1. Introduction

In China, with the advent of iron, iron implements soon became widespread and were important factors in economic development as well as daily life (

Lam, 2022). Scholarly inquiry into these iron tools has predominantly concentrated on the implements themselves, whereas experimental archaeological investigations into their use, operational effectiveness, and the materials processed have been notably scant. This imbalance in research has resulted in a tendency to overlook the broader context, focusing merely on the individual components rather than the overarching system.

This paper employs micro-wear analysis to undertake experimental archaeological research on the incisions on animal bones created by iron and steel knives. Such research has the potential to enhance the comparative study of iron knives of varying sizes, as well as providing evidence of the use of kitchen knives in the Han dynasty.

Micro-wear analysis was initially championed and implemented by Soviet archaeologist S.A. Semenov, whose groundbreaking work

Prehistoric Technology (

Semenov, 1964) pioneered the use of microscopic examination to observe and interpret the usage of stone tools. In recent years, researchers have employed micro-wear analysis techniques to investigate the traces left by stone and metal cutting, delving into the beginnings of metallurgy (

Greenfield, 1999;

Wang et al., 2022). This approach has enabled the differentiation of various tools based on their cutting traces, the identification of metal tool usage across different social classes, and the examination of how new technologies have influenced societal shifts (

Greenfield, 2000). Ethnographic research has also been conducted on cutting and tooth marks (

Lupo & O’Connell, 2002). Scholars have not only examined the “cut marks” themselves (

Bello et al., 2009;

De Juana et al., 2010;

Merritt, 2012), but have also sought to observe and analyse them using innovative technologies and methodologies (

Bello, 2011;

González et al., 2015;

Yravedra et al., 2017;

Maté-González et al., 2018).

In current research on animal bone “cut marks”, studies predominantly focus on the Palaeolithic period, where stone tools such as hand axes, picks, and scrapers left distinct traces on bones during animal slaughter and butchery (

Galán & Domínguez-Rodrigo, 2012). For the Bronze Age, experimental simulations and microwear analyses of bone surface marks have centred on animal slaughter practices (

Greenfield & Marciniak, 2018;

Greenfield et al., 2022) and comparisons with tool marks left by stone implements (

Greenfield, 1999;

Okaluk & Greenfield, 2022). This study, however, investigates truncation marks produced by “iron tools” on animal bones, encompassing not only cut marks but also “snapping marks”.

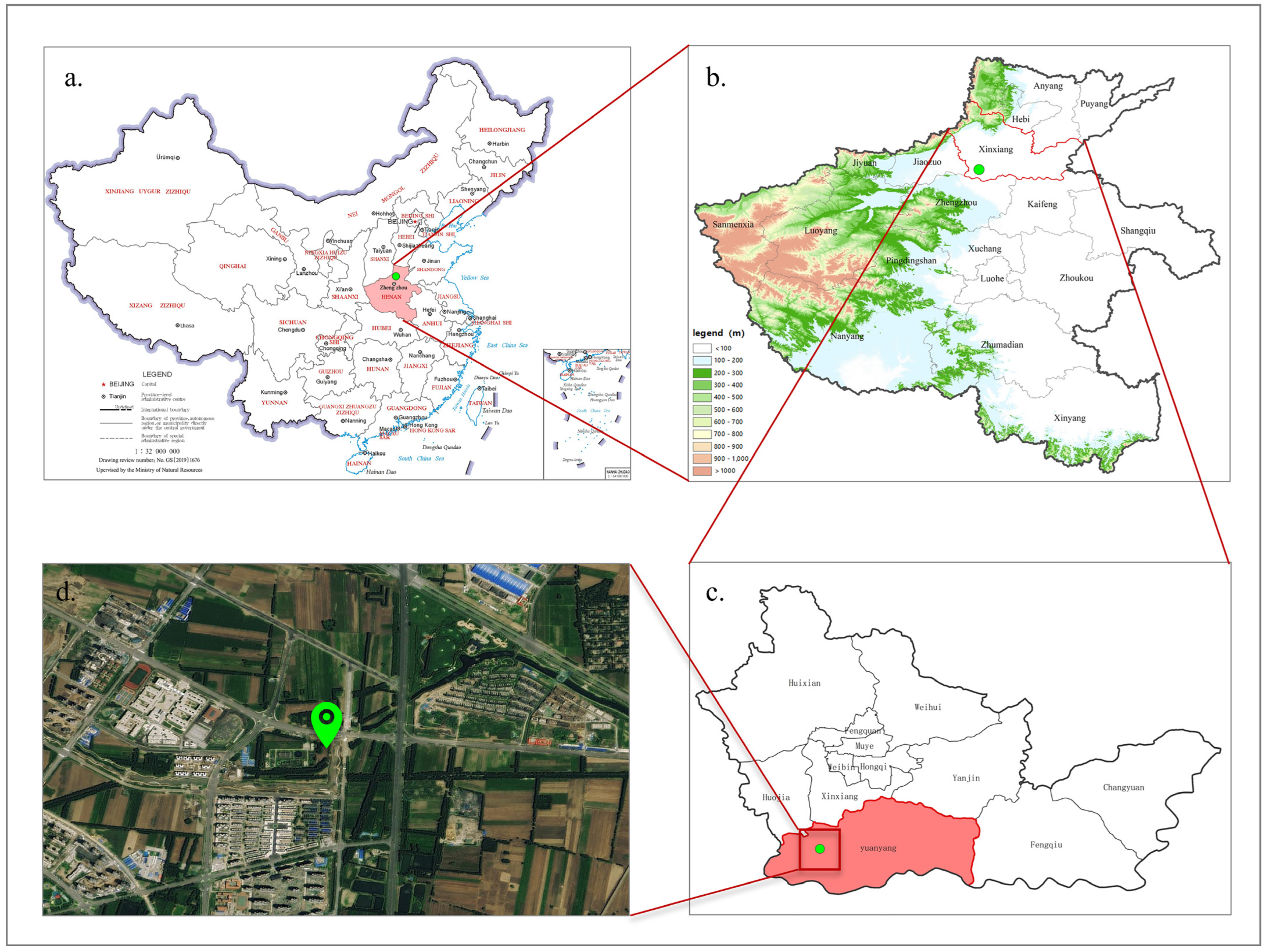

The archaeological materials featured in this article originate from animal bones excavated from Han dynasty tombs situated at Fenghu, within the Pingyuan New District of Xinxiang City, Henan Province, China (

Figure 1). The tomb complex is situated in Wuzhuang Village, Yuanwu Town, Pingyuan New District. This particular Han dynasty tomb complex comprises 16 ancient tombs, with 13 being Western Han dynasty hollow brick tombs and the remaining 3 being Eastern Han dynasty brick chamber tombs, yielding over 30 artefacts (

H. Li et al., 2020).

Among the Fenghu Han dynasty tombs, one tomb yielded animal bones with clear tool marks. The left ulna (2017XPFM6:1) and the left radius (2017XPFM6:2) of a dog were severed with some sort of cutting tool. Under the observation of a stereomicroscope, it was preliminarily inferred that these two specimens were severed using metal tools with techniques and skills such as rocking slicing, rolling slicing, and breaking. To verify this result, this article conducted experiments for further argumentation.

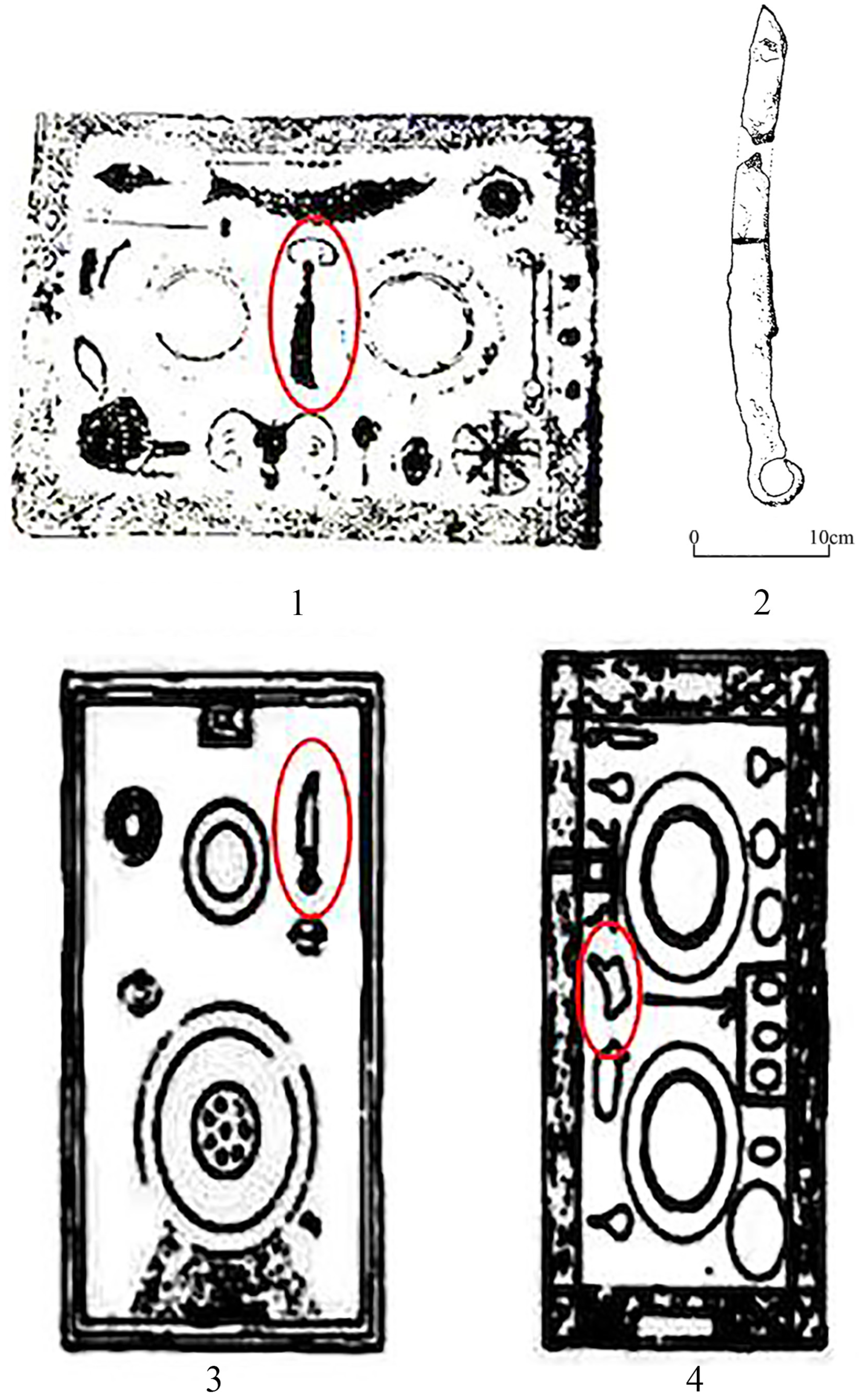

During the Han dynasty (202BC–AD220), a knife akin to the broad-bladed chopper knives commonly used today was imprinted on the surface of a Han-Wei period (202BC–AD266) earthen stove unearthed in Henan (

Figure 2(1)), signifying the presence of such kitchen knives in the Central Plains region during that era (

G. Li & Yang, 2014). During the excavation of Han dynasty tombs at Shaogou in Luoyang, a broad-backed short knife, distinct from typical weapons or hand tools, was consistently found in association with pottery stoves or rectangular food boxes. This knife, crafted from iron, is argued to have been utilised for culinary purposes (

Su, 2014). Moreover, archaeological findings reveal that a substantial quantity of narrow slicing or filleting knives have been unearthed in the Henan area (

Figure 2(2)) (

Institute of Archaeology, 1959). On the unearthed pottery stoves, narrow filleting knives (

Figure 2(3)) as well as broad-bladed chopping knives are depicted (

Figure 2(4)) (

Cai et al., 2006). This period witnessed a diverse array of kitchen knives, with a greater prevalence of broad-bladed chopping knives in archaeological discoveries, although this might be partially due to a preservation bias against smaller, thinner iron knives.

This study aims to address the research gap in experimental archaeology and micro-wear analysis concerning the cut marks on animal bones created by iron tools. This article will explore the types of kitchen knives utilised during the Han dynasty in China, as well as the culinary knife techniques of “rocking” and “rolling slicing”.

2. Materials and Methods

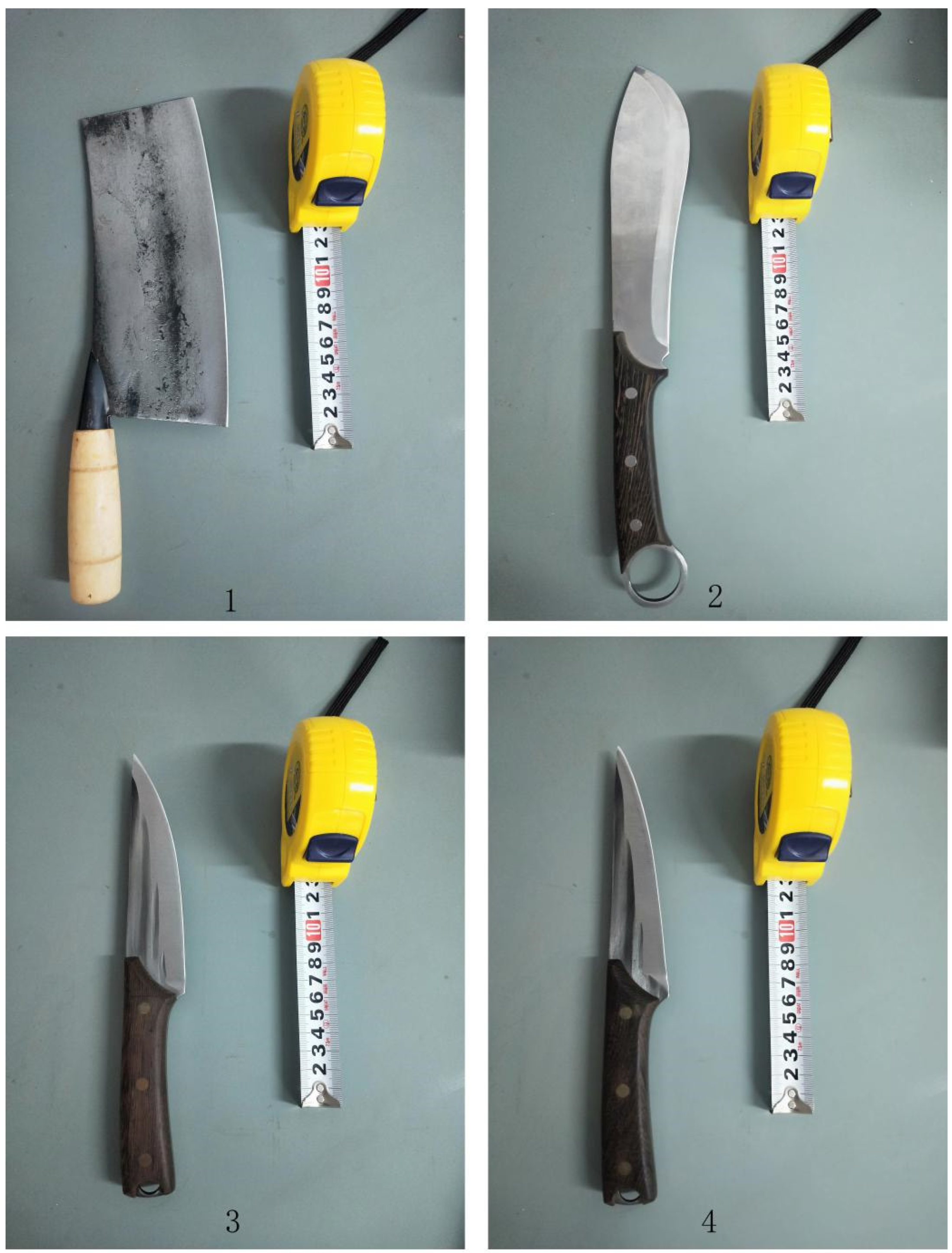

This article examines four types of kitchen knives from the Han dynasty as evidenced by archaeological discovery. The first category is the broad-bladed chopper, designated as knife No. 1. This was a prevalent household tool in ancient China, akin to the knives depicted in

Figure 2(2,3). The second type is a cleaver, designated as knife No. 2, featuring a long blade and a ringed handle. Both the blade and its reverse curve slightly inward, similar to the knife in

Figure 2(1). The third type is a slicing knife, designated as knife No. 3, characterised by a straight handle, an outwardly curved blade, and a straight back, comparable to the knife in

Figure 2(4). The fourth type is a boning knife, designated as knife No. 4, which has a straight handle, an outwardly curved blade, a straight back, and a narrower blade body than knife No. 3. These knives—cleavers, boning knives, and slicing knives—are essential implements for butchers, meat vendors, and chefs, used for processing animal hides, flesh, and bones. They were widely used tools. Cleavers are for chopping (e.g., dismemberment), boning knives are for filleting meat off the bone, and slicing knives are generally for the disarticulation of joints. Boning and slicing knives do not leave very different types of marks (slices and scrapes).

In selecting the knives for this article, we referenced the material, shape, and size of ancient kitchen knives, and then purchased contemporary analogues from the market. All the knives acquired for the experiment were crafted from carbon steel, with the exception of knife No. 2, which was made from stainless steel. While not exactly corresponding to ancient iron knives in their technical characteristics, the carbon steel blades are the closest, readily available analogues (see

Table 1,

Figure 3).

The objective of this study is to replicate characteristic features such as chop surfaces, rough planes, and fracture traces, as well as to reconstruct slicing techniques including rocking and rolling methods. This is achieved by employing various steel tool-based cutting techniques to process bone structures, followed by the stereomicroscopic examination of the resulting cross-sections. Consequently, the chosen animal bones must satisfy the operational demands of chopping and rotational slices while also being representative of real-world scenarios.

The experimental materials used in this study primarily consisted of limb bones and ribs from cattle, sheep, pigs, and dogs. During the experimental process, it was observed that excessively thick bones proved uncuttable while extremely thin bones could be directly snapped. Most cattle, sheep, and pig bones exhibited substantial thickness, making it difficult to achieve the required rocking and rolling slicing techniques. Although dog bones contained more slender specimens, sections that were either too fine or too thick still presented slicing challenges. Through experimental screening, qualified bones demonstrated minimum width (SD) with less than 3 mm deviation from archaeological specimens. Based on the width and thickness measurements of experimental bone sections, three groups (a, b, and c) were established: group a specimens approximated the cross-section dimensions of archaeological specimen 2017XPFM6:1 (width: 8.41 mm; thickness: 7.37 mm) and group c matched 2017XPFM6:2 (width: 13.31–14.81 mm; thickness: 7.48–9.61 mm), with group b representing intermediate dimensions.

It should be noted that ideal experimental conditions would require dog radius–ulna specimens matching archaeological samples in length and thickness. This necessity arises from anatomical variations: humeral diaphysis shows uneven compact bone thickness from proximal to distal ends, femoral diaphysis approximates cylindrical form, while the radial compact bone appears thinner and flatter, with the ulna being particularly slender. However, sourcing dog radius–ulna specimens from slaughter markets in Henan Province, China, that precisely match archaeological dimensions proved challenging. To address morphological differences between humero-femoral and radio-ulnar bones, this study implemented material screening to select three standardised bone groups (a, b, and c), ensuring both the experimental feasibility and maximal expression of differential characteristics in results. Additional stabilisation measures were applied during experimentation, as dog humeri and femora, being less flattened than radii, tended to shift during slicing procedures. Although bone morphology variations affected specific manifestations of cut surfaces, rough planes, and fracture traces in terms of morphology and distribution, they did not impede the successful replication of diagnostic features (including fine striations on cut surfaces) or the reconstruction of rocking/rolling techniques.

Experimental dog bone materials, obtained as complete defleshed specimens from slaughter markets, originated from medium-sized Chinese native dogs (Canis familiaris) with fused epiphyses, indicating individuals over 1.5 years old. The study employed two dog femurs and one dog humerus, designated as samples a, b, and c, respectively, with their measurement data detailed in

Table 2. While fresh bone with soft tissue might better approximate historical contexts, multiple uncertainties exist regarding ancient processing methods: whether dismemberment occurred pre- or post-cooking, potential tool variations (boning knives, cleavers, and saws), and specific operational sequences. Considering that soft tissue might increase tool slippage risks, and given our primary objective to replicate diagnostic chop surfaces, rough planes, and fracture patterns, defleshed bones were deemed more appropriate. Nevertheless, it should be acknowledged that the dog radius–ulna specimens from Xinxiang Plain New District Han Tomb were likely processed with soft tissue present using sophisticated techniques, potentially resulting in more refined trace features than our experimental reproductions. Though experimental traces may appear less regular than archaeological specimens due to differences in bone sections, soft tissue conditions, and operator skill levels, this does not affect the fundamental replication of diagnostic features and technical reconstruction.

This experimental design derives from the detailed observation of trace characteristics on archaeological faunal specimens. Given the limited quantity of both archaeological and experimental samples, our conclusions remain case-specific. Whether these findings represent broader social practices requires verification through additional archaeological evidence.

Furthermore, the formation of animal bone fracture traces involves multiple possibilities. Processes such as slaughtering, dismemberment, marrow/grease extraction, craft processing, carnivore gnawing/trampling, sediment compression, bioturbation, and *recovery bias* can all contribute to bone breakage (

Outram, 1998,

2001). These fractures are also influenced by bone freshness/dryness (

Morlan, 1984;

Johnson, 1985) and environmental temperature (

Karr & Outram, 2012). Both the archaeological specimens analysed in this study and experimental specimens exhibit spiral-shaped fracture lines forming acute or obtuse angles with the cortical surface. According to established research, classic fresh or green-bone fractures typically produce helical or spiral fracture outlines, characterised by smooth fracture surfaces angled acutely or obtusely relative to the bone’s cortical surface (

Outram, 1998,

2001;

Morlan, 1984;

Johnson, 1985). Dynamic impacts generate conical scars from which helical fractures radiate. As bones desiccate, develop split lines, and lose organic content, fractures tend to become straighter (diagonal, longitudinal, or transverse), with rough-textured fracture surfaces perpendicular to the cortical surface. This evidence indicates that the archaeological specimens analysed were fractured while fresh. Our experimental specimens successfully replicated fresh-bone fracture conditions, ensuring comparability with the archaeological materials in terms of fracture morphology and mechanical properties.

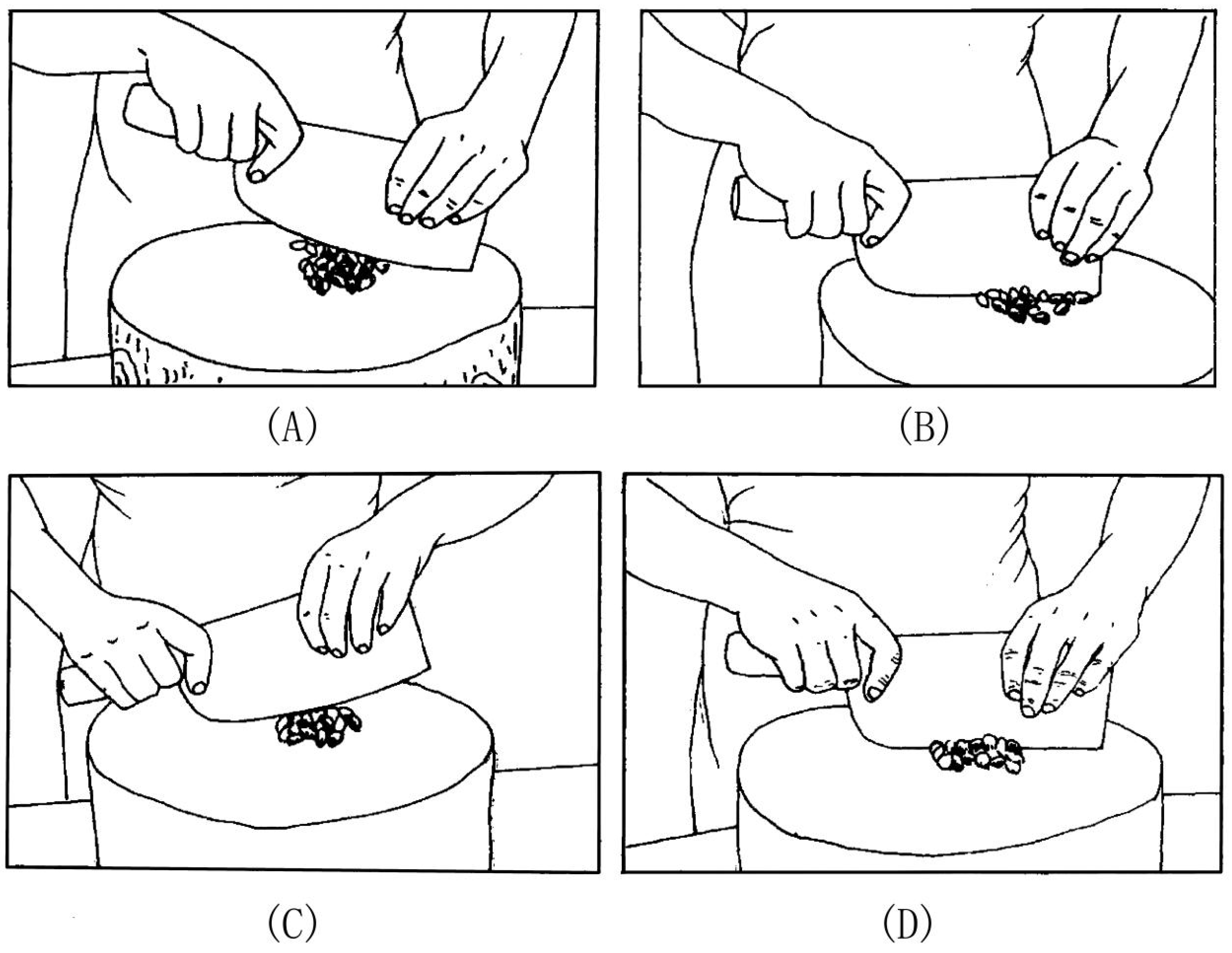

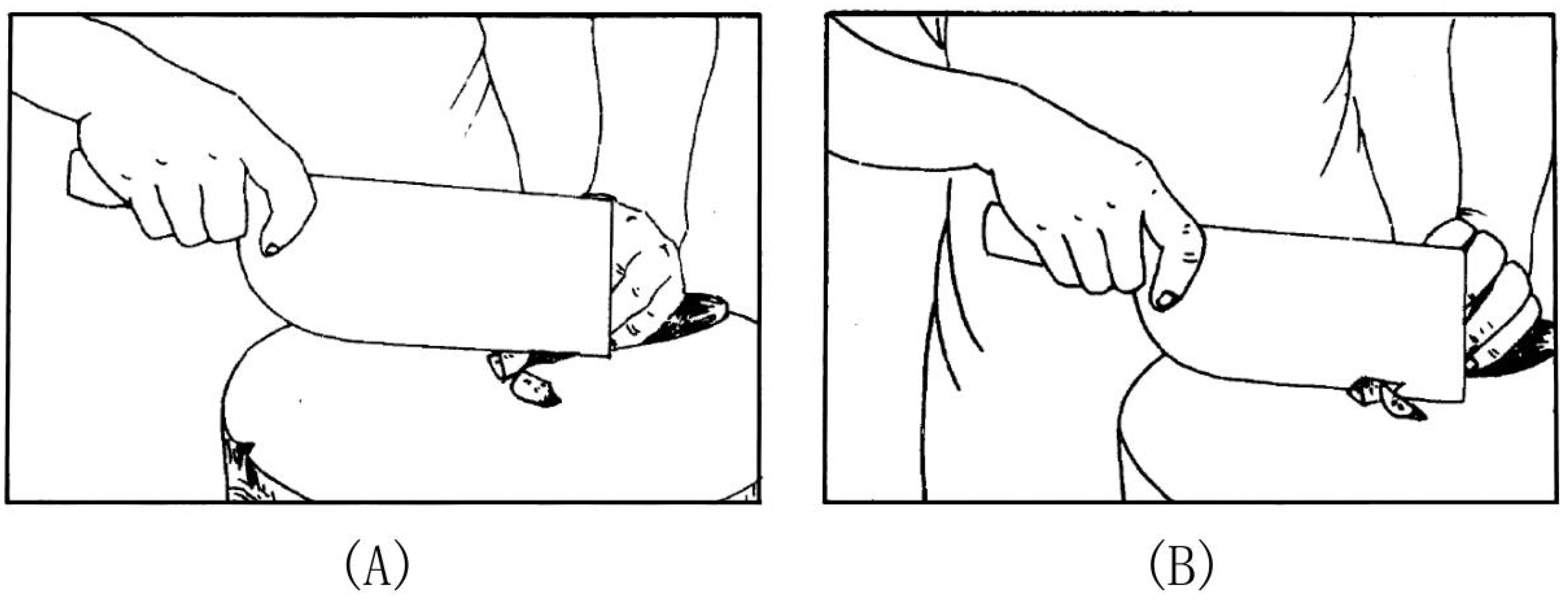

In the experimental procedures of this study, both the “rocking slice” and “rolling slice” techniques were employed. The former is ideal for processing cartilage or smaller hard bone specimens, as well as raw and cooked materials that are small, round, and prone to slipping. The requirements for this knife technique involve holding the handle with one hand and the other hand on the spine of the knife. One performs a continuous downward slicing motion while rocking by alternatingly lifting and pressing down on tip and back of the knife (

Figure 4). This action fundamentally differs from sawing techniques. Sawing requires a reciprocating pull–cut motion, which can be executed either through single-handed operation by one individual or via coordinated effort between two operators working oppositionally, each grasping one end of the tool. The essential mechanical principle lies in horizontal reciprocation rather than vertical compression. The “rolling slice” method necessitates that after each slice is completed, the material is immediately rolled in one direction, which is more appropriate for processing circular or near-circular specimens (

Figure 5) (

G. Li, 1988).

In modern culinary knife skills, both the “rocking slice” and “rolling slice” techniques are specialised knife methods employed for the precise processing of ingredients. The artificial incisions found on the surfaces of animal bones from Han dynasty tombs in the Xinjiang region serve as historical evidence of such meticulous ingredient preparation.

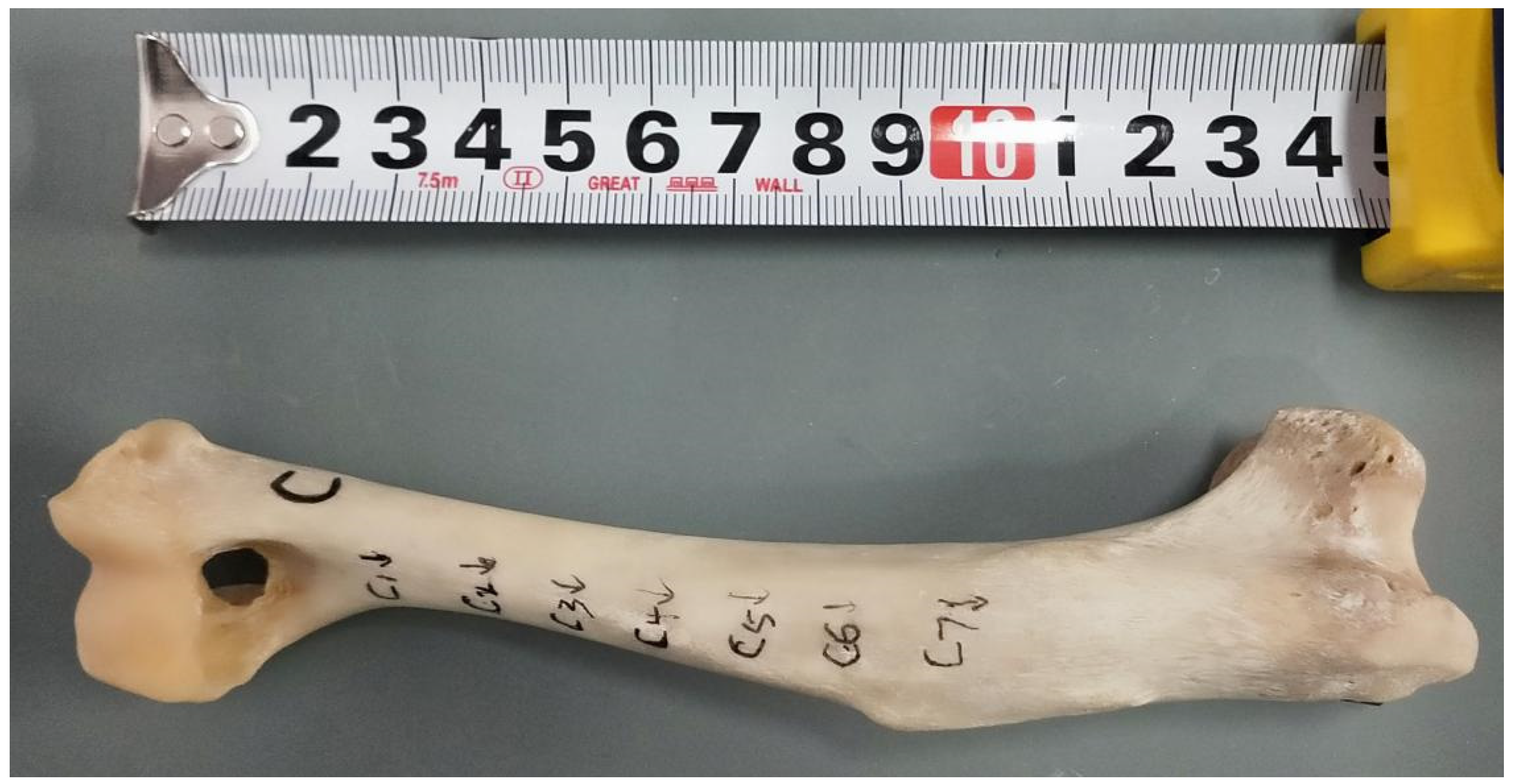

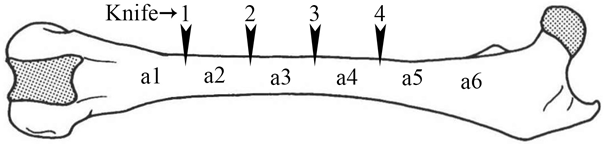

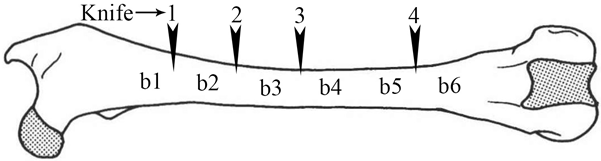

The article details experiments on three bones with four different knives. A mark was made at every centimetre on three bones, A, B, and C (marks a1–a6, b1–b6, c1–c6; see

Figure 6). Subsequently, slices were made at these marked intervals with four different tools. A schematic representation is available in

Table 3 and

Figure 6. Bones A and B were both dog femurs, numbered from the distal to proximal ends, while bone C was a dog’s humerus, numbered from the proximal to distal end, optimising the use of their thinnest portions.

In conclusion, a stereomicroscope was employed to observe and analyse the cross-sectional traces of three sets of ten batches for each of four different types of tools. The analysis was conducted across a range of magnifications from 0.75 to 7. The specific model of the stereomicroscope utilised for this study was the German Zeiss stemi 2000.

3. Results

3.1. Experimental Result

In the trials conducted on specimens A and B, the bones were observed to be easily bisected. Upon the completion of these trials, it was determined that each of the tools—number 1, number 2, number 3, and number 4—were capable of severing the bone. Conversely, during the trials on specimen C, the bone exhibited greater thickness. Post-experiment analysis revealed that only tools 1 and 2 successfully bisected the bone, whereas tools 3 and 4 experienced significant difficulty in slicing through the bone using the rocking slicing method.

During the experiment involving tool number 1, the thinness of its blade enabled the successful separation of the cortical bone in all three sets of trials. Techniques such as snapping could then be employed to finish dividing the bone body where necessary.

During the experiment involving tool number 2, it was observed that the blade’s greater length and heavier weight contributed to its ease of severing the bone, whether employing the rocking or rolling slice methods. Nonetheless, when force was applied, there was a tendency for the bone structure to fracture along the line of incision, and the resultant bone fragments and notches left on the bone edges are notably large.

During the experiment involving tool number 3, the blade was broad and slender, but comparatively lightweight. The primary techniques employed were rocking and rolling slicing, with rocking being the predominant method. Experiments A and B demonstrated that as the applied force escalated, the bone was cleaved into multiple fragments along its tangential plane, ultimately necessitating fracture through bending and snapping.

During the experiment involving tool number 4, although its design bears a resemblance to tool number 3, it features a narrower blade and a lighter weight. Throughout the experimental procedure, the rocking technique was predominantly employed, complemented by the rolling slice method. The process closely mirrors that of tool number 3, allowing for the initial separation of a portion of the skeletal structure. Through successive attempts, the majority of the cortical bone could be dissected. Ultimately, the residual segment can be efficiently detached using a snapping technique.

In the group c experiment, the use of tools 3 and 4 posed challenges due to their lightweight and slender blades, as the bone was comparatively large and cumbersome.

3.2. Micro-Trace Analysis

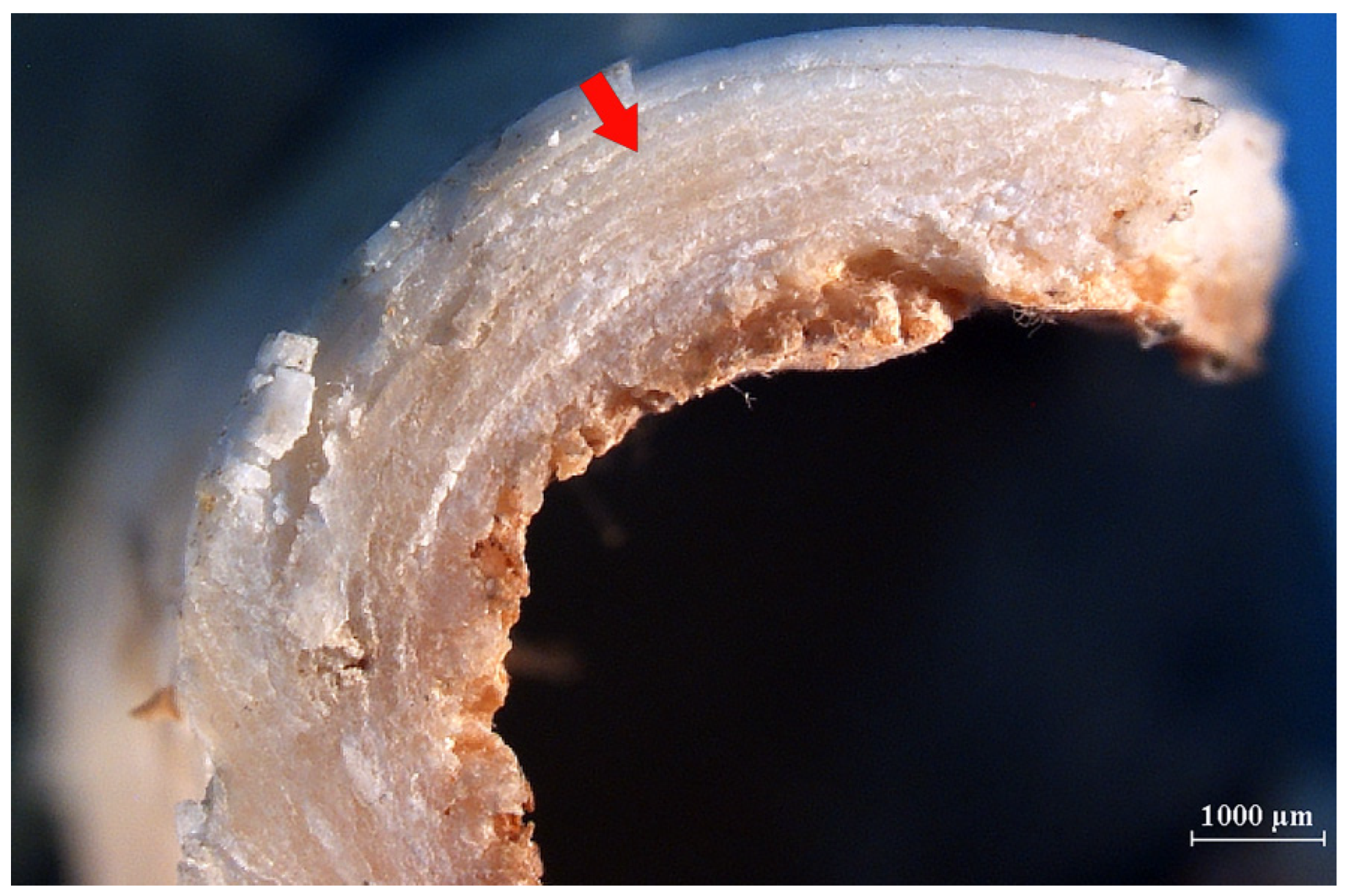

3.2.1. Slicing Surface

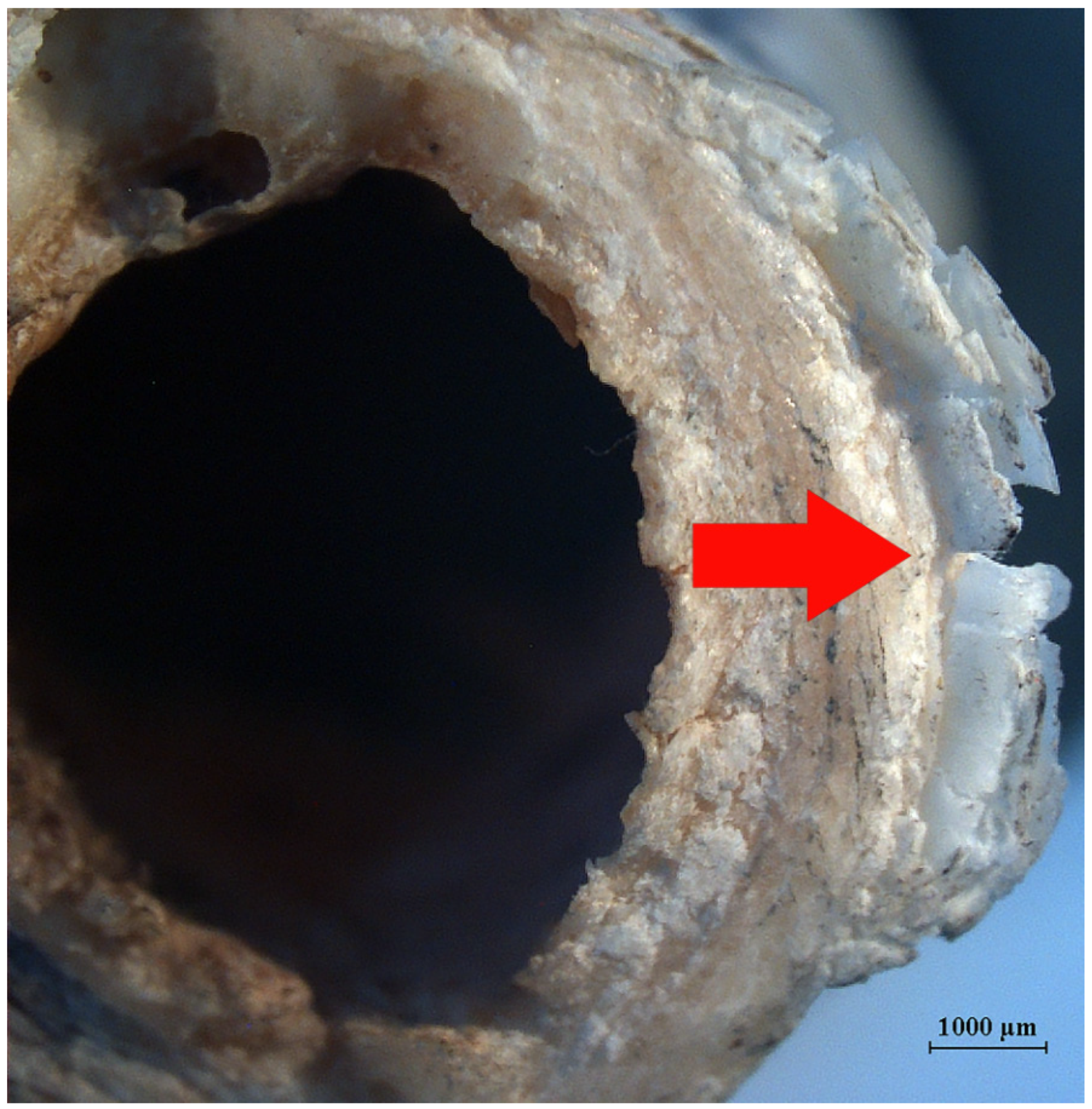

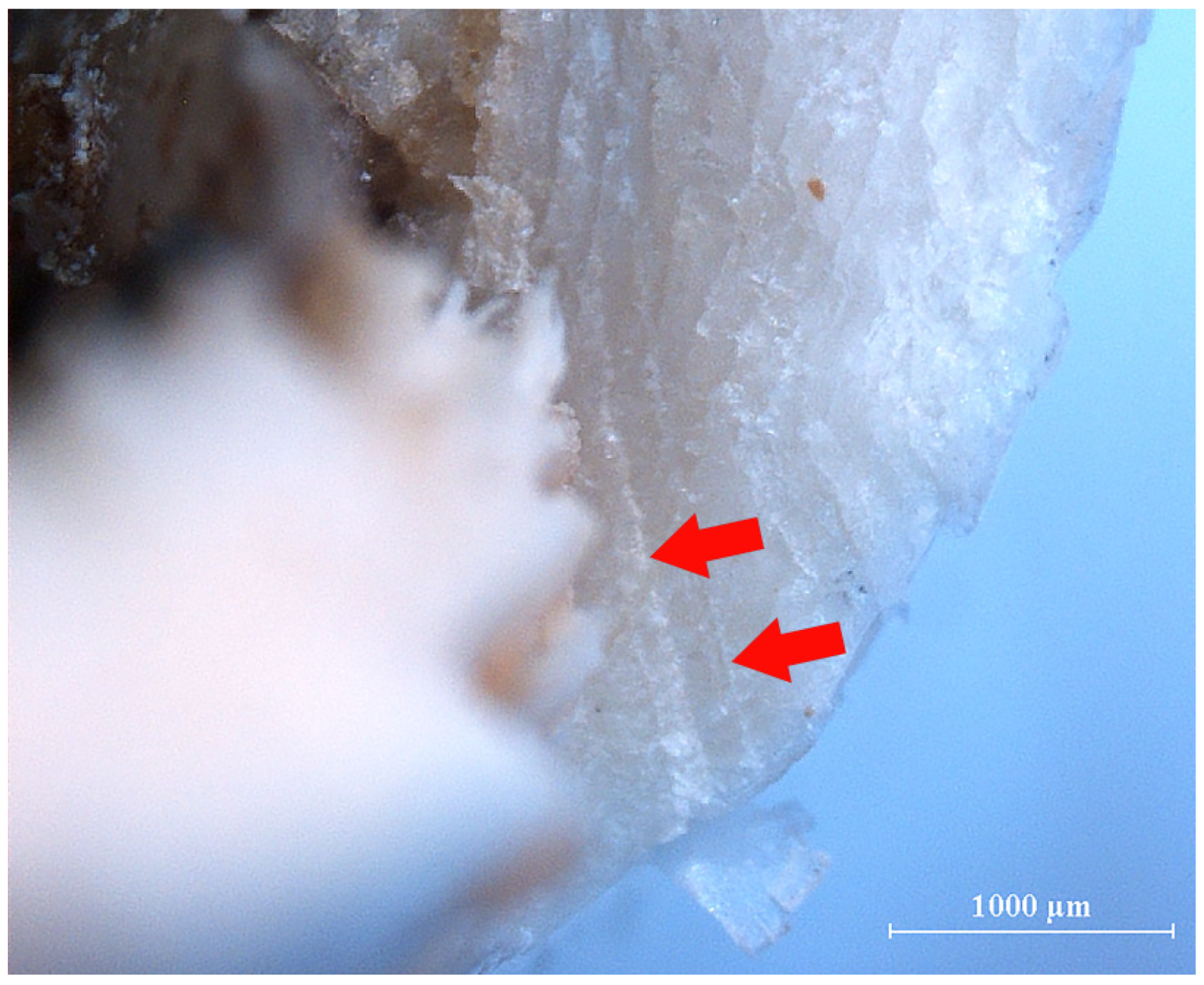

The slicing surface (

Figure 7→) represents the area of the bone that has been subjected to the slicing process, where the blade has incised to create a flat and smooth surface. When illuminated obliquely by the light, the slice surface gleams with a glossy lustre. The primary visual features on the slicing surface encompass fine striations (

Figure 8), a feathered edge (

Figure 9), internal fissures within the compact bone (

Figure 10), surface fracturing of the compact bone (

Figure 11), slicing edge lines (

Figure 12), scale marks (

Figure 13), lifted skin (

Figure 14), and instances of crushing, among others. Fine striations can be attributed to the friction of minuscule particles against the blade’s surface during successive slices, or they may arise from the presence of multiple, small, uneven striations on the tool’s edge (

Shipman, 1981). Given the substantial variability in the micro-morphology of these edges, there exists a marked disparity in the dimensions and contours of the striations, with their distribution being irregular. These striations frequently “spill over” onto the inner surface of the slicing trace, extending along the trace’s two edges, a phenomenon referred to as the “shoulder effect” (

Shipman & Rose, 1983). This effect is a pivotal feature in discerning the technique employed in rocking slices. The feathered edge predominantly manifested in the group a experiment with tool 1—the broad-backed chopper. The formation of this feature was likely due to a decrease in force as the blade moves laterally, resulting from the repeated pressure and friction during slicing. Overly forceful operations can induce internal cracks within the compact bone, causing it to fracture towards the medullary cavity. The splitting of the cortical bone surface is attributed to the internal and lateral extrusion and rolling cuts produced by the tool. Additionally, the non-parallel motion between the blade and the bone surface is a primary factor in the surface cracking. The edge tangent represents the linear mark that remains on the cutting surface once the blade ceases movement. Scale marks predominantly manifest during experiments involving cleavers, which are closely associated with the extended blade length, robust slicing edge, and increased weight. The broad and thick blade applies a substantial amount of force during the slicing process. As the pressure and slicing force are progressively elevated, due to the repetitive rocking slices, a stratified pattern of scale marks emerges. Flaking ensues when minute bone chips are dislodged due to the persistent pressure of the blade’s edge. Fracturing transpires during the rocking slicing process, where the bone is cleaved into multiple fragments along the slicing path as the force intensifies. The experimental micro-trace observation conditions are elaborated on in

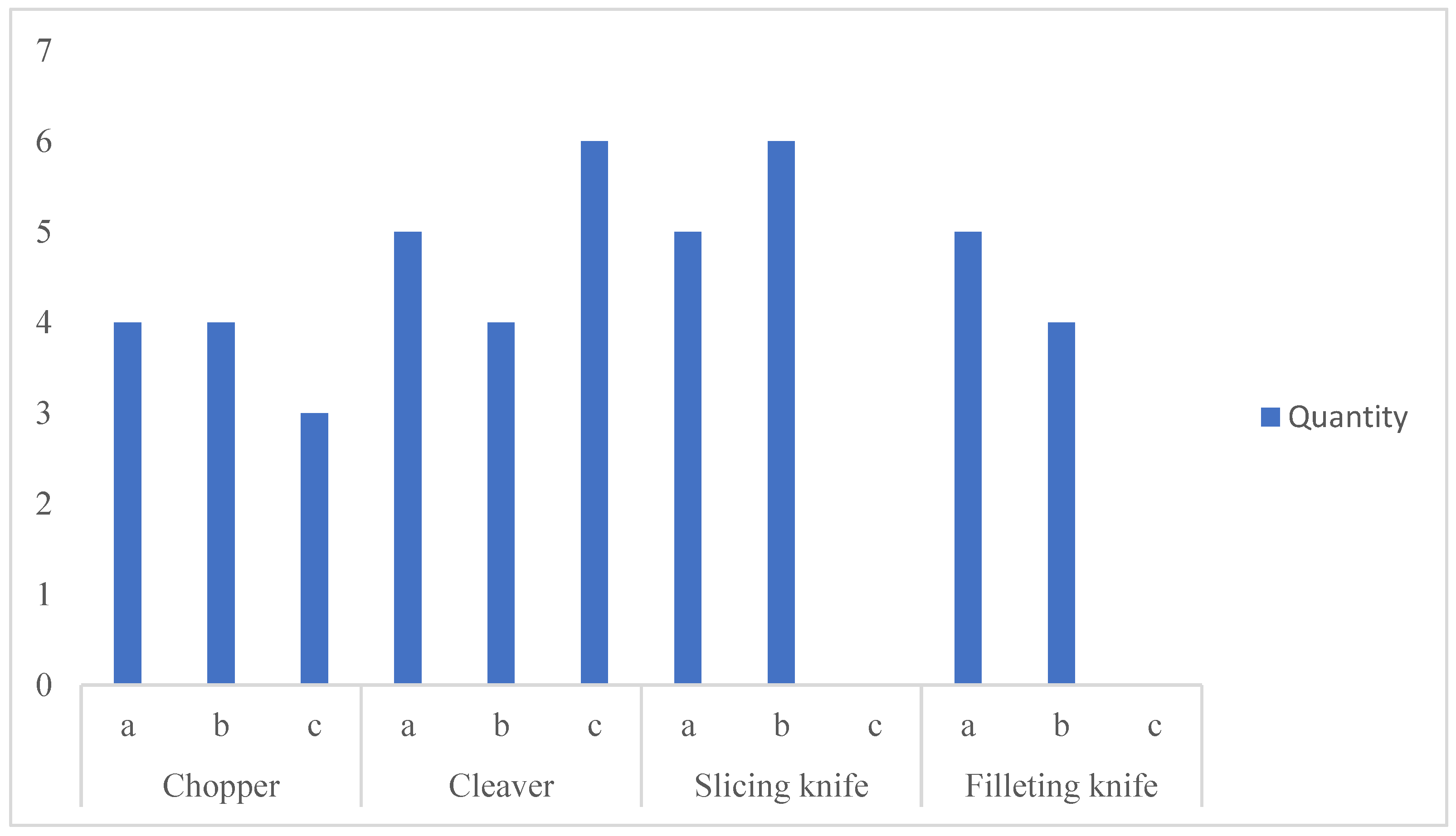

Table 4.

From the perspective of the different experimental groups, the experiments conducted on bone C using the cleaver (tool 2) and group b using the slicing knife (tool 3) exhibited the most pronounced trace features. Trials involving slicing and filleting knives in group c were excluded due to implementation challenges. Notably, the experiment with the broad-bladed chopper in group c exhibited the fewest visual trace characteristics (

Figure 15). The greater the variety of traces, the higher the relative operational difficulty. In the comparative data, the broad-backed chopper slightly outperformed other knives, suggesting that it offers enhanced operational stability. This may also be the primary reason why this type of knife has been historically popular and became the principal everyday knife in Chinese kitchens.

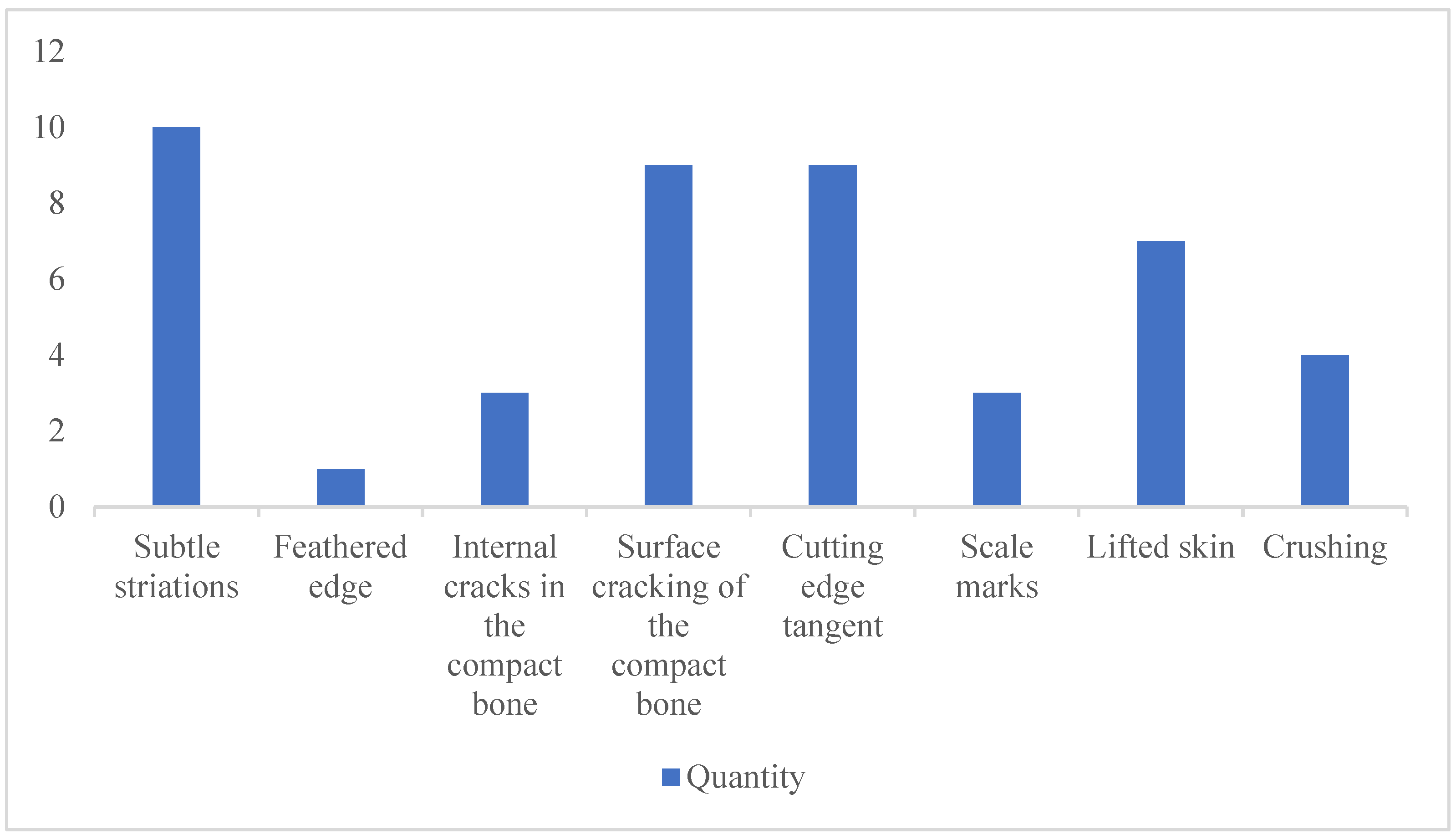

Upon examining the frequency and percentage of various marks (

Figure 16), it becomes evident that micro-striations are the most prevalent and are present in every set of experiments. This suggests that the application of the rocking slicing method results in the presence of micro-striations on the bone cross-sections.

Secondary factors contributing to the issue encompass the fracturing of the compact bone’s epidermis and its tangential edges and the fracturing of the cortical bone with the tool’s movement direction and the extent of bone desiccation. Notably, when the blade’s trajectory deviates from being parallel to the bone’s surface joints, the likelihood of fracturing increases. The blade edge’s tangential explanation suggests that during the slicing process, interruptions and body rotations occur, which are direct outcomes of employing left and right pressure slicing techniques, as well as the rolling slicing method.

The peeling phenomenon occurs at an intermediate frequency and is closely associated with the exertion of increased force. When the blade’s slicing force surpasses the resistance of the dense bone tissue, the tissue will fracture. Compression and “dragging” cause the fracture site to display peeling. With fewer repetitive actions, minor peeling is observed, whereas more vigorous and forceful repetitive actions result in more pronounced peeling.

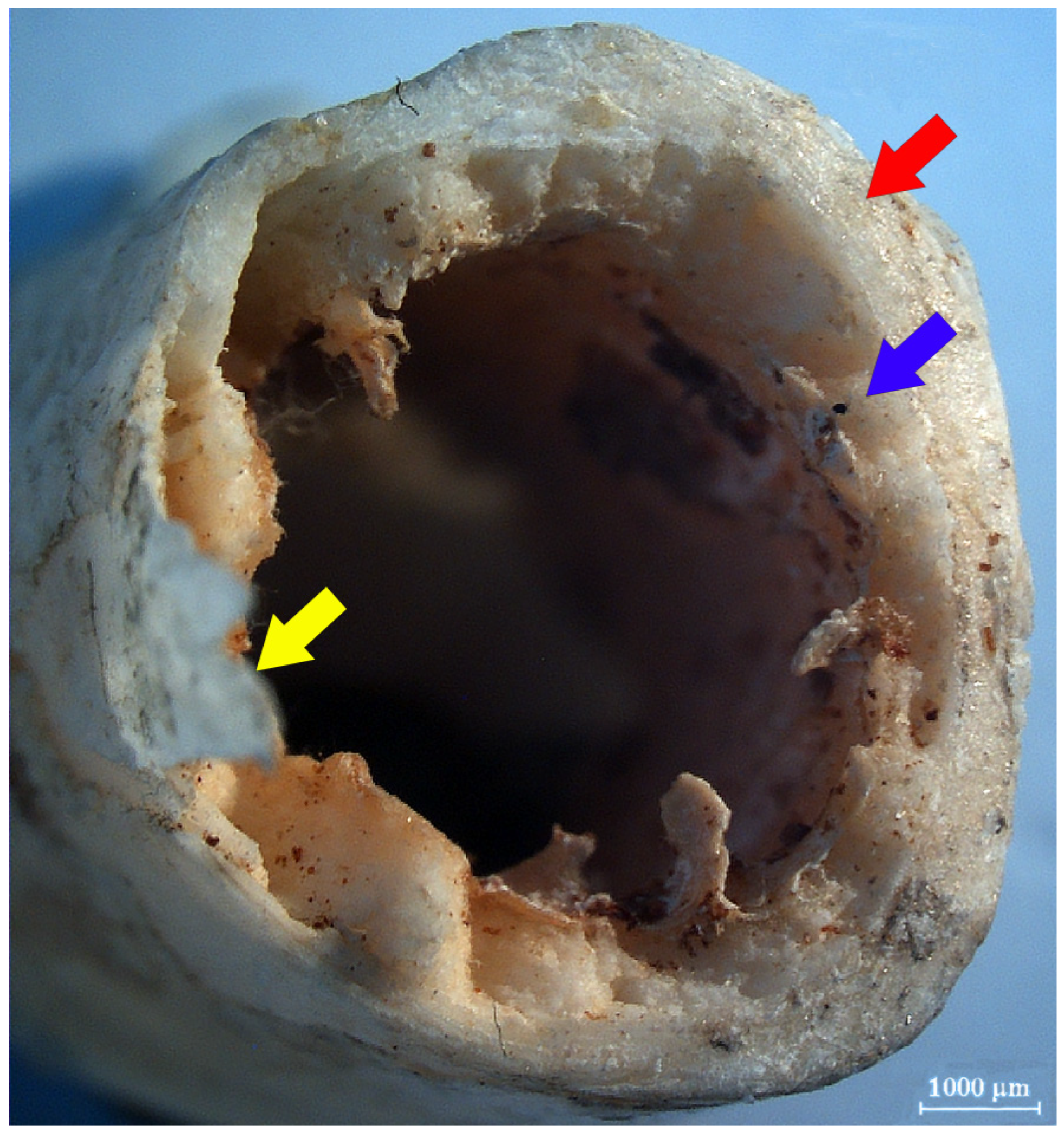

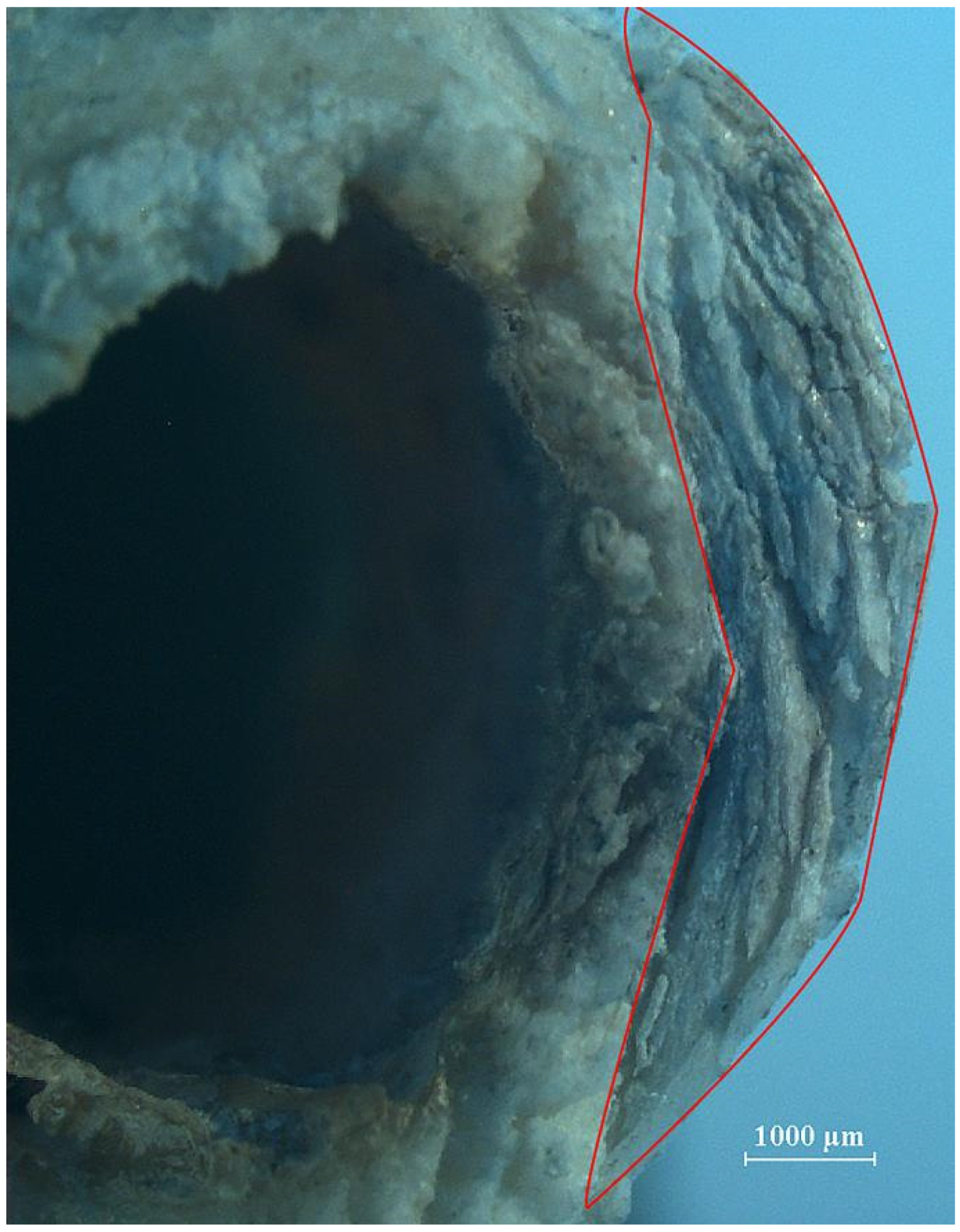

3.2.2. Rough Surface

In the course of bone slicing, regions untouched by the blade must be fractured through bending. Once fractured, a rough and uneven surface emerges on the slice section. The edges of this irregular surface, located opposite the incision entry point, exhibit bone splinters and notches resulting from tensile breakage. Under the scrutiny of a stereomicroscope, even with oblique lighting from a spotlight, the rough surface (

Figure 7→) retains a dull and dark appearance, its topography reminiscent of a landscape with peaks and valley and deep ravines. The bone splinters and fracture edges (

Figure 7→) are typically larger and serve as significant indicators of the breakage direction and human manipulation patterns.

3.3. Comparison with Archaeological Materials

In 2017, the Henan Provincial Institute of Cultural Relics and Archaeology undertook emergency excavations at the Han dynasty tomb complex located in the Pingyuan New Area of Xinxiang City. During these excavations, animal bone remains were discovered in tombs M5, M6, and M7. Notably, two of these specimens exhibited signs of having been sliced with iron implements.

Sample 2017XPFM6:1, a left ulna from a canine (

Figure 17(1)), exhibits cut surfaces in the middle and distal regions and is preserved in two segments, designated as 2017XPFM6:1-1 and 2017XPFM6:1-2. The overall size is medium and robust. The anteroposterior thickness, which is the shortest distance from the coronoid process to the posterior edge of the ulna (DPA), measures 25.40 mm; the minimum thickness of the olecranon (SDO) is 22.56 mm; and the maximum width of the coronoid process, representing the largest extent of the proximal articular surface (BPC), is 18.83 mm. The proximal olecranon exhibits mottled small holes on its lateral sides and superior surface, while the lateral aspect of the proximal shaft displays a more concentrated pattern of pitted erosions.

Upon visual examination both with the unaided eye and under a microscope, one can discern various marks indicative of processing, including shearing, rolling, slicing, and bending, on the cross-section.

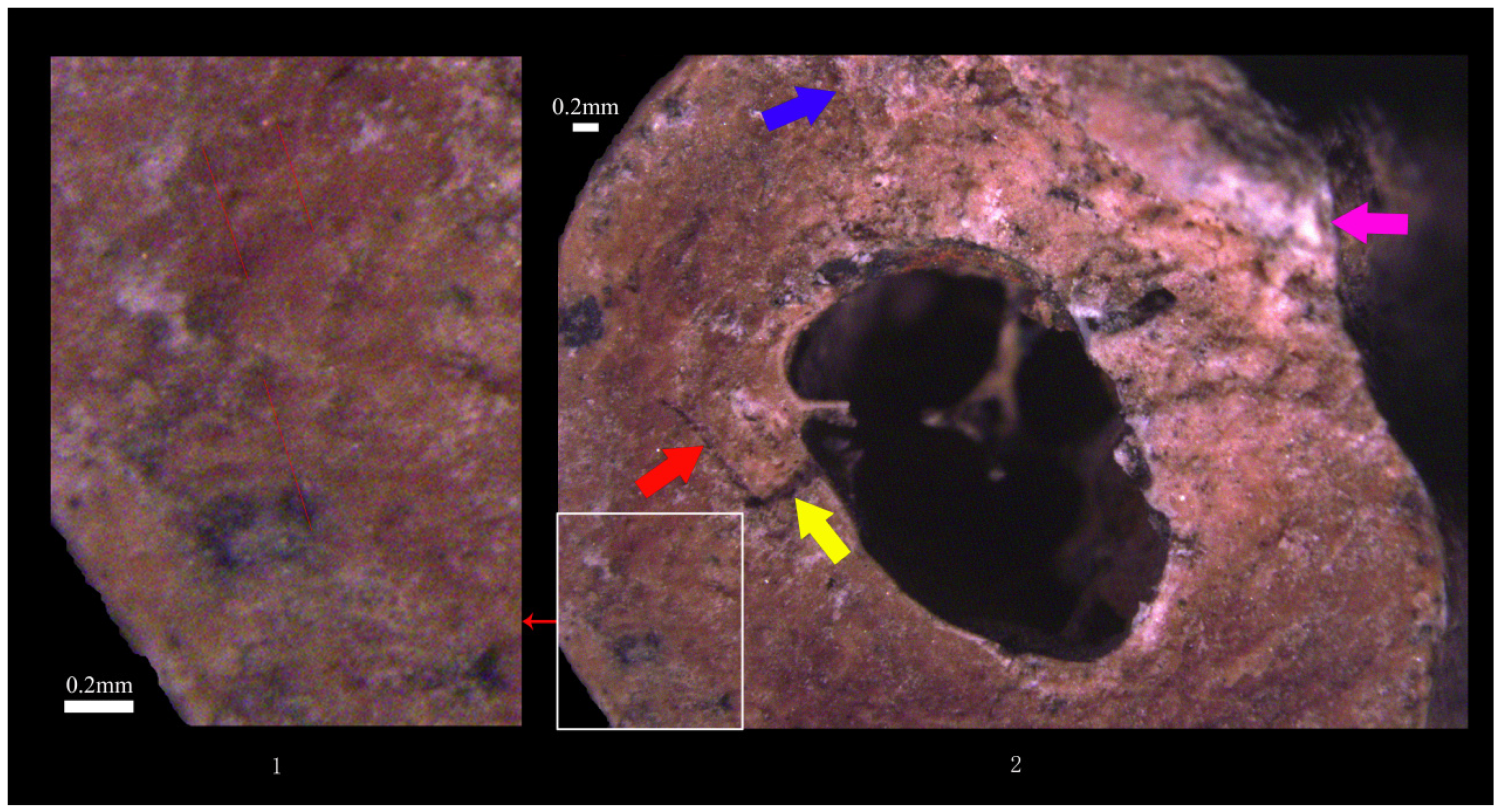

2017XPFM6:1-2 represents the central portion of a dog’s left ulna, featuring a straight cut surface on the proximal cross-section and the edges of the caudal and lateral sides. Fine, obliquely extending striations are visible on the surface (

Figure 18(1)). These striations could result from the friction of tiny particles against the blade’s surface during repetitive slicing, or they might be due to the uneven micro edges of the slicing tool (

Shipman, 1981).

Upon examining this specimen, three distinct slicing edges are evident (

Figure 18(2)), suggesting that the processing of this material might have been challenging, necessitating three rolling slices. One of the tangents (

Figure 18(2)

→) runs parallel to the caudal–rostral axis, with the interior revealing the medullary cavity. Given that this line does not extend to the cranial end of the bone, it is plausible that one hand was employed to steady the bone while the other hand applied pressure with the blade to create an incision. The blade would have reached only as far as the interior of the medullary cavity, avoiding any incision into the cranial side of the bone. This method of rotating with each slice is fundamentally akin to the rolling slicing technique.

The medullary cavity within the section is surrounded by somewhat coarse walls, which are uneven. During the slicing process, the tool’s cutting edge may have penetrated from the bone’s edge, yet it does not incise into the bone’s deeper regions. After the cortical bone was sliced, the internal spongy bone was manually fractured, resulting in the formation of a relatively rough wall encircling the medullary cavity. The bone ends on the lateral side were not severed by the blade, and their connecting tissues are relatively robust. Subjected to outward tensile stress, they fractured around the bone body’s connecting tissue, creating a protruding bone splinter (

Figure 18(2)

→), whereas on the opposing segment, an irregular notch was produced.

The distribution of various marks along the proximal portion of the bones can be analysed to understand the slicing techniques and tools. Throughout the slicing process, rolling slices were employed; once the majority of the bone tissue had been detached, the bone was not further sliced with a knife but rather broken directly, facilitating the separation of the internal and lateral connecting parts. This resulted in a rougher wall surrounding the medullary cavity and left behind protruding bone splinters and irregular slices on the lateral sides.

Sample 2017XPFM6:2 (

Figure 17(2)) represents the left radius of a canine specimen. The bone exhibits an overall medium and robust build. The maximum length (GL) measures 211.9 mm, the maximum proximal width (Bp) is 25.72 mm, the minimum shaft diameter (SD) is 13.41 mm, and the maximum distal width (Bd) is 19.43 mm. The proximal and middle segments originate from within the container and display a surface with black stains and reddish-brown rust marks. In contrast, the distal section features a greyish-white surface. The longitudinal walls of the main body are characterised by a dense pattern of corrosion indentations.

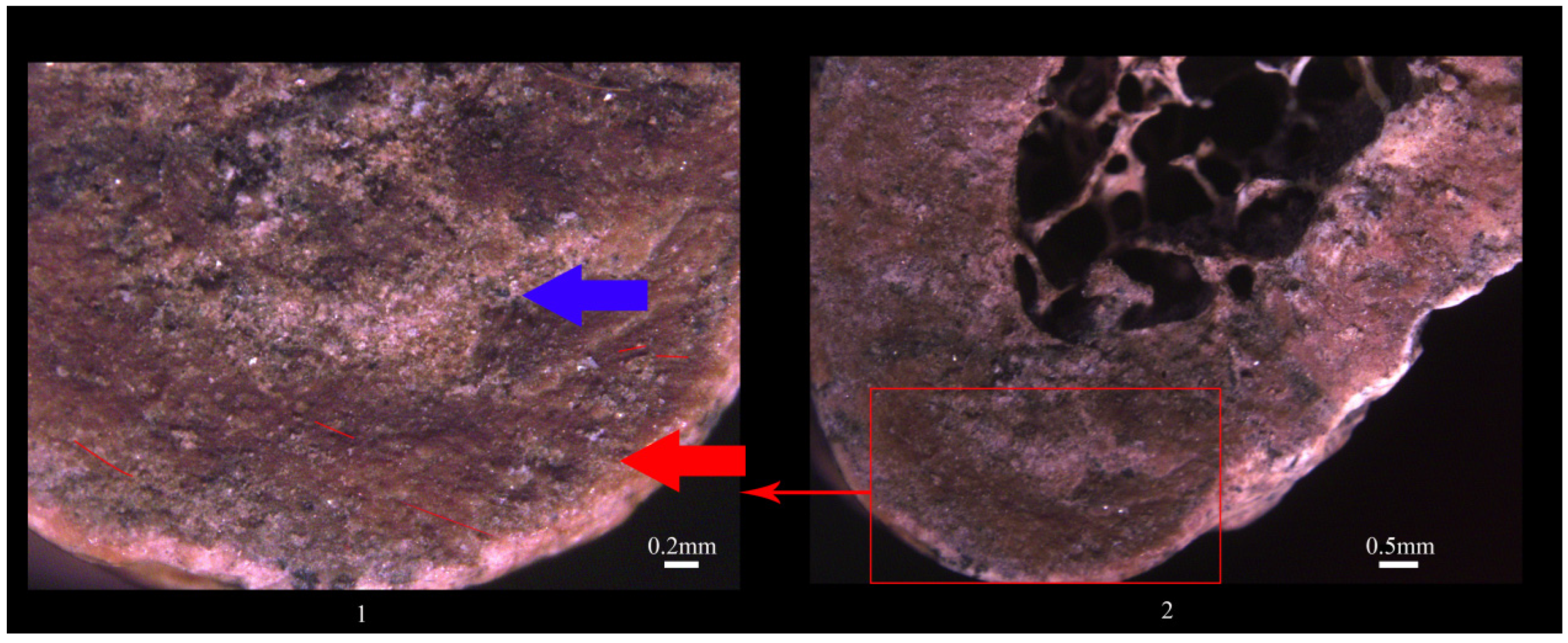

Upon examining the artificial incisions on the left radius of a canine specimen (2017XPFM6:2), one can observe straight and steep slice marks, rough interior surfaces, bone splinters, and irregular fracture edges resulting from breakage, among other indicators. Upon examination under the microscope, we focused on the proximal portion of the middle segment of the left radius (2017XPFM6:2-2). We chose a specific area within this section for detailed observation (

Figure 19(2)). Within this area, a cross-section (

Figure 19(1

→)) with a rough-textured surface can be seen (

Figure 19(1

→)). On the cross-section, fine striations can be seen extending obliquely in both directions (

Figure 19(1

—)).

Furthermore, the left radius of the specimen (2017XPFM6:2) was divided into three segments (

Figure 17(2)), exhibiting bone slice marks at both the proximal and distal ends. The middle segment displays irregular slice marks that align with those at both extremities. Upon examining the slices, it is evident that the fragments resulting from snapping are situated on opposite sides of the bone shaft. This suggests that during the ancient processing of the bone, after an initial slice and break, the bone was rotated before a second slice was made.

The microscopic examination of the cross-sections of dog bones excavated from Han dynasty tombs located in the Pingyuan New District of Xinxiang City, Henan Province, China, have uncovered evidence of slicing marks, rough surfaces, bone splinters, and signs of fractures. Upon examining the cross-section, one can observe fine striations and slicing edge tangents, suggesting that these specimens were processed using the rocking slicing method and the rolling slicing technique. Owing to the extended duration of their interment, it is challenging to ascertain if these two specimens display characteristics such as cortical bone fracturing and surface peeling. Neither specimen show signs of crushing, nor are there any lamellar markings or internal fissures within the compact bone. When viewed in cross-section, the surface appears smooth, featuring minute striations that are diminutive and exhibit distinct directional patterns. Considering the experimental results, it was challenging for both the slicing knife and the filleting knife to penetrate the bone structures of group c experiments. During the slicing process, the cleaver tended to leave numerous scale-like marks, which are absent in the archaeological specimens. Consequently, it is speculated that the two specimens from the archaeological site were probably sliced using a broad-bladed chopper.

4. Discussion

When discussing contemporary culinary knife skills, three primary categories typically emerge. The first category encompasses the fundamental knife techniques applied during the preliminary preparation of ingredients, including chopping and cleaving. The second category involves the precision cutting techniques utilised for detailed ingredient processing, such as slicing and dicing. Notably, the artificial incisions found on the surfaces of animal bones from Han dynasty tombs in the Xinjiang region serve as historical evidence of such meticulous ingredient preparation. The third category focuses on the embellishment of ingredients, exemplified by techniques such as the creation of colourful dishes and elaborate food carving for festive banquets. Each category of knife technique encompasses a variety of hand movements. For instance, the “slicing” technique from the second category includes straight slices, push slices, pull slices, sawing, rocking slices, rolling slices, and more. Each slicing method is tailored to specific ingredients and entails unique action requirements (

G. Li, 1988). Reconstructing the historical facets of ancient culinary knife skills, which are often undocumented, poses a significant challenge when relying solely on literary sources. However, by examining archaeological materials, one can reconstruct the intuitive and precise operational processes and knife techniques. The cross-sections of the ulna and radius from a dog interred in a Han dynasty tomb located in the New Town district of Xinxiang City not only unveil the meticulous processing workflow undertaken by the ancients, but also exhibit fine striations that extend obliquely on both sides, indicating the use of a “rocking” knife-slicing technique. Furthermore, the varying directional slicing edges reveal a knife technique known as “rolling slicing”, evidencing that during the Western Han dynasty, individuals had already mastered both the “rocking” and “rolling slicing” techniques for working with circular and slippery bone materials. This article, via simulation experiments involving the use of iron tools of varying sizes to cut animal bones, and through comparative analysis with the marks on archaeological animal remains, concludes that the slices on the canine bones were most likely made by broad-backed choppers such as those common in Chinese cooking today.

In international zooarchaeological research, numerous microwear analyses have been conducted on butchering marks on animal bones, with studies predominantly focusing on the Stone Age and Bronze Age (

Greenfield, 1999,

2000;

Greenfield & Marciniak, 2018;

Greenfield et al., 2022;

Okaluk & Greenfield, 2022). Even those extending into the Iron Age (

Krasinski, 2018;

Odell & Cowan, 1986) have not specifically addressed truncation marks on animal bones produced by iron tools. Current analyses of bone fracture patterns primarily investigate marrow and grease extraction (

Outram, 1998,

2001), with isolated studies on bone ornament production using bronze knives and saws (

Ludvik et al., 2024). Experimental studies on bone processing reveal that, while cast bronze tools can complete all stages of antler or bone artefact manufacturing, they require frequent resharpening during operations, indicating their inefficiency for bone truncation (

Stasik et al., 2024;

Tyler, 1990). This study innovatively employs iron tools in the experimental truncation of animal bones from Han dynasty tombs excavated at the Pingyuan New District, Xinxiang City, Henan Province, China, thereby contributing novel insights to experimental archaeological research on osseous cut marks.