Sustainability of Biogas Production from Anaerobic Digestion of Food Waste and Animal Manure

Abstract

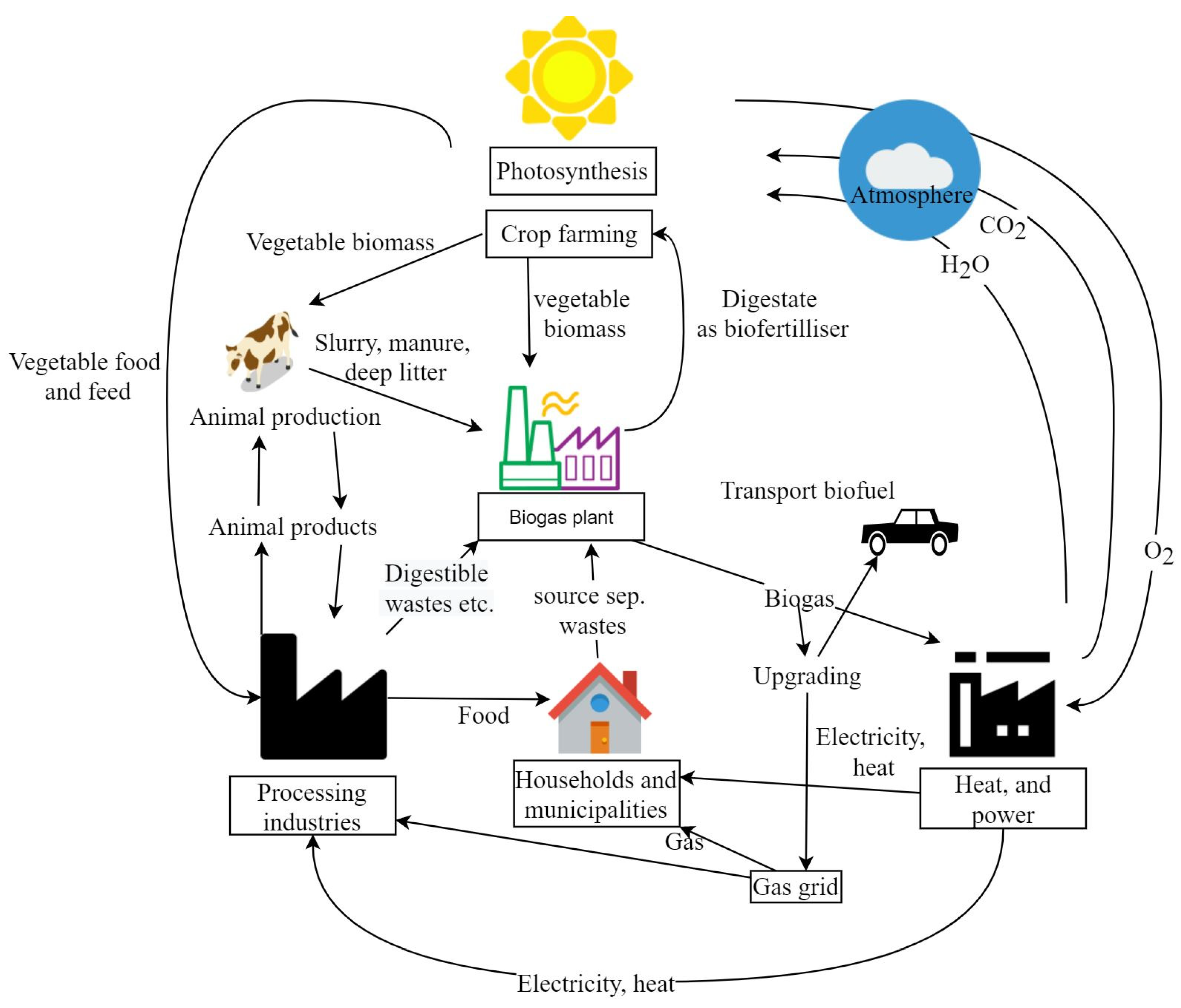

1. Introduction

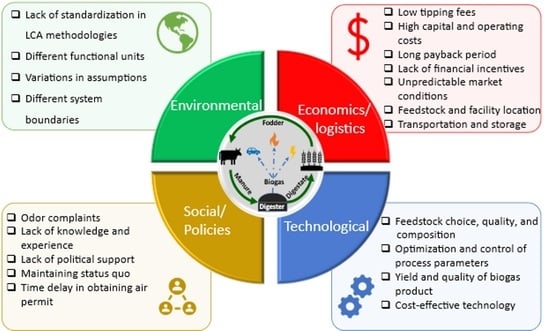

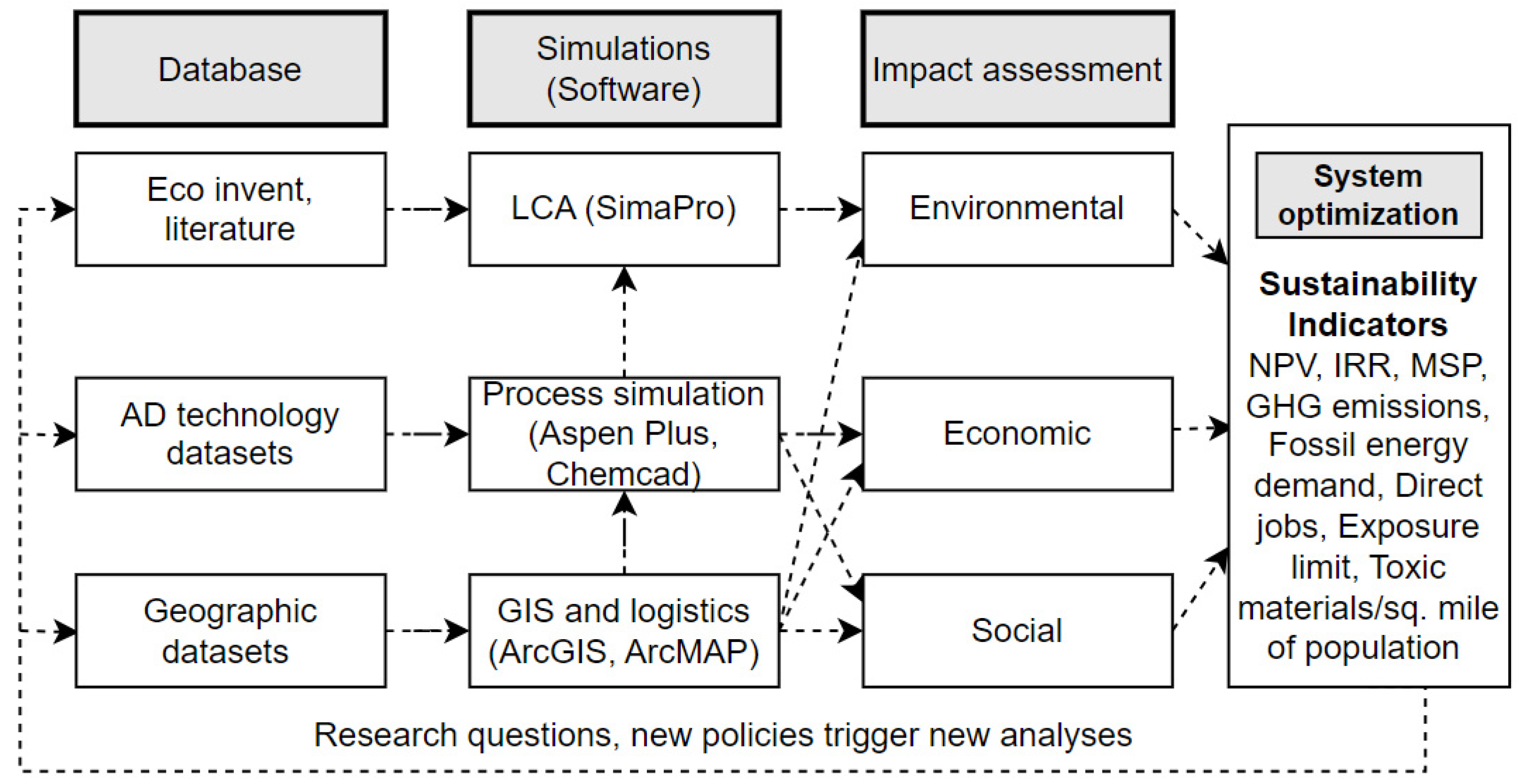

2. Review of Existing Frameworks on Sustainability Assessment of Biogas Systems

Proposed Biogas/Biomethane Sustainability Assessment Framework

3. Current Federal and State Policies on Biogas in the U.S.

4. Social Factors with Biogas Applications in the U.S.

5. Economic Costs and Benefits

6. Environmental Issues of Biogas Production

7. Conclusions and Future Work

- The co-digestion of feedstocks to produce renewable energy has been shown to be environmentally and economically advantageous over mono-digestion [92].

- The review of AcoD LCAs indicated a need for the standardization of methodology so that alternative production concepts can be objectively compared.

- Most of the reviewed TEA studies lacked detailed information on the TEA methodology. There is inconsistency in the TEA assumptions between publications.

- This paper presented a review of different frameworks for the sustainability assessment of biogas systems, and the proposed framework helps us to integrate large multi-disciplinary datasets such as geographic data, environmental data, socio-economic data, and policy data for developing a multi-criteria decision-making tool.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AcoD | Anaerobic co-digestion |

| AD | Anaerobic digestion |

| BAU | Business-as-usual |

| BMP | Biomethane potentials |

| CAPEX | Capital expenditure |

| CHP | Combined heat and power |

| C/N | Carbon/Nitrogen |

| CNG | Compressed natural gas |

| DM | Dairy manure |

| DOE | Department of Energy |

| DR | Discount rate |

| EPA | Environmental Protection Agency |

| FAO | Food and Agriculture Organization |

| FiT | Feed in tariff |

| FU | Functional unit |

| FW | Food waste |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| GIS | Geographical information systems |

| HRT | Hydraulic retention time |

| IRR | Internal rate of return |

| IWA | International Water Association |

| LCA | Life cycle assessment |

| LCFS | Low Carbon Fuel Standard |

| LFG | Landfill gas |

| LMOP | Landfill Methane Outreach Program |

| MILP | Mixed integer linear programming |

| MMT | Million metric tons |

| MSW | Municipal solid waste |

| MW | Megawatts |

| NPV | Net present value |

| OFMSW | Organic fraction of municipal solid waste |

| OLR | Organic loading rate |

| OPEX | Operational expenditure |

| PBP | Payback period |

| PTC | Production Tax Credit |

| REV | Reforming the Energy Vision |

| RFS | Renewable Fuel Standard |

| RNG | Renewable natural gas |

| RPS | Renewable Portfolio Standards |

| VS | Volatile solids |

| USDA | United States Department of Agriculture |

| USD | United States Dollar |

References

- Food and Agriculture Organization (FAO). Food Wastage Footprint: Impacts on Natural Resources. In Summary Report; FAO: Rome, Italy, 2013; Available online: http://www.fao.org/3/i3347e/i3347e.pdf (accessed on 26 July 2020).

- Forbes, H.; Quested, T.; O’Connor, C. United Nations Environment Programme (UNEP). In Food Waste Index Report; UNEP: Nairobi, Kenya, 2021; Available online: https://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 16 April 2021).

- Xu, C.; Shi, W.; Hong, J.; Zhang, F.; Chen, W. Life cycle assessment of food waste-based biogas generation. Renew. Sustain. Energy Rev. 2015, 49, 169–177. [Google Scholar] [CrossRef]

- Taelman, S.; Tonini, D.; Wandl, A.; Dewulf, J. A holistic sustainability framework for waste management in European cities: Concept development. Sustainability 2018, 10, 2184. [Google Scholar] [CrossRef]

- Ingrao, C.; Faccilongo, N.; Di Gioia, L.; Messineo, A. Food waste recovery into energy in a circular economy perspective: A comprehensive review of aspects related to plant operation and environmental assessment. J. Clean. Prod. 2018, 184, 869–892. [Google Scholar] [CrossRef]

- Al Seadi, T.; Stupak, I.; Smith, C.T. Governance of environmental sustainability of manure-based centralised biogas production in Denmark. IEA Bioenergy 2018, 7. [Google Scholar]

- Ontario Ministry of the Environment and Climate Change. Discussion Paper: Addressing Food and Organic Waste in Ontario; Ontario Ministry of the Environment and Climate Change: Toronto, ON, USA, 2017. Available online: https://opha.on.ca/wp-content/uploads/2020/09/FINAL_MOECC_Consultation_OPHA_OSNPPH_DC_PROOF_AUG01-2017-1.pdf?ext=pdf (accessed on 8 January 2024).

- European Commission (EU). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Closing the Loop—An EU Action Plan for the Circular Economy; EU: Brussels, Belgium, 2015; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52015DC0614 (accessed on 26 July 2020).

- USEPA. National Overview: Facts and Figures on Materials, Wastes and Recycling. 2018. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials (accessed on 16 April 2021).

- The Water Research Foundation. Executive Summary: Sustainable Food Waste Evaluation. In WERF Report; 2012; p. OWSO5R07e. Available online: https://www.waterrf.org/research/projects/sustainable-food-waste-evaluation (accessed on 8 January 2024).

- Environmental Protection Agency. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2021; U.S. Environmental Protection Agency: Washington, DC, USA, 2023; EPA 430-R-23-002. Available online: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-andsinks-1990-2021 (accessed on 8 January 2024).

- Global Methane Initiative (GMI). Global Methane Initiative: An Overview. Available online: https://www.globalmethane.org/documents/gmi-factsheet.pdf (accessed on 26 July 2020).

- Environmental Protection Agency. Inventory of US Greenhouse Gas Emissions and Sinks: 1990–2016; EPA 430-R-18-003; EPA: Washington, DC, USA, 2018; pp. 1–655.

- Hristov, A.N.; Johnson, K.A.; Kebreab, E. Livestock methane emissions in the United States. Proc. Natl. Acad. Sci. USA 2014, 111, E1320. [Google Scholar] [CrossRef]

- US EPA. 2023. Available online: https://www.epa.gov/lmop/landfill-gas-energy-project-data (accessed on 8 January 2024).

- Advanced Disposal. Landfill Gas-to-Energy Turning Waste into Energy. Available online: https://www.advanceddisposal.com/for-mother-earth/education-zone/landfill-gas-to-energy.aspx (accessed on 26 July 2020).

- Baldi, E.; Toselli, M.; Marcolini, G.; Quartieri, M.; Cirillo, E.; Innocenti, A.; Marangoni, B. Compost can successfully replace mineral fertilizers in the nutrient management of commercial peach orchard. Soil Use Manag. 2010, 26, 346–353. [Google Scholar] [CrossRef]

- Taiwo, A.M. Composting as a sustainable waste management technique in developing countries. J. Environ. Sci. Technol. 2011, 4, 93–102. [Google Scholar] [CrossRef]

- Goldstein, N. The state of organics recycling in the US. BioCycle 2017, 58, 22. [Google Scholar]

- Containers, Packaging, and Non-Durable Good. Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM). 2016. Available online: https://www.epa.gov/warm/documentation-waste-reduction-model-warm (accessed on 8 January 2024).

- Ankathi, S.K.; Potter, J.S.; Shonnard, D.R. Carbon footprint and energy analysis of bio-CH 4 from a mixture of food waste and dairy manure in Denver, Colorado. Environ. Prog. Sustain. Energy 2018, 37, 1101–1111. [Google Scholar] [CrossRef]

- Komilis, D.; Ham, R.; Stegmann, R. The effect of municipal solid waste pretreatment on landfill behavior: A literature review. Waste Manag. Res. 1999, 17, 10–19. [Google Scholar] [CrossRef]

- Fricke, K.; Santen, H.; Wallmann, R. Comparison of selected aerobic and anaerobic procedures for MSW treatment. Waste Manag. 2005, 25, 799–810. [Google Scholar] [CrossRef]

- De Gioannis, G.; Muntoni, A.; Cappai, G.; Milia, S. Landfill gas generation after mechanical biological treatment of municipal solid waste. Estimation of gas generation rate constants. Waste Manag. 2009, 29, 1026–1034. [Google Scholar] [CrossRef]

- Di Maria, F.; Sordi, A.; Micale, C. Experimental and life cycle assessment analysis of gas emission from mechanically–biologically pretreated waste in a landfill with energy recovery. Waste Manag. 2013, 33, 2557–2567. [Google Scholar] [CrossRef] [PubMed]

- National Renewable Energy Laboratory. Energy Analysis: Biogas Potential in the United States. 2013. Available online: https://www.nrel.gov/docs/fy14osti/60178.pdf (accessed on 29 March 2020).

- USDA. Biogas Opportunities Roadmap: Voluntary Actions to Reduce Methane Emissions and Increase Energy Independence. 2014. Available online: https://www.epa.gov/sites/production/files/2015-12/documents/biogas-roadmap.pdf (accessed on 26 July 2020).

- National Conference of State Legislatures. State Renewable Portfolio Standards and Goals. 2020. Available online: https://www.ncsl.org/research/energy/renewable-portfolio-standards.aspx (accessed on 26 July 2020).

- Höhn, J.; Lehtonen, E.; Rasi, S.; Rintala, J. A Geographical Information System (GIS) based methodology for determination of potential biomasses and sites for biogas plants in southern Finland. Appl. Energy 2014, 113, 1–10. [Google Scholar] [CrossRef]

- Pantaleo, A.; De Gennaro, B.; Shah, N. Assessment of optimal size of anaerobic co-digestion plants: An application to cattle farms in the province of Bari (Italy). Renew. Sustain. Energy Rev. 2013, 20, 57–70. [Google Scholar] [CrossRef]

- Park, Y.S. Three Essays on Sustainability of Transportation and Supply Chain. Ph.D. Thesis, North Dakota State University, Fargo, ND, USA, 2018. [Google Scholar]

- Laasasenaho, K.; Lensu, A.; Lauhanen, R.; Rintala, J. GIS-data related route optimization, hierarchical clustering, location optimization, and kernel density methods are useful for promoting distributed bioenergy plant planning in rural areas. Sustain. Energy Technol. Assess. 2019, 32, 47–57. [Google Scholar] [CrossRef]

- Bioteau, T.; Boret, F.; Tretyakov, O.; Béline, F.; Balynska, M.; Girault, R. A GIS-Based Approach for Optimizing the Development of Collective Biogas Plants. In Global Assessment for Organic Resources and Waste Management; Verlag ORBIT: London, UK, 2012; p. 8. [Google Scholar]

- Balaman, Ş.Y.; Selim, H. A network design model for biomass to energy supply chains with anaerobic digestion systems. Appl. Energy 2014, 130, 289–304. [Google Scholar] [CrossRef]

- Shonnard, D.R.; Tipaldo, E.; Thompson, V.; Pearce, J.; Caneba, G.; Handler, R.M. Systems analysis for PET and olefin polymers in a circular economy. In Proceedings of the 26th CIRP Life Cycle Engineering (LCE) Conference, West Lafayette, IN, USA, 7–9 May 2019; Volume 80, pp. 602–606. [Google Scholar]

- USDA. Biogas Opportunities Roadmap Progress Report. 2015. Available online: https://www.epa.gov/sites/production/files/2015-12/documents/biogas-roadmap-progress-report.pdf (accessed on 27 July 2020).

- Gasper, R.; Searchinger, T. The Production and Use of Renewable Natural Gas as a Climate Strategy in the United States; World Resources Institute: Washington, DC, USA, 2018. [Google Scholar]

- American Biogas Council. American Biogas Council—State Profiles. Available online: https://americanbiogascouncil.org/resources/state-profiles/ (accessed on 27 July 2020).

- American Biogas Council. Biogas State Profile: Maryland. Available online: https://americanbiogascouncil.org/wp-content/uploads/2019/02/ABCBiogasStateProfile_MD.pdf (accessed on 27 July 2020).

- DSIRE. Database of State Incentives for Renewables & Efficiency (DSIRE). Available online: https://www.dsireusa.org/ (accessed on 27 July 2020).

- von Loesecke, E.; Chermak, C. The Inflation Reduction Act: Impacts on Utilities and Power Producers. Clim. Energy 2023, 39, 1–10. [Google Scholar] [CrossRef]

- Willis, J.; Stone, L.; Durden, K.; Beecher, N.; Hemenway, C.; Greenwood, R. Barriers to Biogas Use for Renewable Energy; Water Environment Research Foundation: online, 2012. [Google Scholar]

- Nevzorova, T.; Kutcherov, V. Barriers to the wider implementation of biogas as a source of energy: A state-of-the-art review. Energy Strategy Rev. 2019, 26, 100414. [Google Scholar] [CrossRef]

- Thrän, D.; Schaubach, K.; Majer, S.; Horschig, T. Governance of sustainability in the German biogas sector—Adaptive management of the Renewable Energy Act between agriculture and the energy sector. Energy Sustain. Soc. 2020, 10, 3. [Google Scholar] [CrossRef]

- Zemo, K.H.; Termansen, M. Farmers’ willingness to participate in collective biogas investment: A discrete choice experiment study. Resour. Energy Econ. 2018, 52, 87–101. [Google Scholar] [CrossRef]

- Arthur, R.; Baidoo, M.F.; Antwi, E. Biogas as a potential renewable energy source: A Ghanaian case study. Renew. Energy 2011, 36, 1510–1516. [Google Scholar] [CrossRef]

- Mwirigi, J.; Balana, B.B.; Mugisha, J.; Walekhwa, P.; Melamu, R.; Nakami, S.; Makenzi, P. Socio-economic hurdles to widespread adoption of small-scale biogas digesters in Sub-Saharan Africa: A review. Biomass Bioenergy 2014, 70, 17–25. [Google Scholar] [CrossRef]

- Mengistu, M.; Simane, B.; Eshete, G.; Workneh, T. A review on biogas technology and its contributions to sustainable rural livelihood in Ethiopia. Renew. Sustain. Energy Rev. 2015, 48, 306–316. [Google Scholar] [CrossRef]

- Bong, C.P.C.; Ho, W.S.; Hashim, H.; Lim, J.S.; Ho, C.S.; Tan, W.S.P.; Lee, C.T. Review on the renewable energy and solid waste management policies towards biogas development in Malaysia. Renew. Sustain. Energy Rev. 2017, 70, 988–998. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, T. Biogas system in rural China: Upgrading from decentralized to centralized? Renew. Sustain. Energy Rev. 2017, 78, 933–944. [Google Scholar] [CrossRef]

- Mittal, S.; Ahlgren, E.O.; Shukla, P. Barriers to biogas dissemination in India: A review. Energy Policy 2018, 112, 361–370. [Google Scholar] [CrossRef]

- Bajgain, S.; Shakya, I.S. A Successful Model of Public Private Partnership for Rural Household Energy Supply; SNV: Kigali, Rwanda, 2005. [Google Scholar]

- Gautam, R.; Baral, S.; Herat, S. Biogas as a sustainable energy source in Nepal: Present status and future challenges. Renew. Sustain. Energy Rev. 2009, 13, 248–252. [Google Scholar] [CrossRef]

- Garfí, M.; Martí-Herrero, J.; Garwood, A.; Ferrer, I. Household anaerobic digesters for biogas production in Latin America: A review. Renew. Sustain. Energy Rev. 2016, 60, 599–614. [Google Scholar] [CrossRef]

- Kabir, H.; Yegbemey, R.N.; Bauer, S. Factors determinant of biogas adoption in Bangladesh. Renew. Sustain. Energy Rev. 2013, 28, 881–889. [Google Scholar] [CrossRef]

- Mandal, S.; Ghosh, S. Evaluation of biogas as an alternative driving force of electrically operated vehicles: A case study. Int. J. Eng. 2018, 31, 834–840. [Google Scholar]

- Fike, J.H.; Parrish, D.J.; Alwang, J.; Cundiff, J.S. Challenges for deploying dedicated, large-scale, bioenergy systems in the USA. CAB Rev. 2007, 2, 1–28. [Google Scholar] [CrossRef]

- Satchwell, A.J.; Scown, C.D.; Smith, S.J.; Amirebrahimi, J.; Jin, L.; Kirchstetter, T.W.; Brown, N.J.; Preble, C.V. Accelerating the deployment of anaerobic digestion to meet zero waste goals. Environ. Sci. Technol. 2018, 52, 13663–13669. [Google Scholar] [CrossRef]

- Waste360. Residents Complain about Odors at the Heartland Biogas Facility in Colorado. 2017. Available online: https://www.waste360.com/waste-energy/residents-complain-about-odors-heartland-biogas-facility-colorado (accessed on 27 July 2020).

- di Perta, E.S.; Cervelli, E.; di Campagna, M.P.; Pindozzi, S. From biogas to biomethane: Techno-economic analysis of an anaerobic digestion power plant in a cattle/buffalo farm in central Italy. J. Agric. Eng. 2019, 50, 127–133. [Google Scholar] [CrossRef]

- Samer, M.; Abdelaziz, S.; Refai, M.; Abdelsalam, E. Techno-economic assessment of dry fermentation in household biogas units through co-digestion of manure and agricultural crop residues in Egypt. Renew. Energy 2020, 149, 226–234. [Google Scholar] [CrossRef]

- Akbulut, A. Techno-economic analysis of electricity and heat generation from farm-scale biogas plant: Çiçekdağı case study. Energy 2012, 44, 381–390. [Google Scholar] [CrossRef]

- Rajendran, K.; Aslanzadeh, S.; Johansson, F.; Taherzadeh, M.J. Experimental and economical evaluation of a novel biogas digester. Energy Convers. 2013, 74, 183–191. [Google Scholar] [CrossRef]

- Klavon, K.H.; Lansing, S.A.; Mulbry, W.; Moss, A.R.; Felton, G. Economic analysis of small-scale agricultural digesters in the United States. Biomass Bioenergy 2013, 54, 36–45. [Google Scholar] [CrossRef]

- Valenti, F.; Porto, S.M.; Dale, B.E.; Liao, W. Spatial analysis of feedstock supply and logistics to establish regional biogas power generation: A case study in the region of Sicily. Renew. Sustain. Energy Rev. 2018, 97, 50–63. [Google Scholar] [CrossRef]

- Lantz, M. The economic performance of combined heat and power from biogas produced from manure in Sweden—A comparison of different CHP technologies. Appl. Energy 2012, 98, 502–511. [Google Scholar] [CrossRef]

- Ullah, M. Techno-economic Assessment of Utilization of Food Processing Waste for Production of Energy and Chemicals. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2017. [Google Scholar]

- Martínez-Ruano, J.A.; Restrepo-Serna, D.L.; Carmona-Garcia, E.; Giraldo, J.A.P.; Aroca, G.; Cardona, C.A. Effect of co-digestion of milk-whey and potato stem on heat and power generation using biogas as an energy vector: Techno-economic assessment. Appl. Energy 2019, 241, 504–518. [Google Scholar] [CrossRef]

- Moriarty, K. Feasibility Study of Anaerobic Digestion of Food Waste in St. Bernard, Louisiana; NREL/TP-7A30-57082; National Renewable Energy Laboratory: Golden, CO, USA, 2013; pp. 1–48.

- Sanscartier, D.; MacLean, H.L.; Saville, B. Electricity production from anaerobic digestion of household organic waste in Ontario: Techno-economic and GHG emission analyses. Environ. Sci. Technol. 2012, 46, 1233–1242. [Google Scholar] [CrossRef]

- Aui, A.; Li, W.; Wright, M.M. Techno-economic and life cycle analysis of a farm-scale anaerobic digestion plant in Iowa. Waste Manag. 2019, 89, 154–164. [Google Scholar] [CrossRef]

- Al-Maghalseh, M. Techno-economic assessment of biogas energy from animal wastes in central areas of Palestine: Bethlehem perspective. Int. J. Energy Appl. Technol. 2018, 5, 119–126. [Google Scholar] [CrossRef]

- Imeni, S.M.; Pelaz, L.; Corchado-Lopo, C.; Busquets, A.M.; Ponsá, S.; Colón, J. Techno-economic assessment of anaerobic co-digestion of livestock manure and cheese whey (Cow, Goat & Sheep) at small to medium dairy farms. Bioresour. Technol. 2019, 291, 121872. [Google Scholar]

- Kamusoko, R.; Jingura, R.M.; Parawira, W.; Sanyika, W.T. Comparison of pretreatment methods that enhance biomethane production from crop residues-a systematic review. Biofuel Res. J. 2019, 6, 1080. [Google Scholar] [CrossRef]

- Haider, J.; Qyyum, M.A.; Kazmi, B.; Ali, I.; Nizami, A.-S.; Lee, M. Simulation study of deep eutectic solvent-based biogas upgrading process integrated with single mixed refrigerant biomethane liquefaction. Biofuel Res. J. 2020, 7, 1245. [Google Scholar] [CrossRef]

- Chiu, S.L.; Lo, I.M. Reviewing the anaerobic digestion and co-digestion process of food waste from the perspectives on biogas production performance and environmental impacts. Environ. Sci. Pollut. Res. 2016, 23, 24435–24450. [Google Scholar] [CrossRef]

- Bartocci, P.; Zampilli, M.; Liberti, F.; Pistolesi, V.; Massoli, S.; Bidini, G.; Fantozzi, F. LCA analysis of food waste co-digestion. Sci. Total Environ. 2020, 709, 136187. [Google Scholar] [CrossRef]

- Esteves, E.M.M.; Herrera, A.M.N.; Esteves, V.P.P.; Morgado, C.d.R.V. Life cycle assessment of manure biogas production: A review. J. Clean. Prod. 2019, 219, 411–423. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Fiala, M.; Feijoo, G.; Lema, J.M.; Moreira, M.T. Life Cycle Assessment of electricity production in Italy from anaerobic co-digestion of pig slurry and energy crops. Renew. Energy 2014, 68, 625–635. [Google Scholar] [CrossRef]

- Hijazi, O.; Munro, S.; Zerhusen, B.; Effenberger, M. Review of life cycle assessment for biogas production in Europe. Renew. Sustain. Energy Rev. 2016, 54, 1291–1300. [Google Scholar] [CrossRef]

- Fusi, A.; Bacenetti, J.; Fiala, M.; Azapagic, A. Life cycle environmental impacts of electricity from biogas produced by anaerobic digestion. Front. Bioeng. Biotechnol. 2016, 4, 26. [Google Scholar] [CrossRef] [PubMed]

- Ebner, J.H.; Labatut, R.A.; Rankin, M.J.; Pronto, J.L.; Gooch, C.A.; Williamson, A.A.; Trabold, T.A. Lifecycle greenhouse gas analysis of an anaerobic codigestion facility processing dairy manure and industrial food waste. Environ. Sci. Technol. 2015, 49, 11199–11208. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Rojas-Downing, M.M.; Zhong, Y.; Saffron, C.M.; Liao, W. Life cycle and economic assessment of anaerobic co-digestion of dairy manure and food waste. Ind. Biotechnol. 2015, 11, 127–139. [Google Scholar] [CrossRef]

- Bolin, L.; Lee, H.M.; Lindahl, M. LCA of biogas through anaerobic digestion from the organic fraction of municipal solid waste (OFMSW) compared to incineration of the waste. In Proceedings of the 6th International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Sapporo, Japan, 6–9 December 2009. [Google Scholar]

- Huang, W.; Zhang, X. Life Cycle Assessment of Anaerobic Digestion of Municipal Waste for Vehicle Biogas Production. In Proceedings of the 2015 International Conference on Advanced Engineering Materials and Technology, Guangzhou, China, 9 November 2015; Atlantis Press: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Boulamanti, A.K.; Maglio, S.D.; Giuntoli, J.; Agostini, A. Influence of different practices on biogas sustainability. Biomass Bioenergy 2013, 53, 149–161. [Google Scholar] [CrossRef]

- Tong, H.; Tong, Y.-W.; Peng, Y.H. A comparative life cycle assessment on mono-and co-digestion of food waste and sewage sludge. Energy Procedia 2019, 158, 4166–4171. [Google Scholar] [CrossRef]

- Lyng, K.-A.; Brekke, A. Environmental life cycle assessment of biogas as a fuel for transport compared with alternative fuels. Energies 2019, 12, 532. [Google Scholar] [CrossRef]

- Hahn, H.; Hartmann, K.; Bühle, L.; Wachendorf, M. Comparative life cycle assessment of biogas plant configurations for a demand oriented biogas supply for flexible power generation. Bioresour. Technol. 2015, 179, 348–358. [Google Scholar] [CrossRef]

- Hung, C.; Solli, C. Biogas from municiapal organic waste–trondheim’s environmental holy grail? Energy Procedia 2012, 20, 11–19. [Google Scholar] [CrossRef]

- Rehl, T.; Lansche, J.; Müller, J. Life cycle assessment of energy generation from biogas—Attributional vs. consequential approach. Renew. Sustain. Energy Rev. 2012, 16, 3766–3775. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Y.; Wang, S.; Wang, Z.; Liu, Y.; Hu, Z.; Zhan, X. Environmental sustainability assessment of pig manure mono-and co-digestion and dynamic land application of the digestate. Renew. Sustain. Energy Rev. 2021, 137, 110476. [Google Scholar] [CrossRef]

- Du, M.; Peng, C.; Wang, X.; Chen, H.; Wang, M.; Zhu, Q. Quantification of methane emissions from municipal solid waste landfills in China during the past decade. Renew. Sustain. Energy Rev. 2017, 78, 272–279. [Google Scholar] [CrossRef]

- Singh, C.K.; Kumar, A.; Roy, S.S. Estimating potential methane emission from municipal solid waste and a site suitability analysis of existing landfills in Delhi, India. Technologies 2017, 5, 62. [Google Scholar] [CrossRef]

- Duan, Y.; Gao, Y.; Zhao, J.; Xue, Y.; Zhang, W.; Wu, W.; Jiang, H.; Cao, D. Agricultural methane emissions in China: Inventories, driving forces and mitigation strategies. Environ. Sci. Technol. 2023, 57, 13292–13303. [Google Scholar] [CrossRef]

| Model | Feedstock | AcoD | LCA | Social | Policy | Economics | Logistics | Ref. |

|---|---|---|---|---|---|---|---|---|

| GIS-based logistics optimization | Manure and energy crops | X | X | [29] | ||||

| Decision support tool | Manure and energy crops | X | X | X | X | [30] | ||

| GIS-integrated MILP optimization | Manure alone | X | X | X | X | X | [31] | |

| GIS- and R programing-based logistics optimization | Ag residues and Biomass | X | X | [32] | ||||

| GIS-based optimization | Crop residues, pig slurry, food waste, sewage sludge, and cattle manure | X | X | [33] | ||||

| MILP optimization | Animal manure and energy crops | X | X | X | X | [34] |

| Agency | Policy/Program | Details |

|---|---|---|

| USDA | (REAP) Rural Energy for America Program | Financing for anaerobic digester projects. Final REAP rule effective from 2015. |

| Biorefinery, Renewable Chemical, and Biobased Product Manufacturing Assistance Program | Funding for commercial, municipal, and industrial biogas plant formation. Final rule effective from 2020. | |

| Rural Utilities Services (RUS) | Federal Financing Bank Loan available from 2015. | |

| NRCS (National Resources Conservation Service) and EQIP (Environmental Quality Incentives Program) | Financial and technical assistance to agricultural producers through contracts. | |

| Program Coordination (Stacking) | Deliver USDA services to producers | |

| EPA | Renewable Fuel Standard (RFS) | Generates credits or Renewable Identification Numbers (RINs) for biofuels. Effective from 2007. |

| Inflation Reduction Act (IRA) | Biomass, landfill gas, hydroelectric, marine, and hydrokinetic eligible for a production tax credit of $0.0275/kWh (2023 value) | |

| DOE | Renewable Hydrogen Potential resource assessment from Biogas in the US | Determines overall potential and net accessibility of methane in raw biogas |

| Bioenergy Technologies Office (BETO) and Multi-Year Program Plan (MYPP) | Identifies potential of high-impact resources for domestic manufacturing of bio-product precursors, biogas, biofuels, electricity, and heat. |

| Ref. | System [Capacity] | Feedstock | CAPEX & OPEX | ESP | NPV | PBT | Results |

|---|---|---|---|---|---|---|---|

| [60] | Converting biopower plant to biomethane plant [4.4 MWhd−1] | Cattle/buffalo manure co-digested with energy crops and whey | EUR 1,205,000 and N/A | EUR 0.093/kWh and EUR 0.23/m3 | (EUR 903,473) | 35.3 | Upgrading to biomethane is not economically feasible, even with incentives, due to the high investment cost of upgrading |

| [61] | Household biogas production [N/A] | Dairy manure co-digested with crop residues (7:3) | EUR 582.28–EUR 1151.31 and EUR 283.99–EUR 851.96 | EUR 0.55 per m3 of biogas | EUR 10,649–EUR 32,543.2 | 3.2–4.8 | Household small-scale biogas in rural Egypt is profitable and the profitability indicators increased with an increase in the size of biogas |

| [62] | Farm-scale biogas plant [289 kW] | Dairy manure co-digested with sheep dung | EUR 2500 to EUR 7500 per kWh/h and EUR 0.019/kWh | EUR 0.1/kWh | EUR 9.88 million | 3.4 | The biogas produced in a CHP unit is more profitable than utilizing biogas in a combustion unit that produces only heat. |

| [63] | Biogas digester for replacing LPG and Kerosene [N/A] | OFMSW, manure, and water | USD 200–300 and 5% of capital costs | N/A | USD 250–USD 3500 | 1.3–3 | Replacing LPG and kerosene in both subsidized and non-subsidized scenarios is economically viable |

| [64] | Small-scale Ag digesters [0.8 MWh/cow/year] | Cow manure | USD 12,000–USD 61,000 per annum and 25% to 50% of annual capital costs | Heat and electricity USD 47–100/cow/year | 8 of 16 digesters showed positive NPV at 50% cost share | N/A | Economically viable on 250 cow dairies but tipping fee from food waste may reduce the size |

| [65] | Regional biogas power generation [3.6 MW-e] | Citrus pulp, Olive pomace, cattle manure, whey, poultry manure, silage | EUR 2,690,000–EUR 3,156,000 and 4% for digester 3% for CHP unit | 0.16 EUR/kWh | <6.5 | This system can satisfy 27% of Italy’s electricity needs | |

| [66] | Biogas CHP plant from manure [1–6 GWh/annum] | Manure | 17,000 EUR/yr. to 90,000 EUR/yr. and 2.5–4% of investment costs | EUR 20–50/MWh | 1. CHP from biogas based on manure is not profitable under current market conditions in Sweden. 2. Biogas process operated under thermophilic conditions is more profitable than under mesophilic conditions. | ||

| [67] | AD of Food Processing Waste | Food waste and water | 38,142,439 Canadian dollars and 1,970,400 Canadian Dollars | CAD 0.035/kWh | With C.C: —Economically viable at 10% IRR with a tipping fee of CAD 81/t for S.S (500 t/yr.), CAD 64/t for M.S (10,000 t/yr.), and CAD 57/t for L.S (2000 t/yr.) | ||

| [68] | Co-digestion of Milk whey and potato [13,277 kW of power] | 1000 m3/day for MW and 300 t/day for PS | USD 5.49 M.–USD 34.28 M. and USD 7.96 M.–USD 15.35 M. per year | USD 0.14/kWh | (USD 21.15) to (USD 45.21) M. at $10/ton digestate sale price | High organic load has the best economic feasibility | |

| [69] | AD of food waste [1,739,866–3,717,514 kWh/year] | Food waste | USD 561/ton of FW and USD 48/ton of FW | USD 0.078/kWh | (USD 6,762,992) | Poor financial performance includes low area tipping fees and energy prices as well as high capital costs | |

| [70] | Electricity Production from AD of household waste [0.5–10 MW] | 78% kitchen organic waste and 22% nondegradable material | USD 0.147/kWh | 11 | Current FiT rate (USD 0.147/kWh), a 200 kt/yr. facility requires a USD 50/t fee to attain an 11% IRREQUITY, while a 50 kt/yr. facility requires a USD 95/t fee to reach an 11% IRREQUITY | ||

| [71] | Farm-scale AD [950 kW] | Biomass, manure, and glycerin | USD 0.44–USD 0.55/kWh and Glycerin reduces the operating cost by 32%. | USD 0.064/kWh and (USD 0.015)/kWh-e renewable tax | Greater NPV for glycerin case | 3.51 and 5.57 | Increased the ROI by 27% with glycerin addition |

| [72] | Biogas energy from animal wastes [7 MW] | Cow, Sheep, Goat, and Chicken manure | USD 21,600,000 and USD 5,108,000 | USD 7,392,000 | Economically feasible with an ROI of 15% | ||

| [73] | Co-digestion of animal manure and cheese whey | Livestock manure (Cow, Goat, and Sheep) and cheese whey | N/A and EUR 7200/year. | 0.14 ± 0.03 EUR/kWh. | >0 | 5–10 | Co-digestion of manure with cheese whey found to be economical compared to mono-digestion of animal manure. NPV is negative and the IRR ranges from 0.97 to 5.88% for low cheese whey % ratio |

| Ref. | Functional Unit | System Boundary | Feedstock | Biogas Application | Results |

|---|---|---|---|---|---|

| [79] | 100 kWh of combined heat and power electricity | Cradle-to-gate | Pig manure, energy crops | As electricity and as heat | Total net emissions: −0.016 kg CO2-eq/100 kWh-e; combustion emissions from biogas power plants contribute more towards GWP. |

| [82] | 1 metric ton of influent processed | Cradle-to-grave | Dairy manure and food waste | As electricity and as heat | Conventional management emissions: 6348 tCO2-eq/year AcoD emissions: 1836 tCO2-eq/year. |

| [83] | 7153 dry metric tons of dairy manure and 2382 dry tons of food waste per year | Cradle-to-grave | Dairy manure, bakery process waste, and food waste | As electricity and as heat | Co-digestion: 1.6 × 104 t CO2-eq, AD of DM and FW to landfill 2.7 × 104 t CO2-eq. |

| [84] | 1 ton of organic fraction of municipal solid waste | Cradle-to-grave | Municipal solid waste | As fuel and as electricity | Incineration gives about 130 kg more CO2-eq/FU than the medium- and large-scale scenarios and about 80 kg CO2-eq/FU more than the small-scale scenario. |

| [77] | 1 kWh of electricity produced | Cradle-to-grave | Food waste and energy crops | As electricity | Emissions in kg CO2-eq/kWh-e: Biogas plants with energy crops as feedstock 0.37. 209 tons of food waste instead of energy crops 0.36; 6809 tons of food waste from malls and food industry: 0.15. |

| [85] | 1 ton of municipal solid waste | Cradle-to-grave | Municipal solid waste | As fuel | Total GHG emissions reported: 61 kg CO2/t MSW, and 0.25 kg CH4/t municipal solid waste. |

| [86] | 1 MJ of electricity (MJe) | Cradle-to-grave | Dairy manure, silage maize | As electricity and as heat | Emission in g CO2/MJe: Biogas from maize—open and closed storage: 140 and 90; Biogas from manure—open and closed storage: 160 and 330; Biogas from co-digestion—open and closed storage: 70 and 10, respectively. |

| [3] | 1 ton of food waste volatile solid | Cradle-to-grave | Food waste, sludge | As electricity and as heat | Anaerobic digestion for food waste and sludge: 213 kgCO2-eq/ton of functional units. Anaerobic digestion of food waste: 169 kg CO2-eq/functional units. Food waste to landfill: 181 kg CO2-eq/functional units. |

| [87] | 1000 tons of food waste and 4400 tons of sewage sludge | Cradle-to-grave | Food waste and sludge | As fuel | Mono-anaerobic digestion 7.01 × 104 kg CO2-eq/functional unit, Co-anaerobic digestion had higher greenhouse gas emissions than mono-anaerobic digestion. |

| [88] | Per km of transport | Gate-to-grave | Dairy manure, food waste | As fuel | 0.28 kg CO2-eq/km from biogas (food waste); 0.41 kg CO2-eq/km from biogas (manure). |

| [89] | 1 MJ of biogas | Cradle-to-grave | Dairy manure, press fluid, energy crops | As electricity | In contrast to an alternative supply of power generators with natural gas, biogas supplied on demand by adapted biogas plant configurations saves greenhouse gas emissions by 54–65 g CO2-eq/MJ and primary energy by about 1.17 MJ. |

| [90] | 10,000 tons of organic fraction of municipal solid waste | Cradle-to-grave | Dairy manure, municipal solid waste, food waste | As fuel, electricity, and heat | Anaerobic digestion of source separated organic waste to produce biogas then used as vehicle fuel: 11,949 t CO2-eq/functional units. |

| [21] | kg Bio-CH4 | Cradle-to-grave | Dairy manure, food waste | As fuel | AD Bio-CH4 pathway has 15.5% lower GHG emissions compared to composting, AD conversion of FW and manure avoids FW landfilling, and conventional management of dairy manure emits −3.5 kg CO2 equivalents/kg Bio-CH4 assuming the electricity was generated using collected landfill gas. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ankathi, S.K.; Chaudhari, U.S.; Handler, R.M.; Shonnard, D.R. Sustainability of Biogas Production from Anaerobic Digestion of Food Waste and Animal Manure. Appl. Microbiol. 2024, 4, 418-438. https://doi.org/10.3390/applmicrobiol4010029

Ankathi SK, Chaudhari US, Handler RM, Shonnard DR. Sustainability of Biogas Production from Anaerobic Digestion of Food Waste and Animal Manure. Applied Microbiology. 2024; 4(1):418-438. https://doi.org/10.3390/applmicrobiol4010029

Chicago/Turabian StyleAnkathi, Sharath Kumar, Utkarsh S. Chaudhari, Robert M. Handler, and David R. Shonnard. 2024. "Sustainability of Biogas Production from Anaerobic Digestion of Food Waste and Animal Manure" Applied Microbiology 4, no. 1: 418-438. https://doi.org/10.3390/applmicrobiol4010029

APA StyleAnkathi, S. K., Chaudhari, U. S., Handler, R. M., & Shonnard, D. R. (2024). Sustainability of Biogas Production from Anaerobic Digestion of Food Waste and Animal Manure. Applied Microbiology, 4(1), 418-438. https://doi.org/10.3390/applmicrobiol4010029