1. Introduction

Current research trajectories are focused on achieving sustainability through the intelligent usage of non-renewable energy resources and the development of novel alternative renewable energy systems. This has been one of the primary research focuses over the last 20 years and remains so to this day. Most sources of alternative renewable energy typically rely on centralized energy management, storage, and distribution systems, as seen in solar, wind, and hydroelectric power stations, each of which requires complex and non-eco-friendly manufactured parts and electronics that necessitate an expert to implement, operate, and harness their generated power. Although these systems may work for large-scale commercial architectural and urban applications, such as factories, the complexity of these systems hinders their domestic use on a small-scale, average user level for urban and architectural purposes. For example, one study (Atasu, et al., 2021) [

1] reported a high cost of managing solar panel waste, imposing environmental and economic concerns in terms of managing these non-organic or eco-digestible wastes. The recycling cost of one panel was usually USD 20–USD 30, in comparison to the USD 1–USD 2 cost of sending that same panel to landfill. Similarly, Kuby Renewable Energy Ltd. (2019) [

2] detailed the components of a standard solar panel, exhibiting their high energy demand for manufacturing their silicon semiconductors as well as their incorporation of hazardous chemicals that require strict control in the manufacturing process. Similarly, wind power is costly due to the need to build remotely located stations due to their high noise and threat to wildlife [

3], and their efficiency in terms of power generation is also questionable [

4]. This deficiency in the performance, sustainability, and economic competence of solar and wind power has mainly led to a shift toward searching for bioenergy solutions, for instance, modern solid and liquid bioenergy [

5]. The trajectory of bioenergy research and applications incorporates various and expanding options by exploiting biomass in microbial fuel cells for generating light and/or electricity from non-pathogenic microbial strains. For example, in 2007–2008, the bacterial “Barcelona Biolamps” [

6] employed the

Aliivibrio fischeri bacterial strain in bioreactors to fully illuminate an apartment with living light, while Abdallah, et al., 2019 [

7] employed a cathodic immobilized laccase-secreting, non-pathogenic fungal strain

Aspergillus sydowii NYKA 510 in a single-chamber microbial fuel cell to generate 0.76 V, 380 mAm

−2, 160 mWm

−2, and 0.4 W at 2000 Ω, which was later employed in a self-sufficient lighting unit employing a system of two sets of four MFCs each, connected in series, for electricity generation. Despite the successful implantation of these bacteria- and fungi-powered devices, their non-photosynthetic characteristics have hindered the autonomous durability of these biobatteries or biolamps. This has led to the focus on algae-powered bioreactors for energy generation as an integral sustainable solution, where the benefits include not only the generation of sustainable, self-maintained, and self-sufficiently generated bioelectricity but also carbon dioxide mitigation, oxygen, and industrially valuable enzyme production and even the production of nutritious elements such as proteins [

8]. Still, these liquid batteries did not solve the complexity of the above operation and maintenance problems. It might have complicated the issue by introducing these wet liquid battery systems that operate using living organisms that are sensitive to their environmental conditions. Added to this is their low energy production and the high cost of electrolyte membranes [

9], adding further constraints to their architectural and urban applications, as reported in [

10], with the criteria for the implementation of these bioactive liquid systems in architecture and urban applications taking into consideration their life cycle and maintenance rate and boosting their energy output in reasonable applications.

Therefore, a third research trajectory sought to implement the intrinsic nature of bio-emitted light, known as “bioluminescent” activity, at the material-scale level. For example, Mitiouchkina, et al., 2020 [

11] engineered tobacco lines expressing a fungal bioluminescent system [

12], which converts caffeic acid present in all plants into luciferin and reports self-sustained luminescence that is easily visible to the naked eye, in the search for integrating fluorescent and bioluminescent genes in plants. However, such endeavors did not consider architectural or urban applications by proposing the genetic modification of plants or trees that are growing or can be adopted on the urban scale. Therefore, an easier and more sustainable procedure was proposed in the “Genetic Barcelona Project” by applying genetic modification to lemon tree leaves to make them autonomously fluorescent in the first phase (2003–2006) in seven lemon trees, which was achieved by introducing the GFP gene into their DNA, offering a renewable, sustainable, autonomous, and passive source of urban lighting [

13]. These genetically modified lemon trees were kept alive for 13 years and would still be alive today if it were not for the need to relocate the research work and its infrastructure. They remained actively fluorescent at night despite their trivial level of emitted light intensity, which could only be sensed in total darkness. These steps fueled research interest in biomanufacturing novel, advanced bioluminescent or fluorescent materials. For example, a group of researchers [

14] explored the idea of making of a bio-luminescent micro-architecture, exploring the use of light-emitting bacteria as an architectural material by investigating the 3D printing of bioluminescent bacteria. The project employed cutting-edge 3D bioprinting technologies to create the bacterial culture and carrier media using a collaborative robot with a bespoke micro-dispenser to liberate the form of the medium at an architectural scale of fabrication. However, the feasibility of scaling-up the project to architectural-scale applications remains questionable due to the complex biomanufacturing processes, which can only be performed inside a laboratory under strict sterile conditions and with expert management of the sensitive bioprinting process, which itself imposes stress on the viability of the bacterial cells in the culture. This is due to the well-known rheological deferential effect pre-, during, and post-printing caused by the pressure at the 3D bioprinter extruder tip [

15]. Additionally, the scale of the developed bacterial bioink is inapplicable, as the hydrogel base cannot sustain itself alone, especially when the number of 3D-printed layers becomes higher at the architectural scale, due to its poor rheological properties which were not measured in the reported project. In addition, there is a potential need for crosslinking this reported bioink to sustain its form post-printing, which might again affect the viability of the cells. And the possible contamination of this biocompatible hydrogel, which might lead to the coexistence of undesired bacterial and fungal pathogenic and harmful strains. Still, that is not everything; the feasibility of bioluminescent activity operation varies definitely across varied scales because of the spaces between the cells, oxygen, nutrient exposure, cell migration, and signaling. Similarly, Thomsen et al., 2020 and Tyse et al., 2022 [

16,

17] projects like “Bioluminescent micro-architectures: Imprimer la lumière”, which examined bioluminescent bacterial cultures as an architectural material, suffered from the same issues of the non-feasible scalability of the proposed materials and procedures on an architectural scale. Despite the research merits in terms of developing computational models for simulating the behavior, growth rates, and lifespan of the proposed bacterial materials and taking into consideration the ecosystem in which the light-emitting metabolisms take place, as well as their limited lifespan. However, there is a deviation between the computational simulations and the living cultures, where the most significant deviation between the simulation and real observations is seen in the first hours due to the lag phase, which the simulation does not consider. In addition, there are imperfections in the 3D-printed media compared to its twin 3D model, where the thickness of the extruded media is not consistent. Therefore, such speculations of unrealistic upscaling from the lab scale to the architectural scale must be reevaluated. Therefore, the current research aims to minimize the wide gap between research projects with their pilot-scale micro-models and the architectural scale by understanding the customization and application potential of this bioactive material.

The limitations of this 3D-printed bioluminescent biomaterial trajectory imply the need for customizing and testing these bioink materials in terms of their rheology, biocompatibility, cell viability, activity post-printing, cell migration, and behavior on an scale adequate for architectural applications before attempting to propose them for architectural applications [

18]. This was investigated by (Estevez and Abdallah, 2024) [

19], who developed a bio-cement composed of a self-mineralizing hydrogel with excellent encapsulation properties, cell compatibility, anti-fungal properties, and high calcium phosphate concentration as a bone-replacement and a bioactive self-mineralizing biomaterial that allows for scaling-up to architecture-scale applications with the possibility of incorporating living cells, thanks to its excellent encapsulating and rheological properties, offering a stand-alone structural material, expanding novel research aspects on studying the lifespan, proliferation, migration, and behavior of the encapsulated cells under the chronically mineralizing material and its time-deferential morphology. Furthermore, it opens vast potential for testing this hydrogel with a wide array of microbial and animal cell strains, since it is biocompatible and non-toxic to human cells, as reported in [

19].

Engineered bioluminescent biomaterials, either incorporating a naturally bioluminescent or a GMO organism, are considered the best trajectory for implementing bioluminescent activity on the material-scale level. However, there are still several considerations to be addressed before introducing these bioactive materials into the built environment with direct contact with people.

For example, the specific chemical, physical, and physiological characteristics of the employed bioluminescent microbial strains must be understood, which vary between bacteria, fungi, and algae in terms of their bioluminescent activity stimuli, intensity, and duration. In addition, the maintenance and co-existence of these living materials must be carried out in a safe way for the bioactive agent and for users. Moreover, the limits of the physical translation and morphogenesis of these living materials in the built environment are crucial, as their physical properties will determine their physical existence and functionality within the environment. These aspects and more must still remain under extensive study before these bioluminescent materials can be implemented in the architectural and urban built environment. Therefore, scaffold structures can offer a possible durable and refillable physical transient between bacterial bioink and its environment of implementation, offering customized, sustainable encapsulation of bioactive bioluminescent organisms.

These scaffolds for bioluminescent bioink are borrowed from the field of tissue engineering, where living cells or bioinks are seeded on scaffolds that are both compatible with the cells’ behavior and provide a physical form for these cells to proliferate and differentiate, thereby creating the required tissue [

20]. In addition, they offer easier, more reliable procedures and easier maintenance of these living cultures than bioreactor devices.

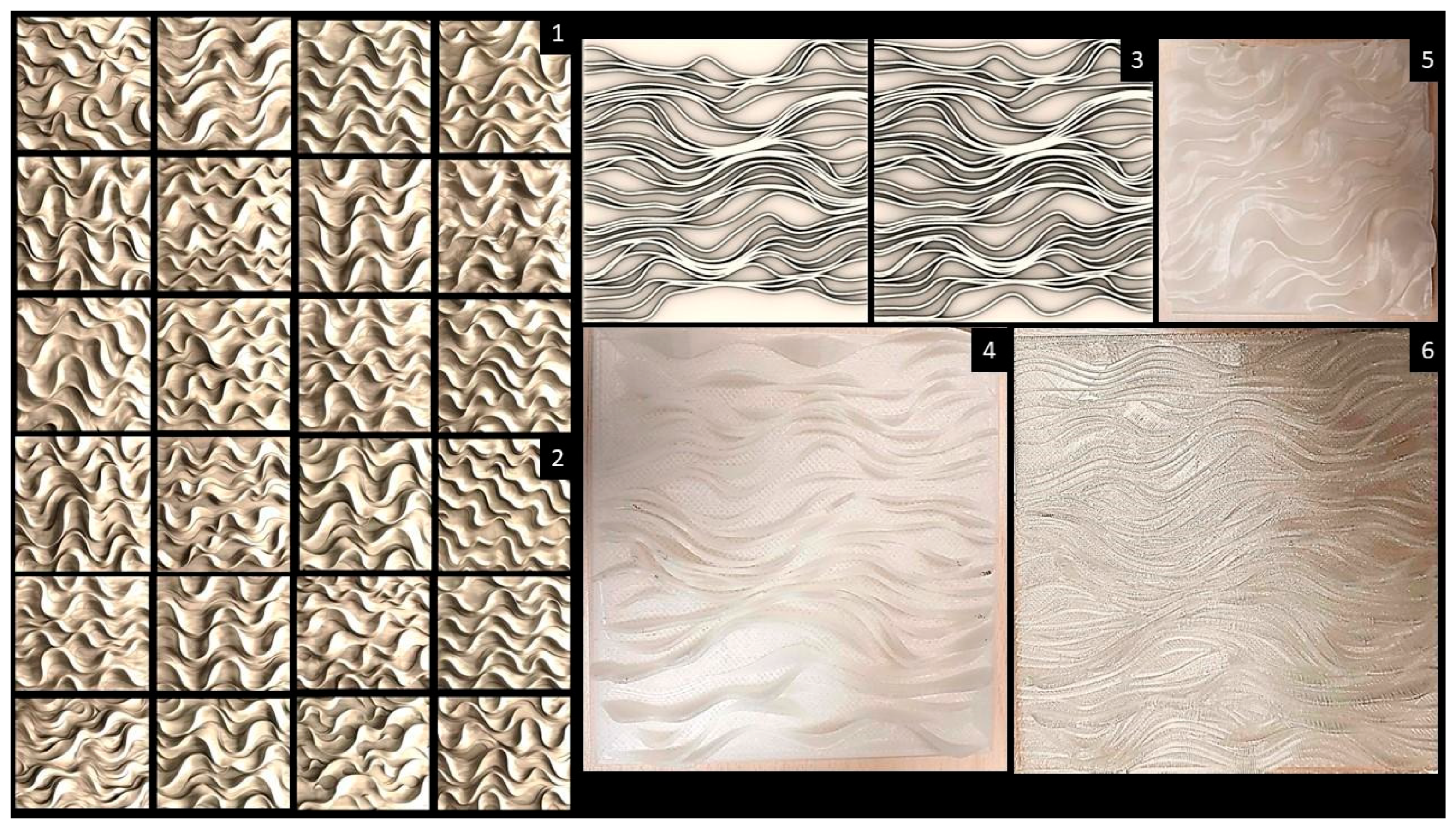

This customized scaffold design was proposed in the paper 3D-Printed Bioreceptive Tiles of Reaction–Diffusion (Gierer–Meinhardt Model) [

21] by adopting a mixed-algae culture with varied algal strains, ranging from filamentous to unicellular, to form a dense mesh of a photosynthetic bioactive scaffold that sustains the existence of the bioluminescent unicellular algae resting on a 3D-printed PLA tile. Although the results of such methods were successful in preserving the life of the bioluminescent algae, the bioluminescent activity was trivial and could not be sensed with the naked eye. Thus, in the current work, the objective is to incorporate the bioluminescent bacterial strain

Aliivibrio fischeri, which is more efficient in terms of its emitted bioluminescent light intensity and duration [

22], in the form of a bioactive bioink layered on a PLA scaffold that will host the system. This approach facilitates the implementation of this system on both the architectural and urban scales, as it requires minimal one-step maintenance for recharging these bioluminescent tiles with new media, which is carried out by spraying new culture media slurry onto these panels. Moreover, these panels can be incorporated on the urban scale with varied options of enclosure by using ion-exchange membranes or dense polycarbonate glass.

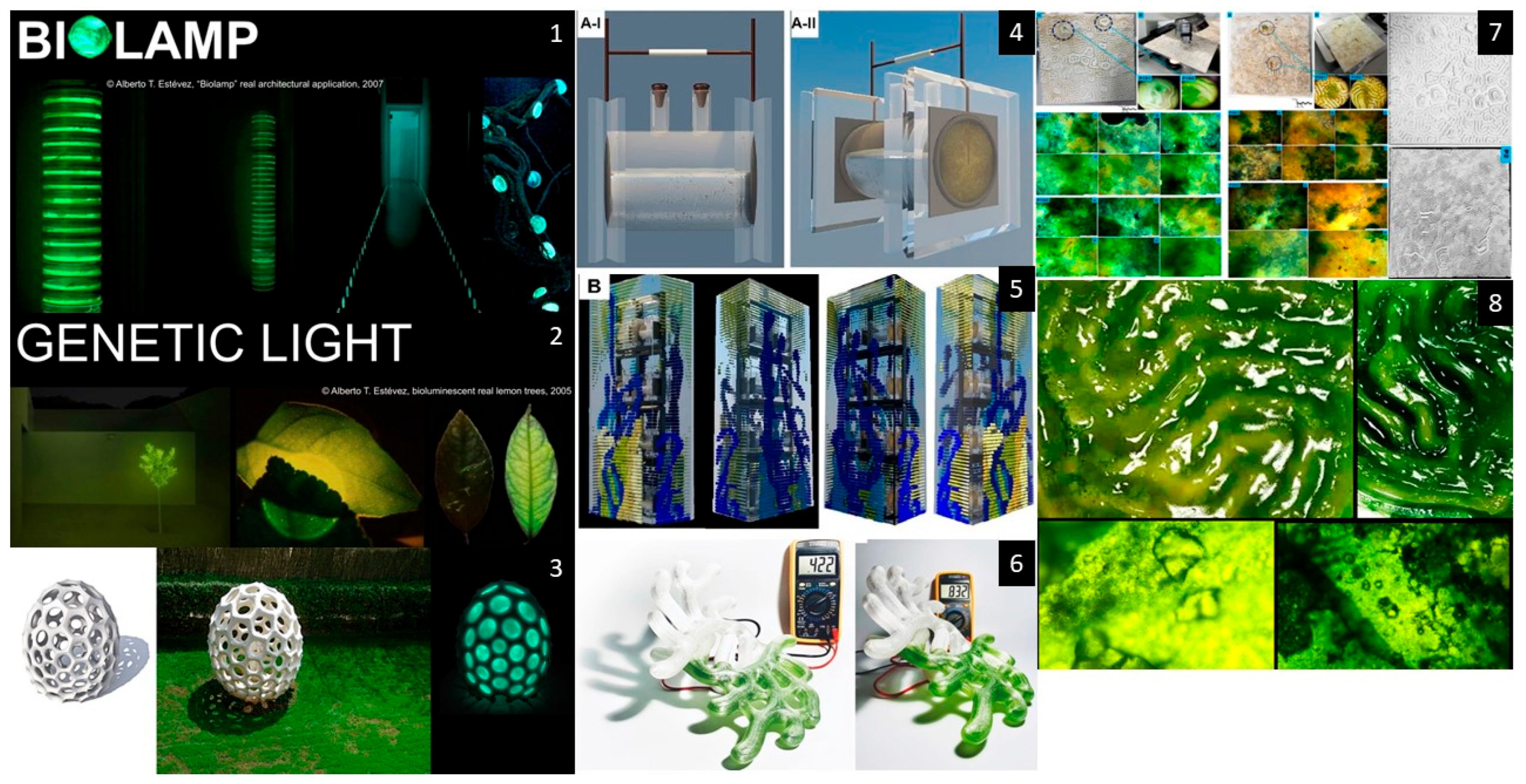

Figure 1 exhibits a collection of research trajectories for obtaining bio-light developed since 2003 by Estévez, and Dollens., 2007. [

13] and later by Abdallah, et al., 2019; Jaafari, et al., 2021; Estevez, and Abdallah, 2024 and Abdallah, and Estévez, 2023 [

7,

8,

19,

21] from 2019 to 2024. These involve using bioluminescent bioreactors, genetically modified plants with the GFP gene or with the

A. vibrio genes responsible for bioluminescence, bioelectricity from fungi and algae in MFCs, bioluminescence panels obtained by immobilization of naturally bioluminescent unicellular marine algae entrapped in a mixed-filamentous-green-algae culture, and self-mineralized hydrogels with excellent encapsulation properties.

Thus, the objective of the current work focuses primarily on bridging the gap between bioluminescent micro-materials, projects, and pilot-scale models and the realistic architectural- and urban-scale applications of these bioluminescent materials through employing a customized biomimetic bioreceptive pattern as a scaffold for bioluminescent bioink to create bioluminescent urban panels, which can be used as cladding at an urban and architectural scale. This can only be achieved by understanding the essential criteria and requirements of the architecture-scale applications to achieve a stand-alone, durable, enclosed, and sustainably maintained bioluminescent material system that employs these urban scaffolds. This study departs from the petri-scale level of bioluminescent bacterial architectures to fully integrated architectural-scale optimized scaffolds that can guarantee an extended and boosted living bioluminescent architectural materials. Thus, the current work will outline the experimental procedures conducted to fabricate a real-scale bioluminescent urban screen model composed of a replica of the screen unit, which is a 3D-printed tile hosting a bioluminescent bacterial culture. The methodology includes developing the biomimetic design of the bioreceptive pattern based on field-diffusion and 3D printing the recipient scaffold (the tile), optimization of the media for the Aliivibrio fischeri culture in terms of the best obtained bioluminescence visibility by the naked eye and the best duration, and the application and bioluminescence performance of the inoculated scaffolds with the bioluminescent bioink from the bacterial culture.

This study aims to prove the economic feasibility and competence of this system on the architectural and urban scales and to pave the way for the following step in this research project, which will involve measuring the spatial bioluminescence light intensity from various spatial points in an interior space and in an exterior space, to determine their efficiency as domestic and urban lights and their functional efficiency. This study is conducted as part of the research project, BioLumCity, funded by Fritz und Trude Fortmann Stiftung.

4. Discussion

The current work aims to scale-up the application of bioluminescent materials as architectural- and urban-scale functional materials to achieve sustainability. Going beyond the previous literature, which was limited to pilot-scale and petri plate research endeavors, to study the bioluminescent behavior of various naturally occurring or GMO-modified organisms [

11,

12,

15,

16,

17]. Therefore, the current work’s novelty and significance lie in exploiting the optimized bioluminescent activity of

A. fischeri culture as an architectural material with a real architecture- and urban-scale applications through the developed bioluminescent urban screens that can be used as cladding at an urban and architecture scale. This is achieved through the customized design of these bioreceptive tiles, which were developed from the physical and chemical fields that are expressed morphologically in nature on various scales through self-organization [

24], deferential growth, or reaction–diffusion mechanisms [

25]. The gradients present in the field patterns signify the gradual transfer (or travel) of force, where the force intensity expressed in the reaction of the topology form decreases congruently with the increase in distance moving away from the force point (attractor point, curve, or region). These gradients create a complex mix of topology, surface, and simple geometry, which can be conceived as a point cloud. This gradual transfer of force and its consequent gradient reaction of particles of self-organization in time and space is the most compatible approach when designing a bioreceptive surface for bioluminescent bacterial culture, facilitating the integration of augmented

A. fischeri bioluminescent bacteria in the built environment. Unlike algae, fungi, and plants that are multicell and tissue-based organisms, bacteria do not have a unified corpus that augments their viability or sustains them across an extended topology. This limitation is reflected in the need for specific conditions for the bacteria to search for nutrients and keep their micro-community alive. Mainly, this involves the need for a continuous, motile topology to facilitate the gliding and swimming of bacteria towards nutrients [

26,

27,

28]. In addition, these continuous topologies need to provide attachment to the bacterial cells in order to keep them attached to the bioreceptive surface and keep them almost embedded within it. Therefore, this was reflected in the bioreceptive tile design, incorporating high peaks, projected strips, and wells, translating this field-based pattern into a bioreceptive scaffold that facilitates the anchorage of the bacterial cells without hindering their motility. Moreover, this was also reflected in the seeding procedures of the bioluminescent bacterial bioink on the panels first to boost the culture attachability to the tiles and then covering it with the optimized media slurry to offer the nutrients required to maintain the culture as well as offering a refiling mechanism for these bioluminescent urban screens by spraying new media slurry every 10 days, as exhibited in the results of the bioluminescence activity durability testing of these tiles, a process which is more feasible in terms of maintenance than a typical bioreactor.

The field pattern design employed in the urban screen panels goes beyond the literature on developing customized bioreceptive surfaces for passive immobilization of specific strains, either one- or multi-scale length microbial strains, since Abdallah and Estevez, 2023 [

21] employed a sharper and tighter gradient-based reaction diffusion mechanism pattern, where the optimum ratio between the hosted algal strain cells size and the niche size was 0.05% to 0.75%. The current work modifies this methodology by balancing a localized immobilization pattern technique with a continuous topology, since the

A. fischeri bioluminescent bacteria requires motility and decreased distance travels between each agent in the culture to boost the emitted light intensity and duration of its bioluminescent activity, given the difference in scale between bacteria and algae [

21] and also given that the bacterial strain used is not photosynthetic and is dependent on the micro-community (culture) to sustain its viability through searching for nutrients or escaping toxins through chemotaxis, which is reflected in the emitted light from its bioluminescence activity [

29,

30].

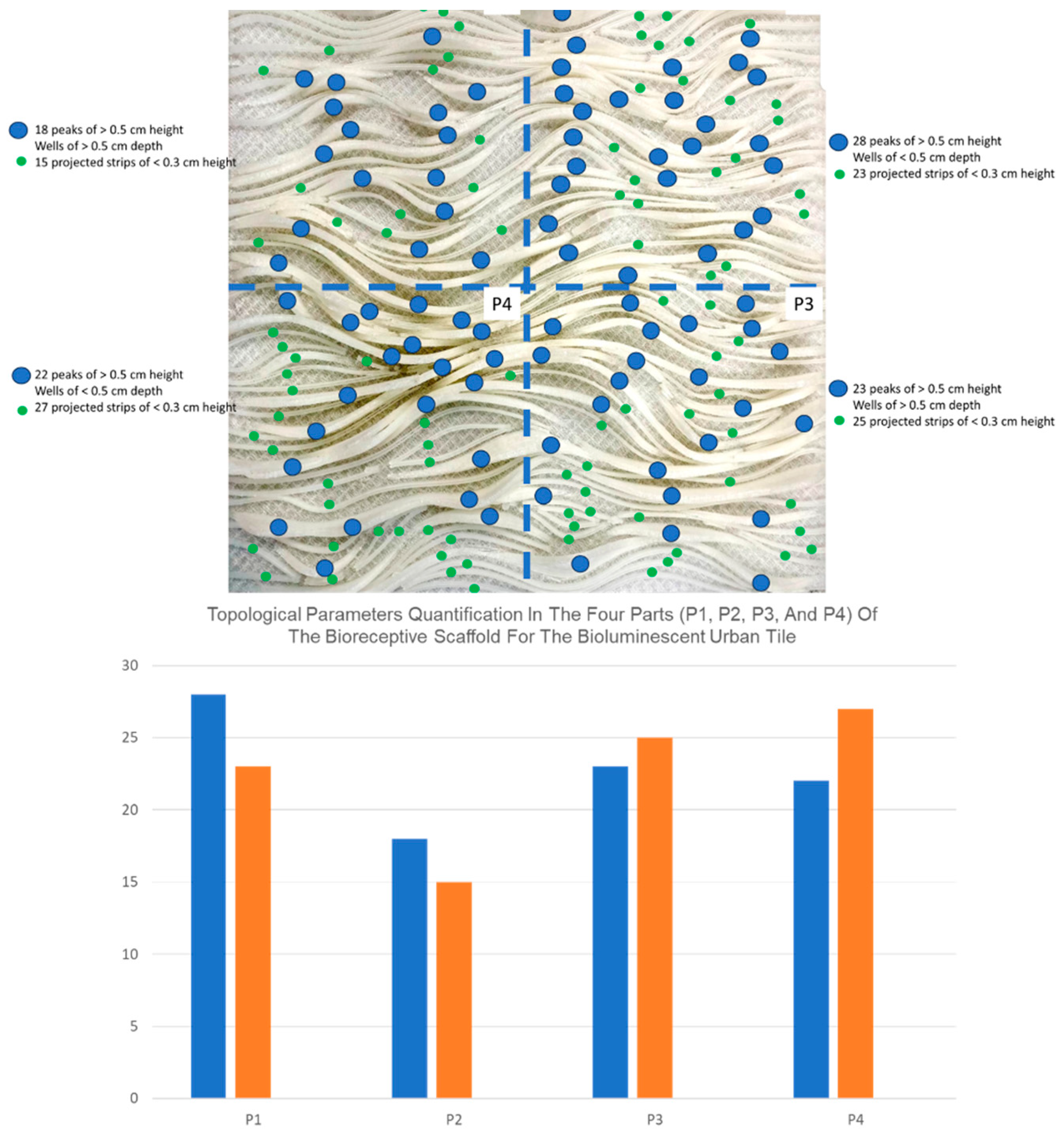

The efficiency of the proposed design based on the field topology was proven by the differential efficiency of some parts of the tile compared to other parts, as reported in the Results section. P1 achieved the longest and most visible light, maintaining the hosted bacterial culture’s viability and bioluminescence activity for 10 days without refilling the media. This is justified by the denser curvilinear peaks in this part, P1, of the tile compared to the other parts, which incorporate fewer peaks and wider wells. As reported in the Results section, higher light intensity was observed at the thin curvilinear peaks of the tile parts. Two reasons justify this: 1. The scale of the bacterial colonies requires minimal distance (shortest path) between their agents (bacterium) in the colony to activate and maintain the bioluminescence activity most economically in terms of exerted energy and consumption of media [

31,

32,

33]; 2. The inhibition of motility and, likely, the growth of the bacterial culture in the wells was due to the physical density of the layered media (five layers) above the seeded bacterial culture bioink on the tiles, imposing a three-dimensional challenge for the bacteria to travel not only horizontally to accumulate and densify the culture for more intense and durable bioluminescence but also to travel vertically from its original location on the micro-textured surface of the tile to top over these layers of media to acquire nutrition and oxygen, which are mandatory to sustain the culture and activate the bioluminescence reaction [

34]. These findings play a crucial role in optimizing the urban screen panel design and the seeding procedure of the bioluminescent bacterial culture. The optimization trajectories include the following: 1. Minimizing the depth and width of the wells of the field pattern and focusing more on a curvilinear peaks with minimum thickness to follow the shortest path strategy of the bacterial migration mechanism [

30] and on a scale more compatible with the bacterial culture. This would minimize the physical resistance on the tile topology in 2D and 3D, resulting in enhanced culture viability, density, biofilm formation, and bioluminescence intensity and duration. 2. Altering the order of the seeding steps by covering the tile first with the optimized media slurry and then seeding the bacterial culture bioink on top of it; this would solve the three-dimensional challenge of the media on the bacterial migration; however, there would still be 2D resistance from the distance between the evenly distributed agents (bacterium) of the bioluminescent bacterial bioink over the tile topology, as well as 3D resistance when new media slurry is sprayed over the tiles to replenish the nutrients. Thus, the third trajectory combines the first two solutions by optimizing the tile design, focusing on the minimum thickness of the curvilinear peaks, seeding the bacterial bioink on top of the optimized media hosted on the urban screen tiles, and minimizing the number applied media layers to less than five and limiting spraying the refill media to 1–2 layers only.

In the current work,

Aliivibrio fischeri CECT 524, a marine species found in temperate and subtropical waters [

35], was employed as a naturally bioluminescent agent, as it is known for an intensity of its bioluminescence at ~490 nm in the blue–green range, as documented in the literature [

22].

A. fischeri produces bioluminescence only when its cell density exceeds a critical threshold; therefore, the optimized media and scaffold design play crucial role in boosting culture viability, density, and bioluminescence behavior. This bioluminescence is a form of chemiluminescence catalyzed by enzymes, differing from fluorescence and phosphorescence in that light emission is not reliant on the absorption of photons. This made it the best choice for the current work objective of developing self-sufficient bioluminescent urban screens that can emit light in darkness without an auxiliary source of light or electricity. In

A. fischeri, the process involves two substrates: luciferin, a reduced form of flavin mononucleotide (FMNH2), and a long-chain fatty aldehyde (RCHO), typically tetra decanal. An external reductant facilitates the reduction of flavin mononucleotide (FMN) to FMNH2 via flavin mono-oxygenase oxidoreductase. The reduced flavin (FMNH2) binds to the enzyme and reacts with oxygen to form a 4a-peroxy-flavin intermediate. This intermediate oxidizes the aldehyde into the corresponding acid (RCOOH). It produces a stable luciferase–hydroxyflavin complex in an excited state, which slowly decays to its ground state, emitting blue–green light with a peak intensity around 490 nm [

36]. The activity of the electron transport system is crucial for producing the reduced substrates necessary for bioluminescence. This process is driven by central carbon and energy metabolism reactions, and any disturbance in these processes or in electron transport itself impacts the bioluminescence. Thus, monitoring changes in bioluminescence offers a direct and rapid means of assessing the effects of perturbations (physical or chemical) on microbial metabolism [

37,

38]. Therefore, the other side of optimizing the bioluminescence activity of the culture is through optimizing the culture media.

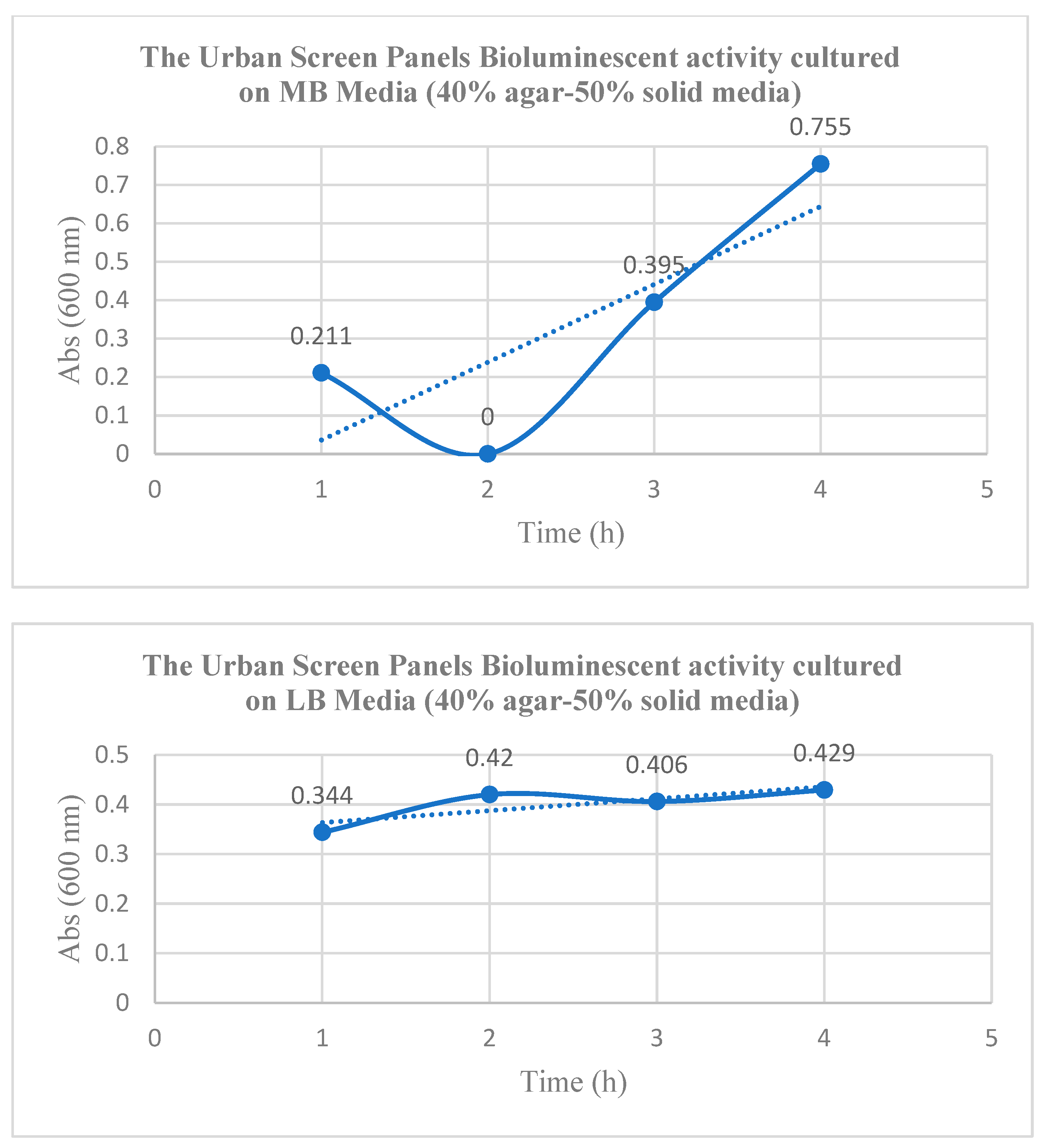

The Marine Broth media yield the highest growth and bioluminescence activity of the bacterial culture compared to the LB and TSB media tested in the current study. This is justified by its composition, which is rich in nutrients, salt, and trace elements, all of which are required for the growth of the marine bacteria

A. fischeri, simulating its natural environment [

39].

Meanwhile, the Tryptone Soy Broth (TSB) media failed to record any visible bioluminescence activity of the culture, since it is a general-purpose broth used for the growth of a wide range of microorganisms. It is not customized for culturing marine bacteria [

40].

The media-to-agar concentration ranging from a 40% to 50% agar concentration for the solid media applied on the urban screen panels achieved the best results in terms of enabling the bioluminescent chemotaxis behavior based on the enhanced mobility of

A. fischeri at lower agar concentrations, which ensures better nutrient availability. This is congruent with the reported results of Tyse, et al., 2022 [

17], which justified having diminishing lights at the peaks with more light intensity in the wells due to deferential media drying, which is congruent with the bioluminescence reaction mechanism and requirements as a colony-based chemotaxis behavior, where the motility of the surface or topology is essential to activating the bioluminescence reaction. In the current work, the 3D altitude of the media expressed in the wells submerged with five layers of slurry media imposed physical resistance on the bacterial culture in terms of gliding in search for nutrients, migration, and clustering to perform the chemiluminescence behavior, which is the typical case in [

17], where a bacterial bioink was 3D-bioprinted, where the cells have to move against gravity towards the 3D pattern peaks, justifying the results obtained in the current work, where the thin curvilinear peaks were more intense in terms of bioluminescence than the wells, since the bacterial cells were seeded on the 3D-printed PLA scaffold first and then covered with the media. This means that in this work’s case, the peaks carry less media volume than the wells, proving the efficiency of the scaffold-based bioluminescent material integration in architecture applications in terms of sustainability in materials and processes. The method also uses less media and delivers more durable bioluminescence activity, as achieved by the lower 3D media resistance to cell migration and clustering.

In the current work, it was not possible to perform typical bioluminescent light and duration intensity assays due to their incompatibility with the objective or the 3D culture topology of the bioluminescent urban panels (tiles). Usual methods focus on testing the bioluminescence of a bacterial culture in liquid medium or at a specific given point in a solid medium. This was not the case in the current work, as testing the bioluminescence intensity and duration on the bioluminescent urban panel requires diluting a sample taken from a specific zone on the 3D culture immobilized on the 3D-printed scaffolds (panels). This dilution by any solution (for example, PBS) would have resulted in a diluted and localized quantification of the bioluminescence intensity on the scale of the cellular level within the microculture. This is not the objective of these bioluminescent panels, which are designed for architectural and urban applications that require a different methodology of spatial quantification of the bioluminescence intensity and duration within the space. Another reason is the differential topology design of the customized bioreceptive panels (tiles) following the field-based pattern, making it impossible to depend on a singular or even multiple local samples taken from the 3D bioluminescent culture as a representative of the bioluminescent intensity, as they represent the microscale and not the architectural scale of the application. Therefore, the current work did not use the cellular bioluminescence intensity (BLcell) or population bioluminescence intensity due to the uneven 3D topology of the tiles and the need for a holistic and spatial estimation of the emitted light from the tile in the space.

Spatial luminometry is being currently conducted by testing the emitted light from the full tile at varying distances, starting from 1cm3 and reaching 1 m3 away from the tile´s imaginary bounding box to record the luminous spatial effect of these tiles in the architectural space and determine their functional applications in various activities. This will be published in a following paper that will compare the micro-scale cell-based bioluminescence intensity to the architecture-scale bioluminescence intensity to deduce a factor for scaling this application of the bioluminescent 3D-printed panels in architecture and urban applications.

The proposed stand-alone system of bioluminescent urban tiles is considered safe for applications on an architectural and urban scale, since Aliivibrio fischeri is a marine bacterium that generally does not cause pathology. Instead, it is known for its beneficial symbiotic relationship with marine animals [

41]. Moreover, the Marine Broth Media used in the current study is a specialized medium for growing and studying marine bacteria, including various species. Its composition, which mimics the salinity and mineral content of seawater, provides the necessary nutrients for these specialized microorganisms that often do not thrive in standard lab media [

42]. This reduces the likelihood that the Marine Broth Media used in the current study will be contaminated with other microbial strains that naturally occur in the air, soil, or water. This was also demonstrated by the observations in the current work, with 10-day sustained bioluminescent tiles that required no recharge and that maintained their morphology. While the agar used in the preparation of the slurry media of the bioluminescent bioink is just a solidifying and nutrient transmission agent. Further analysis of the extracellular matrix ECM and the microenvironment within the tiles is still required to further understand the bioluminescent bacterial growth kinetics and their possible contamination with other unwanted microbial strains, such as fungi or bacteria. Such a study would require varying and comparing the incubation environment across architectural and urban scales and varying the environmental conditions, including temperature, humidity, aeration, light and dark cycles, and orientation, which will be explored in a future study due to the current work’s scope and length.

Nevertheless, as a proof-of-concept step in the current work, the proposed bioluminescent tiles are safe to use for an average user, since they are contained inside closed petri dishes and are proposed to be enclosed within an architectural system that will offer chemically and physically customized enclosures of the system, as mentioned before, through ion-exchange membranes.