Effect of Channel Roughness on Micro-Droplet Distribution in Internal Minimum Quantity Lubrication

Abstract

1. Introduction

- (i).

- Characterize the effect of channel surface roughness and air flow on MQL droplet size.

- (ii).

- Study methods of modifying the surface of WC–Co drill channels to improve high aspect ratio drilling performance.

- (iii).

- Compare experimental data with those from computer simulation.

2. Literature Review

2.1. MQL and Systems

- MQL reduced tool flank wear and surface roughness of machined parts.

- MQL resulted in a 1.5 kW reduction in peak milling machine power when compared with flood coolant. This showed that MQL was more economic than flood coolant not only because of the reduction in lubricant used, but a reduction in energy consumption as well.

- Smooth surfaces were achieved at a higher feed rate using MQL as compared with flood coolant (0.02 mm/rev and 0.01 mm/rev, respectively).

- MQL and flood coolant resulted in similar cutting forces (approximately 200 N), but MQL achieved a 30% reduction in surface roughness of workpieces when compared with those with flood coolant.

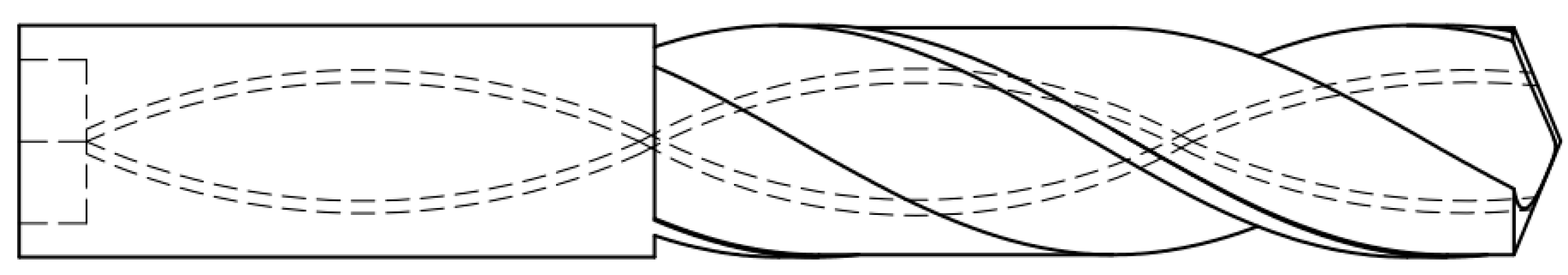

2.1.1. Effect of Internal Channel Geometry

2.1.2. Effect of Oil Type

- Low viscosity resulted in high wettability, high mist concentration, and larger droplet diameters.

- Large mist diameters correlated with less energy consumption, smoother surface finish, and more accurate machined dimensions.

- Higher wettability led to better dimensional accuracy.

2.1.3. Effect of MQL on Machining

- In drilling, dry machining resulted in a much shorter tool life when compared with MQL (0.2 mm of tool wear at cumulative drilling depths of 100 mm and 450 mm, respectively) due to tool chipping, high temperatures, and increased frictional force [16]. Davim et al. [17] showed that after drilling AA1050 aluminum, the resulting surface roughness measurements were approximately 3.5 µm, 2 µm, and 1.5 µm Ra for dry, flood coolant, and MQL, respectively, after drilling at 0.15 mm/rev feed rate and 75 m/min cutting speed. In these experiments, MQL was achieved using fluid deliveries in order of mL/h compared with L/h for flood coolant.

- In milling, MQL was more effective than flood coolant as it led to an approximately 50 N reduction in cutting force due to a reduction in adhesion and frictional forces at a high cutting speed of 3500 m/min [18]. Iskandar et al. [19] studied the effect of air and oil flow rate and nozzle distance from the cutting zone on external MQL flow characteristics. Particle image velocimetry and phase Doppler anemometry visualization methods were used to characterize the external MQL flow. Air flow rates of 20, 25, 28, 31 L/min and oil flow rates of 10, 17.5, 24 mL/min were tested. The study showed that as air and oil flow rate increased, flow velocity increased. As the distance from the nozzle to the cutting zone increased the flow velocity decreased, and the droplet size and count also decreased. The optimal MQL spray was obtained by combining the maximum air flow rate (31 L/min) and minimum oil flow rate (10 mL/min), generating a large number of 50µm-droplets at a distance 40 mm away from the nozzle. The effects of MQL, compressed air, dry, and flood coolant in milling operations of carbon fiber reinforced plastic composites were performed. Various combinations of MQL air and oil flow rates showed similar tool temperatures (only 7% variation). The study found that the optimal MQL spray generated temperatures on the high end of the dataset while feed force was the same for MQL and flood coolant. Tool wear was 20–30% less using MQL when compared with cooling methods using flood, dry, or compressed air. The optimal MQL spray generated the lowest tool wear (17% less than other MQL combinations). MQL also held better dimensional accuracy than flood coolant, with the optimal spray satisfying the tool requirement of ±10 µm.

- In micromilling, MQL was studied to compare the effect of droplet size and air speed on surface roughness and tool wear [3]. High pressurized MQL (550 kPa) increased air speed, and when paired with a rough lubricant delivery channel (16.8 µm Sa) a Ø5 µm average droplet size was achieved. Low pressurized MQL (275 kPa) decreased air speed, and when paired with a smooth lubricant delivery channel resulted in a Ø9 µm average droplet size. At a milling distance of 20 mm the high-pressure rough channel test resulted in approximately 1.5 µm Sa surface roughness and 10 µm tool wear. At the same milling distance, the low-pressure smooth channel resulted in approximately 2.75 µm Sa surface roughness and 25 µm tool wear.

- In turning operations, MQL resulted in a surface roughness of 4.25 µm Ra compared with 5.00 µm Ra in dry machining. MQL also improved surface finish by reduced abrasion, tool chipping, and built-up edge (BUE) formation. The maximum flank wear for MQL inserts was ~200 µm less than that of dry machining [20]. Chetan et al. [21] characterized the wear behavior of PVD TiN-coated carbide turning inserts when machining Nimonic 90 and Ti6Al4V. An external MQL emulsion mixture (10:1 ratio of water and sunflower oil) was used in comparison with dry machining. The results showed that applying the mixture to Ti6Al4V allowed ample wetting, decreasing the intensity of flank wear at high cutting speeds. The lubricant also better penetrated the surface of the Ti6Al4V workpiece, reducing flank wear when compared with Nimonic 90.

2.2. Surface Modification

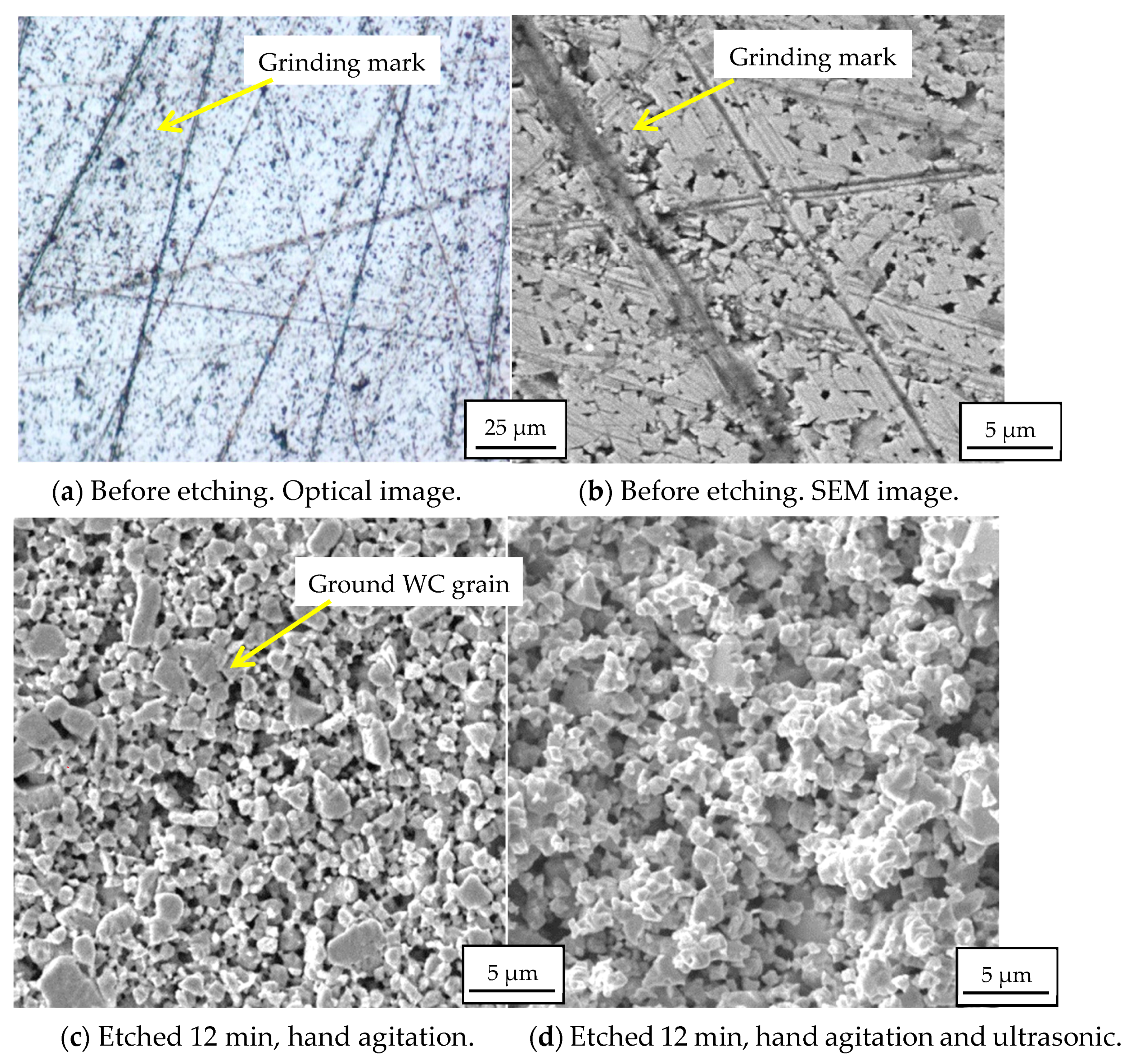

- The Murakami solution dissolved WC particles, leaving the Co binder unetched.

- Following the Murakami solution etch, Caro’s acid partially dissolved the Co binder, leaving a textured surface finish. Caro’s acid etching caused oxidation of the Co binder to a soluble Co2+ compound.

- Without the primary Murakami etching, Caro’s acid had little effect on the WC–Co substrate.

2.3. Ultrasonic Cleaning

2.4. Summary of Literature Review and Research Gap

3. Materials and Methods

3.1. MQL Droplet Characterization

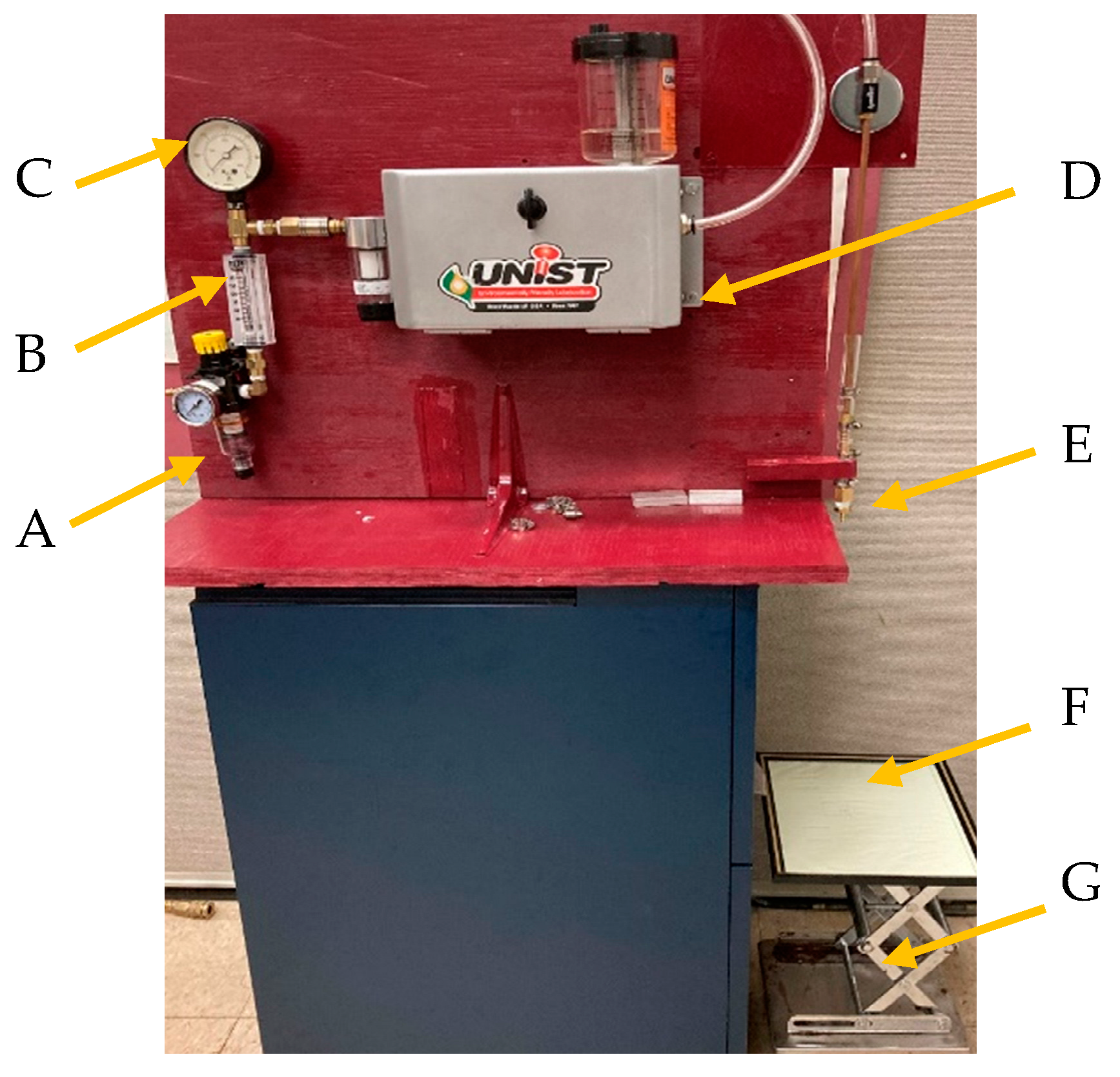

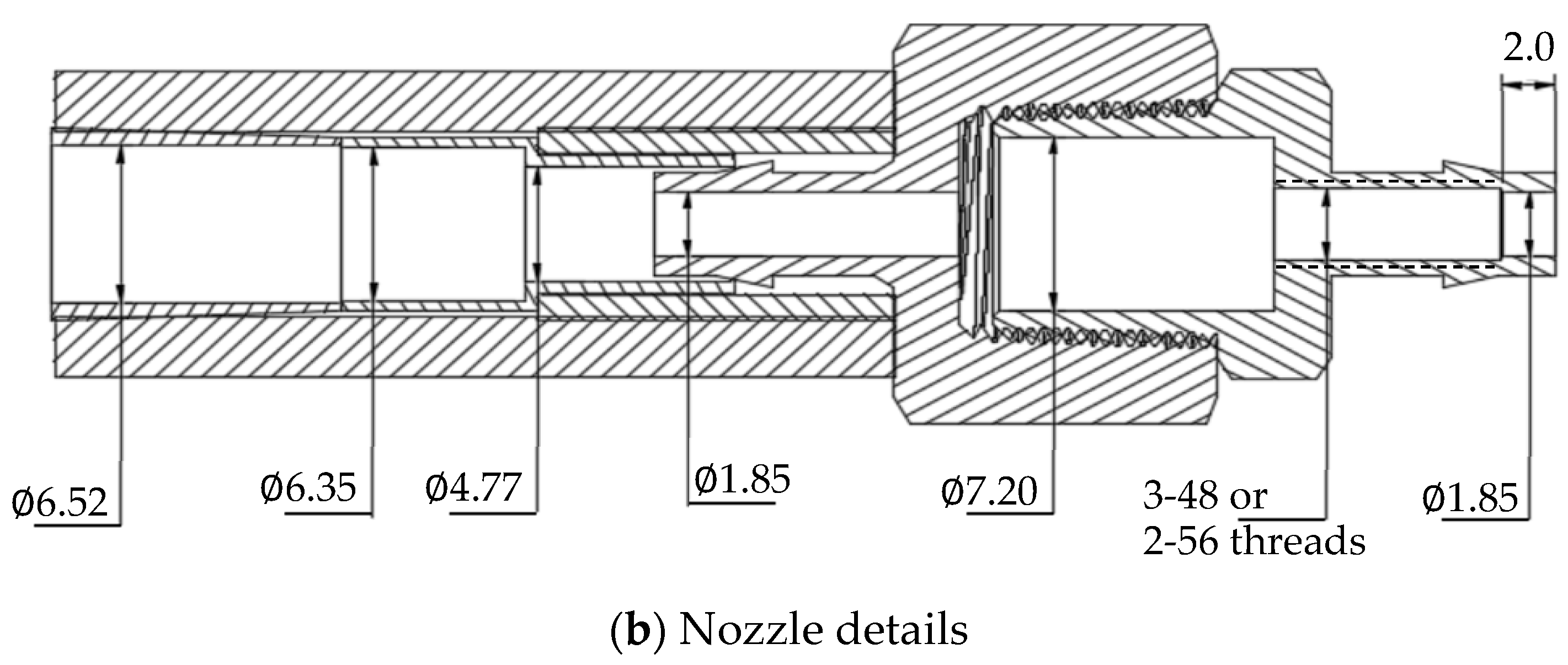

3.1.1. Equipment

3.1.2. Materials

3.1.3. Methods

- (a)

- The MQL droplet system was set up using the parameters shown in Table 3.

- (b)

- The tip was centered above the origin at location #5.

- (c)

- The system was purged for 15 s, immediately followed by a 1 s droplet collection. Cardboard was used to block and control the flow of MQL droplets onto the collecting glass plate.

- (d)

- One 7 × 7 mm2 microscopic image of droplet distribution was captured at the center of each zone seen in Figure 4.

3.2. MQL Lubricant Flow Simulations

3.3. Chemical Etching and Metrology

4. Results and Discussion

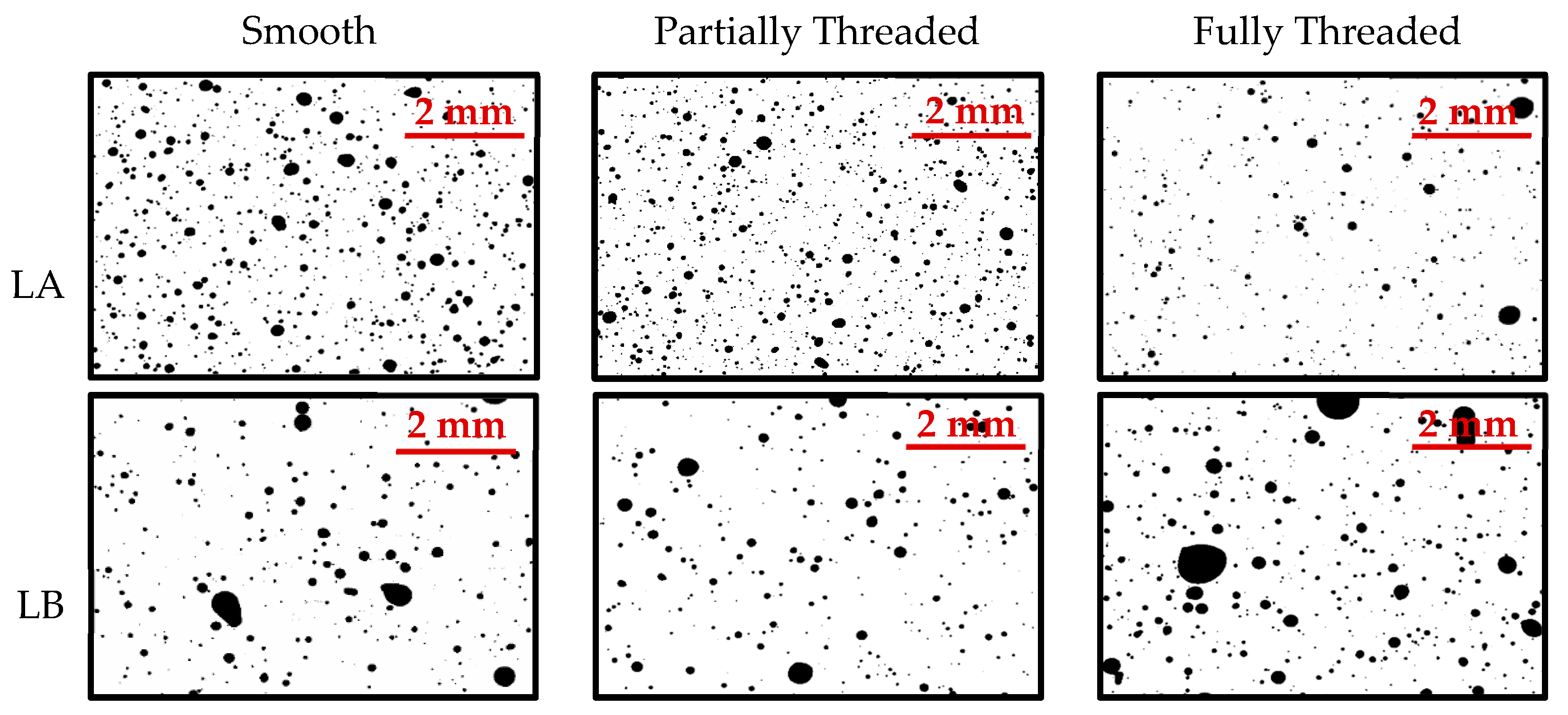

4.1. MQL Droplet Characterization

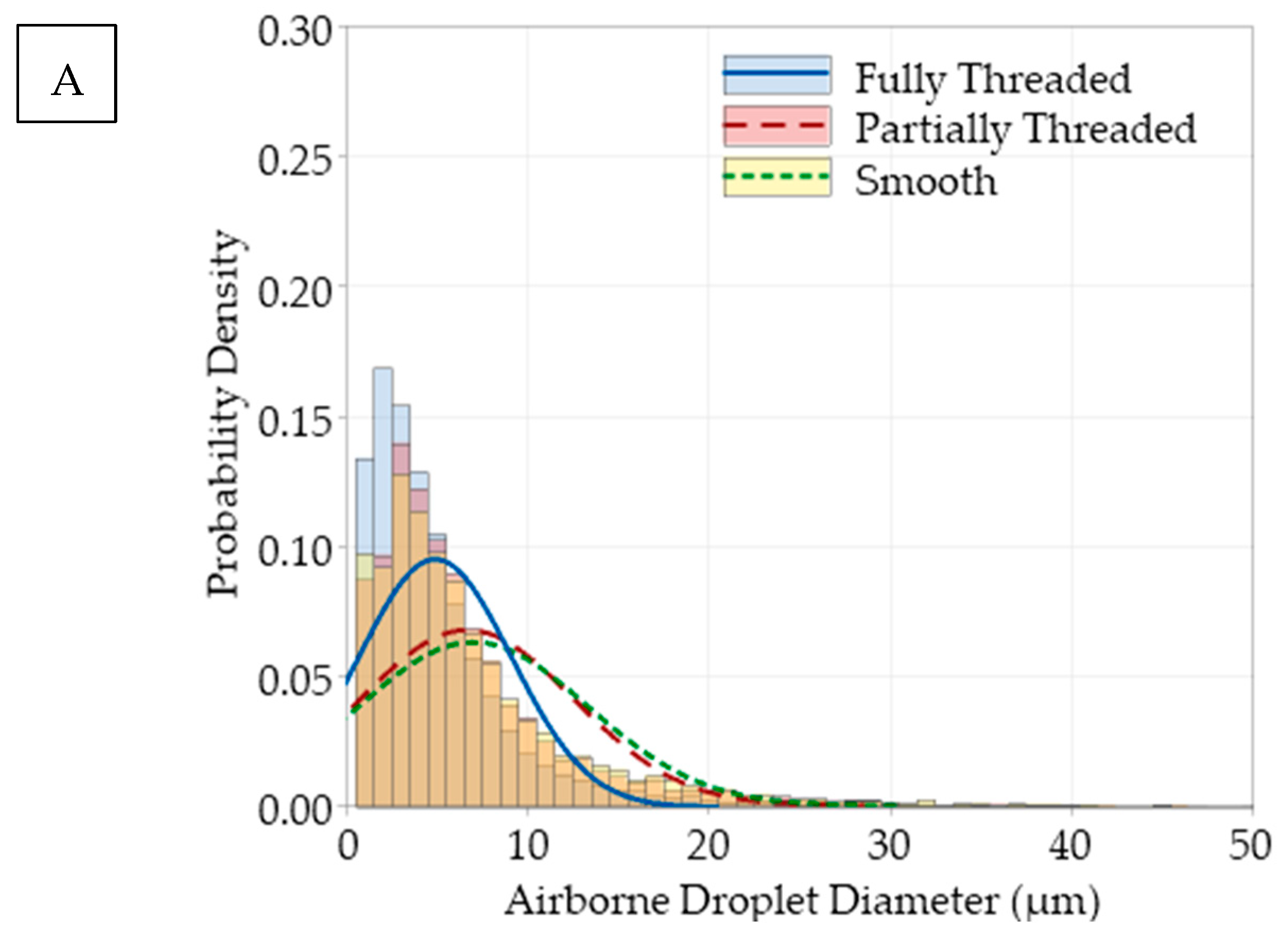

- The low-viscous lubricant A was easily broken into smaller droplets. The ability to self-divided into smaller droplets was enhanced by a rougher surface as evidenced with the change from smooth to partially threaded and fully threaded channels.

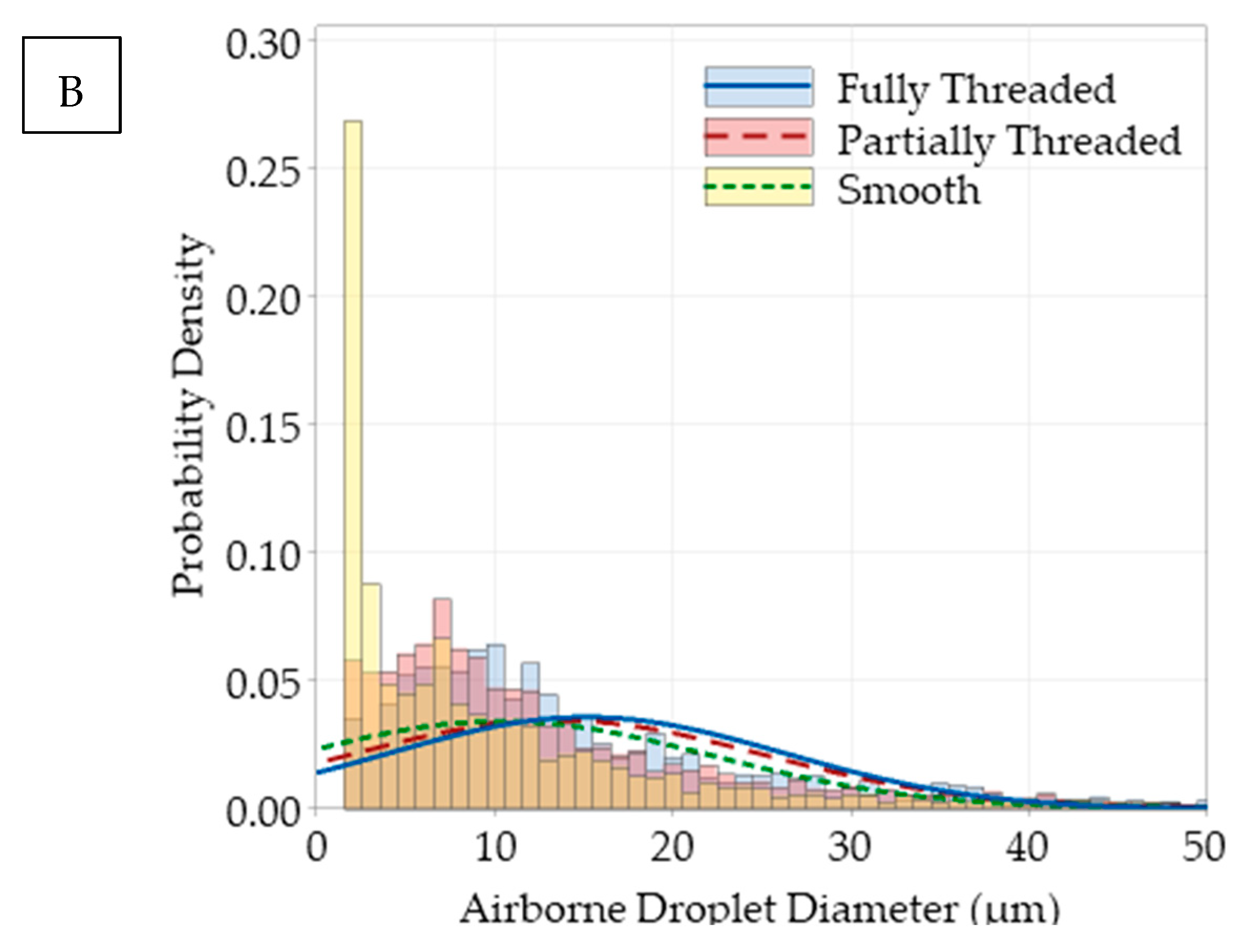

- The high-viscous lubricant B showed the opposite trend. Higher viscosity and perhaps lower surface energy forced a lubricant droplet to adhere to the channel wall, forming larger droplets. A rougher surface would promote this characteristic, i.e., more lubricant adhering to the channel wall and fewer airborne droplets.

- Droplet dispersion: The high droplet density was found directly below the nozzle since compressed air exited within a cone shape and diverged away from the tip. Higher central air velocity constrained the droplets near the central axis of the cone and deposited most droplets in the central zone #5.

- Airborne drop size: The drop size was larger at the central zone #5 compared with other zones. A large droplet with heavy mass and inertia would travel straight out of the nozzle and have less tendency to deviate from a flight path due to minor turbulence.

- Effect of viscosity: The LA lubricant, with viscosity of 14.5 mm2/s compared with 28 mm2/s of lubricant LB (Table 2), would easily breakdown into smaller droplets to form mist with smaller airborne drop size and higher droplet density. This reasoning also agreed with the relationship of contact angle, drop size, and surface tension in the Gibbs equation [34]:

4.2. MQL Air Flow Simulations

- In a smooth channel, the velocity of the air is parallel to the wall; therefore, once the droplets stick to the wall, it is very difficult for the droplets to reenter the bulk of the fluid (Figure 8a).

- In a partially threaded channel, turbulent flow was seen due to the threaded wall. The thread geometry, typically 60°, allowed air to recirculate back and disrupt the boundary layer (Figure 8b).

- The effect was more significant in fully threaded channel. The returning air in a threaded portion effectively disrupted the stagnant layer and reintroduced oil drop-lets back to the main air flow above the threaded wall. As the result, there was more pressure drop in the fluid and the velocity of the air was lower (approximately 125 m/s) compared with that in a smooth channel (approximately 250 m/s) (Figure 8c).

4.3. Chemical Etching

5. Conclusions and Recommendations

- A rough channel surface helped to break down lubrication droplets to form higher quantities of finer airborne droplets when using low-viscous lubricant such as the LA lubricant in this study. The opposite trend was seen for the higher viscous lubricant LB. Computational fluid dynamic simulations showed that a rough surface, such as threaded channel, induced turbulent flow at the channel surface. Such turbulent air flow would disrupt the stagnant lubricant liquid in the boundary layer and reintroduce the lubricant droplets into the downstream air flow. The effect was more drastic on the low-viscous lubricant LA compared with the high-viscous lubricant LB.

- For both lubricant types, the average droplet size and droplet density decreased as a function of increased radial distance. This showed that the dispersion of lubricant was most concentrated directly beneath the outlet tip and decreased at further collection points. This result was expected due to the conical shape of air flow out of a circular nozzle.

- A rough lubricant channel of a WC–Co cutting tool can be etched chemically to produce desirable roughness from nanometer to micrometer levels. A low-frequency hand agitation helped to refresh the tool surface with new etchant, while a high-frequency ultrasonic agitation accelerated the material removal rate by cavitation mechanism. Scanning electron microscopy examination showed that all grinding marks on WC–Co inserts were effectively removed after etching for 12 min with hand and ultrasonic agitation.

- (a)

- Modify internal surface of coolant channels to achieve desirable surface roughness. This can be performed by flowing etchant through a channel for roughening, or pumping abrasive slurry through a channel for polishing.

- (b)

- Simulating oil–air mixture flow through simulated chemically etched surface. The result can be verified experimentally to characterize the airborne droplet, and confirmed with actual machining of metallic workpieces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| EDM | Electrical discharge machining |

| FT, PT | Fully threaded, partially threaded |

| HA | Hand agitation |

| HA + US | Hand agitation and ultrasonic pulsation |

| LA, LB | Lubricant A, B |

| MQL | Minimum quantity lubrication |

| MIP | Male iron pipe |

| T1, T2 | Trial 1, Trial 2 |

| a | Droplet radius |

| A | Area of droplet calculated by ImageJ |

| C | Constant for contact angle calculation |

| d | Airborne droplet diameter |

| K | Line tension |

| P | Projected droplet diameter |

| V | Volume of droplet |

| θ | Contact angle |

| γLG | Surface tension of liquid relative to gas |

| γSG | Surface tension of solid relative to gas |

| γSL | Surface tension of solid relative to liquid |

References

- Sharma, V.S.; Singh, G.; Sørby, K. A Review on Minimum Quantity Lubrication for Machining Processes. Mater. Manuf. Process. 2014, 30, 935–953. [Google Scholar] [CrossRef]

- Tai, B.L.; Stephenson, D.A.; Furness, R.J.; Shih, A.J. Minimum Quantity Lubrication (MQL) in Automotive Powertrain Machining. Procedia CIRP 2014, 14, 523–528. [Google Scholar] [CrossRef]

- Khan, W.A.; Hoang, N.M.; Tai, B.; Hung, W.N. Through-tool minimum quantity lubrication and effect on machinability. J. Manuf. Process. 2018, 34, 750–757. [Google Scholar] [CrossRef]

- Stephenson, D.A.; Agapiou, J.S. Metal Cutting Theory and Practice; CRC Press: Boca Raton, FL, USA, 2019; pp. 803–822. [Google Scholar]

- Race, A.; Zwierzak, I.; Secker, J.; Walsh, J.; Carrell, J.; Slatter, T.; Maurotto, A. Environmentally sustainable cooling strategies in milling of SA516: Effects on surface integrity of dry, flood and MQL machining. J. Clean. Prod. 2020, 288, 125580. [Google Scholar] [CrossRef]

- Hwang, Y.K.; Lee, C.M. Surface roughness and cutting force prediction in MQL and wet turning process of AISI 1045 using design of experiments. J. Mech. Sci. Technol. 2010, 24, 1669–1677. [Google Scholar] [CrossRef]

- Tasdelen, B.; Wikblom, T.; Ekered, S. Studies on minimum quantity lubrication (MQL) and air cooling at drilling. J. Mater. Process. Technol. 2008, 200, 339–346. [Google Scholar] [CrossRef]

- Maruda, R.W.; Feldshtein, E.; Legutko, S.; Krolczyk, G. Research on emulsion mist generation in the conditions of minimum quantity cooling lubrication (MQCL). Teh. Vjesn.-Tech. Gaz. 2015, 22, 1213–1218. [Google Scholar]

- Maruda, R.W.; Krolczyk, G.M.; Feldshtein, E.; Pusavec, F.; Szydlowski, M.; Legutko, S.; Sobczak-Kupiec, A. A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL). Int. J. Mach. Tools Manuf. 2016, 100, 81–92. [Google Scholar] [CrossRef]

- Raval, J.K.; Tai, B.L. An optical tomographic method to characterize the mist distribution in MQL Tools. J. Manuf. Process. 2021, 62, 275–282. [Google Scholar] [CrossRef]

- Raval, J.K.; Kao, Y.-T.; Tai, B.L. Characterizing Mist Distribution in Through-Tool Minimum Quantity Lubrication Drills. J. Manuf. Sci. Eng. 2020, 142, 031002. [Google Scholar] [CrossRef]

- Kao, Y.-T.; Takabi, B.; Hu, M.; Tai, B.L. Coolant Channel and flow characteristics of MQL drill bits: Experimental and numerical analyses. In Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference Collocated with the JSME/ASME 2017 6th International Conference on Materials and Processing, Los Angeles, CA, USA, 4–8 June 2017; Volume 2. [Google Scholar]

- Yıldırım, Ç.V.; Kıvak, T.; Sarıkaya, M.; Erzincanlı, F. Determination of MQL Parameters Contributing to Sustainable Machining in the Milling of Nickel-Base Superalloy Waspaloy. Arab. J. Sci. Eng. 2017, 42, 4667–4681. [Google Scholar] [CrossRef]

- Tai, B.L.; Dasch, J.M.; Shih, A.J. Evaluation and Comparison of Lubricant Properties in Minimum Quantity Lubrication Machining. Mach. Sci. Technol. 2011, 15, 376–391. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S.K. Hard turning using HiPIMS-coated carbide tools: Wear behavior under dry and minimum quantity lubrication (MQL). Measurement 2014, 55, 536–548. [Google Scholar] [CrossRef]

- Rahim, E.A.; Sasahara, H. Investigation of tool wear and surface integrity on MQL machining of Ti-6AL-4V using biodegradable oil. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1505–1511. [Google Scholar] [CrossRef]

- Davim, J.P.; Sreejith, P.S.; Gomes, R.; Peixoto, C. Experimental studies on drilling of aluminium (AA1050) under dry, minimum quantity of lubricant, and flood-lubricated conditions. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1605–1611. [Google Scholar] [CrossRef]

- Kishawy, H.; Dumitrescu, M.; Ng, E.-G.; Elbestawi, M. Effect of coolant strategy on tool performance, chip morphology and surface quality during high-speed machining of A356 aluminum alloy. Int. J. Mach. Tools Manuf. 2005, 45, 219–227. [Google Scholar] [CrossRef]

- Iskandar, Y.; Tendolkar, A.; Attia, M.; Hendrick, P.; Damir, A.; Diakodimitris, C. Flow visualization and characterization for optimized MQL machining of composites. CIRP Ann. 2014, 63, 77–80. [Google Scholar] [CrossRef]

- Dhar, N.; Kamruzzaman, M.; Ahmed, M. Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel. J. Mater. Process. Technol. 2006, 172, 299–304. [Google Scholar] [CrossRef]

- Chetan; Behera, B.; Ghosh, S.; Rao, P. Wear behavior of PVD TiN coated carbide inserts during machining of Nimonic 90 and Ti6Al4V superalloys under dry and MQL conditions. Ceram. Int. 2016, 42, 14873–14885. [Google Scholar] [CrossRef]

- Said, Z.; Gupta, M.; Hegab, H.; Arora, N.; Khan, A.M.; Jamil, M.; Bellos, E. A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int. J. Adv. Manuf. Technol. 2019, 105, 2057–2086. [Google Scholar] [CrossRef]

- Carou, D.; Rubio, E.M.; Davim, J.P. A note on the use of the minimum quantity lubrication (MQL) system in turning. Ind. Lubr. Tribol. 2015, 67, 256–261. [Google Scholar] [CrossRef]

- Davim, J.P.; Sreejith, P.S.; Silva, J. Turning of Brasses Using Minimum Quantity of Lubricant (MQL) and Flooded Lubricant Conditions. Mater. Manuf. Process. 2007, 22, 45–50. [Google Scholar] [CrossRef]

- Sadeghi, M.H.; Haddad, M.J.; Tawakoli, T.; Emami, M. Minimal quantity lubrication-MQL in grinding of Ti–6Al–4V titanium alloy. Int. J. Adv. Manuf. Technol. 2008, 44, 487–500. [Google Scholar] [CrossRef]

- Haubner, R.; Kubelka, S.; Lux, B.; Griesser, M.; Grasserbauer, M. Murakami and H2SO4/H2O2 Pretreatment of WC-Co Hard Metal Substrates to Increase the Adhesion of CVD Diamond Coatings. In Proceedings of the Tenth European Conference on Chemical Vapour Deposition, Venice, Italy, 10–15 September 1995; Volume 5, pp. 753–760. [Google Scholar] [CrossRef][Green Version]

- Chakravarthy, G.V.; Chandran, M.; Bhattacharya, S.S.; Ramachandra Rao, M.S.; Kamaraj, M. A comparative study on wear behavior of tin and diamond coated WC–co substrates against hypereutectic Al–Si Alloys. Appl. Surf. Sci. 2012, 261, 520–527. [Google Scholar] [CrossRef]

- Sha, L.; Zhiming, Y.; Danqing, Y.; Yongxia, L. Chemical pretreatments at the surface of WC-15 wt% Co for diamond coatings. In Powder Metallurgical High Performance Materials Proceedings. Volume 2: P/M Hard Materials, Proceedings of the 15th International Plansee Seminar, Reutte, Austria, 15–17 May 2001; Kneringer, G., Rodhammer, P., Wildner, H., Eds.; Plansee Holding AG: Reutte, Austria, 2001; Volume 2, p. 896. [Google Scholar]

- Jung, S.-W.; Kim, J.; Kang, S.-J.L. Etching for microstructural observation of cemented sub-micrometer-sized carbides. J. Am. Ceram. Soc. 2001, 84, 899–901. [Google Scholar] [CrossRef]

- Brujan, E.; Ikeda, T.; Matsumoto, Y. On the pressure of cavitation bubbles. Exp. Therm. Fluid Sci. 2008, 32, 1188–1191. [Google Scholar] [CrossRef]

- Pecha, R.; Gompf, B. Microimplosions: Cavitation Collapse and Shock Wave Emission on a Nanosecond Time Scale. Phys. Rev. Lett. 2000, 84, 1328–1330. [Google Scholar] [CrossRef]

- AZO Materials. Properties: Tungsten Carbide-An Overview. 2022. Available online: https://www.azom.com/properties.aspx?ArticleID=1203 (accessed on 10 April 2022).

- Patil, A.; Raval, J.; Bangma, T.; Edinbarough, I.; Tai, B.; Stephenseon, D.; Suleiman, O.; Hung, W.N. Characterization and Performance of Minimum Quantity Lubricants in Through-Tool Drilling. Int. J. Eng. Mater. Manuf. 2020, 5, 98–115. [Google Scholar] [CrossRef]

- Gibbs, J.W. The Scientific Papers in Two Volumes; Wiley: New York, NY, USA, 1961. [Google Scholar]

- Park, K.-H.; A Olortegui-Yume, J.; Joshi, S.; Kwon, P.; Yoon, M.-C.; Lee, G.-B.; Park, S.-B. Measurement of droplet size and distribution for minimum quantity lubrication (MQL). In Proceedings of the 2008 International Conference on Smart Manufacturing Application, Goyang-Si, Korea, 9–11 April 2008. [Google Scholar]

| Pressure (kPa) | Rough Channel (16.2 µm Ra) | Polished Channel (3.2 µm Ra) |

|---|---|---|

| 275 | 9.2 | 11.42 |

| 415 | 7.25 | 9.31 |

| 550 | 4.69 | 7.6 |

| Properties | LA | LB |

|---|---|---|

| Oil Type | Fatty acid + alcohol | Vegetable |

| Kinematic viscosity at 40 °C (mm2/s) | 14.5 | 28 |

| Kinematic viscosity at 100 °C (SUS) | Not available | 148 |

| Flashpoint (°C) | 93 | 194 |

| Density (kg/L) | 0.82–0.92 @60 °C | 0.838 @20 °C |

| Thermal conductivity at 40 °C (W/m°K) | Not available | 0.1593 |

| Contact angle on glass | 6° | 22° |

| Solubility | Hydrocarbons, alcohols | Insoluble in water |

| Parameter | Tip to Grid Distance (mm) | Air Flow Rate (m3/h) | Air Pressure (kPa) | Oil Pump Frequency (Strokes/min) | Collection Time (s) | Lubricant Flow Rate (mL/h) |

|---|---|---|---|---|---|---|

| Set Point | 356 | 0.566 | 690 | 40 | 1 | 60 |

| Total Inlet Pressure (MPa) | Static Inlet Pressure (MPa) | Outlet Pressure (MPa) | Inlet Temperature (°K) | Outlet Temperature (°K) | Primary Phase | Secondary Phase |

|---|---|---|---|---|---|---|

| 0.41 | 0.17 | 0 | 300 | 300 | air | lubricant |

| Lubricant A (14.5 mm2/s Viscosity) | Lubricant B (28.0 mm2/s Viscosity) | |||||

|---|---|---|---|---|---|---|

| Channel Surface | Mean (µm) | S. Deviation (µm) | Droplet Count | Mean (µm) | S. Deviation (µm) | Droplet Count |

| Fully threaded | 4.93 | 4.20 | 8445 | 15.15 | 11.12 | 1905 |

| Partially threaded | 6.71 | 5.90 | 6988 | 13.53 | 11.64 | 2033 |

| Smooth | 7.05 | 6.33 | 6132 | 10.41 | 11.75 | 2744 |

| Before Etching | After 5 min Etching | Before Etching | After 12 min Etching | Before Etching | After 20 min Etching | ||

|---|---|---|---|---|---|---|---|

| HA Ra | Average T1, T2 (nm) | N/A | N/A | 64, 202 | 67, 462 | 62, 125 | 1001, 997 |

| S. Deviation T1, T2 (nm) | N/A | N/A | 10, 18 | 9, 11 | 13, 6 | 213, 36 | |

| HA Sa | Average T1, T2 (nm) | N/A | N/A | 97, 292 | 129, 636 | 112, 309 | 1207, 1453 |

| S. Deviation T1, T2 (nm) | N/A | N/A | 6, 51 | 21, 97 | 5, 39 | 49, 139 | |

| HA + US Ra | Average T1, T2 (nm) | 81, 70 | 88, 74 | 72, 56 | 760, 150 | 107, 154 | 1436, 1166 |

| S. Deviation T1, T2 (nm) | 32, 9 | 31, 7 | 15, 3 | 158, 19 | 6, 3 | 80, 21 | |

| HA + US Sa | Average T1, T2 (nm) | 233, 277 | 263, 293 | 260, 106 | 1089, 289 | 155, 242 | 1447, 1236 |

| S. Deviation T1, T2 (nm) | 97, 35 | 108, 37 | 29, 5 | 115, 40 | 31, 19 | 247, 153 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Craig, M.; Raval, J.; Tai, B.; Patterson, A.; Hung, W. Effect of Channel Roughness on Micro-Droplet Distribution in Internal Minimum Quantity Lubrication. Dynamics 2022, 2, 336-355. https://doi.org/10.3390/dynamics2040019

Craig M, Raval J, Tai B, Patterson A, Hung W. Effect of Channel Roughness on Micro-Droplet Distribution in Internal Minimum Quantity Lubrication. Dynamics. 2022; 2(4):336-355. https://doi.org/10.3390/dynamics2040019

Chicago/Turabian StyleCraig, Michael, Jay Raval, Bruce Tai, Albert Patterson, and Wayne Hung. 2022. "Effect of Channel Roughness on Micro-Droplet Distribution in Internal Minimum Quantity Lubrication" Dynamics 2, no. 4: 336-355. https://doi.org/10.3390/dynamics2040019

APA StyleCraig, M., Raval, J., Tai, B., Patterson, A., & Hung, W. (2022). Effect of Channel Roughness on Micro-Droplet Distribution in Internal Minimum Quantity Lubrication. Dynamics, 2(4), 336-355. https://doi.org/10.3390/dynamics2040019