1. Introduction

Concerns about supply constraints and environmental effects have emerged, according to the International Energy Agency’s report, which shows a 49% increase in primary energy consumption and a 43% increase in CO

2 emissions over the previous 20 years [

1]. In 2020, the average annual growth rate of emerging economies’ energy consumption in developing countries was predicted to surpass that of developed countries, which is projected to grow at a rate of 1.1% [

2]. People presently consume more energy as economies expand and quality of life increases. In other words, there is a strong correlation between economic growth, energy consumption, and carbon emissions [

3]. This correlation unfolds in various degrees depending on context. For instance, Asian and developing nations are projected to experience potentially more rapid growth trends in the future [

4]. Despite having low energy use and carbon emissions per capita, China’s primary energy requirement increased from 1978 to 2010, reaching 3200 million tons of standard coal equivalent (Mtce), making it the nation with the highest energy consumption and CO

2 emissions in 2009 [

5]. According to a study by Li et al. [

6], China’s total primary energy requirement (PER) will surge to 6200 Mtce by 2050, with fossil fuels accounting for over 70% of emissions. Furthermore, the energy consumption of emerging economies surpassed that of developed nations in Western Europe, North America, Japan, Australia, and New Zealand in 2020 [

2]. This relationship between population growth, economic development, and energy consumption calls into question international efforts to promote efficiency in policy. Globalization, better living standards, and communication networks encourage the lifestyles of developed and developing countries, increasing building efficiencies, the environment, and energy consumption [

7].

Around the world, buildings use a large amount of energy and emit CO

2; in the United States of America (USA) and Europe, this percentage is 39% and 40%, respectively [

8]. As one of the major emitters historically, the building stock made up 24.1% of China’s total energy consumption in 1996; this percentage increased to 27.5% in 2001 and reached 35% by 2020 [

9]. Building energy consumption forecasting is essential for making decisions to optimize energy use, allowing for a thorough assessment of operational and design options while lowering CO

2 emissions and air pollution [

10]. Predicting building energy use is essential to minimize ecological impacts and conserve energy. However, energy prediction is difficult because of several variables that affect actual consumption, such as equipment performance, outside weather, occupant energy behavior, and building envelope characteristics [

11]. The complexity of buildings makes it difficult to predict consumption with precision. These discrepancies between actual and predicted consumption are known as building energy performance gaps (BEPGs).

Performance gaps in buildings are a growing concern in the built environment industry, with significant ramifications. It presents challenges in managing energy demand-and-supply needs in the building sector [

12]. In some cases, it leads to financial “bottlenecks” between service providers and clients [

13]. The presence of BEPGs means that the expected performance does not materialize in the real world and implies limited progress towards addressing the building sector’s contributions to climate change. During building performance simulations, more focus is often given to the energy expended in operating the building (i.e., operational energy) because it characteristically accounts for over 80% of a building’s life cycle energy use [

14]. However, several studies (such as Röck et al. [

15], which is based on an analysis of over 650 building life cycle cases worldwide) conclude that embodied energy and emissions typically increase when operational energy is optimized [

16,

17]. Largely related to the construction materials, embodied energy was observed to rise from approximately 20% of life cycle energy use in inefficient buildings to between 50% and 90% in energy-efficient buildings, globally [

15].

To address BEPGs, many researchers focus on better modeling, engaging accurate data, and improving design and construction practices, amid other avenues [

18]. Other studies also seek to develop strategies to encourage energy-efficient behavior among building occupants. However, a holistic approach to building design is necessary to ensure that the building sector experiences real-world performance improvements. Innovative technologies like bio-fabrication, 3D printing, and self-healing materials can improve energy efficiency and reduce waste. In other words, sustainable materials are essential for reducing energy consumption, and a life cycle assessment of materials is often beneficial for CO

2 emission reduction. Such approaches could also encourage a circular economy. Stronger regulations and standards are also needed to meet higher energy efficiency requirements. This holistic approach provides the opportunity to consider interactions between systems and materials, continuing the much needed research and development in exploring new materials and strategies [

19].

Several studies have evaluated the literature on the BEPG research focus areas. However, a critical analysis of the literature on sustainable building materials is lacking, especially from the perspective of their potential to improve real-world energy performance and mitigate energy-related CO2 emissions in the building sector. Therefore, this paper presents a comprehensive review to address this gap. Specifically, the aim of this paper is to further develop the understanding of energy efficiency in buildings by critically reflecting on the challenge of energy performance gaps and the potential of sustainable materials. This study examines and provides a view of existing research into six bio-waste materials and their reuse in the construction industry. The insights potentially support the development of energy-efficient buildings and facilitate a circular economy.

The remaining sections of the study adopt the following structure:

Section 2 outlines the method implemented in this paper, showing a clear framework.

Section 3 discusses the context of climate change and emissions, explores why the building sector persists as a major contributor by unpacking the challenge of performance gaps, and highlights the critical role of sustainable materials for life cycle energy efficiency.

Section 4 highlights the application of novel bio-waste materials as sustainable substitutes in the building sector and their potential based on research testing.

Section 5 reflects on the challenges and directions for future research, recommending concerted efforts to promote energy efficiency and sustainability.

2. Methods

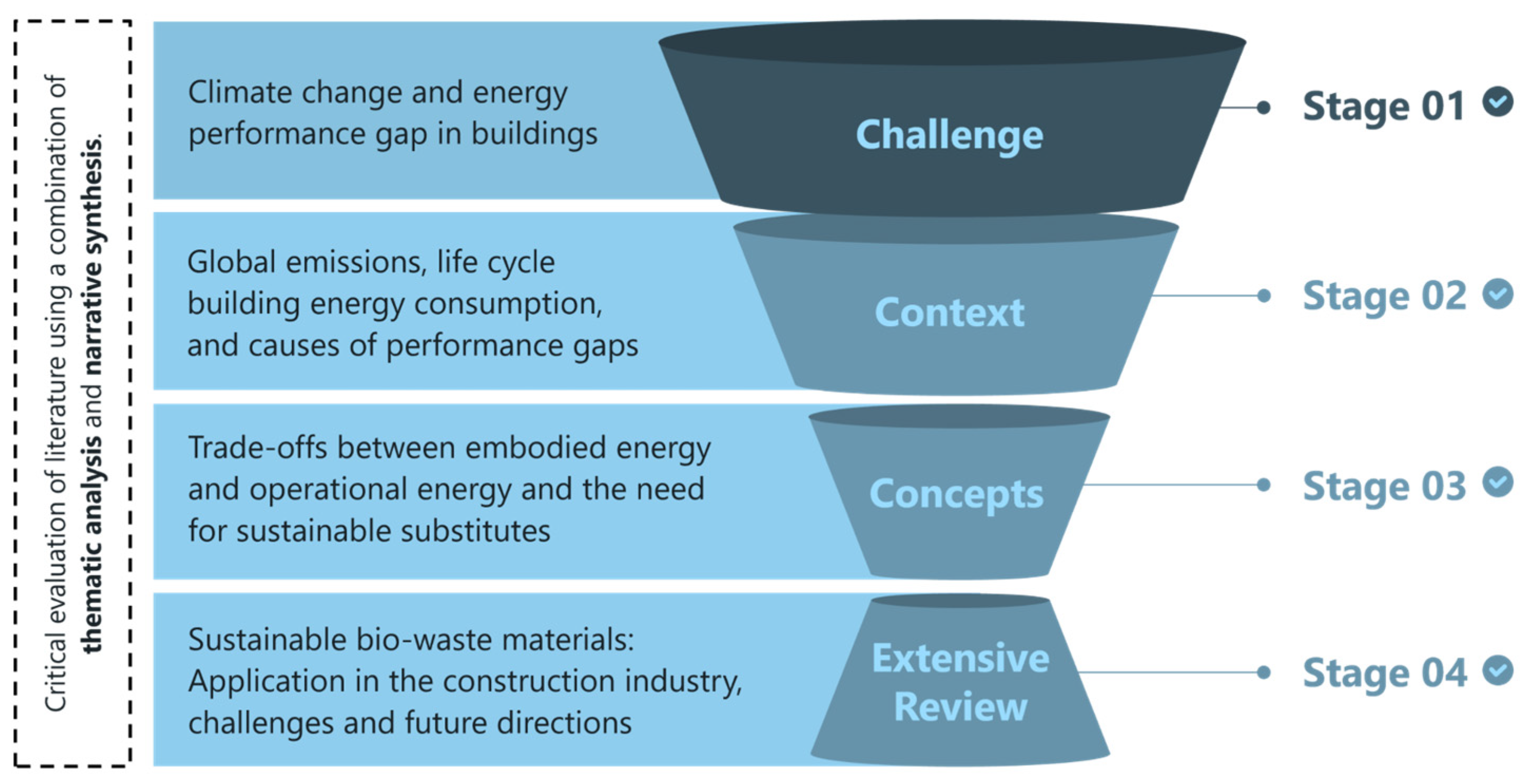

The framework of this study is divided into four stages, as presented in

Figure 1. These include (1) the main high-level challenges, (2) the context within which the study is situated, (3) the concepts which define the paper’s focus, and (4) the focused review of the pertinent literature. All through the different stages, the study implements a combination of thematic analysis and narrative synthesis to structure and review existing research on the relevant subjects. In addition, this framework helps the reader clearly navigate the work.

Two criteria were used to determine the bio-waste materials as follows:

Firstly, the materials needed to originate from industries that generate substantial amounts of waste. This criterion ensures the opportunity for scaling innovation due to the size of these industries.

Secondly, evidence of promising results from testing their application in developing construction materials was required.

Based on these two criteria, specific substitute materials were selected and discussed from the agricultural, food production, and paper manufacturing industries.

3. Climate Change, the Performance Gap, and Prospects for Sustainable Materials

3.1. The Context of Global Emissions Inducing Climate Change

The 2022 report regarding climate change mitigation by the Intergovernmental Panel on Climate Change (IPCC) detailed the present scenario for global emissions. One of the major conclusions was that global cumulative greenhouse gas (GHG) emissions need to peak no later than 2025 if global warming is limited to 1.5 °C by 2100 [

20]. This appears to be a concerning scenario considering that global GHG emissions increased by 12% and CO

2 emissions by 13% within the 2010–2019 period, as further stated by the IPCC report. In addition, the International Energy Agency (IEA) reported that global CO

2 emissions from energy-related activities experienced 6% growth between 2020 and 2021 [

21]. Contributions to GHG emissions vary by region and sectoral distribution. These contributions are examined further by focusing on the top-emitting countries, the link to building energy efficiency, and the challenge of BEPGs.

Table 1 shows the top ten (10) GHG emitters by country distribution while simultaneously reflecting on their respective developmental statuses and the projected 2050 country population. The data presented are an amalgamation of information from leading sources such as the World Bank and the United Nations Framework Convention on Climate Change (UNFCCC). China is observed as the world’s largest emitter, at 12,300,200 Gg CO

2-eq, translating to 28.73%. This is followed by India and the USA, which produce 6.63% and 15.58% of the global GHG emissions. Notably, the top ten (10) countries account for two-thirds of the emissions, at a combined 67.9%. Given the urgency of the timeline as stated by the IPCC and the expected growth in urban population, countries must introduce measures to limit their emissions significantly.

The data presented in

Table 1 indicate overall emissions. In other words, the total GHG emissions represents several contributing sectors, including the built environment [

25]. The IPCC sectoral estimates further showed that buildings have historically accounted for approximately one-third of all GHG emissions worldwide [

26]. For countries to limit emission levels, energy efficiency in buildings has a significant role [

27]. Therefore, the following section unpacks the contribution of building energy consumption to GHG emissions and the adverse impact of performance gaps on efforts to develop an energy-efficient built environment.

3.2. Building Energy Consumption and the Performance Gap Challenge

The challenge of building energy consumption and its contribution to climate change has been extensively researched. In 2009, the United Nations Environment Program (UNEP) argued that buildings account for over 30% of global energy consumption and GHG emissions [

28,

29,

30]. More recent studies also show similar figures. The challenge of direct and indirect emissions by buildings originates from the final energy consumption during the operational phase of buildings (constituted by residential and commercial/non-residential) and sectorial metrics, which include technological energy intensity, carbon intensity, activity, population, and gross domestic product, among others [

8,

29,

31]. Globally, regions have responded differently to rising energy consumption and related emissions in the building sector. For example, nearly 40% of Europe’s energy consumption was attributed to commercial and residential buildings, which prompted the creation of programs such as the Energy Performance Building Directive (EPBD) 2002/91/EC and its update, 36/EC/2010 [

32]. Because of dynamic factors like population growth, improvements in comfort, and human activity, historical data analysis is challenging and has given rise to mathematical models and artificial intelligence techniques [

33].

Building energy consumption is predicted to be significantly impacted by climate change; by 2100, residential cooling demand is forecasted to increase by 72%, while residential heating demand is expected to decrease by 34% globally. Due to population decline and decreased heating intensity, Europe’s heating demand is expected to decline, whereas China’s and the USA’s residential heating demand are expected to rise because of growing populations and housing areas. The rising number of air conditioner owners, especially in developing countries, shows evidence of a warming climate, which leads to an increase in the need for cooling. Passive techniques such as harnessing natural ventilation through openable windows can sometimes be limited in effectiveness by practical concerns such as safety [

34].

Yang et al. [

34] highlighted various specific building energy efficiency themes that have previously been researched. Despite the available literature, three decades of global historic sectoral energy consumption data (1990–2020) show that buildings persist as a significant contributor to rising energy use and emissions [

35]. Furthermore, the 2022 tracking report by the IEA indicates that the global building sector’s energy consumption and emissions will not meet the 2050 net zero efficiency targets [

36]. Therefore, there is an urgent need to increase the development of energy-efficient buildings. To create economical, ecologically sustainable, and energy-efficient (while still offering a comfortable living space) buildings, designers must test and employ holistic design principles [

37].

Built environment professionals use building energy modeling (BEM) to prepare building performance models (BPMs), test design principles, and analyze decisions impacting energy performance [

38]. Thus, evaluating building energy performance during the design process is a growing practice in the architecture, engineering, and construction (AEC) industry. Building energy use can be simulated at the individual building scale or the building stock level. It can include thousands of buildings characterizing a district, regional, or country scale [

39]. The energy performance analysis of a singular building (i.e., BEM) and the building stock (i.e., urban building energy modeling (UBEM)) serve different functions [

40]. This potential to optimize operational energy use in buildings at predefined building conditions provides opportunities for built environment professionals to help limit energy consumption and emission levels [

41,

42]. However, there are often discrepancies between the design-based estimates using the BPM and the measured energy performance of the occupied buildings [

43,

44,

45]. These performance discrepancies are called building energy performance gaps (BEPGs) and can exist at both the building and urban scale [

46,

47]. The ideas in this paper focus on addressing performance gap at the building scale because BEM accounts for individual building characteristics, while UBEM typically relies on building archetypes [

40].

The presence of performance gaps implies that the expected energy efficiency in the built environment does not materialize in the real world. This poses a significant challenge considering that the extent of BEPGs can be substantial in many cases. For example, Bordass et al. [

48] observed an increase of 100% or more in the reported energy use over the design estimations of several commercial buildings in the United Kingdom (UK). The Carbon Trust [

49] reported average performance variations of approximately 16% in case study buildings and nearly 400% in a specific case study building. Fowlie et al. [

50] observed that the estimated savings were over 200% greater than the measured energy savings. Considering the urgent need for energy-efficient buildings addressing increasing CO

2 and GHG emissions and the IPCC targets, the variations in building energy performance imply a significant hurdle to global sustainability. This hurdle is present in developed countries like the UK (as the previously cited examples show) but more so in developing regions, which often have less energy performance regulations and industry coordination [

51]. As mentioned earlier, the term BEPGs describes the discrepancy between the actual energy consumption of a building during its operational phase and its predicted energy consumption [

52,

53]. However, researchers have asserted that this definition is not sufficiently comprehensive and that numerous classifications exist [

54]. To develop a more thorough understanding of BEPGs, discussing BEPG definitions in greater depth is necessary.

The study by Zou et al. [

12] described two main performance gaps in energy simulations. The first refers to the variation between the specified targets for a simulation exercise and the actual energy performance. The second type refers to the variation between the requirements of regulatory standards and actual energy performance. Studies by Burman [

55] and de Wilde [

54] detected and mentioned similar energy performance gap types. In this description by Zou et al. [

12], the first performance gap classification is often more extensive than the second, as regulatory standards usually specify minimum performance requirements [

56]. At the same time, targets tend to be much higher. Comparably, de Wilde [

54] categorized BEPGs into three distinctive categories. Firstly, the variations between predictions based on first-principal modeling and the measured data on actual buildings. Secondly, there are variations between ML methods and measured data on actual buildings. The third category refers to the variations between the energy ratings issued after evaluation using compliance test methods and the energy display certifications. The third study implored to describe BEPGs was carried out by van Dronkelaar et al. [

57].

The three categories into which the authors divided the performance gaps are the dynamic, regulatory, and static performance gaps. A significant difference with this categorization is the dynamic performance gap, which refers to the gap between calibrated simulation results and measured energy consumption data from successive years when the building is in operation. Gap 1, Category 1, and the static performance gap are similar when the different groupings in the three studies are compared. These classifications denote the largest and most significant gap [

58]. Furthermore, the definitions by different authors highlight the complexities of BEPGs. Several factors contribute to the variations in the energy consumption profile of buildings. The following section furthers the discussion by unpacking specific causes.

3.3. Identifying the Causes of BEPGs

Numerous authors have identified varying reasons for BEPGs and have categorized the causes using different classification systems. Notably, the life cycle of a building is a metric that is widely used to categorize, measure, and understand building energy use [

59,

60,

61]. Furthermore, it also provides a framework for simulating and analyzing building energy performance [

62]. Therefore, this makes the building life cycle one of the most relevant classifications for understanding the root causes of BEPGs, as demonstrated by Zou et al. [

12]. The three phases include the design phase, the construction phase, and the operation phase. Many studies, such as this one, provide extensive reviews of the causes of discrepancies associated with the different stages of a building’s life cycle.

Table 2 includes several causes of BEPGs, as discussed by various authors, to present a summary. Some causes are recurring across varied studies, suggesting their prominence in the BEPG research discussion. These include occupant behavior, difficulty managing building information due to design variations and complexities, and modelers’ ability (or inability) to implement accurate assumptions while accounting for uncertainties. Other studies that provide further compelling studies of the causes of BEPGs include [

47,

63,

64].

It is well established that the opportunity to optimize building performance is highest and at the least resource cost during the design phase by implementing better design choices [

66,

67]. These design choices especially include the materials selected for the building envelope. Building envelope design affects the extent of energy used for providing optimum indoor conditions, which will ultimately influence the building sector’s CO

2 and GHG energy-related emission levels. Cutting energy loads by 30–70% is possible with advanced or appropriate building envelope design, which helps with equipment downsizing and lowers energy consumption [

68]. However, the conventional approach to appropriate building envelope design typically includes using more materials (e.g., using more insulation, increasing wall thickness, and varying the type and layers of glazing, to state a few) [

69]. This conventional approach amplifies concerns around the embodied energy of buildings and necessitates an investigation into alternative sustainable materials.

3.4. Sustainable Materials: Implications for Energy-Efficient Buildings

A major challenge with improving the building envelope is the corresponding rise in the embodied energy due to increased material use. The embodied energy related to building materials (i.e., the energy expended in manufacturing and transporting construction materials to the building site) often increases as operational energy is reduced [

16,

17,

70]. Therefore, it is important to adopt a holistic view of life cycle energy efficiency and material selection to decarbonize the construction sector as the largest emitter [

71]. The ISO-EN-UNE-14.040 regulation defines the life cycle of a product system as the series of steps from acquiring raw materials to the product’s ultimate disposal. A life cycle assessment (LCA) over the lifespan of a material, product, or system creates the opportunity to evaluate its possible environmental effects. It considers the building’s lifespan, reuse, demolition, and the potential for material or energy reuse [

72]. This view can also include the following considerations based on [

73,

74,

75,

76,

77]:

Limited adverse environmental impacts;

Reusability and recyclability of the materials;

Less need for the maintenance, repair, and replacement of materials;

Limited contribution to pollution and construction waste;

Durability and longevity of performance.

Using sustainable alternative materials could potentially aid in resolving embodied and operational energy consumption simultaneously across a building’s life cycle. It also helps to holistically address the built environment’s contribution to climate change.

This section emphasized the importance of addressing energy efficiency and the building’s significant role in global energy use. It highlighted the causes and implications of performance gaps for sustainability and energy efficiency, showing the necessity of sustainable materials. Reducing BEPGs, enhancing building design, and using sustainable alternative materials creates a nexus for novel measures which could be introduced in the built environment to achieve real-world energy efficiency. Following these insights, the next section explores various alternatives focusing on the opportunities provided by bio-waste materials.

4. Sustainable Bio-Waste Materials for Effective Building Energy Performance

The application of novel materials like bio-waste as sustainable substitutes in the building sector is examined in this section, emphasizing how they might increase life cycle energy efficiency and foster sustainability. Six substitutes which researchers are testing are explored. These include mycelium extracts from mushrooms, microalgae, straw bales, wood waste, food waste, and paper pulp. Various applications are reviewed to present their potential in construction. Limitations and challenges are also discussed.

Utilizing bio-waste materials in buildings can help to promote a circular economy, reduce emissions in the atmosphere through carbon sequestration, and address sustainability issues. They provide unique qualities that enhance energy efficiency, such as natural insulation and thermal regulation. Bio-waste materials are also more affordable to source than conventional materials, which makes them a desirable choice for sustainable architecture. Improving biowaste materials’ durability, performance consistency, and market acceptance encapsulates the need for further development to realize their full potential. Integrating bio-waste materials into building designs for sustainable and energy-efficient structures contributes to the study’s objectives of ensuring real-world and holistic building performance.

4.1. Mushroom-Powered Buildings

Mushrooms are frequently utilized in cuisine, medicine, and cosmetics. According to research, mycelium extract from mushrooms may have therapeutic and nutritional advantages that support sustainable environmental practices and healthier lifestyles. The most widely used fungal strain for mycelium composites is G. lucidum, where growth kinetics, cell wall composition, and hyphal architecture are all influenced by both intrinsic and extrinsic factors. Basidiomycetes that break down lignin, such as P. ostreatus and G. lucidum, can quickly colonize and grow on cellulose, hemicelluloses, and lignin substrates. Mycelium composites—made from the micelles of a fungus—are becoming increasingly popular in the bio-building industry because of their low-energy bio-fabrication method. These materials can replace more conventional materials found in door cores, insulation, paneling, cabinets, flooring, and furnishings such as foams, wood, and plastics. Durability, strength, fire resistance, acoustic absorption, and low thermal conductivity are some of their best qualities. Their high water absorption capacity and foam-like mechanical characteristics, however, are limitations [

78].

Examples of non-structural applications of mycelium composites instead of conventional building materials are the Hy-Fi organic mushroom brick tower, The Growing Pavilion, and the MycoTree Project in South Korea [

79]. With a density ranging from 0.10 to 0.39 g/cm

3, mycelium composite materials are less dense than other wood composites. By incorporating natural or synthetic rubbers, hybridization enhances mechanical performance. The compressive strength of ostreatus fungi can be doubled to 343 kPa using styrene–butadiene rubber. High-performance natural insulators like hemp and straw fibers can be added to improve its thermal insulation. Pleurotus ostreatus was grown in rye berry feedstocks to create a novel mycelium-composite insulation brick. When the humidity is low, the composites’ mechanical qualities are better. In contrast, their flexural strength is reduced when the humidity is high. Mycelium-composite insulation is a promising sustainable building insulation material because, according to EnergyPlus analyses, it lowers annual heating and cooling energies and indoor temperature fluctuations [

78].

A novel composite material based on mycelium and wood veneer has been created as a sustainable and environmentally friendly substitute for conventional building materials. Prototype structural testing revealed that composite bending resistance was enhanced by compressing with pressure and heat and integrating a veneer lattice with a topological design. Although the results from a single low-density veneer layer were encouraging, samples with two lattices experienced shear failure [

80]. Fungal mycelium cultivated on agricultural waste streams can be used to create sustainable building materials. These bio-composites may lower energy use and emissions during their useful lives because they are lightweight and highly insulating. A thorough life cycle analysis showed that compared to typical building materials, there was a 1.5–6-fold decrease in embodied energy and embodied carbon. Of the total energy used to produce mycelium bio-composites, 73% came from the incubation stage and 21% came from metabolic CO

2. This shows that materials made of bio-composites may provide a sustainable substitute for existing methods [

81].

Buildings using mycelium composites have better energy performance but have mixed financial results. Since they are novel materials, their higher initial costs could result in higher wall and insulation material costs. Limited supply could lead to more expensive labor, and transportation could raise short-term labor costs. Because mycelium is lightweight with insulating qualities, it can simplify construction, cut labor costs, and save material costs. In comparison to traditional materials, it can also speed up construction due to its rapid growth in molds. Long-term cost comparisons are challenging due to the need for additional data regarding the durability and upkeep of mycelium composites in buildings. Despite the potential higher initial costs when using mycelium composites in construction, advantages like insulation and quicker construction might offset these costs in the future. In packaging, fashion, and architecture, mycelium-bound composite materials offer a cost-effective and environmentally friendly substitute for conventional synthetic materials. However, because of their poor mechanical qualities, high water absorption, and a lack of standardized production techniques, their use in the construction industry may be restricted, hence the need for further research. The potential of mycelium-bound composites as a substitute for drywall and tiles, as well as for thermal and acoustic insulation could also be explored further [

82].

Mycelium composites have several benefits for the energy efficiency of sustainable buildings. In addition to being lightweight, fireproof, bio-degradable, quickly renewable, and able to be grown on-site, they also offer thermal insulation and lower transportation-related emissions. At the end of their lives, they can be composted, treated with fire retardants, and quickly renewed using agricultural waste. Ongoing research aims to enhance their innate fire safety characteristics. Because of their lack of fire safety regulations, the cost, availability, structural strength, and water resistance, mycelium composites may have some limitations regarding their uptake in sustainable building construction. Though there is a lack of long-term performance data on energy efficiency and durability in real-world building applications, research is still being carried out to improve their mechanical properties. The costs of production could go down as technology advances [

83,

84,

85,

86].

4.2. MicroAlgae-Powered Buildings

Energy use intensity (EUI), which divides the total yearly energy use by total floor area, is a crucial metric for assessing the energy efficiency of buildings. Space heating, cooling, lighting, water heating, and ventilation are some factors that impact energy consumption. Energy loss can result from inefficient HVAC systems and poor building envelope construction. Building geometry, the energy properties of windows and opaque walls, and microclimate control are additional factors. Along with other factors, building enclosures impact indoor air quality. Effective energy use, waste and pollution control, and the preservation of air, water, and lighting quality are all necessary for energy management [

87]. A quicker financial payback period can result from operational energy savings when climate-responsive design strategies are combined with energy-efficient active systems.

Microalgae are photosynthetic microorganisms that use light energy to transform carbon dioxide and water into organic compounds and oxygen. Being the most ancient inhabitants of our planet, they play a crucial part in constructing our atmosphere. Their quick growth rate and high nutritional value allow them to be grown for various uses in the food, pharmaceutical, bio-energy, and cosmetics industries [

88]. Their biomass productivity and biochemical composition can be influenced by multiple factors, including but not limited to cultivation systems, algal species, environmental conditions, and algae–bacteria interaction. Since microalgae have a large capacity to sequester CO

2, they are called carbon mitigators. They can bio-remediate anthropogenic pollutants, such as by decontaminating soil, treating wastewater, and decarbonizing the atmosphere. Although open cultivation systems are less expensive to set up and maintain, they are more vulnerable to environmental factors and contamination [

89].

Algae-powered buildings are considered more sustainable. However, they come with hefty upfront costs because they require specialized installation, cutting-edge technology, and changes to the building’s design. Algae facades have the potential to qualify for carbon credits, lower energy consumption, and improve air quality. However, the building performance and technological maturity are still unknown, and more data are needed for practical applications to meet long-term energy savings and maintenance requirements. According to Sedighi et al. [

89], by 2050, it is predicted that the world’s urban population will have doubled, necessitating twice as much building space. Algae are a potential option for sustainable architectural materials because of their ability to store carbon dioxide and generate clean energy [

90]. Algal cells find applications in indoor air conditioning systems, solar thermal collectors, lighting, and shading.

Algal photobioreactors are not yet covered by green building regulations. Therefore, biologists, civil engineers, and architects must work closely together to produce more environmentally friendly, sustainable algae-based architecture. Ahmad et al. [

91] stated that cities account for 75 percent of carbon emissions and 60–80% of the world’s energy consumption. At the same time, urbanization and the depletion of non-renewable resources contribute significantly to environmental harm. Although renewable energy sources, such as wind and solar power, are vital, there are problems with pollution and cost. Algal biomass can absorb greenhouse gasses like CO

2 and act as a potential green energy source. Green cities can benefit from microalgal bio-reactive façades that reduce their adverse environmental effects [

91]. Reducing GHG emissions from buildings could substantially mitigate global warming because buildings account for approximately 40% of total emissions.

Given that the global temperature is expected to rise by three degrees Celsius by 2100, buildings can be constructed and retrofitted using cutting-edge technologies that incorporate on-site energy generation and minimize energy consumption. Over time, technological advancements like bio-energy and solar energy will become profitable and productive. When algae was used as a renewable energy source in a residential building in Hamburg, Germany, constructed in 2013, concerns were raised regarding the technology’s production, viability, and appropriateness for different buildings [

92]. To retrofit urban built environments, the costs and advantages of solar PV panels and closed photobioreactor (PBR) systems were compared by Biloria et al. [

93]. It was discovered that closed PBR systems have an annual return value of 24 years, whereas solar panels require 16 years for short-term financial compensation. On the other hand, the closed PBR system provides longer-term advantages like oxygen production, wastewater treatment, and carbon sequestration.

According to the research, incorporating algae building technologies into the built environment can result in sustainable structures and provide feedstock for the food, cosmetics, health, and biofuel industries. The construction industry seeks to create energy-efficient and sustainable buildings. The capacity for passive energy conservation, shading, thermal insulation, and thermal energy storage increases when PBRs are integrated with external façades. Microalgae on building facades and its energy efficiency potential require further research. Future studies could examine environmental performance, daylighting, lighting, affordability, technical suitability, and esthetics [

93]. Biloria et al. [

93] further mentioned that esthetics, temperature control, enhanced air quality, energy generation, carbon sequestration, and sound absorption are some benefits of using algae to power buildings. Algae can produce electricity or biofuels through photosynthesis, which lessens the need for conventional energy sources. Additionally, they absorb carbon dioxide, which lowers pollution and enhances both indoor and outdoor air quality.

Algae growth is dynamic and colorful, which could result in visually appealing facades. Due to their low energy efficiency, high maintenance needs, water consumption, reliance on the climate, technical difficulties, and restricted construction applications, algae-powered buildings might be unable to power an entire building. Existing systems might increase a building’s energy requirements, needing constant upkeep and observation, and may not be appropriate for all kinds of buildings or climates. Nonetheless, this is subject for more investigation.

4.3. Straw Bale-Powered Buildings

Nebraska saw the construction of its first straw house circa 1890 because of its sandy soil and lack of wood. Straw was packed by a machine that produced “big bricks” with staggered joints—a construction method referred to as the Nebraska style or loadbearing style. In France, straw construction also debuted with the 1920 completion of the Maison Feuillette in Montargis. In 1970, Barbara Jones improved building methods in England by switching out steel for wooden structures, applying plaster made of lime or clay, and adjusting to the local climate. Self-construction was used in the 2004 construction of a straw house in Italy. Around 180 straw houses have been constructed in Italy since the early 2000s because of the growing popularity of these homes.

Compared to countries in Northern Europe, straw construction is more suited to Italy’s Mediterranean climate. The 2008–2010 “Technical Standards for Construction” could be the reason for the lack of widescale straw use in Italy—they prohibit the self-supporting bale method. Only the energy performance requirements need to be verified; no procedures are required for building or retrofitting straw houses. Compressed straw bales resemble big bricks and are investigated as a potential building material for intricate construction systems that can be used in developing nations. Expert designers and thorough planning are needed for straw construction. In developed countries with affluent economies, like Europe, straw buildings and their thermal properties with those of standard materials should be investigated. Straw construction offers several technical possibilities and is not linked to a specific esthetic typology [

94,

95].

Straw bales, plaster, and other materials are used in the construction system to transfer loads from horizontal elements and roofs to foundations, offering thermal insulation and structural support. Although this approach is less expensive, it has drawbacks for building sites and a lower wall-bearing capacity. Straw bales are used in in-fill as an insulating filler between supporting structures, while other materials are used to fill cavities. Straw, wood, and plaster are used in mixed systems as the final layer. The selection of an appropriate technological system is influenced by economic, cultural, and technical aspects. On the other hand, self-builders in nations with less stringent regulations or areas of great value have created load-bearing structures. The utilization of controlled methods that offer security and design flexibility has led to the rise in popularity of in-fill construction. Associations in Germany and France have released in-fill guidelines that include details on the characteristics of straw and how it interacts with wall, roofing, and in-fill systems. Furthermore, straw construction is being promoted internationally as an environmentally friendly and creative technique [

96].

There are two ways water impacts straw construction that are key for this discussion. Firstly, water greatly impacts how long straw construction lasts because too much humidity can physically and chemically change the material. Secondly, because straw does not readily absorb moisture into its inner layers like other hygroscopic materials, it reduces humidity problems. However, it is necessary to avoid overexposure to high humidity levels after construction to prevent possible condensation that can lead to decomposition. Ultimately, the structure’s longevity will be influenced by its raw material quality, how it is stored, how it is installed, and the construction processes. It is also noteworthy to state that hay is not the same as straw; hay is grass mowed for animals.

In straw buildings, good performance is not guaranteed by straw quality alone. The thermo-hygrometric and energy-saving performance of construction systems depends on the supervision of straw bale supply and system implementation. Building features such as roof overhangs can effectively restrict the direct exposure of straw bale walls to water loads. In addition to the insulation properties of straw bale walls, the raw material can achieve high levels of thermal resistance and sound insulation. Straw is a renewable and sustainable building material with low embodied energy that is also affordable. It can effectively reduce heating and cooling loads, making it an economical and environmentally sound alternative to conventional walling systems. The significant challenges of straw bale construction include its susceptibility to moisture, insect infestation, specificity of construction methods, the need for skilled craft persons with the necessary expert knowledge, and restrictive building codes [

97]. Straw use can be encouraged by formalizing its use in building regulations and building codes, for example, as part of the Integrated National Energy and Climate Plan.

Research results indicate that straw buildings perform well thermally, with high time shifts and low thermal transmittance. Moreover, it has the potential to be zero energy. Marques et al. [

95] studied the performance of walls constructed from 80 to 100 kg/m

3 of straw bales. The study evaluates their acoustic and hygrothermal qualities, including biological resistance, hygroscopic sorption qualities, and specific heat capacity. The findings raise the construction industry’s confidence in the safe application of non-conventional building solutions by demonstrating that rice straw bales can be used to construct sustainable, high-performance walls. Koh et al. [

94] stated that because straw bale constructions can be both load-bearing and offer thermal insulation, they present a viable option for the building industry’s decarbonization. The performance, LCA, and material properties are reviewed in this study. Recent research confirmed the ability of straw bales to insulate against heat and their potential for low-emission buildings. However, the inconsistent portrayal of material attributes still leads to debate. By 2050, the global population is expected to reach approximately 9.8 billion, which raises concerns about the unsustainable exploitation of non-renewable resources. The use of straw bale and other alternative building materials such as bamboo and rammed earth can lessen their negative effects on the environment.

4.4. Wood Waste-Powered Buildings

Researchers have successfully produced concrete from agricultural residues such as corn cob ash, sugar cane bagasse, palm oil ash, and rice husk ash. Since wood waste ashes improve workability, porosity, and drying shrinkage, they have emerged as a viable substitute for kaolin and binders in the fractional form of geopolymer formation. On the other hand, using forest biomass ashes can reduce the need for alkaline activators by up to 20% without sacrificing their qualities. Various process variables can affect the final product’s properties, including the kind of curing, humidity control, temperature, alkaline activator concentration and proportions, raw material type and quantity, and starting material proportions. The mechanical compressive strength is positively impacted by the increases in SiO

2/Al

2O

3 ratios [

97].

In recent years, over four billion tons of cement is consumed annually across global construction activities [

98]. Since the population is expected to grow by 24.74% by 2050, this will increase demand for building supplies like cement. Creating substitute materials can help achieve the goals of the 2030 Agenda for Sustainable Development by lowering related costs and emissions. Burning wood produces wood waste, which also has an adverse effect on the environment. Furthermore, due to its fine size, it can pollute the air, putting both humans and animals at risk for respiratory issues. Its varied chemical structure and slow delivery rates can also pollute land, requiring further research. Wood waste recycling may be an effective solution in forestry or agricultural systems, but it has difficulties in complex systems.

Furthermore, wood waste can alter the pH of the topsoil, which would be detrimental to crop or tree nutrition. Slow pH transfer from the topsoil to bottom soil occurs over time because of wood waste land dumping. Because potassium, magnesium, calcium oxide, and phosphorus have different solubilities, wood waste’s pH impacts the soil’s level of nutrition. The concentration of organic matter, hydrous oxide, and pH all affect the amount of heavy metal contamination in soil. Metals are exposed to a lower pH than ash when wood waste dissolves in acidic environments, which increases their solubility. Because wood from wood preservers and demolitions has lower volatilization temperatures, the concentrations of heavy metals are higher. Increased calcium and potassium concentrations in soils and groundwaters are observed in soil water leachate, along with some magnesium and aluminum movement. Considering the CO

2 emissions and the depletion of natural aggregates resulting from urbanization and as construction-induced cement and aggregate demand increase, wood waste ash (WWA) could act as a substitute material. Nonetheless, its production leads to pollution while requiring ample space. Tamanna et al. [

97] examined the application of WWA in building, its trends in development, and its impact on eco-concreting applications. In addition to addressing environmental concerns and strategies to lessen hazardous impacts, they emphasize the advantages of WWA for sustainable development and zero-waste technology. Yadav et al. [

99] conveyed that bio-based building materials are energy-efficient, socially responsible, and sustainable. They use less energy to operate, offer thermal comfort, and lower carbon and energy emissions. Their study investigates the benefits, opportunities, and difficulties associated with using bio-based WWA building materials.

Ince et al. [

100] investigated the environmentally friendly use of waste wood materials in cement mortars as a substitute for conventional disposal methods. It shows that although wood powders can replace sand in construction projects, their physical characteristics and strength make them suitable for structural applications in civil engineering. In addition to saving resources and reducing CO

2 emissions from producing raw materials, their paper presents a more environmentally friendly option for recycling industrial waste. WWA is lightweight, inexpensive, and made of renewable materials. Its insulation properties can reduce environmental impacts while increasing the life cycle energy performance of buildings. The production of acoustic panels, structural elements, and insulation panels can also help create a circular economy by lowering the need for virgin wood. Additionally, wood waste provides versatility in a building [

101].

4.5. Food Waste-Powered Buildings

Unused, thrown away, or lost produce from the food supply chain’s four phases is food waste (FW). Each year, approximately 1.3–1.6 billion metric tons of food waste is produced, costing the global economy USD 750 billion [

102]. Significant losses of valuable materials, especially from FW, a possible feedstock for the bio-production of high-value chemicals, lead to economic and environmental management problems. The nutrients found in FW, such as proteins, lipids, and starch, make it a desirable material for microbial fermentation. This potential is unlocked by conversion processes, which produce various commodity chemicals.

Sustainable development goals are aligned with the use of renewable carbon by the bio-refinery. The bioconversion of food waste (FW) into chemicals with commercial significance presents challenges. It is possible to extract, concentrate, and convert functionalized molecules. Succinic acid, a top platform chemical fabricated from biomass, synthesizes gamma-butyrolactone, tetrahydrofuran, and 1,4-butanediol. Actinobacillus succinogenes was utilized by researchers Zheng et al. [

101] and Leung et al. [

103] to produce microbiological succinic acid from bakery wastes such as cake, pastries, and bread. A hydrolysate rich in sugars and amino nitrogen was produced when fungal enzymes broke down proteins and starch into glucose and amino acids. After processing the hydrolysate, succinic acid crystals with a purity level of 96–98% were obtained. The food chain creates a lot of waste and byproducts, which makes disposal and waste management difficult.

Despite the European Union (EU) recommendations, waste is frequently sent to disposal facilities without improvement or expense. Waste biomass can be pyrolyzed to produce chemical energy, and the solid byproduct, biochar, has potential uses in the field of concrete technology. Studies have demonstrated that cement mortars containing FW nanoparticles exhibit greater compressive and flexural strengths in comparison to standard mortars. By using a sealed reactor for the pyrolysis of hazelnut shells, an inert atmosphere with constant nitrogen flow was guaranteed. Hazelnut shells were first pyrolyzed, and then attrition milled for an hour. The resulting char had a low impurity content and a high carbon content. The material’s potential as an inert material in a cementitious matrix was evaluated using an X-ray fluorescence (XRF) analysis [

104]. The results showed that it is a suitable replacement for conventional materials used in concrete production.

AGROTESs panel prototypes are considered appropriate for the thermal insulation of vertical building envelopes because of their stiff structure, high density, and positive results from thermal laboratory testing [

105]. These completely biodegradable materials could be utilized for energy retrofitting conventional building systems and demountable dry construction systems made of steel or wood. FW is being investigated for use in traditional vertical envelope technology and dry wooden building walls in new construction and energy retrofitting initiatives. A 2.2 cm natural clay board was used to seal the wall stratigraphy after double plasterboard or plywood panels were used to finish it. This method met environmental requirements and increased the wall’s heat capacity. Every simulated application demonstrated noteworthy dynamic thermal performances and satisfied national standards. AGROTESs performed better in terms of steady-state thermal transmittance [

105].

Furthermore, lactic acid is another essential chemical. Biodegradable plastics such as polylactic acid (PLA) and poly(3-hydroxybutyrate-co-lactate) can be made from it through polymerization. Isomers such as D- and L-lactic acid that are optically pure can be produced by microbial fermentation. In their study, Kwan et al. [

106] demonstrated high lactic acid productivity using a hydrolysate from mixed food and bakery waste. Their analysis shows that environmentally friendly technology facilitates the shift from the existing linear to the circular bio-economy by recycling nutrients from food waste with competitive economic performance.

New research on valorization has made it possible to produce bio-based products in large quantities, but commercialization will require more work. Mwandira et al. [

107] stated that bio-cement is made of renewable, eco-friendly microorganisms and is a sustainable substitute for traditional building materials. Nevertheless, its implementation is hampered by the high cost of raw materials. This chapter examines and argues for the cost- and efficiency-saving use of food waste in bio-cementation. It examines various possible raw materials and reviews the literature on the application of food waste in bio-cement technology. Utilizing FW in the building sector reduces landfill waste and methane emissions, encourages waste diversion and sustainability, and can be processed through anaerobic digestion to produce renewable energy [

103,

105,

106,

108]. More studies and development are needed for large-scale implementation, and efficiency depends on a consistent feedstock. Permit requirements and regulations may also differ depending on the location.

4.6. Paper Pulp-Powered Buildings

The manufacturing process of paper places increasing demand on natural resources. While the paper industry contributes to economic growth, it does show an increasing adverse impact on environmental sustainability. For instance, Taiwan’s pulp and paper sector is a significant consumer of fossil fuels, contributing to 3.9% of the nation’s GDP. As a result, both vehicle emissions and GHG emissions from manufacturing have increased [

109]. Furthermore, significant amounts of waste are generated in the paper manufacturing process which often are disposed of in landfills, contributing to pollution [

110,

111]. The pulp and paper industry, whose yearly production is predicted to rise from 365 million tons in 2006 to 700 million tons in 2050, significantly contributes to direct CO

2 emissions and global energy consumption. The potential for energy conservation can be found by analyzing the supply, distribution, conversion, and end-use energy consumption flows [

112]. However, identifying opportunities to repurpose waste material from the paper pulp industry into the building sector could enhance the circular economy and facilitate improved life cycle energy performance.

The waste generated during paper production primarily takes the form of dregs, grits, and lime mud. Numerous researchers are testing different avenues for application in the building sector. In Brazil, Mymrin et al. [

113] incorporated these paper and pulp waste as critical elements in developing bricks and other construction materials. Systematic testing revealed that the newly developed materials demonstrated excellent compressive strength and water resistance. The authors emphasized that the new materials could act as construction alternatives while maintaining profitability and advancing sustainability. Further work has been carried out by Saeli et al. [

114] on testing calcareous sludge, which is a waste product generated during paper pulp manufacturing, as an alternative green geopolymeric binder. The outcome showed improved mechanical performance of the binding material. The recycling and repurposing of calcareous sludge further serves to enhance sustainability. The study by Lee et al. [

115] highlighted the possibility of recycling waste from the paper and pulp industry, specifically silica aerogel and cellulose-based fibers, into insulation materials. Using 3D printing mechanisms, they developed an insulation material with superior thermal and hydrophobic properties. While this approach offers an opportunity to develop eco-friendly building envelopes, practical implementation may need to consider accessibility to the technology and the possibility for scaling adoption. The building type is also a critical context which requires consideration. A study in the UK similarly concluded that the application of cellulose-based insulation from recycled paper and pulp is plausible and is more suitable for residential buildings. However, it can be applied in commercial and industrial buildings [

116].

A recent study evaluated the paper and pulp global industry landscape to develop nation-specific plans for aligning the industry with achieving net zero by 2050 [

117]. Essentially, it is important to view sustainability and energy efficiency in the built environment holistically. This could help in identifying points of multiple benefits across industries which could initially appear to be mutually independent. Recycling waste paper and pulp for construction materials reduces the energy required to develop buildings using conventional material options while reducing landfills and waste.

Ultimately, enhancing the energy efficiency of buildings can be facilitated using sustainable biowaste materials. Better airtightness, lower embodied energy, lighter construction, improved insulation, recyclability, and biodegradability are among the benefits they provide. These materials support a circular economy through their natural decomposition, landfill and waste reduction, and lower emissions. Furthermore, by absorbing heat, sustainable materials could lessen the impact of the urban heat island effect when used creatively and possibly lower the energy required in buildings [

118].

5. Challenges, Future Directions, and Research Gaps

There are several energy efficiency and sustainability challenges in both new and existing buildings. Knowledge tools, development and evaluation challenges, and environmental, economic, and social impacts are the three categories of these challenges. A lack of awareness, comprehension, experience, information, studies, and findings or evidence are some problems with knowledge tools. Energy-insensitive activities, climate-inefficient architectural design, and the slow integration of the benefits of clean technologies also pose challenges.

The development and evaluation challenges are divided into the lack of parameters, systems, models, and methods. Challenges to social, economic, and environmental impacts are based on lowering energy inefficiencies, optimizing energy consumption, and reducing carbon pollution and the improper use of natural resources. Furthermore, difficulties with building energy efficiency include low satisfaction with the indoor comfort index, energy-oblivious activities, and poor maintenance. Indoor environment quality and occupant behavior are influenced by various factors such as building features, maintenance protocols, and tenant equipment.

Building energy performance research also needs to acknowledge the unique issues facing the different building sectors. For instance, the residential sector faces several challenges, including financial difficulties, limitations on achieving high performance, and dynamics in leasing to tenants. Energy and operational costs in relation to environmental concerns are some main drivers behind adopting sustainable building practices in this sector. In addition, academic buildings have limited financial incentives to reduce their energy use. There are also obstacles to becoming a certified green building, such as perceived increased building costs and information gaps. Green buildings represent the high-performance sector of the building stock and often incorporate advanced building envelope design. Furthermore, there is a global push towards growing the green building sector [

83,

84] due to the perceived benefits of improved energy and climate performance. Advances in construction materials potentially help to optimize the energy performance and related carbon emissions of green buildings [

119]. Further research could test sustainable alternatives in the context of green buildings.

The Mediterranean region especially presents challenges for facility managers because of shifting building types, a diverse range of occupants, and different sustainable building practices. In tropical regions, refurbishing pre-existing structures is difficult and expensive. Operating old buildings also becomes unfeasible due to high energy consumption and cost overruns.

The development of an energy-artificial intelligent facility management system, a comparison of energy model predictions, and the application of passive building technologies are just a few of the strategies to increase energy efficiencies. Upgrading green building rating systems, modifying older residential villas, examining energy-saving strategies, employing renewable energy sources, choosing energy-efficient technologies for high-performance buildings, and examining government initiatives can also be beneficial.

The development of sustainable building materials is revolutionizing energy-efficient construction. Employing recycled materials for precise on-site construction and 3D printing could be explored to lower waste and operational expenses. The use of bacteria or healing agents in self-healing materials has the potential to reduce maintenance costs and increase building lifespans. At the same time, 3D printed construction minimizes waste and lowers transportation costs. These innovative trends are advancing the future of building materials.

Future research goals include investigating multifunctional materials, creating high-performance bio-based composites, and incorporating LCA into the design process and its development. To maximize performance, sophisticated digital design and modeling techniques can be applied. Sustainable and scalable manufacturing techniques could be created with waste minimization, water conservation, and energy efficiency in mind. Investigating methods for biomanufacturing and 3D printing could be implemented at scale. Adoption and policy issues include certification and standardization, incentives, and outreach regarding the advantages of sustainable materials.

Essential techniques for developing sustainable materials include biomimicry, material recycling and reuse, and life cycle cost analysis. These techniques highlight the long-term financial advantages of sustainable materials, such as upkeep, energy savings, and reuse potential. In addition to investigating mycelium-based materials for sustainable building, fire resistance, and soundproofing, researchers are creating advanced insulation materials such as plant-derived aerogels and bio-based panels. Research gaps are identified in developing the next sustainable material for energy-efficient buildings concerning life cycle considerations, including integration with current systems, long-term performance data, and material performance. It is critical to balance performance and sustainability, assess long-term energy efficiency, and ensure that existing systems are fully operational. To address the lack of industry expertise and promote the market acceptance of new materials, research is required to create cost-effective production methods, raise awareness within the construction industry, and establish clear standards and certifications for new materials.

6. Conclusions

This paper aimed to provide an analysis of the literature on sustainable building materials. It reviewed their potential to improve real-world energy performance and mitigate energy-related CO2 emissions in the building sector. As the world moves towards net zero energy and emissions, the concepts of embodied energy related to building materials can be expected to play a crucial role in the future of BEPG research. Furthermore, when alternative materials like mycelium extracts, microalgae, straw bales, and waste from wood, food, and paper production are used as substitutes in sustainable building envelope design, it promotes a circular economy. The development of sustainable materials for energy-efficient buildings can be expected to bring a significant transformation to the construction industry. This innovation can reduce adverse environmental impacts while increasing efficiency in the built environment.