Environmental Assessment of Tannin Extraction from Bark Residues for Application in Water Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Bibliometric Analysis

2.1.1. Database Search

2.1.2. Meta-Analysis

2.1.3. Bibliometric Analysis

2.1.4. Systematic Analysis

2.2. Life Cycle Assessment

2.2.1. Definition of Goal and Scope

2.2.2. Life Cycle Inventory

3. Results

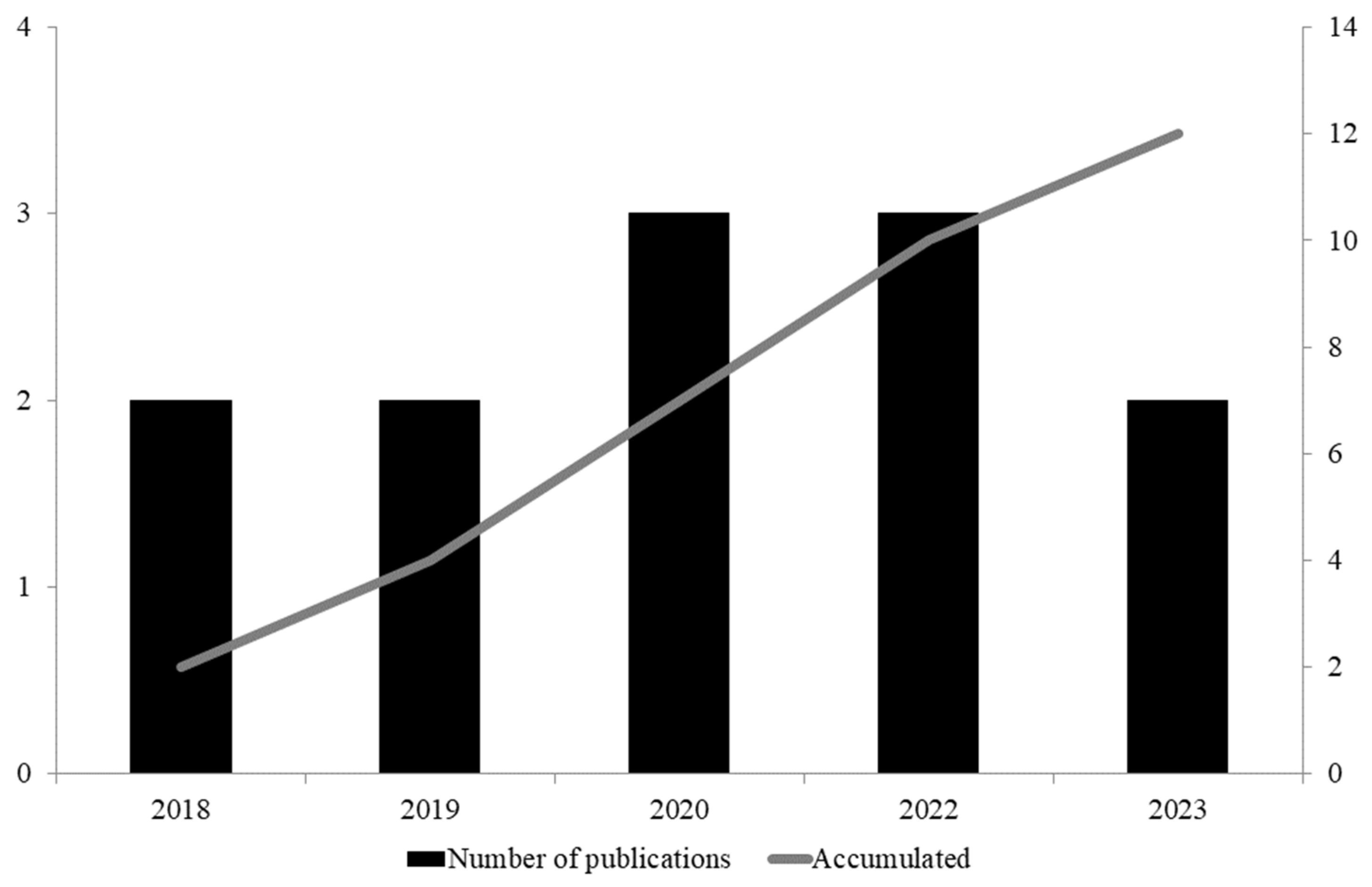

3.1. Bibliometric Analysis

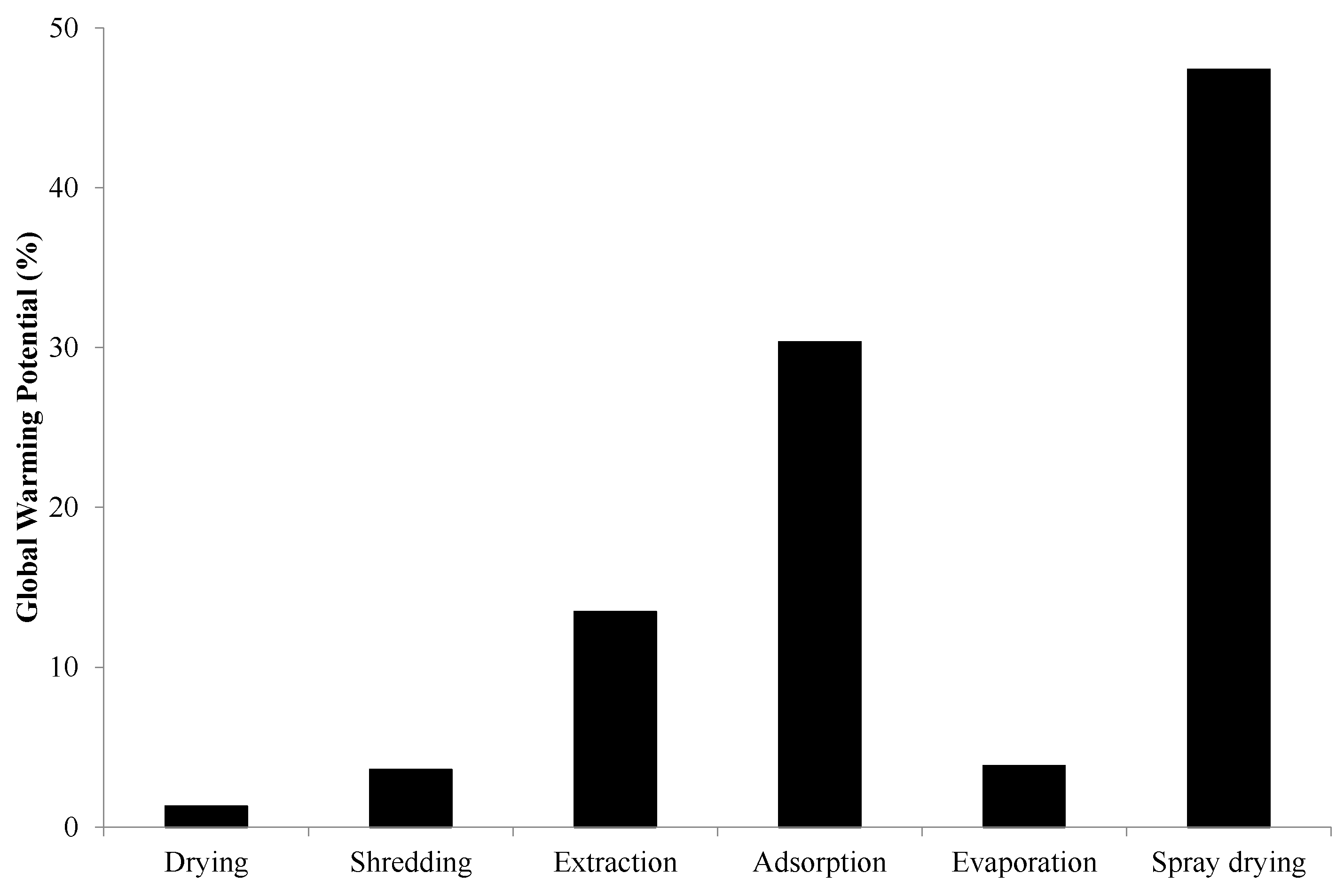

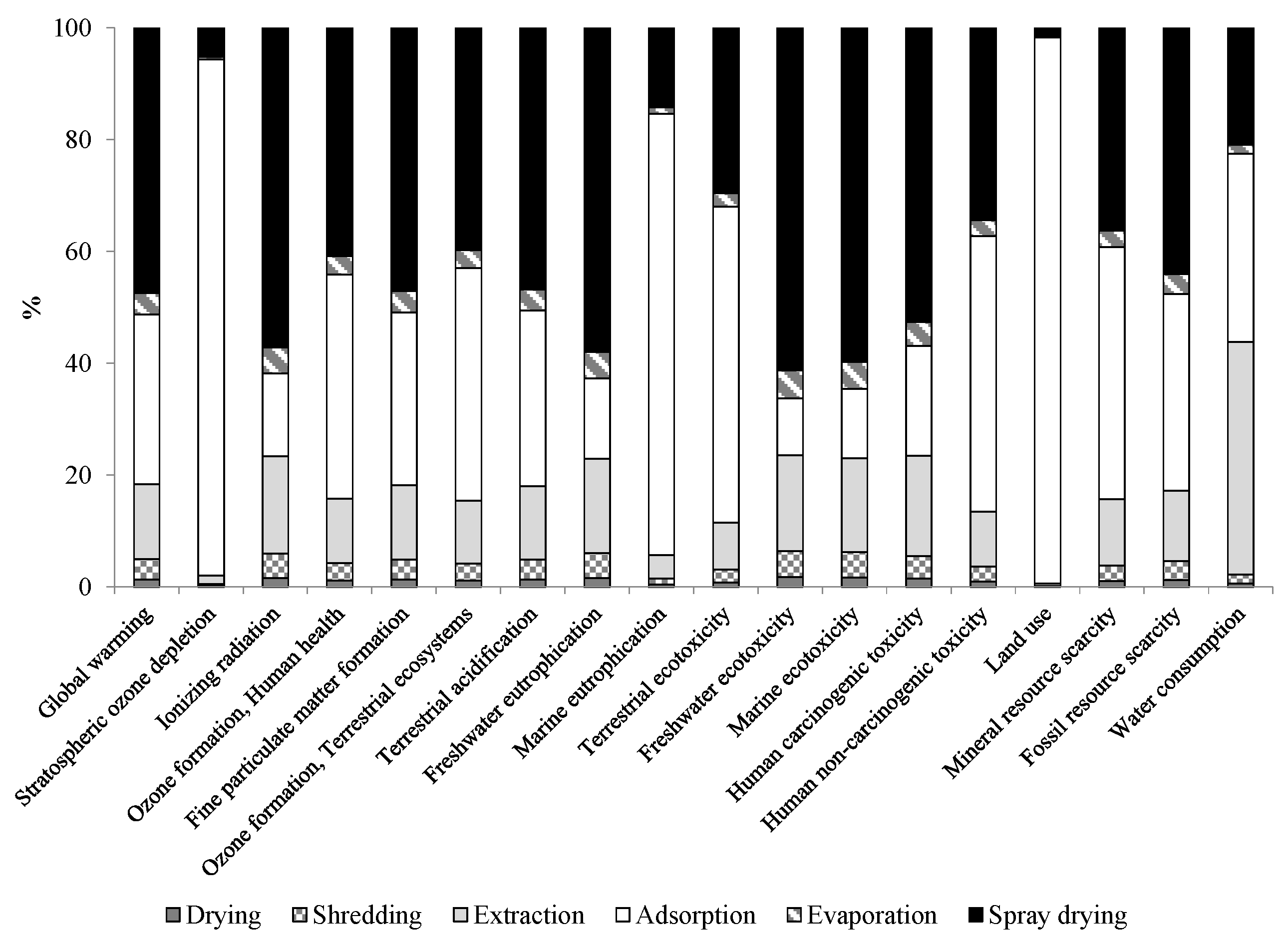

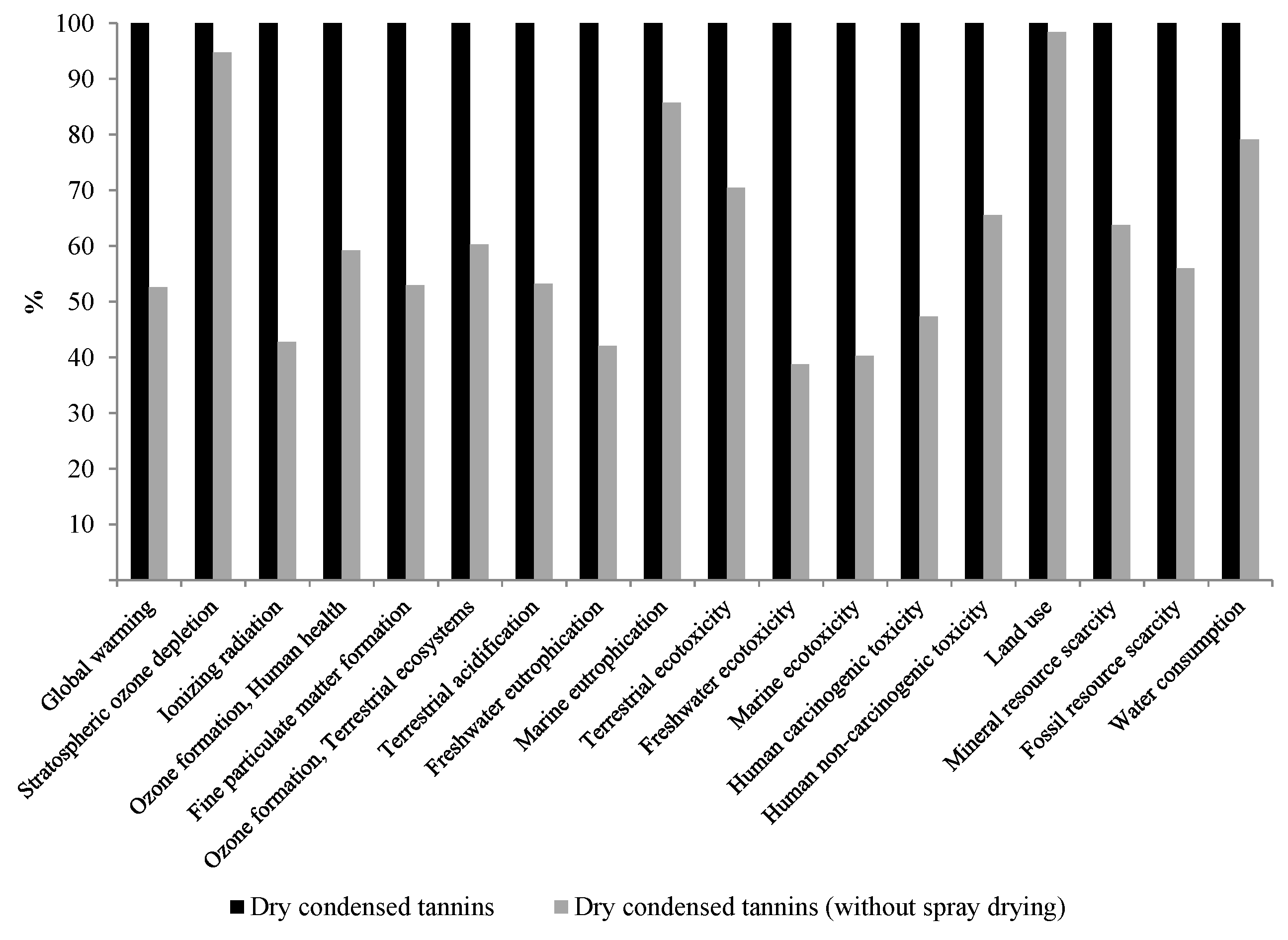

3.2. Life Cycle Assessment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ercin, A.E.; Hoekstra, A.Y. Water footprint scenarios for 2050: A global analysis. Environ. Int. 2014, 64, 71–82. [Google Scholar] [CrossRef] [PubMed]

- Jones, E.R.; van Vliet, M.T.H.; Qadir, M.; Bierkens, M.F.P. Country-level and gridded estimates of wastewater production, collection, treatment and reuse. Earth Syst. Sci. Data 2021, 13, 237–254. [Google Scholar] [CrossRef]

- van Vliet, M.; Flörke, M.; Wada, Y. Quality matters for water scarcity. Nat. Geosci. 2017, 10, 800–802. [Google Scholar] [CrossRef]

- Yateh, M.; Li, F.; Tang, Y.; Li, C.; Xu, B. Energy consumption and carbon emissions management in drinking water treatment plants: A systematic review. J. Clean. Prod. 2024, 437, 140688. [Google Scholar] [CrossRef]

- Jones, E.; Qadir, M.; van Vliet, M.T.H.; Smakhtin, V.; Kang, S.-M. The state of desalination and brine production: A global outlook. Sci. Total Environ. 2019, 657, 1343–1356. [Google Scholar] [CrossRef]

- Hanasaki, N.; Fujimori, S.; Yamamoto, T.; Yoshikawa, S.; Masaki, Y.; Hijioka, Y.; Kainuma Kanamori, Y.; Masui, T.; Takahashi, K.; Kanae, S. A global water scarcity assessment under Shared Socio-economic Pathways—Part 2: Water availability and scarcity. Hydrol. Earth Syst. Sci. 2013, 17, 2393–2413. [Google Scholar] [CrossRef]

- Kummu, M.; Guillaume, J.; Moel, H.; Eisner, S.; Flörke, M.; Porkka, M.; Siebert, S.; Veldkamp, T.I.E.; Ward, P. The world’s road to water scarcity: Shortage and stress in the 20th century and pathways towards sustainability. Sci. Rep. 2016, 6, 38495. [Google Scholar] [CrossRef]

- Gude, V.G. Desalination and water reuse to address global water scarcity. Rev. Environ. Sci. Biol. 2017, 16, 591–609. [Google Scholar] [CrossRef]

- Foglia, A.; González-Camejo, J.; Radini, S.; Sgroi, M.; Li, K.; Eusebi, A.L.; Fatone, F. Transforming wastewater treatment plants into reclaimed water facilities in water-unbalanced regions. J. Clean. Prod. 2023, 410, 137264. [Google Scholar] [CrossRef]

- Morote, Á.; Olcina, J.; Hernández, M. The Use of Non-Conventional Water Resources as a Means of Adaptation to Drought and Climate Change in Semi-Arid Regions: South-Eastern Spain. Water 2019, 11, 93. [Google Scholar] [CrossRef]

- Qadir, M.; Drechsel, P.; Jiménez Cisneros, B.; Kim, Y.; Pramanik, A.; Mehta, P.; Olaniyan, O. Global and regional potential of wastewater as a water, nutrient and energy source. Nat. Resour. Forum 2020, 44, 40–51. [Google Scholar] [CrossRef]

- Luthy, R.G.; Sedlak, D.L.; Plumlee, M.H.; Austin, D.; Resh, V.H. Wastewater-effluent-dominated streams as ecosystemmanagement tools in a drier climate. Front. Ecol. Environ. 2015, 13, 477–485. [Google Scholar] [CrossRef]

- Macedo, H.E.; Lehner, B.; Nicell, J.; Grill, G.; Li, J.; Limtong, A.; Shakya, R. Distribution and characteristics of wastewater treatment plants within the global river network. Earth Syst. Sci. Data 2022, 14, 559–577. [Google Scholar] [CrossRef]

- Pakharuddin, N.H.; Fazly, M.N.; Ahmad Sukari, S.H.; Tho, K.; Zamri, W.F.H. Water treatment process using conventional and advanced methods: A comparative study of Malaysia and selected countries. IOP Conf. Ser. Earth Environ. Sci. 2021, 880, 012017. [Google Scholar] [CrossRef]

- Wang, Z.; Luo, P.; Zha, X.; Xu, C.; Kang, S.; Zhou, M.; Nover, D.; Wang, Y. Overview assessment of risk evaluation and treatment technologies for heavy metal pollution of water and soil. J. Clean. Prod. 2022, 379, 134043. [Google Scholar] [CrossRef]

- Ang, W.L.; Mohammad, A.W. State of the art and sustainability of natural coagulants in water and wastewater treatment. J. Clean. Prod. 2020, 262, 121267. [Google Scholar] [CrossRef]

- Jiang, J.Q. The role of coagulation in water treatment. Curr. Opin. Chem. Eng. 2015, 8, 36–44. [Google Scholar] [CrossRef]

- Rabiee, A.; Ershad-Langroudi, A.; Zeynali, M.E. A survey on cationic polyelectrolytes and their applications: Acrylamide derivatives. Rev. Chem. Eng. 2015, 31, 239–261. [Google Scholar] [CrossRef]

- Bolto, B.; Gregory, J. Organic polyelectrolytes in water treatment. Water Res. 2007, 41, 2301–2324. [Google Scholar] [CrossRef]

- Carlqvist, K.; Arshadi, M.; Mossing, T.; Östman, U.-B.; Brännström, H.; Halmemies, E.; Nurmi, J.; Lidén, G.; Börjesson, P. Life-cycle assessment of the production of cationized tannins from Norway spruce bark as flocculants in wastewater treatment. Biofuels Bioprod. Biorefin. 2020, 14, 1270–1285. [Google Scholar] [CrossRef]

- Dichtl, N.; Rogge, S.; Bauerfeld, K. Novel strategies in sewage sludge treatment. Clean. Soil. Air Water 2007, 35, 473–479. [Google Scholar] [CrossRef]

- ESPP—European Sustainable Phosphorus Platform (2019). Available online: https://www.phosphorusplatform.eu/ (accessed on 22 March 2024).

- Sichler, T.C.; Adam, C.; Montag, D.; Barjenbruch, M. Future nutrient recovery from sewage sludge regarding three different scenarios—German case study. J. Clean. Prod. 2022, 333, 130130. [Google Scholar] [CrossRef]

- MRP—MarketsandMarkets Research Private Ltd. 2024. Available online: https://www.marketsandmarkets.com/ (accessed on 22 March 2024).

- Coral, L.A.; Bergamasco, R.; Bassetti, F.J. Estudo da viabilidade de utilização do polímero natural (TANFLOC) em substituição ao sulfato de alumínio no tratamento de águas para consumo. In Proceedings of the 2nd International Workshop—Advances in Cleaner Production, São Paulo, Brazil, 20–22 May 2009. [Google Scholar]

- Fiorentini, V. Uso do Tanino No Processo de Tratamento de Água Como Melhoria em Sistema de Gestão Ambiental; Universidade Federal de Santa Maria: Santa Maria, Brazil, 2005. [Google Scholar]

- Yin, C.-Y. Emerging usage of plant-based coagulants for water and wastewater treatment. Process Biochem. 2010, 45, 437–1444. [Google Scholar] [CrossRef]

- Martins, A.A.; Oliveira, R.M.S.; Guarda, E.A. Potencial de uso de compostos orgânicos como, coagulantes, floculantes e adsorventes no tratamento de água e efluentes. Periódico Eletrônico Fórum Ambient. Alta Paul. 2014, 10, 168–183. [Google Scholar] [CrossRef]

- Bauman, H.; Tillman, A.M. The Hitch Hiker’s Guide to, L.C.A; Studentlitteratur: Lund, Sweden, 2004. [Google Scholar]

- Kurniawan, S.B.; Abdullah, S.R.S.; Imron, M.F.; Said, N.S.M.; Ismail, N.I.; Hasan, H.A.; Othman, A.R.; Purwanti, I.F. Challenges and Opportunities of Biocoagulant/Bioflocculant Application for Drinking Water and Wastewater Treatment and Its Potential for Sludge Recovery. Int. J. Environ. Res. Public. Health 2020, 17, 9312. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, S.B.; Imron, M.F.; Chik, C.E.N.C.E.; Owodunni, A.A.; Ahmad, A.; Alnawajha, M.M.; Rahim, N.F.M.; Said, N.S.M.; Abdullah, S.R.S.; Kasan, N.A.; et al. What compound inside biocoagulants/bioflocculants is contributing the most to the coagulation and flocculation processes? Sci. Total Environ. 2022, 806, 150902. [Google Scholar] [CrossRef]

- Hoyos-Martínez, P.L.; Merle, J.; Labidi, J.; Charrier-El Bouhtoury, F. Tannins extraction: A key point for their valorization and cleaner production. J. Clean. Prod. 2019, 206, 1138–1155. [Google Scholar] [CrossRef]

- Ibrahim, A.; Yaser, A.Z. Colour removal from biologically treated landfill leachate with tannin-based coagulant. J. Environ. Chem. Eng. 2019, 7, 103483. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Pennington, D.W.; Potting, J.; Finnveden, G.; Lindeijer, E.; Jolliet, O.; Rydberg, T.; Rebitzer, G. Life cycle assessment Part 2: Current impact assessment practice. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 721–739. [Google Scholar] [CrossRef]

- Arias, A.; González-García, S.; Feijoo, G.; Moreira, M.T. Tannin-based bio-adhesives for the wood panel industry as sustainable alternatives to petrochemical resins. J. Ind. Ecol. 2022, 26, 627–642. [Google Scholar] [CrossRef]

- Carlqvist, K.; Wallberg, O.; Lidén, G.; Börjesson, P. Life cycle assessment for identification of critical aspects in emerging technologies for the extraction of phenolic compounds from spruce bark. J. Clean. Prod. 2022, 333, 130093. [Google Scholar] [CrossRef]

- Conde, M.; Combalia, F.; Baquero, G.; Ollé, L.; Bacardit, A. Exploring the feasibility of substituting mimosa tannin for pine bark powder. A LCA Perspect. Clean. Eng. Technol. 2022, 7, 100425. [Google Scholar] [CrossRef]

- Ding, T.; Bianchi, S.; Ganne-Chédeville, C.; Kilpeläinen, P.; Haapala, A.; Räty, T. Life cycle assessment of tannin extraction from spruce bark. iForest 2017, 10, 807–814. [Google Scholar] [CrossRef]

- González-García, S.; Lacoste, C.; Aicher, T.; Feijoo, G.; Lijó, L.; Moreira, M.T. Environmental sustainability of bark valorisation into biofoam and syngas. J. Clean. Prod. 2016, 125, 33–43. [Google Scholar] [CrossRef]

- Ferreira, A.G.C. Bibliometrics in the evaluation of scientific journals. Rev. Ciência Informação 2010, 11, 1–9. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Prisma Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Int. J. Surg. 2009, 8, 336–341. [Google Scholar] [CrossRef]

- Guinée, J.B. Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- ISO 14040:2006; Environmental Management e Life Cycle Assessment e Principles and Framework. ISO 14000 International Standards Compendium. International Organization for Standardization (ISO): Genéve, Switzerland, 2006.

- ISO 14040:2006; Environmental Management e Life Cycle Assessment e Requirements and Guidelines. ISO 14000 International Standards Compendium. International Organization for Standardization (ISO): Genéve, Switzerland, 2006.

- SuperPro Designer, version 10; Intelligen, Inc.: Scotch Plains, NJ, USA, 2020.

- Canizales, L.; Rojas, F.; Pizarro, C.A.; Caicedo-Ortega, N.H.; Villegas-Torres, M.F. SuperPro Designer®, User-Oriented Software Used for Analyzing the Techno-Economic Feasibility of Electrical Energy Generation from Sugarcane Vinasse in Colombia. Processes 2020, 8, 1180. [Google Scholar] [CrossRef]

- Arias, A.; Barreiro, D.; Feijoo, G.; Moreira, M.T. Waste biorefinery towards a sustainable biotechnological production of pediocin: Synergy between process simulation and environmental assessment. Environ. Technol. Innov. 2022, 26, 102306. [Google Scholar] [CrossRef]

- Ferreira, R.; Coura, R.D.; Nunes, L.; Ferraz, A.I.; Rodrigues, A.C. Acacia sp. bark: From waste to a nature-based solution for water treatment. In WASTES: Solutions, Treatments and Opportunities IV—Selected Papers, Proceedings of the 6th International Conference Wastes 2023, Coimbra, Portugal, 6–8 September 2023, 1st ed.; Vilarinho, C., Castro, F., Quina, M.J., Eds.; CRC Press: Boca Raton, FL, USA, 2023; ISBN 9781003345084. [Google Scholar] [CrossRef]

- The Swiss Centre for Life Cycle Inventories. Ecoinvent Database Version 3.4; The Swiss Centre for Life Cycle Inventories: Zürich, Switzerland, 2017. [Google Scholar]

- Kalverkamp, M.; Helmers, E.; Pehlken, A. Impacts of life cycle inventory databases on life cycle assessments: A review by means of a drivetrain case study. J. Clean. Prod. 2020, 269, 21329. [Google Scholar] [CrossRef]

- Pré Consultants, B.V. SimaPro 8.5; Pré Consultants, B.V.: Amersfoort, The Netherlands, 2017. [Google Scholar]

- Kavitha, V.U.; Kandasubramanian, B. Tannins for wastewater treatment. SN Appl. Sci. 2020, 2, 1081. [Google Scholar] [CrossRef]

- Feria-Reyes, R.; Ramírez-Cruz, S.O.; Ruiz-Aquino, F.; Robledo-Taboada, L.H.; Sánchez-Medina, M.A.; Mijangos-Ricárdez, O.F.; Gabriel-Parra, R.; Suárez-Mota, M.E.; Puc-Kauil, R.; Porcallo-Vargas, J. Pine Bark as a Potential Source of Condensed Tannin: Analysis through Fourier Transform Infrared Spectroscopy (FTIR), Scanning Electron Microscopy (SEM), and Energy Dispersive X-ray (EDX). Forests 2023, 14, 1433. [Google Scholar] [CrossRef]

- Borah, A.; Selvaraj, S.; Holla, S.R.; De, S. Extraction and characterization of total phenolic and flavonoid contents from bark of Swietenia macrophylla and their antimicrobial and antioxidant properties. Arab. J. Chem. 2022, 12, 104370. [Google Scholar] [CrossRef]

- Jyske, T.; Liimatainen, J.; Tienaho, J.; Brännström, H.; Aoki, D.; Kuroda, K.; Reshamwala, D.; Kunnas, S.; Halmemies, E.; Nakayama, E.; et al. Inspired by nature: Fiber networks functionalized with tannic acid and condensed tannin-rich extracts of Norway spruce bark show antimicrobial efficacy. Front. Bioeng. Biotechnol. 2023, 11, 1171908. [Google Scholar] [CrossRef]

- Cano, A.; Contreras, C.; Chiralt, A.; González-Martínez, A. Using tannins as active compounds to develop antioxidant and antimicrobial chitosan and cellulose based films. Carbohydr. Polym. Technol. Appl. 2021, 2, 100156. [Google Scholar] [CrossRef]

- Khan, S.R.; Khan, S.M.; Khan, R.U. Eco-Friendly Valorization and Utilization of Plant Waste as a Source of Tannin for Leather Tanning. Sustainability 2023, 15, 3884. [Google Scholar] [CrossRef]

- Pandey, S.; Pant, P. Possibilities and challenges for harnessing tree bark extracts for wood adhesives and green chemicals and its prospects in Nepal. For. Sci. Technol. 2023, 19, 68–77. [Google Scholar] [CrossRef]

- Sain, S.; Matsakas, L.; Rova, U.; Christakopoulos, P.; Öman, T.; Skrifvars, M. Spruce Bark-Extracted Lignin and Tannin-Based Bioresin-Adhesives: Effect of Curing Temperatures on the Thermal Properties of the Resins. Molecules 2021, 26, 3523. [Google Scholar] [CrossRef]

- Jeżo, A.; Wronka, A.; Dębiński, A.; Kristak, L.; Reh, R.; Rizhikovs, J.; Kowaluk, G. Influence of Upcycled Post-Treatment Bark Biomass Addition to the Binder on Produced Plywood Properties. Forests 2023, 14, 110. [Google Scholar] [CrossRef]

- Bacelo, H.; Vieira, B.R.; Santos, S.C.; Boaventura, R.A.; Botelho, C.M. Recovery and valorization of tannins from a forest waste as an adsorbent for antimony uptake. J. Clean. Prod. 2018, 198, 1324–1335. [Google Scholar] [CrossRef]

- Grenda, K.; Arnold, J.; Hunkeler, D.; Gamelas, J.A.F.; Rasteiro, M.G. Tannin-based coagulants from laboratory to pilot plant scales for coloured wastewater treatment. BioResources 2018, 13, 2727–2747. [Google Scholar] [CrossRef]

- João, J.J.; Júnior, W.S. Utilização da Casca de Pinus para Extração de Taninos e aplicar como Coagulante no Tratamento do Efluentes Industriais. Rev. Virtual Química 2019, 11, 1044–1053. [Google Scholar]

- Panzella, L.; Moccia, F.; Toscanesi, M.; Trifuoggi, M.; Giovando, S.; Napolitano, A. Exhausted woods from tannin extraction as an unexplored waste biomass: Evaluation of the antioxidant and pollutant adsorption properties and activating effects of hydrolytic treatments. Antioxidants 2019, 8, 84. [Google Scholar] [CrossRef] [PubMed]

- Grenda, K.; Arnold, J.; Gamelas, J.A.; Rasteiro, M.G. Up-scaling of tannin-based coagulants for wastewater treatment: Performance in a water treatment plant. Environ. Sci. Pollut. Res. 2020, 27, 1202–1213. [Google Scholar] [CrossRef] [PubMed]

- Jing, W.; Yin, L.; Lin, X.; Yu, Y.; Lian, D.; Shi, Z.; Chen, P.; Tang, M.; Yang, C. Simultaneous Adsorption of Cu2+ and Cd2+ by a Simple Synthesis of Environmentally Friendly Bamboo Pulp Aerogels: Adsorption Properties and Mechanisms. Polymers 2022, 14, 4909. [Google Scholar] [CrossRef]

- Bello, A.; Bergmann, U.; Vepsäläinen, J.; Leiviskä, T. Effects of tree harvesting time and tannin cold/hot-water extraction procedures on the performance of spruce tannin biocoagulant for water treatment. Chem. Eng. J. 2022, 449, 137809. [Google Scholar] [CrossRef]

- Nicomel, N.R.; Otero-Gonzalez, L.; Williamson, A.; Ok, Y.S.; Van Der Voort, P.; Hennebel, T.; Du Laing, G. Selective copper recovery from ammoniacal waste streams using a systematic biosorption process. Chemosphere 2022, 286, 131935. [Google Scholar] [CrossRef]

- Jinze, D.; Toni, V.; Juha-Pekka, S.; Sari, T.; Sami, H.; Maria, H.; Tao, H.; Ulla, L.; Tapani, V. Willow bark proanthocyanidins with potential for water treatment: Chemical characterization and zinc/bisphenol A removal. Sep. Purif. Technol. 2023, 318, 123943. [Google Scholar] [CrossRef]

- Tomasi, I.T.; Santos, S.C.; Boaventura, R.A.; Botelho, C.M. Microwave-Assisted Extraction of Polyphenols from Eucalyptus Bark—A First Step for a Green Production of Tannin-Based Coagulants. Water 2023, 15, 317. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe 2016 v1.1: A harmonized life cycle impact assessment method at midpoint and endpoint level. In Report I: Characterization; RIVM—National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2017. [Google Scholar]

- Sim, J.W.; Lee, H.; Jo, S.; Oh, S.; Kim, S.; Kim, D.R. Increasing energy saving of pilot-scale spray dryers with enhanced yield by low-adhesive surfaces. Case Stud. Therm. Eng. 2023, 49, 103218. [Google Scholar] [CrossRef]

| Keywords | Web of Science | Scopus |

|---|---|---|

| “tannin” | 33,416 | 51,848 |

| “tannin” + “bark OR biomass” | 3628 | 1189 |

| “tannin” + “bark OR biomass” + “extraction OR production” | 999 | 31 |

| “tannin” + “bark OR biomass” + “extraction OR production” + “Water” | 341 | 4 |

| Author | Title | Journal |

|---|---|---|

| Bacelo et al., 2018 [63] | Recovery and valorisation of tannins from a forest waste as an adsorbent for antimony uptake | Journal of cleaner production |

| Grenda et al., 2018 [64] | Tannin-based coagulants from laboratory to pilot plant scales for coloured wastewater treatment | Bioresources |

| João and Júnior, 2019 [65] | Utilization of the Pinus bark for tannin extraction to apply with as coagulant in the treatment of industrial effluents | Revista Virtual de Química |

| Panzella et al., 2019 [66] | Exhausted woods from tannin extraction as an unexplored waste biomass: evaluation of the antioxidant and pollutant adsorption properties and activating effects of hydrolytic treatments | Antioxidants |

| Grenda et al., 2020 [67] | Up-scaling of tannin-based coagulants for wastewater treatment: performance in a water treatment plant | Environmental science and pollution research |

| Carlqvist et al., 2020 [20] | Life cycle assessment of the production of cationized tannins from Norway spruce bark as flocculants in wastewater treatment | Biofuels bioproducts and biorefining (Biofpr) |

| Kavitha and Kandasubramanian, 2020 [54] | Tannins for wastewater treatment | SN applied sciences |

| Jing et al., 2022 [68] | Simultaneous adsorption of Cu2+ and Cd2+ by a simple synthesis of environmentally friendly bamboo pulp aerogels: adsorption properties and mechanisms | Polymers |

| Bello et al., 2022 [69] | Effects of tree harvesting time and tannin cold/hot-water extraction procedures on the performance of spruce tannin bio coagulant for water treatment | Chemical engineering journal |

| Nicomel et al., 2022 [70] | Selective copper recovery from ammoniacal waste streams using a systematic biosorption process | Chemosphere |

| Jinze et al., 2023 [71] | Willow bark proanthocyanidins with potential for water treatment: chemical characterization and zinc/bisphenol A removal | Separation and purification technology |

| Tomasi et al., 2023 [72] | Microwave-assisted extraction of polyphenols from Eucalyptus Bark—A first step for a green production of tannin-based coagulants | Water |

| Author | Objectives | Methodologies and Technologies |

|---|---|---|

| Bacelo et al., 2018 [63] | Removal of antimony that may be present in mine drainage and mine flotation wastewater and/or from much more dilute solutions, such as contaminated surface water or groundwater | Treatment of raw bark chemically to decontaminate synthetic solutions and industrial effluents on a laboratory and pilot scale and by regeneration, pyrolysis, or incineration of saturated bark |

| Grenda et al., 2018 [64] | Producing nature-based treatment agents to remove color from water | Modified tannin extract on a laboratory and pilot plant scale using the Mannich condensation reaction |

| João and Júnior, 2019 [65] | Reuse Pine bark to extract tannins and use it as a coagulant in the treatment of effluent generated in the household cleaning products industry | Extraction of tannins using different solvents such as 5% sodium bisulphite, ethanol, and water |

| Panzella et al., 2019 [66] | To characterize the antioxidant properties and other properties of practical interest of chestnut wood and quebracho wood, together with those of a chestnut wood fiber produced from steamed chestnut wood for the adsorption and removal of pollutants | Tannins extracted by immersing the wood chips in an autoclave with water at 120 °C under pressure; the extracts were concentrated in a multiple-effect evaporator under vacuum until the water was removed, and the tannin powder was obtained by spray drying |

| Grenda et al., 2020 [67] | Production of nature-based cationic coagulants for wastewater treatment using different origins and sources of tannin to analyze the performance of the eco coagulants obtained and their biodegradability in an effluent treatment plant for industrial effluent treatment | Modification of tannins through Mannich aminomethylation with formaldehyde and dimethylamine hydrochloride for water treatment on a pilot plant scale |

| Carlqvist et al., 2020 [20] | Elaborate the LCA of the production of a flocculation agent based on cationic tannins from Norway spruce bark, from the production of spruce trees to the flocculation product, identifying the potential for optimization and comparing it with the three conventional flocculants normally used: polyacrylamide, aluminum sulfate, and iron (III) chloride | The Ecoinvent 3.6 database was used to assess the life cycle impact (LCA) of the extraction, purification and drying, and cationization phases of tannins for the production of flocculants in wastewater treatment |

| Kavitha and Kandasubramanian, 2020 [54] | Analyze the literature and describe polyphenols and their efficiency in removing cationic heavy metal ions and dyes from polluted industrial wastewater | Literature review |

| Jing et al., 2022 [68] | Synthesis of a tannin/chitosan/bamboo pulp aerogel (TCPA) as an ecological, renewable, and low-density adsorbent for the treatment of wastewater containing mixtures of heavy metals | Aerogel synthesized using a simple freeze-drying method and analyzed using FTIR, XPS, SEM, TEM, TGA, and surface area and porosity methods |

| Bello et al., 2022 [69] | Investigating the effect of seasonal variation (winter and summer) on spruce bark tannin extracts as biocoagulants for water treatment applications | Tannins obtained directly after dry peeling in the factories, extracted using three different water extraction procedures—cold water extraction (21 °C), cold water extraction plus hot water extraction (85 °C), and direct hot water extraction (85 °C)—and synthesized using the Mannich reaction |

| Nicomel et al., 2022 [70] | Analyzing 23 biosorbents for Cu adsorption from a synthetic Cu-NH 3 leachate | Batch experiments, discontinuous experiments, and adsorption analysis at different pHs |

| Jinze et al., 2023 [71] | Study the chemical structure of crude extracts rich in proanthocyanidins from the bark and carry out tests as adsorbents for artificial wastewater treatment | Soft water extraction and chromatographic fractionation, purification by nuclear magnetic resonance (NMR) and ultra-performance liquid chromatography mass spectrometry and adsorption tests |

| Tomasi et al., 2023 [72] | Optimizing the extraction of tannin from eucalyptus bark to produce a coagulant for water and effluent treatment | Different extraction techniques, such as SLE, PLE, UAE, and MAE, using distilled water as a solvent, vacuum filtration through a glass microfiber membrane, calculation of extraction yield (EY), analysis of polyphenol (TPC) and condensed tannin (CT) content, microwave-assisted extraction, and JMP statistical software (trial version 16) |

| Authors | Tannin Extraction for Use in Water Treatment | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tannin Origin | Extraction Methodology | Water Treatment | |||||||||

| B | W | P | PY | C | M | T | CL | MT | OM | CC | |

| Bacelo et al., 2018 [63] | + | + | + | + | |||||||

| Grenda et al., 2018 [64] | + | + | + | + | + | + | + | ||||

| João and Júnior, 2019 [65] | + | + | + | + | + | + | + | + | |||

| Panzella et al., 2019 [66] | + | + | + | + | + | + | + | + | |||

| Grenda et al., 2020 [67] | + | + | + | + | + | + | + | ||||

| Carlqvist et al., 2020 [20] | + | + | + | ||||||||

| Jing et al., 2022 [68] | + | + | + | + | + | ||||||

| Bello et al., 2022 [69] | + | + | + | + | + | + | |||||

| Nicomel et al., 2022 [70] | + | + | + | + | + | ||||||

| Jinze et al., 2023 [71] | + | + | + | + | + | ||||||

| Tomasi et al., 2023 [72] | + | + | + | + | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simões, C.L.; Neto, A.B.P.S.; Rodrigues, A.C.; Ferreira, R.; Simoes, R. Environmental Assessment of Tannin Extraction from Bark Residues for Application in Water Treatment. Biomass 2025, 5, 15. https://doi.org/10.3390/biomass5010015

Simões CL, Neto ABPS, Rodrigues AC, Ferreira R, Simoes R. Environmental Assessment of Tannin Extraction from Bark Residues for Application in Water Treatment. Biomass. 2025; 5(1):15. https://doi.org/10.3390/biomass5010015

Chicago/Turabian StyleSimões, Carla L., Alice B. P. Santos Neto, Ana C. Rodrigues, Ricardo Ferreira, and Ricardo Simoes. 2025. "Environmental Assessment of Tannin Extraction from Bark Residues for Application in Water Treatment" Biomass 5, no. 1: 15. https://doi.org/10.3390/biomass5010015

APA StyleSimões, C. L., Neto, A. B. P. S., Rodrigues, A. C., Ferreira, R., & Simoes, R. (2025). Environmental Assessment of Tannin Extraction from Bark Residues for Application in Water Treatment. Biomass, 5(1), 15. https://doi.org/10.3390/biomass5010015