Circular Economics in Agricultural Waste Biomass Management

Abstract

1. Introduction

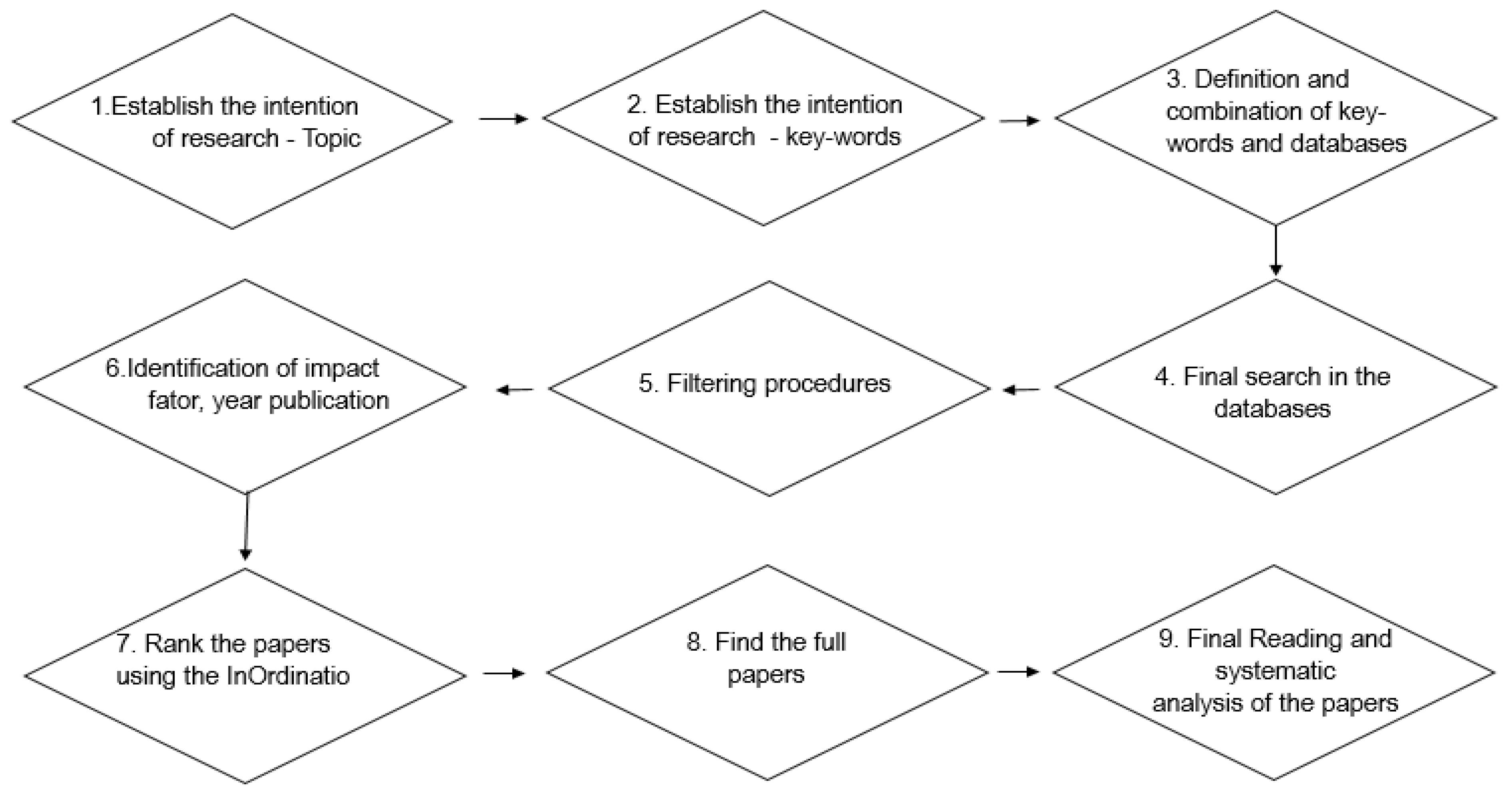

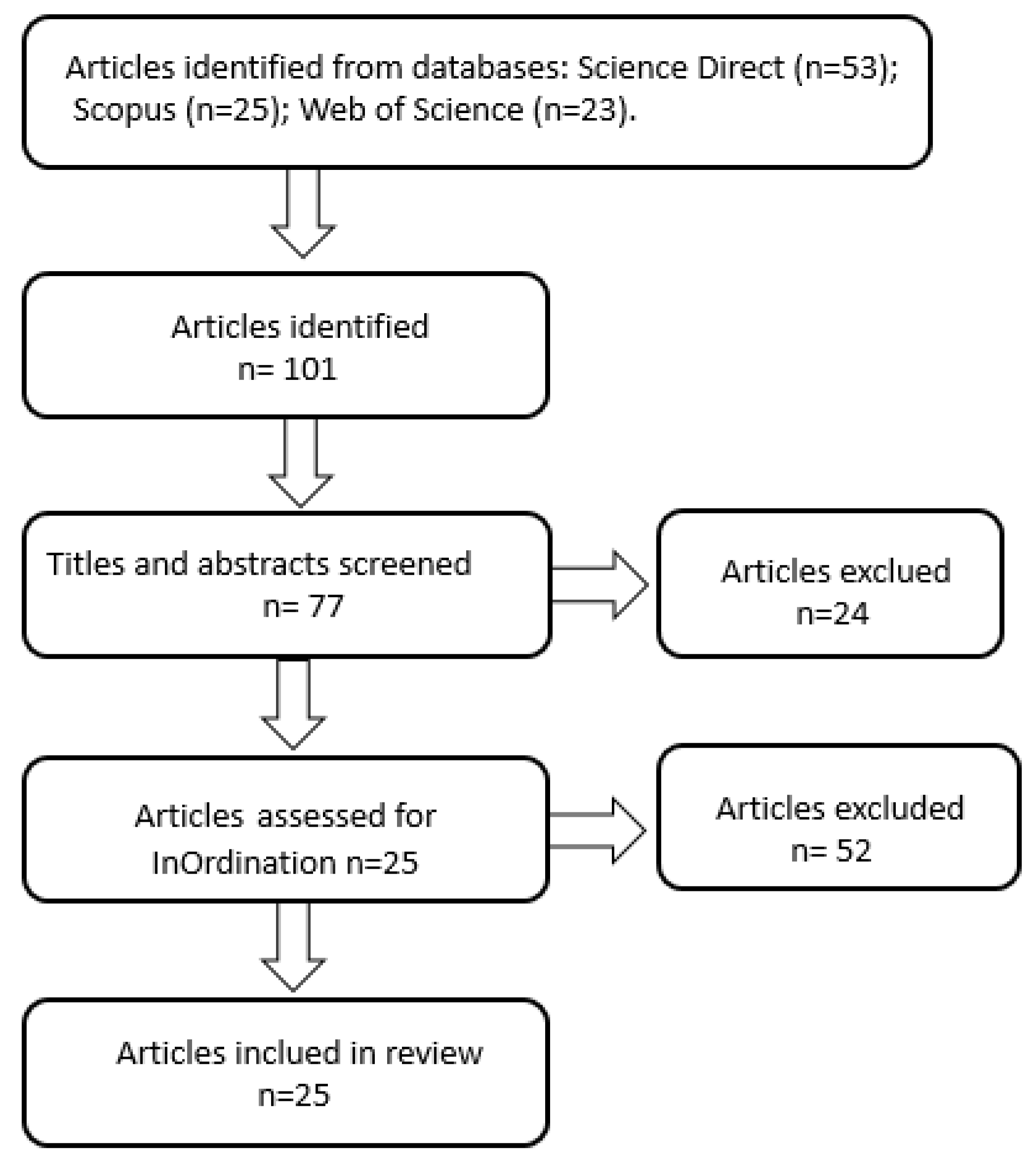

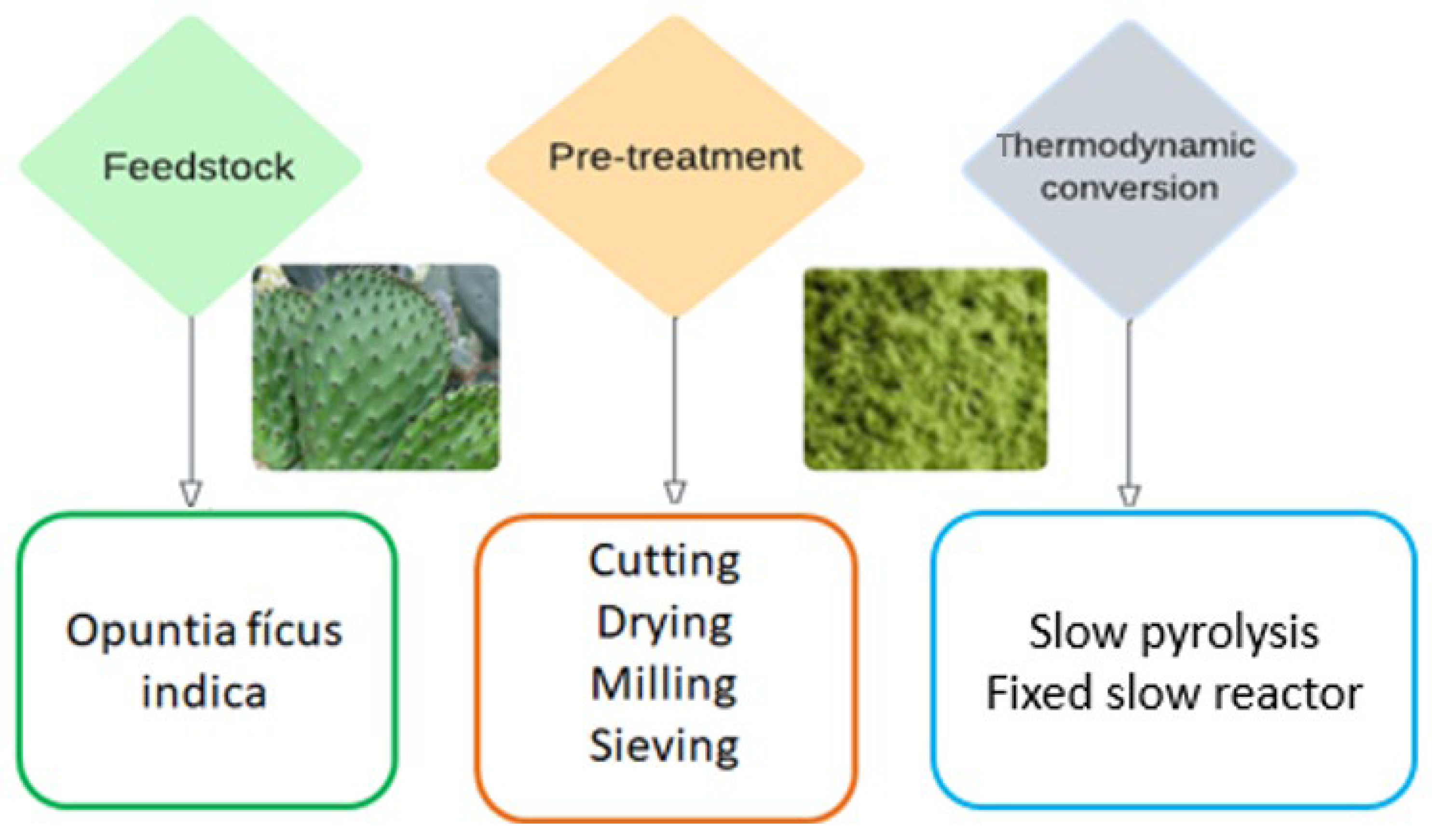

2. Materials and Methods

3. Results and Discussion

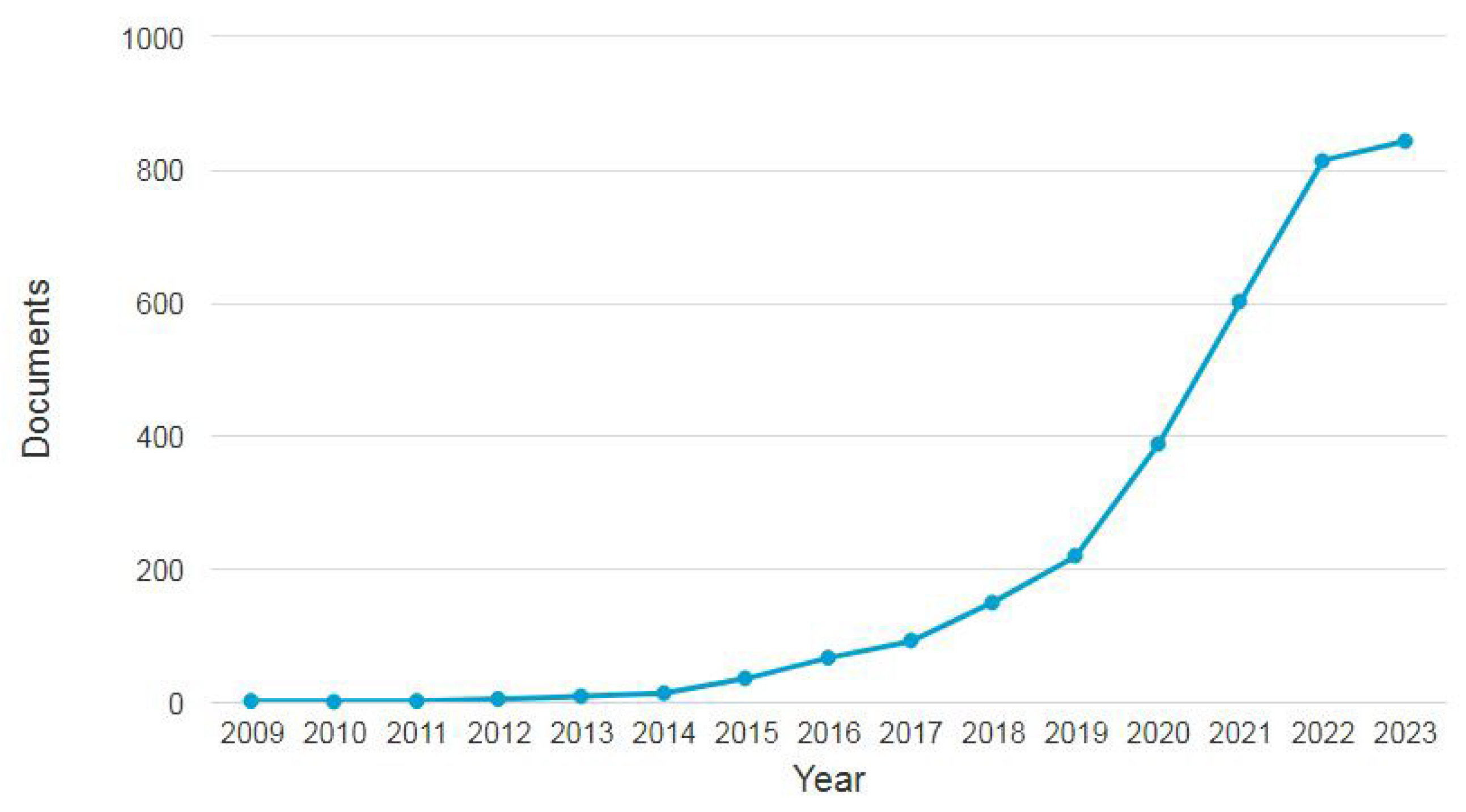

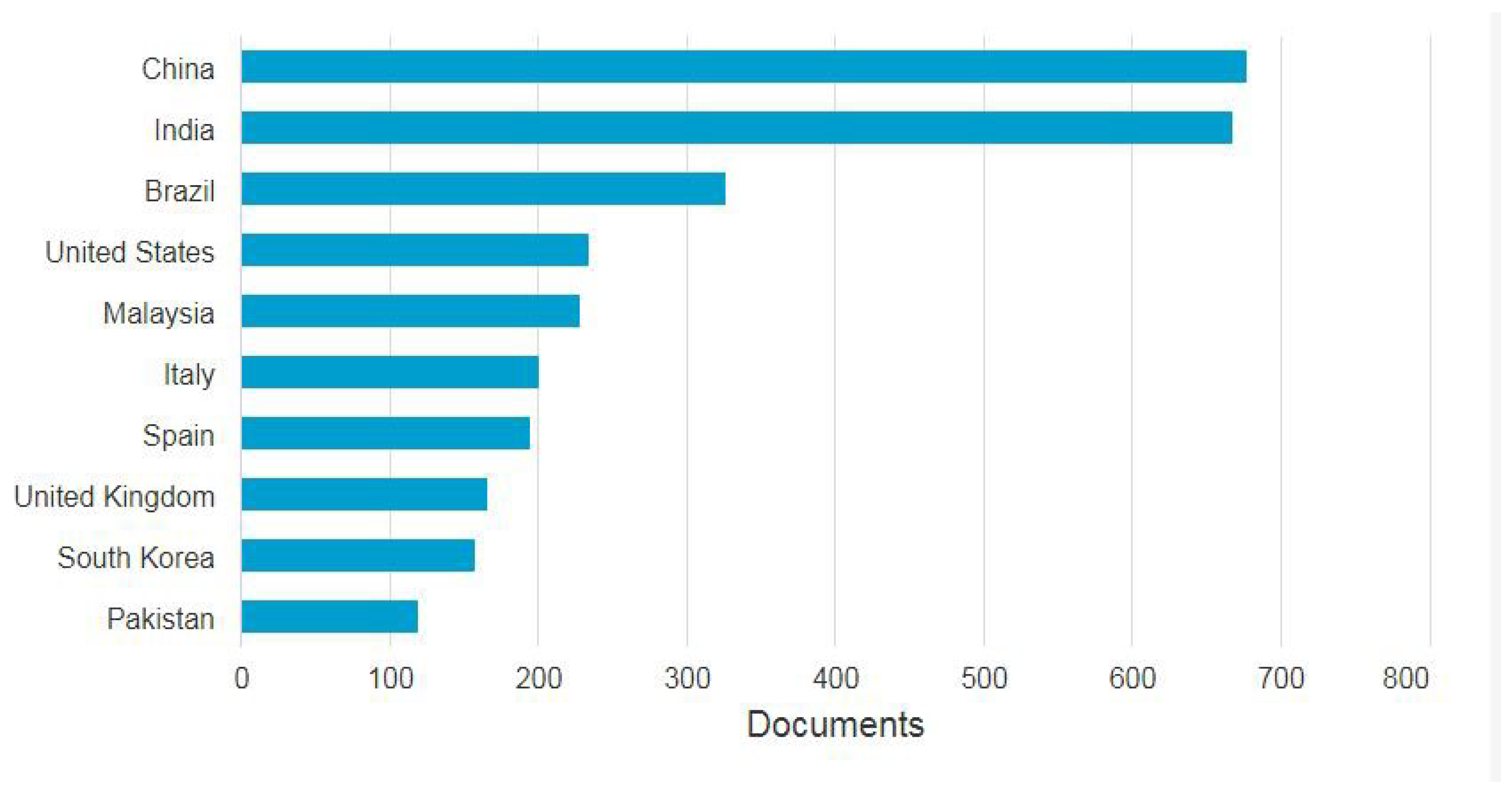

3.1. Bibliometric Study

3.2. Agro-Industrial Waste

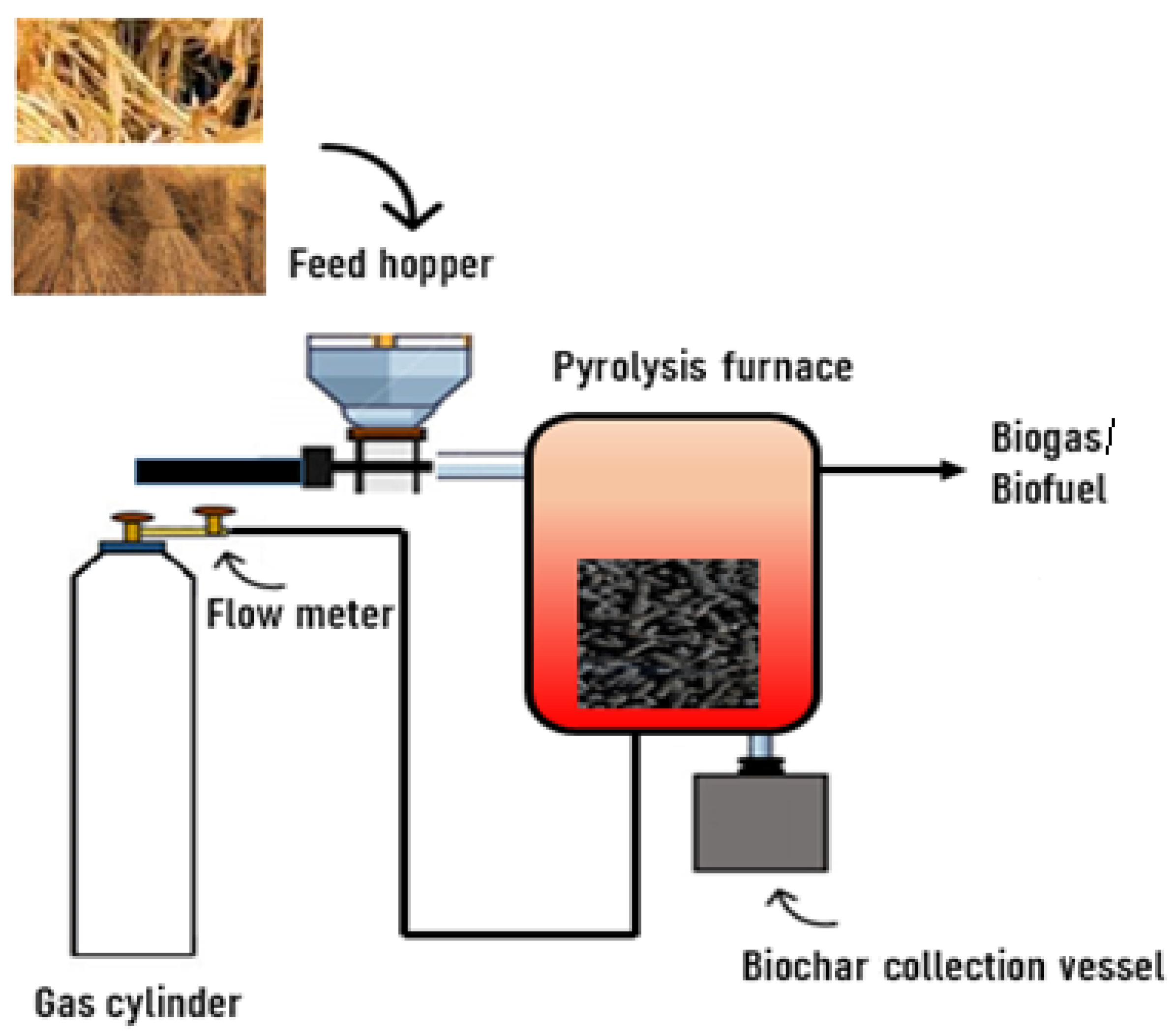

3.3. Pyrolysis Process

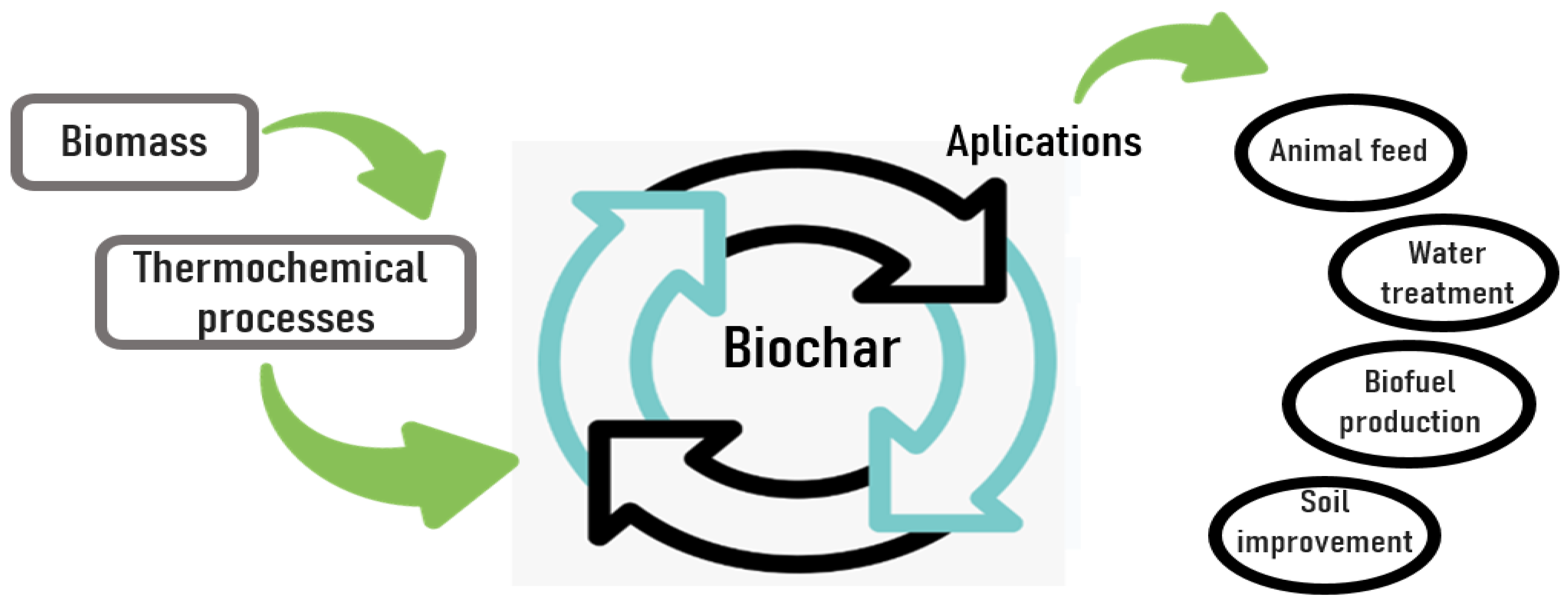

3.4. Aspects of Biochar Production

3.5. Biochar Applications

3.5.1. Treatment of Polluted Water

3.5.2. Biochar as an Additive for Cement Mortar

3.5.3. Application of Biochar for Soil Improvement

3.5.4. Application of Biochar in Animal Feed and Livestock Farming

3.5.5. Application of Biochar in the Production of Biofuels

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Phiri, R.; Rangappa, S.M.; Siengchin, S.; Oladijo, O.P.; Dhakal, H.N. Development of sustainable biopolymer-based composites for lightweight applications from agricultural waste biomass: A review. Adv. Ind. Eng. Polym. Res. 2003, 6, 436–450. [Google Scholar] [CrossRef]

- Lima, A.R.; Cristofoli, N.L.; da Costa, A.M.R.; Saraiva, J.A.; Vieira, M.C. Comparative study of the production of cellulose nanofibers from agro-industrial waste streams of Salicornia ramosissima by acid and enzymatic treatment. Food Bioprod. Process. 2023, 137, 214–225. [Google Scholar] [CrossRef]

- Yang, S.S.; Chen, Y.D.; Kang, J.H.; Xie, T.R.; He, L.; Xing, D.F.; Ren, N.Q.; Ho, S.H.; Wu, W.M. Generation of high-efficient biochar for dye adsorption using frass of yellow mealworms (larvae of Tenebrio molitor Linnaeus) fed with wheat straw for insect biomass production. J. Clean. Prod. 2019, 227, 33–47. [Google Scholar] [CrossRef]

- Mishra, R.K.; Kumar, D.J.P.; Narula, A.; Chistie, S.M.; Naik, S.U. Production and beneficial impact of biochar for environmental application: A review on types of raw materials, chemical compositions, operational parameters, technical-economic study and life cycle assessment. Fuel 2023, 343, 127968. [Google Scholar]

- Ding, Z.; Ge, Y.; Gowd, S.C.; Singh, E.; Kumar, V.; Chaurasia, D.; Kumar, V.; Rajendran, K.; Bhargava, P.C.; Wu, P.; et al. Production of biochar from tropical fruit tree residues and ecofriendly applications-A review. Bioresour. Technol. 2023, 376, 128903. [Google Scholar] [CrossRef]

- Safarian, S. Performance analysis of sustainable technologies for biochar production: A comprehensive review. Energy Rep. 2023, 9, 4574–4593. [Google Scholar] [CrossRef]

- Pagani, R.N.; Kovaleski, J.L.; Resende, L.M. Methodi Ordinatio: A proposed methodology to select and rank relevant scientific papers encompassing the impact factor, number of citation, and year of publication. Scientometrics 2015, 105, 2109–2135. [Google Scholar] [CrossRef]

- Yafetto, L.; Odamtten, G.T.; Kwagyan, M.W. Valorization of agro-industrial residues through microbial fermentation: A global and Ghanaian state review. Helyion 2023, 9, e14814. [Google Scholar]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-industrial wastes and their utilization using solid state fermentation: A review. Bioresour. Bioprocess 2018, 5, 1. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, Y.; Chen, P.; Liu, S.; Zhou, N.; Ding, K.; Fan, L.; Peng, P.; Min, M.; Cheng, Y.; et al. Gasification Technologies and Their Energy Potentials. In Sustainable Resource Recovery and Zero Waste Approaches; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 14; pp. 193–206. [Google Scholar]

- Makepa, D.C.; Chihobo, C.H.; Ruziwa, W.R.; Musademba, D. Microwave-assisted pyrolysis of pine sawdust: Process modelling, performance optimization and economic evaluation for bioenergy recovery. Helyion 2023, 9, e14688. [Google Scholar] [CrossRef]

- Gao, N.; Wang, F.; Quan, C.; Santamaria, L.; Lopez, G.; Williams, P.T. Tire pyrolysis charcoal: Processes, properties, update and applications. Prog. Energy Combust. Sci. 2022, 93, 101022. [Google Scholar] [CrossRef]

- Xing, J.; Xu, G.; Li, G. Comparison of pyrolysis process, various fractions and potential soil applications between sewage sludge-based biochars and lignocellulose-based biochars. Ecotoxicol. Environ. Saf. 2021, 208, 111756. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Zhang, H. Influence of pyrolysis conditions on nitrogen speciation in a biochar ‘preparation-application’ process. J. Energy Inst. 2018, 91, 916–926. [Google Scholar] [CrossRef]

- Prasannamedha, G.; Kumar, P.S.; Mehala, R.; Sharumitha, T.J.; Surendhar, D. Enhanced adsorptive removal of sulfamethoxazole from water using biochar derived from hydrothermal carbonization of sugarcane bagasse. J. Hazard. Mater. 2021, 407, 124825. [Google Scholar] [CrossRef] [PubMed]

- Seow, Y.X.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Ibrahim, M.L.; Ghasemi, M. A review on biochar production from different biomass wastes by recent carbonization technologies and its sustainable applications. J. Environ. Chem. Eng. 2022, 10, 107017. [Google Scholar] [CrossRef]

- Mazarji, M.; Bayero, M.T.; Minkina, T.; Sushkova, S.; Mandzhieva, S.; Bauer, T.V.; Soldatov, A.; Sillanpää, M.; Wong, M.H. Nanomaterials in biochar: Review of their effectiveness in remediating heavy metal-contaminated soils. Sci. Total Environ. 2023, 880, 163330. [Google Scholar] [CrossRef] [PubMed]

- Campion, L.; Bekchanova, M.; Malina, R.; Kuppens, T. The costs and benefits of biochar production and use: A systematic review. J. Clean. Prod. 2023, 408, 137138. [Google Scholar] [CrossRef]

- Ganesapillai, M.; Metha, R.; Tiwari, A.; Sinha, A.; Bakshi, H.S.; Chellappa, V.; Drewowoski, J. Waste to energy: A review of biochar production with emphasis on mathematical modelling and its applications. Heliyon 2023, 9, e14873. [Google Scholar] [CrossRef] [PubMed]

- Spath, J.; ArumugamII, P.; LindbergI, R.H.; AbafeIII, O.A.; JanssonI, S.; FickI, J.; BuckleyII, C.A. Biochar for the removal of detected micropollu-tants in South African domestic wastewater: A case study from a demonstration-scale decentralized wastewater treatment system in eThekwini. Water SA 2021, 47, 396–416. [Google Scholar]

- Li, X.; Shi, J. Simultaneous adsorption of tetracycline, ammonium and phosphate from wastewater by iron and nitrogen modified biochar: Kinetics, isotherm, thermodynamic and mechanism. Chemosphere 2022, 29, 3133574. [Google Scholar] [CrossRef]

- Fernandes, J.O.; Bernardino, C.A.R.; Mahler, C.F.; Santelli, R.E.; Braz, B.F.; Borges, R.C.; Veloso, M.C.C.; Romeiro, G.A.; Cincotto, F.H. Biochar generated from agro-industry sugar cane residue by low temperature pyrolysis utilized as an adsorption agent for the removal of thiamethoxam pesticide in wastewater. Water Air Soil Pollut. 2021, 232, 67. [Google Scholar] [CrossRef]

- Xu, L.; Wu, C.; Chai, C.; Cao, S.; Bai, X.; Ma, K.; Jin, X.; Shi, X.; Jin, P. Adsorption of micropollutants from wastewater using iron and nitrogen co-doped biochar: Performance, kinetics and mechanism studies. J. Hazard. Mater. Part C 2022, 424, 127606. [Google Scholar] [CrossRef] [PubMed]

- Steigerwald, J.M.; Ray, J.R. Adsorption behavior of perfluorooctanesulfonate (PFOS) onto activated spent coffee grounds biochar in synthetic wastewater effluent. J. Hazard. Mater. Lett. 2021, 2, 100025. [Google Scholar] [CrossRef]

- Gupta, S.; Krishnan, P.; Kashani, A.; Kua, H.W. Application of biochar from coconut and wood waste to reduce shrinkage and improve physical properties of silica fume-cement mortar. Constr. Build. Mater. 2020, 262, 120688. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Gupta, S.; Kua, H.W. Application of rice husk biochar and thermally treated low silica rice husk ash to improve physical properties of cement mortar. Theor. Appl. Fract. Mech. 2019, 104, 102376. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 2018, 619–620, 419–435. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.P.S.; Bhandari, S.; Bhatta, D.; Poudel, A.; Bhattarai, S.; Yadav, P.; Ghimire, N.; Paudel, P.; Paudel, P.; Shrestha, J.; et al. Biochar application: A sustainable approach to improve soil health. J. Agric. Food Res. 2023, 11, 100498. [Google Scholar]

- Zou, Z.; Mi, W.; Li, X.; Hu, Q.; Zhang, L.; Zhang, L.; Fu, J.; Li, Z.; Han, W.; Yan, P. Biochar application method influences root growth of tea (Camellia sinensis L.) by altering soil biochemical properties. Sci. Hortic. 2023, 315, 111960. [Google Scholar]

- Mirheidari, A.; Torbatinejad, N.M.; Shakeri, P.; Mokhtarpour, A. Effects of biochar produced from different biomass sources on digestibility, ruminal fermentation, microbial protein synthesis and growth performance of male lambs. Small Rumin. Res. 2020, 183, 106042. [Google Scholar] [CrossRef]

- Awogbemi, O.; Kallon, D.V.V. Application of biochar derived from crop residues for the production of biofuels. Fuel Commun. 2023, 15, 100088. [Google Scholar] [CrossRef]

- Sirohi, R.; Vivekanand, V.; Pandey, A.K.; Tarafdar, A.; Awasthi, M.K.; Shakya, A.; Kim, S.H.; Sim, S.J.; Tuan, H.A.; Pandey, A. Emerging trends in role and significance of biochar in gaseous biofuels production. Environ. Technol. Innov. 2023, 30, 103100. [Google Scholar] [CrossRef]

- Maaoui, A.; Trabelsi, A.B.H.; Hamdi, M.; Chagtmi, R.; Jamaaoui, F.; Lopez, G.; Cortazar, M.; Olazar, M. Towards local circular economy through Opuntia Ficus Indica cladodes conversion into renewable biofuels and biochars: Product distribution and kinetic modelling. Fuel 2023, 332, 126056. [Google Scholar] [CrossRef]

| Keywords and Combinations | A Scopus | B Science Direct | C Web of Science | Total | |

|---|---|---|---|---|---|

| 1 | “agro-industrial waste” AND “waste processing” AND biochar | Title: “agro-industrial waste” AND “waste processing” AND biochar; 1 result. | Title: “agro-industrial waste” AND “waste processing” AND biochar; 36 results. | Title: “agro-industrial waste” AND “waste processing” AND biochar; 1 result. | 38 |

| 2 | “agro-industrial waste” AND “waste processing” | Title: “agro-industrial waste” AND “waste processing”; 4 results. | Title: “agro-industrial waste” AND “waste processing”; 2 results. | Title: “agro-industrial waste” AND “waste processing”; 3 results. | 9 |

| 3 | “agro-industrial waste” AND biochar | Title: “agro-industrial waste” AND biochar; 10 results. | Title: “agro-industrial waste” AND biochar; 3 results. | Title: “agro-industrial waste” AND biochar; 7 results. | 20 |

| 4 | “waste processing” AND biochar | Title: “waste processing” AND biochar; 10 results. | Title: “waste processing” AND biochar; 12 results. | Title: “waste processing” AND biochar; 12 results. | 34 |

| Biochar | Pyrolysis Temperature | Contaminants | Adsorption Capacity (mg g−1) | Removal Efficiency (%) | Reference |

|---|---|---|---|---|---|

| Olive residues | 260 °C | Analgesics, anti-inflammatory drugs, antiretrovirals, abiotics and ciprofloxacin | - | 62.00 | [20] |

| Tomato residues | 46.00 | ||||

| Rice husks | 53.00 | ||||

| African palm tree | 44.00 | ||||

| Walnut shell (iron- and nitrogen-modified) | - | Tetracycline, ammonium and phosphate | 238.94 | 75.00 | [21] |

| Sugar cane filter cake | 380 °C | Tiametoxam | 10.17 | 70.00 | [22] |

| Sawdust (iron and nitrogen co-doped) | 800 °C | Bisphenol A | 55.00 | - | [22] |

| Ciprofloxacin | 69.00 | - | [23] | ||

| Phenol | 15.00 | - | |||

| Acetaminophen | 40.00 | - | |||

| Sulfamethoxazole | 34.00 | - | |||

| Tetracycline | 28.00 | - | |||

| Naproxeno | 38.00 | - | |||

| Ibuprofen | 12.00 | - | [23] | ||

| Coconut shells | 900 °C | Perfluorinated carboxylic acids | 1269.00 | 60.00 | [23] |

| Spent coffee grounds | 400 °C | Perfluorinated carboxylic acids | 43.40 | 90.40 | [24] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sant’ Ana, L.H.; Oliveira, J.R.P.; Gonçalves, G.; Tusset, A.M.; Lenzi, G.G. Circular Economics in Agricultural Waste Biomass Management. Biomass 2024, 4, 543-554. https://doi.org/10.3390/biomass4020029

Sant’ Ana LH, Oliveira JRP, Gonçalves G, Tusset AM, Lenzi GG. Circular Economics in Agricultural Waste Biomass Management. Biomass. 2024; 4(2):543-554. https://doi.org/10.3390/biomass4020029

Chicago/Turabian StyleSant’ Ana, Luiz Henrique, Jessica R. P. Oliveira, Giovanna Gonçalves, Angelo M. Tusset, and Giane G. Lenzi. 2024. "Circular Economics in Agricultural Waste Biomass Management" Biomass 4, no. 2: 543-554. https://doi.org/10.3390/biomass4020029

APA StyleSant’ Ana, L. H., Oliveira, J. R. P., Gonçalves, G., Tusset, A. M., & Lenzi, G. G. (2024). Circular Economics in Agricultural Waste Biomass Management. Biomass, 4(2), 543-554. https://doi.org/10.3390/biomass4020029