Abstract

The objectives set in the 2030 agenda gravitate towards the concept of sustainability, a concept that is closely related to the efficiency of port operations. As a direct derivative of the search for more efficient logistics and port operations, a disruption of new technologies, associated with the term ‘Smart’, is making its way with a large range of new digital applications. The logistics and port sector is also undergoing a process of transition towards this kind of operational intelligence through digitized and increasingly automated devices. In this work, an analysis of the most relevant Spanish dry ports is carried out, with the clear objective of discovering their degree of adaptation to the ideal Smart concept. This was developed through the implementation of a descriptive statistical analysis and a Delphi methodology, a battery of indicators and measurement variables that classify, in an integral and objective way, the degree of the adaptation of these ports to the concept of the ideal Smart Dry Port; in this way, we obtained a ranking of the ports. The current and future trend of this type of Smart facilities is solid and clearly points towards a greater digitalization of port processes and an openness of information, with port facilities interconnected with each other through automated processes. The analysis gives a clear picture of the adaptation to digitalization and automation of three of the largest Spanish dry ports, in which there are ongoing efforts to adapt to this concept but for which there is still a long way to go.

1. Introduction

Economies on a global level are vulnerable to the efficiency of their trade balances, and these in turn are related to the efficiency of their ports and logistics systems. This is why the ports and logistics sector of a country is of crucial importance to the development of the region. The impact that a deficient port system has on the economy is directly correlative, and, in the same way, the strengthening of a port system’s governance and the optimization of its operations will have a direct positive impact on the economy. In Spain, there are three ports that are currently among the 100 most important ports in the world with regard to the international trade sector [1]; Spain is ranked at number 11 as a global port power [2], after the Asian giants, the United States, Germany, and Holland, which occupy the first positions. This can give us an idea of the large number of port operations that are carried out per year. On the other hand, rail freight operations elsewhere reached a total of 5.8 million tons greater than those in the European countries mentioned above, measured in tons/kilometer, as detailed in [3]. This is because the Spanish railway system needs to implement new technologies that make intermodal transport more efficient. Therefore, the emergence of the Smart concept has generated great interest across all dry port and logistics platforms, not only as a way to improve their efficiency, but also to improve their competitiveness.

The Smart concept is already quite integrated and assimilated in the governance of cities because it allows data and services to be opened to citizens, in addition to consolidating policies much more committed to reducing carbon footprints. This is why it is widely recognized that the implementation of this concept in dry ports will improve services to users.

Systems such as Big Data or Blockchain have disrupted society by transforming the conventional methods of governance, and there are many sectors (banking, energy, telecommunications, concessions) in Spain today that integrate them. The profitability of the commercial sectors in Spain, which traditionally have greater import–export demands, depends, among other things, on the improvement of their final prices, and a high percentage of these are affected by the prices of transport, insurance, customs, etc. The improvement of port and rail facilities, where traffic is traceable in real time and there is effective intermodal synchronization, will have an impact on the final price of the export or import and therefore on the commercial profitability and economy of the country.

In the environmental field, without a doubt, the adaptation of a dry port, where the transfer of goods has a high impact on air and acoustic quality and the potential to discharge hazardous substances, to the Smart concept will allow the mapping, monitoring, and mitigation of these risks in real time and thus will improve the environment of the populations affected by these facilities. Likewise, the application of an intelligent system in port governance will allow institutions to simplify port management. Improving security in procedures and simplifying customs’ records and controls, in short, will improve transparency and accountability.

Although growing academic trends are showing the benefits of the Smart concept, and, at a theoretical level, the definition of an intelligent system is highly documented, the adaptation of the sector itself is behind, despite the fact that the acquisition of processes based on information and communications technology (ICT) and automated processes is settling in the market little by little.

The purpose of this analysis is to design and develop an indicator applicable to Spanish dry ports that allows them to be ranked based on the degree of the adaptation of their facilities to the ideal Smart concept and that can also serve for the characterization of other dry ports in other territories.

The organization of the analysis follows the basic structure of an informative article, starting with a review of the state of the art in terms of what dry ports are, their evolution, their current technology, and how the Smart concept associated with them is interpreted. Subsequently, the methodology used for the elaboration of this indicator is presented, which is based on the identification of the axes, as well as each of the indicators and measurement variables, which constitute these pillars.

With the help of the Delphi methodology, the suitability of these indicators shall be considered, as well as the weighting of each of them obtained, thus allowing us to obtain a system of indicators. Finally, based on a process of research and documentation of intelligence for the selected dry ports, a ranking of their positioning in terms of their Smart installation will be obtained with the application of this indicator.

2. Literature Review

The convergence of economies towards a global model has placed the logistics and ports sector as an essential sector for the economic growth of these regions, and international markets are creating effective competitions between port systems worldwide; “an important part of the flow of economic and social activity is derived from transport systems and the logistical performance of nations, regions and people” [3]. This competition is encouraging the development of more efficient, productive, and, above all, profitable methods of port operation.

The maritime industry has incorporated digitalization in a transversal way, as a tool that improves its management; “Digitalization has taken the maritime industry beyond its traditional limits and provided new opportunities to improve productivity, efficiency and sustainability of logistics” [4]. The port sector, without discretizing its nature, still remains at some distance.

According to the definition provided by [5], a dry port is a “non-coastal facility for public use, other than a port and airport, equipped with fixed facilities that offer services to handle and temporarily store any kind of goods (including containers) that is considered as “in Transit” for customs purposes, by any mode of non-coastal surface transport, and which also has the capacity to carry out customs controls that allow these goods to continue their transit, complete the journey and be used locally, cleared for export, or re-exported as the case may be”.

According to this definition, dry ports are breakpoints in the transport chain that aim to effectively and efficiently expand the areas of port influence in logistics; as is argued, “Dry ports are designed to guarantee mainly the transport of containerized goods quickly, secure, cost-effective and efficiently through the use of container block trains, using the advantages offered by rail transport and the direct connection between two logistics centers” [6].

The concept of Smart is challenging to contextualize, especially when applied to specific approaches in ports or logistics ports, and even more so within the domain of dry ports. That is because the concept “Smart” or smart growth emerged in 1990 as an action for the sustainable and intelligent development of cities. In essence, it emerged within the realm of sustainable urbanism in response to the continual population growth in metropolitan areas, as argued in the article “Conceptualizing smart city with dimensions of technology, people, and institutions” [7].

Assuming the concept of Smart, as defined in the model of sustainable urban growth, it was proposed, for ports, that it represents a system of technological solutions aimed at implementing actions aligned with mitigating widespread problems in port operations, the environment, energy, and security. Recognizing that resolving these issues aligns with improvements in sustainability [8].

Thanks to digital and modeling developments, there is also the opportunity to find optimal locations for dry ports taking into account, for example, the associated logistic transport costs [9], although we must not lose sight of the importance of the participation of the different stakeholders involved in the supply chain [10].

The concept in which the Smart Dry Port is framed comes from the adaptation of intelligent port systems in the maritime regime. They are based on IoT or “Internet of Things” technology, which interconnects different physical devices of the different operating subsystems (loading–unloading, storage, reception and delivery, interfaces, or services) with the objective of data exchange that results in a more efficient management of them. “The implementation of the IoT paradigm in freight transport is a reality today” [11].

While it is true that the first appearance of the dry port concept was in technical publications that specialized in transport, dating back to 1980 [12], it was not until six years later that they were published in scientific journals [13]. With the increase in environmental problems associated with maritime transport and its facilities, almost two decades later, there was a renewed interest among researchers in the concept of dry ports [14,15,16,17].

Many authors have discussed the term intermodal cargo terminals [18,19], and, in all of them, the concept revolves around goods being transferred from one mode of transport to another, in which a series of auxiliary services such as customs, workshops, warehouses, and warehouses is required.

The environmental problems derived from the high number of container transport operations [20], which have aroused in the scientific community the interest to consider hinterland logistics systems as elements to mitigate the environmental impact [21].

Authors such as Roso et al. state in their studies that the concept of the dry port as a logistics system not only mitigates the environmental impact but also contributes to the achievement of benefits in other lateral areas of the transport system [22].

Globalization had an exponential increase in maritime port operations as output, directly impacting congestion at maritime port facilities due to this overload caused by the over-occupation of the facility. To reduce this saturation, inland ports were developed. These ports, in addition to decongesting the occupation, allowed new commercial opportunities to be taken advantage of and represent an evolution of the transport chain towards a more efficient and environmentally sustainable way.

In a dry port, like a seaport, any type of cargo can be operated, but the containerized system is the most standardized, making it the predominant system for moving goods in most operations. This is a competitive advantage for the rail system and is the preferred transport system in this type of facility [23,24]. In addition, the rail transport mode is the system that enjoys the most sustainable land transport label, and this represents an added value for dry ports and should be enhanced.

2.1. Evolution of Dry Ports

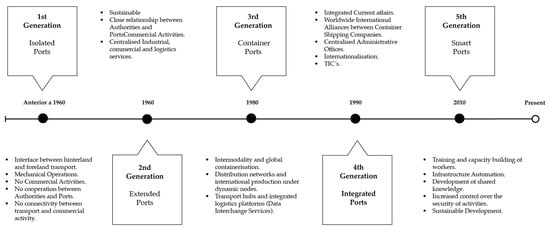

The evolution and history of dry ports are closely related to the development of seaports given that, as mentioned, these are “an intermodal freight terminal located within the territory, directly connected to the ports, origin destination of their cargoes through a railway network” [6] (Figure 1). In addition, that is why its development is linked to congestion of facilities in maritime regime.

Figure 1.

Ports development throughout history [5,25].

Ports have been a strategic piece in the development of markets and territories, so, with the saturation of port space and its areas of influence, intermodal cargo platforms became relevant for their connectivity with the port and modal versatility. With the disruption of ICT technologies that improved the ability to process and share data in real time, supply chain management was deeply transformed. ICT developed digitized and automated processes where data were the key to this competitive intelligence system. These two processes have transformed the management model of port operation, moving it from a mechanical or physical operation to fully automated management through safer and more efficient interface systems.

Taking as a starting point the 1980s with the third generation of ports, we find a port system dominated by containerized cargoes and port node systems developed under international production and distribution networks organized under a digital data interchange system or “EDI” (Electronic Data Interchange service).

This system that was born from UN/EDIFACT (United Nations/Electronic Data Interchange for Administration, Commerce and Transport) was adapted as an ISO standard.

Certainly, the EDI system meant a revolution in the maritime port industry because, among other benefits, it led to the reduction of waiting times for goods in port stages (ship, terminals, and customs inspections) [26], ship stopovers were optimized in terms of waiting time, and there was better coordination of inspections, improvement in the occupancy of terminals and depots, and a more efficient and safe administrative circuit. It was not until the 1990s that port facilities equipped with ICTs were found, which allowed a much more aggressive internationalization of ports. The fourth generation of ports in the 1990s was dominated by integrated port systems and characterized by the centralization of data and commercial synergies in the global containerized transport market (Figure 1).

Currently, the port system is in the fifth generation, in which the Smart port concept is being consolidated with a solid transition towards the concept of a digital logistics platform with an IoT nature with the ability to collaborate and share data in real time.

This generation of ports is based on the collaborative distribution of data by public and private agents, who go far beyond the community of operators or freight forwarders, integrating them within the territory with intelligent transport systems such as railways, roads, and waterways. In short, this model of digital governance of ports contributes to managing direct and indirect operations not only within the port system but also outside.

2.2. Smart Dry Port Axes

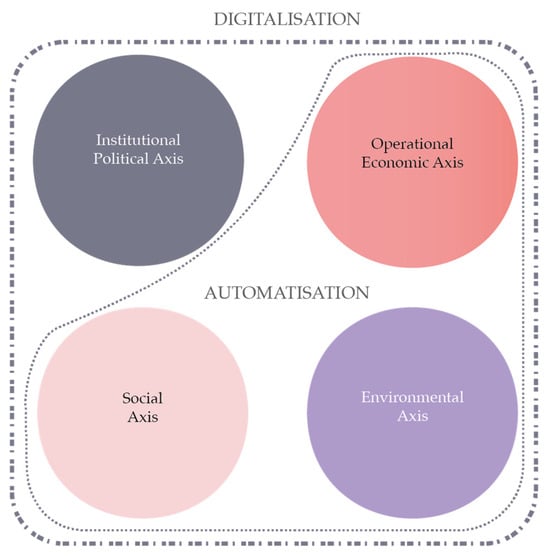

Building on the grouping of Smart port axes that other authors have proposed for conventional ports [27], the same framework is applied to dry ports. It starts from this relationship with four fundamental axes that are: operational economic, social, institutional political, and environmental. In a transversal way, all of them gravitate around two influence areas: digitalization and automation.

It is understandable that the four axes considered have an integral foundation within the three areas that make up sustainability (Society, Economy, and Environment). Although the digitalization pillar crosses the four defined axes, the automation pillar only includes those axes in which the procedures or operations are automatable, as defined in the following figure (Figure 2).

Figure 2.

Smart axes and influences areas for dry ports. Source: own elaboration.

Automation has a great impact on the operational economic axis of the port since its implementation provides the optimization of times and costs of operations not only in the transfer of goods but also in the management of the space of the facilities. “Finally, from the point of view of economic and financial profitability, the automation of PCT (Port Container Terminals) means a reduction in variable costs per container (OPEX) since labor costs are reduced by generating savings in operations and maintenance” [28].

The social impact that automated processes can generate in operations carried out by conventional labor can be very representative and also have a direct implication on social policies; “In any case, although it is true that through automation direct human intervention in operations is reduced, the level of training necessary to carry out the tasks of the jobs involved increases significantly” [28]. The loss of jobs as a first consequence of an increase in automated processes undoubtedly has an impact on the workforce, associations, and professional guilds.

The implications on the environmental axis are also of high impact, not only because the automation of loading–unloading and storage systems allows these operations to be carried out with much lower consumption and therefore leaves a lower carbon footprint, but also because the use of rail transport is encouraged. “Likewise, transporting one tonne/km by rail consumes 4 times less fuel than if the transport is done by road and 1380 times less than by plane” [29].

2.3. Technology

The technological development that has existed in port management systems for more than ten years has made it possible to achieve a considerable degree of sustainability but is still not sufficient. Dry ports as intermodal systems represent a socio-technological ecosystem that develops commercial and business intelligence in real time. The adaptation of a port facility to open digital systems, shared with other sources of the logistics industry, represents today the greatest challenge to be faced by the port rail industry.

The improvement of digital technology and its implementation in this type of facilities are clearly mandatory requirements to be able to move forward in these disruptive times with changes in mobility dynamics, new regulations, and a growing demand for freight transport.

As in many other sectors, some areas may bring much room for improvement to this digitalization, while others may have a more limited capacity. For example, with the incorporation into the DCSA (Digital Container Shipping Association), there is a clear and firm commitment of shipping companies to homogenizing the digital standards of TEUs (Twenty-Foot Equivalent Units).

With the incorporation of systems such as Blockchain, Big Data, or more modern systems such as those based on AI such as Machine Learning, efficiency levels will be reached in very highly automated processes, which will allow the definition of intelligent routes and schedules, allowing a forecast increasingly closer to the short term.

With the interconnection of ports and real-time data exchange, information management is improved, allowing different scenarios to be predictively modeled and thus optimizing the resources of the connected port network. The digitalization of systems and the incorporation of new technologies must be accompanied by a strengthening and training at the technical level of personnel, and internal governance procedures, because otherwise it would be doomed to failure.

3. Methodology

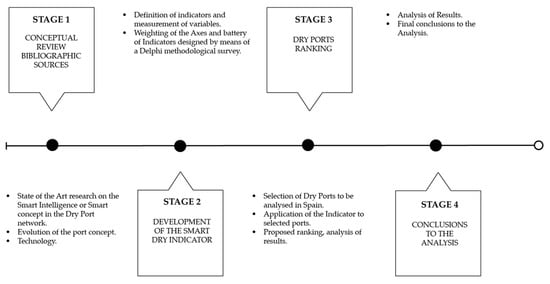

The purpose of this study is none other than to develop a system of indicators that allows measurement of the degree of digitalization of a list of dry ports in Spain, obtaining a ranking of the facilities and their degree of adaptation to an ideal concept of Smart Dry Port, “SDP”. This indicator is justified based on the four axes defined above and structured by the degree of its digitalization and automation. The methodology applied is defined in the following figure (Figure 3).

Figure 3.

Methodology used, phases and blocks. Source: own elaboration.

3.1. Phase 1: Review and Bibliographic Sources in Network

In-depth research is carried out on published documents around the concept of dry ports: What are they? What do they contribute to the supply chain? What has been their evolution throughout their history? What impact has it had on economic, environmental, and social systems? As a result of this competitive intelligence, the axes that underpin the Smart concept are identified, particularized for dry ports. The analysis undoubtedly embraces the idea of Smart Dry Ports from both a conceptual and practical standpoint. Additionally, the adaptation of current dry ports to new intelligent systems is also valued in this preliminary analysis, based on questions such as: What is the degree of intelligence of dry ports in the Spanish logistics system? How can you acquire current trends in digitalization, automation?

3.2. Phase 2: Development of the “SDP” or Smart Dry Port Indicator

From the previous phase, the concept of Smart Dry Port is precisely derived, leading to the development of an indicator that offers a holistic and measurable scale for the adaptation to the term ‘Smart’. This enables measurement and comparison when applied to dry ports. With the concept of the indicator, it is sought to obtain a global scale, easily applicable, that can be implemented directly in all the dry ports of the Spanish state and thus be able to obtain solid, balanced, and objective results. The indicators, the measurement variables, and the scoring procedures are dimensioned looking for and attending to concepts that have easy access and, above all, are measurable, avoiding those that are very decisive due to their specificity. In short, it is a question of looking for easily weightable, precise, and decisive indicators.

The consolidation of the “SDP” indicator is proposed under a system of blocks and stages of work well differentiated and independent of each other, as discussed below.

3.2.1. Block 2.1. Definition of Indicators and Measurement of Variables

The first block is developed with the aim of obtaining the indicators, their measurement variables, and the instructions or scoring rules which, in the case of dry ports, have been considered more relevant. For this phase, the Delphi methodology is used, which is the most widespread for the formal search for consensus. For the determination of the indicators, a phased method based on objectivity is assessed, in which we try not to contaminate the processes and develop them independently. The ultimate goal is to obtain a sampling of the most representative indicators for the assessment of digitalization and automation that a dry port must consider in the four axes justified above.

3.2.2. Block 2.2. Weighting of Axes and Indicators

In this block, the weight in terms of importance of each of the indicators selected as most representative in the previous phase is determined. The process is developed in two stages which are carried out consecutively to achieve, as in the first block, the highest possible sensitivity of the system.

- Stage 1 Weighting of the General Axes.

Each of the selected indicators is classified within the four axes determined in Phase 1, and it is in this block where the weights with which each of these axes contribute to the calculation are determined. It is important to consider these values as the starting point because it allows limitation of the importance of each axis within the final indicator. In this way, this weighting limits the overall weight of the total indicators associated with each axis. This allows us to avoid the weight of the indicators being more preponderant than the weight of the axes, assuming that the indicators of each axis will have less aggregate value than each of the axes to which it belongs;

- Stage 2 Weighting of Indicators.

The impact that each of the indicators will have, in terms of digitalization and automation in each of the axes in which it is framed, is analyzed and assessed. In this way, the sum of the values of the indicators made for each axis results in the weighted total weight for each of the axes in the previous stage.

3.3. Phase 3: Obtaining a Ranking of Smart Dry Ports in Spain

In this phase of the study, the “SDP” indicator, generated in the previous stage, is applied to each of the most representative dry ports in Spain so that, in this way, a ranking can be established in terms of its adaptation to the Smart concept.

3.3.1. Block 3.1: Selection of Dry Ports to Be Analyzed

This block proposes the selection of the most representative dry ports that currently operate in Spain from the angle of four variables. These variables, in our view, objectively justify their selection and are:

- Public information available;

- Smart systems implemented in the port;

- Importance of the port as a pole of economic development;

- Importance of the port at the level of social impact.

3.3.2. Block 3.2: Application of the Indicator to the Selected Ports

Once we define the relationship of the dry ports to be evaluated, an investigation is carried out of the characteristics that could be identified within each weighted indicator. Public and private sources are used to contrast data and avoid poor or poorly justified data. From this developed documentary intelligence, the valuations following the stages detailed below are obtained.

- Stage 1. Assignment of values to each indicator.

The values are assigned to each of the indicators according to the rules that were defined in Block 2.1 of Phase 2 and for which values were detailed in the calculation section;

- Stage 2. Application of weights to score each indicator.

In this stage, the weight of each indicator is obtained as the product of the value of the indicator multiplied by the weight of the axis to which it belongs, thus obtaining how much is the contribution in absolute terms to the SDP indicator. Subsequently, all the indicators already weighted are added in order to reflect the degree of adaptation of each particular axis to the ideal SDP.

3.3.3. Block 3.3: Proposed Ranking, Analysis of Results

As a result of the sum of each of the axes already weighted above, the ranking of scores is obtained. At the level of final analysis and in order to obtain a more understandable result, the scores are adapted in base 100.

3.4. Phase 4: Conclusions

In this phase, all the results obtained during the year of obtaining the indicator and its application in the different selected dry ports are consolidated, based on the most generalized results and those conclusions that, based on the numbers obtained, reflect a synthesis of the study.

4. Calculation and Results

4.1. Indicators and Measurement Variables

The indicators that were selected and validated by the expert system consulted using the Delphi survey method are identified below (Table 1).

Table 1.

Indicators and measurement variables proposed for the study.

From the list of indicators presented above, as well as the variables and their measurement scales, the following system and scoring rules were considered:

- We chose those variables by indicator that can be found almost homogeneously in the different facilities studied. However, some dry ports could not be considered for certain indicators because they did not present evidence of the variables analyzed, or the information was scarce or did not exist, so, in those cases, they were assigned null scores;

- The score chosen for each indicator was scaled from 0 to 4 points, considering 0 as low importance and 4 as of maximum importance;

- Each indicator was considered according to the criterion of importance with which it contributes to the adoption of the Smart concept within each axis. The sum of the weights of all indicators added up to 100. The following section details the methodology applied to obtain the weights of each of the indicators.

Weight of Axes and Indicators

Once the indicators had been definitively chosen, as well as the measurement rules and their score, we defined the weights of each of the axes that groups the corresponding indicators, as well as each of the indicators that make it up.

Before implementing a decision-making process that considered all the indicators previously selected, the Delphi method was used to define the significance or weight of those indicators. The Delphi method is a technique for systematically gathering data to reach conclusions about qualitative issues [30]. The primary objective of the Delphi method is to obtain the most reliable collection of expert opinions through a series of structured polls with regulated feedback. As a result, the Delphi survey technique was applied in this study to establish and categorize the criteria [31], just as it has been in previous studies [32]. For instance, using the Delphi method, Kuo and Chen [30] created performance appraisal indicators for the mobility of the service industries. In another study, Sarvari et al. [33] evaluated risk detection methodologies for public–private partnership (PPP) projects using the Delphi method. Using this technique, which involves the assignment of a group of specialists, researchers can identify and prioritize issues and provide a framework for identifying them. A Delphi survey panel should include enough experts to provide a diverse range of opinions while maintaining a manageable size for efficient communication and analysis [34].

Several criteria have been used regarding selecting experts known as Delphi questionnaire respondents. The criteria depend on the specific research question and the characteristics of the population being studied. In this case, experts were selected based on their experience and knowledge of logistics and port, hinterland, or logistic facilities and knowledge of rail operations. It is essential to note, however, that the quality of the specialists is more significant than their quantity, which is often between 15 and 50 [34]. The number of experts is determined by sample homogeneity, the objective of the Delphi method, the difficulty range, the quality of the decision, the expertise of the research team, internal and external validity, the amount of time required to collect data, and the available resources [30]. In prior contributions of a similar sort, data collection was conducted using the Delphi approach. The targeted snowball strategy is a widely used method for selecting research specialists. It is the procedure through which a qualified participant invites specialists who meet the study standards [35]. For this study, experts who have awareness and knowledge of the ports and rail operation (including project managers, facilities managers, maintenance and consultants, construction professionals, and university professors) were invited. Typically, snowball sampling is a steady process that continues until data are collected [36]. Therefore, two experts were selected, and, after data collection, they were tasked with recommending further specialists. When the factors became saturated, the outreach specialists were terminated. Therefore, when no new factors were discovered during data collection, the data were considered saturated [37].

During the Delphi survey study, a questionnaire with six sections was distributed among experts via email. Section 1 was a presentation of the survey, 2 was related to the allocation weights of each axis in the Smart concept. In Section 3, Section 4, Section 5 and Section 6, the panel members were asked to indicate the extent of their agreement with each identified criterion based on the four-point Likert scale of measurement. In addition to rating the criteria, the panel members were also allowed to add new criteria that they thought could affect the identification of a Smart Dry Port indicator. This is a common practice in the Delphi survey technique as it allows experts to provide input and feedback that may not have been considered in the initial questionnaire.

Feedback from the panel members was essential to refine and improve the criteria used in the study. After collecting, analyzing, and averaging the responses from the first round of panelists, it became clear that none of the indicators proposed was in disagreement. It became evident that all respondents were in accord with the specified selected group of indicators and the classes allocated to them.

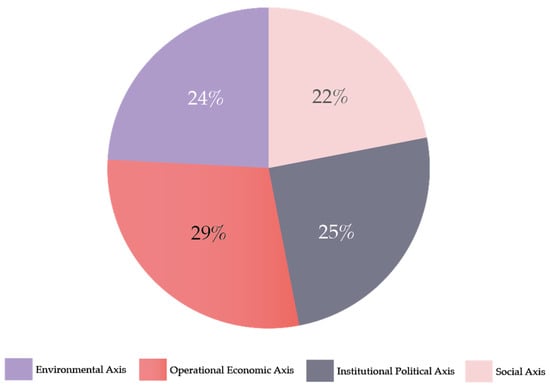

As has been told, to assign weights to each of the four proposed axes, the Delphi methodology was used, from which the result exposed in the following graph was obtained (Figure 4).

Figure 4.

Smart axes weights (rounded values). Source: own elaboration.

The profile that formed the Delphi panel was composed of 31 experts from the professional and academic sectors, in a 48/52 ratio, both from the public and private sectors (Table 2). This methodology allowed us to obtain a varied analysis of information objectively, based on the opinion of a group of expert professional profiles, that supported us in considered decision making.

Table 2.

Characterization of panel of experts participating in Delphi.

From the opinions expressed in the survey carried out, a broad consensus was obtained, and this gave us great confidence because the panel considered was highly qualified in railway and logistics matters. The goal was to minimize the different predictive possibilities.

In this survey, the fusion of two scales, the numerical and the written, was considered because both complement each other and can provide the expert with a greater justification for his answer. We considered this formula with the aim of strengthening the expert’s decision making when assessing indicators or variables.

While it is universally accepted that the numerical scale indicates the intensity with which an expert expresses his opinion, also in an easy way, the complement of the written scale that has been incorporated into the values allows description of the category in a more descriptive way.

The scales considered in the questionnaire for the expert panel were as follows (Table 3).

Table 3.

Scales considered in the questionnaire.

From a first analysis with the Panel of Experts of the indicators to be weighted, the list that can be seen in Table 1 of Section 4.1 “Indicators and Measurement Variables” was obtained, with which each of the indicators that was valued had an effective importance for the final indicator. The choice of scale (between a scale with even and one with odd numbers) was determined by the possibility of being able to give respondents a neutral option with which they could express their opinion.

That is why a scale of odd numbers was considered, since only scales of odd numbers can have a middle point.

The weight was then assigned to each indicator on the total weight in its axis (Table 4).

Table 4.

Weight of axes and indicators proposed for the study.

4.2. Selection of Dry Ports for Analysis

We made a selection of those facilities that deserve to be considered dry ports and that are located within the national territory based on the criteria defined in point Section 3.3.1 “Block 3.1: Selection of Dry Ports to Be Analyzed”(Table 5).

Table 5.

Selection of dry ports to analyze.

Only those ports that objectively, clearly, and openly present the necessary information to be scored were considered, obtaining based on these variables the following dry ports to be analyzed (Figure 5):

Figure 5.

Dry ports selected. Source: own elaboration.

- Dry port of Azuqueca de Henares (Guadalajara);

- Puerto Seco de Coslada (Madrid);

- Puerto Seco de TMZ (Zaragoza).

Results of the SDP Indicator Application Process

From the application of the indicator system and the weighting of the measurement variables, the following ranking of dry ports was obtained in terms of its adaptation to an ideal SDP indicator (Table 6 and Table 7).

Table 6.

Ranking of dry ports under Smart Dry Port concept.

Table 7.

Percentages achieved with respect to ideal SPD.

5. Analysis of Results

From the ranking of dry ports obtained, as justified in the previous section, the position of each of the three facilities can be observed in reference to the global indicator “SDP” and particularly in each of the four thematic axes. From the values obtained, it is possible to solidly validate those strategies in terms of digitalization and automation of processes that have been implemented by administrators.

The proposed ranking is relatively limited as many intermodal platforms or LAZ (Logistics Activity Zones) that were evaluated for weighting did not meet the strict criteria to be considered dry ports. Additionally, even among those that did, some lacked the necessary contrasted and openly available information required for this analysis. From the data obtained in the study, the adaptation of these three ports in each of the areas studied is observed. Although there is a certain consistency in the values per axis with respect to the global value, it is observed that certain facilities, despite not having a relevant position in the ranking at a global level, have strong positions in a particular axis with the same score or one very close even to that of ports that are in first position globally.

At a global level, this list is led in first position by the Zaragoza Modal Terminal “TMZ”, followed, in second position, at 42.5 (rounded) points, by the dry port of Coslada. In the last position, with 104.5 (rounded) points of difference with respect to the first position, we have the dry port of Azuqueca de Henares.

In the operational economics category, the difference between the TMZ and the port of Coslada is 21.75 points, maintaining the same second position with respect to the position globally; however, the distance of TMZ with respect to the score of the port of Azuqueca is 47 points in this area. Regarding the ideal score for this axis, which amounts to 116 points (rounded), both TMZ and the port of Coslada are 18–39.5 points apart, so, for the Coslada terminal, there is still enough room for improvement.

In reference to the axis that analyzes the adaptation of digitalization in social terms, there are no differences with respect to global positioning given that the port of Azuqueca remains in third position with respect to the port of Coslada at 16 points, the same distance as the TMZ terminal that in this area obtains the same as Coslada. In this axis, the differences in points are smaller since all remain in the range of 48–63 points, which is far from what would be the ideal score for this axis, which would reach 87 points.

In the institutional political axis, the ranking is led by the port of TMZ followed by Coslada at 18 points (rounded), and, closing the list, we find the port of Azuqueca with a difference of 36.6 points with respect to the first. The score of this axis for the port of Coslada is positive since it is the one with the least difference with respect to the one with the best score and considering the ideal weight for this axis. However, with respect to the ideal score, which amounts to 101 (rounded), the difference in the scores achieved by the first two ports reaches almost 23 points of difference for TMZ and 41 for Coslada.

Following an analogy with the previous axis, for the environmental axis, it is observed that the port of TMZ continues to lead, followed by the 2.5 points (rounded) of Coslada and the 5 points (rounded) of Azuqueca de Henares. It is undoubtedly the axis where there are fewer differences and in which there is still much room for improvement by the three facilities since their score achieved is far from the ideal score for this axis, which would reach about 96 points rounded, and in which the average difference is 85.6 points.

The distribution of the importance of the axes (operational economic, environmental, social, and institutional political) in the study reveals valuable information on how these aspects are valued in the adaptation of Spanish dry ports to the concept of an ideal Smart Dry Port.

The fact that the operational economic axis has the highest importance (29%) suggests that operational and economic efficiency is a critical factor in the adaptation of dry ports to the Smart concept. This may imply that aspects such as process optimization, cost reduction, and efficiency improvement are being prioritized as key elements in becoming a Smart Dry Port.

The emphasis on the economic axis as the most important aspect may vary according to the specific sector and context. However, there are several sectors where the economic aspect tends to be prioritized. In the financial industry, such as banking and investment institutions, economics is key. Profitability, risk management, and maximizing return on investment are critical factors. Financial institutions must maintain a solid economic foundation to operate effectively and provide services to their customers. Other industries where the same is true are energy, manufacturing, technology and startups, and retail and trade.

The relatively balanced distribution of importance between the environmental (24%), social (22%), and institutional political (25%) axes indicates that these aspects are also considered significant in the adaptation of dry ports to the Smart concept. This suggests a holistic approach encompassing not only economic efficiency, but also environmental, social, and political considerations in the evolution towards smart dry ports.

The balanced distribution of importance among these axes indicates that none of them can be neglected. Dry ports must find a balance between economic efficiency, environmental sustainability, social impact, and the political and institutional framework to achieve a true adaptation to the Smart concept.

In other sectors and research, conclusions may vary depending on the context and specific objectives of the research. However, this multi-dimensional approach, as reflected by the distribution of importance in this study of dry ports, may be relevant in many other fields. For example, in the transition to smart cities, sustainable enterprises, or digital industries, it is also crucial to consider multiple aspects, such as economic efficiency, environmental sustainability, social welfare, and government policies, to achieve meaningful and sustainable change.

In these sectors and contexts, the institutional aspect is understood as an organization’s ability to interact effectively with government institutions, comply with specific regulations and policies, and adapt to changes in the regulatory and political environment. Success in these areas often depends heavily on managing relationships and collaboration with government entities and other relevant institutions.

Emphasis on the institutional aspect tends to be especially important in sectors and contexts where regulation, governance, and government policies have a significant impact on operations and decision making. Examples of sectors include healthcare, education, public sector and government, highly regulated industries (such as the pharmaceutical industry, the food industry, or the financial industry), and nonprofit organizations and NGOs.

The institutional component is particularly relevant in several sectors and areas of transportation, where regulation, government policies, and collaboration with public institutions play a key role. Some of these sectors and areas include public transport, freight transport, air transport regulation, maritime transport and ports, intelligent transport and urban mobility, passenger and freight rail transport, and transport of people with special needs. Therefore, the results of this study show the greater importance of the economic-operational component compared to the institutional component, which is much more traditional in the transport sector.

6. Conclusions

The conclusions reached in this study, based on the development of an ideal SDP indicator to measure the degree of adaptation of dry ports, are diverse and are presented below.

A set of ports as representative as possible was selected and presents a higher degree of objectivity in its data reliably and openly. The network of intermodal facilities or ZAL is extensive in the Spanish territory; there are few facilities that deserve to be considered dry ports, and even fewer that could be the subject of this study due to the lack of published and updated information.

From the Delphi study that was prepared, there was a solid consistency in the axes and indicators most weighted by the panel surveyed. Among the four axes analyzed, it was observed that the indicators that were most related to the digitalization and automation of processes and their management obtained a greater weight.

As a first conclusion from the study, we would place the idea that the Smart concept which focuses on the application of ICTs must be considered gradually and holistically on the four dimensions that structure the SDP concept. Remember that the concepts of triple bottom line or sustainability are concentrated on three pillars, economic, social, and environmental, and that is why the idea of implementing the digitalization of railway and intermodal management in the port facility must be transverse to all of them. This is the only way to consolidate the concept of the Smart Dry Port and account for sustainability and efficiency, leading to a positive cost–benefit ratio.

From the analysis carried out of the selected facilities and assessing the degree of adaptation to digital or automated management systems, the idea was distilled that the current scenario still presents a lot of room for improvement given that the scores obtained not only globally, but also in each of the axes assessed, are very low.

At a global level, two of the three facilities analyzed can be considered to be above 60% in terms of adaptation to an ideal SDP, which is achieved above all by the operational economic axis in which a greater investment is seen. Although a remarkable investment in new digital systems can be appreciated, the distance of these ports analyzed in relation to the most cutting-edge dry ports in Europe such as the Interporto of Verona in Italy and the GVZ of Bremen or Nürnberg in Germany is very long. The facilities analyzed are presented as intermodal terminals with a very clear railway preponderance, with semi-automated systems and facilities not entirely adapted to single digital windows, which means that they are not fully efficient. Considering the results in each of the four axes analyzed, it is observed that the environmental dimension obtained significantly very low scores compared to the rest of the axes, reaching only 31% average adaptation with respect to the ideal indicator for this axis.

It is clear that, based on these results, efforts should be directed to obtain a greater degree of adaptation in this dimension, above all, acquiring new digitalization systems and implementing automation in those processes where it is possible to advance in the ranking and to achieve a greater degree of adaptation to the concept of a Smart port. The improvement in this dimension is not associated with large disbursements or investments compared to in the other three that do need more commitment and that must be driven by competent administrations. To conclude, the dry ports analyzed must invest and acquire a greater degree of digitalization and automation of processes, not only to improve their efficiency and sustainability, but also to improve their added value to society. The digitalization of this type of facilities is no longer a choice, but the possibility of surviving in the global logistics market.

Finally, the findings of the study suggest several areas of future research and actions that could be addressed to improve the adaptation of dry ports to the Smart Dry Port (SDP) concept and advance the transformation to more efficient and sustainable facilities. Here are some areas of research and actions that could be considered:

Improving the Environmental Dimension: Given that the environmental dimension scored significantly low, it could be important to research and develop specific strategies to improve the environmental sustainability of dry ports. This could include the implementation of cleaner technologies, waste management, and carbon footprint reduction.

Best Practice Analysis: Conduct an in-depth analysis of leading dry ports in Europe, such as Verona Interport in Italy or Bremen GVZ in Germany, to understand the best practices and strategies they have adopted in terms of digitization and automation. This could provide insights and lessons for improvement.

Public–Private Collaboration: Encourage collaboration between dry ports and government authorities to drive investment in digitization and automation. This could include tax incentives or specific funding programs for modernization projects.

Author Contributions

All the authors have contributed on each of the themes. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

Authors would like to thank the Technical University of Madrid in general and in particular the support received from the Department of Transport, Territory and Urban Planning Engineering of the same University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- One Hundred Container Ports 2020: Lloyd’s List. [Online]. Available online: https://lloydslist.maritimeintelligence.informa.com/one-hundred-container-ports-2020 (accessed on 18 May 2023).

- Informa UK Limited. Containerisation International Yearbook 2002; Informa UK Limited: London, UK, 2002. [Google Scholar]

- Arvis, J.-F.; Mustra, M.A.; Ojala, L.; Shepherd, B.; Saslavsky, D. Connecting to Compete 2012: Trade Logistics in the Global Economy—The Logistics Performance Index and Its Indicators; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- González-Cancelas, N.; Moli, B.; Soler-Flores, F. Study to Improve the Digitalization of the Spanish Port System through an Affinity Diagram. J. Marit. Transp. Logist. 2020, 1, 51–68. [Google Scholar]

- UNCTAD. 1992. [Online]. Available online: https://unctad.org/system/files/official-document/tdc4ac7_d14_en.pdf (accessed on 18 May 2023).

- Orive, A.C. Logística Portuaria: Puertos Secos y Zona de Actividades Logísticas, Funcas. [Online]. Available online: https://www.funcas.es/articulos/logistica-portuaria-puertos-secos-y-zona-de-actividades-logisticas/ (accessed on 18 May 2023).

- Nam, T.; Pardo, T.A. Conceptualizing smart city with dimensions of technology, people, and institutions. In Proceedings of the 12th Annual International Digital Government Research Conference: Digital Government Innovation in Challenging Times, College Park, MD, USA, 12–15 June 2011; Association for Computing Machinery: New York, NY, USA, 2011; pp. 282–291. [Google Scholar] [CrossRef]

- Molavi, A.; Lim, G.J.; Race, B. A framework for building a smart port and smart port index. Int. J. Sustain. Transp. 2020, 14, 686–700. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Q.; Huang, R. Locating dry ports on a network: A case study on Tianjin Port. Marit. Policy Manag. 2018, 45, 71–88. [Google Scholar] [CrossRef]

- Nguyen, L.C.; Thai, V.V.; Nguyen, D.M.; Tran, M.D. Evaluating the role of dry ports in the port-hinterland settings: Conceptual framework and the case of Vietnam. Asian J. Shipp. Logist. 2021, 37, 307–320. [Google Scholar] [CrossRef]

- Fort, E.H. Internet of Things en Sistemas de Monitorización Inteligente con Aplicación en Transporte e Infraestructuras. Universidad de Sevilla. 2020. [Online]. Available online: https://dialnet.unirioja.es/servlet/tesis?codigo=282513 (accessed on 18 May 2023).

- Munford, C. Buenos Aires-congestion and the dry port solution. Cargo Syst. Int. J. ICHCA 1980, 7, 26–27. [Google Scholar]

- Hanappe, P. Plates-formes de fret, centres de logistique, ports secs. Rech. Transp. Sécurité 1986, 12, 21–26. [Google Scholar]

- Tsilingris, P.; Laguardia, C. Dry Vis-a-Vis water ports: Partners or competitors? In Proceedings of the International Scientific Conference: Competitiveness and Complementarity of Transport Modes–Perspectives for the Development of Intermodal Transport, University of the Aegean, Chios, Greece, 10–12 May 2007. [Google Scholar]

- Leveque, P.; Roso, V. Dry Port Concept for Seaport Inland Access with Intermodal Solutions. Master’s Thesis, Department of Logistics and Transportation, Chalmers University of Technology, Gothemburg, Sweden, 2002. [Google Scholar]

- Roso, V. Evaluation of the dry port concept from an environmental perspective: A note. Transp. Res. Part Transp. Environ. 2007, 12, 523–527. [Google Scholar] [CrossRef]

- Roso, V. Factors influencing implementation of a dry port. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 782–798. [Google Scholar] [CrossRef]

- Tsamboulas, D.A.; Dimitropoulos, I. Appraisal of investments in European nodal centres for goods—Freight villages: A comparative analysis. Transportation 1999, 26, 381–398. [Google Scholar] [CrossRef]

- Höltgen, D. Terminals, Intermodal Logistics Centres and European Infrastructure Policy. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 1995. [Google Scholar]

- Jeevan, J.; Chen, S.-L.; Cahoon, S. The impact of dry port operations on container seaports competitiveness. Marit. Policy Manag. 2019, 46, 4–23. [Google Scholar] [CrossRef]

- Aronsson, H.; Brodin, M.H. The environmental impact of changing logistics structures. Int. J. Logist. Manag. 2006, 17, 394–415. [Google Scholar] [CrossRef]

- Roso, V.; Woxenius, J.; Lumsden, K. The dry port concept: Connecting container seaports with the hinterland. J. Transp. Geogr. 2009, 17, 338–345. [Google Scholar] [CrossRef]

- Ballis, A.; Golias, J. Comparative evaluation of existing and innovative rail–road freight transport terminals. Transp. Res. Part Policy Pract. 2002, 36, 593–611. [Google Scholar] [CrossRef]

- Kozan, E. Optimising container transfers at multimodal terminals. Math. Comput. Model. 2000, 31, 235–243. [Google Scholar] [CrossRef]

- Barros, C.F.D.S.; Barros, C.M. Suitability of Brazilian ports to international standards of port needs: A case study in the port of Salvador. J. Transp. Lit. 2013, 7, 23–49. [Google Scholar] [CrossRef]

- Gorgone, S. La Mensajería EDI Como Células de un Sistema Portuario Inteligente. [Online]. Available online: https://porthink.com/zoom-a-la-transformacion-digital-parte-1-el-edi-como-las-celulas-de-un-sistema-portuario-inteligente (accessed on 25 May 2023).

- González, A.R.; González-Cancelas, N.; Serrano, B.M.; Orive, A.C. Preparation of a Smart Port Indicator and Calculation of a Ranking for the Spanish Port System. Logistics 2020, 4, 9. [Google Scholar] [CrossRef]

- Martín-Soberón, A.M.; Monfort, A.; Sapiña, R.; Monterde, N.; Calduch, D. Automation in Port Container Terminals. Procedia-Soc. Behav. Sci. 2014, 160, 195–204. [Google Scholar] [CrossRef]

- Hofheinz, K.H. Digitalización y Automatización en el Sector Ferroviario: Un Tren que Europa no Debe Perder. 2019. Universidad de Comillas. Available online: https://repositorio.comillas.edu/xmlui/handle/11531/32171 (accessed on 18 May 2023).

- Kuo, Y.-F.; Chen, P.-C. Constructing Performance appraisal indicators for mobility of the service industries using Fuzzy Delphi Method. Expert Syst. Appl. 2008, 35, 1930–1939. [Google Scholar] [CrossRef]

- Khosravi, M.; Sarvari, H.; Chan, D.W.; Cristofaro, M.; Chen, Z. Determining and assessing the risks of commercial and recreational complex building projects in developing countries: A survey of experts in Iran. J. Facil. Manag. 2020, 18, 259–282. [Google Scholar] [CrossRef]

- Sarvari, H.; Rakhshanifar, M.; Tamošaitienė, J.; Chan, D.W.; Beer, M. A risk based approach to evaluating the impacts of Zayanderood drought on sustainable development indicators of riverside urban in Isfahan-Iran. Sustainability 2019, 11, 6797. [Google Scholar] [CrossRef]

- Ariffin, K.M.; Milala, S.I.; Kasim, R. Facilities Management Business Opportunities. Int. J. Sustain. Constr. Eng. Technol. 2022, 13, 258–267. [Google Scholar]

- Archibald, M.M.; Ambagtsheer, R.C.; Casey, M.G.; Lawless, M. Using Zoom Videoconferencing for Qualitative Data Collection: Perceptions and Experiences of Researchers and Participants. Int. J. Qual. Methods 2019, 18, 160940691987459. [Google Scholar] [CrossRef]

- Dusek, G.; Yurova, Y.; Ruppel, C.P. Using social media and targeted snowball sampling to survey a hard-to-reach population: A case study. Int. J. Dr. Stud. 2015, 10, 279. [Google Scholar] [CrossRef]

- Sarvari, H.; Chan, D.W.; Banaitiene, N.; Noor, N.M.; Beer, M. Barriers to development of private sector investment in water and sewage industry. Built Environ. Proj. Asset Manag. 2021, 11, 52–70. [Google Scholar] [CrossRef]

- Chan, D.W.; Choi, T.N. Critical analysis of the application of the safe working cycle (SWC) interview findings from Hong Kong. J. Facil. Manag. 2015, 13, 244–265. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).