Comprehensive Environmental Impact Analysis of Dry Processing Methods for Specialty Coffee Beans in Bondowoso, Indonesia Using Life Cycle Assessment

Abstract

1. Introduction

2. Materials and Methods

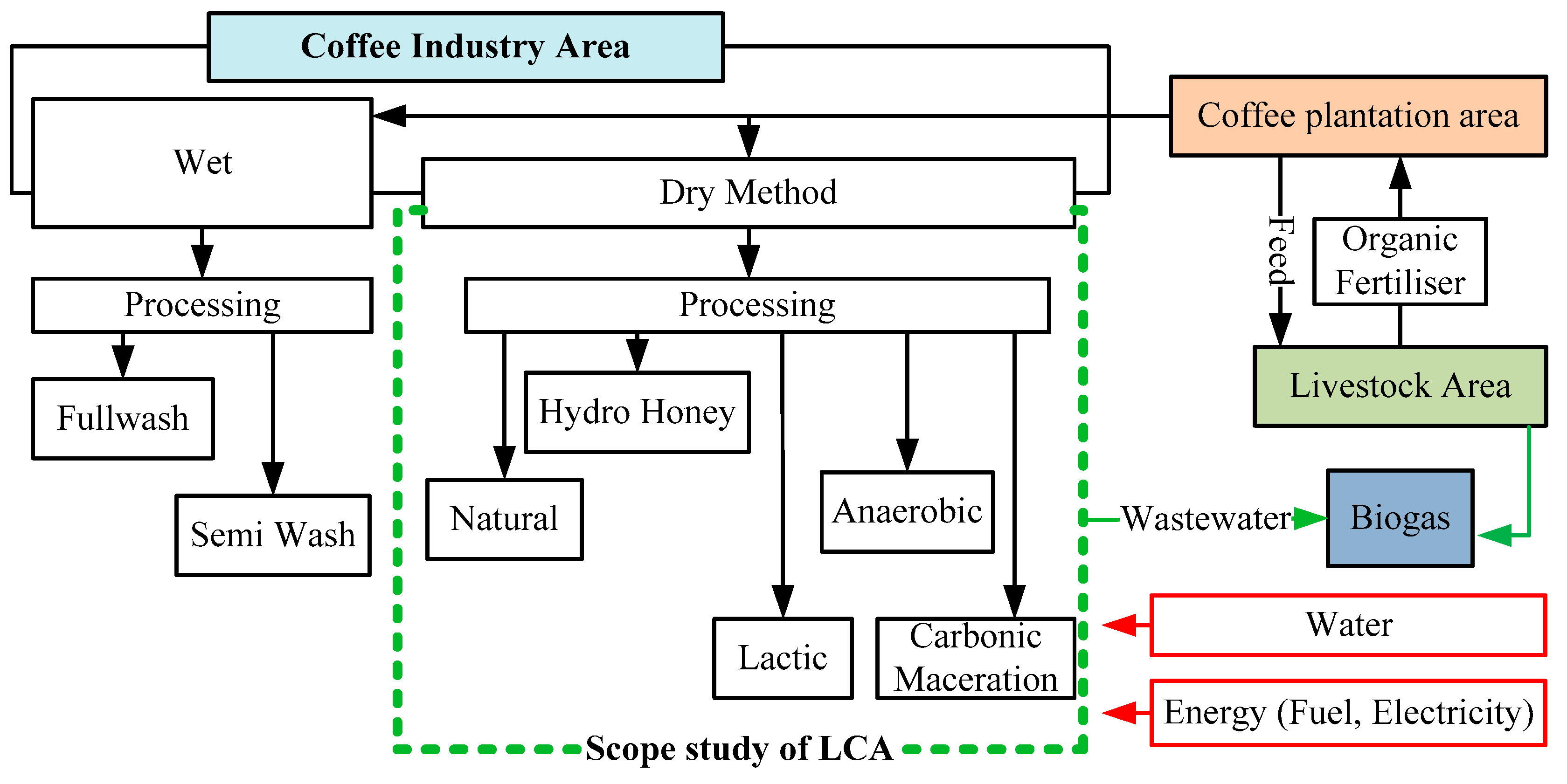

2.1. Study Area and System Boundary

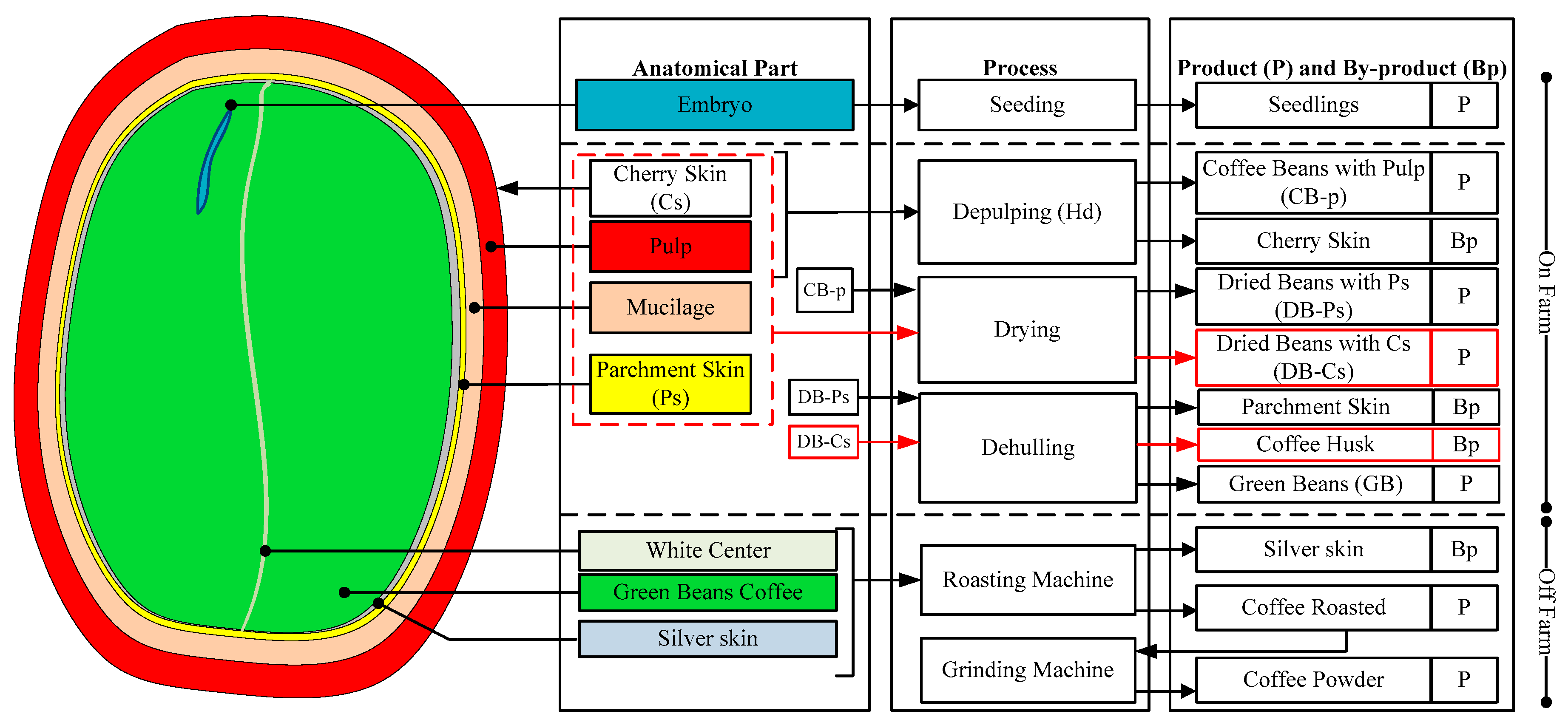

2.2. Coffee Processing through Dry Methods

2.2.1. Natural Processing

2.2.2. Hydro Honey Processing

2.2.3. Lactic Processing

2.2.4. Anaerobic Processing

2.2.5. Carbonic Maceration (CM)

2.3. Environmental Impact Analysis

2.3.1. Goal and Scope

2.3.2. Inventory Analysis

2.3.3. Impact Assessment

- CO2 = Estimated CO2 emission rate (mg/batch)

- Qww = Wastewater produced (mg/batch)

- EffBOD = Oxygen demand removal efficiency

- CFCO₂ = Conversion factor for maximum CO2

- MCFww = Correction factor wastewater treatment

- BG = Fraction of carbon

- λ = Biomass yield

2.3.4. Interpretation

3. Results

3.1. Comparison of Input-Output and Yields from the Different Dry Processing Methods

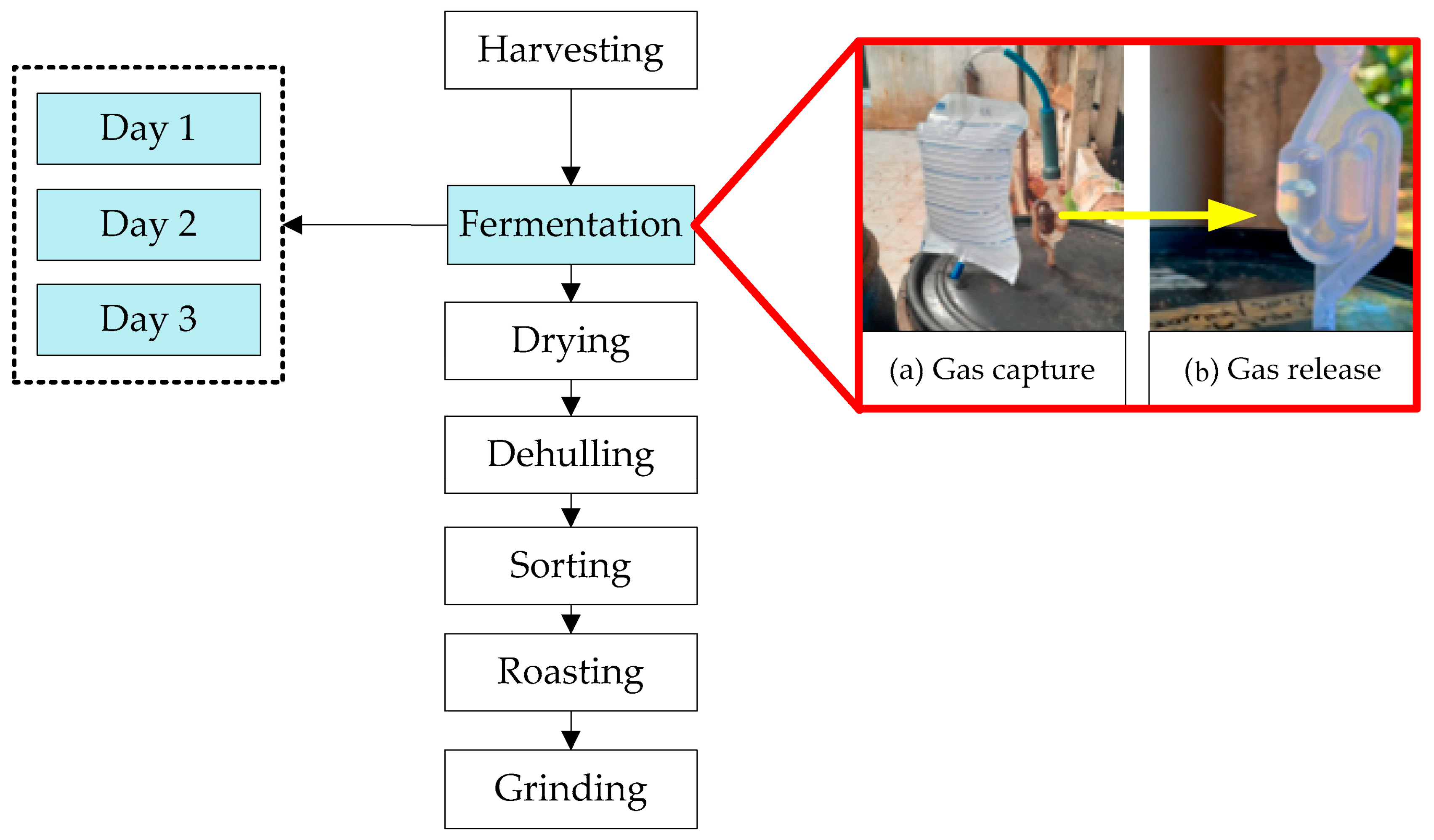

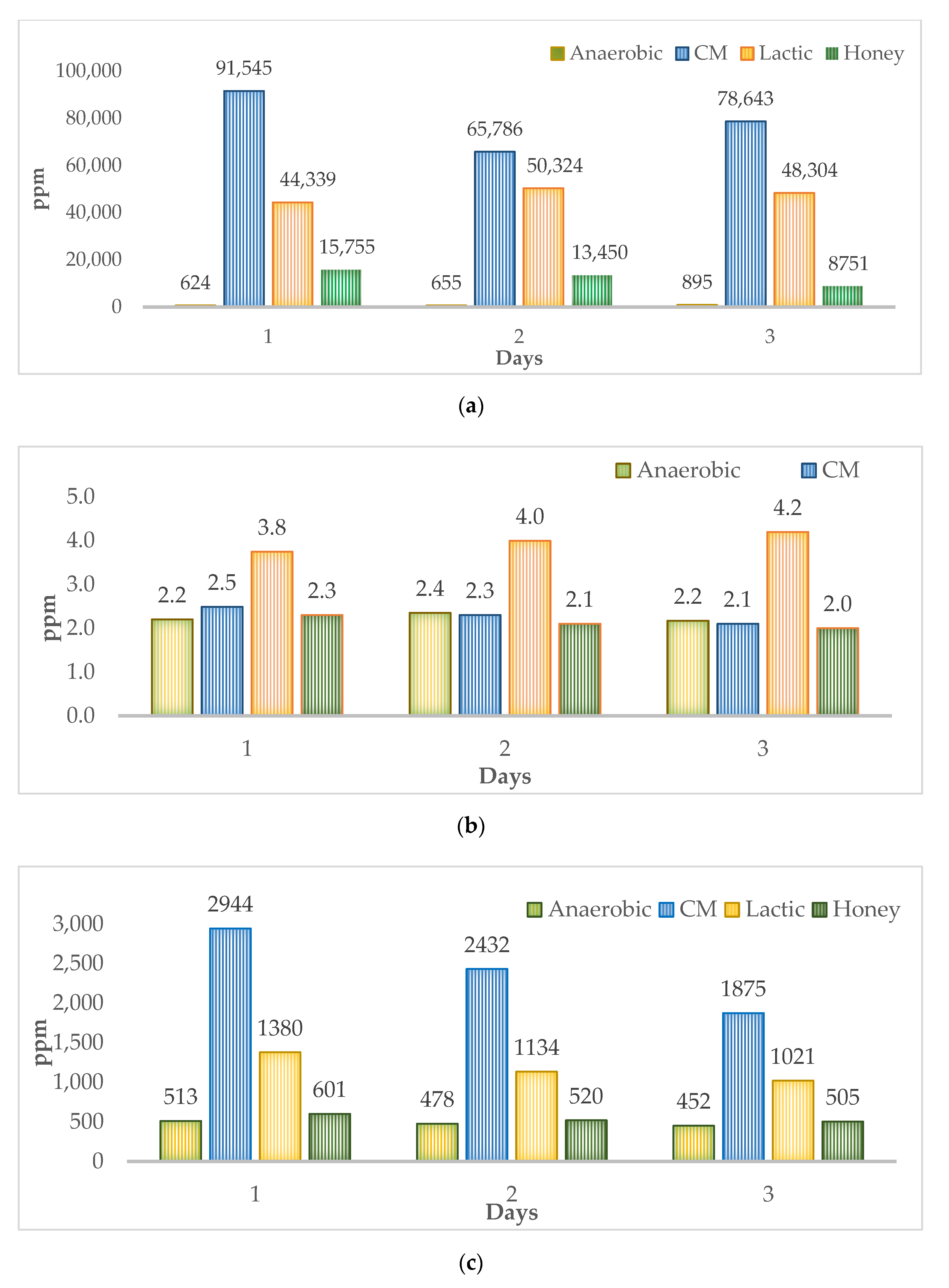

3.2. Coffee Fermentation, Gas Release, and Wastewater

3.3. Life Cyle Impact Characterization

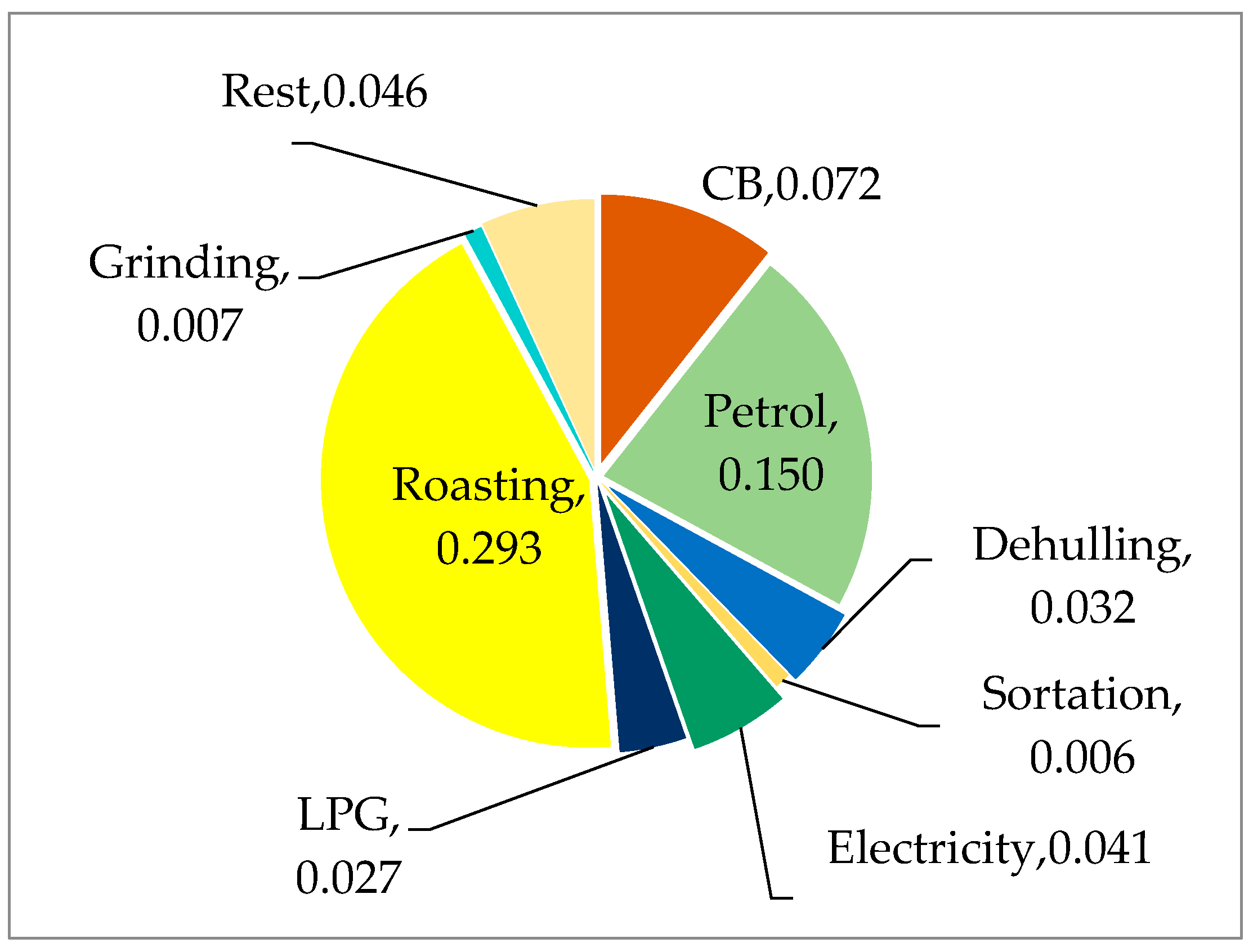

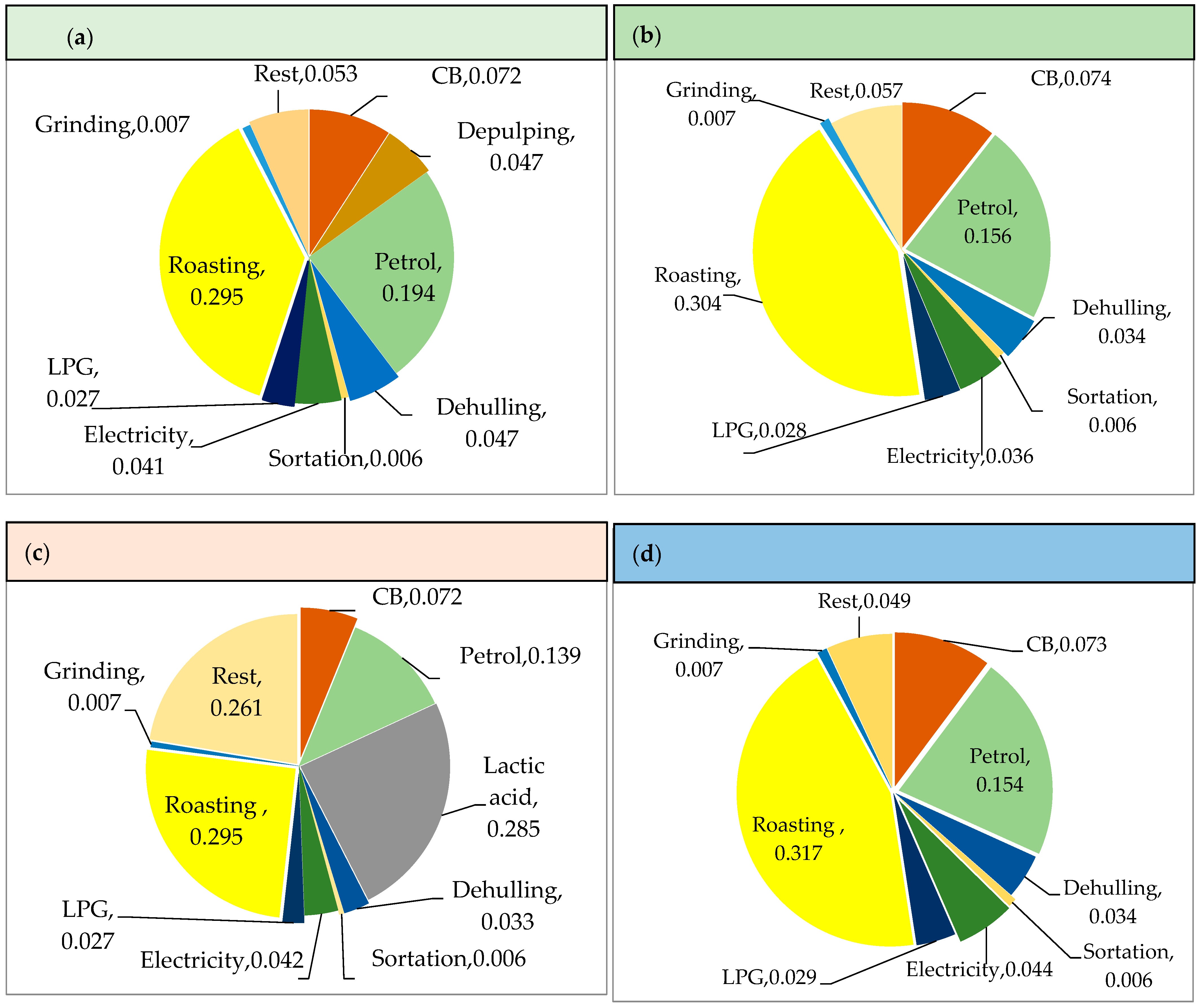

3.3.1. Global Warming Potential (GWP)

3.3.2. Stratospheric Ozone Depletion Potential (ODP)

3.3.3. Ionizing Radiation Potential (IRP)

3.3.4. Ozone Formation, Human Health (HOFP) and Terrestrial Ecosystems (EOFP)

3.3.5. Fine Particulate Matter Formation (FPMF)

3.3.6. Terrestrial Acidification Potential (TAP)

3.3.7. Eutrophication Potentials (FEP and MEP)

3.3.8. Ecotoxicity Potentials (TETP, FETP, METP)

3.3.9. Human Toxicity Potentials (HTPc and HTPnc)

3.3.10. Land Use (LOP)

3.3.11. Mineral and Fossil Resource Scarcity (SOP and FFP)

3.3.12. Water Consumption Potential (WCP)

3.4. Comparison between GWP and Total Energy Consumption

4. Discussion

| Ref. | Farming | On-Farm | Off-Farm | LCA Method | |

|---|---|---|---|---|---|

| Cultivation (/kg CBs) | Harvesting (/kg CBs) | Primary (/kg GBs) | Secondary (/kg CP) | ||

| [19] | NA | 0.29 kg CO2-eq/kg CBs | 0.336 kg CO2-eq/kg GBs | 2.794 kg CO2-eq/kg CP | Calculated |

| Organic Farming to produce CBs | Process CBs to GBs (/kg GBs) | Process CBs to CP (/kg CP) | |||

| [21] | 0.74 kg CO2-eq | NA | NA | Calculated | |

| Conventional Farming to Harvest of CBs | |||||

| 0.5 kg CO2-eq | NA | NA | |||

| Integrated Farming to Harvest of CBs | |||||

| 0.16 kg CO2-eq | NA | NA | |||

| Organic Farming to Harvest of CBs | |||||

| [51] | NA | NA | 1.8 kg CO2-eq/kg GBs | NA | Calculated |

| Conventional Farming to Harvest of CBs | Process CBs to GBs | ||||

| [52] | NA | NA | NA | 0.318 kg CO2-eq/kg CR | LCA Sima Pro |

| Process GBs to CP (Solar Panel) | |||||

| NA | NA | NA | 0.744 kg CO2-eq/kg CR | ||

| Process GBs to CP (Local Hydro Electricity) | |||||

| [53] | NA | NA | 16.04 kg CO2-eq | NA | Calculated |

| Conventional Farming in Vietnam from Harvest of CBs to Processed GBs | |||||

| NA | NA | 14.61 kg CO2-eq | NA | ||

| Integrated Farming in Brazil from Harvest of CBs to Processed GBs | |||||

| 2.82 kg CO2-eq | 2.82 kg CO2-eq | 2.90 kg CO2-eq/kg CP | |||

| [54] | Conventional Farming to Harvest of CBs | Process CBs to GBs | Process GBs to CP | Calculated | |

| 1.89 kg CO2-eq | 1.50 kg CO2-eq | 1.58 kg CO2-eq/kg CP | |||

| Organic Farming to Harvest of CBs | Process CBs to GBs | Process GBs to CP | |||

| [55] | NA | NA | NA | 0.27 to 0.70 kg CO2-eq/l CD | Calculated |

| Coffee Consumed in Finland | |||||

| [56] | NA | 0.27 kg CO2-eq/kg CB | NA | 1.31 kg CO2-eq/kg CP | Calculated |

| Conventional Farming to Harvest of CBs | Process CBs to CP (Fossil Fuel and Local Electricity) | ||||

| [26] SW | 0.039 kg CO2-eq | 0.275 kg CO2-eq | 0.568 kg CO2-eq | 0.765 kg CO2-eq | LCA Sima Pro |

| [26] FW | 0.473 kg CO-2-eq | 0.741 kg CO2-eq | |||

| Cultivation (/kg CBs) | Harvest CBs (/kg CBs) | Process CBs to GBs (/kg GBs) | Process CBs to CP (/kg CP) | ||

| This study | Cultivation (/kg CB) | Harvest CBs (/kg CB) | Process CBs to GBs (/kg GBs) | Process CBs to CP (/kg CP) | LCA Sima Pro |

| Nat | 0.072 kg CO2-eq | 0.276 kg CO2-eq | 0.302 kg CO2-eq | 0.676 kg CO2-eq | |

| An | 0.306 kg CO2-eq | 0.702 kg CO2-eq | |||

| Hd | 0.407 kg CO2-eq | 0.788 kg CO2-eq | |||

| L | 0.577 kg CO2-eq | 1.168 kg CO2-eq | |||

| Cm | 0.310 kg CO2-eq | 0.713 kg CO2-eq | |||

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Quintão, T.; Brito, P.Z. Connoisseurship Consumption and Market Evolution: An Institutional Theory Perspective on the Growth of Specialty Coffee Consumption in the USA. Rev. Bras. De Mark. 2016, 15, 1–15. [Google Scholar] [CrossRef]

- Córdoba, N.; Moreno, F.L.; Osorio, C.; Velásquez, S.; Fernandez-Alduenda, M.; Ruiz-Pardo, Y. Specialty and regular coffee bean quality for cold and hot brewing: Evaluation of sensory profile and physicochemical characteristics. LWT 2021, 145, 111363. [Google Scholar] [CrossRef]

- Irawan, A. The smallholder coffee farmer’s livelihood adaptation strategies in Bengkulu, Indonesia. J. Strateg. Manag. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Campos, A.D.S.N.; Satolo, E.G.; Mac-Lean, P.A.B.; Júnior, S.S.B. Economic sustainability analysis of the specialty coffee farmers in Garça/SP. Coffee Sci. 2021, 16, e161993. [Google Scholar] [CrossRef]

- Krishnan, S. Sustainable Coffee Production. Oxf. Res. Encycl. Environ. Sci. 2017. Available online: https://oxfordre.com/environmentalscience/view/10.1093/acrefore/9780199389414.001.0001/acrefore-9780199389414-e-224 (accessed on 15 June 2024).

- Nugroho, A. The Impact of Food Safety Standard on Indonesia’ s Coffee Exports. Procedia Environ. Sci. 2014, 20, 425–433. [Google Scholar] [CrossRef][Green Version]

- Widaningsih, R. Outlook Komoditas Perkebunan Kopi, Pusat Data dan Sistem Informasi PertanianSekretariat Jenderal; Kementerian Pertanian: Jakarta, Indonesia, 2022; ISSN 1907-1507. [Google Scholar]

- Mulyara, B.; Supriyadi, S.; Rahmadian, Y.; Ichsan, O.A.N. Sensory Properties and Volatile Compound Profile of Anaerobic Fermented Gayo Arabica Coffee in Non-Washed Processing. Pelita Perkeb. A Coffee Cocoa Res. J. 2021, 37, 239–254. [Google Scholar] [CrossRef]

- Yusuf, E.S.; Ariningsih, E.; Ashari; Gunawan, E.; Purba, H.J.; Suhartini, S.H.; Tarigan, H.; Syahyuti; Hestina, J.; Saputra, Y.H.; et al. Sustainability of Arabica coffee business in West Java, Indonesia: A multidimensional scaling approach. Open Agric. 2022, 7, 820–836. [Google Scholar] [CrossRef]

- Maspul, K.A. The Emergence of Local Coffee Brands: A Paradigm Shift in Jakarta Coffee Culture. EKOMA J. Ekon. Manaj. Akunt. 2023, 3, 135–149. [Google Scholar] [CrossRef]

- Pritantiwi, S.; Fatimah, F.; Hermawan, H. Determination of Product Life Cycle (PLC) for Formulation of Marketing Strategy UD. Matt Coffee Bondowoso. Int. J. Bus. Technol. Organ. Behav. 2023, 3, 1–10. [Google Scholar] [CrossRef]

- Antezana, R.N.V.; Luna-Mercado, G.I. Effect of processing methods (washed, honey, natural, anaerobic) of catimor coffee on physical and sensory quality in Alto Inambari, Peru. Coffee Sci. 2023, 18, e182111. [Google Scholar] [CrossRef]

- Wintgens, J.N.; Zamarripa, C.A. Coffee Propagation. In Coffee: Growing, Processing, Sustainable Production: A Guidebook for Growers, Processors, Traders, and Researchers; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Byrareddy, V.; Kouadio, L.; Mushtaq, S.; Stone, R. Sustainable production of robusta coffee under a changing climate: A 10-year monitoring of fertilizer management in coffee farms in Vietnam and Indonesia. Agronomy 2019, 9, 499. [Google Scholar] [CrossRef]

- Traore, T.M.; Wilson, N.L.W.; Fields, D. What explains specialty coffee quality scores and prices: A case study from the cup of excellence program. J. Agric. Appl. Econ. 2018, 50, 349–368. [Google Scholar] [CrossRef]

- Maspul, K.A. Improving the Creative Process Strategy of the Specialty Coffee in Eastern Province Saudi Arabia in Strengthening Sustainability in the Coffee Value Chain. EKOMA J. Ekon. Manaj. Akunt. 2022, 2, 244–254. [Google Scholar] [CrossRef]

- Trinh, L.T.K.; Hu, A.H.; Lan, Y.C.; Chen, Z.H. Comparative life cycle assessment for conventional and organic coffee cultivation in Vietnam. Int. J. Environ. Sci. Technol. 2020, 17, 1307–1324. [Google Scholar] [CrossRef]

- Diyarma, I.; Bantacut, T.; Suprihatin. Assessment of Environmental Impact of the Gayo Arabica Coffee Production by Wet Process using Life Cycle Assessment. Acta Univ. Cibiniensis. Ser. E Food Technol. 2019, 23, 27–34. [Google Scholar] [CrossRef]

- Novita, E.; Irfani, M.E. Life Cycle Assessment of Organic Arabica Coffee Products. J. Agric. Eng. 2023, 12, 186–200. [Google Scholar] [CrossRef]

- Pramulya, R.; Bantacut, T.; Noor, E.; Yani, M.; Romli, M. Life Cycle Assessment of Gayo Arabica Coffee Green Bean at Aceh Province. Habitat 2022, 33, 308–319. [Google Scholar] [CrossRef]

- Basavalingaiah, K.; Paramesh, V.; Parajuli, R.; Girisha, H.; Shivaprasad, M.; Vidyashree, G.; Thoma, G.; Hanumanthappa, M.; Yogesh, G.; Misra, S.D.; et al. Energy flow and life cycle impact assessment of coffee-pepper production systems: An evaluation of conventional, integrated and organic farms in India. Environ. Impact Assess. Rev. 2022, 92, 106687. [Google Scholar] [CrossRef]

- Noponen, M.R.A.; Edwards-Jones, G.; Haggar, J.P.; Soto, G.; Attarzadeh, N.; Healey, J.R. Greenhouse gas emissions in coffee grown with differing input levels under conventional and organic management. Agric. Ecosyst. Environ. 2012, 151, 6–15. [Google Scholar] [CrossRef]

- Irawan, A.; McLellan, B.C. Study on biogas production from coffee wastes and cow-dung fermentation and its use towards reducing emissions from coffee roasting. IOP Conf. Ser. Earth Environ. Sci. 2023, 1201, 012004. [Google Scholar] [CrossRef]

- Jimenez, E.J.M.; Martins, P.M.M.; Vilela, A.L.d.O.; Batista, N.N.; da Rosa, S.D.V.F.; Dias, D.R.; Schwan, R.F. Influence of anaerobic fermentation and yeast inoculation on the viability, chemical composition, and quality of coffee. Food Biosci. 2023, 51, 102218. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; Salomone, R.; Petti, L.; Mondello, G.; Raggi, A. Is there a simpli fi ed LCA tool suitable for the agri-food industry? An assessment of selected tools. J. Clean. Prod. 2017, 149, 406–425. [Google Scholar] [CrossRef]

- Irawan, A.; McLellan, B.C. A comparison of life cycle assessment (LCA) of Andungsari Arabica coffee processing technologies towards lower environmental impact. J. Clean. Prod. 2024, 447, 141561. [Google Scholar] [CrossRef]

- Borém, F.M.; De Andrade, E.T. Processing and drying of coffee. Dry. Roasting Cocoa Coffee 2019, 3, 141–170. [Google Scholar] [CrossRef]

- Martins, P.M.M.; Batista, N.N.; Miguel, M.G.d.C.P.; Simão, J.B.P.; Soares, J.R.; Schwan, R.F. Coffee growing altitude influences the microbiota, chemical compounds and the quality of fermented coffees. Food Res. Int. 2020, 129, 108872. [Google Scholar] [CrossRef] [PubMed]

- Martinez, S.J.; Rabelo, M.H.S.; Bressani, A.P.P.; Da Mota, M.C.B.; Borém, F.M.; Schwan, R.F. Novel stainless steel tanks enhances coffee fermentation quality. Food Res. Int. 2021, 139, 109921. [Google Scholar] [CrossRef]

- Bertarini, P.L.L.; Gomes, M.S.; Santos, L.D. Evaluation of Arabica Coffee Fermentation Using Machine Learning. Foods 2024, 13, 454. [Google Scholar] [CrossRef]

- Mejía, F.T.; Fuentes, J.M.; Mejía, J.T.; Bonilla, F.H.; Alemán, R.S.; Varela, I.; Kazemzadeh, S.; Fernández, I.M. Energy Evaluation of the Mechanical Drying of the Grain of Coffea arabica from Honduras. Asian J. Biol. 2021, 11, 8–14. [Google Scholar] [CrossRef]

- Prono-Widayat, H.; Arpi, N.; Andini, R.; Muzaifa, M.; Gunawan, F. Chemical analysis of cascara tea from wine coffee processing with a different fermentation times. IOP Conf. Ser. Earth Environ. Sci. 2021, 667, 2–7. [Google Scholar] [CrossRef]

- Suseno, H.; Haryanto; Galih, N.R.P.; Hidayati, N.; Alonto, C.; Irfan, M. Panduan Penerapan dan Sertifikasi SNI Produk Kopi Bubuk; Badan Standardisasi Nasional: Jakarta, Indonesia, 2020; ISBN 978-602-9394-36-8.

- Rizkya, I.; Syahputri, K.; Sari, R.M.; Christin, S. Analysis of Defective Causes in Coffee Product Using Decision Tree Approach. IOP Conf. Ser. Mater. Sci. Eng. 2020, 851, 012029. [Google Scholar] [CrossRef]

- Garc, M.; Candelo-becerra, J.E. Quality and Defect Inspection of Green Coffee Beans Using a Computer Vision System. Appl. Sci. 2019, 9, 4195. [Google Scholar] [CrossRef]

- Kingston, N.F.L. How to Make Coffee: The Science Behind the Bean; Harry N. Abrams: New York, NY, USA, 2017; Volume 53. [Google Scholar]

- Nigam, P.S.; Singh, A. Cocoa and Coffee Fermentations. In Encyclopedia of Food Microbiology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Wang, C.; Sun, J.; Lassabliere, B.; Yu, B.; Zhao, F.; Zhao, F.; Chen, Y.; Liu, S.Q. Potential of lactic acid bacteria to modulate coffee volatiles and effect of glucose supplementation: Fermentation of green coffee beans and impact of coffee roasting. J. Sci. Food Agric. 2019, 99, 409–420. [Google Scholar] [CrossRef]

- de Melo Pereira, G.V.; da Silva Vale, A.; de Carvalho Neto, D.P.; Muynarsk, E.S.; Soccol, V.T.; Soccol, C.R. Lactic acid bacteria: What coffee industry should know? Curr. Opin. Food Sci. 2020, 31, 1–8. [Google Scholar] [CrossRef]

- Rossi, E.; Pasciucco, F.; Iannelli, R.; Pecorini, I. Environmental impacts of dry anaerobic biorefineries in a Life Cycle Assessment (LCA) approach. J. Clean. Prod. 2022, 371, 133692. [Google Scholar] [CrossRef]

- Ariefandie, N.; Zhu, F. Coffee bean processing: Emerging methods and their effects on chemical, biological and sensory properties. Food Chem. 2023, 412, 135489. [Google Scholar] [CrossRef]

- Catalán, E.; Komilis, D.; Sánchez, A. Environmental impact of cellulase production from coffee husks by solid-state fermentation: A life-cycle assessment. J. Clean. Prod. 2019, 233, 954–962. [Google Scholar] [CrossRef]

- Zampori, L.; Saouter, E.; Schau, E.; Cristobal, J.; Castellani, V.; Sala, S. Guide for Interpreting Life Cycle Assessment Result; Publications Office of the European Union: Luxembourg, 2016; p. 60. [CrossRef]

- RTI. Greenhouse Gas Emissions Estimation Methodologies for Biogenic Emissions from Selected Source Categories: Solid Waste Disposal Wastewater Treatment Ethanol Fermentation; US Environmental Protection Agency: Washington, DC, USA, 2010; pp. 1–43.

- Doorn, M.R.J.; Towprayoon, S.; Vieira, S.M.M.; Palmer, C.; Pipatti, R.; Wang, C. Chapter 6: Wastewater Treatment and Discharge. In IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2006. [Google Scholar]

- Hobson, J. CH4 and N2O emissions from waste water handling. Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories. In IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2000; pp. 441–454. [Google Scholar]

- Ijanu, E.M.; Kamaruddin, M.A.; Norashiddin, F.A. Coffee processing wastewater treatment: A critical review on current treatment technologies with a proposed alternative. Appl. Water Sci. 2020, 10, 11. [Google Scholar] [CrossRef]

- Miller, R. Review Essay: The Third Way. Polit. Sci. 2000, 52, 174–180. [Google Scholar] [CrossRef]

- Hernández-Sarabia, M.; Sierra-Silva, J.; Delgadillo-Mirquez, L.; Ávila-Navarro, J.; Carranza, L. The potential of the biodigester as a useful tool in coffee farms. Appl. Sci. 2021, 11, 6884. [Google Scholar] [CrossRef]

- Irawan, A.; Mclellan, B.C.; Hastutik, S.D. Developing Coffee Cherry Skin and Coffee Husk by Products as Sustainable Novel Food and Fuel. Int. J. Technol. Food Agric. 2024, 1, 33–42. [Google Scholar] [CrossRef]

- Harsono, S.S.; Wibowo, R.K.K.; Supriyanto, E. Energy Balance and Green House Gas Emisson on Smallholder Java Coffee Production at Slopes Ijen Raung Plateau of Indonesia. J. Ecol. Eng. 2021, 22, 271–283. [Google Scholar] [CrossRef]

- de los Á, M.; Bartl, K. Carbon Footprint of the Coffee Roasting Process Based on Two Technologies with Different Sources of Energy in Peru. Eur. J. Sustain. Dev. 2018, 7, 90–98. [Google Scholar] [CrossRef]

- Nab, C.; Maslin, M. Life cycle assessment synthesis of the carbon footprint of Arabica coffee: Case study of Brazil and Vietnam conventional and sustainable coffee production and export to the United Kingdom. Geo Geogr. Environ. 2020, 7, e00096. [Google Scholar] [CrossRef]

- Giraldi-Díaz, M.R.; De Medina-Salas, L.; Castillo-González, E.; León-Lira, R. Environmental impact associated with the supply chain and production of grounding and roasting coffee through life cycle analysis. Sustainability 2018, 10, 4598. [Google Scholar] [CrossRef]

- Usva, K.; Sinkko, T.; Silvenius, F.; Riipi, I.; Heusala, H. Carbon and water footprint of coffee consumed in Finland—Life cycle assessment. Int. J. Life Cycle Assess. 2020, 25, 1976–1990. [Google Scholar] [CrossRef]

- Adiwinata, F.; Rahayuningsih, M. Analisis Daur Hidup (Life Cycle Assessment) Pengolahan Kopi Bubuk Robusta Secara Basah Di Industri Kecil Menengah (Ikm) Beloe Klasik Lampung. Agrointek 2021, 15, 1175–1182. [Google Scholar] [CrossRef]

- Mahushi, D.J.; Machunda, R.L.; Science, E.; Nelson, T.; African, M. Optimization of Biogas Production Process in Solid. Glob. J. Environ. Sci. Manag. 2018, 44, 205–213. [Google Scholar] [CrossRef]

- Ibnu, M. A Systemic Approach For a Sustainable Coffee Production in Indonesia. SOCA J. Sos. Ekon. Pertan. 2022, 16, 15. [Google Scholar] [CrossRef]

| Process Stages | Equipment Specifications | Unit | N | Hd | A | L | CM |

|---|---|---|---|---|---|---|---|

| Harvesting | Motorcycle (100 kg/batch) | MJ | 31.40 | 31.40 | 31.40 | 31.40 | 31.40 |

| Pulping | Petrol Engine 5 Hp, 200 kg/h | MJ | - | 20.41 | - | - | - |

| Fermentation | CO2 injection | kg | - | - | - | - | 1.50 |

| Dehulling | Petrol Engine 5 Hp, 200 kg/h | MJ | 14.13 | 7.20 | 14.24 | 14.26 | 14.44 |

| Grading/Sizing | Electric 0.5 kW, 50 kg/h | kWh | 0.28 | 0.28 | 0.28 | 0.28 | 0.29 |

| Roasting Coffee | Electric 1 kW, 10 kg/h | kWh | 1.17 | 1.18 | 1.18 | 1.19 | 1.26 |

| LPG 0.75 kg/h | 1.96 | 1.97 | 1.96 | 1.98 | 2.10 | ||

| Coffee Grinding | Electric 0.5 kW, 40 kg/h | kWh | 0.33 | 0.33 | 0.33 | 0.33 | 0.35 |

| Parameter | Factor | Unit |

|---|---|---|

| MCFWW | 0 | |

| λ | 0.65 | |

| CFCO₂ | 1375 | mg |

| BG | 0.65 |

| Steps | Input-Output | Amount (kg) | ||||

|---|---|---|---|---|---|---|

| N | Hd | A | L | CM | ||

| Input | ||||||

| Handpicking | Cherry Coffee | 150.0 | 150.0 | 150.0 | 150.0 | 150.0 |

| CO2 | - | - | - | - | 1.5 | |

| Lactic Acid Bacteria | - | - | - | 2.0 | - | |

| Water (Fermentation) | - | 50.0 | - | - | - | |

| Output | ||||||

| Pulping | De-pulping | - | 70.2 | - | - | - |

| Cherry skin | - | 79.8 | ||||

| Fermentation | Wet Fermented | - | 73.2 | 137.5 | 136.5 | 134 |

| Wastewater | 47.0 | 12.5 | 15.5 | 16.0 | ||

| Drying | Dried beans | 67.5 | 34.4 | 68.0 | 68.1 | 69.0 |

| Dehulling | Dehulled beans | 27.8 | 27.8 | 27.9 | 27.8 | 28.8 |

| Coffee skin | - | 31.0 | - | - | - | |

| Coffee husk | 39.8 | - | 40.1 | 40.4 | 40.2 | |

| Parchment | - | 6.6 | - | - | - | |

| Sortation | Grade beans | 26.1 | 26.2 | 26.2 | 26.4 | 28.0 |

| Defective GBs | 1.6 | 1.5 | 1.1 | 1.4 | 0.8 | |

| Roasting | Roasted beans | 22.8 | 22.8 | 22.8 | 23.4 | 22.9 |

| Silver skin | 1.0 | 1.1 | 1.1 | 1.1 | 1.2 | |

| Grinding | Coffee powder | 22.7 | 22.7 | 22.7 | 22.8 | 22.4 |

| Process | Gas Released (mg) | ||

|---|---|---|---|

| CO2 | CH4 | N2O | |

| Anaerobic | 8.6 | 0.0087 | 5.7 |

| Hd | 150.3 | 0.0083 | 6.4 |

| Lactic | 566.2 | 0.0155 | 13.9 |

| CM | 934.5 | 0.0090 | 28.6 |

| Properties | Units | A | CM | L | Hd |

|---|---|---|---|---|---|

| Chemical Oxygen Demand (COD) | mg/L | 9850 | 10,400 | 11,950 | 6700 |

| Biological Oxygen Demand (BOD) | mg/L | 5642 | 6444 | 7248 | 4844 |

| Total Suspended Solid (TSS) | mg/L | 145 | 151 | 257 | 134 |

| Total Dissolved Solid (TDS) | mg/L | 296 | 309 | 397 | 203 |

| Brix | °BX | 5.2 | 5.6 | 6.4 | 5 |

| pH | 4.1 | 3.9 | 3.8 | 4.2 |

| Impact Category | Unit | Processing CBs to CP | ||||

|---|---|---|---|---|---|---|

| Natural | Anaerobic | Lactic | Hd | CM | ||

| GWP | kg CO2-eq | 0.676 | 0.702 | 1.168 | 0.788 | 0.713 |

| ODP | kg CFC11eq | 2.1 × 10−7 | 2.19 × 10−7 | 3.34 × 10−7 | 2.4 × 10−7 | 2.2 × 10−7 |

| IRP | kBq Co−60eq | 0.008 | 0.008 | 0.027 | 0.008 | 0.009 |

| HOFP | kg NOxeq | 0.001 | 0.001 | 0.002 | 0.002 | 0.001 |

| FPMF | kg PM2.5eq | 0.001 | 0.001 | 0.002 | 0.001 | 0.001 |

| EOFP | kg NOxeq | 0.001 | 0.002 | 0.002 | 0.002 | 0.002 |

| TAP | kg SO2eq | 0.001 | 0.001 | 0.002 | 0.001 | 0.001 |

| FEP | kg Peq | 1.1 × 10−4 | 3.1 × 10−4 | 5.3 × 10−4 | 4.6 × 10−4 | 3.9 × 10−4 |

| MEO | kg Neq | 3.5 × 10−6 | 3.7 × 10−6 | 1.9 × 10−5 | 3.6 × 10−6 | 3.8 × 10−6 |

| TETP | kg 1,4-DCB | 0.952 | 1.004 | 2.570 | 1.161 | 0.988 |

| FETP | kg 1,4-DCB | 0.003 | 0.003 | 0.015 | 0.003 | 0.003 |

| METP | kg 1,4-DCB | 0.005 | 0.005 | 0.021 | 0.005 | 0.005 |

| HTPc | kg 1,4-DCB | 0.003 | 0.003 | 0.018 | 0.003 | 0.003 |

| HTPnc | kg 1,4-DCB | 0.284 | 0.296 | 0.562 | 0.348 | 0.294 |

| LOP | m2 a cropeq | 0.008 | 0.009 | 0.014 | 0.009 | 0.009 |

| SOP | kg Cueq | 2.3 × 10−4 | 2.5 × 10−4 | 5.6 × 10−4 | 2.6 × 10−4 | 2.4 × 10−4 |

| FFP | kg oileq | 0.176 | 0.182 | 0.344 | 0.192 | 0.187 |

| WCP | m3 | 0.0003 | 0.0003 | 0.0063 | 0.0025 | 0.0003 |

| No | Coffee Process | On-Farm (kg CO2-eq/kg GBs) | Off-Farm (kg CO2-eq/kg CP) | Total Energy CBs to CP (MJ) |

|---|---|---|---|---|

| CBs to GBs | CBs to CP | |||

| 1 | Natural | 0.302 | 0.676 | 147.79 |

| 2 | Anerobic | 0.306 | 0.702 | 148.23 |

| 3 | Hydro honey | 0.407 | 0.788 | 161.81 |

| 4 | Lactic | 0.577 | 1.168 | 149.00 |

| 5 | CM | 0.310 | 0.713 | 155.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irawan, A.; Rabemanolontsoa, H.; McLellan, B.C. Comprehensive Environmental Impact Analysis of Dry Processing Methods for Specialty Coffee Beans in Bondowoso, Indonesia Using Life Cycle Assessment. Biomass 2024, 4, 843-864. https://doi.org/10.3390/biomass4030047

Irawan A, Rabemanolontsoa H, McLellan BC. Comprehensive Environmental Impact Analysis of Dry Processing Methods for Specialty Coffee Beans in Bondowoso, Indonesia Using Life Cycle Assessment. Biomass. 2024; 4(3):843-864. https://doi.org/10.3390/biomass4030047

Chicago/Turabian StyleIrawan, Andik, Harifara Rabemanolontsoa, and Benjamin C. McLellan. 2024. "Comprehensive Environmental Impact Analysis of Dry Processing Methods for Specialty Coffee Beans in Bondowoso, Indonesia Using Life Cycle Assessment" Biomass 4, no. 3: 843-864. https://doi.org/10.3390/biomass4030047

APA StyleIrawan, A., Rabemanolontsoa, H., & McLellan, B. C. (2024). Comprehensive Environmental Impact Analysis of Dry Processing Methods for Specialty Coffee Beans in Bondowoso, Indonesia Using Life Cycle Assessment. Biomass, 4(3), 843-864. https://doi.org/10.3390/biomass4030047