Feasibility of Using Green Laser in Monitoring Local Scour around Bridge Pier

Abstract

:1. Background

2. Introduction

- (i)

- Laser scan devices can be operated from various floating and unmanned platforms. Floating platforms such as small boats, barges, pontoons and unmanned platforms such as drones and UAVs (Unmanned Aerial Vehicles) can be used for this purpose.

- (ii)

- These devices can provide real time scour data.

- (iii)

- The service of an underwater diver is not needed in the operation of the laser devices during the scour monitoring since these devices can be operated from unmanned aerial vehicles or unmanned surface vehicles and also from fixed stations.

- (iv)

- The same device can be reused multiple times in multiple locations

3. Materials and Methods

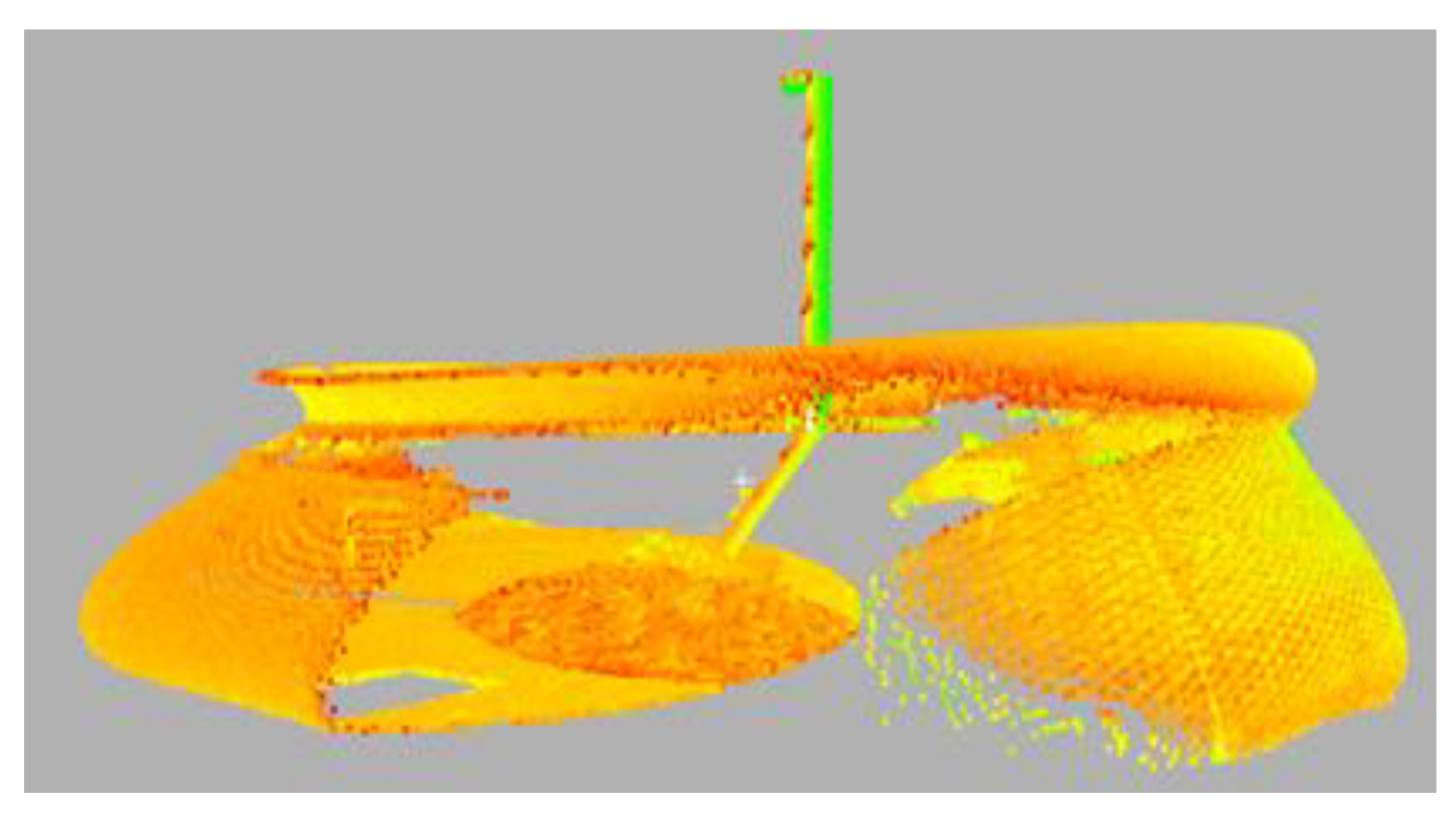

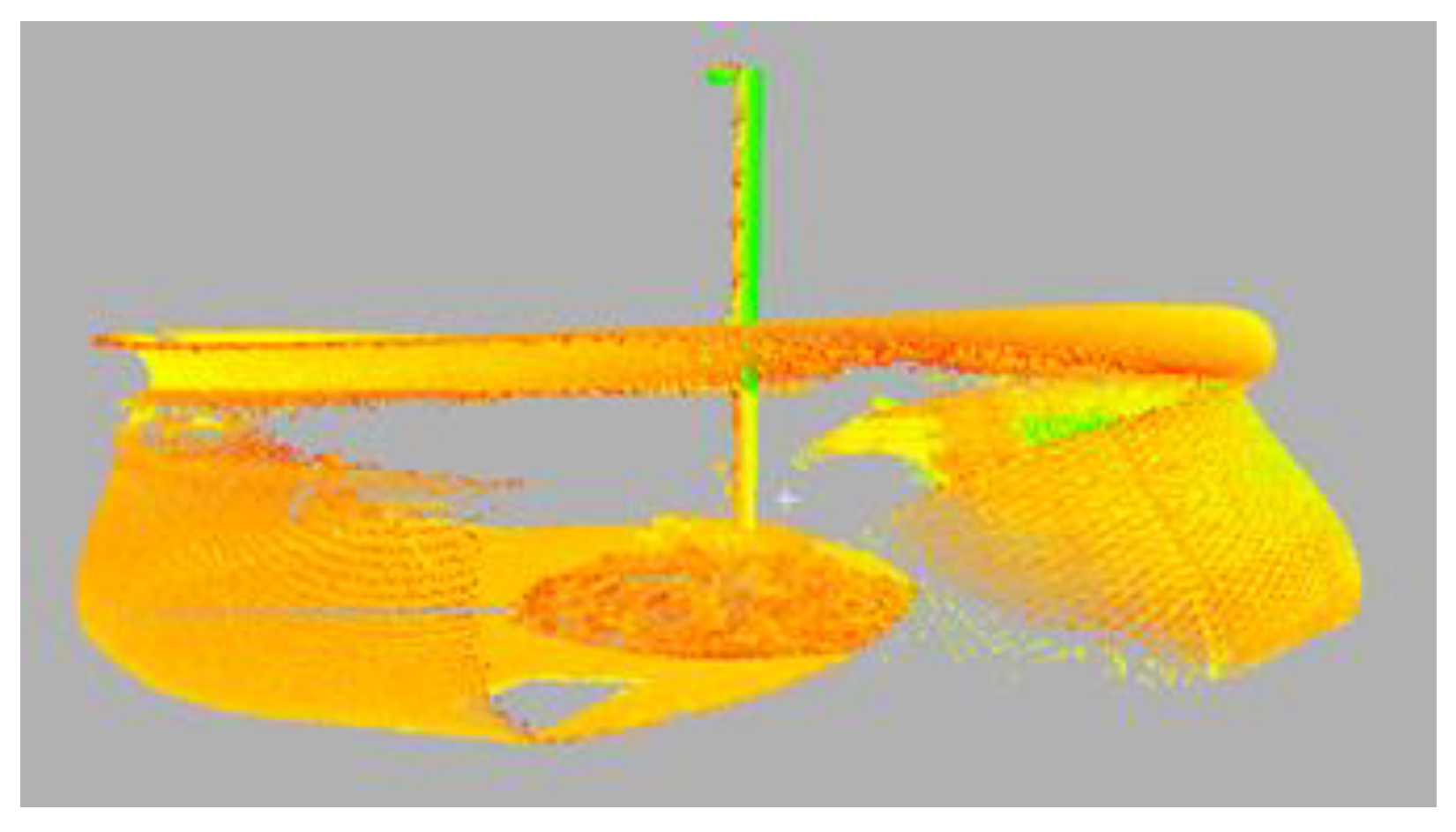

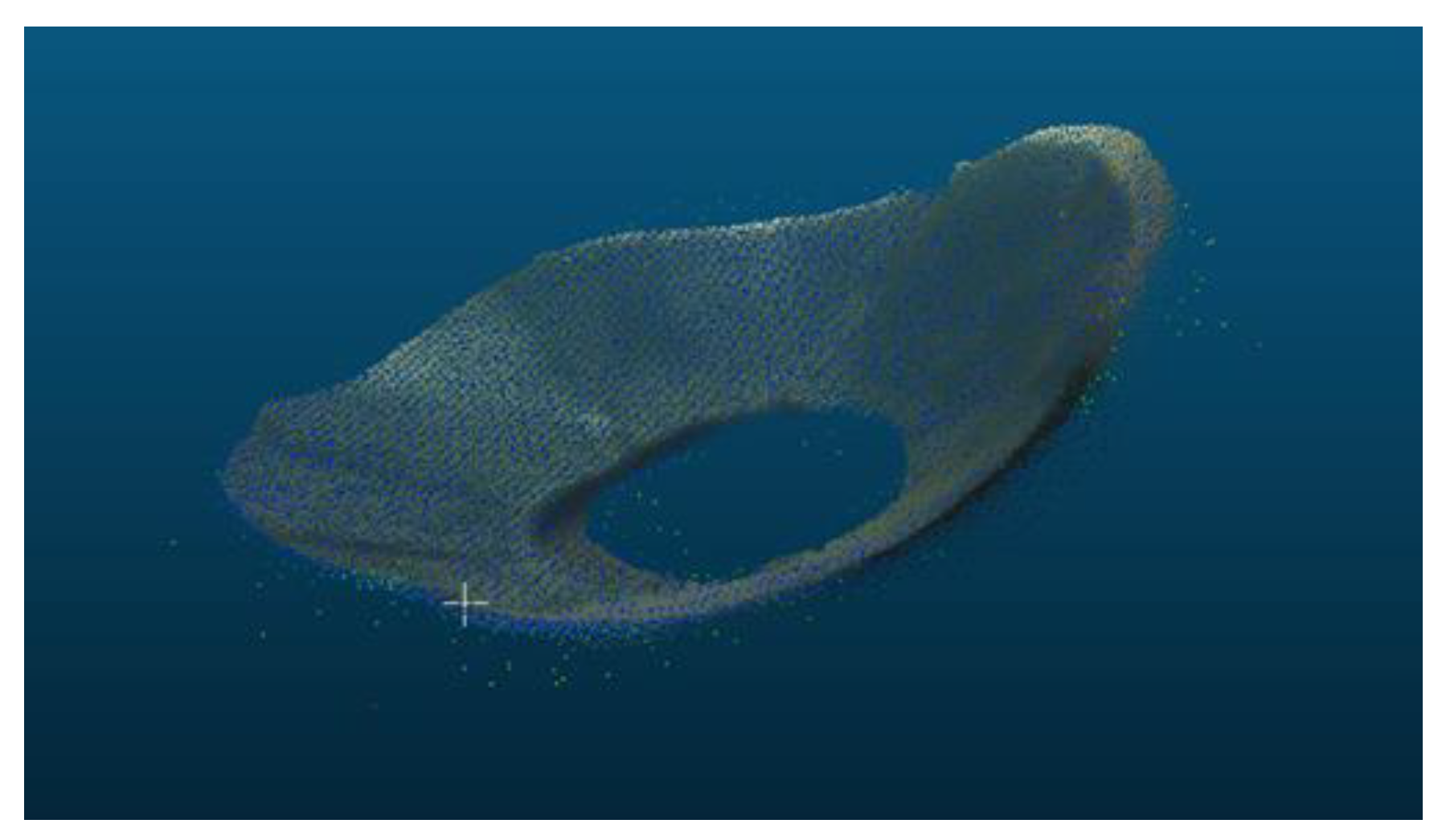

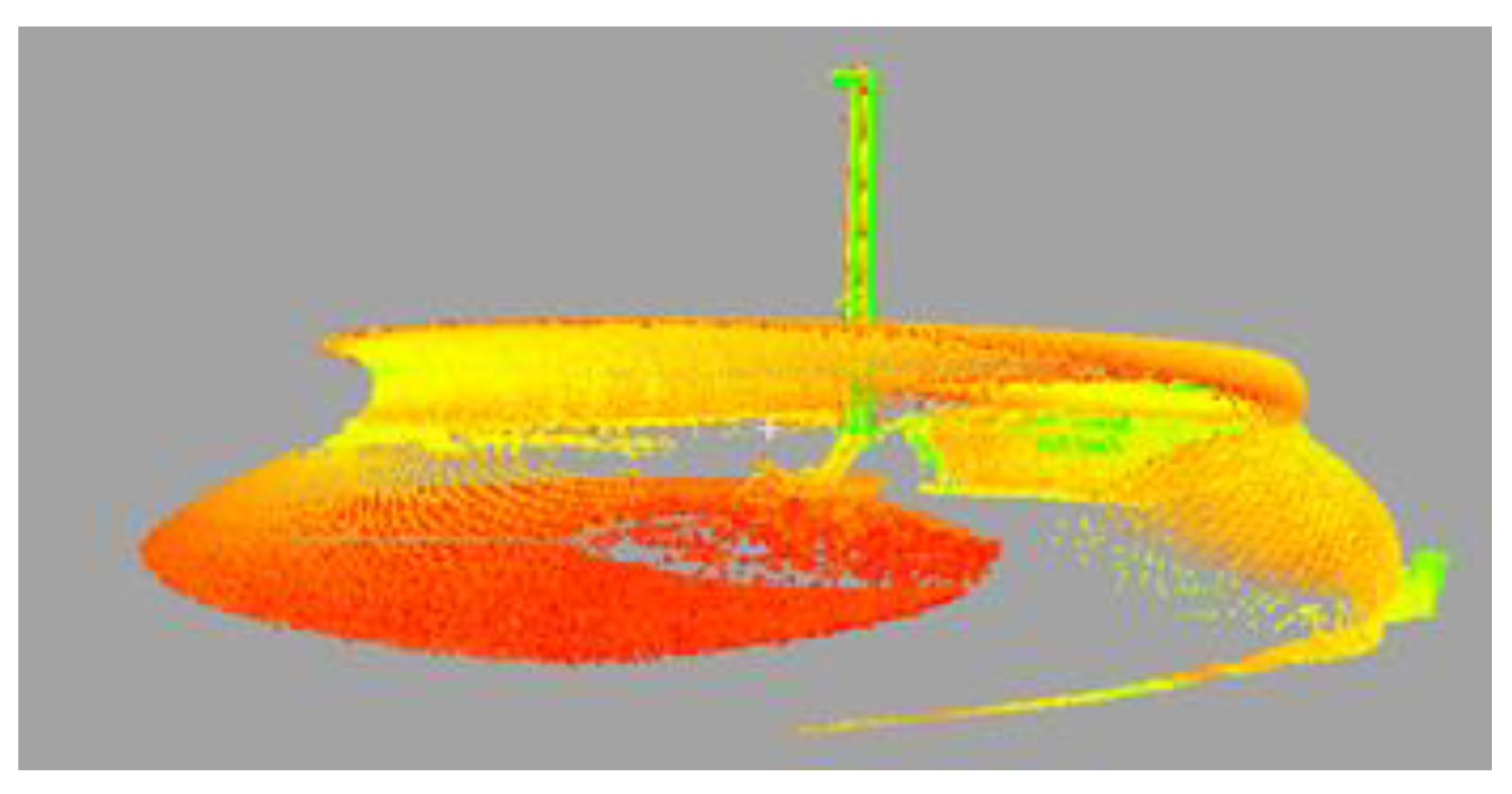

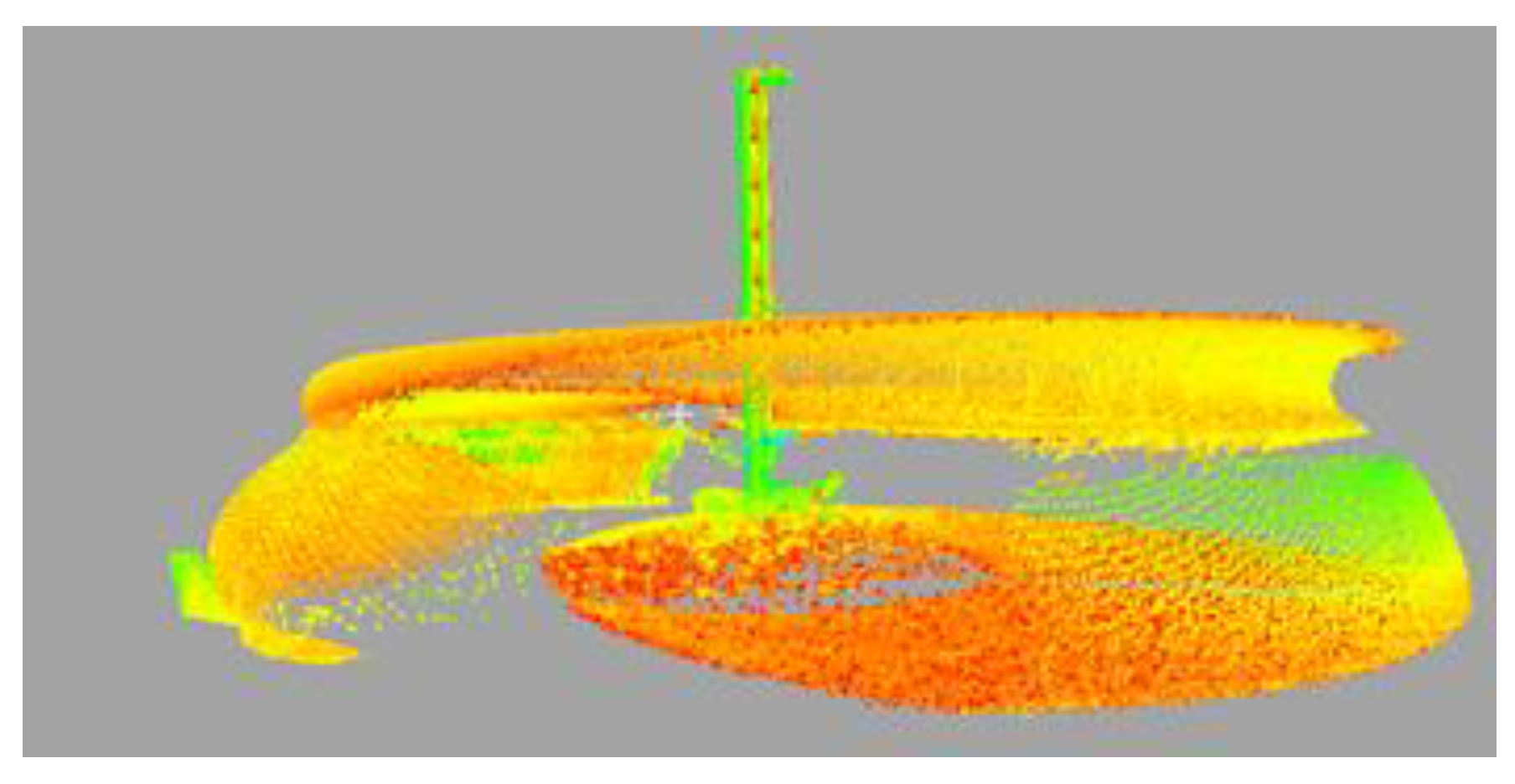

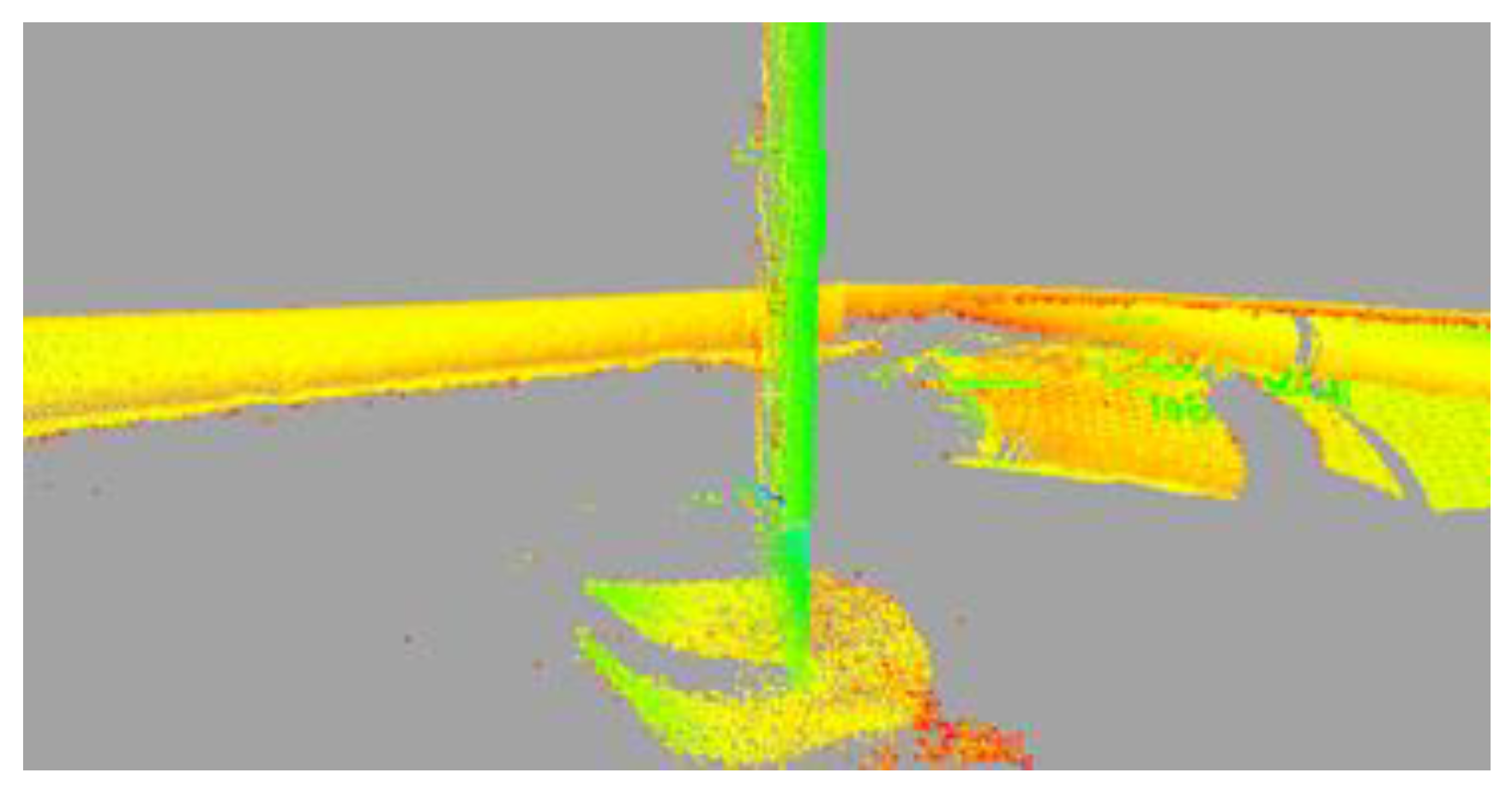

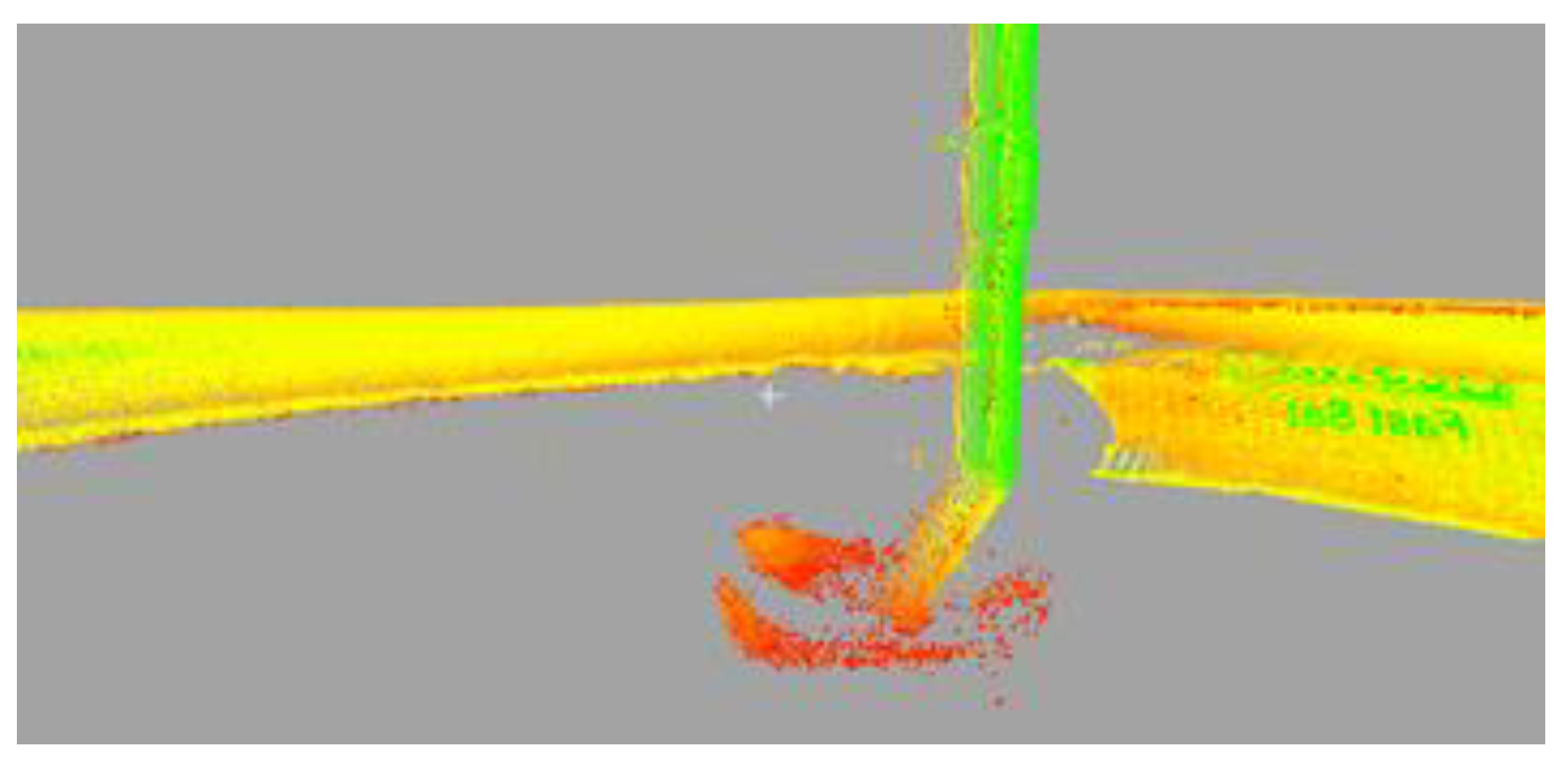

3.1. Experimental Set-Up

Turbidity

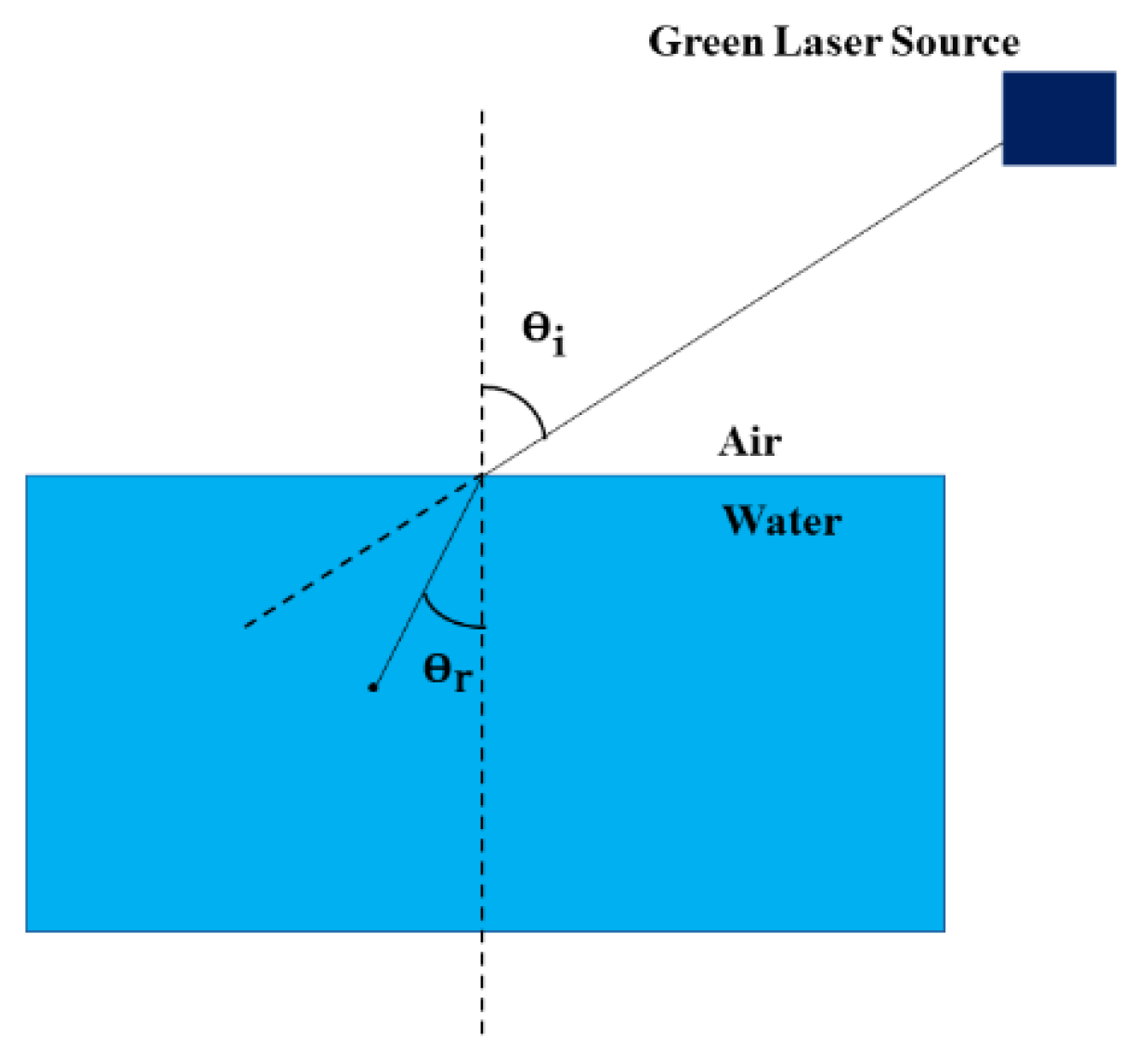

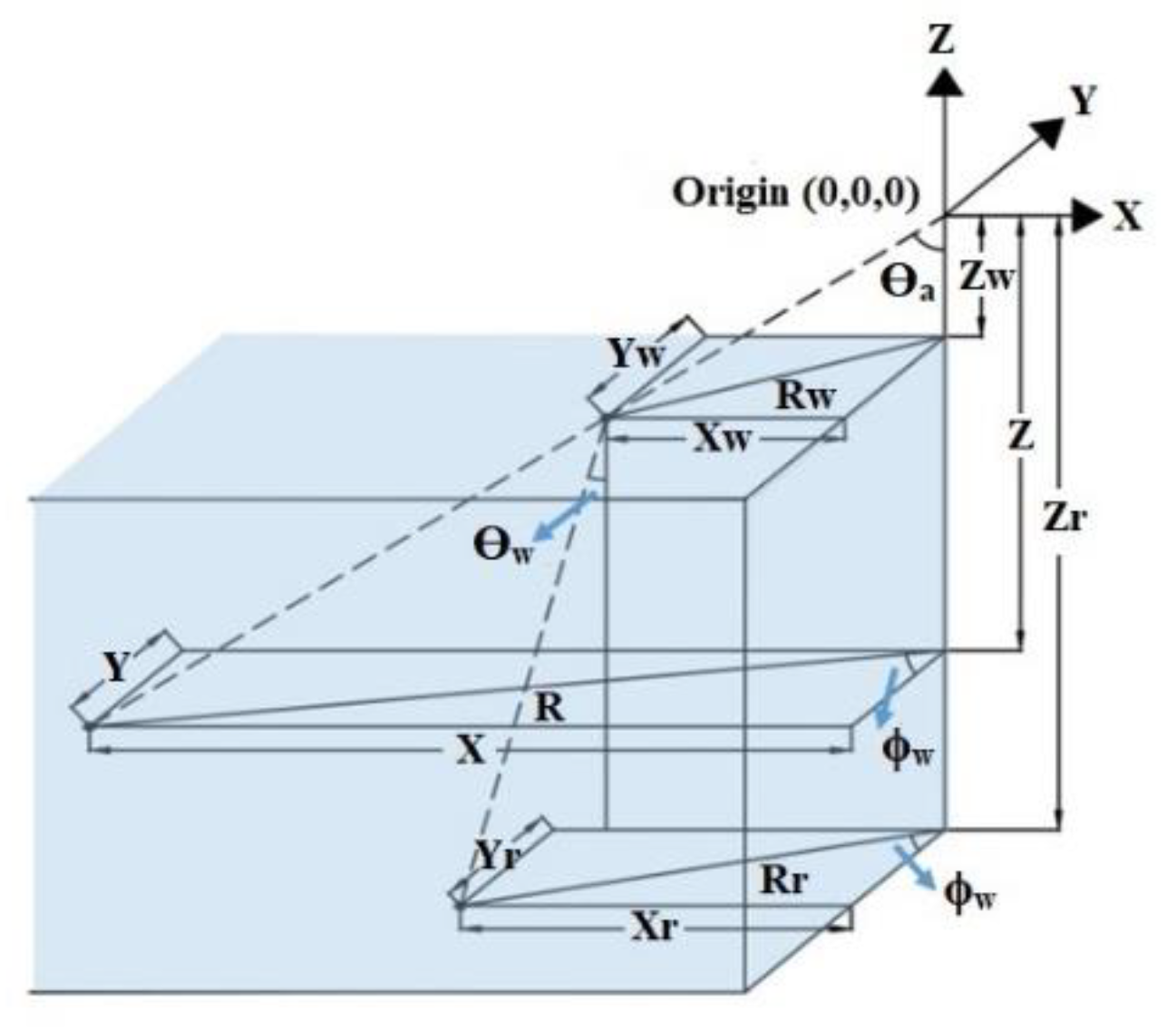

3.2. Refraction Correction Model

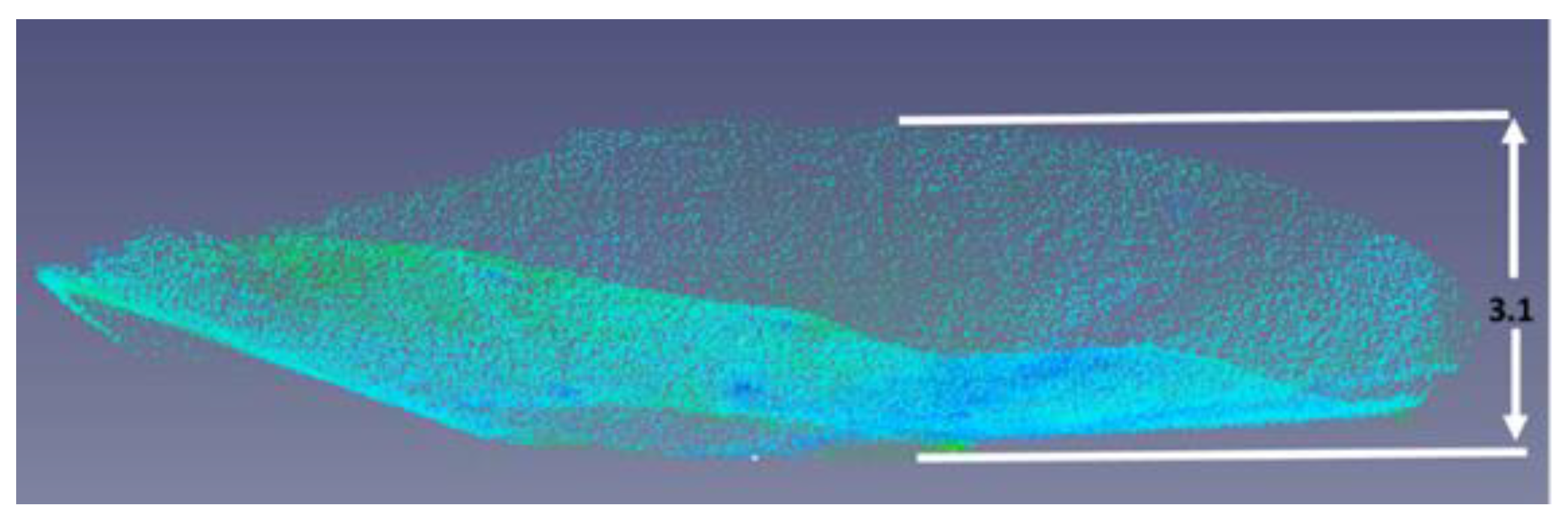

3.3. Reference Model

4. Results and Discussion

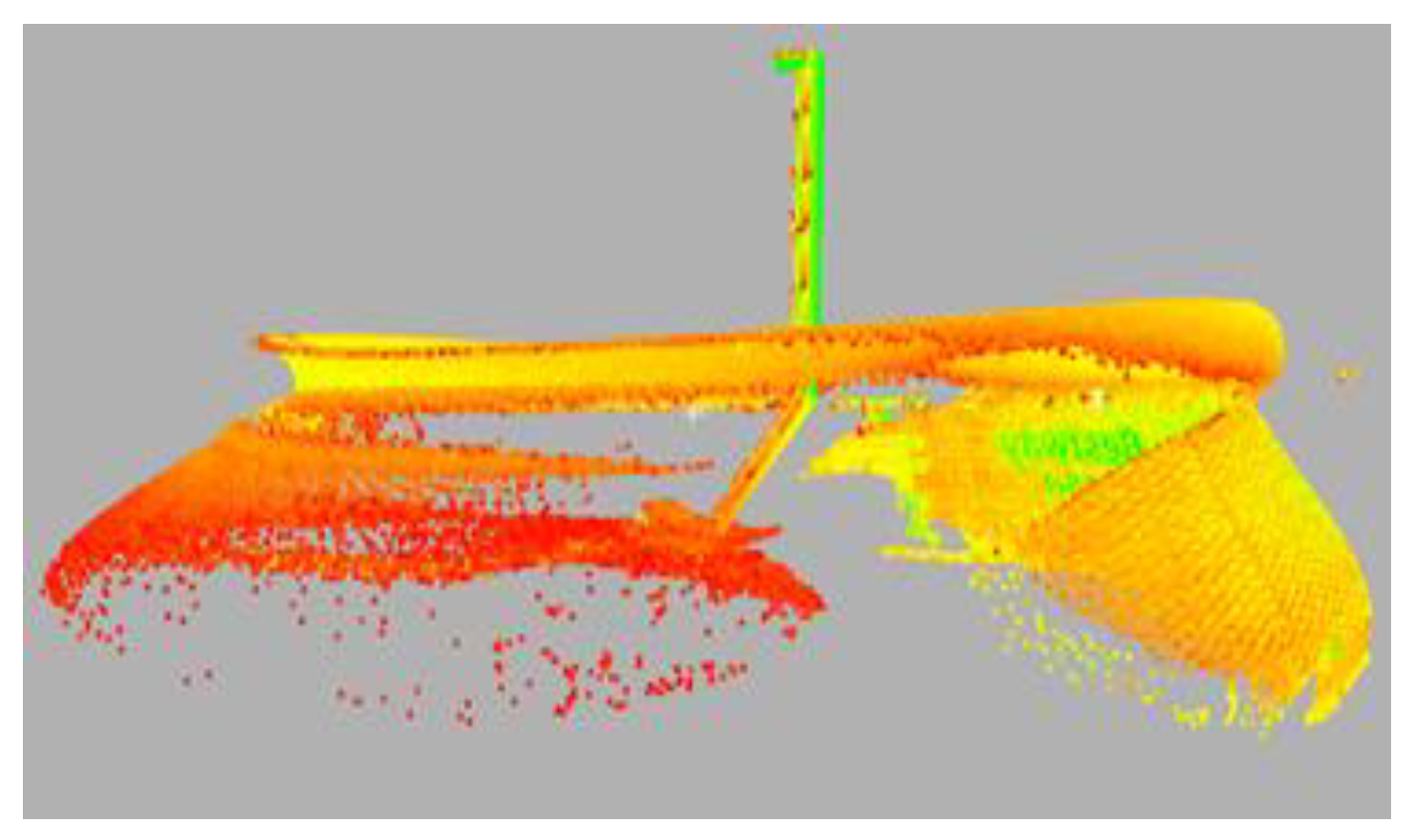

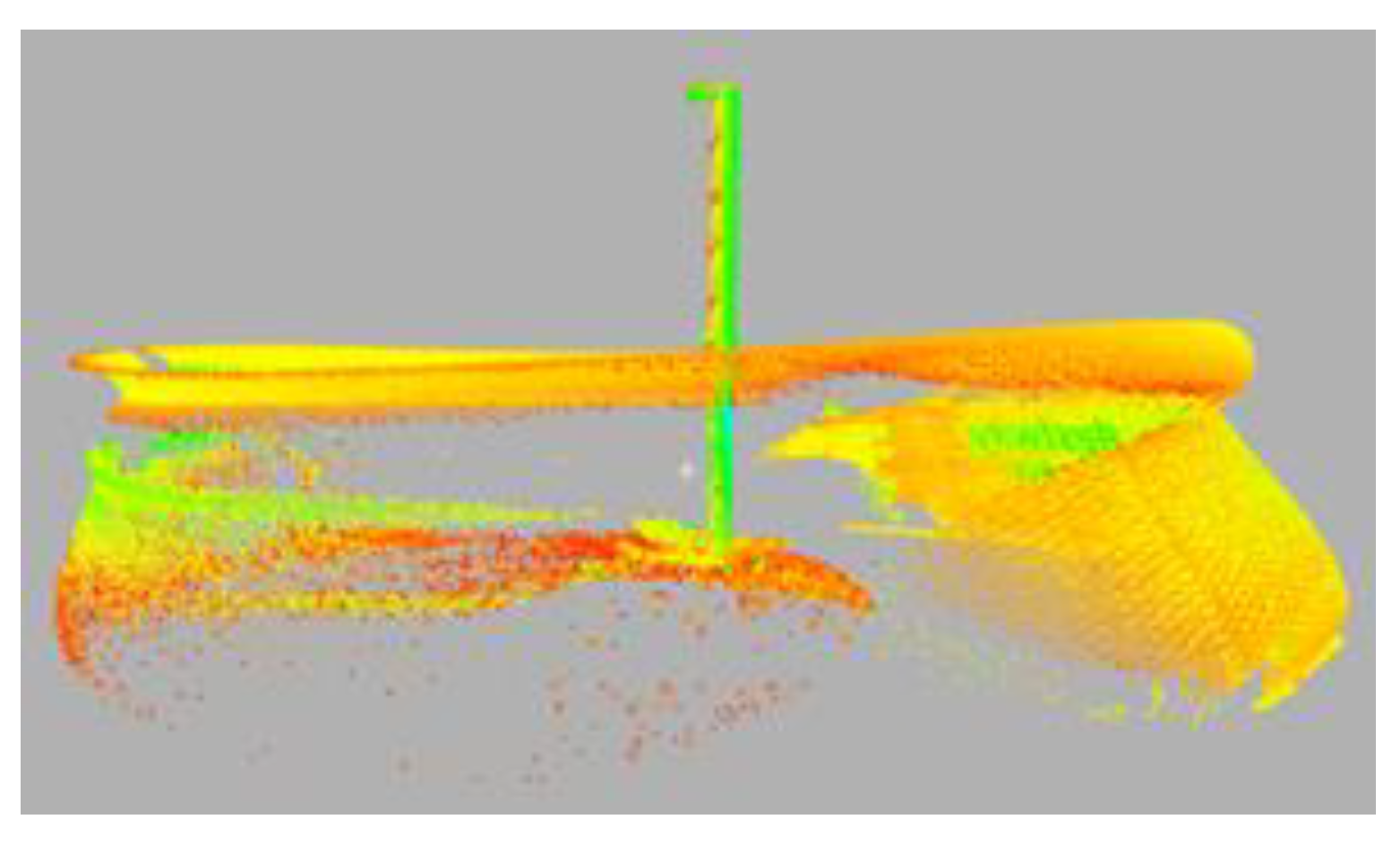

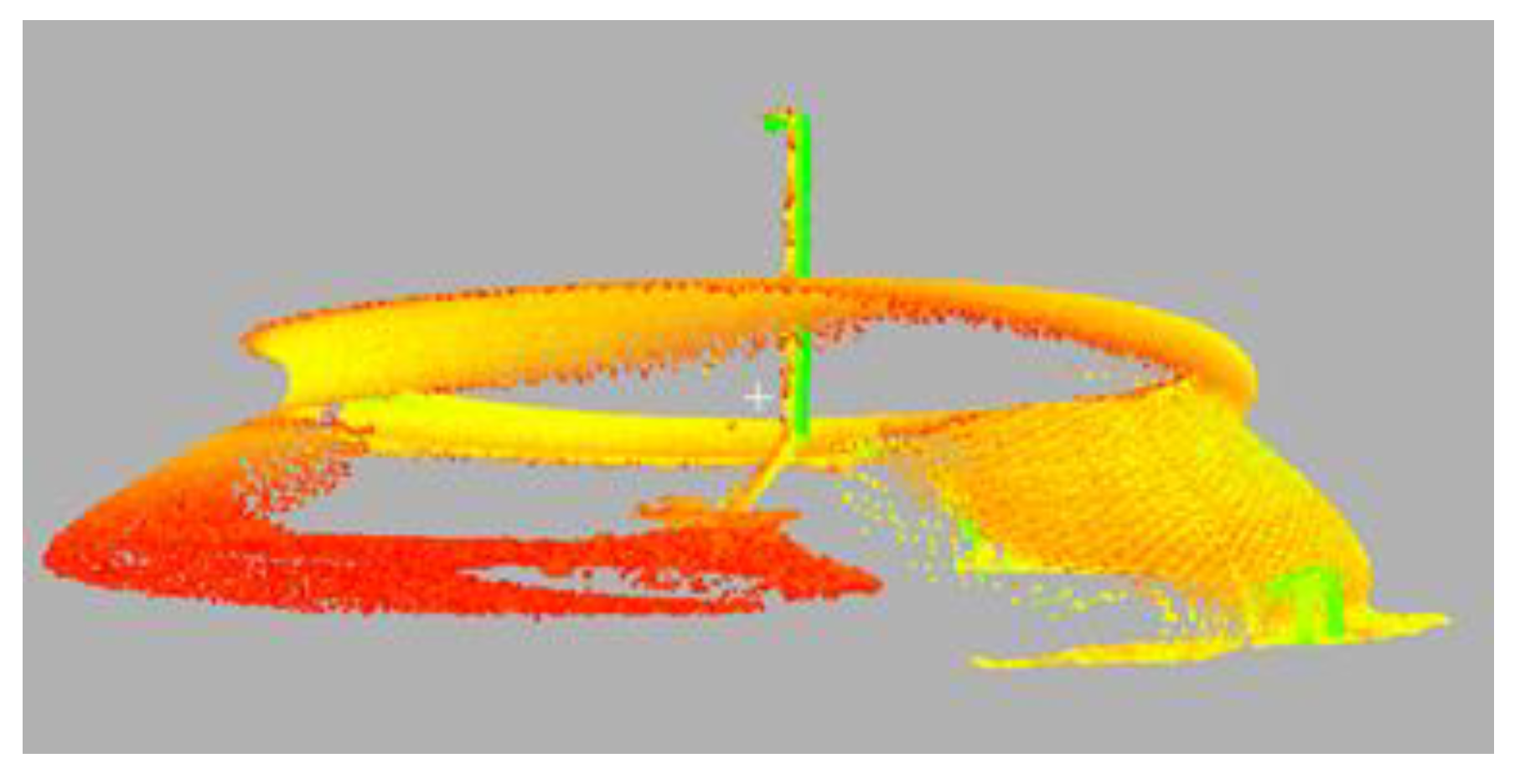

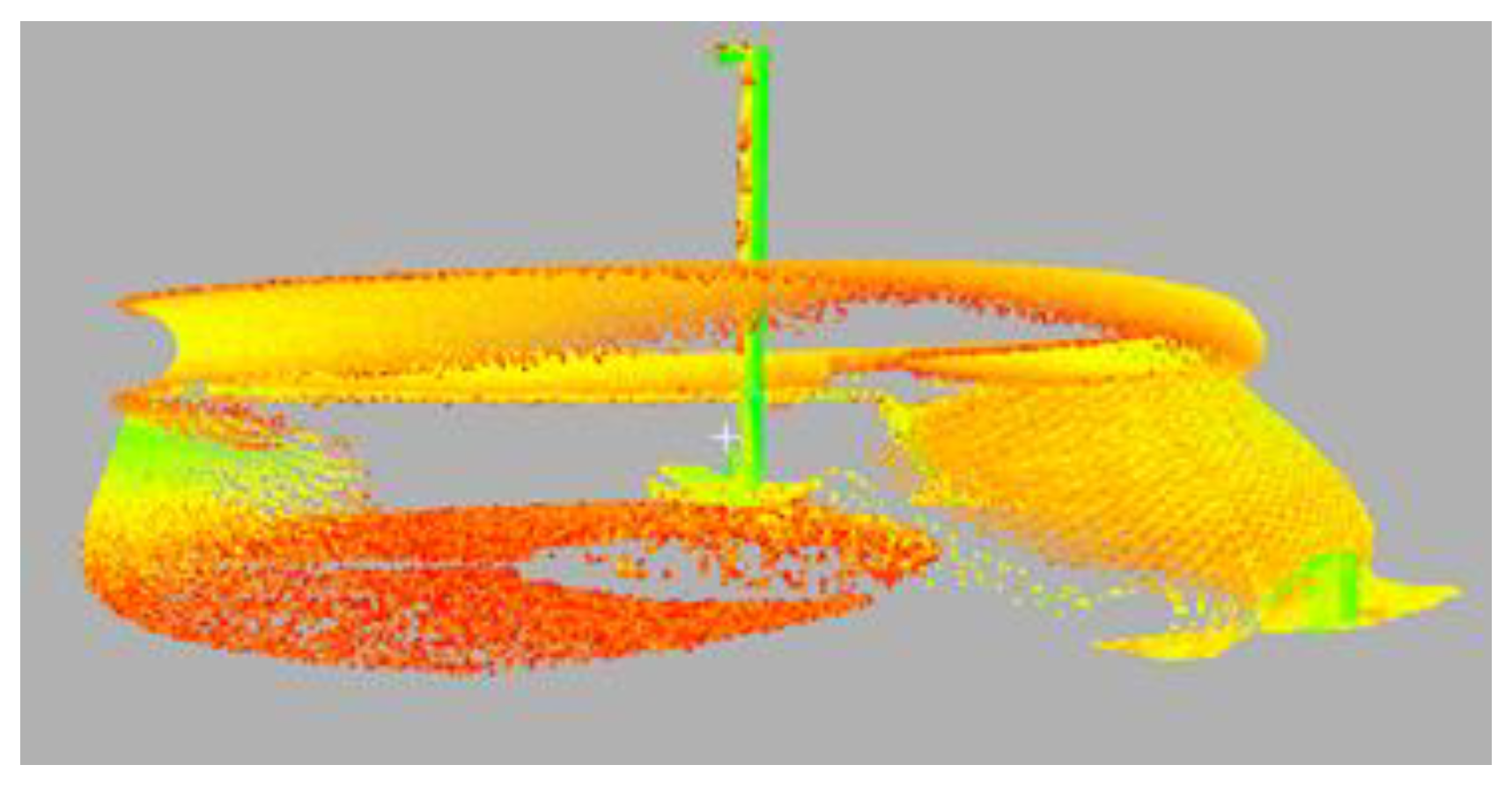

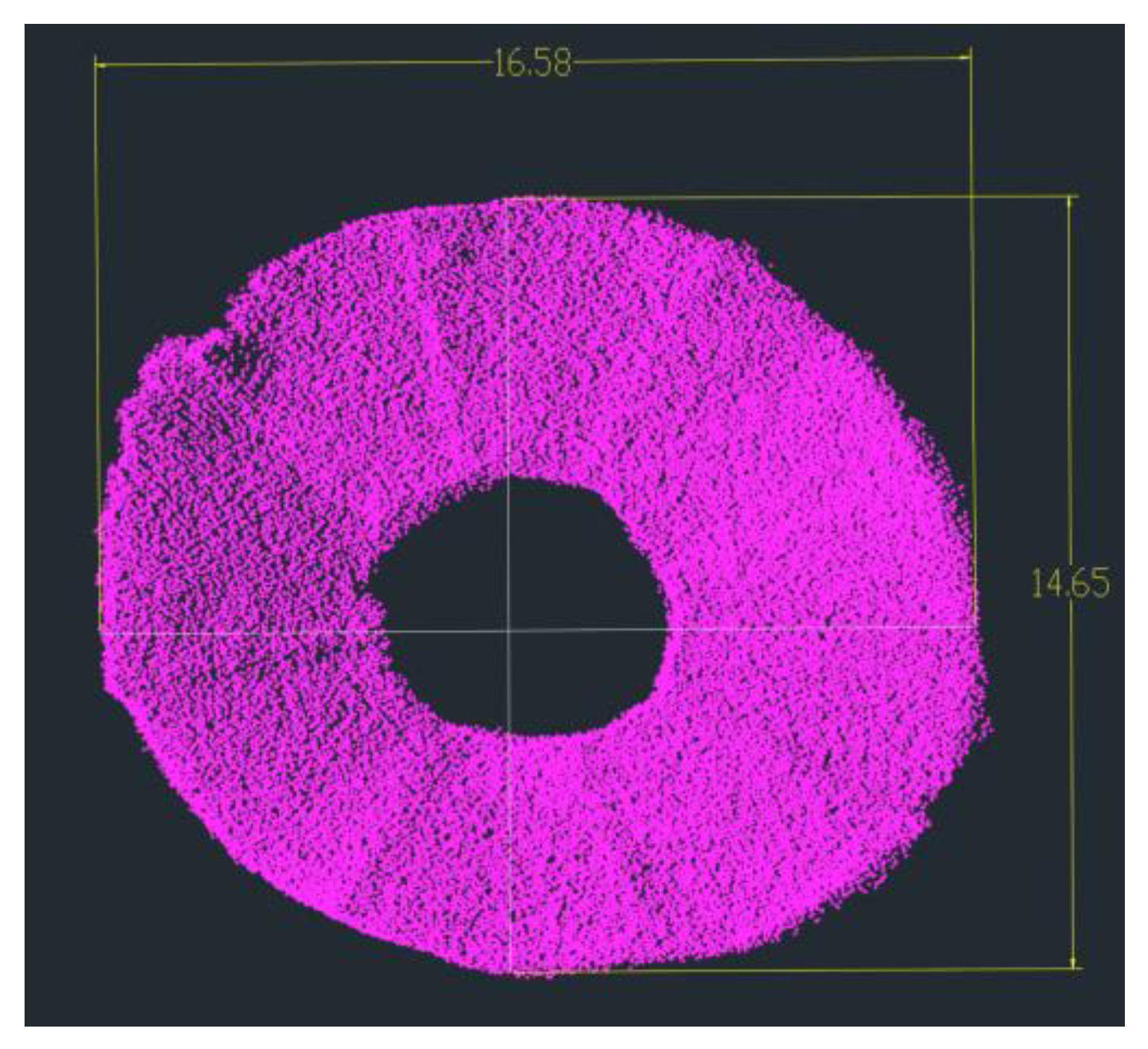

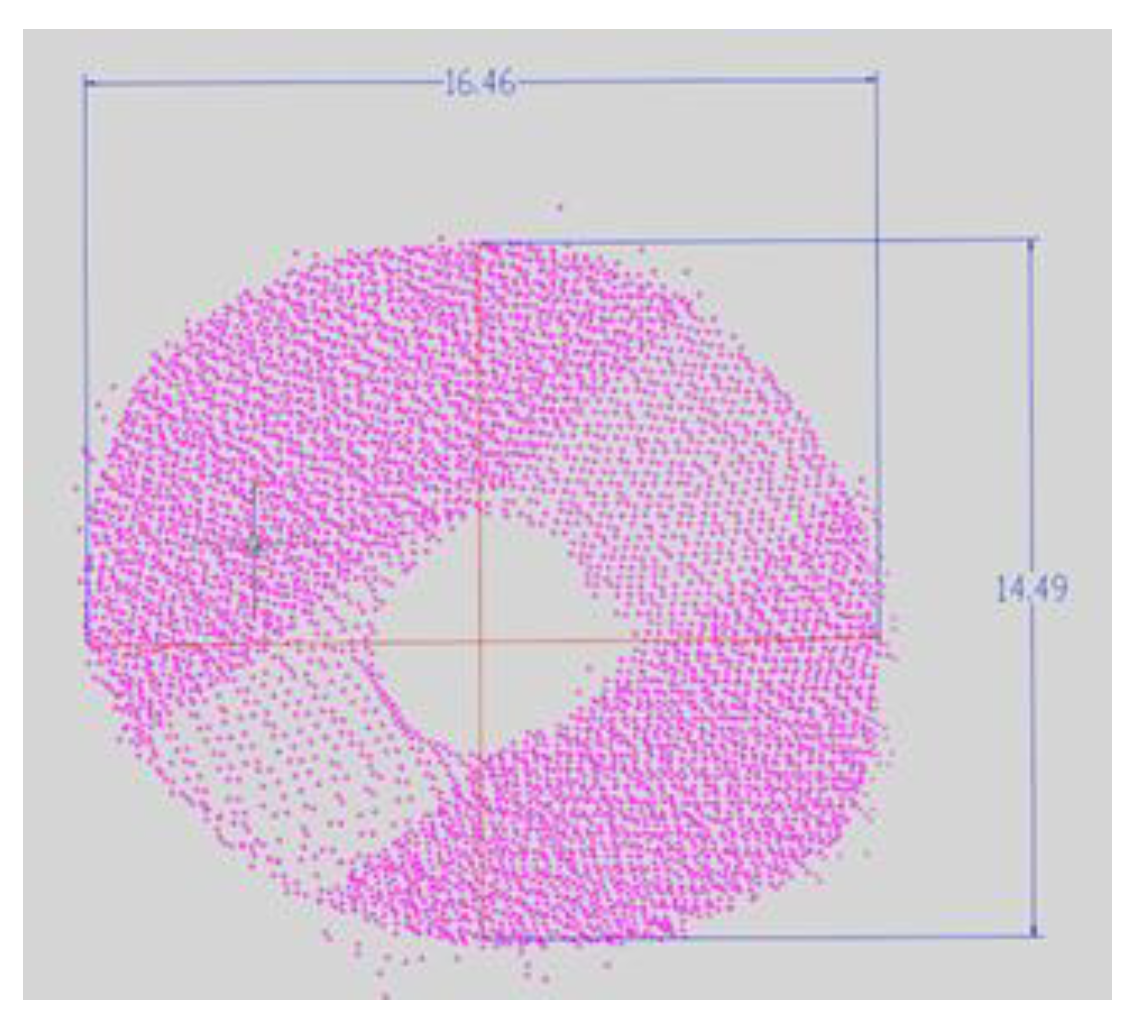

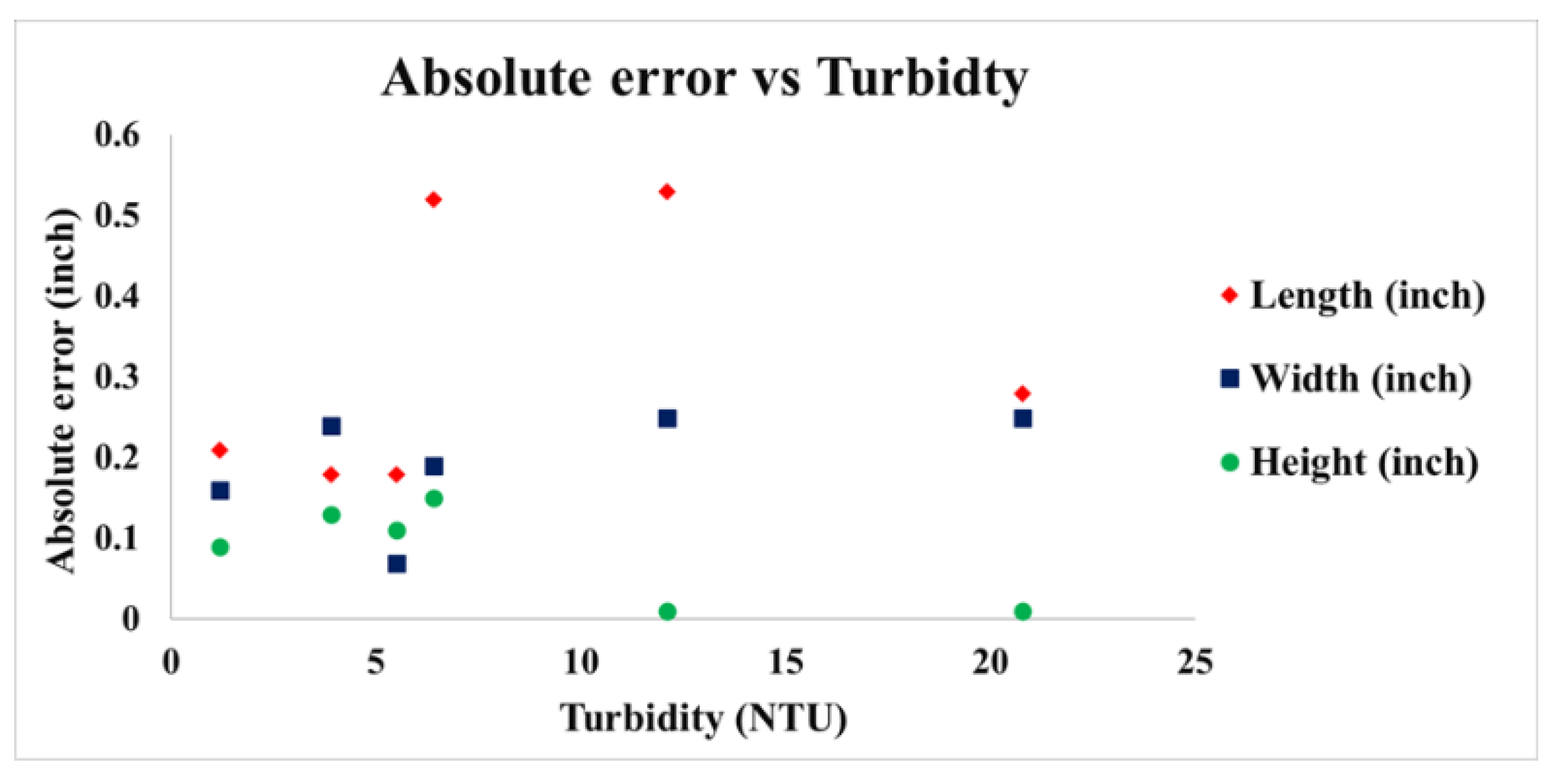

4.1. Turbidity 1.2 NTU (Trial 1)

4.2. Turbidity 3.9 NTU (Trial 2)

4.3. Turbidity 5.5 NTU (Trial 3)

4.4. Turbidity 6.4 NTU (Trial 4)

4.5. Turbidity 12.1 NTU (Trial 5)

4.6. Turbidity 20.8 NTU (Trial 6)

5. Conclusions

6. Field Testing

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Browne, T.M.; Collins, T.J.; Garlich, M.J.; O’Leary, J.E.; Stromberg, D.G.; Heringhaus, K.C. Underwater Bridge Inspection (No. FHWA-NHI-10-027); Federal Highway Administration, Office of Bridge Technology: Washington, DC, USA, 2010.

- Wardhana, K.; Hadipriono, F.C. Analysis of recent bridge failures in the United States. J. Perform. Constr. Facil. 2003, 17, 144–150. [Google Scholar]

- Arneson, L.A.; Zevenbergen, L.W.; Lagasse, P.F.; Clopper, P.E. Evaluating Scour at Bridges (No. FHWA-HIF-12-003); National Highway Institute (US), Repository and Open Science Access Portal, Naional Transportation Library: Washington, DC, USA, 2012.

- Lamb, R.; Garside, P.; Pant, R.; Hall, J.W. A probabilistic model of the economic risk to Britain’s railway network from bridge scour during floods. Risk Anal. 2019, 39, 2457–2478. [Google Scholar]

- Benedict, S.T.; Caldwell, A.W. A Pier-Scour Database: 2427 Field and Laboratory Measurements of Pier Scour; 845; U.S. Geological Survey: Reston, VA, USA, 2014. [CrossRef]

- Hearn, G. Bridge Inspection Practices (Vol. 375); Transportation Research Board: Washington, DC, USA, 2007. [Google Scholar]

- Deng, L.; Wang, W.; Yu, Y. State-of-the-art review on the causes and mechanisms of bridge collapse. J. Perform. Constr. Facil. 2016, 30, 04015005. [Google Scholar]

- Lagasse, P.F.; Richardson, E.V. ASCE compendium of stream stability and bridge scour papers. J. Hydraul. Eng. 2011, 127, 531–533. [Google Scholar]

- Lu, J.Y.; Hong, J.H.; Su, C.C.; Wang, C.Y.; Lai, J.S. Field measurements and simulation of bridge scour depth variations during floods. J. Hydraul. Eng. 2008, 134, 810–821. [Google Scholar]

- Prendergast, L.J.; Gavin, K. A review of bridge scour monitoring techniques. J. Rock Mech. Geotech. Eng. 2014, 6, 138–149. [Google Scholar]

- Kobayashi, T.; Oda, K. Experimental study on developing process of local scour around a vertical cylinder. In Coastal Engineering, Proceedings of Twenty-Fourth International Conference, Kobe, Japan, 23–28 October 1994; ASCE: Columbia, MD, USA; pp. 1284–1297.

- Anderson, N.L.; Ismael, A.M.; Thitimakorn, T. Ground-penetrating radar: A tool for monitoring bridge scour. Environ. Eng. Geosci. 2007, 13, 1–10. [Google Scholar]

- Yao, C.; Darby, C.; Hurlebaus, S.; Price, G.R.; Sharma, H.; Hunt, B.E.; Yu, O.-Y.; Chang, K.-A.; Briaud, J.-L. Scour monitoring development for two bridges in Texas. Proceedings 5th International Conference on Scour and Erosion (ICSE-5), San Francisco, CA, USA, 7–10 November 2010; pp. 958–967. [Google Scholar]

- Whitehouse, R.J.; Sutherland, J.; Harris, J.M. Evaluating scour at marine gravity foundations. In Proceedings of the Institution of Civil Engineers-Maritime Engineering; Thomas Telford Ltd.: London, UK, 2011; Volume 164, pp. 143–157. [Google Scholar]

- Lin, Y.B.; Chen, J.C.; Chang, K.C.; Chern, J.C.; Lai, J.S. Real-time monitoring of local scour by using fiber Bragg grating sensors. Smart Mater. Struct. 2005, 14, 664. [Google Scholar]

- Kong, X.; Ho, S.C.M.; Song, G.; Cai, C.S. Scour monitoring system using fiber Bragg grating sensors and water-swellable polymers. J. Bridge Eng. 2017, 22, 04017029. [Google Scholar]

- Prendergast, L.J. Monitoring of bridge scour using changes in natural frequency of vibration-a field investigation. In Proceedings of the 5th International Young Geotechnical Engineer’s Conference, Paris, France, 31 August–1 September 2013; IOS Press: Amsterdam, The Netherland, 2013. [Google Scholar]

- Fisher, M.; Atamturktur, S.; Khan, A.A. A novel vibration-based monitoring technique for bridge pier and abutment scour. Struct. Health Monit. 2013, 12, 114–125. [Google Scholar]

- Lagasse, P.F.; Richardson, E.V.; Schall, J.D. Fixed instrumentation for monitoring scour at bridges. Transp. Res. Rec. 1998, 1647, 1–9. [Google Scholar]

- Deng, L.; Cai, C.S. Bridge scour: Prediction, modeling, monitoring, and countermeasures. Pract. Period. Struct. Des. Constr. 2010, 15, 125–134. [Google Scholar]

- Schall, J.D. Sonar Scour Monitor: Installation, Operation, and Fabrication Manual; Transportation Research Board, National Academy Press: Washington, DC, USA, 1997. [Google Scholar]

- Fisher, M.; Chowdhury, M.N.; Khan, A.A.; Atamturktur, S. An evaluation of scour measurement devices. Flow Meas. Instrum. 2013, 33, 55–67. [Google Scholar]

- Webb, D.J.; Anderson, N.L.; Newton, T.; Cardimona, S. Bridge scour: Application of ground penetrating radar. In Proceedings of the First International Conference on the Application of Geophysical Methodologies and NDT to Transportation Facilities and Infrastructure, St. Louis, MO, USA, 11–15 December 2000; Federal Highway Commission and Missouri Department of Transportation: St. Louis, MO, USA, 2000. [Google Scholar]

- Park, I.; Lee, J.; Cho, W. Assessment of bridge scour and riverbed variation by a ground penetrating radar. In Proceedings of the Tenth International Conference on Grounds Penetrating Radar, GPR 2004, Delft, The Netherland, 21–24 June 2004; IEEE: Piscataway, NJ, USA, 2004; Volume 1, pp. 411–414. [Google Scholar]

- Placzek, G. Surface-Geophysical Techniques Used to Detect Existing and Infilled Scour Holes Near Bridge Piers; US Department of the Interior, US Geological Survey: Hartford, CT, USA, 1995; Volume 95.

- Porter, K.; Simons, R.; Harris, J. Comparison of three techniques for scour depth measurement: Photogrammetry, echosounder profiling and a calibrated pile. Coast. Eng. Proc. 2014, 34, 64. [Google Scholar]

- Lasa, I.R.; Hayes, G.H.; Parker, E.T. Remote Monitoring of Bridge Scour Using Echo Sounding Technology. In Transportation Research Circular 498; Proceedings of the Presentations from 8th International Bridge Management Conference, Denver, CO, USA, 26–28 April 1999; Transportation Research Board: Washington, DC, USA, 2000; Volume 1. [Google Scholar]

- Mueller, D.S.; Landers, M.N. Portable Instrumentation for Real-Time Measurement of Scour at Bridges (No. FHWA-RD-99-085); Federal Highway Administration, Repository and Open Science Access Portal, Naional Transportation Library: Washington, DC, USA, 2000.

- Yagci, O.; Yildirim, I.; Celik, M.F.; Kitsikoudis, V.; Duran, Z.; Kirca, V.O. Clear water scour around a finite array of cylinders. Appl. Ocean Res. 2017, 68, 114–129. [Google Scholar]

- Banyhany, M. 3D Reconstruction of Simulated Bridge Pier Local Scour Using Green Laser and Hydrolite Sonar. Master’s Thesis, Florida Atlantic University, Boca Raton, FL, USA, 2018. [Google Scholar]

- Nagarajan, S.; Arockiasamy, M.; Banyhany, M. Bridge Pier Scour Hole Simulation and 3D Reconstruction Using Green Laser (No. 18-05495). In Proceedings of the Compendium of Transportation Research Board 97th Annual Meeting, Washington DC, USA, 7–11 January 2018. [Google Scholar]

- Paul, J.D.; Buytaert, W.; Sah, N. A Technical Evaluation of Lidar-Based Measurement of River Water Levels. Water Resour. Res. 2020, 56, e2019WR026810. [Google Scholar]

- Brando, V.E.; Anstee, J.M.; Wettle, M.; Dekker, A.G.; Phinn, S.R.; Roelfsema, C. A physics based retrieval and quality assessment of bathymetry from suboptimal hyperspectral data. Remote Sens. Environ. 2009, 113, 755–770. [Google Scholar]

- Fabricius, K.E.; De’ath, G.; Humphrey, C.; Zagorskis, I.; Schaffelke, B. Intra-annual variation in turbidity in response to terrestrial runoff on near-shore coral reefs of the Great Barrier Reef. Estuarine. Coast. Shelf Sci. 2013, 116, 57–65. [Google Scholar]

- Nagarajan, S.; Arockiasamy, M. Non-Contact Scour Monitoring System for Railroad Bridges (No. Rail Safety IDEA Project 39); Transportation Research Board: Washington, DC, USA, 2020. [Google Scholar]

- Nagarajan, S.; Arockiasamy, M. Non-Contact Scour Monitoring for Highway Bridges; Repository and Open Science Access Portal, Naional Transportation Library: Washington, DC, USA, 2020.

- Milan, D.J.; Heritage, G.L.; Hetherington, D. Application of a 3D laser scanner in the assessment of erosion and deposition volumes and channel change in a proglacial river. Earth Surf. Processes Landf. J. Br. Geomorphol. Res. Group 2007, 32, 1657–1674. [Google Scholar]

- Smith, M.; Vericat, D.; Gibbins, C. Through-water terrestrial laser scanning of gravel beds at the patch scale. Earth Surf. Processes Landf. 2012, 37, 411–421. [Google Scholar]

- Zhao, J.; Zhao, X.; Zhang, H.; Zhou, F. Shallow water measurements using a single green laser corrected by building a near water surface penetration model. Remote Sens. 2017, 9, 426. [Google Scholar]

- Guenther, G.C.; Cunningham, A.G.; LaRocque, P.E.; Reid, D.J. Meeting the Accuracy Challenge in Airborne Bathymetry; National Oceanic Atmospheric Administration/Nesdis Silver Md.: Silver Spring, MD, USA, 2000.

| Trial No. | Turbidity (NTU) | Water Depth Near the Scour Hole (Inches) | Water Depth in Other Parts of the Pool (Inches) | Measured Scour Hole Dimensions | ||

|---|---|---|---|---|---|---|

| Length (Inches) | Width (Inches) | Height (Inches) | ||||

| 1 | 1.2 | 16.5 | 20.5 | 14.49 | 16.46 | 3.01 |

| 2 | 3.9 | 16.5 | 20.5 | 14.41 | 16.4 | 2.97 |

| 3 | 5.5 | 12.5 | 16.5 | 14.72 | 16.4 | 2.99 |

| 4 | 6.4 | 12.5 | 16.5 | 14.46 | 17.1 | 2.95 |

| 5 | 12.1 | 8 | 12 | 14.4 | 17.11 | 3.09 |

| 6 | 20.8 | 8 | 12 | 14.4 | 16.3 | 3.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raju, R.D.; Nagarajan, S.; Arockiasamy, M.; Castillo, S. Feasibility of Using Green Laser in Monitoring Local Scour around Bridge Pier. Geomatics 2022, 2, 355-369. https://doi.org/10.3390/geomatics2030020

Raju RD, Nagarajan S, Arockiasamy M, Castillo S. Feasibility of Using Green Laser in Monitoring Local Scour around Bridge Pier. Geomatics. 2022; 2(3):355-369. https://doi.org/10.3390/geomatics2030020

Chicago/Turabian StyleRaju, Rahul Dev, Sudhagar Nagarajan, Madasamy Arockiasamy, and Stephen Castillo. 2022. "Feasibility of Using Green Laser in Monitoring Local Scour around Bridge Pier" Geomatics 2, no. 3: 355-369. https://doi.org/10.3390/geomatics2030020

APA StyleRaju, R. D., Nagarajan, S., Arockiasamy, M., & Castillo, S. (2022). Feasibility of Using Green Laser in Monitoring Local Scour around Bridge Pier. Geomatics, 2(3), 355-369. https://doi.org/10.3390/geomatics2030020