A State-of-the-Art Review on Core–Shell Pigments Nanostructure Preparation and Test Methods

Abstract

:1. Introduction

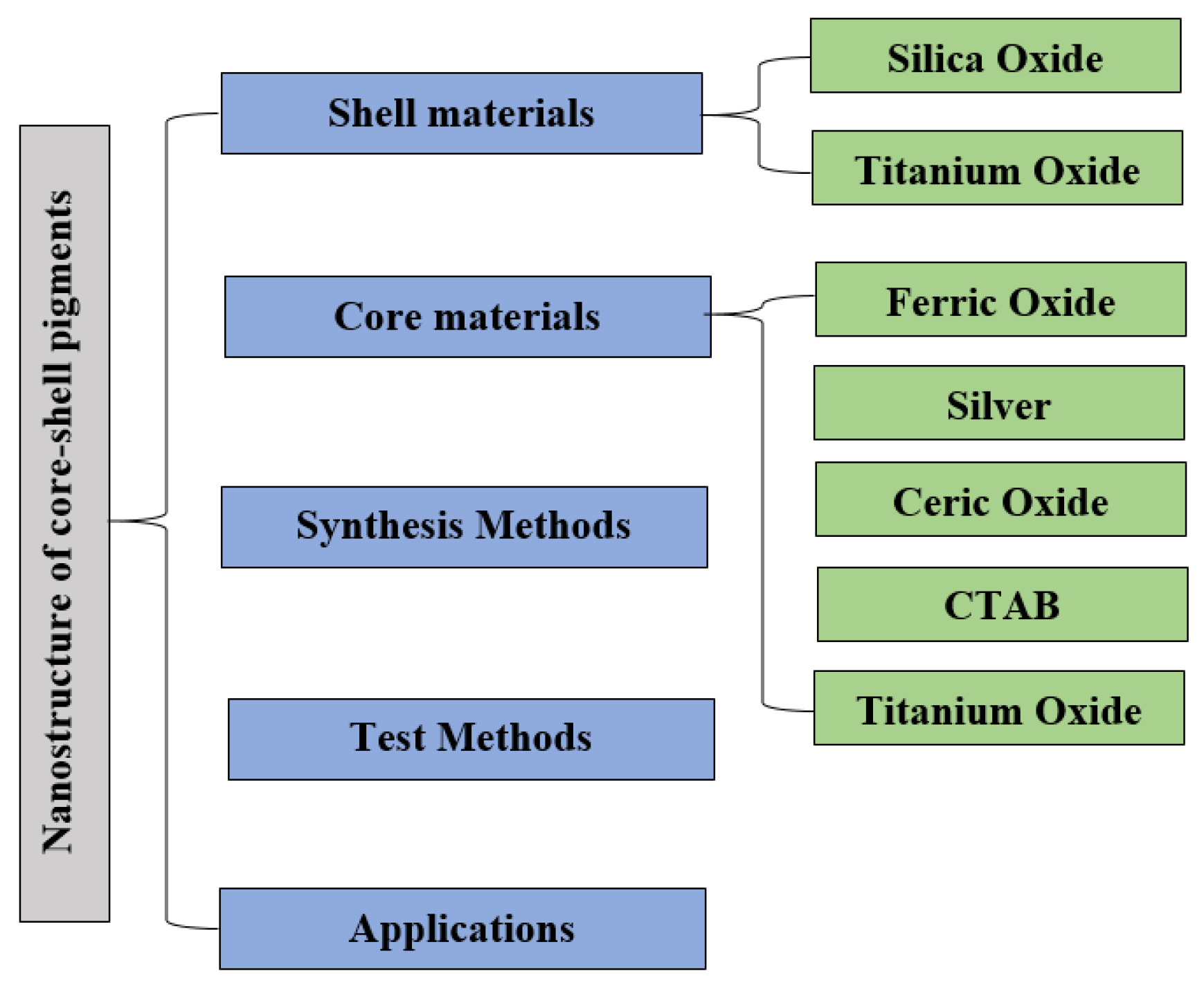

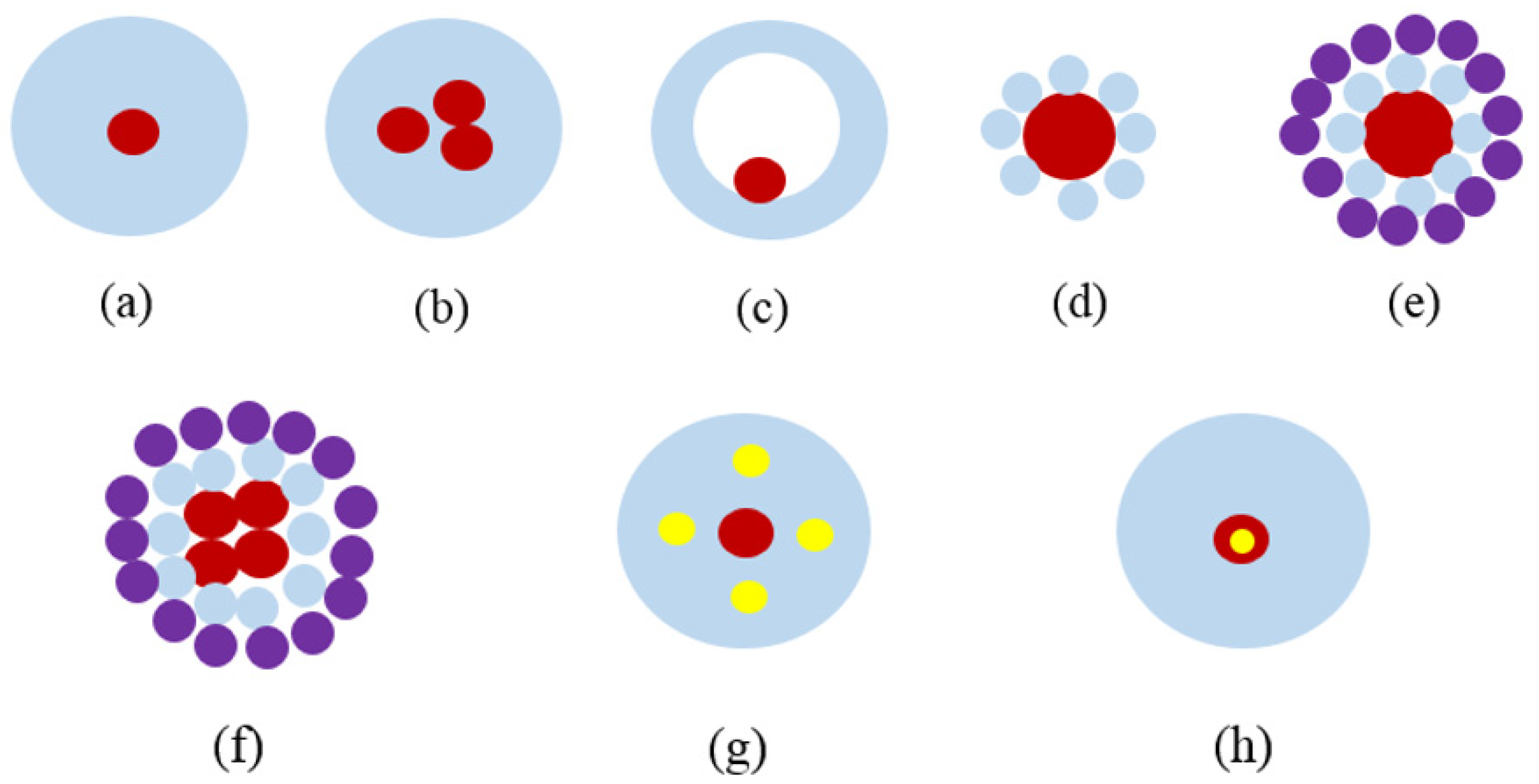

2. Core–Shell Nanoparticle: Synthesis Approach and Importance

3. Materials Based Shell Component

3.1. SiO2-Based Shells

3.2. TiO2-Based Shells

| No. | Core–Shell NPs | Synthesis Method | Synthesis Details (Brief) | Ref. |

|---|---|---|---|---|

| 1 | Fe2O3@SiO2 | Sol–gel method | The sol–gel method to hydrolyze tetraethyl orthosilicate (TEOS) in an attempt to cover iron oxide nanoparticles in uniform shells. By changing the sol–gel precursor concentration, it was possible to modify the thickness of these silica shells. | [53] |

| 2 | CeO2@SiO2 | Sol–gel method | To synthesize the SiO2-covered CeO2 nanoparticles, cyclohexane (99%) was applied as the organic phase in order to perform reverse micelles on polyoxyethylene (15) cetylether. | [54] |

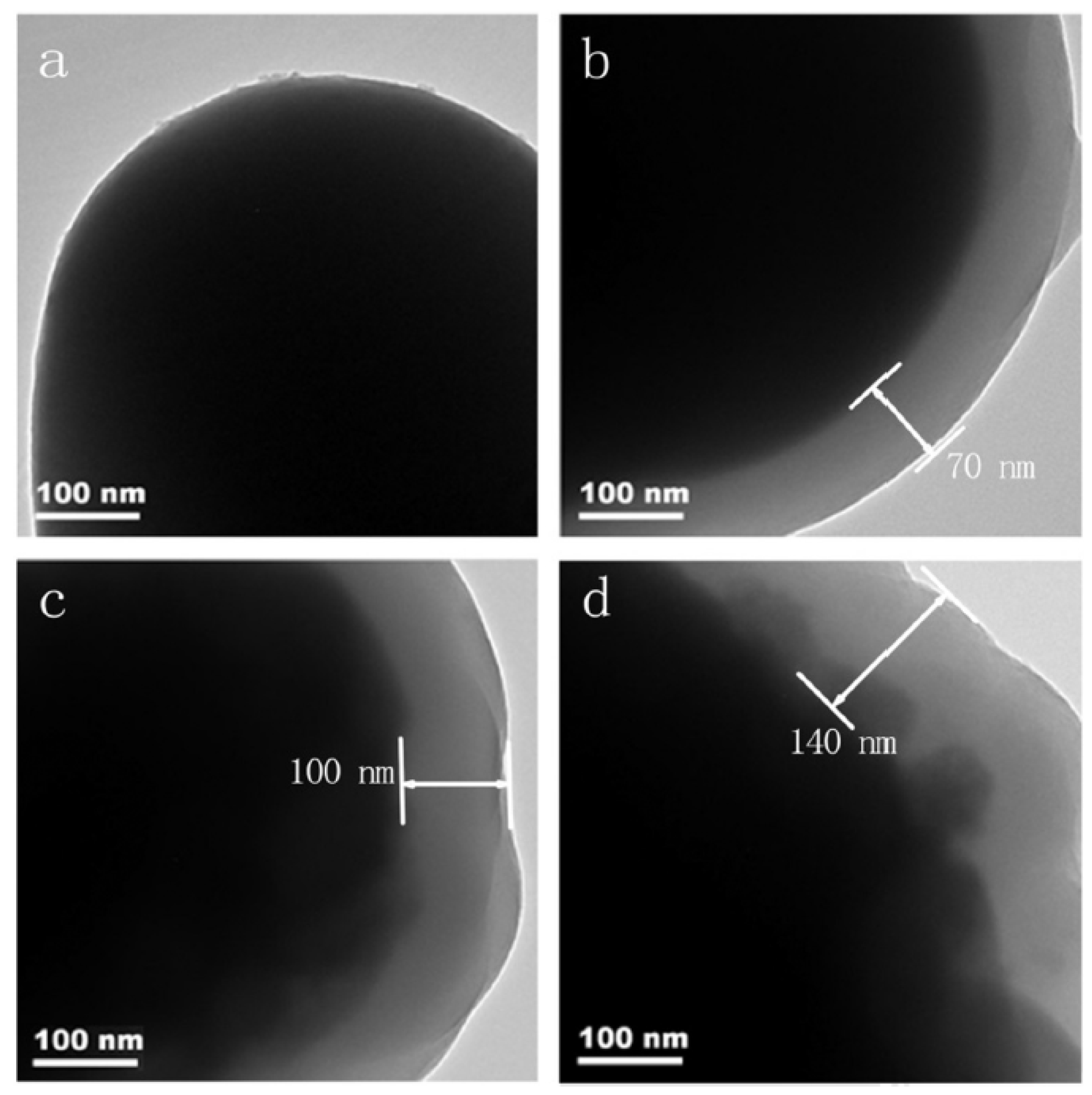

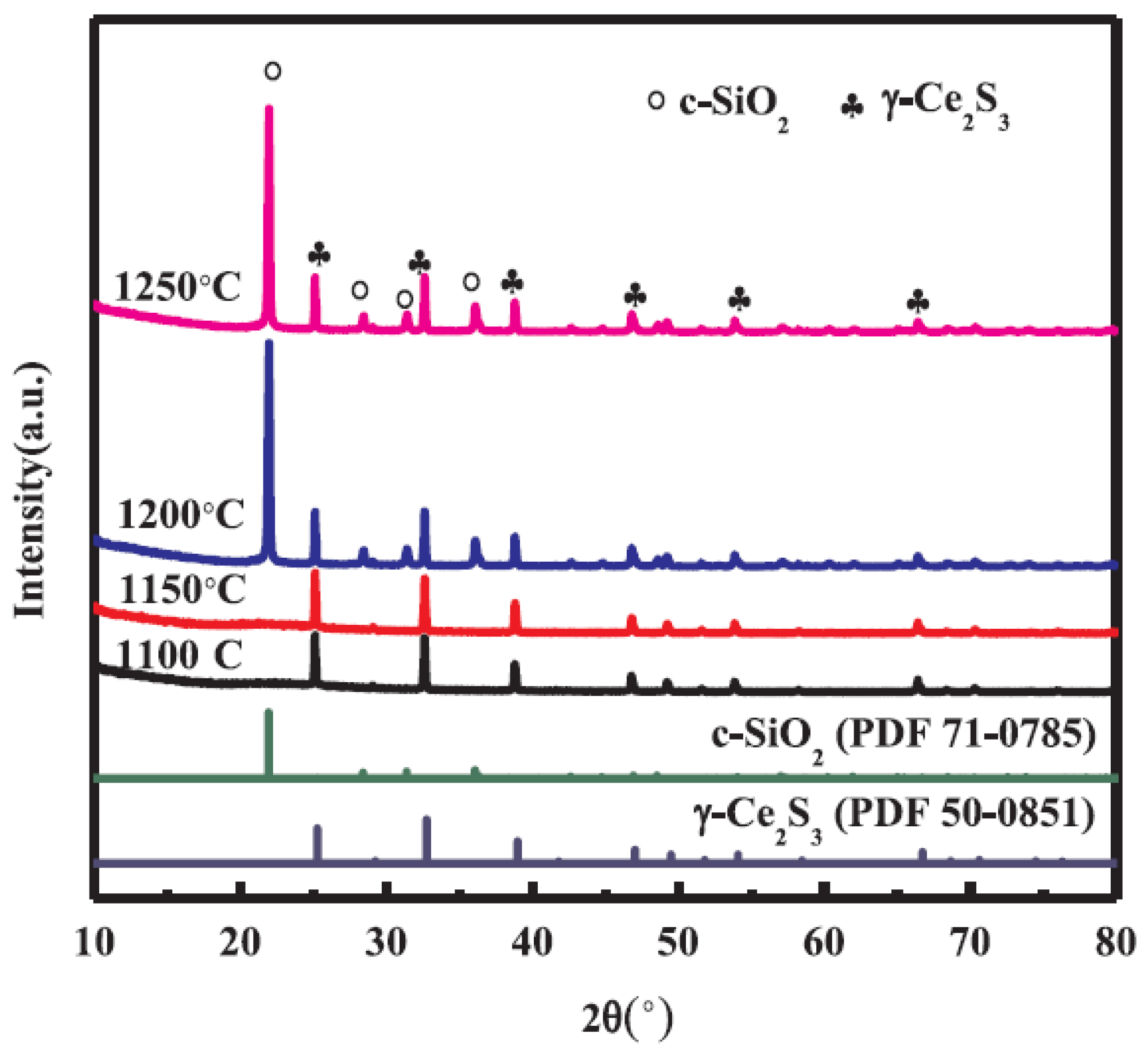

| 2 | Sr2+-doped γ-Ce2S3@c-SiO2 | Stöber method | Amorphous SiO2 (a-SiO2) sol and Sr2+-doped CeO2 were employed as precursors. The original materials used in this experiment were Si(OC2H5)4 (TEOS), Sr(NO3)2, Ce(NO3)3·6H2O, (NH4)2CO3, ammonia water, and ethanol. | [57] |

| 3 | Zn1−xCoxO@SiO2 | Stöber method | A polyol process was used to form ZnO doped with Co2+, a well-known substitute for chromium-based inorganic pigments. Additionally, to source the zinc and cobalt needed in the experiment, zinc acetate dihydrate (Zn(CH3OO)2·2H2O) and cobalt nitrate (Co(NO3)2·6H2O) were employed, with diethylene glycol (H10C4O3) being used as a template. | [58] |

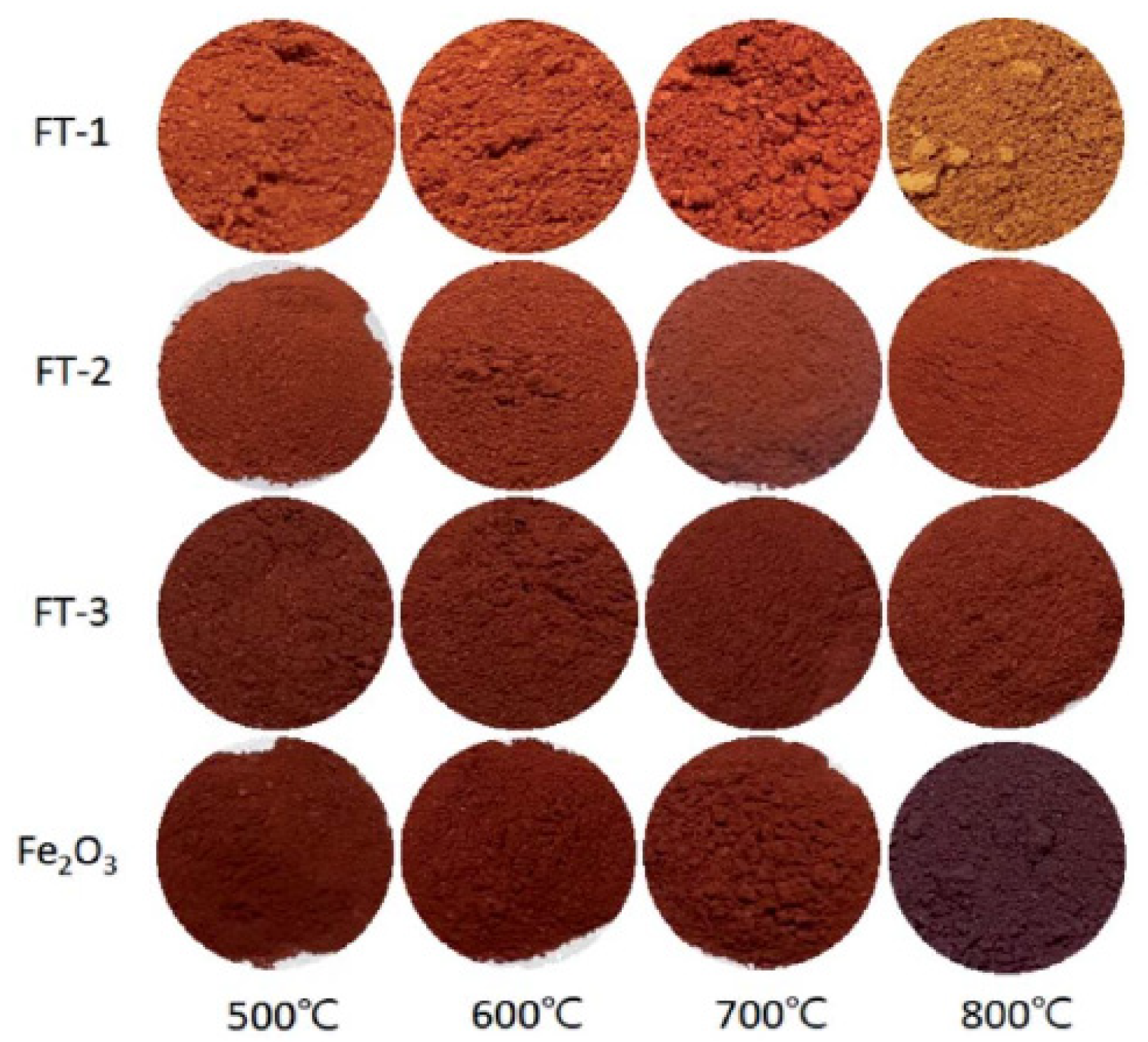

| 4 | Fe2O3@SiO2 | Hydrothermal and Stöber methods | The Stöber method was carried out to fabricate the reddish pigments using α-Fe2O3 as chromophore particles and tetraethoxysilane (TEOS, AR) to source the silica. | [28] |

| 5 | α-Fe2O3@SiO2 | Sol–gel method | The original materials used in the process were FeCl3·6H2O (97%), tetraethylorthosilicate (TEOS 99.99%), cetyltrimethylammonium bromide (CTAB, 99%), and NH4OH (28% in water, 99.99%), which were obtained from Aldrich. Additionally, DI water was employed. | [60] |

| 6 | ZnS@SiO2 | Homogeneous deposition method | ZnS@SiO2 core–shell nanoparticles were produced through a homogeneous deposition method in which deionized water (1 mL) and ammonia (0.5 mL) were placed into a 30-mL colloidal solution of ZnS (0.5–2 wt%). | [61] |

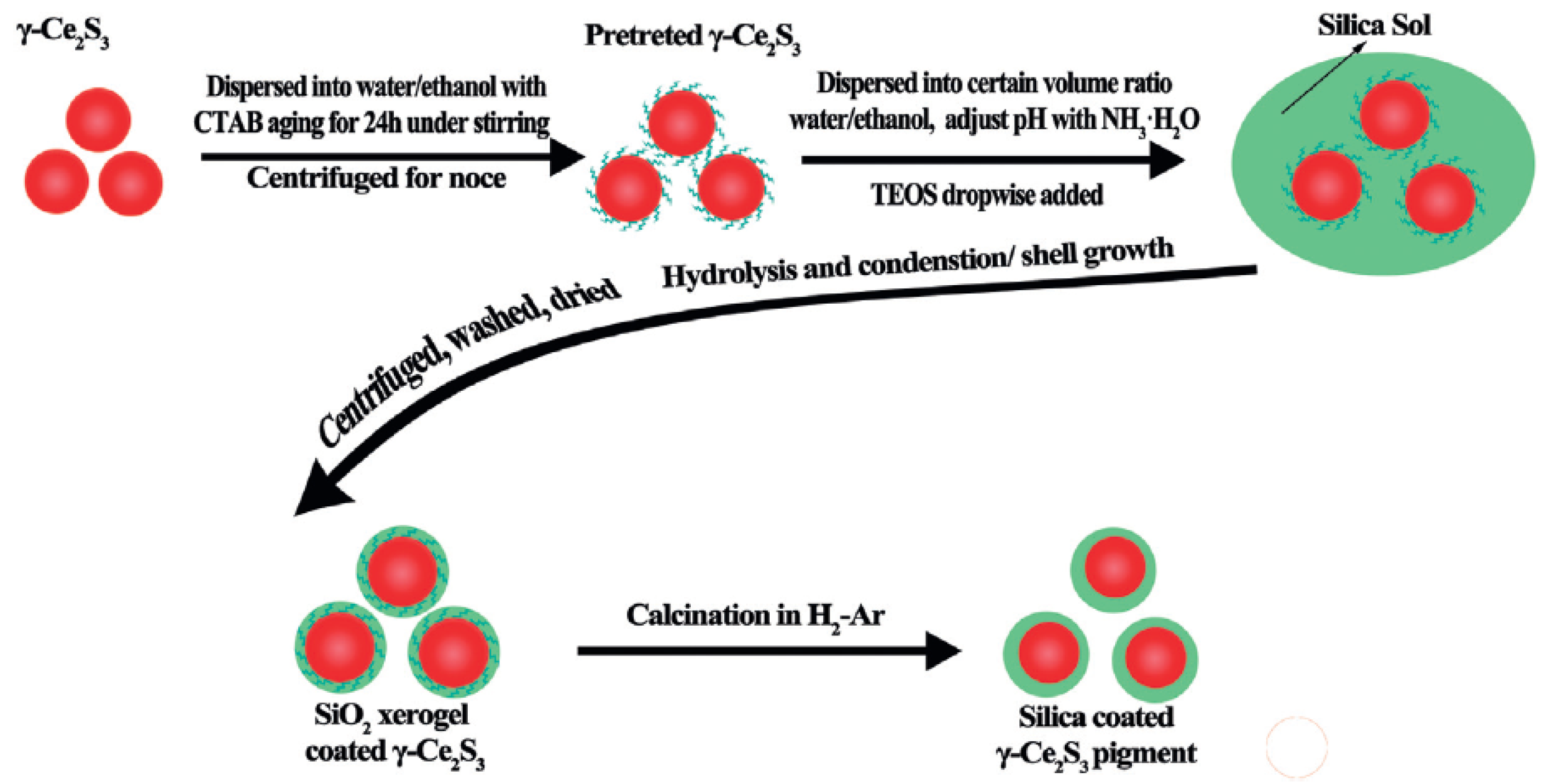

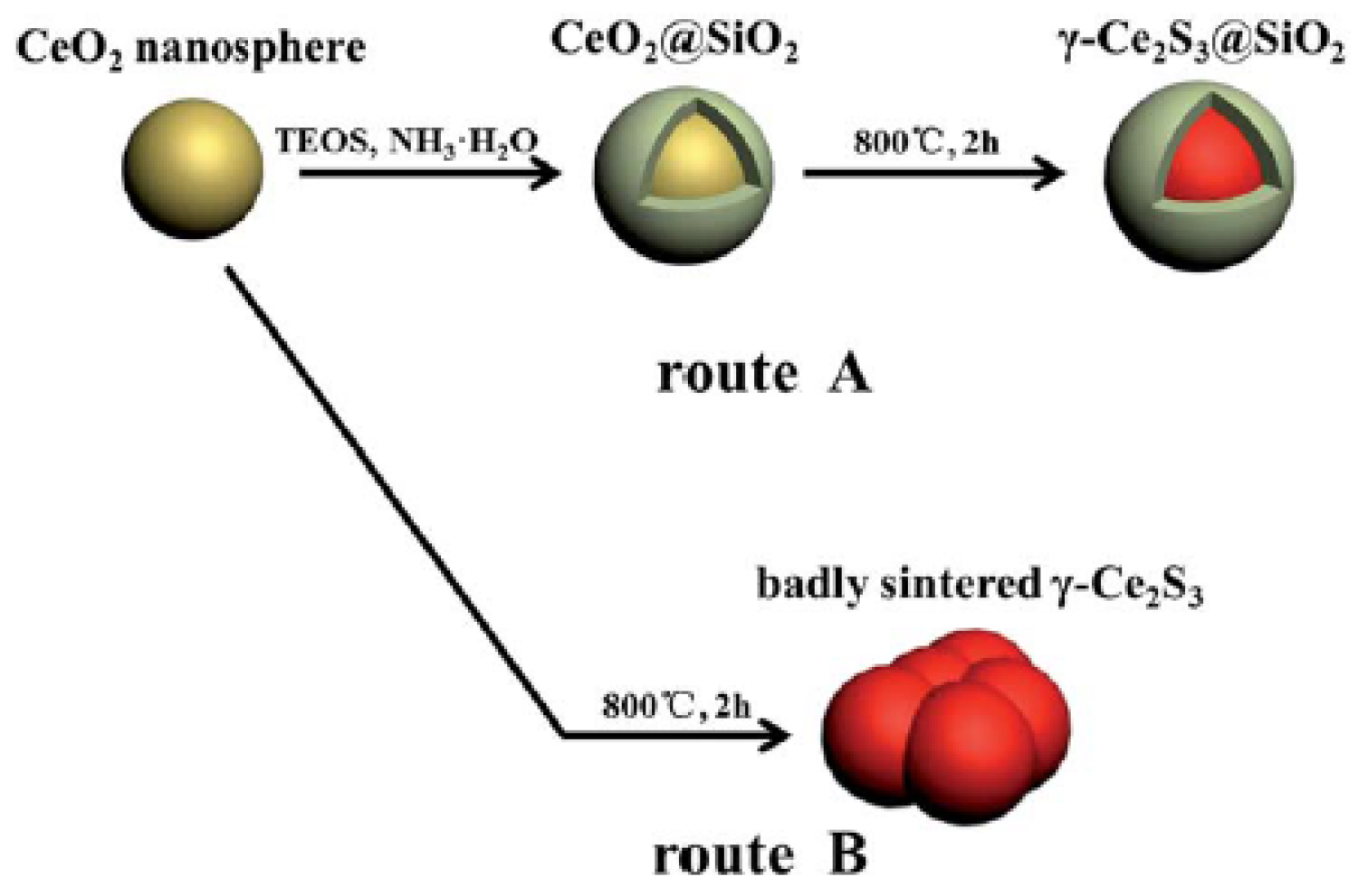

| 7 | γ-Ce2S3@SiO2 | Stöber method | The γ-Ce2S3 red pigments with a silica layer using the Stöber technique combined with hydrogen–argon atmosphere heat treatment (700 °C). | [62] |

| 8 | α-Fe2O3@SiO2 | Sol–gel process | Silica nanoparticles were used in a sol–gel process to coat the natural pigment of hematite (red ocher, α-Fe2O3), the objective of which was to produce a long-lasting hematite pigment of the Fe2O3@SiO2 nanocomposite that could be used to preserve artefacts. To achieve this, 2.2 wt% of pure α-Fe2O3 in the silica sol was charged over a period of time and continually stirred. | [63] |

| 9 | PS@TiO2 and Air@C@TiO2 | Soap-free emulsion polymerization and sol–gel methods | The experiments were conducted using titanium butoxide (TBOT), acetic acid (99%), ethanol, potassium persulfate, sulphuric acid (98%), and hydrogen peroxide (H2O2) (28−30%). | [64] |

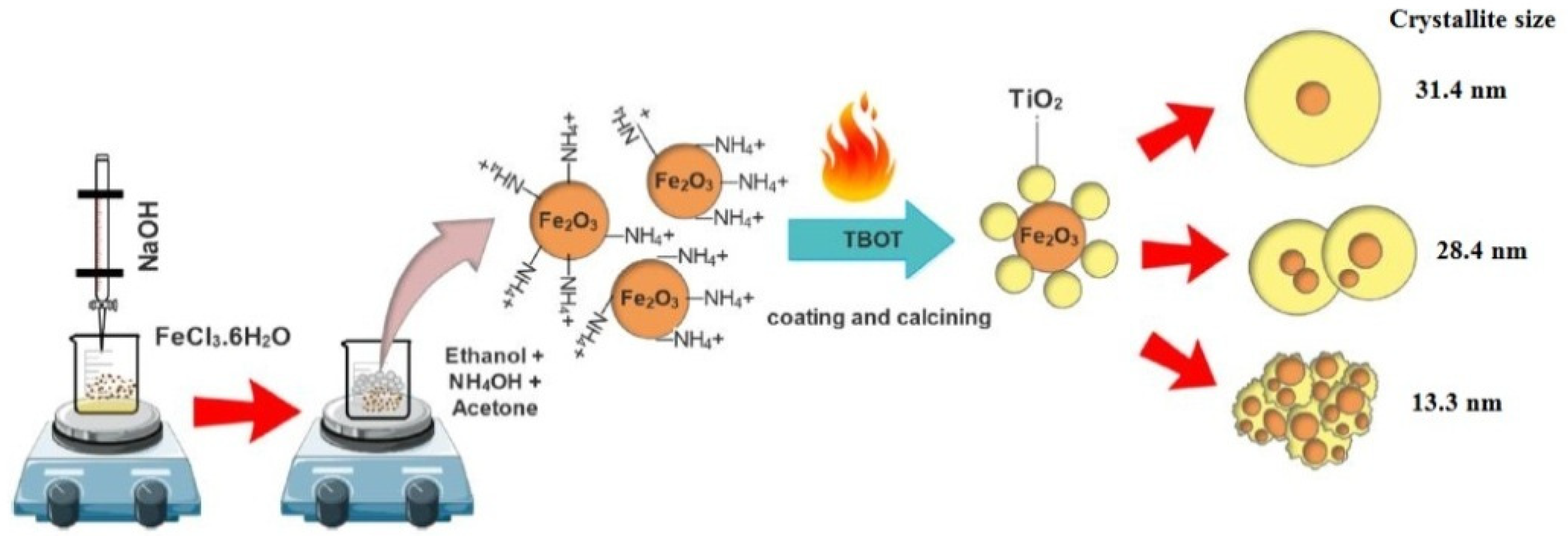

| 10 | Fe2O3@TiO2 | Sol–gel method | To create Fe2O3@TiO2 nanoparticles, various materials were used, including ethanol, acetone, NH3, TBOT, and Fe2O3. The following ratios of Fe2O3:TiO2 were also used: 0.02, 0.06, 1.0, 0.62, 1.24, and 0 for 0.05, 0.05, 0.05, 0.5, 1, and 0 g of Fe2O3, respectively. Usually, 0.05 g of Fe2O3 are dispersed in solutions containing 25 mL of acetone, 25 mL of ethanol, and 0.15 mL of ammonia. | [65] |

| 11 | α-Fe2O3@TiO2 | Hydrothermal method/sol–gel method | The α-FeOOH nanoparticles were subjected to a hydrothermal process. Additionally, to create the homogeneous TiO2 shell, a TBOT was employed, and a sol–gel reaction was performed for 24 h at 45 °C. | [66] |

| 12 | β-FeOOH nanorod@TiO2 | Plasma-assisted chemical vapor deposition | A two-stage solution preparation process was then carried out to produce α-Fe2O3 @amorphous TiO2 core–shell particles, the first stage of which involved preparing α-Fe2O3 nanoparticles through the performance of a surfactant-free solvothermal method. | [67] |

| 13 | α-Fe2O3@TiO2 | Plasma-assisted chemical vapor deposition | Similar to the above approach in point 12, the α-Fe2O3@TiO2 particles were fabricated with porous structures, the key objective of which was to improve the photocatalytic activity. | [68] |

| 14 | NiTiO3@TiO2 | Sol–gel method | First stage, 300 mL of ethanol and 1.0 mL of KCl liquid solution (0.4 mM) were mixed and stirred for 20 min; after which, 5 mL of TBOT was added. It was then stirred for 10 min. Secondly, 0.2 gas-prepared TiO2 powder was dispersed into 200 mL of distilled water ultrasonically, and then, Ni (NO3)2·6H2O and CO(NH2)2 were added to the suspension, and the solution was stirred for 30 min. | [69,70] |

4. Core Materials

4.1. Ferric Oxide

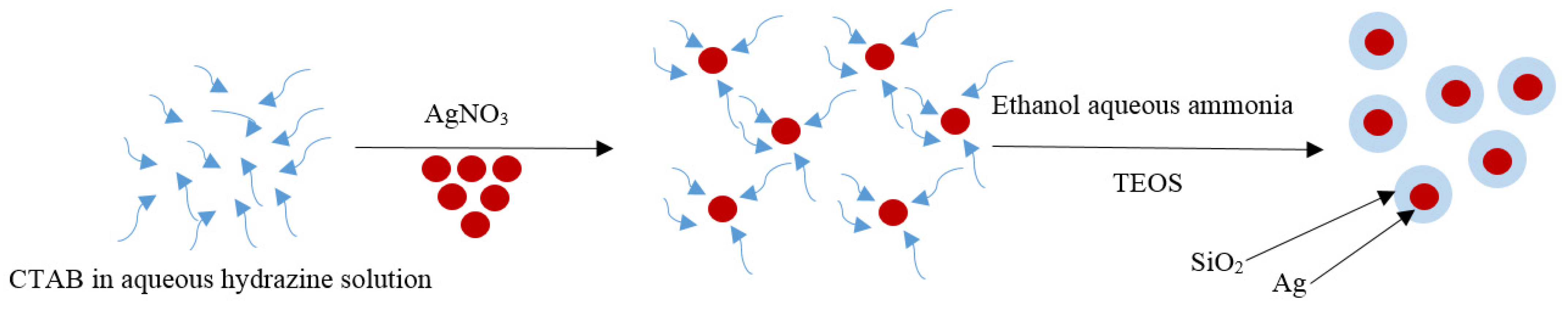

4.2. Silver

4.3. Ceric Oxide

4.4. Cetrimonium Bromide

4.5. Titanium

5. Core–Shell Synthesis Methods

6. Efficiency and Test Methods

6.1. Structure and Morphology

6.2. Reflectivity

6.3. Toleration of High Temperatures

7. Applications of Core–Shell Pigments

8. Conclusions

- The ability to manipulate particle structures at the nanoscale has led to the emergence of a new class of engineered hybrid NPs and core–shell NPs.

- With the rapid development of synthetic chemistry and colloid and interfacial science, as well as devices, many core–shell nanostructures have been successfully fabricated using different strategies.

- All the fabrication processes aim for the green color core–shell NPs with controllable sizes, compositions, architectures, and properties through rational molecular design and appropriate materials (inexpensive and environmentally friendly).

- Using core–shell NPs, it is possible to enhance a pigment’s durability, performance, and sustainability, which is demanded for several applications.

- Owing to their efficiency and distinct traits, SiO2 and TiO2 are the most-recommended materials for shell formation in core–shell nanostructures.

- The TEM, SEM, EDX, FTIR, and XRD tests can reliably be used to measure and evaluate various characteristics of core–shell nanostructures.

- Greener and sustainable synthetic methods can reduce environmental pollution to some extent, while attaining economic growth via green chemistry.

- Each method for core–shell nanostructure growth has some merits and demerits. Thus, it is difficult to recommend a particular method. The recent trends show that the one-step synthesis technique, due to its simplicity and low cost, is more viable for the commercial-scale production of the various core–shell nanostructures required for widespread application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Lin, C.; Li, Y.; Yu, M.; Yang, P.; Lin, J. A facile synthesis and characterization of monodisperse spherical pigment particles with a core/shell structure. Adv. Funct. Mater. 2007, 17, 1459–1465. [Google Scholar] [CrossRef]

- Torres-Cavanillas, R.; Lima-Moya, L.; Tichelaar, F.D.; Zandbergen, H.W.; Giménez-Marqués, M.; Coronado, E. Downsizing of robust Fe-triazole@SiO2 spin-crossover nanoparticles with ultrathin shells. Dalton Trans. 2019, 48, 15465–15469. [Google Scholar] [CrossRef]

- Alexander, M.; Mackechnie, J.; Yam, W. Carbonation of concrete bridge structures in three South African localities. Cem. Concr. Compos. 2007, 29, 750–759. [Google Scholar] [CrossRef]

- Sadeghi-Niaraki, S.; Ghasemi, B.; Ghasemi, E.; Ghahari, M. Preparation of (Fe, Cr)2O3@TiO2 cool pigments for energy saving applications. J. Alloys Compd. 2019, 779, 367–379. [Google Scholar] [CrossRef]

- Soranakom, P.; Vittayakorn, N.; Rakkwamsuk, P.; Supothina, S.; Seeharaj, P. Effect of surfactant concentration on the formation of Fe2O3@SiO2 NIR-reflective red pigments. Ceram. Int. 2021, 47, 13147–13155. [Google Scholar] [CrossRef]

- Dong, X.; Zhang, X.; Yu, X.; Jiang, Z.; Liu, X.; Li, C.; Sun, Z.; Zheng, S.; Dionysiou, D.D. A novel rutile TiO2/AlPO4 core–shell pigment with substantially suppressed photoactivity and enhanced dispersion stability. Powder Technol. 2020, 366, 537–545. [Google Scholar] [CrossRef]

- Yao, B.; Geng, S.; Wang, J.; Wang, L. Synthesis, Characterization, and Optical Properties of Near-Infrared Reflecting Composite Inorganic Pigments Composed of TiO2/CuO Core–Shell Particles. Aust. J. Chem. 2018, 71, 373–379. [Google Scholar] [CrossRef]

- Huseien, G.F.; Shah, K.W.; Sam, A.R.M. Sustainability of nanomaterials based self-healing concrete: An all-inclusive insight. J. Build. Eng. 2019, 23, 155–171. [Google Scholar] [CrossRef]

- Izu, N.; Uchida, T.; Itoh, T.; Shin, W. Decreasing the shell ratio of core–shell type nanoparticles with a ceria core and polymer shell by acid treatment. Solid State Sci. 2018, 85, 32–37. [Google Scholar] [CrossRef]

- Ahmed, N.; Fathi, A.; Mohamed, M.; Abd El-Gawad, W. Evaluation of new core–shell pigments on the anticorrosive performance of coated reinforced concrete steel. Prog. Org. Coat. 2020, 140, 105530. [Google Scholar] [CrossRef]

- Sanchis-Gual, R.; Torres-Cavanillas, R.; Puchau, M.C.; Giménez-Marqués, M.; Coronado, E. Plasmon-assisted spin transition in gold nanostar@spin crossover heterostructures. J. Mater. Chem. C 2021. [Google Scholar] [CrossRef]

- Torres-Cavanillas, R.; Sanchis-Gual, R.; Dugay, J.; Coronado-Puchau, M.; Giménez-Marqués, M.; Coronado, E. Design of Bistable Gold@Spin-Crossover Core–Shell Nanoparticles Showing Large Electrical Responses for the Spin Switching. Adv. Mater. 2019, 31, 1900039. [Google Scholar] [CrossRef]

- Ahmed, N.M.; Mohamed, M.G.; Abd El-Gawad, W.M. Corrosion protection performance of silica fume waste-phosphates core–shell pigments. Pigment Resin Technol. 2018, 47, 261–271. [Google Scholar] [CrossRef]

- Sertchook, H.; Avnir, D. Submicron silica/polystyrene composite particles prepared by a one-step sol-gel process. Chem. Mater. 2003, 15, 1690–1694. [Google Scholar] [CrossRef]

- Zhuang, Z.; Sheng, W.; Yan, Y. Synthesis of monodispere Au@Co3O4 core–shell nanocrystals and their enhanced catalytic activity for oxygen evolution reaction. Adv. Mater. 2014, 26, 3950–3955. [Google Scholar] [CrossRef]

- Zhong, Z.; Yin, Y.; Gates, B.; Xia, Y. Preparation of mesoscale hollow spheres of TiO2 and SnO2 by templating against crystalline arrays of polystyrene beads. Adv. Mater. 2000, 12, 206–209. [Google Scholar] [CrossRef]

- Samal, A.K.; Polavarapu, L.; Rodal-Cedeira, S.; Liz-Marzán, L.M.; Pérez-Juste, J.; Pastoriza-Santos, I. Size Tunable Au@Ag core–shell nanoparticles: Synthesis and surface-enhanced raman scattering properties. Langmuir 2013, 29, 15076–15082. [Google Scholar] [CrossRef] [Green Version]

- Parashar, M.; Shukla, V.K.; Singh, R. Metal oxides nanoparticles via sol-gel method: A review on synthesis, characterization and applications. J. Mater. Sci. Mater. Electron. 2020, 31, 3729–3749. [Google Scholar] [CrossRef]

- Dugay, J.; Evers, W.; Torres-Cavanillas, R.; Giménez-Marqués, M.; Coronado, E.; Van der Zant, H.S. Charge Mobility and Dynamics in Spin-Crossover Nanoparticles Studied by Time-Resolved Microwave Conductivity. J. Phys. Chem. Lett. 2018, 9, 5672–5678. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, J.; Sharma, S.; Ramanujachary, K.V.; Lofland, S.E.; Ganguli, A.K. Microemulsion-mediated synthesis of cobalt (pure fcc and hexagonal phases) and cobalt–nickel alloy nanoparticles. J. Colloid Interface Sci. 2009, 336, 814–819. [Google Scholar] [CrossRef]

- El-Safty, S.A. Synthesis, characterization and catalytic activity of highly ordered hexagonal and cubic composite monoliths. J. Colloid Interface Sci. 2008, 319, 477–488. [Google Scholar] [CrossRef]

- Ghosh Chaudhuri, R.; Paria, S. Core/shell nanoparticles: Classes, properties, synthesis mechanisms, characterization, and applications. Chem. Rev. 2012, 112, 2373–2433. [Google Scholar] [CrossRef]

- Han, W.; Yi, L.; Zhao, N.; Tang, A.; Gao, M.; Tang, Z. Synthesis and shape-tailoring of copper sulfide/indium sulfide-based nanocrystals. J. Am. Chem. Soc. 2008, 130, 13152–13161. [Google Scholar] [CrossRef]

- Lee, H.; Kim, C.; Yang, S.; Han, J.W.; Kim, J. Shape-controlled nanocrystals for catalytic applications. Catal. Surv. Asia 2012, 16, 14–27. [Google Scholar] [CrossRef]

- Libor, Z.; Zhang, Q. The synthesis of nickel nanoparticles with controlled morphology and SiO2/Ni core–shell structures. Mater. Chem. Phys. 2009, 114, 902–907. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Pee, J.-H.; Chang, J.H.; Choi, K.; Kim, K.J.; Jung, D.-Y. Silica effect on coloration of hematite nanoparticles for red pigments. Chem. Lett. 2009, 38, 842–843. [Google Scholar] [CrossRef]

- Liu, R.; Priestley, R.D. Rational design and fabrication of core–shell nanoparticles through a one-step/pot strategy. J. Mater. Chem. A 2016, 4, 6680–6692. [Google Scholar] [CrossRef]

- Chen, S.; Cheng, M.; Lang, Y.; Tian, C.; Wei, H.; Wang, C.-A. Preparation and characterization of monodispersed spherical Fe2O3@SiO2 reddish pigments with core–shell structure. J. Adv. Ceram. 2019, 8, 39–46. [Google Scholar] [CrossRef] [Green Version]

- Dodd, A.C. A comparison of mechanochemical methods for the synthesis of nanoparticulate nickel oxide. Powder Technol. 2009, 196, 30–35. [Google Scholar] [CrossRef]

- Deng, W.; Xia, W.; Li, C.; Tang, Y. Formation of ultra-fine grained materials by machining and the characteristics of the deformation fields. J. Mater. Process. Technol. 2009, 209, 4521–4526. [Google Scholar] [CrossRef]

- Salari, M.; Marashi, P.; Rezaee, M. Synthesis of TiO2 nanoparticles via a novel mechanochemical method. J. Alloys Compd. 2009, 469, 386–390. [Google Scholar] [CrossRef]

- Sasikumar, R.; Arunachalam, R. Synthesis of nanostructured aluminium matrix composite (AMC) through machining. Mater. Lett. 2009, 63, 2426–2428. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, K.; Yao, X. Facile synthesis of PbTe nanoparticles and thin films in alkaline aqueous solution at room temperature. J. Solid State Chem. 2009, 182, 3383–3386. [Google Scholar] [CrossRef]

- Yoo, S.-H.; Liu, L.; Park, S. Nanoparticle films as a conducting layer for anodic aluminum oxide template-assisted nanorod synthesis. J. Colloid Interface Sci. 2009, 339, 183–186. [Google Scholar] [CrossRef] [PubMed]

- Oldenburg, S.; Averitt, R.; Westcott, S.; Halas, N. Nanoengineering of optical resonances. Chem. Phys. Lett. 1998, 288, 243–247. [Google Scholar] [CrossRef]

- Daniel, M.-C.; Astruc, D. Gold nanoparticles: Assembly, supramolecular chemistry, quantum-size-related properties, and applications toward biology, catalysis, and nanotechnology. Chem. Rev. 2004, 104, 293–346. [Google Scholar] [CrossRef] [PubMed]

- Pal, G.; Rai, P.; Pandey, A. Green synthesis of nanoparticles: A greener approach for a cleaner future. In Green Synthesis, Characterization and Applications of Nanoparticles; Elsevier: Amsterdam, The Netherlands, 2019; Volume 1, pp. 1–26. [Google Scholar]

- Galogahi, F.M.; Zhu, Y.; An, H.; Nguyen, N.-T. Core-shell microparticles: Generation approaches and applications. J. Sci. Adv. Mater. Devices 2020, 5, 417–435. [Google Scholar] [CrossRef]

- Cao, L.; Fei, X.; Zhao, H.; Gu, Y. Inorganic–organic hybrid pigment fabricated in the preparation process of organic pigment: Preparation and characterization. Dye Pigments 2015, 119, 75–83. [Google Scholar] [CrossRef]

- Bongur, R.; Le Nouen, D.; Gaslain, F.; Marichal, C.; Lebeau, B.; Guarilloff, P. Red 33 dye co-encapsulated with cetyltrimethylammonium in mesoporous silica materials. Dye Pigments 2016, 127, 1–8. [Google Scholar] [CrossRef]

- Fei, X.; Zhang, T.; Zhou, C. Modification study involving a Naphthol as red pigment. Dye Pigments 2000, 44, 75–80. [Google Scholar]

- Chen, G.; Zhu, Z.; Liu, H.; Wu, Y.; Zhu, C. Preparation of SiO2 coated Ce2S3 red pigment with improved thermal stability. J. Rare Earths 2013, 31, 891–896. [Google Scholar] [CrossRef]

- Yu, S.; Wang, D.; Liu, Y.; Li, Z.; Zhang, X.; Yang, X.; Wang, Y.; Wang, X.; Su, H. Preparations and characterizations of γ-Ce2S3@SiO2 pigments from precoated CeO2 with improved thermal and acid stabilities. RSC Adv. 2014, 4, 23653–23657. [Google Scholar] [CrossRef]

- Guo, Q.; Zhou, Y.; Nie, W.; Chen, P.; Song, L. Synthesis of highly monodispersed CdS/SiO2 core shell nanoparticles and their photocatalytic activities. J. Nanosci. Nanotechnol. 2015, 15, 2364–2370. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, L.; Chen, H.; Zhang, J.; Zhang, Y.; Wang, A. Learning from ancient Maya: Preparation of stable palygorskite/methylene blue@SiO2 Maya Blue-like pigment. Microporous Mesoporous Mater. 2015, 211, 124–133. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Wang, A. Facile preparation of stable palygorskite/methyl violet@SiO2 “Maya Violet” pigment. J. Colloid Interface Sci. 2015, 457, 254–263. [Google Scholar] [CrossRef] [PubMed]

- Fabjan, E.Š.; Škapin, A.S.; Škrlep, L.; Živec, P.; Čeh, M.; Gaberšček, M. Protection of organic pigments against photocatalysis by encapsulation. J. Sol-Gel Sci. Technol. 2012, 62, 65–74. [Google Scholar] [CrossRef]

- Fabjan, E.Š.; Otoničar, M.; Gaberšček, M.; Škapin, A.S. Surface protection of an organic pigment based on a modification using a mixed-micelle system. Dye Pigments 2016, 127, 100–109. [Google Scholar] [CrossRef]

- Fei, X.; Cao, L.; Liu, Y. Modified CI Pigment Red 170 with a core–shell structure: Preparation, characterization and computational study. Dye Pigments 2016, 125, 192–200. [Google Scholar] [CrossRef]

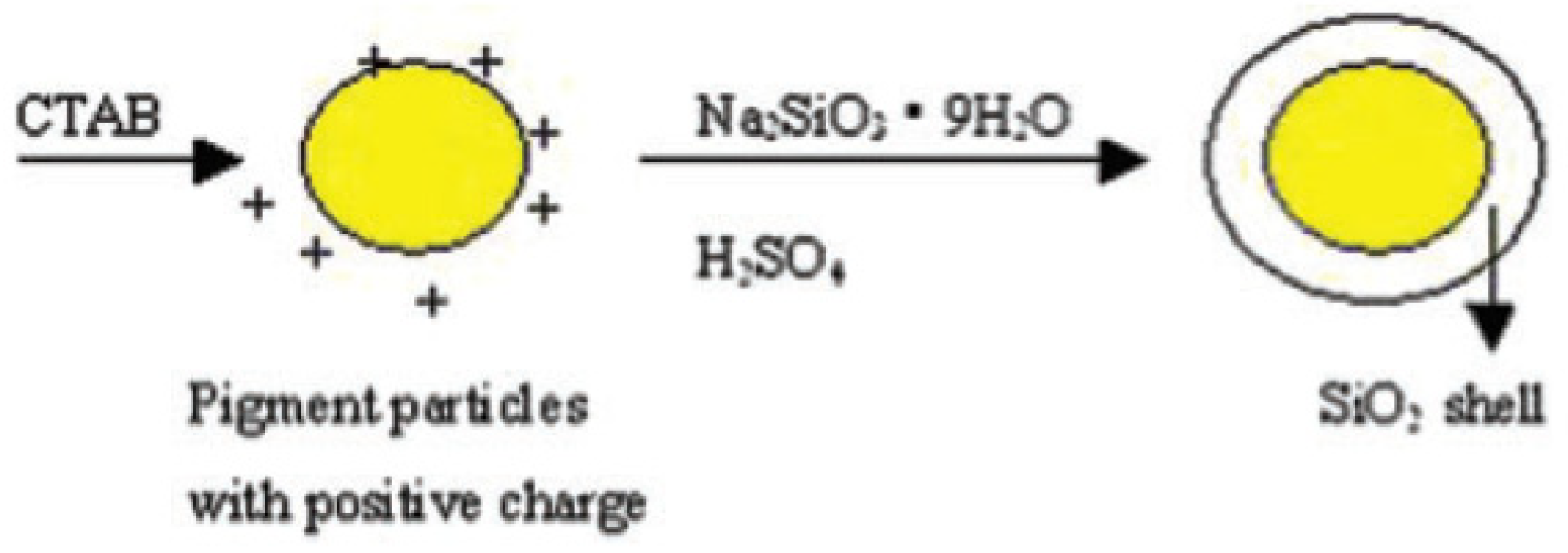

- Yuan, J.; Zhou, S.; Gu, G.; Wu, L. Encapsulation of organic pigment particles with silica via sol-gel process. J. Sol-Gel Sci. Technol. 2005, 36, 265–274. [Google Scholar] [CrossRef]

- Horiuchi, S.; Horie, S.; Ichimura, K. Core–Shell Structures of Silica-Organic Pigment Nanohybrids Visualized by Electron Spectroscopic Imaging. ACS Appl. Mater. Interfaces 2009, 1, 977–981. [Google Scholar] [CrossRef]

- Yuan, J.; Xing, W.; Gu, G.; Wu, L. The properties of organic pigment encapsulated with nano-silica via layer-by-layer assembly technique. Dye Pigments 2008, 76, 463–469. [Google Scholar] [CrossRef]

- Lu, Y.; Yin, Y.; Mayers, B.T.; Xia, Y. Modifying the surface properties of superparamagnetic iron oxide nanoparticles through a sol-gel approach. Nano Lett. 2002, 2, 183–186. [Google Scholar] [CrossRef]

- Tago, T.; Tashiro, S.; Hashimoto, Y.; Wakabayashi, K.; Kishida, M. Synthesis and optical properties of SiO2-coated CeO2 nanoparticles. J. Nanopart. Res. 2003, 5, 55–60. [Google Scholar] [CrossRef]

- Wang, A.; Ge, C.; Yin, H.; Ren, M.; Zhang, Y.; Zhou, Q.; Wu, Z.; Huo, J.; Li, X.; Jiang, T. Evolution of binary Fe2O3/SiO2 coating layers on the surfaces of aluminum flakes and the pigmentary performances. Powder Technol. 2012, 221, 306–311. [Google Scholar] [CrossRef]

- Ahmed, N.M.; Abd El-Gawad, W.M.; Souaya, E.M. Evaluation of the anticorrosive performance of epoxy coatings containing new core/shell pigments. Pigment Resin Technol. 2018, 7, 116–126. [Google Scholar] [CrossRef]

- Li, Y.; Le, S.; Wang, Z.; Hong, Y.; Li, K.; Pu, Q. Preparation and characterization of the Sr2+-doped γ-Ce2S3@c-SiO2 red pigments exhibiting improved temperature and acid stability. Appl. Surf. Sci. 2020, 508, 145266. [Google Scholar] [CrossRef]

- Mjejri, I.; Mornet, S.; Gaudon, M. From nano-structured polycrystalline spheres with Zn1−xCoxO composition to core–shell Zn1-xCoxO@SiO2 as green pigments. J. Alloys Compd. 2019, 777, 1204–1210. [Google Scholar] [CrossRef]

- Fabjan, E.Š.; Saghi, Z.; Midgley, P.A.; Otoničar, M.; Dražić, G.; Gaberšček, M.; Škapin, A.S. Diketopyrrolopyrrole pigment core@multi-layer SiO2 shell with improved photochemical stability. Dye Pigments 2018, 156, 108–115. [Google Scholar] [CrossRef]

- Yu, R.; An, G.S.; Pee, J.-H.; Kim, Y. Evaluation of Color and Structure of α-Fe2O3 Nanocapsules by Tuning of the SiO2 Morphology. J. Nanosci. Nanotechnol. 2018, 18, 6133–6136. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Zhang, X.; Lin, Y.; Wang, L.; Zhu, J. Structural coloration pigments based on carbon modified ZnS@SiO2 nanospheres with low-angle dependence, high color saturation, and enhanced stability. ACS Appl. Mater. Interfaces 2016, 8, 5009–5016. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.-G.; Li, Y.-M.; Wang, Z.-M.; Shen, Z.-Y.; Xie, Z.-X. Enhanced high temperature oxidization resistance of silica coated γ-Ce2S3 red pigments. Appl. Surf. Sci. 2016, 387, 1147–1153. [Google Scholar] [CrossRef]

- Sultan, S.; Kareem, K.; He, L. Synthesis, characterization and resistant performance of α-Fe2O3@SiO2 composite as pigment protective coatings. Surf. Coat. Technol. 2016, 300, 42–49. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, F.; Luo, H.; Zhu, J. Preparation of Noniridescent Structurally Colored PS@TiO2 and Air@C@TiO2 Core–Shell Nanoparticles with Enhanced Color Stability. ACS Appl. Mater. Interfaces 2019, 11, 34355–34363. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi-Niaraki, S.; Ghasemi, B.; Habibolahzadeh, A.; Ghasemi, E.; Ghahari, M. Nanostructured Fe2O3@TiO2 pigments with improved NIR reflectance and photocatalytic ability. Mater. Chem. Phys. 2019, 235, 121769. [Google Scholar] [CrossRef]

- Sun, D.; Cao, Y.; Xu, Y.; Zhang, G.; Sun, Y. Tunable synthesis of core–shell α-Fe2O3/TiO2 composite nanoparticles and their visible-light photocatalytic activity. Chem. Res. Chin. Univ. 2016, 32, 882–888. [Google Scholar] [CrossRef]

- Yang, S.; Xu, Y.; Sun, Y.; Zhang, G.; Gao, D. Size-controlled synthesis, magnetic property, and photocatalytic property of uniform α-Fe2O3 nanoparticles via a facile additive-free hydrothermal route. Cryst. Eng. Commun. 2012, 14, 7915–7921. [Google Scholar] [CrossRef]

- Zhang, X.; Xie, Y.; Chen, H.; Guo, J.; Meng, A.; Li, C. One-dimensional mesoporous Fe2O3@TiO2 core–shell nanocomposites: Rational design, synthesis and application as high-performance photocatalyst in visible and UV light region. Appl. Surf. Sci. 2014, 317, 43–48. [Google Scholar] [CrossRef]

- He, X.; Wang, F.; Liu, H.; Li, J.; Niu, L. Synthesis and coloration of highly dispersed NiTiO3@TiO2 yellow pigments with core–shell structure. J. Eur. Ceram. Soc. 2017, 37, 2965–2972. [Google Scholar] [CrossRef]

- He, X.; Wang, F.; Liu, H.; Li, J.; Niu, L. Fabrication of highly dispersed NiTiO3@TiO2 yellow pigments with enhanced NIR reflectance. Mater. Lett. 2017, 208, 82–85. [Google Scholar] [CrossRef]

- Montes-Hernandez, G.; Pironon, J.; Villieras, F. Synthesis of a red iron oxide/montmorillonite pigment in a CO2-rich brine solution. J. Colloid Interface Sci. 2006, 303, 472–476. [Google Scholar] [CrossRef] [Green Version]

- Legodi, M.A.; de Waal, D. The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste. Dye Pigments 2007, 74, 161–168. [Google Scholar] [CrossRef]

- Kumari, L.S.; Rao, P.P.; Reddy, M.L. Environment-friendly red pigments from CeO2–Fe2O3–Pr6O11 solid solutions. J. Alloys Compd. 2008, 461, 509–515. [Google Scholar] [CrossRef]

- Hosseini-Zori, M.; Bondioli, F.; Manfredini, T.; Taheri-Nassaj, E. Effect of synthesis parameters on a hematite-silica red pigment obtained using a coprecipitation route. Dye Pigments 2008, 77, 53–58. [Google Scholar] [CrossRef]

- Llusar, M.; Royo, V.; Badenes, J.; Tena, M.; Monrós, G. Nanocomposite Fe2O3–SiO2 inclusion pigments from post-functionalized mesoporous silicas. J. Eur. Ceram. Soc. 2009, 29, 3319–3332. [Google Scholar] [CrossRef]

- Hong, R.-Y.; Li, J.-H.; Zhang, S.-Z.; Li, H.-Z.; Zheng, Y.; Ding, J.-m.; Wei, D.-G. Preparation and characterization of silica-coated Fe3O4 nanoparticles used as precursor of ferrofluids. Appl. Surf. Sci. 2009, 255, 3485–3492. [Google Scholar] [CrossRef]

- Yu, R.; Kim, Y.; Pee, J.-H.; Kim, K.J.; Kim, W. Thermal behavior and coloration study of silica-coated α-Fe2O3 and β-FeOOH nanocapsules. J. Nanosci. Nanotechnol. 2011, 11, 6283–6286. [Google Scholar] [CrossRef]

- Rahimi, R.; Heidari-Golafzani, M.; Rabbani, M. Preparation and photocatalytic application of ZnFe2O4@ZnO core–shell nanostructures. Superlattices Microstruct. 2015, 85, 497–503. [Google Scholar] [CrossRef]

- Zhang, X.-S.; Wang, J.-X.; Xu, K.; Le, Y.; Chen, J.-F. Monodisperse Ag@SiO2 Core–Shell Nanoparticles as Active Inhibitors for Marine Anticorrosion Applications. J. Nanosci. Nanotechnol. 2011, 11, 3481–3487. [Google Scholar] [CrossRef]

- Fang, Q.; Liang, X. CeO2–Al2O3, CeO2–SiO2, CeO2–TiO2 core–shell spheres: Formation mechanisms and UV absorption. RSC Adv. 2012, 2, 5370–5375. [Google Scholar] [CrossRef]

- Liang, X.; Xiao, J.; Chen, B.; Li, Y. Catalytically stable and active CeO2 mesoporous spheres. Inorg. Chem. 2010, 49, 8188–8190. [Google Scholar] [CrossRef] [PubMed]

- Chopin, T.; Guichon, H.; Touret, O. Rare Earth Sesquisulfide Compositions Comprising Alkali/Alkaline Earth Metal Values. U.S. Patent No. 5,348,581, 20 September 1994. [Google Scholar]

- Duan, J.; Feng, Y.; Wang, W.; Li, X. Novel modification method of yellow pigment and its potential application in e-ink. Mater. Res. Innov. 2010, 14, 113–118. [Google Scholar] [CrossRef]

- Zou, J.; Zheng, W. TiO2@CoTiO3 complex green pigments with low cobalt content and tunable color properties. Ceram. Int. 2016, 42, 8198–8205. [Google Scholar] [CrossRef]

- Hayes, R.; Ahmed, A.; Edge, T.; Zhang, H. Core–shell particles: Preparation, fundamentals and applications in high performance liquid chromatography. J. Chromatogr. A 2014, 1357, 36–52. [Google Scholar] [CrossRef] [Green Version]

- Mao, W.-X.; Zhang, W.; Chi, Z.-X.; Lu, R.-W.; Cao, A.-M.; Wan, L.-J. Core–shell structured Ce2S3@ZnO and its potential as a pigment. J. Mater. Chem. A 2015, 3, 2176–2180. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, S.Z.; Chen, J.S.; Lou, X.W.D.; Xing, X.; Lu, G.Q.M. Yolk/shell nanoparticles: New platforms for nanoreactors, drug delivery and lithium-ion batteries. Chem. Commun. 2011, 47, 12578–12591. [Google Scholar] [CrossRef]

- Niu, H.-Y.; Li, W.-H.; Shi, Y.-L.; Cai, Y.-Q. A core–shell magnetic mesoporous silica sorbent for organic targets with high extraction performance and anti-interference ability. Chem. Commun. 2011, 47, 4454–4456. [Google Scholar]

- Insin, N.; Tracy, J.B.; Lee, H.; Zimmer, J.P.; Westervelt, R.M.; Bawendi, M.G. Incorporation of iron oxide nanoparticles and quantum dots into silica microspheres. ACS Nano 2008, 2, 197–202. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, J.; Yang, N.; Tang, H.; Dong, Z.; Jin, Q.; Yang, M.; Kisailus, D.; Zhao, H.; Tang, Z.; Wang, D. Accurate control of multishelled Co3O4 hollow microspheres as high-performance anode materials in lithiumion batteries. Angew. Chem. 2013, 125, 6545–6548. [Google Scholar] [CrossRef] [Green Version]

- Lai, X.; Li, J.; Korgel, B.A.; Dong, Z.; Li, Z.; Su, F.; Du, J.; Wang, D. General synthesis and gas-sensing properties of multiple-shell metal oxide hollow microspheres. Angew. Chem. Int. Ed. 2011, 50, 2738–2741. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Xin, H.L.; Hovden, R.; Wang, H.; Yu, Y.; Muller, D.A.; DiSalvo, F.J.; Abruña, H.D. Structurally ordered intermetallic platinum-cobalt core–shell nanoparticles with enhanced activity and stability as oxygen reduction electrocatalysts. Nat. Mater. 2013, 12, 81–87. [Google Scholar] [CrossRef]

- Chae, H.S.; Kim, S.D.; Piao, S.H.; Choi, H.J. Core-shell structured Fe3O4@SiO2 nanoparticles fabricated by sol-gel method and their magnetorheology. Colloid Polym. Sci. 2016, 294, 647–655. [Google Scholar] [CrossRef]

- Guo, X.; Canet, J.-L.; Boyer, D.; Gautier, A.; Mahiou, R. Sol-gel emulsion synthesis of biphotonic core–shell nanoparticles based on lanthanide doped organic-inorganic hybrid materials. J. Mater. Chem. 2012, 22, 6117–6122. [Google Scholar] [CrossRef]

- Li, Y.-M.; Liu, S.-G.; Song, F.-S.; Wang, Z.-M.; Shen, Z.-Y.; Xie, Z.-X. Preparation and thermal stability of silica layer multicoated γ-Ce2S3 red pigment microparticles. Surf. Coat. Technol. 2018, 345, 70–75. [Google Scholar] [CrossRef]

- Nikolaev, P.; Bronikowski, M.J.; Bradley, R.K.; Rohmund, F.; Colbert, D.T.; Smith, K.; Smalley, R.E. Gas-phase catalytic growth of single-walled carbon nanotubes from carbon monoxide. Chem. Phys. Lett. 1999, 313, 91–97. [Google Scholar] [CrossRef]

- El-Gendy, A.; Ibrahim, E.; Khavrus, V.; Krupskaya, Y.; Hampel, S.; Leonhardt, A.; Büchner, B.; Klingeler, R. The synthesis of carbon coated Fe, Co and Ni nanoparticles and an examination of their magnetic properties. Carbon 2009, 47, 2821–2828. [Google Scholar] [CrossRef]

- Mendes, R.G.; Koch, B.; Bachmatiuk, A.; El-Gendy, A.A.; Krupskaya, Y.; Springer, A.; Klingeler, R.; Schmidt, O.; Büchner, B.; Sanchez, S. Synthesis and toxicity characterization of carbon coated iron oxide nanoparticles with highly defined size distributions. Biochim. Biophys. Acta BBA Gen. Subj. 2014, 1840, 160–169. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron size range. J. Colloid Interface Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Bogush, G.; Tracy, M.; Zukoski Iv, C. Preparation of monodisperse silica particles: Control of size and mass fraction. J. Non-Cryst. Solids 1988, 104, 95–106. [Google Scholar] [CrossRef]

- Drašar, P. The Sol-Gel Handbook: Synthesis, Characterization and Applications; David, L., Marcos, Z., Eds.; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Du, G.-H.; Liu, Z.; Xia, X.; Chu, Q.; Zhang, S. Characterization and application of Fe3O4/SiO2 nanocomposites. J. Sol. Gel. Sci. Technol. 2006, 39, 285–291. [Google Scholar] [CrossRef]

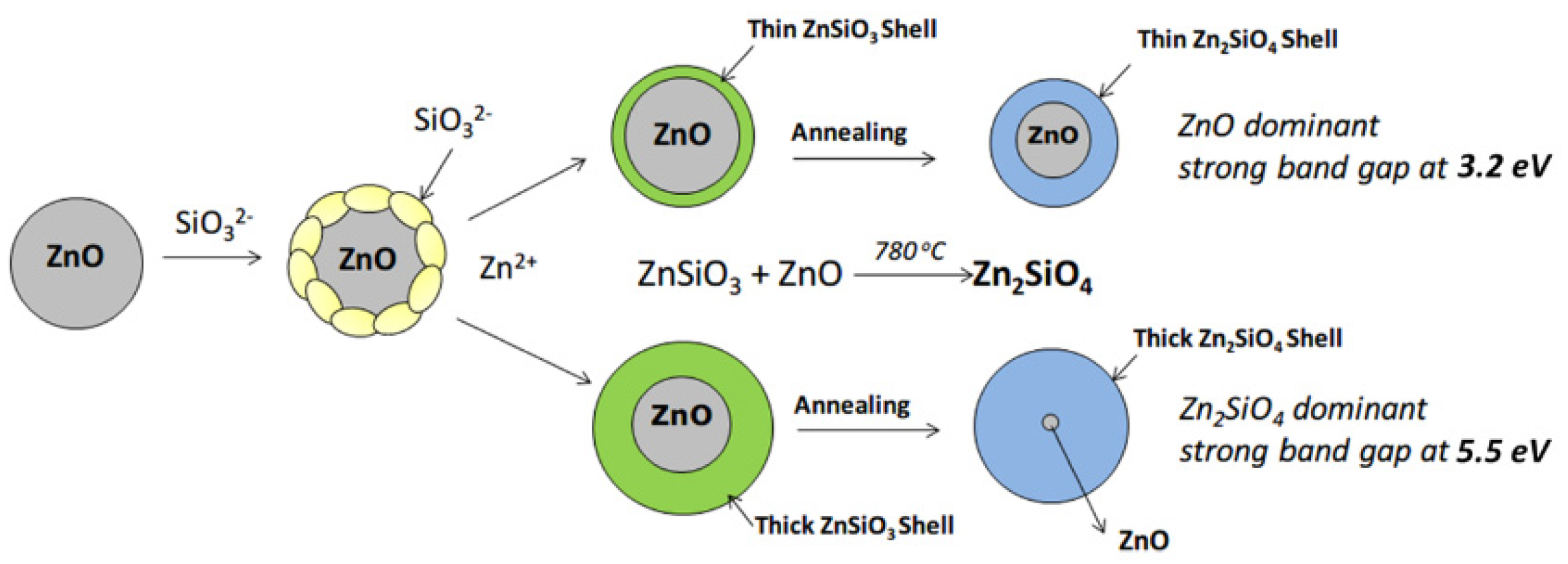

- Li, Z.; Wanjala, B.; Cernigliaro, G.; Nawrocki, D.; Gu, Z. Synthesis of Zn2SiO4@ZnO core–shell nanoparticles and the effect of shell thickness on band-gap transition. Mater. Chem. Phys. 2020, 240, 122144. [Google Scholar] [CrossRef]

- Tsuji, M.; Yamaguchi, D.; Matsunaga, M.; Ikedo, K. Epitaxial growth of Au@Ni core- shell nanocrystals prepared using a two-step reduction method. Cryst. Growth Des. 2011, 11, 1995–2005. [Google Scholar] [CrossRef]

- Fan, F.-R.; Liu, D.-Y.; Wu, Y.-F.; Duan, S.; Xie, Z.-X.; Jiang, Z.-Y.; Tian, Z.-Q. Epitaxial growth of heterogeneous metal nanocrystals: From gold nano-octahedra to palladium and silver nanocubes. J. Am. Chem. Soc. 2008, 130, 6949–6951. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Jiang, P.; Jiang, M.; Wang, T.-W.; Guo, C.-F.; Xie, S.-S.; Wang, Z.-L. The shape evolution of gold seeds and gold@silver core–shell nanostructures. Nanotechnology 2009, 20, 305602. [Google Scholar] [CrossRef]

- Tsuji, M.; Yamaguchi, D.; Matsunaga, M.; Alam, M.J. Epitaxial Growth of Au@Cu Core- Shell Nanocrystals Prepared Using the PVP-Assisted Polyol Reduction Method. Cryst. Growth Des. 2010, 10, 5129–5135. [Google Scholar] [CrossRef]

- Habas, S.E.; Lee, H.; Radmilovic, V.; Somorjai, G.A.; Yang, P. Shaping binary metal nanocrystals through epitaxial seeded growth. Nat. Mater. 2007, 6, 692–697. [Google Scholar] [CrossRef]

- Tsuji, M.; Hikino, S.; Tanabe, R.; Yamaguchi, D. Synthesis of Ag@Cu Core–Shell Nanoparticles in High Yield Using a Polyol Method. Chem. Lett. 2010, 39, 334–336. [Google Scholar] [CrossRef]

- Sharma, R.; Tiwari, S. Synthesis of fly ash based core–shell composites for use as functional pigment in paints. In Proceedings of the AIP Conference Proceedings 2016, Jaipur, Rajasthan, India, 24–25 October 2015; pp. 020083-1–020083-6. [Google Scholar]

- Zhang, J.; Li, X.; Shi, X.; Hua, M.; Zhou, X.; Wang, X. Synthesis of core–shell acrylic-polyurethane hybrid latex as binder of aqueous pigment inks for digital inkjet printing. Prog. Nat. Sci. Mater. Int. 2012, 22, 71–78. [Google Scholar] [CrossRef] [Green Version]

- Guan, L.; Fan, J.; Zhang, Y.; Guo, Y.; Duan, H.; Chen, Y.; Li, H.; Liu, H. Facile preparation of highly cost-effective BaSO4@BiVO4 core–shell structured brilliant yellow pigment. Dye Pigments 2016, 128, 49–53. [Google Scholar] [CrossRef]

- Li, Y.; Gao, Y.; Wang, Z.; Shen, Z.; Hong, Y.; Song, F. Synthesis and characterization of aluminum-based γ-Ce2S3 composite red pigments by microemulsion method. J. Alloys Compd. 2020, 812, 152100. [Google Scholar] [CrossRef]

- Ahmed, N.M.; Abdel-Fatah, H.T.M.; Youssef, E.A. Corrosion studies on tailored Zn·Co aluminate/kaolin core–shell pigments in alkyd based paints. Prog. Org. Coat. 2012, 73, 76–87. [Google Scholar] [CrossRef]

- Jang, H.-S.; Kang, H.-S.; So, S.-Y. Color expression characteristics and physical properties of colored mortar using ground granulated blast furnace slag and White Portland Cement. KSCE J. Civ. Eng. 2014, 18, 1125–1132. [Google Scholar] [CrossRef]

- Lee, H.J.; Jung, K.Y.; Kim, Y.S. Nanostructured Fe2O3/TiO2 composite particles with enhanced NIR reflectance for application to LiDAR detectable cool pigments. RSC Adv. 2021, 11, 16834–16840. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, K.W.; Huseien, G.F.; Kua, H.W. A State-of-the-Art Review on Core–Shell Pigments Nanostructure Preparation and Test Methods. Micro 2021, 1, 55-85. https://doi.org/10.3390/micro1010006

Shah KW, Huseien GF, Kua HW. A State-of-the-Art Review on Core–Shell Pigments Nanostructure Preparation and Test Methods. Micro. 2021; 1(1):55-85. https://doi.org/10.3390/micro1010006

Chicago/Turabian StyleShah, Kwok Wei, Ghasan Fahim Huseien, and Harn Wei Kua. 2021. "A State-of-the-Art Review on Core–Shell Pigments Nanostructure Preparation and Test Methods" Micro 1, no. 1: 55-85. https://doi.org/10.3390/micro1010006

APA StyleShah, K. W., Huseien, G. F., & Kua, H. W. (2021). A State-of-the-Art Review on Core–Shell Pigments Nanostructure Preparation and Test Methods. Micro, 1(1), 55-85. https://doi.org/10.3390/micro1010006