1. Introduction

Onion (

Allium cepa L.) has the second greatest global production value, among vegetable crops, after tomatoes, with over five million hectares grown in 2021, while about 380,000 tonnes of dry onions and 15,000 tonnes of green onions were produced in the UK in 2021 [

1]. Nitrogen is the primary essential nutrient required by plants with onions requiring a high amount of nitrogen and high nitrogen availability [

2]. Previous work in the UK showed that 150 kg N ha

−1 gives the optimal yield as further nitrogen applications do not result in increased yields [

3], and the information in this source is still forming the basis of nitrogen recommendations for UK growers over 20 years later [

4]. The Agricultural and Horticulture Development Board (AHDB) in the UK recommends that up to 160 kg ha

−1 of N is applied depending on the field conditions [

5].

Published work on onion nutrition used a range of nitrogen application rates, for example, 100 and 200 kg N ha

−1 [

6], 0–270 kg N ha

−1 [

7], 210–315 kg N ha

−1 [

8] and 102–302 kg N ha

−1 [

9], and the optimal rates for production were 92 kg N ha

−1 [

7], 263 kg N ha

−1 [

8], 162 kg N ha

−1 [

9] and 134 kg N

−1 ha [

10]. Additionally, the form of the nitrogen (urea, ammonium nitrate or calcium nitrate) was shown to not influence yield [

6]. Onions have shallow roots which means that they often exhibit low recovery rates for the nitrogen that was applied, which can be only 30–40% or lower [

2]. The low recovery can also be linked to how onions are grown as they are widely spaced (compared to some other crops) in the field, which means broadcast granular fertilisers do not effectively supply nitrogen [

3]. It is possible to obtain the same yield with a reduction in nitrogen application (20 kg N ha

−1) if it is targeted at the seed during drilling [

3], especially if a top dressing of nitrogen is used to fine tune the available nitrogen to the needs of the onions [

11]. The majority of the nitrogen required by onions is taken up in the second half of its growing season [

2], which means that much of the nitrogen applied at sowing will no longer be available.

Using traditional fertilisation schedules for onions can result in overapplication of nitrogen that results in increased nitrate leaching that causes environmental problems and increases the cost of production [

12]. To enable suitable and sustainable fertiliser application, it needs to meet the 4R requirements to come from the right source, be applied at the right rate, right time and right place [

13]. For example, nitrogen in the nitrate form does not interact with any types of soil and rain can wash it out of the soil and below the root zone, while ammonium can be held within certain soils due to cation exchange sites, but under the right conditions, ammonium can quickly undergo nitrification to become nitrate [

2]. While urea can be quickly broken down by bacteria in soil to ammonia which is lost to the atmosphere [

14]. Previous work showed that nitrogen can be stabilised as a urea-sourced amine N (stabilised amine nitrogen—SAN) that offers yield increases over traditional non-stabilised urea and industry standard N-P-K fertiliser [

14]. SAN was shown to increase yield in potato [

14,

15,

16], ornamentals [

17], wheat [

18], tomato [

19] and lettuce [

20] when used in a research glasshouse as well as in the field under commercial conditions. In these previous studies, the SAN was applied at lower nitrogen rates than would be traditionally applied with the control forms of nitrogen used. In some studies, rates of the control nitrogen applications were reduced to the same level as in the SAN [

14,

17,

18,

19,

20], while in other studies, the control nitrogen application rates were maintained and the SAN was applied in addition [

15,

16], and in all these cases, the SAN resulted in increased yield and nitrogen use efficiency (NUE). Additionally, the SAN was applied foliarly during the growing season, so it would be present when the plant required it, rather than being applied to the soil, as is common with much agricultural nitrogen application.

As shown above, onion often has too much nitrogen applied and that, due to the crop’s growth habit in commercial production, there is a wide scope for the loss of traditionally applied forms of nitrogen, onion is a good candidate for use with SAN applied foliarly later in the growing season when the requirement for nitrogen is highest. By implementing this and significantly reducing the amount of nitrogen applied, it will be possible to increase the NUE of commercial onion production. Therefore, the aim of this work was to assess the potential for SAN to maintain onion growth and yield while reducing the amount of urea applied.

2. Materials and Methods

Experiments were conducted in a heated but unlit research glasshouse at Myerscough College in the northwest of the UK. The first repeat of the experiment used F1 Hybound (pelleted) onion (Allium cepa var. cepa) seeds (Moles Seeds, Colchester, UK) that were planted in 15 cm diameter pots filled with John Innes No. 2 potting medium, which was grown and harvested as a ‘summer’ onion when the plant was still green. The second repeat of the experiment used Ramrod onion (A. cepa var. cepa) seeds (Moles Seeds, Colchester, UK) that were planted in plug trays and transplanted at the one-leaf stage into 9.5 cm diameter pots, both filled with John Innes No. 2 potting medium, which was grown as a spring or salad onion. Water was applied as required to maintain soil moisture, so that the potting medium did not become dry (about three times per week). The first repeat of the experiment was planted on 24 March 2022, the plants were scored for the first time on 26 April 2022 and the final scoring and harvest took place on 12 June 2022. The second repeat of the experiment was planted on 20 September 2022, the plants were transplanted on 14 October 2022, they were scored for the first time on 21 October 2022 and the final scoring and harvest took place on 02 December 2022.

There were two fertiliser treatments applied to each repeat of the experiment, which were standard commercial practice for UK production of 150 kg N ha−1 as urea mixed into the potting medium at planting in repeat one and at transplant in repeat two. While the second treatment was a stabilised amine nitrogen (SAN) (Lono K, Levity Crop Science, Preston, UK) that was applied at 5 L ha−1 in 200 L ha−1 water at the three, four and five leaf stages; each application of the SAN contained 0.9 kg N ha−1, so the three applications gave 2.7 kg N ha−1 in total. The treatments were set out in a randomised blocked design with six and 10 replicates for the first and second repeats, respectively. No other fertiliser was applied, and the potting medium supplied all other nutrients.

From the first scoring date, each repeat was scored weekly for the number of leaves and height, and at harvest the weight of the whole plant (excluding roots), weight of the bulb (just first repeat), bulb diameter and stem diameter just above the bulb were recorded. The survival percentage was the number of plants that survived to harvest.

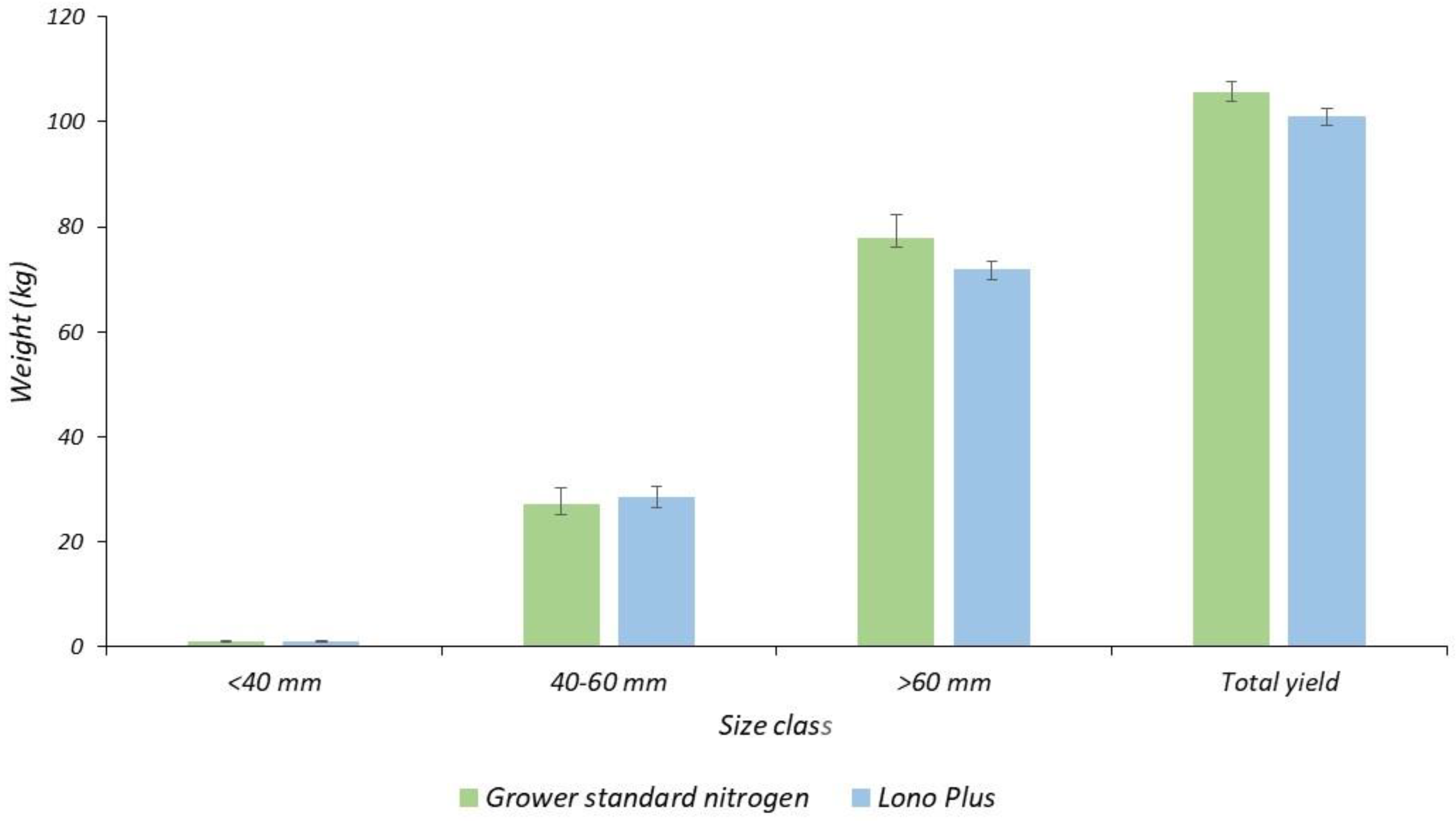

A field plot trial was conducted in the Netherlands (52.57983° N, 5.60522° E) to compare the yield of onion under a standard grower nitrogen application, which was 150 kg ha−1 applied to the soil at planting, to SAN (Lono Plus, Levity Crop Science, Preston, UK) applied foliarly at 3.5 L ha−1 application−1 for 12 applications throughout the growing season. Each SAN application contained 0.63 kg N ha−1, and so, the 12 applications gave 7.56 kg N ha−1. Each plot was 12 m2 and all other management was the same between the two plots. The soil in the field site was a loam. At maturity, the onions were harvested, and the total weight was recorded as well as the weight of the graded size classes <40 mm, 40–60 mm and >60 mm.

Statistical analysis was performed using the Jamovi 2.3.18 for Windows software [

21]. Student’s

t-tests or Mann–Whitney U tests (depending on the normality of the data) were used to identify significant differences at the

p < 0.05 level between treatments.

3. Results

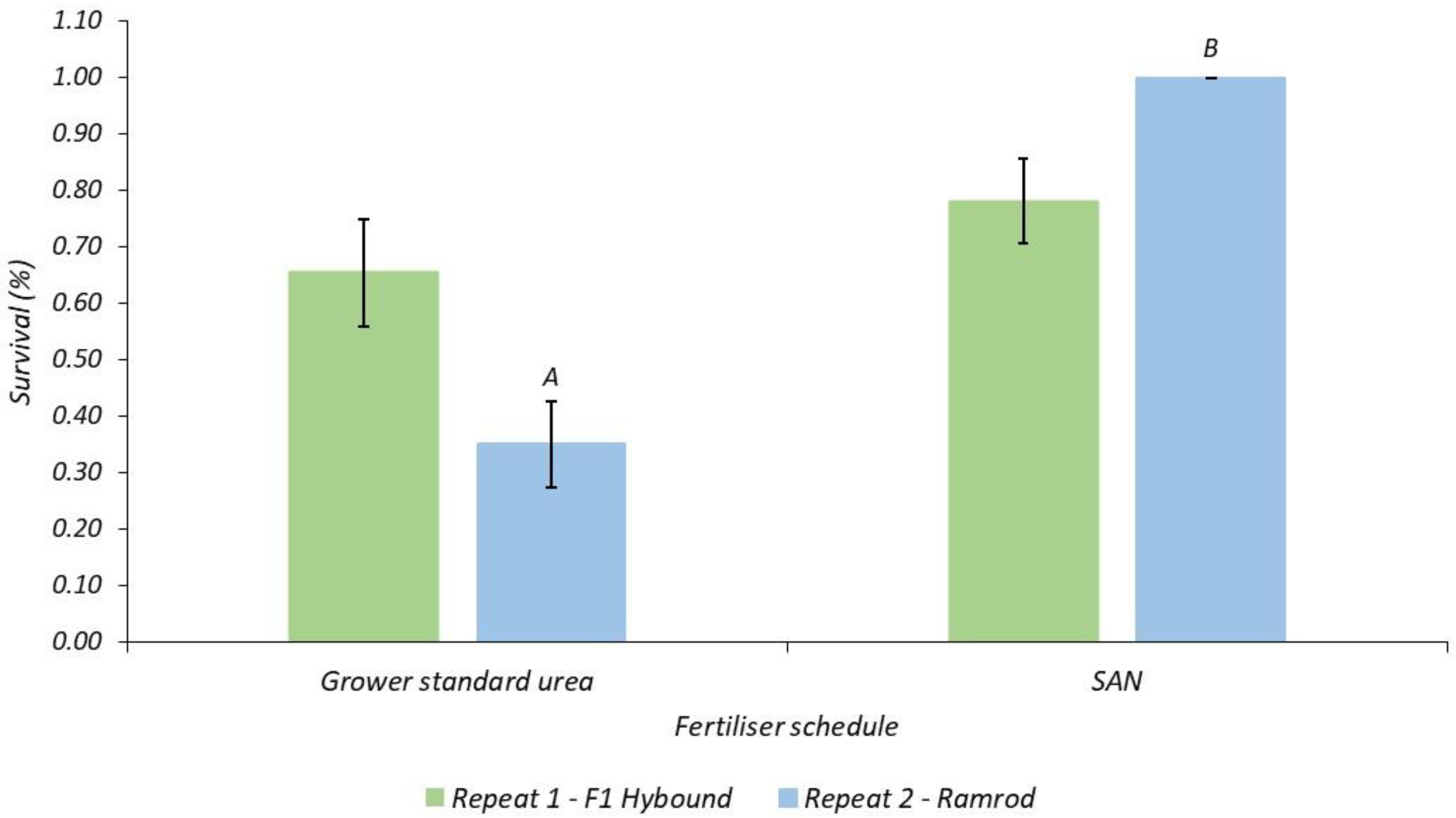

In the first repeat of the experiment, the survival to harvest rates of 65% for the urea and 78% for the SAN were not significantly different. For the second repeat, the SAN treatment resulted in 100% survival to harvest, while for the urea it was only 35%, which was a significant difference (Mann–Whitney U,

p < 0.05) (

Figure 1). For all the following results, only the surviving plants in the urea treatment were used for the analysis.

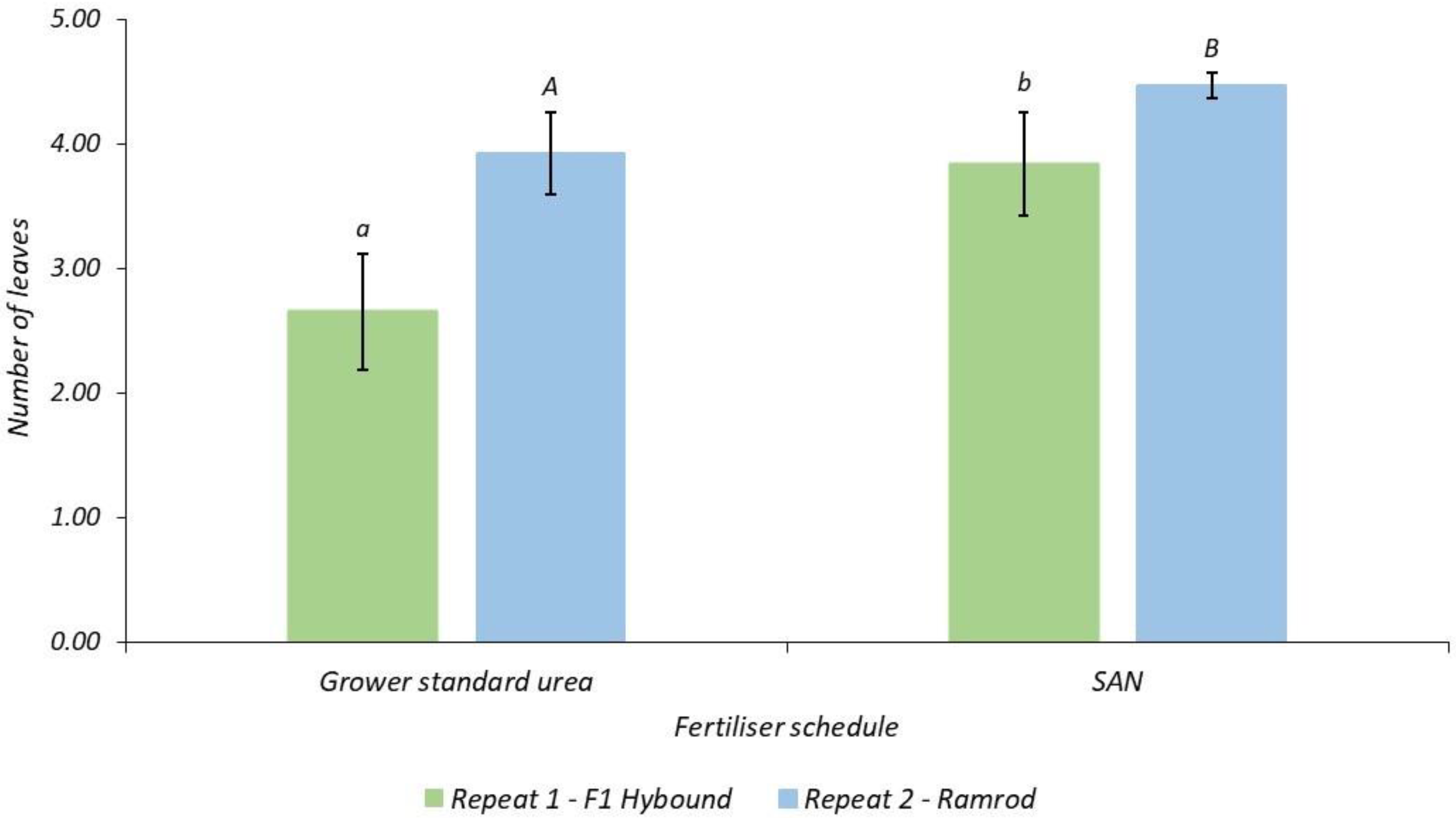

Figure 2 shows that for both repeats, the SAN treatment gave significantly greater leaf numbers than the urea (repeat 1: 2.7 leaves for urea and 3.8 for SAN (Mann–Whitney U, 1-tailed,

p < 0.05), repeat 2: 3.9 leaves for urea and 4.5 leaves for SAN (Mann–Whitney U, 1-tailed,

p < 0.05)). For both repeats, the SAN treatment gave plants with significantly increased heights (

Figure 3) (repeat 1: 21.7 cm for urea and 31.9 cm for SAN (Mann–Whitney U, 1-tailed,

p < 0.05), repeat 2: 23.6 cm for urea and 30.8 cm for SAN (independent sample

t-test,

p < 0.05)).

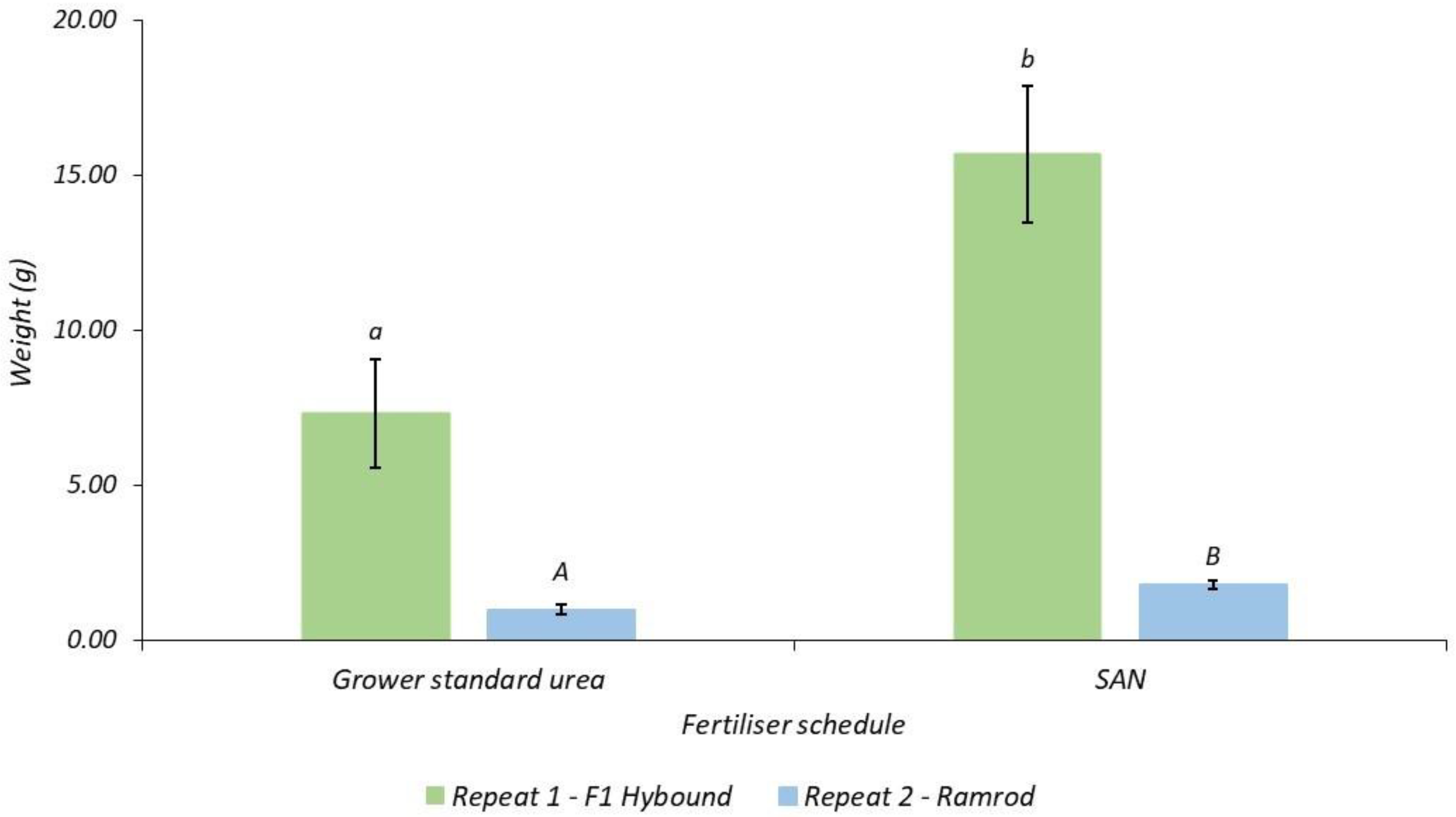

In both repeats, the plant weight at harvest of the complete plant excluding the roots was significantly increased under the SAN treatment (

Figure 4) (repeat 1: 7.3 g for urea and 15.7 g for SAN (Mann–Whitney U,

p < 0.05), repeat 2: 1 g for urea and 1.8 g for SAN (Mann–Whitney U,

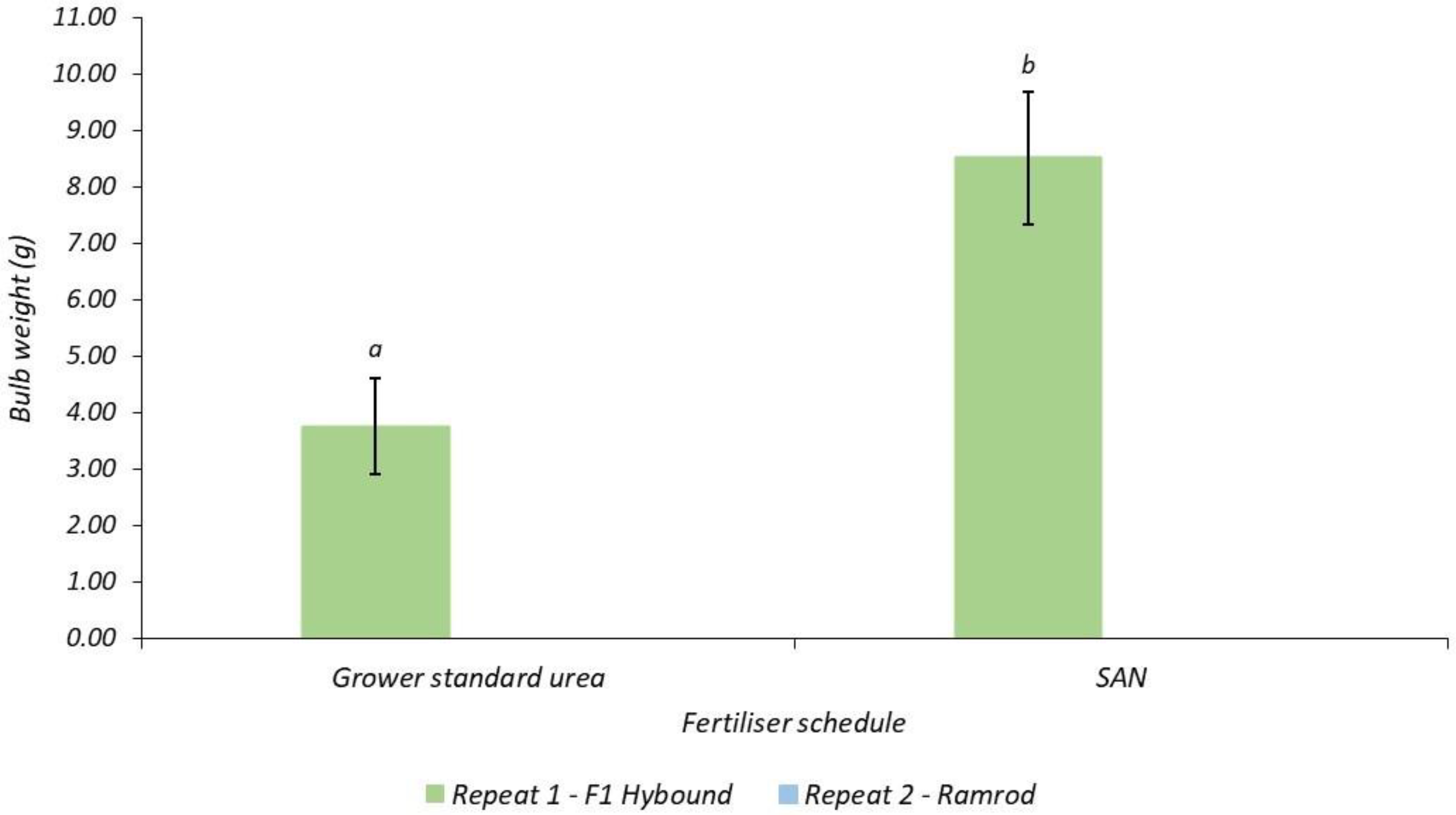

p < 0.05)). For the first repeat, as the cultivar grown was a maincrop type, the bulb weight was also measured, and this again was significantly increased under the SAN treatment (

Figure 5) (3.8 g for urea and 8.5 g for SAN (Mann–Whitney U,

p < 0.05)).

Yield was further analysed by measuring the diameter of the bulbs and stems just above the bulb where the tapering top of the bulb became straight. For the bulb diameter, SAN gave a significant increase (

Figure 6) (repeat 1: 10 mm for urea and 16.5 mm for SAN (Mann–Whitney U,

p < 0.05), repeat 2: 3 mm for urea and 3.5 mm for SAN (independent sample

t-test,

p < 0.05)).

Figure 7 shows that the stem diameter was also significantly increased by the SAN treatment (repeat 1: 2.9 mm for urea and 4.9 mm for SAN (Mann–Whitney U,

p < 0.05), repeat 2: 2.1 mm for urea and 2.9 mm for SAN (independent sample

t-test,

p < 0.05)).

Figure 8 contains some photographs showing a comparison between onions from repeat 1 (F

1 Hybound) taken from the same blocks within the experimental layout for each image with nitrogen fertiliser schedules using either soil applied urea at 150 kg ha

−1 or SAN applied foliarly three times at 0.9 kg ha

−1 application

−1. It is possible to observe the impact of all the results presented above about the increased height, weight, bulb diameter and stem diameter.

The field plot trial showed that there was a non-significant difference (independent sample

t-test,

p < 0.05) in the total yield weight and the weight within each of the assessed size classes (<40 mm, 40–60 mm and >60 mm) between the grower standard nitrogen applications of 150 kg ha

−1 and the SAN giving 7.56 kg ha

−1 in total over 12 applications (

Figure 9). These data came from 12 m

2 plot trials and when scaled up would give yields of 88.05 and 84.13 tons ha

−1 for the grower standard and SAN applications, respectively.

4. Discussion

This work was undertaken using two different onion cultivars that produced two separate crops: F1 Hybound (pelleted) onion that was grown and harvested as a ‘summer’ onion when the bulb and leaves were still green and Ramrod onion that is a spring or salad onion, but the results were comparable between both cultivars. This shows that the impact of the SAN was not related to a specific interaction with a single cultivar. SAN could be applied widely for onion production.

The first key aspect of profitable crop production is ensuring that the correct density of plants is achieved, so that they are not competing for resources while also filling the available area. In this work, the SAN treatment resulted in increased survival to harvest for both cultivars, with Ramrod having significantly increased survival (

Figure 1). For all further analysis of the results, only the surviving plants were used so that any differences in the growth habit of the onions under the different treatments were only due to the impact of the fertiliser on growth rather than the survival of individuals in each repeat.

For both cultivars, the SAN treatment resulted in a significantly greater number of leaves (

Figure 2) and plant height (

Figure 3). For spring and summer onions, the leaves are part of the harvested crop for sale, and so, an increase in their number and size will have an impact on the marketable yield. While for production of onion bulbs, a greater leaf area, linked to the number and size of the leaves, will result in a greater ability to produce below ground mass.

The harvestable weight is generally the key metric for measuring yield, and for both cultivars, the SAN treatment resulted in significantly increased weight at harvest (

Figure 4) and for the summer cultivar where the bulb had started to form, it also had a significantly increased weight at harvest (

Figure 5). In most types of onion, the bulb is the key harvested part, and for both cultivars in this work, the SAN treatment gave a significantly larger bulb size (

Figure 6). For spring and summer onions, in addition to the bulb being important, the stem and leaves also form a key part of the harvest, and for both cultivars the SAN treated plants had significantly thicker stems (

Figure 7).

As can be seen from the pairs of onions (one treated with urea and one treated with SAN) in the pictures in

Figure 8, the SAN treatment resulted in increased size and harvestable yield while the amount of nitrogen applied was only 2.7 kg N ha

−1 in the SAN treatment compared to the UK industry standard of 150 kg N ha

−1 [

3]. Previous work found that the optimum rate of nitrogen application for onions was between 92 and 263 kg N ha

−1 [

7,

8,

9,

10,

22], while with targeted applications during the growing season a rate of 20 kg N ha

−1 [

3] was shown to be suitable for achieving good yields. This work showed that it is possible to use even lower nitrogen rates of 2.7 kg N ha

−1. This could be due to onions having shallow roots that results in limited recovery of 30–40% or less of the nitrogen from the soil [

2], and so, when traditional amounts of nitrogen fertiliser are applied, a lot will be unavailable to the plant due to the rooting structure, or the leaching problem linked to traditional application of nitrogen [

12]. As onions need more nitrogen in the second half of the growing season [

2], applying urea to the soil, as in traditional nitrogen applications, would mean that the majority of it is not available to the plants; however, as the SAN was applied foliarly at the three, four and five leaf stages, it is available to the onion plant when it is needed. Previous work found that there is no consensus about the best form of N for onion fertilisation [

2], but this work shows that SAN is superior to urea for onion fertilisation.

When the findings from the glasshouse, supported by the literature, were transferred to a field plot trial, it was shown that statistically similar yields could be obtained with much less nitrogen applied when it was in the SAN form (

Figure 9). The grower standard nitrogen application was 150 kg N ha

−1 applied at planting to the soil, which was compared to SAN applied foliarly for 12 applications throughout the season, which gave 7.56 kg N ha

−1 in total, and the total yield as well as yield in each of the three size classes were not significantly different between the two treatments. This shows that when SAN is used in the field, it is possible to greatly increase the NUE.

These results support previous work that showed that SAN can increase the NUE and enhance the growth and yield of a range of crops, such as potatoes where, in glasshouse trials, SAN increased the root/shoot ratio just after tuber initiation when compared to the same amount of N applied as an IS fertiliser; while in field trials, the addition of SAN to the grower standard N applications resulted in an increased number of marketable tubers and yield (t ha

−1) [

14,

15,

16]. In ornamentals [

17], a comparison between SAN and IS fertiliser gave 25–130% increases in flowers due to increased longevity of the N in the soil and impacts on biomass partitioning in the plants. In a glasshouse trial using wheat [

18], SAN compared to other forms of N applied at the same rate as in the SAN found that the chlorophyll content was increased, with more upright tillers and increased diameters of the tiller bases while the roots were longer. In glasshouse trials with tomato [

19], it was found that SAN, when compared to other forms of N applied at the same rate, gave significant increases in the yield and a shorter growth habit and in field trials, SAN applied, in addition to the grower standard applications, gave significant increases in marketable red fruit. For lettuce [

20], SAN was compared to other forms of N applied at the same rate as in the SAN under glasshouse conditions, where it was found that the SAN resulted in greater harvestable head weights being achieved more quickly. These previous studied showed that when SAN is applied in addition to grower standard N applications and when the amount of N applied in other forms of N is reduced to the same level as that found in SAN, it results in increased yields. This current work showed that when comparing a much lower rate of N in SAN to the current industry standard N rate for onion production, yield was increased. Therefore, SAN can enable the production of onions with reduced nitrogen use and increased NUE.

SAN can meet the 4R requirements [

13] as it is the right source of stabilized nitrogen and so, it will not be lost via leaching or volatilization, it is applied at the right rate rather than the traditional 150 kg N ha

−1, it is applied at the right time as it is applied during the growth of the onion rather than being applied at sowing and it is applied in the right place as it is applied foliarly rather than in the soil where the shallow roots are not as effective. When N is applied as nitrate at high rates, it can result in leaching to groundwater, and it was found that there often were large amounts of N in the soil; so, N applications did not result in large increases in yield, and that applying N during bulking would enhance NUE [

23], which this work supports and suggests that SAN is a better option than urea for application during bulb formation. Previous work showed that green fertilisers, when combined with N applications, could have an impact on onion yield and bioactive component profiles of onions [

24,

25], and it would be interesting in the future to assess the impact of green fertiliser application along with SAN. Onion was suggested to be an important crop that could benefit from integrated nutrient management [

26], as providing adequate and balanced nutrition to onions resulted in yield increases, and SAN could be a key component of this due to the results presented here, showing that it enables improvements in NUE. SAN is an effective option for onion production.