1. Introduction

About 14 billion liters of beer are produced annually in Brazil, occupying third place in the list of world producers, standing behind China and the USA, respectively, with a 5% share of the world beer market [

1]. The brewing process can be summarized as the production of fermentable wort through the enzymatic breakdown of the starch present by the action of the enzymes contained in the barley malt. This wort is then boiled with the addition of hops, cooled, and then fermented by the addition of brewer’s yeast. After fermentation, the beer can be physically separated from the yeast and biologically stabilized by pasteurization or another physical method [

2].

Brazil has shown an increasing number of registered beer companies, as can be seen in

Figure 1. The data reported by the Ministry of Agriculture, Livestock and Food Supply (Ministério da Agricultura, Pecuária e Abastecimento, MAPA 2022), showed a rapid increase in beer companies registered in Brazil, especially between 2015 and 2021 [

3].

According to the 2020 report, if the country maintains the increase rate of 36%, observed especially between 2015 and 2021, by the end of 2025, Brazil could have a total of 7504 beer companies, and hence, more generations of BSG per year [

3]. The 2022 report indicated the impact of the COVID-19 pandemic on the growth of the brewing sector, especially in beer production, as can be seen by the decrease in volume produced in 2020 and the decrease in growth percentage of registered companies that went from 14.4% (between 2019 and 2020) to 12% (from 2020 to 2021). The report does not mention the exact impact of the COVID-19 pandemic. Those numbers may need to be reviewed to reflect their true impact, which deserves a separate study.

BSG is well known as the major lignocellulosic biomass waste produced over the years by the beer industry, which, to economics and environmental aspects, showed potential to be utilized for diverse uses, such as animal feed, to strengthen human food, as diverse substrates (cultivation of microorganisms and enzyme production, fermentation processes, lactic acid production, ethanol production, lignocellulosic yeast carriers, prebiotics), as an adsorbent, as a source of polyphenolic compounds, in microalgae production, in biogas and biofuel production, as a protein extract, as antioxidative substances, as fiber, for polymers, and in other applications [

5,

6]. Usually, these compounds are obtained through various processes such as fermentation, hydrothermal carbonization, pyrolysis, and organosolv extraction [

5,

6,

7]. There is about 15 kg of BSG generated for each 100 L of beer [

8]; given this, based on global beer production, the amount of BSG disposal is estimated to be approximately 36.4 million tons [

9].

The amount of BSG produced accompanies the Brazilian beer market’s exponential growth, which raises even more concerns about its destination. Some Brazilian companies already manage this waste from microbreweries by collecting and destining it to promote the lowest environmental liability, and they use the bagasse for animal feed due to its practicality and low cost, or simply leading to environmental degradation [

10,

11]. This leads to a significant loss of valuable material that could otherwise be exploited. However, due to its composition and the possibility to be converted into new products, the concept of biorefinery in the brewery sector can be used to add value to the process and provide a positive circular economy system [

10,

11].

This raw material is mainly constituted by sugars (glucose, xylose, and arabinose) polymerized in cellulose and hemicellulose structures, which represent 41%

w/

w of its composition on a dry-weight basis. Besides sugars, BSG also contains noticeable fractions of proteins (24.69%

w/

w) and lignin (19.40%

w/

w), while extractives and ashes are present in minor proportions. Extractives may include components such as waxes, alkaloids, pectins, mucilages, gums, resins, terpenes, saponins, and tall oil. Ashes are formed by a large variety of minerals, including phosphorus, potassium, calcium, magnesium, sulfur, iron, manganese, boron, zinc, copper, molybdenum, sodium, aluminum, barium, strontium, chromium, tin, lead, cobalt, iodine, cadmium, nickel, selenium, and gallium [

12].

Due to the significant amount produced annually, the low market value, the environmental awareness composition, and the recognition that BSG may represent a nutritionally valuable co-product, efforts should be increasingly focused on its valorization [

11]. In

Table 1, there are some applications and production from BSG. Bolwig et al. reported several alternatives for the reuse of BSG beyond the widespread animal feed, such as its reuse for human consumption, its use in the production of chemicals and drugs, and its use in energy production, among others [

10].

The BSG has been usually allocated for animal feed with no further necessities and manufacturing procedures [

13]. However, its composition has some valuable by-products, such as proteins and other components such as arabinoxylans and β-glucans (which are also associated with potential health benefits), showing more possibilities to produce high-value low-volume products [

14]. Ortiz et al. discussed a circular economy strategy based on alternative energy production [

15]. However, according to Buffington et al., there is no technology that is able to use BSG as a raw material for its applications, such as in the biotechnology environment. Unfortunately, the technology readiness level (TRL) shows lower values, between three and six, according to the corresponding scale [

16]. Besides the advancement and implementation of industrial biomass conversion technologies, the use of specific biomass on a large scale is still an issue for an integrated system, such as the food and beverage industry with solutions with bioenergy and bioproduct applications, implicating the lower TRL status.

Table 1.

Brewers’ spent grains (BSG) applications by scientific literature.

Table 1.

Brewers’ spent grains (BSG) applications by scientific literature.

| Application | TRL a | References b |

|---|

| Animal feed | 9 | [17,18,19] |

| Syngas production by gasification | 6–7 | [20,21,22] |

| Pyrolysis | 7–8 | [23,24,25] |

| Bioethanol, Biobuthanol | 6–7 | [26,27,28] |

| Enzyme production, Enzymatic hydrolysis | 5–6 | [29,30,31,32] |

| Cellulose and derivatives | 5–6 | [33,34] |

| Carbonaceous materials—absorptive properties | 5–6 | [35,36,37] |

| Polimeric materials | 2–3 | [38,39,40] |

| Biogas (anaerobic digestion) | 8–9 | [41,42] |

In 2013, Mussatto et al. reported a techno-economic study considering the use of BSG on a biorefinery concept in Brazil [

46]. The study concluded that a great number of biorefining alternatives to obtain added-value products are possible. However, the researchers concluded that to achieve a good result from an economic, environmental, and social point of view, some adjustments must be made to obtain a scenario that combines mass integration and energy consumption. This study showed that it is very important to evaluate the technical feasibility of a certain scenario from an experimental point of view.

Indeed, to develop the conception of a biorefinery integrated into a brewery, it is essential to analyze and point out which of these technologies have already been applied and which are still in the development stage, pointing out which would be the main products obtained in the Brazilian scenario. Based on the literature [

47], technology roadmaps are useful tools for the evaluation of the maturity of the development and the long-term planning and application of a specific technology. Therefore, it is an important step for accessing not only the state of some product but also how it is being commercialized [

47].

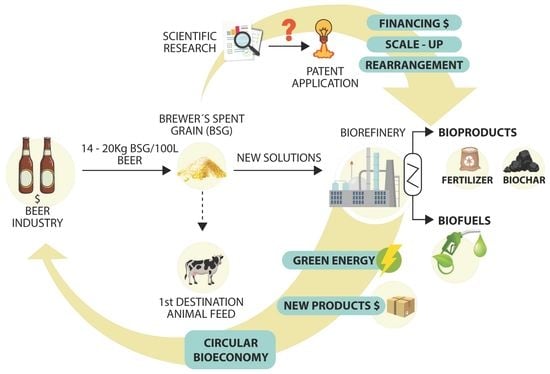

So, this work presents an overview of BSG’s scientific, technological, and marketing products and applications, emphasizing sustainable processes and destinations, such as the synthesis of new materials and production of biofuels, among others, which are roles that can be correlated to the production process using BSG. The present work carries out a technological study with the aid of bibliographic review and patent analysis tools, aiming to investigate the maturity of certain technologies and to investigate the implementation possibility of a biorefinery in the brewer’s context, considering the main BSG by-products already commercialized.

The main objective of this article is to highlight the gap between research and technology development in the field of BSG use and transformation into high-added-value products since there is a lack of literature in this area comparing both scientific production and technology production.

This study brings up this correlation, focusing on an even more integrated production chain, applying the biorefinery concept and circular bioeconomy for this product sector in the present time.

2. Materials and Methods

A technological and scientific roadmap was carried out following two main searches: patent analysis and bibliographic review using research articles up to 2021. The study was carried out with the aid of the Questel Orbit Intelligence patent database and research articles in the Web of Science database involving the period from 2001 to 2021. The Brazilian scenario was also evaluated by the documents found in the INPI (National Institute of Industrial Property) patent database with no period restriction.

The main theme of the research was the “beer production malt bagasse”, whose literature has different terms to refer to this subject, among the main ones being “brewers’ spent grains” or “malt bagasse”. The terms chosen for patents and articles search were “spent”, “grain”, “brew”, “bagasse”, “malt”, and “residue”. For INPI research, these terms were added in Portuguese: “bagaço”, “malte”, “cerveja”, “cevada”, and “resíduo”; this was done focusing on combinations using boolean operators and truncation elements (*), which brought the research closer to the focus of the work.

During the patent research, an expressive number of documents (150 patent documents) were found as related to the inventor “Oleg Ivanovich Kvasenkov”. Those documents do not represent the scope of this study; therefore, they were removed from this research. Such an observation must have the attention of readers that will use this information or repeat the presented methodology.

A technological and scientific roadmap was carried out using the terms presented in the methodology and

Table 2. A total of 7 keyword combinations were defined for search in the computational tool.

3. Results and Discussion

3.1. Technological and Scientific Roadmap Study Based on Journal Publications

Monitoring over time shows the exponential growth of publications demonstrating the incentive to studies driven by the use of biomass as feedstock to industrial processes. In Brazil, there is a national policy of solid waste management prescribed by Law No. 12.305/10 [

48], which institutes the National Solid Waste Policy (Política Nacional de Resíduos Sólidos or PNRS). The regulation deals with the responsibility of the productive sector to make and control their waste management. Worldwide, the biorefinery concept, based on specific laws, also showed expressive growth in Europe, China, and the USA.

As a result of these state policies, China and the USA, as the first and second top beer producers, respectively, are also the first and second countries with more patents filed geographically, contributing to approximately 40% of all patent filings over the referred period.

In Brazil, the related state policies are still incipient and under implementation. However, due to international environmental and climate treaties, the perspective is that inspections and obligations regarding the management of solid waste over time will be completed, as has occurred in other continents.

Figure 2 presents the number of article publications related to BSG between 2001 and 2021.

Five areas of great interest were found in the scientific articles: food science and technology (423 articles), biotechnology and applied microbiology (265 articles), engineering (243 articles), chemistry (203 articles), and agriculture (199 articles). The top 10 countries that stand out in the number of publications are Brazil (160), Spain (121), Portugal (115), Italy (85), the USA (83), China (82), Germany (66), Ireland (66), England (64), and Poland (60).

Figure 3 shows the distribution of the scientific production related to BSG research in the world.

Coincidentally, these countries have the most restrictive state policies and incentives for waste management processes reducing environmental liabilities. Indicating this is the prioritization of the country’s budget to encourage research in this regard. Some international cooperative research projects have been financed by private banks and the European government, aiming for some green technologies development based on biorefinery development [

49]. Specifically concerning BSG, there is a prevalence in the area of food science, technology, and bioprocesses that make it possible to understand how those industrial processes can be connected to generate new products focused in the same area that generated the residue.

Currently, Brazil (first in the ranking of publications) has more than 1200 breweries registered [

50]. Of the total volume produced, less than 3% of the volume is concentrated in microbreweries [

13]. In other words, the largest producers of beer and, consequently, larger producers of BSG, are large industrial plants that produce mainstream beers and tons of bagasse per hour. These companies contract and sell BSG to large dairy and cattle breeders that routinely remove BSG and apply it immediately to ruminants’ consumption due to its short microbiological stability [

8]. In addition, as of 2010, all functioning breweries were inspected, and planning for the disposal and management of the waste became mandatory to reduce the environmental impact [

51].

The institutions that have published the most on subjects related to the technologies of BSG use and conversion are indicated in

Figure 4. The University of Minho (Portugal), University of São Paulo (Brazil), University of Limerick (Ireland), University of College Cork (Ireland), and University of Porto (Portugal) stand out with the greatest number of publications. These results indicate the opportunity for strengthening and establishing new collaborations in this research area, especially between Brazilian and Portuguese institutions, that may be facilitated by bilateral international agreements such as the “Tratado de Amizade, Cooperação e Consulta” (translated to English, “Treaty of Friendship, Cooperation, and Consultation”) celebrated by the two countries in 2001 [

52].

3.2. Technological and Scientific Forecasting Study Based on Patents

Scientific publications do not fully indicate the degree of innovation associated with technology, although they demonstrate an important path in the transformation process and evolution in a given technological segment. Associated with the research outcomes, patents can be more accurate at pointing out products and processes with the potential to become commercially available products with social impact. So, it is interesting to associate the scientific and technological forecasting study of BSG with a prospective study based on patents to evaluate the technological horizon regarding the industrial options for the biomass economy.

The technological forecasting study through the Brazilian patent office database is shown in

Table 3. There were 25 patents found, of which 13 are not in the scope of the research (the keywords were found in these documents, but they are not related directly to brewers’ spent grain or the synonyms attributed to it). That way, 12 patents address the malt bagasse, to which this study refers. Five were deposited by independent inventors and only two among them were filed. The others are under analysis or have already been granted. Among them, six were deposited by Science and Technology Institutes (STIs), including one from Denmark and another that was deposited by a Chilean company.

When the number of patents presented in

Table 3 is compared with the number of articles in Brazil (160), it is observed that the development of technologies is still incipient. In a perspective where technological progress is achieved by the transposition from basic research to applied technologies, the comparison of articles versus patents shows in this case that the solutions proposed by research articles are not being transformed or maturated to viable technologies (patents of new products and/or processes).

Some questions arise from this process. If there is research in the area of BSG conversion and it generates a considerable environmental liability for the factories, why are such technologies not becoming products capable of transforming the management of this waste? Where is scientific research developed in Brazil, and how does it interact with the productive sector, especially the industrial sector? Are the large breweries interested in developing advanced technological solutions capable of making the residue from their production economically viable?

Analyzing the context of the scientific-technological development in Brazil, it is possible to observe that, in great part, the scientific research is concentrated in the technology parks of scientific research institutions (mostly universities and lesser participation of public companies, such as Embrapa—Empresa Brasileira de Pesquisa Agropecuária—The Brazilian Agricultural Research Corporation) [

53]. Associated with this, there is a huge distance between these institutions and the companies. This distance means that research is not matured to the point of becoming viable technologies for commercial insertion. This interaction may explain in part what is observed in the discrepancy of articles and patents observed in Brazil.

Looking from the breweries’ point of view, we observed that the cost of destination of the malt bagasse for feeding cattle or landfills is more economically attractive to investors when compared with research. The number of research publications indicates to government incentives for the management of solid waste in the form of Law No. 12.305/10, besides the primary destination [

48]. Innovation projects in general show low success rates, and bioprocess innovations seem to perform no better. Concerning product development, in general, the literature indicates a wide range of failure rates (30–80%) [

54,

55].

Evaluating in a larger spectrum and identifying whether the process observed in the Brazilian scenario was able to be replicated at a global level, the patent search was conducted via the

Questel Orbit software.

Figure 5 presents important information regarding the stage of technology development in the sector.

From the carried-out analysis, it can be concluded that this type of technology is in an embryonic stage, considering that the number of articles in comparison with the number of patents is still quite divergent, with the number of articles being much higher, the same scenario analyzed for the Brazilian context. This data reveals that there is still much to be studied and developed for robust and conceptual technologies to appear on the market more frequently.

To lower the failure rate of complex innovation projects, companies tend to form research and development (R&D) collaborations [

15]. These inter-organizational R&D collaborations—more specifically, R&D consortia—are defined as relationships between three or more R&D partners to pursue both individual and shared goals [

16].

In Brazil, to encourage innovative processes, the law entitled “Lei do Bem” (Law No. 11.196/05) [

56] was instituted to allow companies that contribute to technological research and development to deduct from the basis of calculation of income tax and social contribution on net profit up to one hundred percent of its operating expenses. To be contemplated by this tax benefit, interactions have already been observed between large breweries with startups aiming for the development of new technologies. For example, a large brewery has moved its technology development center to a science and technology park to approach innovation environments that have provided greater interaction with other companies and access to highly equipped laboratories [

57].

Even though there has been a new look at solid waste management in breweries in recent years [

7,

9], the production of technology can still be very much linked to waste management focused on animal and human food, since it is a well-known solution practiced by the industry and would only need a few increments. In the case of human food, for instance, pre-treatment processes and nutritional assessment have become essential.

Analyzing the distribution of patent families by technological field, presented in

Figure 6, one can see a large concentration of patents in Food Chemistry (215 patent families), obviously due to the direct relationship of the subject with the beverage industry. At the same time, it is necessary to note that four other areas stand out: basic materials chemistry (49 patents), biotechnology (47 patents), chemical engineering (27 patents), environmental technology (20 patents), and other special machines (24 patents). The patent families can be assigned to more than one technological domain, and, although the vast majority of them are associated with the nearest sector, the topics that stand out in sequence already correlate with the conversion processes of BSG.

Figure 7 shows the ratio of the number of patents filed for each International Patent Classification (IPC) between 2001 and 2021. The IPC classification is a system of classification of patents by symbol according to the different technological areas to which they belong.

From the analysis of

Figure 7, it can be seen that the majority of the patents are classified in Section A, which refers to human necessities, and C, which refers to chemistry and metallurgy. The largest number of patents were deposited in the category and A23K (42%), which refers to the IPC classification for “feeding stuff specially adapted for animals; methods specially adapted for production thereof”.

This observation corroborates the fact that BSG technologies were mostly related to animal nutrition. Analyzing closely, it can also be observed that in the past, even a patent that was not related to animal feed would get the code A23K (with the specification as A23K-010/38), which, in the time of protection of some brewer’s residue technologies, was directly reported to it. Second comes the category C12C, which refers to the IPC classification for “beer, preparation of beer by fermentation, preparation of malt for making beer; preparation of hops for making beer”, corresponding to 23% of the patent families, followed by categories A23L and A23J, also related to food processing. Observed with a low percentage (2%) is the presence of patents registered with the B09B code, which refers directly to the IPC classification for “disposal of solid waste”. This is important since independently from the technology used for converting BSG, it is always a residue disposal solution; future filling patents may come with this association.

It is noticeable that the largest number of patent registrations on this subject is related to beer production and quality. It is also possible to realize the variety of subclasses of patents, and this is an indicator that BSG is used for several applications, from food products to biofuel production.

There is a clear change in the profile of patents from the observation of the IPC codes. In recent years the technological products associated with BSG have become increasingly advanced, associated with the production of materials and chemical compounds. The C12F code refers to the IPC classification for “recovery of by-products of fermented solutions; denatured alcohol; preparation thereof” and C05G to “mixtures of fertilizers covered individually by different subclasses of class C05”, which is associated with products intended for the area of ethanol synthesis and fertilizers.

4. Discussion

4.1. The Biorefinery Concept in a Brewery Context

Observing the number of scientific articles in the BSG conversion area and the technologies already deposited as patent documents, even if in lesser quantity, it is possible to conclude that there is an incipient diversity of technologies aimed specifically at BSG treatment.

Additionally, a new biorefinery business model assessment that impacts economic growth and employment should be considered, since some of the patents found may lead the transition to a sustainability model with chain coordination related to BSG treatment. The natural processes and the industrial ones should be able to work in tandem, and the technologies now available should allow economic efficiency to provide the new business model enough appeal to engage R&D optimization, modeling new organizational arrangements and the interplay of the biomass sector and alternative resources.

Budzianowski, in 2017, already explored the necessity to maximize the valorization of biomass by-products to achieve a competitive business model [

58]. Examples such as biomass disintegration (combustion, gasification, or fermentation) to usable bioenergy do not lead to optimal utilization of biomass by itself. Bonfiglio & Esposti (2015) demonstrated by two multi-regional closed Input-Output models that a biomass power plant coupled to biopolymer production can do so through supra-local effects generated by trade across local industries [

59].

Towards the implementation of new technologies associated with the brewery industry, it is feasible to think that this will be only related to the enhancement of beer production such as new reactors and effective recovery systems, better fermentation control, efficient filling/packaging systems, and many other examples that will impact in the production process. Indeed, those possibilities inside the industrial plant occur in large companies that seek out continually the most and better cost-benefits as well a high-quality product.

What is gaining attention over several kinds of industries and could be easily related to the brewery industry is the concern with systems that integrate a major perspective of its production using new technologies under sustainability parameters. Energy, water consumption, and wastewater treatment (as well as sewage sludge) will appear as one of its main projects designed to achieve those sustainable goals, as well, waste treatment and disposal can be a significant path to be incorporated, already described for algae biomass in a closed-loop process [

60]. The conversion of lignocellulosic biomass in a closed-loop model was also demonstrable for the bioconversion of carob pod biomass to polyhydroxybutyrate biopolymer [

61]. These concerns will be addressed as the technological step requires to be developed, as an example, any extraction process that will deal with solvent use; the way to do so is to look for not only this step’s implementation but also for the raw material that will be necessary (use of green solvents).

Looking closely at the classic brewing process, three by-products stand out for their composition, volume produced, and diversity of ways to transform/reuse them. Hot trub (mainly hop residue and coagulated protein) is estimated to be generated from 0.2–0.4 kg per 100 L of beer produced; cold trub (residual yeast) is estimated to be 1.5–3.0 kg per 100 L and BSG (the main solid residue) on a much large scale, ≈15.0 kg per 100 L. As already discussed, BSG could be a source of protein and a lignocellulosic matrix that can be converted into different materials, as well as biofuels and energy, showing a range of new possibilities, as the scientific research and technological advances that were made over the past year showed in the data from the scientific and technological forecasting study. However, a question that takes place in this context is how those new routes to transform BSG can be incorporated into a large industrialized chain such as the brewing sector in Brazil. The challenge that rises with this discussion is focused mainly on how to connect those emerging technologies to transform BSG into high-added-value products with the origin that produced it (inside the industry).

4.2. Pathways to BSG Biorefinery Implementation

To materialize and connect the BSG roadmap data (recovery and conversion) with the brewing process, it was possible to set up a concept of a brewing process connected with a sustainable biorefinery, aligned with a model of circular economy.

Figure 8 shows a general flowchart of the brewing process and a proposed scheme to represent the variety of possibilities to convert BSG into new bioproducts.

Biorefinery, in general, can be defined as a sustainable system capable of processing renewable feedstock, biomass/organic waste, into a diverse range of products such as energy, materials, biofuels, and chemicals counterpointing the classic refinery of non-renewable petroleum-based derivatives [

62,

63]. Two main business models were employed during the generational evolution of biorefinery complexes, as described by Ceapraz et al. (2016). They classify them as the port biorefinery, based on the import of raw materials, and the territorial biorefinery, based on strong relationships with local (or regional) supply bases [

64].

Biorefineries face along, with any other renewable energy system, competition, mostly in comparison with conventional non-renewable energy and fuel productivity. Vu et al. (2020) reviewed lignocellulosic biomass processing toward high-value low-volume bioproducts and the different ways to effectively pretreat lignocellulosic biomass to enhance its digestibility. This key process may allow a higher product yield, chemical recycling, and by-pro conversion to increase environmental sustainability [

65] being possible to be compared with the non-renewable efficiency.

In

Figure 8, five BSG conversion technologies (reactors illustrations numbered from 1 to 5) are represented as possible viable ways that have been studied so far. The routes presented cover the main biorefinery processes: chemical, thermochemical, and biochemical [

63].

It is important to consider that pretreatment methods are very important in this context. Biomass pretreatment may include some thermochemical techniques, solvent extraction (aqueous and/or organic), or biochemical process (fermentation and/or enzymatic hydrolysis) that also may be combined with ultrasound and other approaches [

26,

28,

41]. This step also includes basic physical processes such as milling and granulometric classifications as prior steps to prepare raw biomass. Taking this into consideration, BSG pretreatment may be incorporated before each process described in

Figure 8.

Reactor 1 refers to the use of BSG through a chemical or biochemical process called hydrolysis. This process uses an aqua medium using a catalyst, which can be a chemical or enzymatic catalysis, aiming to rupture the lignocellulosic matrix; this way, the post-fermentation process could transform the fermentable sugars into bioethanol. Depending on the hydrolysis conditions and catalysis types this process can lead to the formation of other value-added compounds such as furfural and hydroxymethylfurfural, important chemical platforms [

66].

Reactors 2, 3, and 5 refer to the thermochemical process in different parameter conditions leading to different outcomes [

20,

22,

25]. Since BSG is generated from an edible source comprising a final composition of 20% protein, such material nowadays is mostly directed to animal feed; that way, on a large scale, it could be dried and milled to produce protein-rich flour (Reactor 3 requires temperatures from 60–100 °C). Reactor 2 refers to the type of thermochemical process in which atmosphere and temperature influence the production of three different phases: solid (carbon or biochar), liquid (bio-oil), and gas (syngas). Those processes are represented by pyrolysis (low oxygen condition; temperature 300–700 °C) and gasification (substoichiometric oxidized atmosphere; temperature 800–1200 °C), one focusing on the production of biochar and bio-oil and the other in syngas, respectively [

22]. The solution adopted by agroindustries to recover energy uses its residues in direct combustion to produce heat and thus, thermal energy (Reactor 5); besides low efficiency and the comparison that the other possibilities could generate more “noble” products, it is very common for such systems, in a more integrated plant, that the energy recovered this way could be integrated not only into beer production but also for other technologies.

Alaska Brewery protected the invention (US 2013 0055622A1) relating to the novel use of such a fuel product of spent grain as a primary fuel for a steam boiler that could be used in a brewing process. It provides a novel fuel product made from spent grain that is processed to change its composition and structure to sufficiently increase its combustibility to allow it to be used as a fuel product by air quality standards and other environmental regulations and laws. After removing the moisture content (80% to 10%), the dried waste is fed into a combustion chamber for a steam boiler that is used for beer brewing, and the spent grain is advanced downward through the combustion chamber with agitation to aid combustion.

Biochemical routes include, along with enzymatic hydrolysis and the fermentation process, the possibility of digestion systems, proposed with Reactor 4. In specific conditions (room temperature and moisture control), microorganism digestion can produce biogas (gas biofuel) and also a carbon-rich liquid (liquor) that can be redirected as fertilizer. This kind of technology could favor the agroindustry chain since barley cultivation is used to produce the malt grains that go into beer production [

67].

BSG has been used as an inexpensive substrate for the fermentative production of enzymes (Reactor 4). Puligundla and Mok’s (2021) review article showed that several studies demonstrated successful growth of both fungal (e.g., Pleurotus, Lentinus, Aspergillus, Agrocybe, Trametes, and Neurospora) and bacterial (e.g.,

Bacillus subtilis and

Streptomyces avermitilis) species on this substrate without the need for, in most cases, additional nutritional source. The production of various microbial extracellular enzymes, such as amylases, cellulases, xylanases, proteases, laccases, a feruloyl esterase, and a-L-arabinofuranosidase, using BSG as substrate [

67].

Saba et al. (2019) showed the suitability of BSG as a substrate for earthworms in vermicomposting (Reactor 4) [

68]. Following five months of bioconversion, vermicomposts containing BSG and cow manure (1:1) exhibited increased levels of total nitrogen and total humic substances and reduced total organic carbon content, indicating higher mineralization and stabilization.

Other conventional applications of BSG include pulp and paper production and as an adsorbent for the removal of dyes from wastewater or organic compounds from waste gases (Reactor 3) [

69].

Alternative utilization of BSG, especially as a fermentation substrate, has gained momentum in recent years due to technological progress in its processing and the emergence of the circular economy concept. The application of BSG as a potential substrate in different biotechnological processes is feasible due to its nutrients, ready availability, and cost effectiveness. It has been used as a substrate in the production of value-added products, including biofuels (bioethanol, biobutanol, biogas, biohydrogen, and bio lipids [for biodiesel]), organic acids (lactic acid and citric acid), enzymes (cellulases, xylanases, etc.), single-cell protein, prebiotic oligosaccharides, xylitol, and others. In addition, it has been used as carrier matrices for microorganisms in biotechnological processes [

67].

4.3. Innovation and BSG Technologies

Cherubini (2010) proposed that with the integration of green chemistry into biorefineries and the use of low environmental impact technologies, future sustainable production chains of biofuels and high-value chemicals from biomass can be established. This bio-industry aims to be competitive in the market and lead to the progressive replacement of oil refinery products [

70].

In this way, in Brazil, especially in the brewery industry, the possibilities arising from the development of biorefineries and the efficient use of biomass and agricultural/agro-industrial residues (straws, bagasse, sawdust, etc.) point to the greater economic potential of these facilities for Brazil, a country that still has a great technological demand in the chemical and agro-industrial sectors despite occupying a prominent position in agribusiness and the production of biofuels. Add to this the fact that product diversification will positively impact the various production chains involved, reflecting benefits for society in the generation of jobs and income, conquering foreign markets, reducing imports, etc. Therefore, new technological and economic frontiers have been opened for agribusiness and the other sectors involved. The country should prepare itself, by investing in RD&I, to participate effectively in those opportunities that are in rapid development.

Open innovation models (which refer to the cooperation between companies in the development of a common product/process) may be used to develop third-generation biorefineries focusing on organizational and institutional economics and economic optimization of alternative conversion technologies [

55,

71]. Brazil can develop innovative triple helix models of collaboration between research organizations, institutions, and private companies to anchor biorefinery complexes and expand the relationship between farmers and farmers’ organizations, cooperatives, and professional bodies and related existing policies to promote alternative conversion technologies both within the biomass sector and between other resources (alternative energy production, petrochemical plants, etc.).

Celtic Renewables is a Scottish company that has the mission to re-establish, on a global scale, the Acetone–Butanol–Ethanol (ABE) fermentation process, utilizing local low-value materials to produce low-carbon, high-value, sustainable products. Since 2005, the company has been innovating, enhancing, and optimizing patented technology in terms of science, engineering, and manufacturing excellence to develop world-leading biorefineries in key locations that will grow local economies and shareholder value. Its commitment is to work with strategic partners to create an environmentally and socio-economically viable industry that displaces fossil fuel derivatives. In 2015, they scaled up the technology that produced ABE from whisky bagasse, taking it from the original lab scale to a viable commercial pilot scale. They won several awards, and in 2017 they made history by powering the world´s first-ever car filled with biobutanol derived from local whisky production residues.

For BSG, many possibilities can be applied based on the alternative routes shown. So, the biorefinery concept can easily be applied in the beverage industry, but some financial support is necessary to scale up the potential technologies.

Through technological mapping, it can be seen that the technological development of the sector is in its embryonic stage, and it lacks further technological developments, either by companies or research institutions. The number of articles published reveals that research institutions are playing their part and publishing in different sectors where this type of technology can be applied.

However, in Brazil, investment mechanisms such as the “Lei do Bem” do not suffice for technological investment on BSG conversion and integration with chain supply and value routes. Applied and basic research from academia is needed in the development of new ecological biomass economics and enabling technological platforms, both for state and industry segments. The triple helix model must be enhanced to facilitate the economic development of BSG conversion.

Additionally, by breaking down the search results using cluster analysis within the data from

Figure 6 based on concepts associated with each patent, it is possible to demonstrate technical innovations related to BSG biomass.

Table 4 shows patents related to materials and chemical compounds rather than fuel and animal feedstock.

This selection of inventions is intended to exemplify some of the technical innovations in the last five years regarding BSG biomass. JP2019017370 treats BSG by alkalizing it and acidifying the resulting BSG extract. It is possible to isolate β-glucan and oxidized derivatives of unsaturated fatty acids through a more economically viable route rather than using specific microorganisms or enzymes. Material fabrication as EP3235870 uses BSG and polylactic acid to create biomass plastic granules and EP3235875 is a method to manufacture a bio-plastic composite containing BSG. CN113896778 is a preparation method for BSG-modified protein for food, nutrition, materials, and biopharmaceutical fabrication. IN201711031489 consists of BSG treatment with Micrococcus luteus for low-cost production of canthaxanthin and xanthophyll pigments.

The food industry has now diverse BSG-derived food supplies of protein and fiber. EP3500112 produces BSG-based protein powder with high digestibility. CN113912667 claims a process involving mechanical pretreatment, homogenization, ultrasonic-assisted extraction, and acid precipitation of a BSG protein with good emulsibility, foam characteristics, and oil retention properties. WO2021/023597 is a method for obtaining fiber-rich or protein-rich fractions from BSG. EP3750409 is a method for reducing BSG microorganisms such as Bacillus Cereus and Enterobacteriaceae for the food industry. WO2021/023597 is a method to stabilize, liberate, and separate food-grade BSG fibers and protein. US20190254315 uses infrared radiation to reduce BSG moisture content for economical storage and transport.

5. Conclusions

Brewers’ spent grain (BSG) is known to be a very versatile lignocellulosic material; as the Brazilian beer sector grows over time, it is becoming an important issue to the industry. Additionally, the biomass conversion routes under development show excellent alternative routes to propose new destinations for this abundant residue, and advanced technologies in this sector demonstrate the possibility to generate interesting bioproducts and bioenergy. Connecting those possibilities of waste management and the reality placed by the industrial beer sector, it faces the challenges of implementing sustainable practices and reforming conventional industrial waste disposal. The biorefinery concept may contribute in an effective way to integrate beer production and residue generation to build a self-sustainable system.

This study proposes a pathway to visualize the technology development in BSG conversion technologies using a bibliometric analysis, under the article publications, and technological analysis, under patent protection. Of the patents found on the Brazilian patent database (from INPI), both under evaluation or available for licensing already indicate possibilities for biorefinery models toward fuel and high-value low-volume products, favoring territorial biorefinery models and many chain supply possibilities with other than BSG substrates in the food industry. The appropriation of such models by the Brazilian brewing sector is possible due to technologies already available, as shown by the technologies prospected by the patent forecasting. Moreover, industrial property protection for the development of new technical solutions is open, since not all routes discussed for BSG processing were found in the patent analyses. The exponential growth found in research in this field is strong enough to allow further industrial development. That way, the correlations proposed in this study based on the scientific literature and patent protection is a new approach to the theme since it brings actual possibilities for industrial sector changes into sustainable waste management practices.

Through this technological roadmap study, the development of a brewing process connected with a sustainable biorefinery and aligned with a circular bioeconomy model, it is possible to conclude that, in Brazil, this alternative is in its embryonic stage and, in a correct proportion, around the world as well. The number of articles published and their technological domains reveal that research institutions are playing their part in proposing innovative processes, products, and alternatives with the versatility that BSG composition presents. However, in the same way, it is possible to see that there is a lack of investment in transposing the research basis into actual technology production to become an effective solution. This study, based on the BSG perspective, shows what happens with a diversity of other areas and distance between research and product launch, which can also be observed by the lack of dialogue between universities/research centers and companies. Even though this situation is generalized, there are still possibilities. The “Lei do Bem” in Brazil is an alternative for large companies to be able to reduce tax rates and invest in new routes to take advantage of new technologies and processes.

Brazil can develop innovative triple helix models of collaboration between research organizations, institutions, and private companies to anchor future sustainable biorefinery complexes. BSG is this study’s central point, but the context here highlights that it is easily placed for all biomass produced by the agrifood industry.