On the Use of a Non-Constant Non-Affine or Slip Parameter in Polymer Rheology Constitutive Modeling

Abstract

1. Introduction

2. Model Modification

Asymptotic Behavior of the Model for Steady-State and Transient Shear Flow

3. Molecular Model and System Studied

4. Results and Discussion

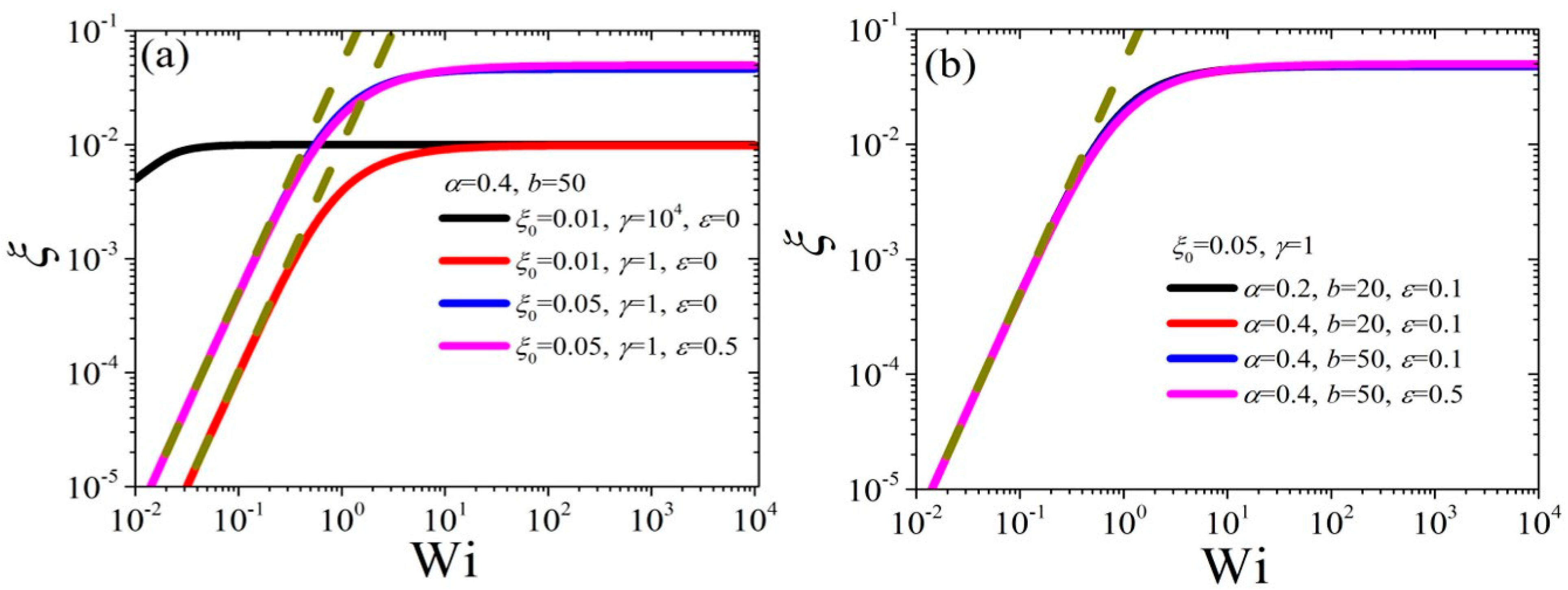

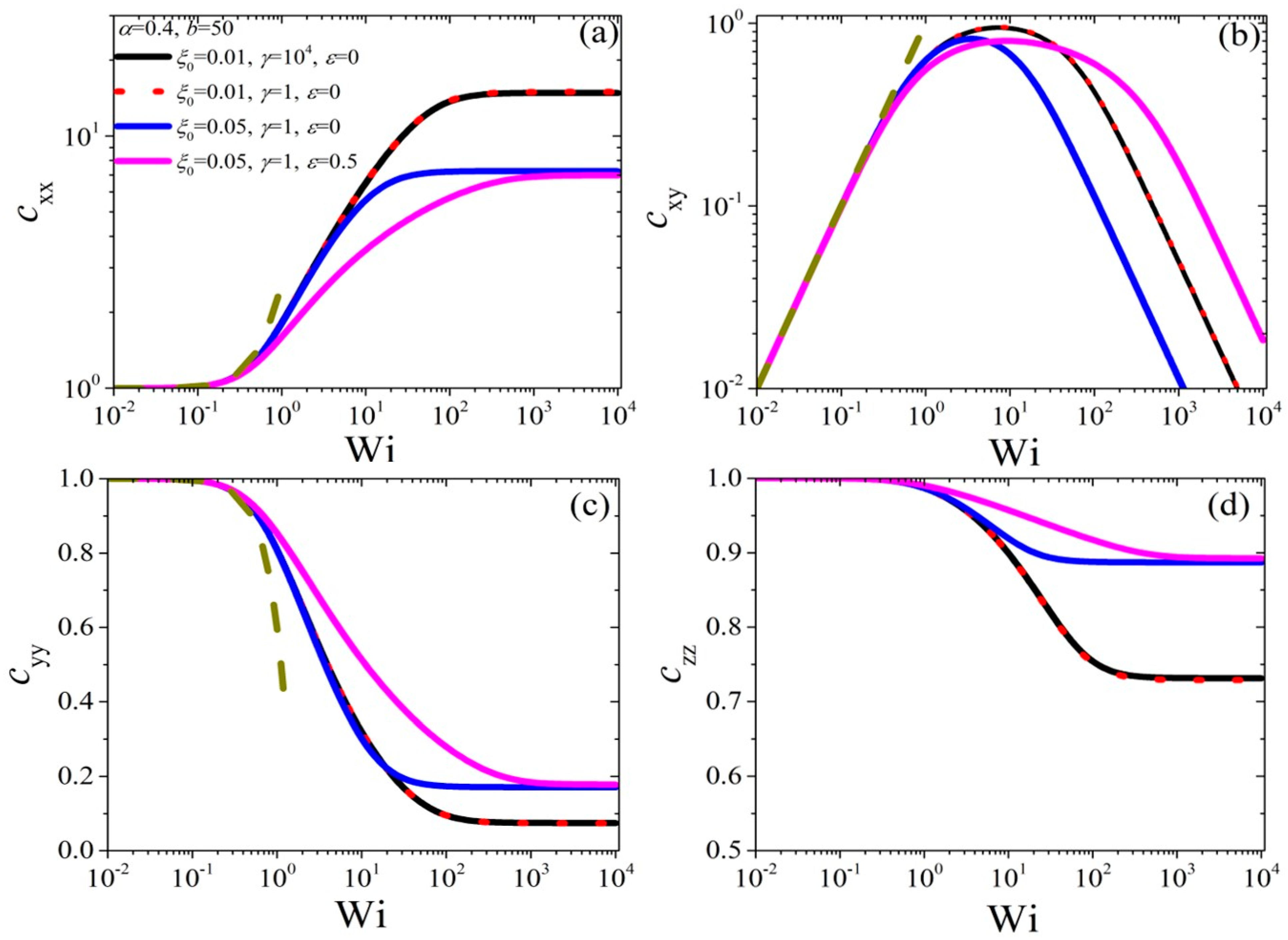

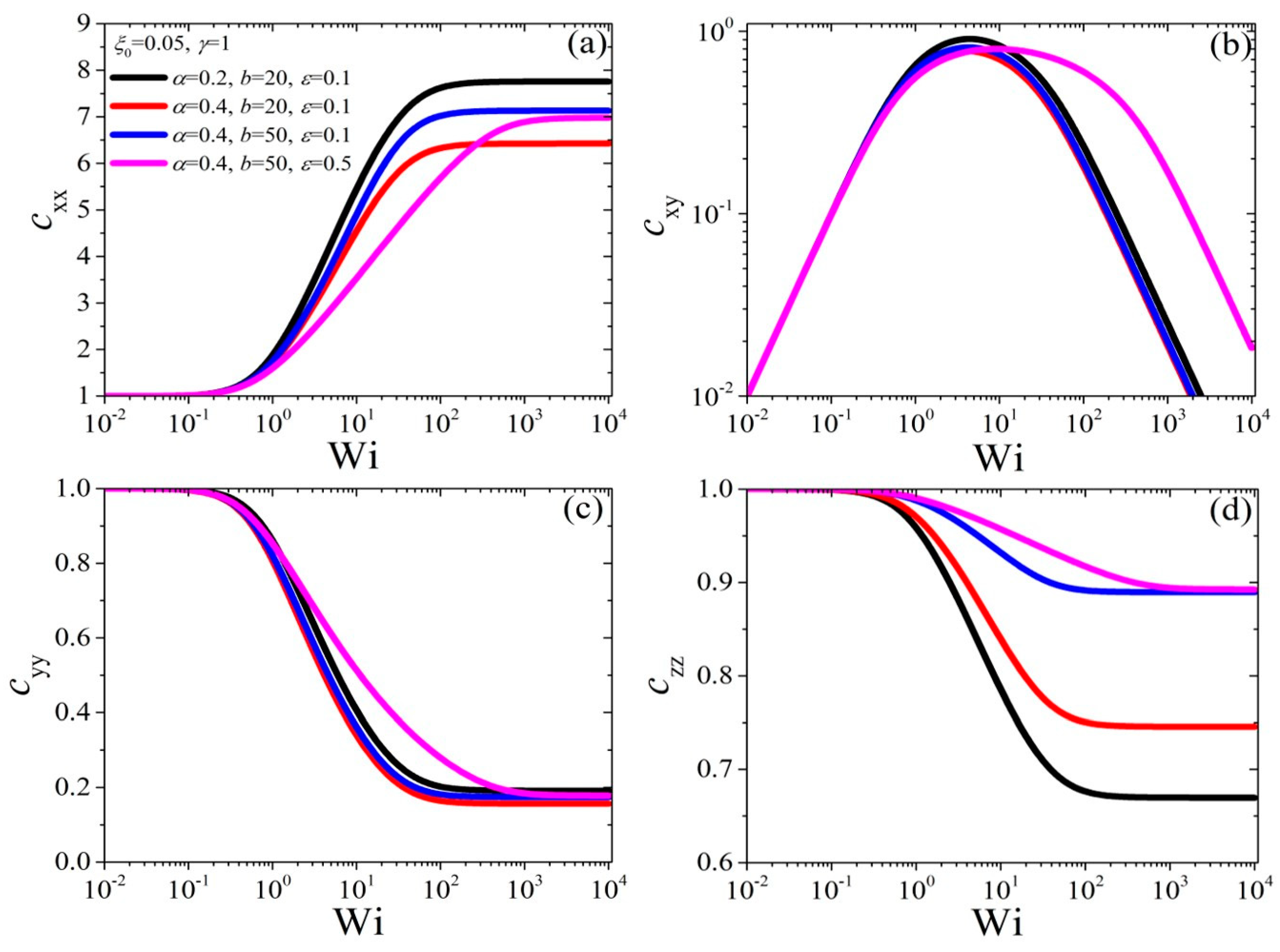

4.1. Model Predictions in Steady-State Shear Flow

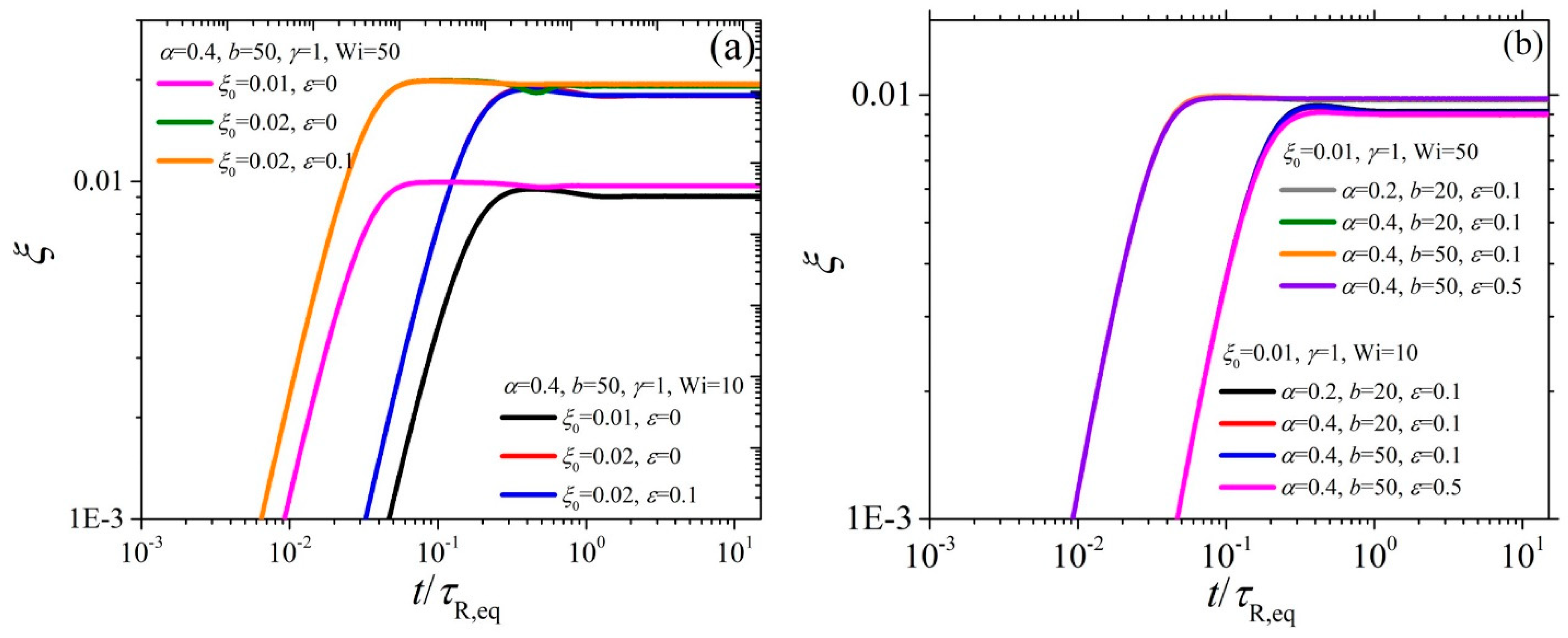

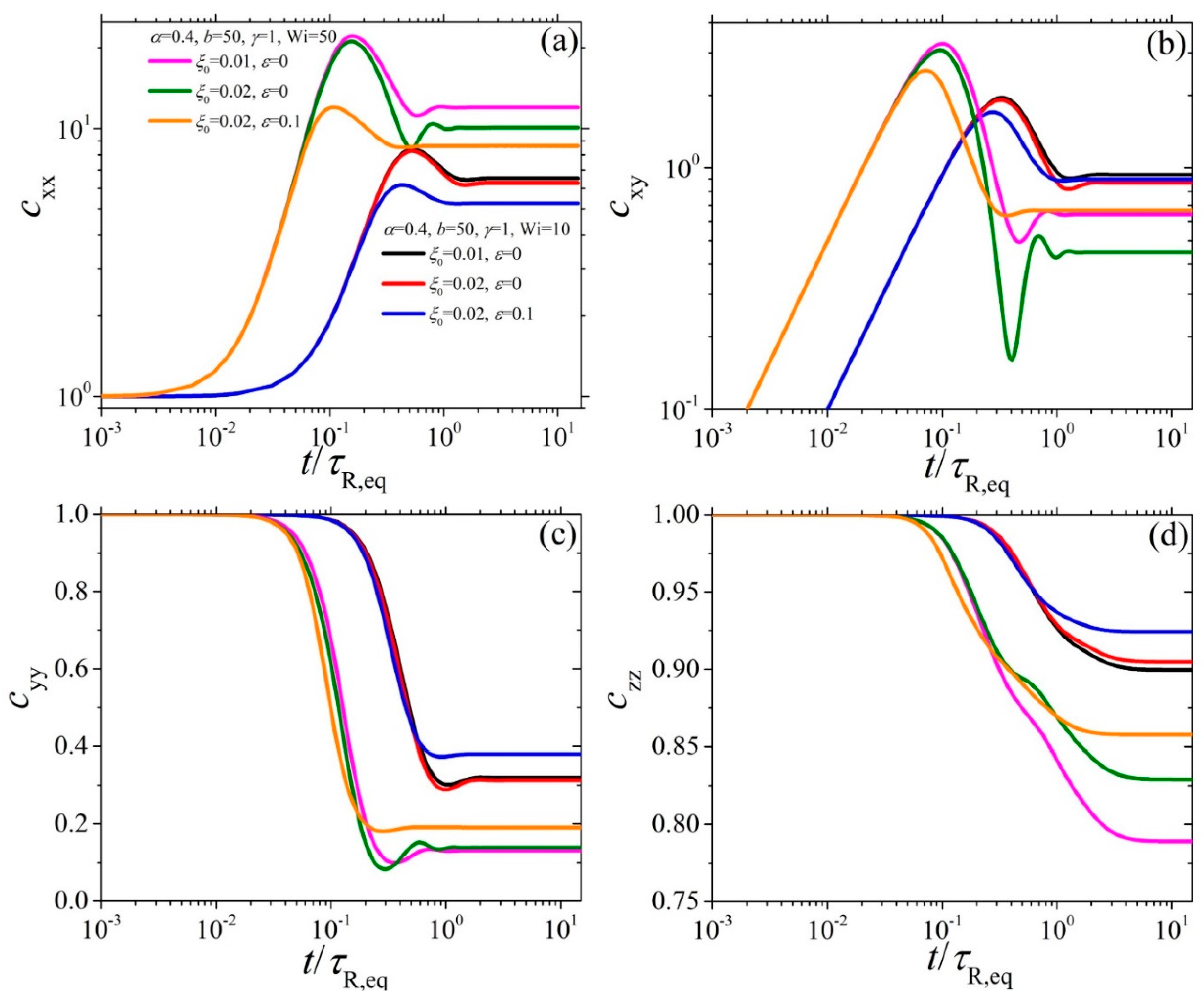

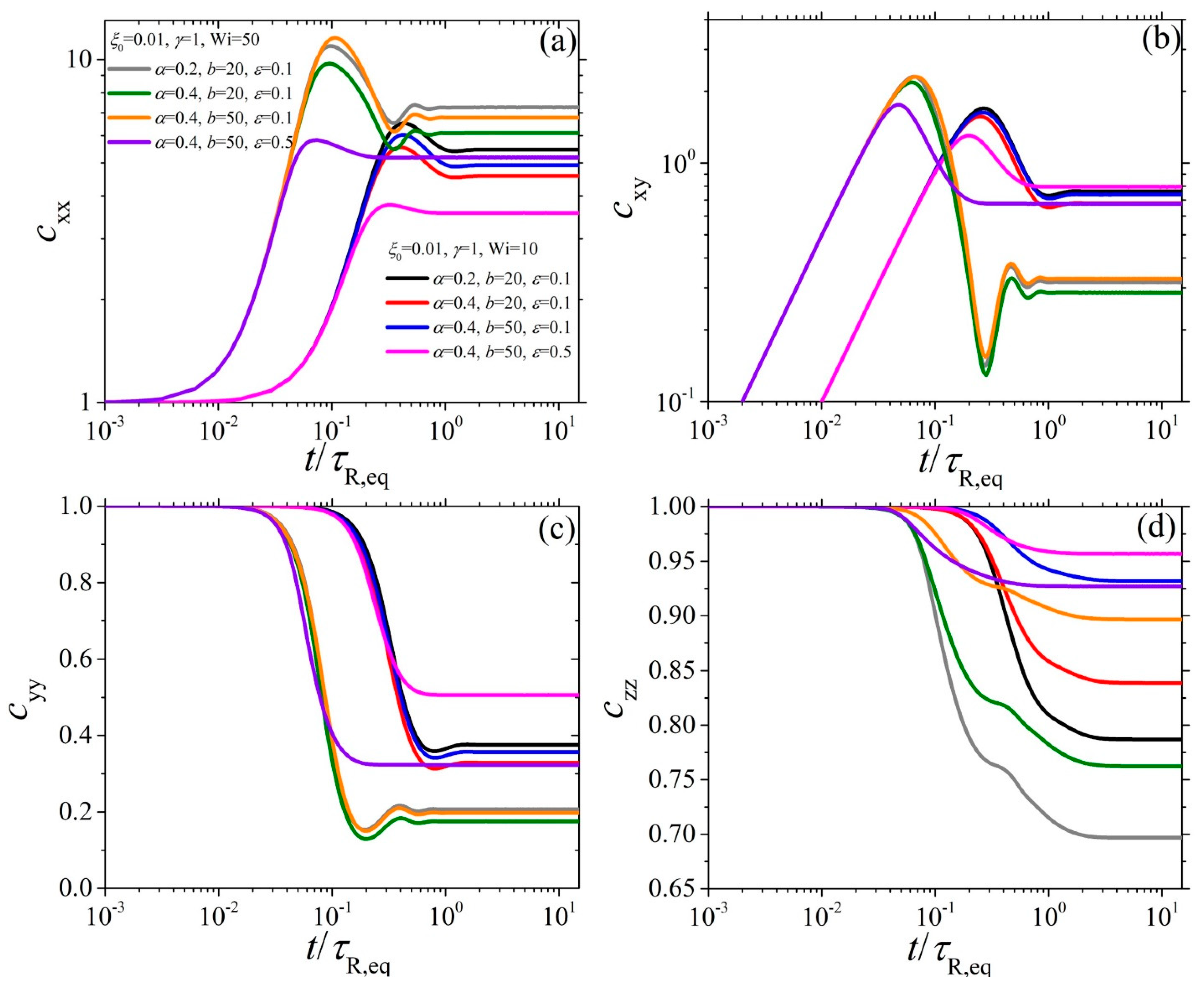

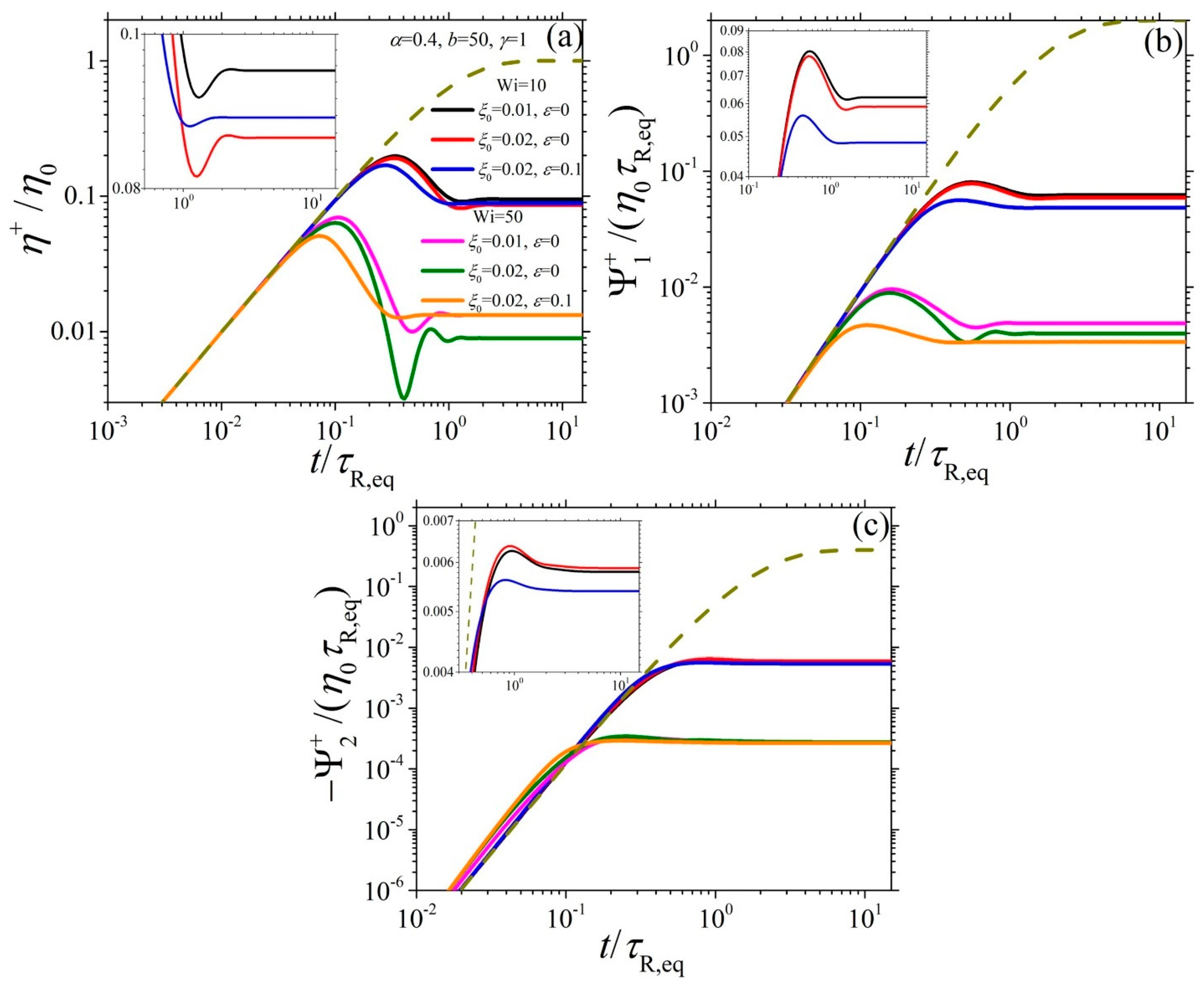

4.2. Model Predictions in Start-Up Shear Flow

4.3. Comparison with NEMD Simulation Data for an Unentangled PE Melt

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pedro, J.; Ramôa, B.; Nóbrega, J.M.; Fernandes, C. Verification and Validation of OpenInjMoldSim, an Open-Source Solver to Model the Filling Stage of Thermoplastic Injection Molding. Fluids 2020, 5, 84. [Google Scholar] [CrossRef]

- Fernandes, C.; Fakhari, A.; Tukovic, Ž. Non-Isothermal Free-Surface Viscous Flow of Polymer Melts in Pipe Extrusion Using an Open-Source Interface Tracking Finite Volume Method. Polymers 2021, 13, 4454. [Google Scholar] [CrossRef]

- Viana, J.C.; Cunha, A.M.; Billon, N. The Thermomechanical Environment and the Microstructure of an Injection Moulded Polypropylene Copolymer. Polymers 2002, 43, 4185–4196. [Google Scholar] [CrossRef]

- Edwards, B.J.; Sefiddashti, M.H.N.; Khomami, B. Atomistic Simulation of Shear Flow of Linear Alkane and Polyethylene Liquids: A 50-Year Retrospective. J. Rheol. 2022, 66, 415. [Google Scholar] [CrossRef]

- Katsarou, A.F.; Tsamopoulos, A.J.; Tsalikis, D.G.; Mavrantzas, V.G. Dynamic Heterogeneity in Ring-Linear Polymer Blends. Polymers 2020, 12, 752. [Google Scholar] [CrossRef] [PubMed]

- Tsalikis, D.G.; Mavrantzas, V.G.; Vlassopoulos, D. Analysis of Slow Modes in Ring Polymers: Threading of Rings Controls Long-Time Relaxation. ACS Macro Lett. 2016, 5, 755–760. [Google Scholar] [CrossRef]

- Tsalikis, D.G.; Mavrantzas, V.G. Size and Diffusivity of Polymer Rings in Linear Polymer Matrices: The Key Role of Threading Events. Macromolecules 2020, 53, 803–820. [Google Scholar] [CrossRef]

- Papadopoulos, G.D.; Tsalikis, D.G.; Mavrantzas, V.G. Microscopic Dynamics and Topology of Polymer Rings Immersed in a Host Matrix of Longer Linear Polymers: Results from a Detailed Molecular Dynamics Simulation Study and Comparison with Experimental Data. Polymers 2016, 8, 283. [Google Scholar] [CrossRef]

- Tsolou, G.; Stratikis, N.; Baig, C.; Stephanou, P.S.; Mavrantzas, V.G. Melt Structure and Dynamics of Unentangled Polyethylene Rings: Rouse Theory, Atomistic Molecular Dynamics Simulation, and Comparison with the Linear Analogues. Macromolecules 2010, 43, 10692–10713. [Google Scholar] [CrossRef]

- Stephanou, P.S.; Mavrantzas, V.G. Accurate Prediction of the Linear Viscoelastic Properties of Highly Entangled Mono and Bidisperse Polymer Melts. J. Chem. Phys. 2014, 140, 214903. [Google Scholar] [CrossRef]

- Smith, D.E.; Babcock, H.P.; Chu, S. Single-Polymer Dynamics in Steady Shear Flow. Science 1999, 283, 1724–1727. [Google Scholar] [CrossRef] [PubMed]

- LeDuc, P.; Haber, C.; Bao, G.; Wirtz, D. Dynamics of Individual Flexible Polymers in a Shear Flow. Nature 1999, 399, 564–566. [Google Scholar] [CrossRef]

- Sefiddashti, M.H.N.; Edwards, B.J.; Khomami, B. Individual Chain Dynamics of a Polyethylene Melt Undergoing Steady Shear Flow. J. Rheol. 2015, 59, 119–153. [Google Scholar] [CrossRef]

- Edwards, C.N.; Sefiddashti, M.H.N.; Edwards, B.J.; Khomami, B. In-Plane and out-of-Plane Rotational Motion of Individual Chain Molecules in Steady Shear Flow of Polymer Melts and Solutions. J. Mol. Graph. Model. 2018, 81, 184–196. [Google Scholar] [CrossRef]

- Batchelor, G.K.; Green, J.T. The Determination of the Bulk Stress in a Suspension of Spherical Particles to Order C2. J. Fluid Mech. 1972, 56, 401–427. [Google Scholar] [CrossRef]

- Sefiddashti, M.H.N.; Edwards, B.J.; Khomami, B. Steady Shearing Flow of a Moderately Entangled Polyethylene Liquid. J. Rheol. 2016, 60, 1227–1244. [Google Scholar] [CrossRef]

- Kim, J.M.; Baig, C. Precise Analysis of Polymer Rotational Dynamics. Sci. Rep. 2016, 6, 19127. [Google Scholar] [CrossRef]

- Tsamopoulos, A.J.; Katsarou, A.F.; Tsalikis, D.G.; Mavrantzas, V.G. Shear Rheology of Unentangled and Marginally Entangled Ring Polymer Melts from Large-Scale Nonequilibrium Molecular Dynamics Simulations. Polymers 2019, 11, 1194. [Google Scholar] [CrossRef]

- Schroeder, C.M.; Teixeira, R.E.; Shaqfeh, E.S.G.; Chu, S. Dynamics of DNA in the Flow-Gradient Plane of Steady Shear Flow: Observations and Simulations. Macromolecules 2005, 38, 1967–1978. [Google Scholar] [CrossRef]

- Schroeder, C.M.; Teixeira, R.E.; Shaqfeh, E.S.G.; Chu, S. Characteristic Periodic Motion of Polymers in Shear Flow. Phys. Rev. Lett. 2005, 95, 018301. [Google Scholar] [CrossRef]

- Huang, C.C.; Sutmann, G.; Gompper, G.; Winkler, R.G. Tumbling of Polymers in Semidilute Solution under Shear Flow. EPL 2011, 93, 54004. [Google Scholar] [CrossRef]

- Xu, X.; Chen, J.; An, L. Shear Thinning Behavior of Linear Polymer Melts under Shear Flow via Nonequilibrium Molecular Dynamics. J. Chem. Phys. 2014, 140, 174902. [Google Scholar] [CrossRef] [PubMed]

- Stephanou, P.S.; Kröger, M. Non-Constant Link Tension Coefficient in the Tumbling-Snake Model Subjected to Simple Shear. J. Chem. Phys. 2017, 147, 174903. [Google Scholar] [CrossRef]

- Costanzo, S.; Huang, Q.; Ianniruberto, G.; Marrucci, G.; Hassager, O.; Vlassopoulos, D. Shear and Extensional Rheology of Polystyrene Melts and Solutions with the Same Number of Entanglements. Macromolecules 2016, 49, 3925–3935. [Google Scholar] [CrossRef]

- Gordon, R.J.; Schowalter, W.R. Anisotropic Fluid Theory: A Different Approach to the Dumbbell Theory of Dilute Polymer Solutions. Trans. Soc. Rheol. 1972, 16, 79–97. [Google Scholar] [CrossRef]

- Johnson, M.W.; Segalman, D. A Model for Viscoelastic Fluid Behavior Which Allows Non-Affine Deformation. J. Nonnewton. Fluid Mech. 1977, 2, 255–270. [Google Scholar] [CrossRef]

- Larson, R.G. Constitutive Equations for Polymer Melts and Solutions, 1st ed.; Butterworth-Heinemann: Oxford, UK, 1988; ISBN 978-0-409-90119-1. [Google Scholar]

- Öttinger, H.C. Beyond Equilibrium Thermodynamics; John Wiley and Sons: Hoboken, NJ, USA, 2005; ISBN 0471666580. [Google Scholar]

- Stephanou, P.S.; Baig, C.; Mavrantzas, V.G. A Generalized Differential Constitutive Equation for Polymer Melts Based on Principles of Nonequilibrium Thermodynamics. J. Rheol. 2009, 53, 309–337. [Google Scholar] [CrossRef]

- Beris, A.N.; Edwards, B.J. Thermodynamics of Flowing Systems: With Internal Microstructure; Oxford University Press: New York, NY, USA, 1994; ISBN 019507694X. [Google Scholar]

- Stephanou, P.S. The Rheology of Drilling Fluids from a Non-Equilibrium Thermodynamics Perspective. J. Pet. Sci. Eng. 2018, 165, 1010–1020. [Google Scholar] [CrossRef]

- Hinch, E.J. Mechanical Models of Dilute Polymer Solutions in Strong Flows. Phys. Fluids 1977, 20, S22–S30. [Google Scholar] [CrossRef]

- Rallison, J.M.; Hinch, E.J. Do We Understand the Physics in the Constitutive Equation? J. Nonnewton. Fluid Mech. 1988, 29, 37–55. [Google Scholar] [CrossRef]

- Beris, A.N.; Stiakakis, E.; Vlassopoulos, D. A Thermodynamically Consistent Model for the Thixotropic Behavior of Concentrated Star Polymer Suspensions. J. Nonnewton. Fluid Mech. 2008, 152, 76–85. [Google Scholar] [CrossRef]

- Stephanou, P.S.; Georgiou, G.G. A Nonequilibrium Thermodynamics Perspective of Thixotropy. J. Chem. Phys. 2018, 149, 244902. [Google Scholar] [CrossRef] [PubMed]

- Housiadas, K.D.; Beris, A.N. Extensional Behavior Influence on Viscoelastic Turbulent Channel Flow. J. Nonnewton. Fluid Mech. 2006, 140, 41–56. [Google Scholar] [CrossRef]

- Souvaliotis, A.; Beris, A.N. An Extended White–Metzner Viscoelastic Fluid Model Based on an Internal Structural Parameter. J. Rheol. 1992, 36, 241–271. [Google Scholar] [CrossRef]

- Stephanou, P.S.; Tsimouri, I.C.; Mavrantzas, V.G. Simple, Accurate and User-Friendly Differential Constitutive Model for the Rheology of Entangled Polymer Melts and Solutions from Nonequilibrium Thermodynamics. Mater. 2020, 13, 2867. [Google Scholar] [CrossRef]

- Siepmann, J.I.; Karaborni, S.; Smit, B. Simulating the Critical Behaviour of Complex Fluids. Nature 1993, 365, 330–332. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Nosé, S. Constant Temperature Molecular Dynamics Methods. Prog. Theor. Phys. Suppl. 1991, 103, 1–46. [Google Scholar] [CrossRef]

- Hoover, W.G. Canonical Dynamics: Equilibrium Phase-Space Distributions. Phys. Rev. A 1985, 31, 1695. [Google Scholar] [CrossRef]

- Parrinello, M.; Rahman, A. Polymorphic Transitions in Single Crystals: A New Molecular Dynamics Method. J. Appl. Phys. 1981, 52, 7182–7190. [Google Scholar] [CrossRef]

- Todd, B.D.; Daivis, P.J. Nonequilibrium Molecular Dynamics: Theory, Algorithms and Applications; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Tuckerman, M.; Berne, B.J.; Martyna, G.J. Reversible Multiple Time Scale Molecular Dynamics. J. Chem. Phys. 1992, 97, 1990–2001. [Google Scholar] [CrossRef]

- Williams, G.; Watts, D.C. Non-Symmetrical Dielectric Relaxation Behaviour Arising from a Simple Empirical Decay Function. Trans. Faraday Soc. 1970, 66, 80–85. [Google Scholar] [CrossRef]

- MathWorks, T. MATLAB (R2020b); MathWorks Inc.: Portola Valley, CA, USA, 2020. [Google Scholar]

- Grmela, M. Stress Tensor in Generalized Hydrodynamics. Phys. Lett. A 1985, 111, 41–44. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikiforidis, V.-M.; Tsalikis, D.G.; Stephanou, P.S. On the Use of a Non-Constant Non-Affine or Slip Parameter in Polymer Rheology Constitutive Modeling. Dynamics 2022, 2, 380-398. https://doi.org/10.3390/dynamics2040022

Nikiforidis V-M, Tsalikis DG, Stephanou PS. On the Use of a Non-Constant Non-Affine or Slip Parameter in Polymer Rheology Constitutive Modeling. Dynamics. 2022; 2(4):380-398. https://doi.org/10.3390/dynamics2040022

Chicago/Turabian StyleNikiforidis, Vasileios-Martin, Dimitrios G. Tsalikis, and Pavlos S. Stephanou. 2022. "On the Use of a Non-Constant Non-Affine or Slip Parameter in Polymer Rheology Constitutive Modeling" Dynamics 2, no. 4: 380-398. https://doi.org/10.3390/dynamics2040022

APA StyleNikiforidis, V.-M., Tsalikis, D. G., & Stephanou, P. S. (2022). On the Use of a Non-Constant Non-Affine or Slip Parameter in Polymer Rheology Constitutive Modeling. Dynamics, 2(4), 380-398. https://doi.org/10.3390/dynamics2040022