Abstract

As the COVID-19 pandemic begins to abate and national public health systems are treating the SARS-CoV-2 virus as endemic, many public health measures are no longer mandated but remain recommended with voluntary participation. One of these is the wearing of fitted face masks, initially mandated to contain, or at least slow, the spread of SARS-CoV-2, which is primarily transmitted via aerosols emitted while breathing, coughing, or sneezing. Although the habit of once wearing fitted face masks recedes into memory for much of the population, so does the knowledge of the various types of masks that were once en vogue. To create a record for the future, this paper provides the first comprehensive documentation of the nature and range of fitted facemasks that circulated during the COVID-19 pandemic.

1. Introduction

During the first three months of 2020 COVID-19, the respiratory disease caused by the SARS-CoV-2 coronavirus [1], rapidly developed into a global pandemic. To contain, or at least slow, the spread of the disease COVID-19, most countries enacted public health measures at national or state levels, ranging from border closures and lockdowns to social distancing measures. Furthermore, given that SARS-CoV-2 is primarily transmitted via aerosols emitted while breathing, coughing, or sneezing [2,3], many governments mandated, or at least recommended, the wearing of fitted face masks [4,5,6,7]. The public had the option of wearing a range of face mask types, ranging from single-use surgical masks to self-made fabric masks. Prior to the emergence of COVID-19, the use of fitted face masks was effectively limited to specific professions and their activities:

- Sterile, single-use surgical-type masks were used by the medical profession;

- Commercial, single-use surgical-type masks were used by the beauty industry (nail salons);

- Disposable KN95/P2 type masks, with and without valves, were used in the construction industry to filter out low levels of dust and paint fumes;

- Full face masks with exchangeable air filters were used for more hazardous work in the construction and manufacturing industry [8,9,10].

The high demand for face masks during the COVID-19 pandemic led to the rapidly expanded production and use of non-sterile, surgical-type single-use face masks, the majority of which were sourced from Chinese manufacturers [11]. Since these were far more common than washable masks from cotton and other fabrics [12,13,14], single-use face masks soon posed environmental issues. The quantity of single-use face masks manufactured is staggering, with China exporting more than 200 billion masks in the year 2020 alone [15].

Elsewhere, it had been argued that COVID-19 was a global, cross-sectoral disruptor not seen since the 1918/19 influenza pandemic. As part of a project to document the tangible evidence and material culture associated with the COVID-19 pandemic for future social history exhibitions and heritage studies, the author systematically documented the usage of reusable vs. disposable fitted face masks [16]. This could be achieved through observational studies of face mask use, assessments of lost and discarded as well as donated masks, and the documentation of the longer-term fate of discarded single-use face masks in the urban and peri-urban environment. Although the majority of mainstream research focused on the environmental aspects of discarded masks [17,18,19,20,21,22,23,24,25,26,27,28,29,30], several authors have conducted work on masks in the social acceptability [31,32,33,34,35] and future heritage spaces [36,37,38,39,40].

Now, three years after COVID-19 first became a global health emergency, the majority of people have ‘learned to live with the virus’ [41,42] with the majority of people, at least in the more affluent countries, being fully vaccinated. Although a considerable number of people are still becoming infected each week, with numerous deaths [43], the public health responses of border closures, lockdowns, social distancing, and the wearing of fitted face masks, are gradually receding from public consciousness and are being relegated to memories.

Witnessing the attitudes and behavior patterns of the populace in March 2023 it appears that the COVID-19 pandemic was an ephemeral event, although it manifested itself as a cross-sectoral disruptor on a global scale. Although systemic changes have been advocated for the way we live, work, and learn, the majority of the population seems to be in the process of returning their lives, and health attitudes, to ‘normal’, i.e., pre-pandemic realities. Fitted face masks will rapidly be relegated to the past and the knowledge of their variety in shape, form, and materials will become dim memories. Thus, this is the time to document and place on record the nature and range of fitted facemasks that were used by residents before such examples of material culture disappear. The aim of this paper is to provide the first comprehensive documentation of, and to serve as a reference point for, the various types of fitted facemasks that circulated during the COVID-19 pandemic in Australia.

2. Methodology

All fitted face masks discussed in this paper were encountered by the author between March 2020 and December 2022 in Albury, a major regional city in southern New South Wales, Australia. This study is based on a total of 3652 different masks which were observed as being worn, lost, discarded, or donated [13,14,44,45,46,47]. The location can be regarded as representative of communities along the eastern seaboard of Australia as there are no significant differences in mask usage between Albury and the metropolitan centers of Sydney or Melbourne [48,49]. Although the observational dataset is comprehensive and includes all different mask designs, it does not include all possible design variations. These are outside the remit of this paper.

The actual examples discussed and illustrated here were acquired by the author for personal protective use or were recorded as part of the above-mentioned documentation of the tangible evidence and material culture associated with the COVID-19 pandemic.

3. Results

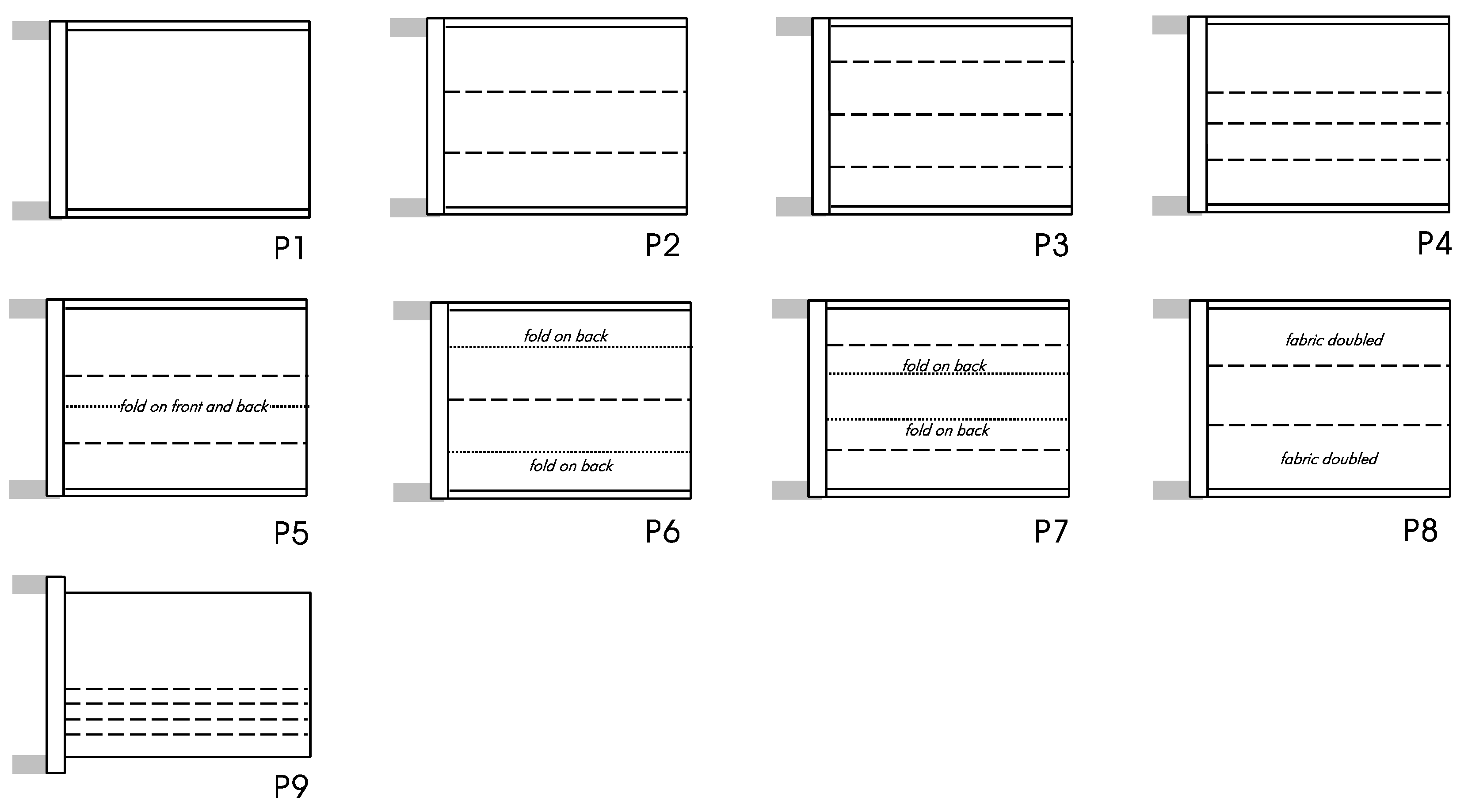

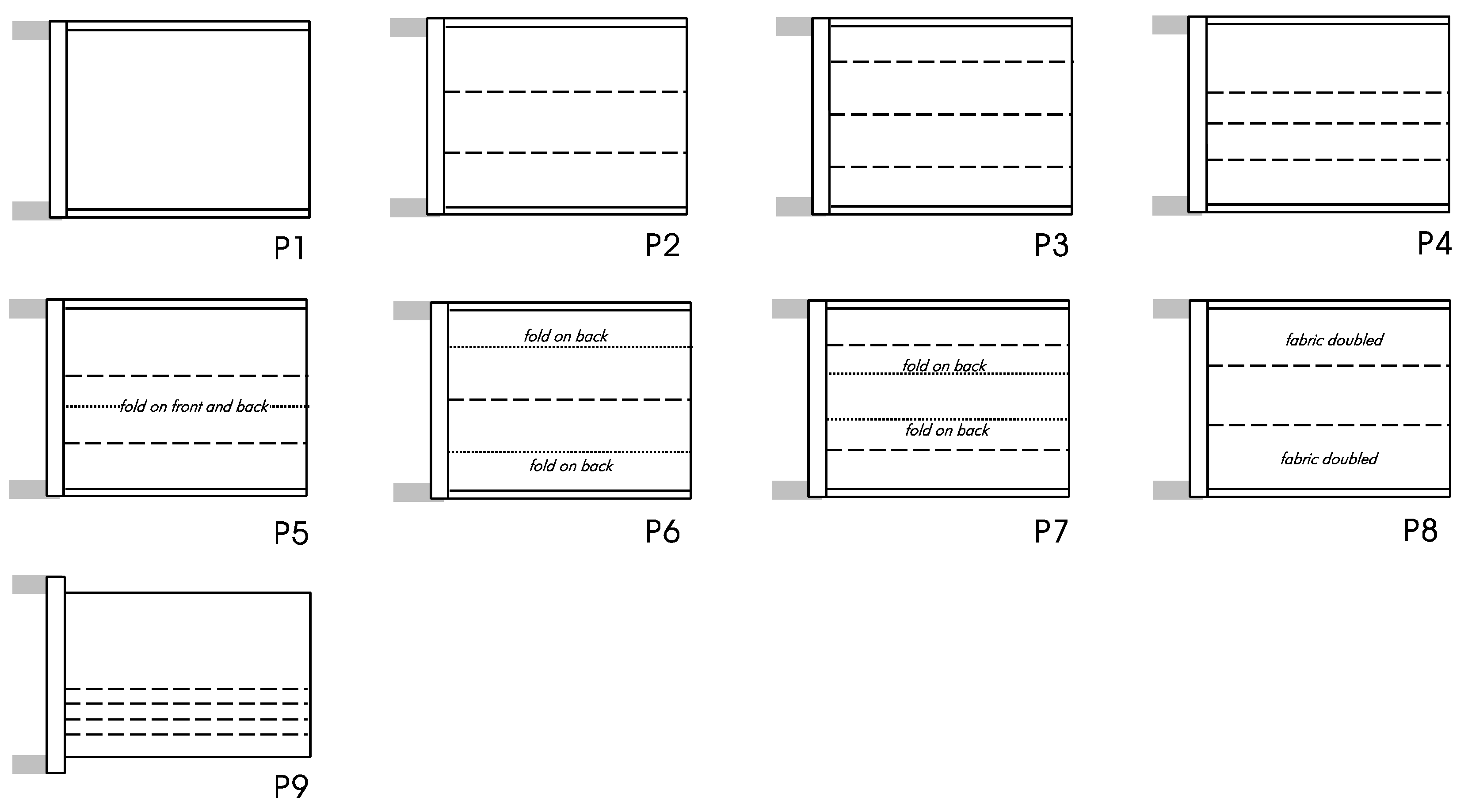

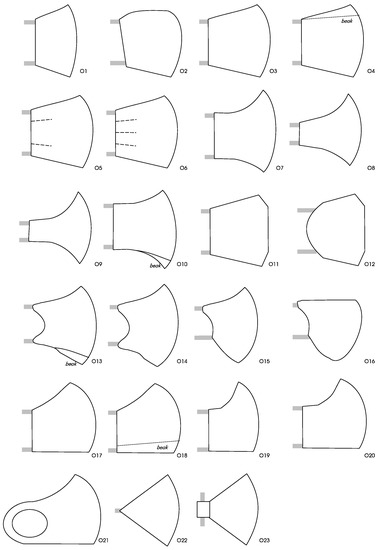

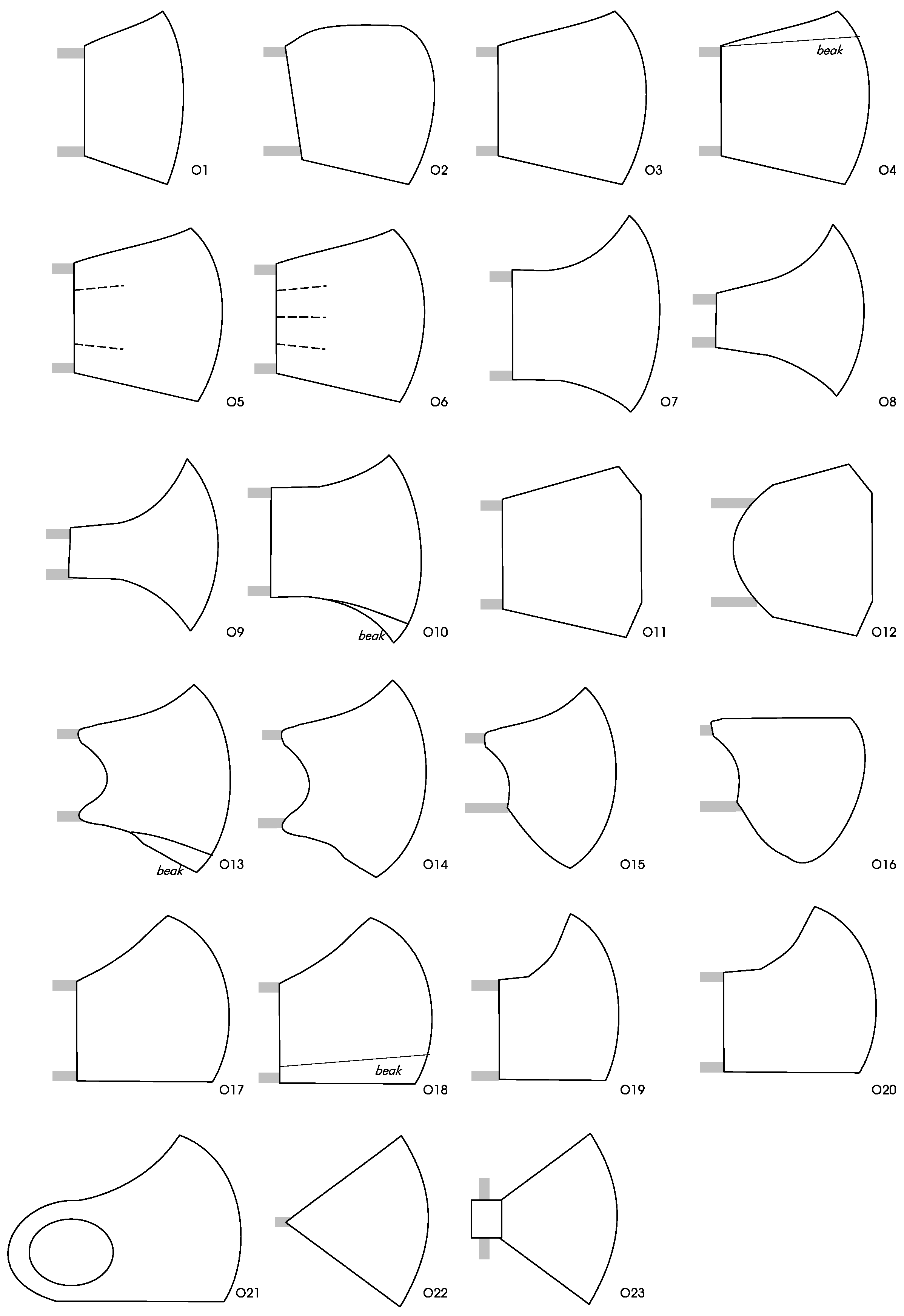

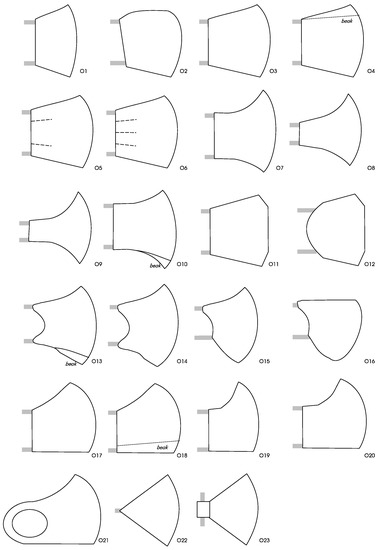

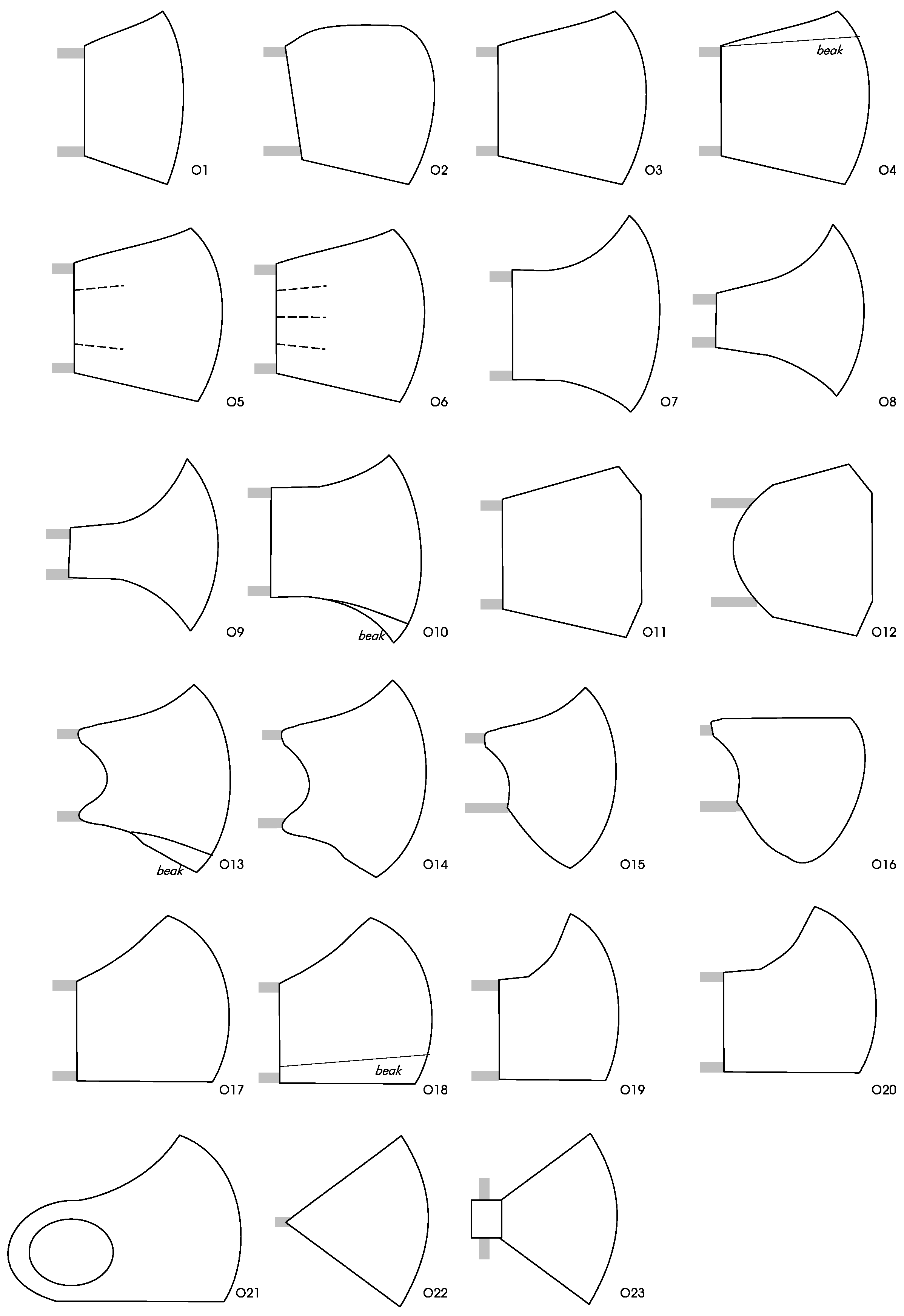

In total, twelve different designs of fitted face masks are represented in the sample and described here. Each of these designs was produced by different manufacturers or artisanal makers, resulting in considerable variation within each design. A study of single-use polypropylene masks, for example, recorded over 80 examples from different manufacturers with minor differences in polypropylene density, the spacing of fold lines (pleat), and the arrangement of thermal weld points along the seams. Documentation of fabric masks lost, discarded, or donated to charity showed a considerable number of variations in the number and placement of pleats among expandable masks (Figure 1) or the shape and ear-loop attachment of one-piece masks (Figure 2). For the purposes of this paper, such variations were omitted.

3.1. Single-Use Polypropylene Three-Ply Masks

Single-use face masks manufactured from three- or four-ply polypropylene, with a melt-blown filter layer sandwiched between outer layers of spunbonded polypropylene fabric, were the most common type of face masks encountered being worn by passers-by during walk-through surveys in Albury, as well as Sydney and Melbourne. They were also the most common type encountered lost or discarded on the ground [14]. A separate study that examined single-use face masks sold in Australia for their morphological characteristics that could allow archaeologists in the future to positively correlate a given mask encountered in deposits with a manufacturer found that the overwhelming majority (80.3%) of single-use face masks in that study was produced by numerous manufacturers in China. Apart from masks manufactured in Australia (12.4%), also encountered were masks fabricated in India, Indonesia, Japan, Spain, and Turkey.

Single-use polypropylene masks were produced in three main types. The most common type is three-ply pleated masks with welded-on ear loops such as the mask shown in Figure 3 (example manufactured in Australia). These masks were sold as ‘utility masks’ and ‘surgical masks’. The latter, which had to be approved for medical use by the Australian Therapeutic Goods Administration, were graded as levels 1–3 depending on their levels of protection and fluid resistance [50]. The majority of masks possess an embedded nose wire that allows the top of the mask to be shaped when fitted, reducing air emission along the nose, which significantly prevents fogging of spectacles that may be worn and the ingress and egress of unfiltered air.

Figure 1.

Typology of pleated masks [13].

Figure 1.

Typology of pleated masks [13].

Pleated masks were also produced with straps, rather than ear loops, which allowed the mask to be fastened around the back of the head rather than placing strain on the earlobes. By and large, the use of these masks was confined to medical settings, particularly surgery. In addition to standard pleat masks, some level 3 masks were fitted with an additional clear polycarbonate anti-splash visor protecting the eyes from projected aerosols (Figure 4) (example manufactured in China).

A different design was the ‘duck bill’ shaped masks fabricated from the same type of polypropylene fabric but cut in a way that they had a better facial fit and less chance of billowing open at the cheeks (compare side-ways fit of masks in Figure 3 and Figure 5). One design folds out completely (hence duck bill), while the other folds out only partially (Figure 5). Both designs have straps that are tightened around the back of the head. The use of these masks, while available on the open market, was largely confined to medical settings (Figure 5) (example manufactured in Japan).

Figure 2.

Typology of one-piece fabric (cloth) masks [13].

Figure 2.

Typology of one-piece fabric (cloth) masks [13].

3.2. Single-Use KN95/P2 Polypropylene Masks

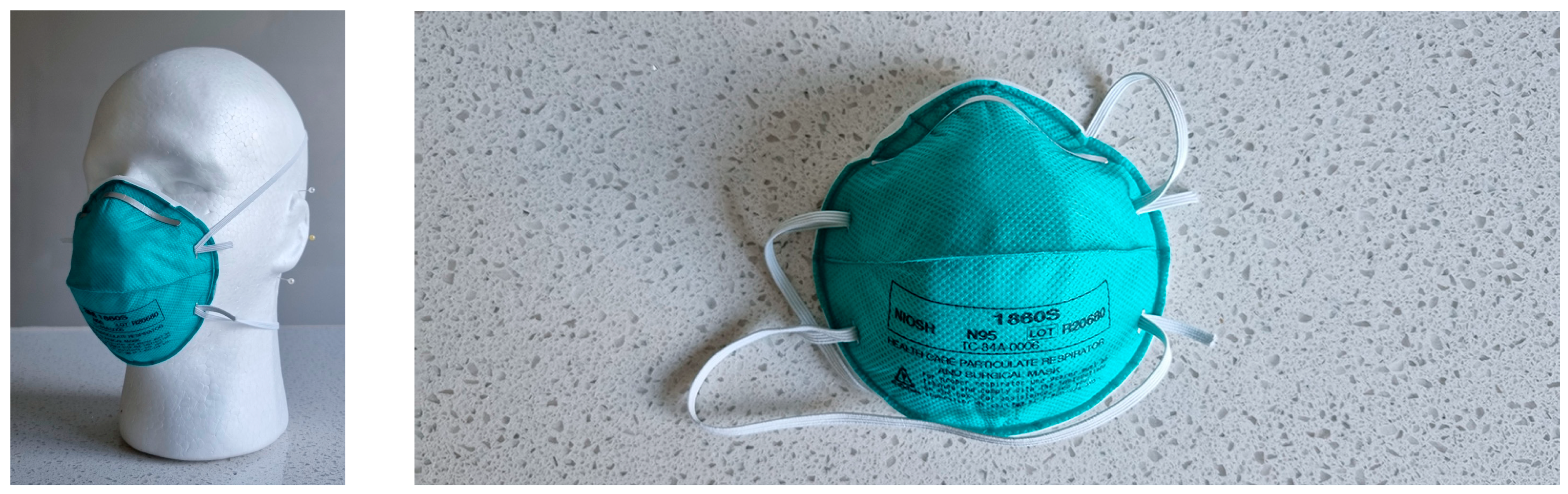

P2/N95 respirators form a close seal around the nose and mouth and are effective in removing a minimum of 95% of aerosols (KN95, KF94, Japan DS2, and European FFP2 are equivalents) [50,51]. Like the foregoing masks, P2/N95 respirators were also sold as utility masks (mainly for the construction trade) and as respirators approved for medical use by the Australian Therapeutic Goods Administration. N95 respirators were manufactured in four main types: flat-fold, cupped, duck-billed, and beak-shaped.

Flat-fold particulate N95 respirators, offered by various companies, are designed with straps that are tightened around the back of the head (Figure 6). Both the top and bottom fold out, with the bottom having a small tab for easy adjustment and the top commonly furnished with a flat nose wire and a polyurethane foam surface for wearer comfort (Figure 7). The respirators comprise a polypropylene filter covered with a polypropylene cover web on the outer and inner surfaces (Figure 6 example manufactured in China; Figure 7 example manufactured in the USA).

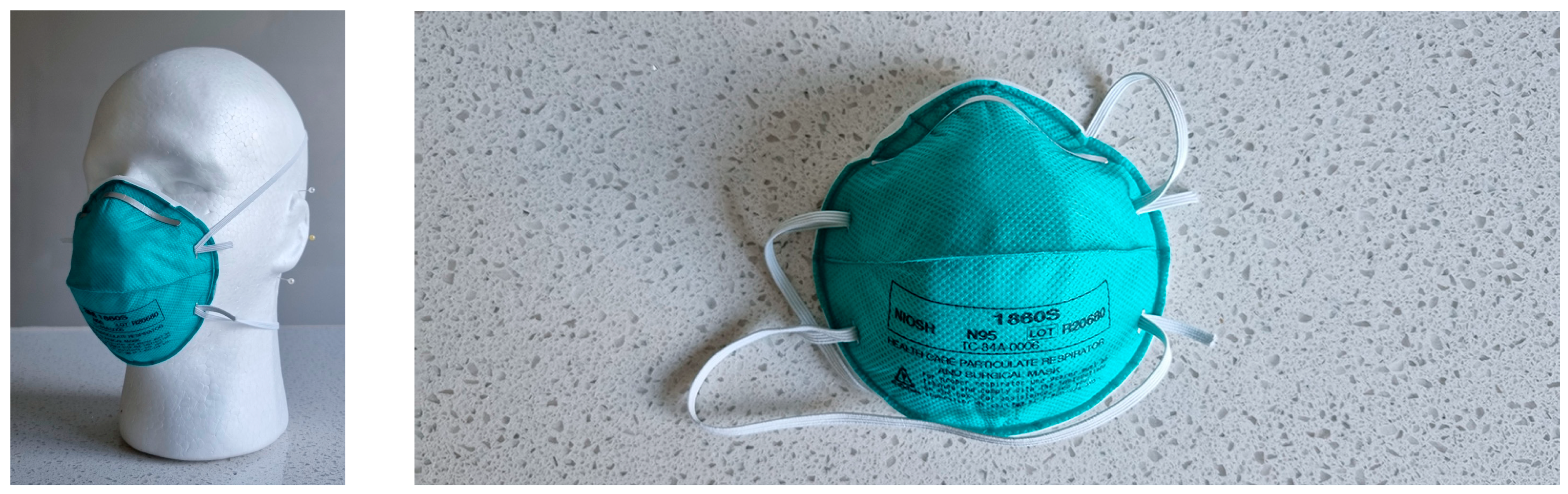

Cupped particulate N95 respirators are designed with straps that are tightened around the back of the head. They comprise a polyester shell with a polypropylene cover web on the outer and inner surfaces. The top is commonly furnished with a flat nose wire and a dense polyurethane foam surface for wearer comfort. Apart from the nose wire that allows the top to be adjusted, the rest of the mask shape cannot be adjusted (Figure 8) (example manufactured in the USA).

Medical-type, beaked particulate N95 respirators, offered by various companies, are designed with straps that are tightened around the back of the head. The respirators comprise a polypropylene filter (sometimes with an additional hot-air blown cotton layer) covered with a polypropylene cover web. Apart from the flat nose wire that allows the top to be adjusted, the rest of the mask shape cannot be adjusted (Figure 9) (example manufactured in China). Consumer-grade, beaked particulate N95 respirators, offered by various companies, are of the same design but can have less dense spunbonded and melt-blown polypropylene fabric. All consumer-grade beaked respirators are fitted with standard ear loops (Figure 10) (example manufactured in China).

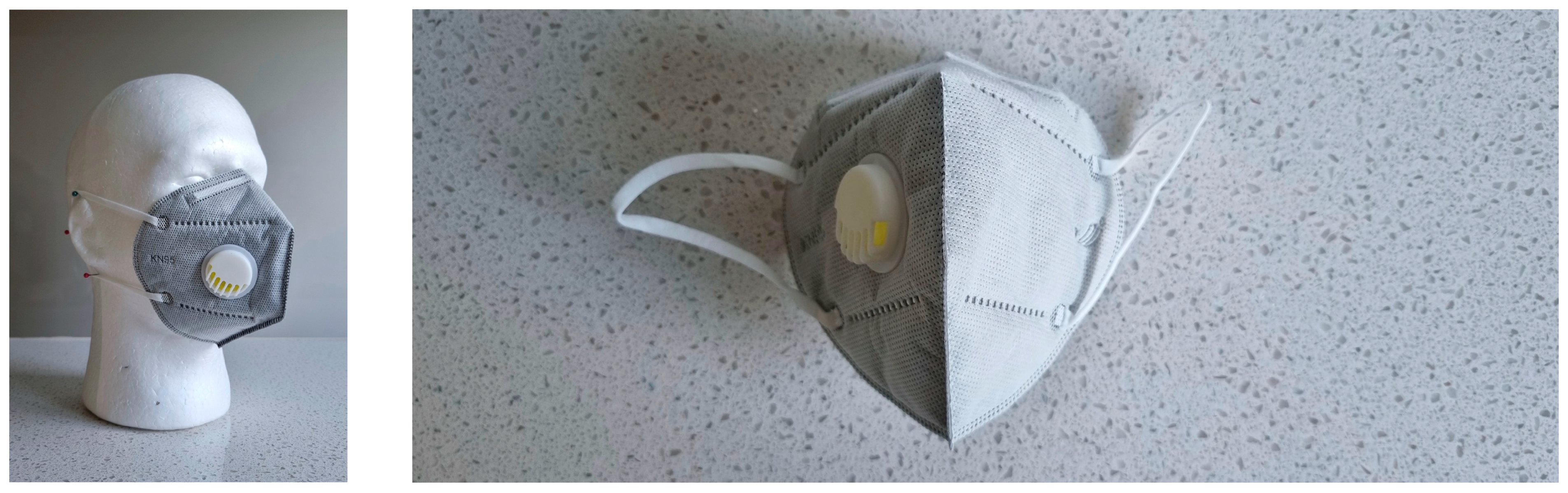

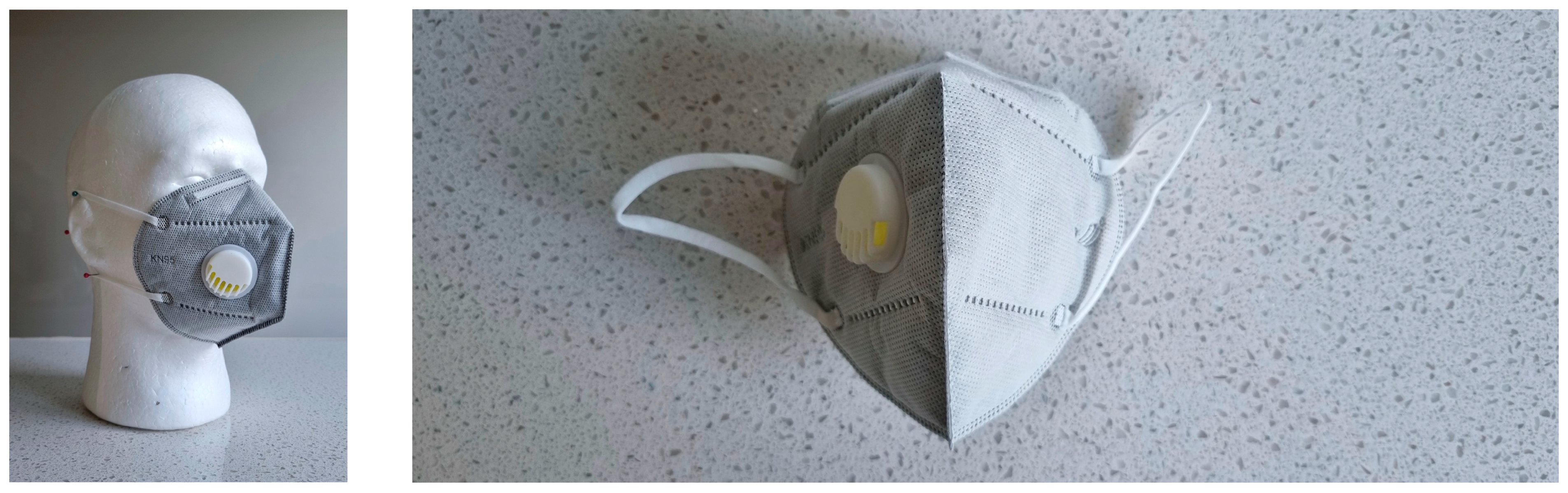

Consumer-grade, particulate N95/P2 respirators had been sold prior to the pandemic and were used by the professional building trade. They commonly have straps that are tightened around the back of the head rather than ear loops. Examples are duck-billed P2 masks sold to the general building trade (Figure 11, example manufactured in China for Scott Safety) as well as cupped masks fitted with filter valves specifically for the gardening (Figure 12, example manufactured in China) and painting trades (Figure 13; example manufactured in Korea). In addition, some consumer-grade, beaked particulate N95 respirators were sold with activated carbon filters (Figure 14) (example manufactured in China).

3.3. Fabric Masks, Commercial Production

Given the shortage of single-use surgical masks in the face of unprecedented demand for fitted face masks, public health advice in early 2020 suggested that wearing a cloth mask, albeit providing lesser protection, was better than wearing no mask at all [52]. Commercial production soon commenced, with corporations and major clothing retailers soon recognizing the promotional and commercial opportunity this provided. The masks were manufactured in a large variety of shapes, both with sewn-on and integrated ear loops (Figure 2).

Companies and government agencies purchased masks in corporate colors that were decorated with slogans and/or company logos and that were made part of the corporate uniforms. These masks were commonly manufactured from cotton, polyester, or a viscose/cotton mix, commonly with a polytetrafluoroethylene membrane as a filter core. The length of the elastic strips used for the ear loops could be adjusted with a sliding shortener. The early mask designs had a rounded shape and lacked a nose wire (Figure 15) [14]. Similarly, companies and corporations distributed masks as promotional items, commonly fitted with nose wires based on the best practice advice at the time (Figure 16).

Figure 3.

Single-use mask—polypropylene—manufacturer branded.

Figure 3.

Single-use mask—polypropylene—manufacturer branded.

Figure 4.

Single-use mask—polypropylene with anti-splash visor—medical retail.

Figure 4.

Single-use mask—polypropylene with anti-splash visor—medical retail.

Figure 5.

Single-use mask, duck bill type—polypropylene—medical retail.

Figure 5.

Single-use mask, duck bill type—polypropylene—medical retail.

Figure 6.

Single-use P2 respirator—polypropylene—medical retail (brand name digitally removed).

Figure 6.

Single-use P2 respirator—polypropylene—medical retail (brand name digitally removed).

Figure 7.

Single-use flat-fold N95 respirator. Unfolded, front, back, and side view (brand name digitally removed).

Figure 7.

Single-use flat-fold N95 respirator. Unfolded, front, back, and side view (brand name digitally removed).

Figure 8.

Single-use cupped N95 respirator—polyester and polypropylene—medical retail (brand name digitally removed).

Figure 8.

Single-use cupped N95 respirator—polyester and polypropylene—medical retail (brand name digitally removed).

Figure 9.

Single-use P2 respirator, beak-shaped—polypropylene—medical retail (brand name digitally removed).

Figure 9.

Single-use P2 respirator, beak-shaped—polypropylene—medical retail (brand name digitally removed).

Figure 10.

Single-use P2 respirator, beak-shaped—commercial retail.

Figure 10.

Single-use P2 respirator, beak-shaped—commercial retail.

Figure 11.

P2 respirator, duckbill shaped—commercial retail.

Figure 11.

P2 respirator, duckbill shaped—commercial retail.

Figure 12.

P2 respirator, cupped—commercial retail (gardening).

Figure 12.

P2 respirator, cupped—commercial retail (gardening).

Figure 13.

P2 respirator, cupped—commercial retail (paint fumes).

Figure 13.

P2 respirator, cupped—commercial retail (paint fumes).

Figure 14.

Single-use P2 respirator, beak-shaped with valve—commercial retail.

Figure 14.

Single-use P2 respirator, beak-shaped with valve—commercial retail.

Figure 15.

Fabric mask—cotton without nose wire—company branded (for staff use).

Figure 15.

Fabric mask—cotton without nose wire—company branded (for staff use).

Figure 16.

Fabric mask—cotton with nose wire—promotional (student association).

Figure 16.

Fabric mask—cotton with nose wire—promotional (student association).

Figure 17.

Fabric mask—cotton with nose wire—community designed (branded).

Figure 17.

Fabric mask—cotton with nose wire—community designed (branded).

The corporate promotional giftware and novelty industry soon saw a market niche offering in short runs using customer-supplied designs. This allowed, inter alia, community organizations to create fabric face masks designed by community members, such as the mask with an Indigenous Australian motif produced by a disability service provider (Figure 17) [12].

Not surprisingly, major clothing retailers soon recognized the commercial opportunity this provided. Especially in the early days, soon after the initial wave of the lockdown period finished, the majority of masks were either plain black or mono color on the outside and often white on the inside (Figure 18a–d). Clothing retailers, in particular those servicing the teen and young adult market, quickly realized that fitted face masks as mandatory items could function as compulsory accessories, and soon produced such masks in a variety of colors and patterns, often with slogans (Figure 19; with slogan “Social distancing like a pro”), some of which carried the same pattern as clothing sold by the same chain (Figure 20).

Figure 18.

Fabric mask—cotton—commercial retail offerings. (a) Bonds (Australia, June 2020); (b) Fashion F (China, mid-2021); (c) Cotton On (China, mid-2021); (d) Sexy Socks (South Africa, April 2020).

Figure 19.

Fabric mask—cotton—commercial retail (branded).

Figure 20.

Fabric mask—cotton—commercial retail. Mask with three filter insets [13].

The materials used for these masks varied from 100% cotton or 100% polyester on both sides (depending on pattern and colors) to combinations [53,54,55], 100% cotton (inner) and or 100% polyester (outer) [55], as well as viscose/cotton mixes (Figure 20, 70% viscose, 30% cotton) [56]. Common to most was that they were fitted with a polytetrafluoroethylene membrane as a filter core in the fabric ‘sandwich.’

Although the majority was being imported from China as soon as supply chains reopened [54,55,57,58], local Australian production also occurred [53], as well as imports from as far afield as South Africa (Figure 18d) [59]. The early masks were limited to a recommended 20 washes, after which, the fabric would lose its filtering capabilities [53], but later masks were fitted with pockets for replaceable PM 2.5 filters (Figure 20). In addition to accessorizing promoted by clothing retailers, masks with novelty designs such as flowers, animals, faces, superheroes, and the like soon came on the market, primarily distributed through online channels (Figure 21 and Figure 22, manufactured in China). Some of these were sold with and without replaceable PM 2.5 filters.

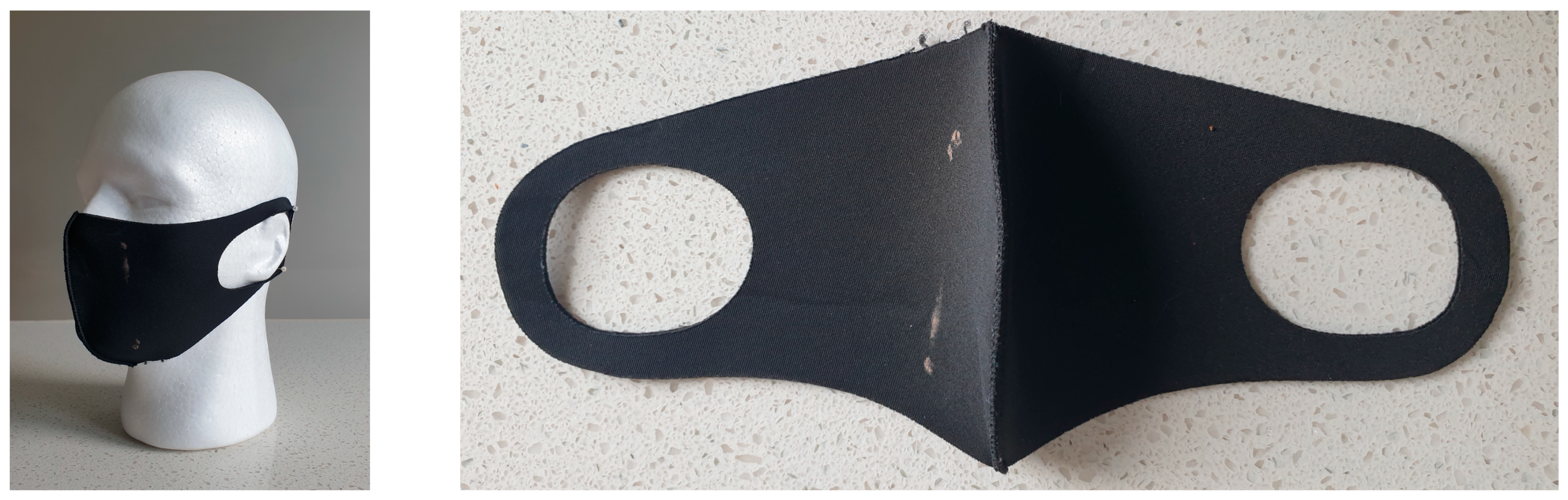

Although the majority of masks were cotton or polyester fabric with sewn-on elastic ear loops, some were single-piece masks with integrated ear loops fabricated from a polyester fiber blend, cotton/Spandex blends, neoprene, or reticulated polyurethane foam (Figure 23 and Figure 24). As these masks did not have a filter insert, their efficacy relied solely on the nature of the fabric. Recommendations for discarding used masks after a set number of washing cycles depended on the material, with polyurethane foam masks reputedly lasting 8–10 cycles [60], although most retailers asserted reuse and washability but did not provide any recommendations on the length of use [61,62,63,64].

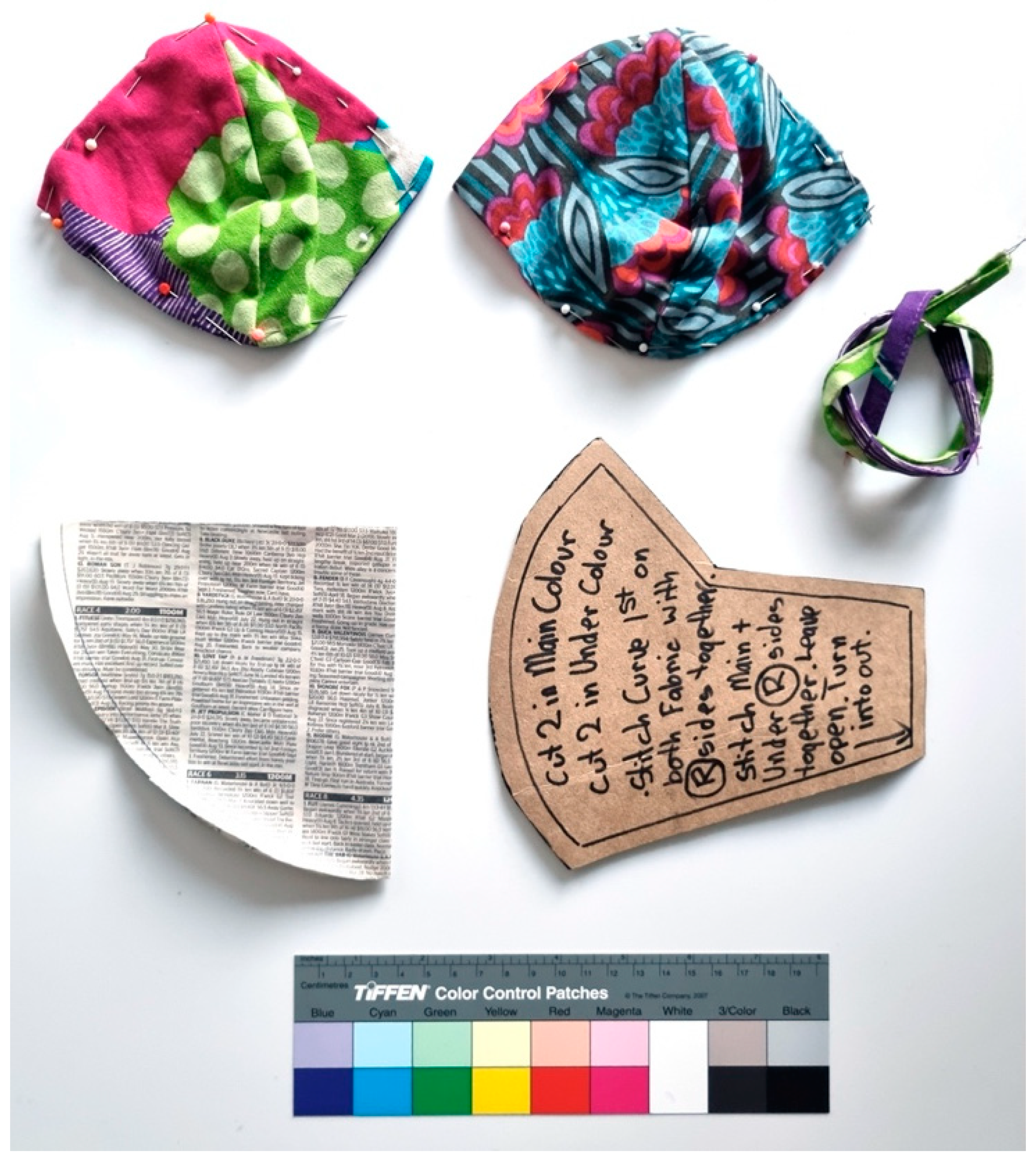

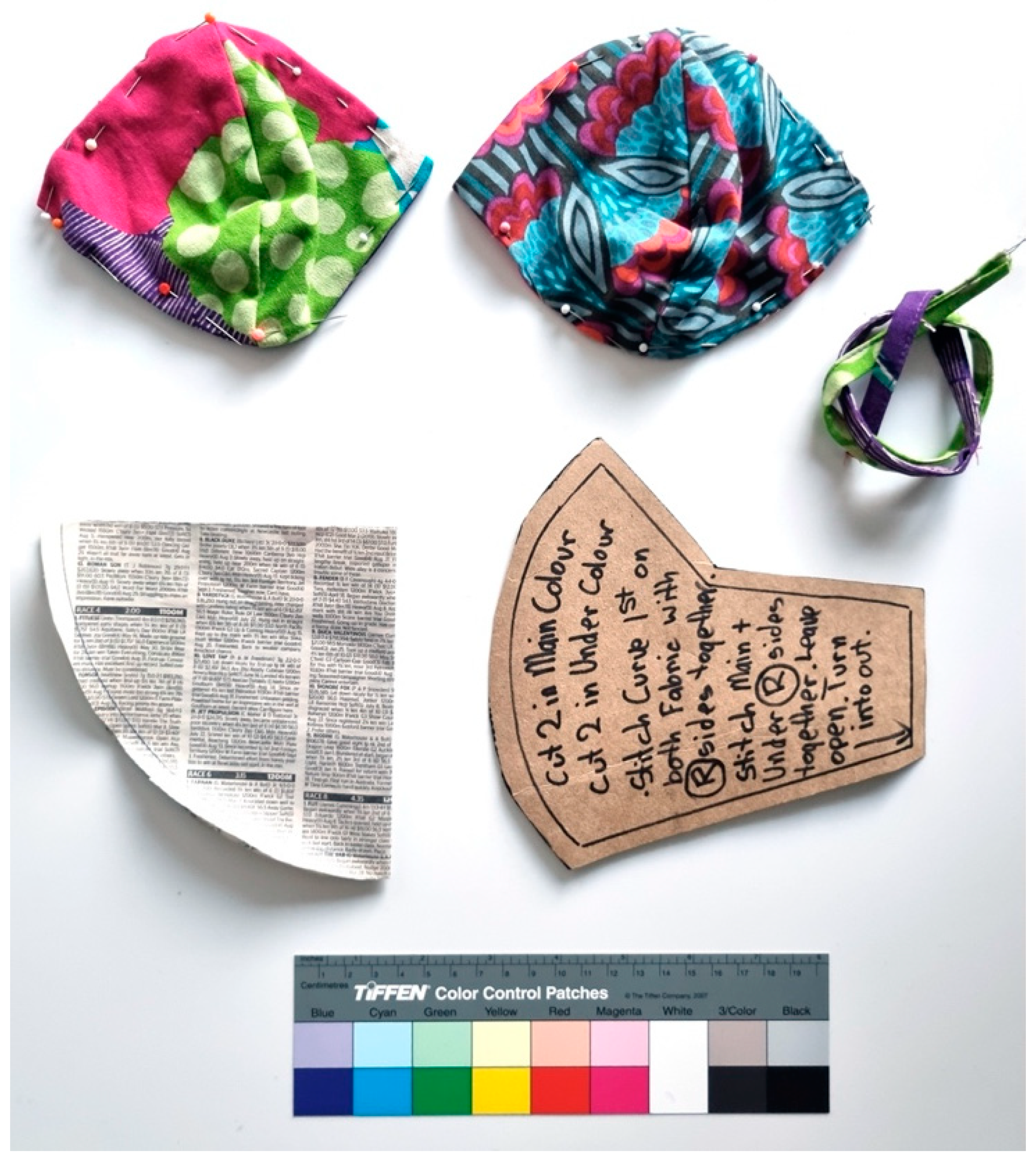

3.4. Fabric Masks, Artisanal Production

The shortage of single-use surgical-type and N95-type face masks during the early period of the pandemic, coupled with the mandate to wear face masks and the advice that fabric face masks would provide adequate, albeit not perfect, protection, resulted in a cottage industry of artisanal productions. Some of the productions were simple and ill-fitting face coverings (Figure 26), that provided little, if any, protection. Soon after the shortage of surgical-type face masks had become evident, public health departments published design instructions for simple masks, [66] while national drapery chains offered sewing templates [67,68]. A wide range of mask types was produced with both pleated (Figure 1 and Figure 27) and one-piece designs (Figure 2) both with (Figure 28) and without nose wires (Figure 29 and Figure 30) [13]. Some artisanal designs even included removable filter layers. All artisanal productions used cotton of various densities (thread count) as raw material, with a wide range of design patterns.

Figure 21.

Fabric masks—cotton with filter insert—commercial, novelty market.

Figure 21.

Fabric masks—cotton with filter insert—commercial, novelty market.

Figure 22.

Fabric masks—cotton with filter insert—commercial, novelty market.

Figure 22.

Fabric masks—cotton with filter insert—commercial, novelty market.

Figure 23.

Fabric masks—polyester fiber blend—commercial retail (neutral).

Figure 23.

Fabric masks—polyester fiber blend—commercial retail (neutral).

Figure 24.

Fabric masks—neoprene—commercial retail (neutral).

Figure 24.

Fabric masks—neoprene—commercial retail (neutral).

Figure 25.

Fabric masks—silk—commercial retail (monochrome). Pleated type.

Figure 25.

Fabric masks—silk—commercial retail (monochrome). Pleated type.

Figure 26.

Fabric mask—cotton—artisanal production. Flat sheet design.

Figure 27.

Fabric masks—cotton—artisanal production. Pleated type.

Figure 28.

Fabric masks—cotton—artisanal production. Beaked type with ear loops.

Figure 29.

Fabric masks—cotton—artisanal production. Rounded type without ear loops.

4. Discussion

The wearing of fitted masks was advocated by public health authorities to (a) partially protect the wearer from inhaling ambient air that may contain a virus load and (b) prevent the wearer, if infected with SARS-CoV-2, from freely shedding the virus. Although masks with exhalation valves (which made breathing easier) had the same level of protection for the user, they were declared unsuitable for many health settings, as the valves either had no filter or the filtering of the exhaled air was insufficient [69,70,71,72].

In the Australian setting, the first few months of the pandemic saw a general shortage of medical-quality protective equipment (PPE), in particular face masks, as well as a shortage of hand sanitizer. In part, this was caused by panic buying and associated hoarding [73], which also extended to other goods, such as household pantry staples and toilet paper [16]. On a more significant scale, the shortages were the result of complex, global supply chains that were predicated on on-time delivery based on predictable demand volumes [74,75,76] with production concentrated in a few countries, primarily China. Although the speed of the spread of the pandemic soon overwhelmed these supply chains [73], restrictions on the movement of people and goods, coupled with border closures, effectively severed of most them [77,78,79]. This led to investigations of sterilization options for the safe reuse of PPE [73,80,81,82,83,84], as well as a repurposing of local production to meet demand, such as gin distilleries pivoting to produce hand sanitizer [16], and a restarting of local PPE production [85,86].

Although masks were generally in short supply during the early days of the pandemic, this in particular applied to masks with higher levels of protection (N95) and those among these masks with tighter and better-fitting designs, such as flat-fold masks [87]. The shortage of standard masks soon resulted in a ‘run’ on P2 and N95 masks used for the professional building and gardening trade, outstripping supply within a week or two.

Figure 30.

Fabric mask—cotton—artisanal production. Two incomplete homemade masks with pins attached, as well as two templates used, donated to charity in mid-2022. The newspaper clipping dates to 25 September 2020 suggesting the commencement of artisanal production [13].

Figure 30.

Fabric mask—cotton—artisanal production. Two incomplete homemade masks with pins attached, as well as two templates used, donated to charity in mid-2022. The newspaper clipping dates to 25 September 2020 suggesting the commencement of artisanal production [13].

Fitted face masks crafted from fabric, rather than polypropylene, were seen as a stop-gap measure given the shortage of single-use surgical masks in the face of an unprecedented demand for fitted face masks, where, in essence, almost every adult and every older child required more than one of these. To offset the initial shortage in commercially manufactured, single-use face masks, the public health advice in 2020 was that wearing a cloth mask, while having a lesser capability of filtering out pathogens and thus providing a lesser level of protection than single-use surgical masks, was better than wearing no mask at all [52]. Initially designed as a stopgap measure, public health departments [66], as well as newspapers [88], provided design instructions for simple, easy-to-sew fabric masks. Given the national health emergency and the collective and community goodwill, national drapery chains published cutting and sewing templates for fitted face masks and made them available free of charge for homemakers and small-scale artisanal creators [67,68]. The fact that these masks were washable and thus reusable favorably contrasted in the minds of many with the environmental concerns about the volumes of single-use PPE entering the municipal waste streams [89,90,91,92,93] and the environment in general [17,18,19,20,21,22,23,24,25,26,27,28,29,30]. Thus, even after single-use surgical-type masks became available once supply chains recovered, many continued to use fabric masks. This was aided by the fact that commercial production soon commenced, with major clothing retailers quickly recognizing the commercial opportunity this provided [16]. At the same time, many corporations, as well as community organizations, recognized the opportunity for branding and promotional use [12,16,94,95,96].

Although the lower effectiveness of cloth masks was soon demonstrated [97,98,99,100,101,102], public health advice maintained that any mask was better than no mask [52]. The emergence of the more infectious Delta and Omicron variants of SARS-CoV-2 in late 2021 and early saw public health advice formally counseling against the use of fabric masks as they were deemed to be less effective than P2/KN 95 masks [103,104], echoing earlier concerns [105,106]. The artisanal production of fabric masks ended almost immediately, with existing stock often donated to charities [13], which, at this point, did not offer such masks for sale or hand-out, but added them into the non-retail (rag) fabric stream.

Fabric masks continued to be sold by clothing retailers, as well as online stores but were offered at discounts, with the lines being discontinued. After the mandate to wear fitted face coverings in all but healthcare settings was repealed (in Australia) in April 2022, [107] the demand for single-use surgical as well as N95 masks dropped dramatically. At the time of writing (February 2023), single-use surgical as well as N95 masks are freely available, but their offerings in pharmacies and chemists have been reduced, with many mainstream supermarkets no longer stocking them in sizeable quantities.

5. Conclusions

As the incidence of COVID-19 infections continues to decrease due to high vaccination rates, as reporting on the pandemic has become the exception, rather than the once-daily norm, the pandemic has begun to recede in the public consciousness as a past to be overcome and rapidly forgotten. This paper has placed on record and contextualized the wide range of face masks used and worn during the pandemic and may serve as a future reference point for the various mask types.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The author declares no conflict of interest.

References

- WHO. Naming the Coronavirus Disease (COVID-19) and the Virus That Causes It. Available online: https://www.who.int/emergencies/diseases/novel-coronavirus-2019/technical-guidance/naming-the-coronavirus-disease-(covid-2019)-and-the-virus-that-causes-it (accessed on 10 August 2020).

- Stadnytskyi, V.; Anfinrud, P.; Bax, A. Breathing, speaking, coughing or sneezing: What drives transmission of SARS-CoV-2? J. Intern. Med. 2021, 290, 1010–1027. [Google Scholar] [CrossRef]

- Gorbunov, B. Aerosol particles generated by coughing and sneezing of a SARS-CoV-2 (COVID-19) host travel over 30 m distance. Aerosol Air Qual. Res. 2021, 21, 200468. [Google Scholar] [CrossRef]

- Karaivanov, A.; Lu, S.E.; Shigeoka, H.; Chen, C.; Pamplona, S. Face masks, public policies and slowing the spread of COVID-19: Evidence from Canada. J. Health Econ. 2021, 78, 102475. [Google Scholar] [CrossRef]

- Cherry, T.L.; James, A.G.; Murphy, J. The impact of public health messaging and personal experience on the acceptance of mask wearing during the COVID-19 pandemic. J. Econ. Behav. Organ. 2021, 187, 415–430. [Google Scholar] [CrossRef]

- Guy, G.P., Jr.; Lee, F.C.; Sunshine, G.; McCord, R.; Howard-Williams, M.; Kompaniyets, L.; Dunphy, C.; Gakh, M.; Weber, R.; Sauber-Schatz, E. Association of state-issued mask mandates and allowing on-premises restaurant dining with county-level COVID-19 case and death growth rates—United States, March 1–December 31, 2020. Morb. Mortal. Wkly. Rep. 2021, 70, 350. [Google Scholar] [CrossRef] [PubMed]

- MacIntyre, C.R.; Nguyen, P.-Y.; Chughtai, A.A.; Trent, M.; Gerber, B.; Steinhofel, K.; Seale, H. Mask use, risk-mitigation behaviours and pandemic fatigue during the COVID-19 pandemic in five cities in Australia, the UK and USA: A cross-sectional survey. Int. J. Infect. Dis. 2021, 106, 199–207. [Google Scholar] [CrossRef] [PubMed]

- Prata, J.C.; Silva, A.L.P.; Duarte, A.C.; Rocha-Santos, T. Disposable over Reusable Face Masks: Public Safety or Environmental Disaster? Environments 2021, 8, 31. [Google Scholar] [CrossRef]

- Kournikakis, B.; Harding, R.K.; Tremblay, J.; Simpson, M. Comparison of protection factors for selected medical, industrial and military masks. Appl. Biosaf. 2000, 5, 12–18. [Google Scholar] [CrossRef]

- Cherrie, J.W.; Apsley, A.; Cowie, H.; Steinle, S.; Mueller, W.; Lin, C.; Horwell, C.J.; Sleeuwenhoek, A.; Loh, M. Effectiveness of face masks used to protect Beijing residents against particulate air pollution. Occup. Environ. Med. 2018, 75, 446–452. [Google Scholar] [CrossRef]

- Park, C.-Y.; Kim, K.; Roth, S. Global Shortage of Personal Protective Equipment Amid COVID-19: Supply Chains, Bottlenecks, and Policy Implications; Asian Development Bank: Mandaluyong, Philippines, 2020. [Google Scholar]

- Sayers, E. Facing COVID: Engaging participants during lockdown. Int. J. Disabil. Hum. Dev. 2022, 21, 353–358. [Google Scholar]

- Spennemann, D.H.R. The Material Culture of the COVID-19 Pandemic. Face Masks Donated to Charity. A Cross-Section of Masks Donated to Charitable Organisations by a Regional Australian Community; SAEVS, Charles Sturt University: Albury, NSW, Australia, 2022. [Google Scholar]

- Spennemann, D.H.R. Patterns of a Pandemic. A Documentation of COVID-19 Masks Sold, Lost and Discarded in a Regional Australian City; No. 164; Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, Australia, 2021. [Google Scholar]

- MedicalXpress. China Exported MORE than 220 Billion Masks in 2020: Government. Available online: https://medicalxpress.com/news/2021-01-china-exported-billion-masks.html (accessed on 2 March 2023).

- Spennemann, D.H.R. Collecting COVID-19 Ephemera: A Photographic Documentation of Examples from Regional Australia; Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, Australia, 2021. [Google Scholar]

- De-la-Torre, G.E.; Dioses-Salinas, D.C.; Dobaradaran, S.; Spitz, J.; Keshtkar, M.; Akhbarizadeh, R.; Abedi, D.; Tavakolian, A. Physical and chemical degradation of littered personal protective equipment (PPE) under simulated environmental conditions. Mar. Pollut. Bull. 2022, 178, 113587. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Chen, X.; Liu, Q.; Zhao, Q.; Xiong, X.; Wu, C. Used disposable face masks are significant sources of microplastics to environment. Environ. Pollut. 2022, 285, 117485. [Google Scholar] [CrossRef] [PubMed]

- Cornelio, A.; Zanoletti, A.; Federici, S.; Ciacci, L.; Depero, L.E.; Bontempi, E. Environmental Impact of Surgical Masks Consumption in Italy Due to COVID-19 Pandemic. Materials 2022, 15, 2046. [Google Scholar] [CrossRef]

- Du, H.; Huang, S.; Wang, J. Environmental risks of polymer materials from disposable face masks linked to the COVID-19 pandemic. Sci. Total Environ. 2022, 815, 152980. [Google Scholar] [CrossRef] [PubMed]

- Fadare, O.O.; Okoffo, E.D. Covid-19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020, 737, 140279. [Google Scholar] [CrossRef]

- Kwak, J.I.; An, Y.J. Post COVID-19 pandemic: Biofragmentation and soil ecotoxicological effects of microplastics derived from face masks. J. Hazard. Mater. 2021, 416, 126169. [Google Scholar] [CrossRef]

- Liang, H.; Ji, Y.; Ge, W.; Wu, J.; Song, N.; Yin, Z.; Chai, C. Release kinetics of microplastics from disposable face masks into the aqueous environment. Sci. Total Environ. 2022, 816, 151650. [Google Scholar] [CrossRef]

- Saliu, F.; Veronelli, M.; Raguso, C.; Barana, D.; Galli, P.; Lasagni, M. The release process of microfibers: From surgical face masks into the marine environment. Environ. Adv. 2021, 4, 100042. [Google Scholar] [CrossRef]

- Selvaranjan, K.; Navaratnam, S.; Rajeev, P.; Ravintherakumaran, N. Environmental challenges induced by extensive use of face masks during COVID-19: A review and potential solutions. Environ. Chall. 2021, 3, 100039. [Google Scholar] [CrossRef]

- Shen, M.; Zeng, Z.; Song, B.; Yi, H.; Hu, T.; Zhang, Y.; Zeng, G.; Xiao, R. Neglected microplastics pollution in global COVID-19: Disposable surgical masks. Sci. Total Environ. 2021, 790, 148130. [Google Scholar] [CrossRef]

- Silva, A.L.P.; Prata, J.C.; Mouneyrac, C.; Barcelò, D.; Duarte, A.C.; Rocha-Santos, T. Risks of Covid-19 face masks to wildlife: Present and future research needs. Sci. Total Environ. 2021, 792, 148505. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; An, C.; Chen, X.; Lee, K.; Zhang, B.; Feng, Q. Disposable masks release microplastics to the aqueous environment with exacerbation by natural weathering. J. Hazard. Mater. 2021, 417, 126036. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.; Li, J.; Lu, X.; Tang, Y.; Cai, Z. Release of tens of thousands of microfibers from discarded face masks under simulated environmental conditions. Sci. Total Environ. 2022, 806, 150458. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Chen, F.; Xu, H.; Jiang, H.; Liu, J.; Li, P.; Chen, C.C.; Pan, K. Face masks as a source of nanoplastics and microplastics in the environment: Quantification, characterization, and potential for bioaccumulation. Environ. Pollut. 2021, 288, 117748. [Google Scholar] [CrossRef] [PubMed]

- Duong, M.C.; Nguyen, H.T.; Duong, B.T. A Cross-Sectional Study of Knowledge, Attitude, and Practice Towards Face Mask Use Amid the COVID-19 Pandemic Amongst University Students in Vietnam. J. Community Health 2021, 46, 975–981. [Google Scholar] [CrossRef] [PubMed]

- Dwivedi, K.; Sharma, E.; Fatima, N. An empirical analysis on consumer’s preferences of face mask during COVID-19 pandemic. Int. J. Home Sci. 2021, 7, 147–151. [Google Scholar]

- Green, D.N.; Kozen, F.H.; Blumenkamp, C.K. Facemasking Behaviors, Preferences, and Attitudes among Emerging Adults in the United States during the COVID-19 Pandemic: An Exploratory Study. Cloth. Text. Res. J. 2021, 39, 216–231. [Google Scholar] [CrossRef]

- Lee, L.Y.-K.; Chan, I.C.-W.; Wong, O.P.-M.; Ng, Y.H.-Y.; Ng, C.K.-Y.; Chan, M.H.-W.; Ng, J.K.-C.; Koo, H.H.-T.; Lam, S.-T.; Chu, A.C.-W. Reuse of face masks among adults in Hong Kong during the COVID-19 pandemic. BMC Public Health 2021, 21, 1267. [Google Scholar] [CrossRef] [PubMed]

- Matusiak, Ł.; Szepietowska, M.; Krajewski, P.K.; Białynicki-Birula, R.; Szepietowski, J.C. The use of face masks during the COVID-19 pandemic in Poland: A survey study of 2315 young adults. Dermatol. Ther. 2020, 33, e13909. [Google Scholar] [CrossRef]

- Angelo, D.; Britt, K.M.; Brown, M.L.; Camp, S.L. Spaces: Documenting COVID-19 Material Culture and Landscapes. J. Contemp. Archaeol. 2021, 8, 154–184. [Google Scholar]

- Magnani, M.; Magnani, N.; Venovcevs, A.; Farstadvoll, S. A contemporary archaeology of pandemic. J. Soc. Archaeol. 2021, 21, 48–81. [Google Scholar] [CrossRef]

- Magnani, M.; Venovcevs, A.; Farstadvoll, S.; Magnani, N. How to record current events like an archaeologist. Adv. Archaeol. Pract. 2021, 9, 379–386. [Google Scholar] [CrossRef]

- Schofield, J.; Praet, E.; Townsend, K.A.; Vince, J. ‘COVID waste’ and social media as method: An archaeology of personal protective equipment and its contribution to policy. Antiquity 2021, 95, 435–449. [Google Scholar] [CrossRef]

- Witcher, R. The materiality of COVID-19. Antiquity 2021, 95, 285–292. [Google Scholar]

- Davis, M.D.M. ‘Live with the Virus’ Narrative and Pandemic Amnesia in the Governance of COVID-19. Soc. Sci. 2022, 11, 340. [Google Scholar] [CrossRef]

- Tanne, J.H. COVID-19: Former advisers urge Biden to adopt new pandemic strategy and learn to live with virus. BMJ 2022, 376, o56. [Google Scholar] [CrossRef]

- Department of Health and Aged Care. Coronavirus (COVID-19) Case Numbers and Statistics. COVID-19 Cases and 7 Day Rolling Average, 01 Jan 2022 to 21 Feb 2023. Available online: https://www.health.gov.au/health-alerts/covid-19/case-numbers-and-statistics (accessed on 27 February 2023).

- Spennemann, D.H.R. The Future Archaeological Signature of Single-Use Surgical Face Masks, the Most Ubiquitous Artefact of the COVID-19 Pandemic: A Typological Study; SAEVS, Charles Sturt University: Albury, NSW, Australia, 2023. [Google Scholar]

- Spennemann, D.H.R. The Material Culture of the COVID-19 Pandemic. Descriptive Catalogue of Reusable COVID-19 Masks Collected on the Streets of Albury (NSW) between August and December 2021. Report to the Albury LibraryMuseum; Charles Sturt University: Albury, NSW, Australia, 2022. [Google Scholar]

- Spennemann, D.H.R. Environmental Decay of Single Use Surgical Face Masks as an agent of plastic micro-fiber pollution. Environments 2022, 9, 94. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. Facing COVID-19: Quantifying the use of reusable vs disposable facemasks. Hygiene 2021, 1, 120–128. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. A Rapid Observational Survey of Face Mask Use in a Major Shopping Centre in Melbourne (Victoria); Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, Australia, 2021. [Google Scholar]

- Spennemann, D.H.R. A Rapid Observational Survey of Face Mask Use in a Major Shopping Centre in Sydney (New South Wales); Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, Australia, 2022. [Google Scholar]

- Safe Work Australia. Comparison of Mask Types for COVID-19. Available online: https://covid19.swa.gov.au/comparison-mask-types-covid-19 (accessed on 20 February 2023).

- Infection Control Expert Group. Infection Control Expert Group. The Use of Face Masks and Respirators in the Context of COVID-19; Departmwent of Health: Canberra, ACT, Australia, 2020. [Google Scholar]

- CDC. Types of Masks and Respirators [Archive Copy]. Available online: https://web.archive.org/web/20210210180932/https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/types-of-masks.html (accessed on 20 February 2023).

- Bonds. Bonds Protective Comfy Face Mask Treated eith HEIQ Viroblock. Available online: https://www.bonds.com.au/bonds-face-mask-3-pack-zynr-blk.html (accessed on 21 February 2023).

- Factorie. Foundation Face Mask Adults. Available online: https://factorie.com.au/show-variation/?pid=9630228 (accessed on 15 October 2021).

- Supre. Foundation Face Mask Junior. Available online: https://supre.com.au/foundation-face-mask-junior/9630171-04.html (accessed on 20 February 2023).

- Ghanda. Face Mask. Available online: https://ghanda.com/product/face-mask_natural_642 (accessed on 21 February 2023).

- Cotton On. Foundation Face Mask Adults. Available online: https://cottonon.com/UK/foundation-face-mask-adults/9357067451063.html (accessed on 15 October 2021).

- Cotton On. Foundation Face Mask Junior. Available online: https://cottonon.com/SG/foundation-face-mask-adults/9630228-05.html?bvstate=pg:9/ct:r (accessed on 18 January 2022).

- Sexy Socks. Our Fabric Face Masks + Active Snood. Available online: https://buysexysocks.com/all-about-our-fabric-face-masks-active-snood/ (accessed on 21 February 2023).

- Carbon Collective. Reticulated Polyurethane Foam Mask. Available online: https://www.carboncollective.com/product/reticulated-polyurethane-foam-mask/ (accessed on 21 February 2023).

- FaceTubes. Pink Face Masks Face Mask Washable Neoprene Reusable Covid. Available online: https://www.facetubes.com.au/products/pink-face-masks-face-mask-washable-neoprene-reusable-covid (accessed on 21 February 2023).

- CHUU. CHUU Fashion Washable Soft Neoprene Face Cover Mask. Available online: https://www.amazon.com.au/CHUU-Fashion-Washable-Neoprene-Summer/dp/B0895JX6D3 (accessed on 20 February 2023).

- FaceTubes Australia. Black Face Masks Face Mask Washable Neoprene Reusable Covid. Available online: https://www.facetubes.com.au/products/black-face-masks-face-mask-washable-neoprene-reusable-covid?_pos=3&_sid=d7228c53f&_ss=r (accessed on 20 February 2023).

- ToBeGear. Reusable Washable Breathable Face Masks Single Layer. Available online: https://tobe.com.au/products/reusable-washable-breathable-face-masks-single-layer?variant=42930353078442 (accessed on 20 February 2023).

- Lovisa. 100% Silk Mask. Available online: www.lovisa.com.au/collections/100-silk-face-masks (accessed on 12 October 2022).

- Department of Health & Human Services. How to Make a Cloth Mask. Instructions for Making a Cloth Face Mask. Available online: https://www.dhhs.vic.gov.au/sites/default/files/documents/202007/Design%20and%20preparation%20of%20cloth%20mask_0.pdf (accessed on 10 December 2020).

- Lincraft. Face Mask; Lincraft: Melbourne, Australia, 2020. [Google Scholar]

- Spotlight. Nose Wire Mask Project Sheet; Spotlight: South Melbourne, Australia, 2020. [Google Scholar]

- Baradaran-Binazir, M.; Heidari, F. The necessity of prohibiting the masks with exhalation valve during emerging infections Like COVID-19. Asia Pac. J. Public Health 2021, 33, 458–459. [Google Scholar] [CrossRef]

- Matuschek, C.; Moll, F.; Fangerau, H.; Fischer, J.C.; Zänker, K.; van Griensven, M.; Schneider, M.; Kindgen-Milles, D.; Knoefel, W.T.; Lichtenberg, A. Face masks: Benefits and risks during the COVID-19 crisis. Eur. J. Med. Res. 2020, 25, 32. [Google Scholar] [CrossRef]

- Chang, J.C.; Johnson, J.S.; Olmsted, R.N. Demystifying theoretical concerns involving respirators with exhalation valves during COVID-19 pandemic. Am. J. Infect. Control 2020, 48, 1564–1565. [Google Scholar] [CrossRef] [PubMed]

- Ippolito, M.; Iozzo, P.; Gregoretti, C.; Grasselli, G.; Cortegiani, A. Facepiece filtering respirators with exhalation valve should not be used in the community to limit SARS-CoV-2 diffusion. Infect. Control Hosp. Epidemiol. 2021, 42, 369–370. [Google Scholar] [CrossRef]

- Kirubarajan, A.; Khan, S.; Got, T.; Yau, M.; Bryan, J.M.; Friedman, S.M. Mask shortage during epidemics and pandemics: A scoping review of interventions to overcome limited supply. BMJ Open 2020, 10, e040547. [Google Scholar] [CrossRef] [PubMed]

- Shin, H.; Tunca, T.I. Do firms invest in forecasting efficiently? The effect of competition on demand forecast investments and supply chain coordination. Oper. Res. 2010, 58, 1592–1610. [Google Scholar] [CrossRef]

- An, C.; Fromm, H. Supply Chain Management on Demand: Strategies and Technologies, Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Li, P. Supply Chain Management; BoD–Books on Demand: Paris, France, 2011. [Google Scholar]

- Francis, J.R. COVID-19: Implications for supply chain management. Front. Health Serv. Manag. 2020, 37, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Rowan, N.J.; Laffey, J.G. Challenges and solutions for addressing critical shortage of supply chain for personal and protective equipment (PPE) arising from Coronavirus disease (COVID-19) pandemic–Case study from the Republic of Ireland. Sci. Total Environ. 2020, 725, 138532. [Google Scholar] [CrossRef] [PubMed]

- Miller, F.A.; Young, S.B.; Dobrow, M.; Shojania, K.G. Vulnerability of the medical product supply chain: The wake-up call of COVID-19. BMJ Qual. Saf. 2021, 30, 331–335. [Google Scholar] [CrossRef] [PubMed]

- Armani, A.M.; Hurt, D.E.; Hwang, D.; McCarthy, M.C.; Scholtz, A. Low-tech solutions for the COVID-19 supply chain crisis. Nat. Rev. Mater. 2020, 5, 403–406. [Google Scholar] [CrossRef] [PubMed]

- Schwartz, A.; Stiegel, M.; Greeson, N.; Vogel, A.; Thomann, W.; Brown, M.; Sempowski, G.D.; Alderman, T.S.; Condreay, J.P.; Burch, J. Decontamination and reuse of N95 respirators with hydrogen peroxide vapor to address worldwide personal protective equipment shortages during the SARS-CoV-2 (COVID-19) pandemic. Appl. Biosaf. 2020, 25, 67–70. [Google Scholar] [CrossRef] [PubMed]

- Boškoski, I.; Gallo, C.; Wallace, M.B.; Costamagna, G. COVID-19 pandemic and personal protective equipment shortage: Protective efficacy comparing masks and scientific methods for respirator reuse. Gastrointest. Endosc. 2020, 92, 519–523. [Google Scholar] [CrossRef] [PubMed]

- Rubio-Romero, J.C.; del Carmen Pardo-Ferreira, M.; Torrecilla-García, J.A.; Calero-Castro, S. Disposable masks: Disinfection and sterilization for reuse, and non-certified manufacturing, in the face of shortages during the COVID-19 pandemic. Saf. Sci. 2020, 129, 104830. [Google Scholar] [CrossRef] [PubMed]

- Gilbert, R.M.; Donzanti, M.J.; Minahan, D.J.; Shirazi, J.; Hatem, C.L.; Hayward-Piatkovskyi, B.; Dang, A.M.; Nelson, K.M.; Bothi, K.L.; Gleghorn, J.P. Mask reuse in the COVID-19 pandemic: Creating an inexpensive and scalable ultraviolet system for filtering facepiece respirator decontamination. Glob. Health Sci. Pract. 2020, 8, 582–595. [Google Scholar] [CrossRef] [PubMed]

- Gibson, C.; Carr, C.; Lyons, C.; Taksa, L.; Warren, A. COVID-19 and the shifting industrial landscape. Geogr. Res. 2021, 59, 196–205. [Google Scholar] [CrossRef]

- Nilasaroya, A.; Kop, A.M.; Collier, R.C.; Kennedy, B.; Kelsey, L.J.; Pollard, F.; Ha, J.F.; Morrison, D.A. Establishing local manufacture of PPE for healthcare workers in the time of a global pandemic. Heliyon 2023, 9, e13349. [Google Scholar] [CrossRef] [PubMed]

- Cameron, S.; Cheung, W.; Cronin, N.; Griffiths, K.; Hunt, R.; Innes, L.; Kol, M.; Lawrence, A.; Shah, A.; Skylas, K.; et al. Quantitative fit testing with limited supplies of respirator masks in hospital personnel during the COVID-19 pandemic. Aust. Health Rev. 2020, 44, 542–543. [Google Scholar] [CrossRef]

- Washington Post Staff. How to Sew Your Own Fabric Mask. Available online: https://www.washingtonpost.com/health/2020/04/05/how-sew-your-own-fabric-mask/ (accessed on 20 February 2023).

- Ammendolia, J.; Coalition, C.O.L.; Saturno, J.; Jacobs, S. Environmental concern emerges from COVID-19 pandemic: PPE waste by the public. Can. Sci. Policy Cent. 2020.

- Wang, Z.; Guy, C.; Ng, K.T.W.; An, C. A new challenge for the management and disposal of personal protective equipment waste during the COVID-19 pandemic. Sustainability 2021, 13, 7034. [Google Scholar] [CrossRef]

- Islam, S.D.-U.; Safiq, M.B.; Bodrud-Doza, M.; Mamun, M.A. Perception and attitudes toward PPE-related waste disposal amid COVID-19 in Bangladesh: An exploratory study. Front. Public Health 2020, 8, 592345. [Google Scholar] [CrossRef] [PubMed]

- Nowakowski, P.; Kuśnierz, S.; Sosna, P.; Mauer, J.; Maj, D. Disposal of personal protective equipment during the COVID-19 pandemic is a challenge for waste collection companies and society: A case study in Poland. Resources 2020, 9, 116. [Google Scholar] [CrossRef]

- Olatayo, K.I.; Mativenga, P.T.; Marnewick, A.L. COVID-19 PPE plastic material flows and waste management: Quantification and implications for South Africa. Sci. Total Environ. 2021, 790, 148190. [Google Scholar] [CrossRef]

- Jiang, M.; Dodoo, N.A. Promoting Mask-Wearing in COVID-19 Brand Communications: Effects of Gain-Loss Frames, Self-or Other-Interest Appeals, and Perceived Risks. J. Advert. 2021, 50, 271–279. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, D.; Ho, W.Y.J. Identity, lifestyle, and face-mask branding: A social semiotic multimodal discourse analysis. Multimodality Soc. 2021, 1, 216–237. [Google Scholar] [CrossRef]

- Faruque, Z. Know how to manage face-mask branding in the time of COVID-19. Campus Leg. Advis. 2020, 21, 1–3. [Google Scholar] [CrossRef]

- Chughtai, A.A.; Seale, H.; Macintyre, C.R. Effectiveness of cloth masks for protection against severe acute respiratory syndrome coronavirus 2. Emerg. Infect. Dis. 2020, 26, e200948. [Google Scholar] [CrossRef] [PubMed]

- Ataei, M.; Shirazi, F.M.; Nakhaee, S.; Abdollahi, M.; Mehrpour, O. Assessment of cloth masks ability to limit Covid-19 particles spread: A systematic review. Environ. Sci. Pollut. Res. 2022, 29, 1645–1676. [Google Scholar] [CrossRef] [PubMed]

- Narayan, Y.; Chatterjee, S.; Agrawal, A.; Bhardwaj, R. Assessing effectiveness and comfortability of a two-layer cloth mask with a high-efficiency particulate air (HEPA) insert to mitigate COVID-19 transmission. Phys. Fluids 2022, 34, 061703. [Google Scholar] [CrossRef]

- Tanisali, G.; Sozak, A.; Bulut, A.S.; Sander, T.Z.; Dogan, O.; Dağ, Ç.; Gönen, M.; Can, F.; DeMirci, H.; Ergonul, O. Effectiveness of different types of mask in aerosol dispersion in SARS-CoV-2 infection. Int. J. Infect. Dis. 2021, 109, 310–314. [Google Scholar] [CrossRef] [PubMed]

- Andrejko, K.L.; Pry, J.M.; Myers, J.F.; Fukui, N.; DeGuzman, J.L.; Openshaw, J.; Watt, J.P.; Lewnard, J.A.; Jain, S.; COVID, C. Effectiveness of face mask or respirator use in indoor public settings for prevention of SARS-CoV-2 infection—California, February–December 2021. Morb. Mortal. Wkly. Rep. 2022, 71, 212. [Google Scholar] [CrossRef]

- Duncan, S.; Bodurtha, P.; Naqvi, S. The protective performance of reusable cloth face masks, disposable procedure masks, KN95 masks and N95 respirators: Filtration and total inward leakage. PLoS ONE 2021, 16, e0258191. [Google Scholar] [CrossRef]

- Pieris, A.; Lozanovska, M.; Dellios, A.; Miller-Yeaman, R.; Eklund, E.; Beynon, D.; Tuffin, R. Industrial sites and immigrant architectures. A case study approach. Fabrications 2019, 29, 257–272. [Google Scholar] [CrossRef]

- Mandavilli, A. The C.D.C. Concedes That Cloth Masks Do Not Protect against the Virus as Effectively as Other Masks [New York Times]. Available online: https://www.nytimes.com/2022/01/14/health/cloth-masks-covid-cdc.html (accessed on 20 February 2023).

- Morris, L.; Noack, R. Europe’s Growing Mask Ask: Ditch the Cloth Ones for Medical-Grade Coverings [The Washington Post]. Available online: https://www.washingtonpost.com/world/europe/europe-coronavirus-masks-regulations/2021/01/20/23463c08-5a74-11eb-a849-6f9423a75ffd_story.html (accessed on 12 February 2023).

- Nirappil, F. Time to Double or Upgrade Masks as Coronavirus Variants Emerge, Experts Say. Available online: https://www.washingtonpost.com/health/2021/01/27/double-mask-variants-guidance/ (accessed on 12 February 2023).

- Commissioner, H.C. Wearing a Face Mask in Healthcare Settings. Available online: https://hcc.vic.gov.au/public/wearing-face-mask-healthcare-settings (accessed on 20 February 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).