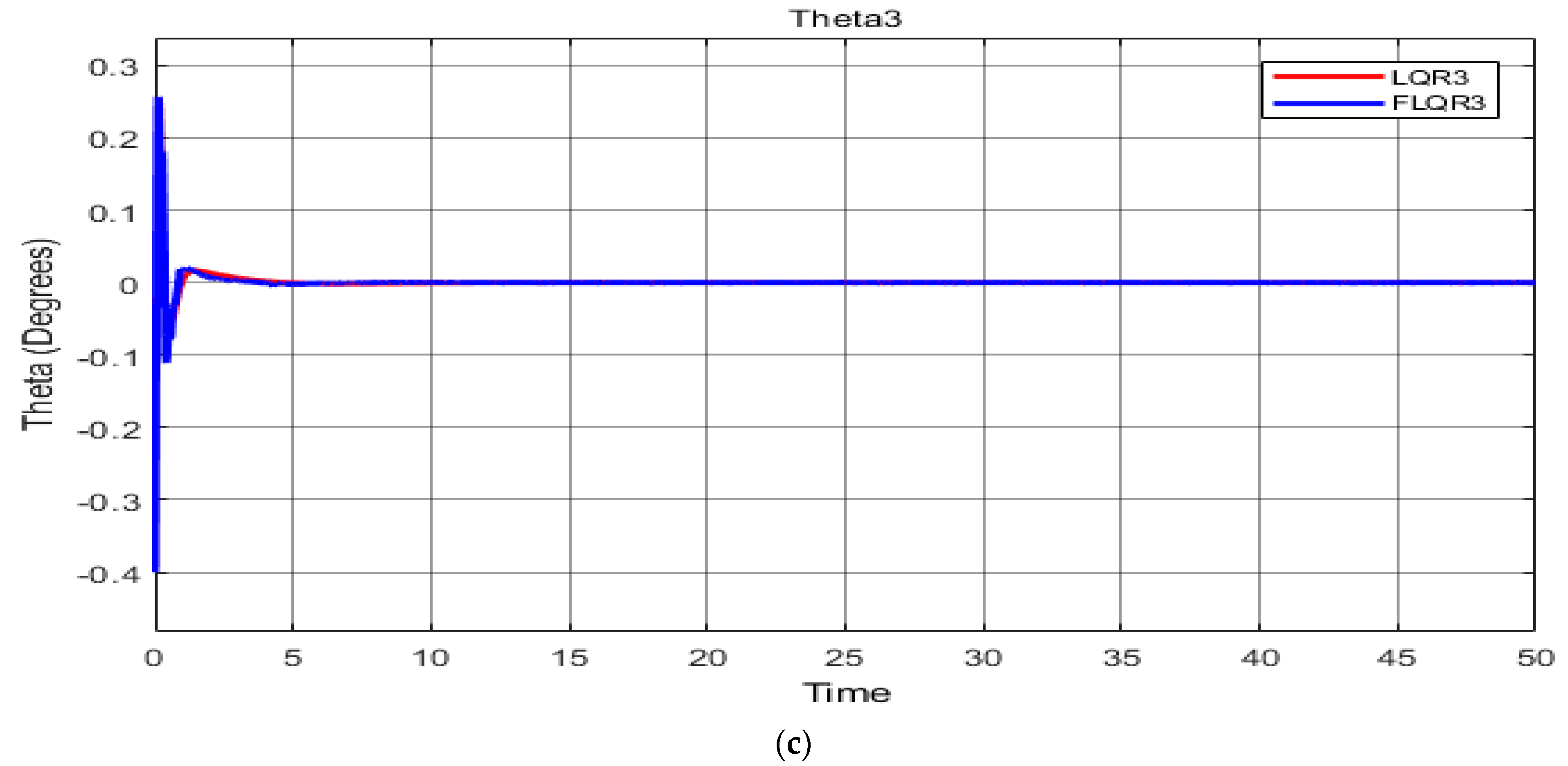

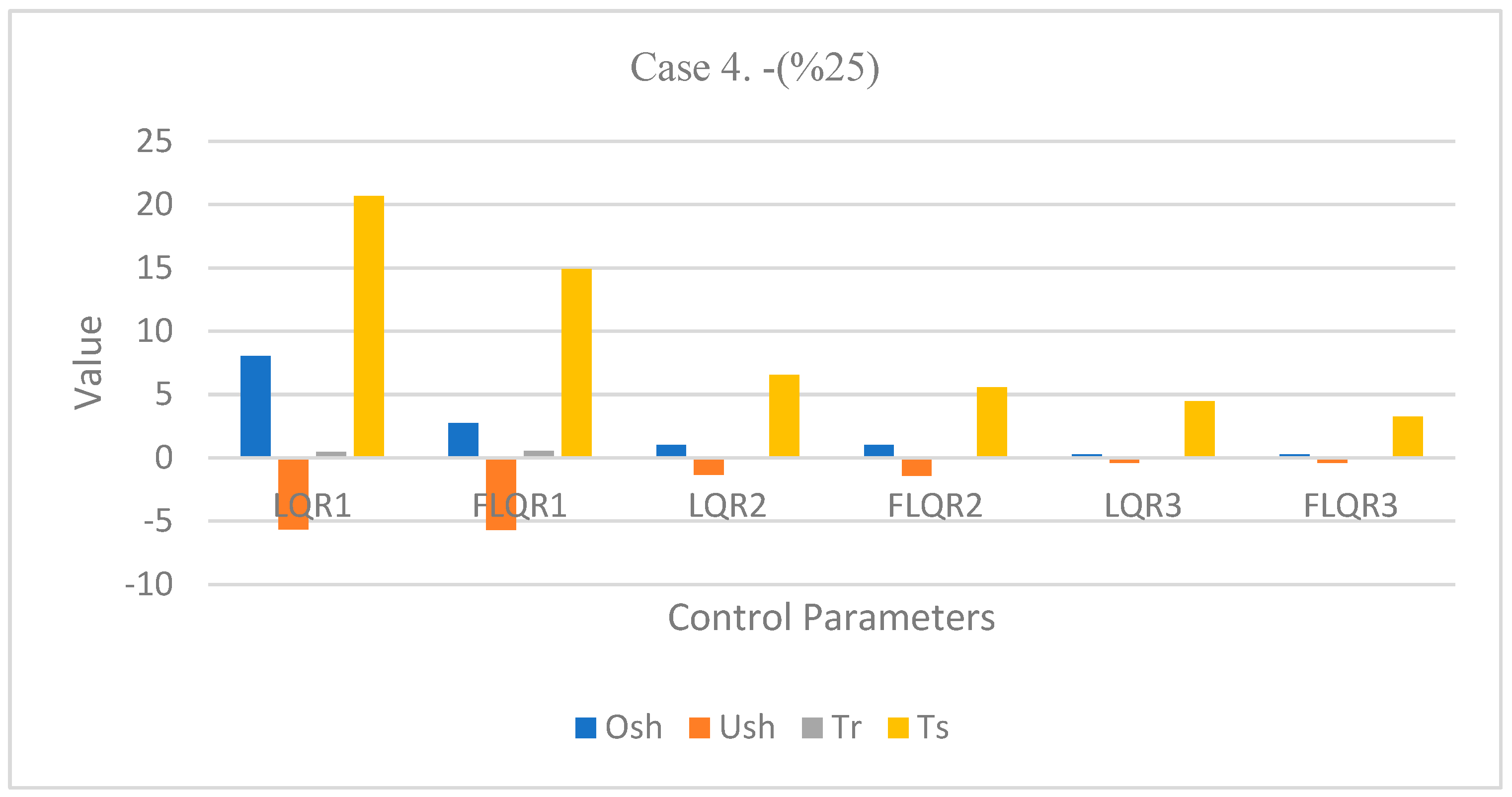

For the fourth scenario, system variables were reduced by 25%, as shown in

Table 7. In the first link, for the LQR, a one-second increase in rising time was recorded for the LQR, and settling time was observed to change by roughly 5 s against the original case, from 15.51 to 20.69 s. By contrast, the FLQR controller produced lower values for each time parameter, and only very small differences for the remaining variables. Moreover, for

, there was little change in under- or overshoot, with reductions in rising and settling times. Finally, for

, a small increase in rising time was seen compared with the original scenario, from 0.052 to 0.0699 s. Settling time was altered by approximately 1 s, with no changes in under- or overshoot.

The final scenario reduced the system parameters by 50% and, again, stability and response were tested to indicate robustness. It is notable here that for the LQR controller, each of the links displayed small increases in rising and settling time differences, with major alterations in overshoot and undershoot. In contrast, FLQR performed markedly better here than the conventional controller. Settling times across each link were 21.37 s, 7.83 s and 4.83 s, with higher rising times for each of the links. Under- and overshoot were also greater across each link.

Table 10 offers a comparison of all the findings in all cases and scenarios between each link.

7. Conclusions and Future Work

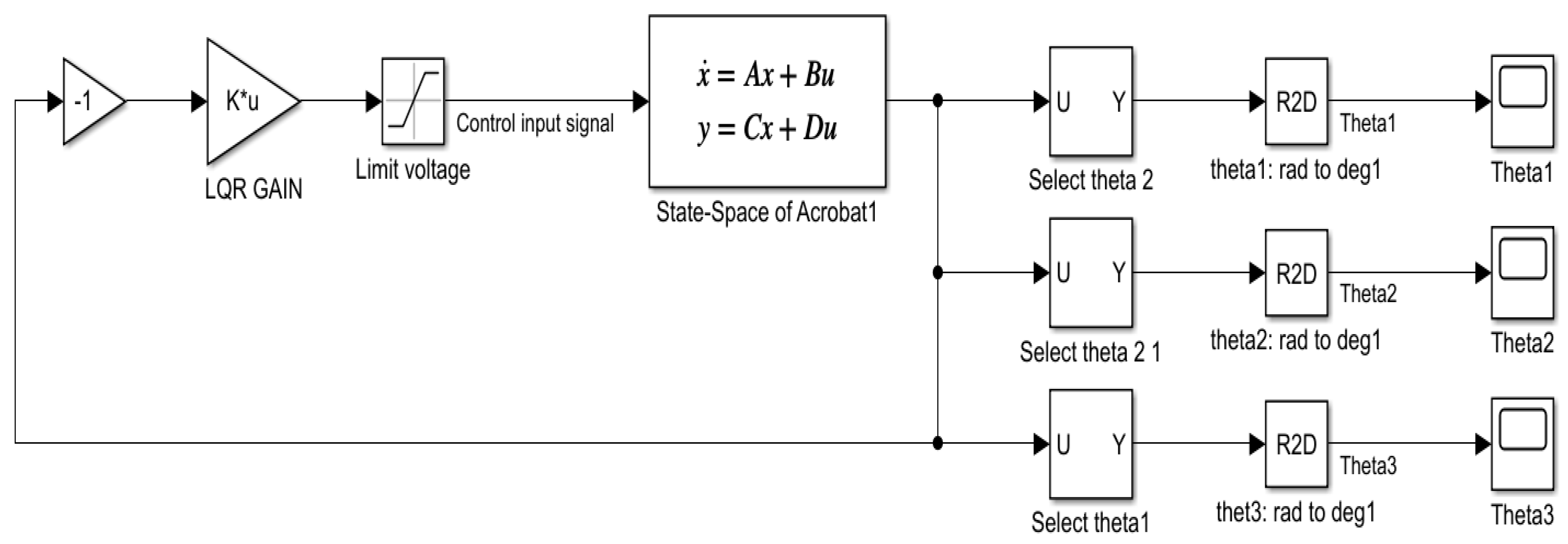

This paper has presented modelling and simulation for the application of an LQR/fuzzy logic controller to stabilise a robotic gymnast system in MATLAB/Simulink. In this study, an FLQR was developed and then compared against an established LQR control approach for the Robogymnast. Mathematical modelling was performed for the starting values of variables within the pendulum-based system, and then a comprehensive model for the simulation of a robotic manipulation drive with the FLQR controller was developed. The primary variables were established, with calculations for overshoot as well as settle and rise times. An assessment was performed for the dynamic performance of the system. Calculations for stability and robustness were performed for each of the FLQR and LQR controllers, with comparisons across each scenario, in which variables were increased or decreased by several values. The results of the comparison show that the proposed FLQR controller performs better with the Robogymnast than does the established LQR controller.

To conclude, it is possible to declare that this work involved the investigation of the modulation of a triple-link robotics mechanism for the swing-up position, and the selected controller can be further extended to implement optimized algorithms for additional studies. In conclusion, this study examining the control of swing-up in three-link robotic systems suggests that the controller proposed here could be studied further and implemented in different optimised algorithms.