Solid State Nanostructured Metal Oxides as Photocatalysts and Their Application in Pollutant Degradation: A Review

Abstract

:1. Introduction

- An adequate bandgap;

- Suitable morphology;

- High surface area;

- Stability and reusability.

- (i)

- Generation of •OH radicals by oxidation of OH− anions;

- (ii)

- Generation of O2− radicals by reduction of O2.

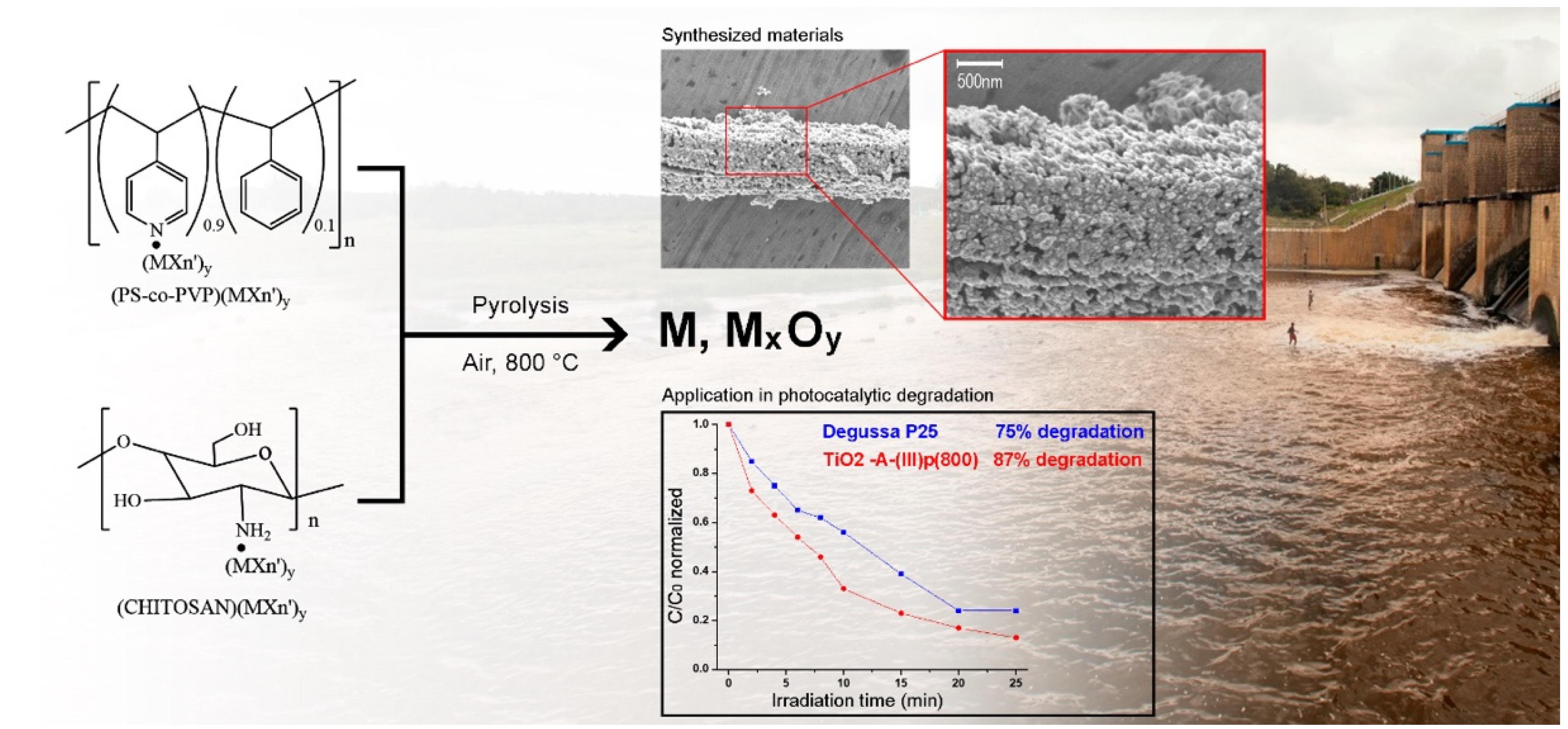

2. Materials and Methods

Nanostructured Metal Oxides Preparation Methods

3. Results

3.1. TiO2

3.2. Fe2O3

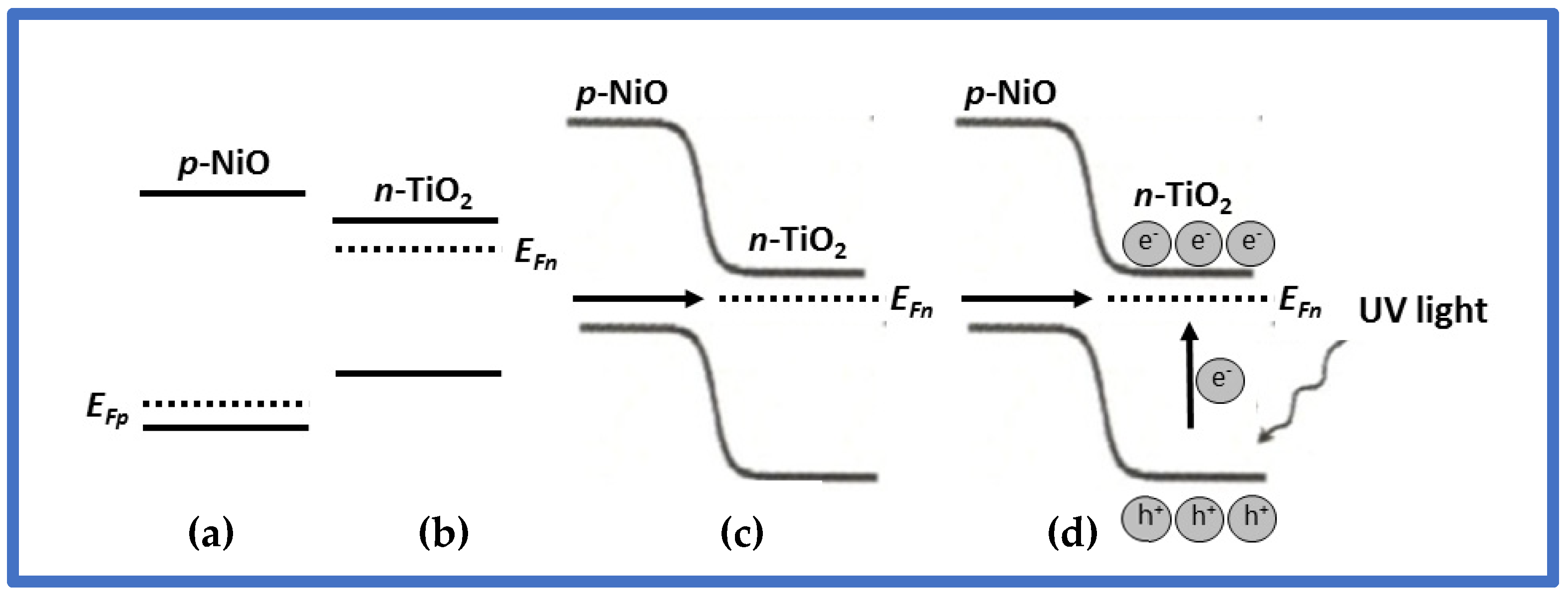

3.3. NiO

3.4. Precious Metal Oxides Ir, Rh, Re: IrO2, Rh/RhO2, Rh2O3, ReO3

3.5. Ir

3.6. Rh

3.7. Re

3.8. Th

3.9. Heterojunction Structure

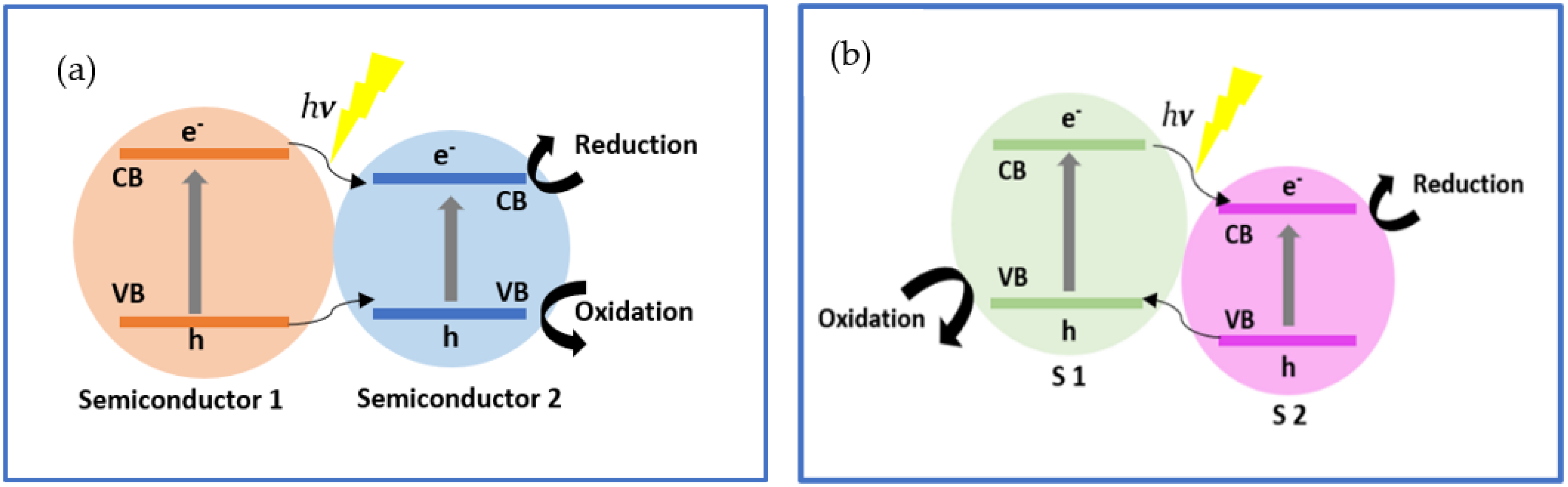

3.10. Photocatalyst Mechanism of Dye Degradation by Nanostructures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hornyak, G.; Tibbals, H.F.; Dutta, J.; Moore, J. Introduction to Nanoscience and Nanotechnology; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Altavilla, C.; Ciliberto, E. Inorganic Nanoparticles; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Khin, M.A.; Sreekumaran Nair, A.; Jagadeesh Babu, V.; Murugan, R.; Ramakrishna, S. A review on nanomaterials for environmental remediation. Energy Environ. Sci. 2012, 5, 8075. [Google Scholar] [CrossRef]

- Edelstein, A.S.; Cammarata, R.C. Nanomaterials, Synthesis and Applications; Institute of Physics Publishing Bristol: Arrowsmith, UK, 2002. [Google Scholar]

- Cao, G. Nanostructures and Nanomaterial, Synthesis, Properties and Applications; Imperial College Press: London, UK, 2004. [Google Scholar]

- Ahmada, R.; Ahmadb, Z.; Ullah Khanb, A.; Riaz Mastoi, N.; Aslama, M.; Kim, J. Photocatalytic systems as an advanced environmental remediation: Recent developments, limitations and new avenues for applications. J. Environ. Chem. Eng. 2016, 4, 4143–4164. [Google Scholar] [CrossRef]

- Adeyemo, A.A.; Adeoye, I.O.; Bello, O.S. Metal organic frameworks as adsorbents for dye adsorption, overview, prospects and future challenges. Toxicol. Environ. Chem. 2012, 94, 1846–1863. [Google Scholar] [CrossRef]

- Chong, M.N.; Jin, B.; Chow, C.W.; Saint, C. Recent developments in photocatalytic water treatment technology: A review. Water Res. 2010, 44, 2997–3027. [Google Scholar] [CrossRef] [PubMed]

- Gunten, V. Oxidation Processes in Water Treatment: Are We on Track? Environ. Sci. Technol. 2018, 52, 5062–5075. [Google Scholar] [CrossRef]

- Nikam, A.V.; Prasad, B.L.V.; Kulkarnia, A.A. Wet Chemical Synthesis of Metal Oxide Nanoparticles, A Review. Cryst. Eng. Comm. 2018, 20, 5091–5107. [Google Scholar] [CrossRef]

- Oska, G. Metal oxide nanoparticles, synthesis, characterization and application. J. Sol. Gel. Sci. Techn. 2006, 37, 161–164. [Google Scholar] [CrossRef]

- Diaz, C.; Valenzuela, M.L.; Laguna-Bercero, M.A. Solid-State Preparation of Metal and Metal Oxides Nanostructures and Their Application in Environmental Remediation. Int. J. Mol. Sci. 2022, 23, 1093. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Liang, X.; Zhang, Y.; Guo, G. Photocatalytic Organic Pollutants Degradation in Metal–Organic Frameworks. Energy Environ. Sci. 2014, 7, 2831–2867. [Google Scholar] [CrossRef]

- Liu, X.; Iocozzia, J.; Wang, Y.; Cui, X.; Chen, Y.; Zhao, S.; Li, Z.; Lin, Z. Noble metal–metal oxide nanohybrids with tailored nanostructures for efficient solar energy conversion, photocatalysis and environmental remediation. Energy Environ. Sci. 2017, 10, 402–434. [Google Scholar] [CrossRef]

- Gaya, U.I.; Abdullah, A.H. Heterogeneous photocatalytic degradation of organic contaminants over titanium dioxide: A review of fundamentals, progress and problems. J. Photochem. Photobiol. C 2008, 9, 1–12. [Google Scholar] [CrossRef]

- Khan, M.M.; Adil, S.F.; Al-Mayouf, A. Metal oxides as photocatalysts. J. Saudi Chem. Soc. 2015, 19, 462–464. [Google Scholar] [CrossRef] [Green Version]

- Preeti, S.; Abdullah, M.M.; Saiga, I. Role of Nanomaterials and Their Applications as Photo-catalst and Sensor, A review. Nano Res. Appl. 2016, 2, 1–10. [Google Scholar]

- Lany, S. Semiconducting transition metal oxides. J. Phys. Condens. Matter 2015, 27, 283203. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, Y.; Huang, Y.; Peijnenburg, J.G.; Chen, J.; Li, X. Development of a nano-QSPR model to predict band gaps of spherical metal oxide nanoparticles. RSC Adv. 2019, 9, 8426–8434. [Google Scholar] [CrossRef] [Green Version]

- Tran, F.; Blaha, P. Accurate Band Gaps of Semiconductors and Insulators with a Semilocal Exchange-Correlation Potential. Phys. Rev. Lett. 2009, 102, 226401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Díaz, C.; Valenzuela, M.L.; Laguna-Bercero, M.A.; Mendoza, K.; Cartes, P. Solventless preparation of thoria, their inclusion inside SiO2 and TiO2, their luminiscent properties and their photocataltytic behavior. ACS Omega 2021, 6, 9391–9400. [Google Scholar] [CrossRef]

- Guo, Y.; Ma, L.; Mao, K.; Ju, M.; Bai, Y.; Zhao, J.; Zeng, X. Eighteen functional monolayer metal oxides: Wide bandgap semiconductors with superior oxidation resistance and ultrahigh carrier mobility. Nanoscale Horiz. 2019, 4, 592–600. [Google Scholar] [CrossRef] [Green Version]

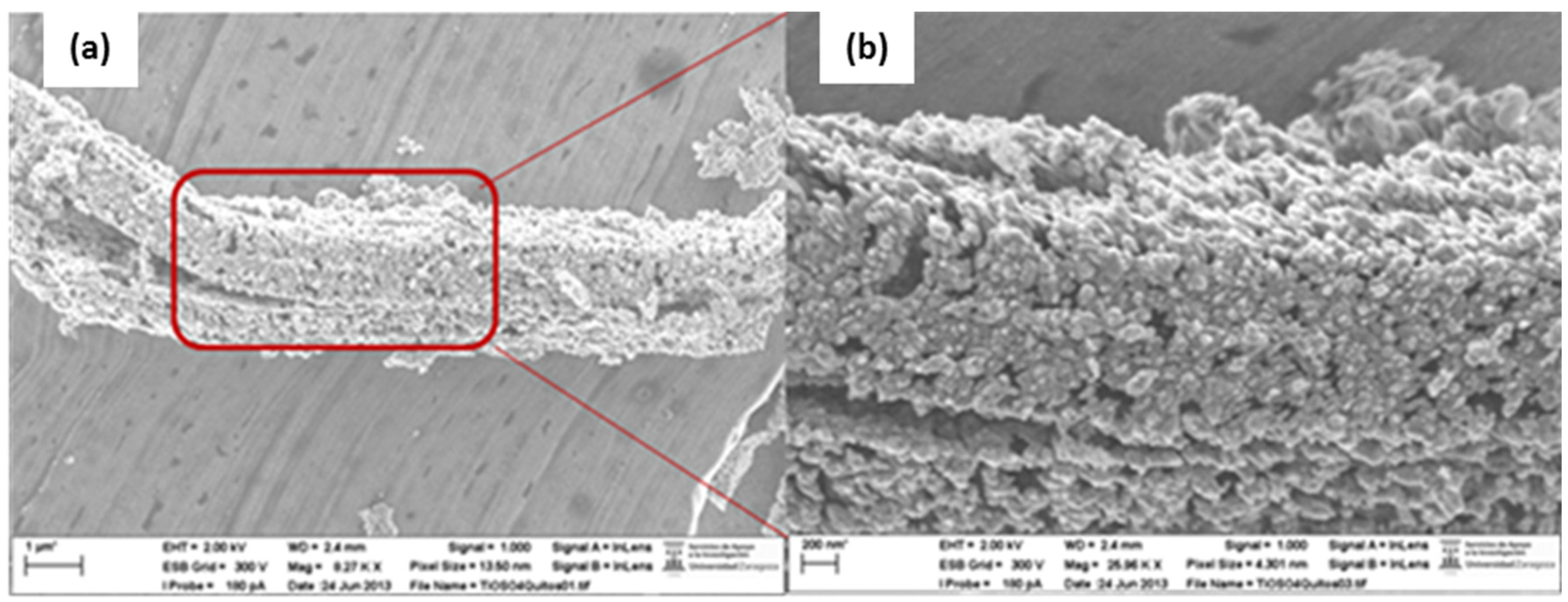

- Allende, P.; Laguna, M.A.; Barrientos, L.; Valenzuela, M.L.; Díaz, C. Solid state tuning Morphology, Crystal Phase and Size through Metal Macromolecular Complexes and Its Significance in the Photocatalytic Response. ACS Appl. Energy Mater. 2018, 1, 3159–3170. [Google Scholar] [CrossRef] [Green Version]

- Ikram, M.; Rashid, M.; Haider, A.; Naz, S.; Haider, J.; Raza, A.; Ansard, M.T.; Uddin, K.; Nageh, M.; Ali, M.; et al. A review of photocatalytic characterization, and environmental cleaning, of metal oxide nanostructured materials. Sustain. Mater. Technol. 2021, 30, e00343. [Google Scholar] [CrossRef]

- Ferreira, D.L.; Sousa, J.C.L.; Maronesi, R.N.; Bettini, J.; Schiavon, M.A.; Silva, A.G. Size-dependent bandgap and particle size distribution of colloidal semiconductor nanocrystals. J. Chem. Phys. 2017, 147, 154102–154111. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmad, M.; Zhu, J. ZnO based advanced functional nanostructures: Synthesis, properties and applications. J. Mater. Chem. 2011, 21, 599–614. [Google Scholar] [CrossRef]

- Wang, Z.L. Zinc oxide nanostructures: Growth, properties and applications. J. Phys. Condens. Matter 2004, 16, R829–R858. [Google Scholar] [CrossRef]

- Chen, X.; Mao, S.S. Titanium Dioxide Nanomaterials, Synthesis, Properties, Modifications, and Applications. Chem Rev. 2007, 107, 2891–2959. [Google Scholar] [CrossRef] [PubMed]

- Ismail, A.A.; Bahnemannb, D.W. Mesoporous titania photocatalysts, preparation, characterization and reaction mechanisms. J. Mater. Chem. 2011, 21, 11686–11707. [Google Scholar] [CrossRef] [Green Version]

- He, H.; Liu, C.; Dubois, K.; Jin, T.; Louis, M.E.; Li, G. Enhanced Charge Separation in Nanostructured TiO2 Materials for Photocatalytic and Photovoltaic Applications. Ind. Eng. Chem. Res. 2012, 51, 11841–11849. [Google Scholar] [CrossRef]

- Ge, M.; Cao, C.; Huang, J.; Li, S.; Chen, Z.; Zhang, K.; Al-Deyab, S.S.; Lai, Y. A Review of One-dimensional TiO2 Nanostructured Materials for Environmental and Energy Applications. J. Mater. Chem. A 2016, 4, 6772–6801. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L. Metallic Nanostructures Using Oligo and Polyphosphazenes as Template or Stabilizer in Solid State in Encyclopedia of Nanoscience and Nanotechnology; Nalwa, H.S., Ed.; American Scientific Publishers: Valencia, CA, USA, 2010; Volume 16, pp. 239–256. [Google Scholar]

- Díaz, C.; Valenzuela, M.L. Macromolecular Complexes MXn Polymer as solid state precursors of metal and metal oxides nanostructures. In Book of CRC Concise Encyclopedia of Nanotechnology; Kharisov, B.I., Kharisov, O.V., Mendez, U., Eds.; CRC Press: Boca Raton, FL, USA, 2016; Chapter 42; pp. 504–524. [Google Scholar]

- Ray, C.; Pai, T. Recent advances of metal–metal oxide nanocomposites and their tailored nanostructures in numerous catalytic applications. J. Mater. Chem. 2017, 5, 9465–9478. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L. Small-Molecule and High-Polymeric Phosphazenes containing oxypyridine side groups and their organometallic derivatives; Useful precursors for metal nanostructured materials. Macromolecules 2006, 39, 103–111. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L. Organometallic Derivatives of Polyphosphazenes as Precursors for Metallic Nanostructured Materials. J. Inorg. Organomet. Polym. Mater. 2006, 16, 419–435. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L.; Zuñiga, L.; O’Dwyer, C. Organometallic derivatives of cyclotriphosphazene as precursors of Nanostructured metallic materials: A new solid state Method. J. Inorg. Organomet. Polym. Mater. 2009, 19, 507–520. [Google Scholar] [CrossRef] [Green Version]

- Díaz, C.; Valenzuela, M.L.; Lavayen, V.; O’Dwyer, C. Layered Graphitic Carbon Host Formation during Liquid-free Solid State Growth of Metal Pyrophosphates. Inorganic Chem. 2012, 51, 6228–6236. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Díaz, C.; Valenzuela, M.L.; Cáceres, S.; O´Dwyer, C. Solution and surfactant-free growth of supported high index facet SERS active nanoparticles of rhenium by phase demixing. J. Mater. Chem. A 2013, 1, 1566–1572. [Google Scholar]

- Díaz, C.; Valenzuela, M.L.; Cáceres, S.; O´Dwyer, C.; Diaz, R. Solvent and stabilizer free growth of Ag and Pd nanoparticles using Metallic salts/cyclotriphosphazenes mixtures. Mater. Chem. Phys. 2013, 143, 124–132. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L.; Zuñiga, L.; O’Dwyer, C. Solid State Pathways to Complex Shape Evolution and Tunable Porosity During Metallic Crystal Growth. Sci. Rep. 2013, 2642, 1–8. [Google Scholar]

- Díaz, C.; Valenzuela, M.L. Nanostructures: Properties: Production Methods and Application. In Organometallic-Metallic-Cyclotriphosphazene Mixtures: Solid-State Method for Metallic Nanoparticle Growth; Nova Science Publishers: New York, NY, USA, 2013; Chapter 5. [Google Scholar]

- Díaz, C.; Valenzuela, M.L. A General Solid-State Approach to Metallic, Metal Oxides and Phosphates Nanoparticles in Advances in Chemical Research; Nova Science Publishers: New York, NY, USA, 2011. [Google Scholar]

- Díaz, C.; Valenzuela, M.L. A general Solid-State approach to Metallic, Metal oxides and Phosphate nanoparticles Gold Nanoparticles: Properties Synthesis and Fabrication. In Solution and Solid State Methods to Prepare Au Nanoparticles: A comparison Chow PE; Nova Science Publishers: New York, NY, USA, 2010; Chapter 14. [Google Scholar]

- Díaz, C.; Valenzuela, M.L.; Lavayen, V.; Mendoza, K.; Peña, O.; O’Dwyer, C. Nanostructured copper oxides and phosphates from a new solid-state route. Inorg. Chim. Acta 2011, 377, 5–11. [Google Scholar] [CrossRef]

- Díaz, C.; Platoni, S.; Molina, A.; Valenzuela, M.L.; Geaney, H.; O’Dwyer, C. Novel Solid-State Route to Nanostructured Tin, Zinc and Cerium Oxides as Potential Materials for Sensors. J. Nanosci. Nanotechnol 2014, 14, 7648–7675. [Google Scholar] [CrossRef]

- Díaz, C.; Barrera, G.; Segovia, M.; Valenzuela, M.L.; Osiak, M.; O’Dwyer, C. Solvent-less method for efficient photocatalytic α-Fe2O3 nanoparticles for using macromolecular polymeric precursors. New J. Chem. 2016, 40, 6768–6776. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L.; Laguna, M.A.; Orera, A.; Bobadilla, D.; Abarca, S.; Peña, O. Synthesis and Magnetic Properties of Nanostructured metallic Co, Mn and Ni oxide materials obtained from solid-state macromolecular complex precursors. RSC Adv. 2017, 7, 27729–27736. [Google Scholar] [CrossRef] [Green Version]

- Díaz, C.; Valenzuela, M.L.; Bobadilla, D.; Laguna-Bercero, M.A. Bimetallic Au//Ag Alloys Inside SiO2 using a solid-state method. J. Clust. Chem. 2017, 28, 2809–2815. [Google Scholar] [CrossRef] [Green Version]

- Díaz, C.; Valenzuela, M.L.; Garcia, C.; De la Campa, R.; Soto, A.-P. Solid-state synthesis of pure and doped lanthanides oxide nanomaterials by using polymer templates. Study of their luminescent properties. Mater. Lett. 2017, 209, 111–114. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L.; Segovia, M.; De la Campa, R.; Soto, A.-P. Solution, Solid-State Two Step Synthesis and Optical Properties of ZnO and SnO Nanoparticles and Their Nanocomposites with SiO2. J. Clust. Sci. 2018, 29, 251–266. [Google Scholar] [CrossRef] [Green Version]

- Díaz, C.; Carrillo, D.; De la Campa, R.; Soto, A.-P.; Valenzuela, M.L. Solid-State synthesis of LnOCl/Ln2O3 (Ln = Eu, Nd) by using chitosan and PS-co-P4VP as polymeric supports. J. Rare Earth 2018, 36, 1326–1332. [Google Scholar] [CrossRef]

- Allende, P.; Barrientos, L.; Orera, A.; Laguna-Bercero, M.A.; Salazar, N.; Valenzuela, M.L.; Diaz, C. TiO2/SiO2 Composite for Efficient Protection of UVA and UVB Rays Through of a Solvent-Less Synthesis. J. Clust. Sci. 2019, 30, 1511–1517. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L.; Cifuentes-Vaca, O.; Segovia, M.; Laguna-Bercero, M.A. Incorporation of Nanostructured ReO3 in Silica Matrix and Their Activity Toward Photodegradation of Blue Methylene. J. Inorg. Organomet. Polym. Mater. 2020, 30, 1726–1734. [Google Scholar] [CrossRef]

- Diaz, C.; Valenzuela, M.L.; Cifuentes-Vaca, O.; Segovia, M.; Laguna-Bercero, M.A. Iridium nanostructured metal oxide, its inclusion in Silica matrix and their activity toward Photodegradation of Methylene Blue. Mater. Chem. Phys. 2020, 252, 123276–123286. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L.; Cifuentes-Vaca, O.; Segovia, M. Polymer precursors effect in the macromolecular metal-polymer on the Rh/RhO2/Rh2O3 phase using solvent-less synthesis and its photocatalytic activity. J. Inorg. Organomet. Polym. Mater. 2020, 30, 4702–4708. [Google Scholar] [CrossRef]

- Díaz, C.; Valenzuela, M.L.; Cifuentes-Vaca, O.; Segovia, M.; Laguna-Bercero, M.A. Incorporation of NiO into SiO2, TiO2, Al2O3, and Na4.2Ca2.8(Si6O18) Matrices, Medium Effect on the Optical Properties and Catalytic Degradation of Methylene Blue. Nanomaterials 2020, 10, 2470. [Google Scholar] [CrossRef]

- Sietsma, J.R.A.; Meeldijk, J.D.; Den Breejen, J.P.; Versluijs-Helder, M.; Jos van Dillen, A.; De Jongh, P.E.; De Jong, K.P. The Preparation of Supported NiO and Co3O4 Nanoparticles by the Nitric Oxide Controlled Thermal Decomposition of Nitrates. Ang. Chem Int. Ed. 2007, 46, 4547–4549. [Google Scholar] [CrossRef]

- Zhang, Z.; Shao, C.; Li, X.; Wang, C.; Zhang, M.; Liu, Y. Electrospun Nanofibers of p~Type NiO/n~Type ZnO Heterojunctions with Enhanced Photocatalytyc Activity. ACS. Appl. Mater. Interface Sci. 2010, 10, 2915–2923. [Google Scholar] [CrossRef]

- Yu, J.; Wang, W.; Cheng, B. Synthesis and Enhanced Photocatalytic Activity of a Hierarchical Porous Flowerlike p–n Junction NiO/TiO2 Photocatalyst. Chem. Asian 2010, 5, 2499–2506. [Google Scholar] [CrossRef] [PubMed]

- Bonomo, M.; Dini, D.; Decker, F. Electrochemical and Photoelectrochemical Properties of Nickel Oxide (NiO) With Nanostructured Morphology for Photoconversion Applications. Front. Chem. 2018, 6, 601. [Google Scholar] [CrossRef] [PubMed]

- Kelly, K.L.; Coronado, E.; Zhao, L.L.; Schatz, G. The optical properties of metal nanoparticles: The influence of size, shape, and dielectric environment. J. Phys. Chem. 2003, 107, 668–677. [Google Scholar] [CrossRef]

- Cotton, F.A.; Wilkinson, G. Advanced Inorganic Chemistry; John Wiley and Sons: New York, NY, USA, 1980; Chapters 22 and 30. [Google Scholar]

- Jin, R. The impacts of nanotechnology on catalysis by precious metal nanoparticles. Nanotechnol. Rev. 2012, 31–56. [Google Scholar] [CrossRef]

- Fernandez-Garcia, M.; Martinez-Arias, A.; Hanson, J.; Rodriguez, C. Nanostructured Oxides in Chemistry: Characterization and Properties. Chem. Rev. 2004, 104, 4063–4104. [Google Scholar] [CrossRef]

- Chen, R.S.; Korotcov, A.; Huiang, Y.S.; Tsai, D. One-dimensional conductive IrO2. Nanocrystals Nanotechnol. 2006, 17, 67–87. [Google Scholar] [CrossRef] [Green Version]

- Xu, D.; Diao, P.; Jin, T.; Wu, Q.; Liu, X.; Guo, X.; Gong, H.; Li, F.; Xiang, M.; Ronghai, Y. Iridium oxide nanoparticles and Iridium/Iridium Oxide Nanocompósites: Photochemical Fabrication and Application in Catalytic Rediction of Notrophenol. ACS Appl. Interfaces 2015, 7, 16738–16749. [Google Scholar] [CrossRef]

- Zhao, Y.; Hernandez, E.A.; Vargas-Barbosa, N.M.; Dysart, J.L.; Mallouk, T.E. A high yield Synthesis of ligand-free iridium oxide nanoparticles with high electrocatalytic activity. J. Phys. Chem. Lett. 2011, 2, 402–406. [Google Scholar] [CrossRef]

- Biswas, K.; Rao, C.N. Metallic ReO3 Nanoparticles. J. Phys. Chem. B 2006, 110, 842–845. [Google Scholar] [CrossRef]

- Biswas, K.; Bhat, S.V.; Rao, C.N. Surface-Enhanced Raman Spectra of Aza-aromatics on Nanocrystals of Metallic ReO3. J. Phys. Chem. C 2006, 111, 5689–5693. [Google Scholar] [CrossRef]

- Biswas, K.; Rao, C.N. Synthesis and Characterization of Nanocrystals of the Oxide Metals, RuO2, IrO2, and ReO3. J. Nanosci. Nanotechniol 2007, 7, 1969–1974. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.-W.; Kuang, Q.; Lian, W.; Jiang, Z.-Y.; Xie, Z.-X.; Huang, R.-B.; Zheng, L.-S. Preparation and Optical Properties of ThO2 and Eu-Doped ThO2 Nanotubes by the Sol−Gel Method Combined with Porous Anodic Aluminum Oxide Template. J. Phys. Chem. B 2006, 110, 23007–23011. [Google Scholar] [CrossRef] [PubMed]

- Hudry, D.; Apostolidis, C.; Walter, O.; Gouder, T.; Courtois, E.; Kubel, C.; Meyer, D. Non-aqueous Synthesis of Isotropic and Anisotropic Actinide Oxide Nanocrystals. Chem. Eur. J. 2012, 18, 8283–8287. [Google Scholar] [CrossRef] [PubMed]

- Hudry, D.; Apostolidis, C.; Walter, O.; Gouder, H.; Courtois, E.; Kubel, C.; Meyer, D. Controlled Synthesis of Thorium and Uranium Oxide Nanocrystals. Chem. Eur. J. 2013, 19, 5297–5305. [Google Scholar] [CrossRef]

- Tripathi, V.K.; Narajan, R. Sol–Gel Synthesis of High-Purity Actinide Oxide ThO2 and Its Solid Solutions with Technologically Important Tin and Zinc Ions. Inorg. Chem. 2016, 55, 12798–12906. [Google Scholar] [CrossRef]

- Pereira, F.J.; Castro, M.A.; Vazquez, M.D.; Deban, L.; Aller, A.J. Optical properties of ThO2–based nanoparticles. J. Lumin. 2017, 184, 169–178. [Google Scholar] [CrossRef]

- Huentupil, Y.; Cabello-Guzman, G.; Chornik, B.; Arancibia, R.; Buono-Cuore, G.E. Photochemical deposition, characterization and optical properties of thin films of ThO2. Polyhedron 2019, 157, 225–231. [Google Scholar] [CrossRef]

- Mahmoud, S.A. Characterization of thorium dioxide thin films prepared by the spray pyrolysis technique. Solid State Sci. 2002, 4, 221–228. [Google Scholar] [CrossRef]

- Li, H.; Zhou, Y.; Tu, W.; Ye, J.; Zou, Z. State-of-the-art progress in diverse heterostructured photocatalysts toward promoting photocatalytic performance. Adv. Funct. Mater. 2014, 25, 998–1013. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.; Zhan, X.; Wang, F.; Safdar, M.; He, J. Visible light driven type II heterostructures and their enhanced photocatalysis properties: A review. Nanoscale 2013, 5, 8326–8339. [Google Scholar] [CrossRef]

- Rani, A.; Reddy, R.; Sharma, U.; Mukherjee, P.; Mishra, P.; Kuila, A.; Sim, L.C.; Saravanan, P. A review on the progress of nanostructure materials for energy harnessing and environmental remediation. J. Nanostructure Chem. 2018, 8, 255–291. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Tu, W.; Zhou, Y.; Zou, Z. Z-Scheme Photocatalytic Systems for Promoting Photocatalytic Performance: Recent Progress and Future Challenge. Adv. Sci. 2016, 3, 1500389. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, S.; Feng, J.; Fan, M.; Pi, Y.; Hu, L.; Han, X.; Liu, M.; Sun, J.; Sun, J. Recent developments in heterogeneous photocatalytic water treatment using visible light responsive photocatalysts: A review. RSC Adv. 2015, 5, 14610–14630. [Google Scholar] [CrossRef]

- Dongge, M.; Jundan, L.; Anan, L.; Chuncheng, C. Carbon Gels-Modified TiO2: Promising Materials for Photocatalysis Applications. Materials 2020, 13, 1734. [Google Scholar]

- Yuhang, Q.; Dongge, M. Covalent Organic Frameworks: New Materials Platform for Photocatalytic Degradation of Aqueous Pollutants. Materials 2021, 14, 5600. [Google Scholar]

- Nunes, D.; Pimentel, A.; Branquinho, R.; Fortunato, E.; Martins, R. Metal Oxide-Based Photocatalytic Paper: A Green Alternative for Environmental Remediation. Catalysts 2021, 11, 504. [Google Scholar] [CrossRef]

- Shah, M.; Estrella, L.; Alemaida, I.; Lisin, A.; Moiseev, N.; Ahmadi, M.; Nazari, M.; Wali, M.; Zaheb, H.; Senjyu, T. Photocatalytic Applications of Metal Oxides for Sustainable Environmental Remediation. Metals 2021, 11, 80. [Google Scholar]

| Metal Oxides | Compounds | Bandgap (eV) a,b | Ref. |

|---|---|---|---|

| Metal transition | Cr2O3 | 3.2 | [18] |

| V2O5 | 2.3 | [18] | |

| Co3O4 | 1.5 | [18] | |

| TiO2 | 3.3 (anatase) | [18] | |

| TiO2 | 3.0 (rutile) | [18] | |

| Mn2O3 | 3.27 | [19] | |

| WO3 | 2.8 | [19] | |

| MoO3 | 3.14 | [18] | |

| NiO | 3.5 | [19] | |

| Fe2O3 | 2.1 | [18] | |

| Fe3O4 | 2.61 | [19] | |

| Cu2O | 2.2 | [18] | |

| CuO | 1.6 | [18] | |

| Metal representative | ZnO | 3.2,34 | [19,20] |

| SnO2 | 4.2 | [19] | |

| Ga2O3 | 4.85 | [19] | |

| Sb2O3 | 4.49 | [19] | |

| Lanthanides | CeO2 | 3.0–3.6 | [19] |

| La2O3 | 4.3 | [19] | |

| Actinides | ThO2 | 3.1 | [21] |

| Organic Water Pollutant | Photocatalyst (Concentration) | Irradiation Light | Reaction Kinetic | Removal % | Irradiation Time |

|---|---|---|---|---|---|

| MB (1 × 10−5 M) | TiO2 anatase. 1 g × Lt−1 with 340 nm cut-off filter, 330 nm > λ > 680 nm | Xe lamp (150 W) | Pseudo first-order kinetic | 86.5% | 25 min |

| MB (10 ppm) | TiO2 nanoparticles (2.5 g L−1) | UV lamp (40 W) | Langmuir–Hinshelwood Pseudo first-order kinetic | 71% | 60 min |

| MB (50 ppm) | TiO2 nanofibers | Xenon lamp UV-vis (150 W) with AM 1.5 G filter λ > 400 nm | NM | 100% | 180 min |

| MB(10 mgL−1) | TiO2 nanotubes (0.16 g L−1) | xenon visible light (500 W) | NM | 99.1% | 40 min |

| MB (0.01 mM) | mesoporous TiO2 0.17 g L−1) | UV light irradiation using eight tubes with a power source of 6 W, λ = 365 nm | NM | 85% | 60 min |

| MB (0.75 × 10−5 M) | Hollow titania micro-spheres (HTS) | UV lamp 15 W | Pseudo first-order kinetic | 53% | 90 min |

| MB (1 mM) | TiO2 nanoparticles | Blacklight lamp (1 mW) | NM | 45% | 20 min |

| Other similar organic water pollutants malachite green, MG (10 ppm) | TiO2nanoparticles (2.5 g L−1) | UV lamp (40 W) | Langmuir–Hinshelwood Pseudo first-order kinetic | 78% | 60 min |

| Rhodamine B, RhB, and methyl orange MO (0.01 mM) | TiO2 hollow tetragonal nanocone (0.1 g L−1) | full-arc Xe lamp (300 W) with a cutoff filter, λ > 420 nm | NM | 95.0% for RhB, 90.7% for MO | 30 min |

| Bisphenol A BPA, (200 μM) | TiO2 powder, Degussa P25 (0.5 g L−1) | Xe arc lamp (300 W), IR water filter and cutoff filter, λ > 420 nm | Pseudo first-order kinetic | 75% for BPA | 4 h |

| acetaminophen, Ace (1.3 μM) | TiO2 powder, Degussa P25 (NM) | UVA/LED λmax = 366 nm | NM | 100% | 8 min |

| RhB (NM) | TiO2 nanopowder (0.3 g L−1) | visible light λ > 420 nm | NM | 90% | 5 h |

| Methyl orange 4 × 10−5 M | TiO2 powder (10 mg) | Xe lamp 300 W | NM | 90% | 3 h |

| Photocatalyst | Bandgap | Surface Area |

|---|---|---|

| Bi3+-ZnO | 3.15–2.6 | Increase |

| Co-ZnO | 3.34–3.06 | Increase |

| N-ZnO | 3.15–2.86 | Increase |

| F-ZnO | 3.35–2.51 | Increase |

| Fe-ZnO | 3.24–3.16 | Increase |

| Ag/ZnO | 3.30–3.21 | Increase |

| B/ZnO | 3.2–3.1 | Increase |

| Bi-TiO2 Ni-TiO2 | 2.99–3.08 3.02, 2.99–3.03 | Decrease |

| Ag-TiO2 | 3.0–2.6 | Increase |

| Fe-TiO2 | 3.2–2.98 | Increase |

| N-TiO2 | 3.1–2.7 | Increase |

| Ti/WO3 | 3.4–3.31 | Decrease |

| Zn-WO3 | 3.2–3.12 | Slight decrease |

| Fe-SnO2 | 3.8–1.65 | Increase |

| Zn-SnO2 | 3.50–3.17 | Increase |

| Cu-SnO2 | 3.02–2.2 | Increase |

| N° | Composite | Synthesis Method | Pollutant for Degradation | PC Performance | Irradiation |

|---|---|---|---|---|---|

| 1 | Co-ZnO | Sol-gel | MB | 3 at.% Co-ZnO exhibited 92% degradation in 60 min. | Visible light |

| 2 | La-doped ZnO | Hydrothermal oxidation | MO and MB | Best PCA observed by S0.005 due to defects. | UV light |

| 3 | Pd/ZnO | Microwave hydrothermal, borohydride and photoreduction | CR | Pd/ZnO synthesized by borohydride method has the highest PCA compared to other routes. | UV light |

| 4 | C, N co-doped ZnO | Two-step pyrolysis | MB | 6C25 showed the best degradation due to its larger number of active sites. | Solar stimulated light |

| 5 | X-ZnO (X = Li, Al, N, P) | Mass production technology | RhB | PCA decreased as follows: N > Li > P > Al | Sunlight |

| 6 | Fe-doped ZnO | Combustion | BPA | FexZn1−xO (where x = 0.03) showed noticeable efficacy in the series. | Sunlight |

| 7 | Gd-ZnO films | RF magnetron sputtering | MB | 0.7 at.% Gd-ZnO exhibited higher PCA than ZnO. | UV light |

| 8 | Au-ZnO | Combustion | MB | Ag-ZnO demonstrated better activity than Au-ZnO. | UV light |

| Ag-ZnO | |||||

| 9 | Eu3+-doped ZnO | Coprecipitation | RhB | Doped ZnO (100%) degraded dye faster than ZnO. | UV light |

| 10 | Ce-ZnO | Hydrothermal | Pharmaceutica | Nizatidine, levofloxacin and acetaminophen degraded around 95% within 4 h. | UV light |

| 11 | Cu-ZnO | Chemical growth | MO and MB | Increase in PC efficiency was 57.5% for MO and 60% for MB in 180 min. | UV light |

| 12 | B-ZnO | Sol-gel | CN− | Doped sample with 1.5 wt% exhibited 89% degradation whereas pure ZnO exhibited 75%. | Solar stimulated light |

| 13 | In-ZnO | Plasma assisted chemical vapors | MB | 4 at.% In-ZnO showed improved PCA compared to ZnO and 8 at.% In-ZnO. | Solar stimulated light |

| 14 | Sm-ZnO | Chemical precipitation | MB | Zn1−xSmxO x = 0.04 expressed maximum PC degradation (94.94%). | Visible light |

| 15 | WO3-doped ZnO | hydrothermal | Diazinon | 10 mg/L diazinon, 10 g/cm—2 2% O3-ZnO exhibited 99% degradation in 180 min. | UV light |

| N° | Doped | Pollutants | PCA | Irradiation Source |

|---|---|---|---|---|

| 1 | Ce-TiO2 La-TiO2 V-TiO2 | RhB | 1.0%-Ce-TiO2 > 1.0%-V-TiO2 > undoped TiO2 > 1.0%-La-TiO2 showed degradation (%) 83.43 > 53.74 > 21.56 > 11.09, respectively. | Solar light |

| 2 | PF co-doped anatase TiO2 | MO | It demonstrated excellent PCA compared to undoped TiO2, F-TiO2, P-TiO2 and Degussa P25. | Full-spectrum light |

| 3 | Ga-doped TiO2nanopowder | MO | 0.6 mol% Ga-TiO2 demonstrated up to 82% degradation. | Visible light |

| 4 | F, N co-doped TiO2 | MB | 97.31% degradation was achieved within 5 h. | Visible light |

| 5 | Nd-TiO2 film | MB | 0.1% Nd-doped TiO2 showed maximum degradation (92%). | UV light |

| 6 | Moroccan natural P-TiO2 | IC | Its degradation increased at high values of pH, initial concentration and amount of catalyst. | UV light |

| 7 | Nb2O5-TiO2 | MB | 5 mol% expressed the highest PCA under visible light and equal efficiency as TiO2 under UV. | UV and Visible light |

| 8 | Mesoporous Ag-TiO2 | MO | TiO2 with the lowest content of Ag exhibited higher PCA. | UV and solar light |

| 9 | Fe3+-TiO2 | CV | Degradation kinetics rate increased with an increase in iron content. | UV |

| 10 | Ru/TiO2 | 2-CP | 0.4 wt% Ru/TiO2 showed high PCA using UV light and 0.2% Ru/TiO2 using visible light. | UV and visible light |

| 11 | Gd-TiO2 | RhB | 0.3% Gd-TiO2 demonstrated the best PCA. | Visible light |

| 12 | C-TiO2 | RhB | More decolorization compared to fluorescence spectroscopy. | Visible light |

| 13 | Pd-TiO2 | MB and MO | Maximum degradation shown by 0.75 wt% Pd-TiO2 for mixture of dyes and 0.5 wt% Pd-TiO2 for single dye. | Visible or solar light |

| 14 | Graphene/TiO2 | BPA | It showed remarkable PCA compared to pure TiO2. | Solar light |

| 15 | Ni/TiO2 | Malathion | 94% degradation achieved. | UV light |

| TiO2-(I)p | TiO2-(II)p | ||||

| Temperature (°C) | Phase | Bandgap (eV) | Temperature (°C) | Phase | Bandgap (eV) |

| 500 | Anatase | 3.66 | 500 | Anatase | 3.43 |

| 600 | Mixture | 3.43 | 600 | Anatase | 3.30 |

| 700 | Mixture | 3.63 | 700 | Anatase | 3.22 |

| 800 | Rutile | 3.40 | 800 | Mixture | 3.27 |

| TiO2-(III)p | TiO2-(IV)p | ||||

| Temperature (°C) | Phase | Bandgap (eV) | Temperature (°C) | Phase | Bandgap (eV) |

| 500 | Anatase | 3.32 | 500 | Anatase | 3.53 |

| 600 | Anatase | 3.43 | 600 | Anatase | 3.45 |

| 700 | Anatase | 3.28 | 700 | Mixture | 3.37 |

| 800 | Anatase | 3.65 | 800 | Mixture | 3.38 |

| TiO2-(V)p | TiO2-(VI)p | ||||

| Temperature (°C) | Phase | Bandgap (eV) | Temperature (°C) | Phase | Bandgap (eV) |

| 500 | Anatase | 3.47 | 500 | Anatase | 3.72 |

| 600 | Anatase | 3.42 | 600 | Mixture | 3.57 |

| 700 | Mixture | 3.21 | 700 | Mixture | 3.36 |

| 800 | Mixture | 3.33 | 800 | Rutile | 3.24 |

| Sample | Apparent Photodegradation Rate Constant k (10−2 min−1) | Degradation η (%) | R2 (%) |

|---|---|---|---|

| TiO2-Anatase-(I)p 500 °C | 0.40 ± 0.04 | 11 | 93.9 |

| TiO2-Mixture-(I)p 600 °C | 0.80 ± 0.04 | 20 | 98.4 |

| TiO2-Mixture-(I)p 700 °C | 0.06 ± 0.03 | 14 | 98.0 |

| TiO2-Rutile-(I)p 800 °C | 1.30 ± 0.10 | 30 | 93.8 |

| TiO2-Anatase-(II)p 500 °C | 0.40 ± 0.04 | 11 | 91.9 |

| TiO2-Anatase-(II)p 600 °C | 0.33 ± 0.03 | 7 | 88.8 |

| TiO2-Anatase-(II)p 700 °C | 0.40 ± 0.02 | 10 | 97.6 |

| TiO2-Mixture-(II)p 800 °C | 1.00 ± 0.06 | 23 | 97.2 |

| TiO2-Anatase-(III)p 500 °C | 3.90 ± 0.20 | 65 | 96.9 |

| TiO2-Anatase-(III)p 600 °C | 4.10 ± 0.20 | 65 | 97.4 |

| TiO2-Anatase-(III)p 700 °C | 2.00 ± 0.06 | 39 | 99.2 |

| TiO2-Anatase-(III)p 800 °C | 7.13 ± 0.01 | 87 | 99.8 |

| TiO2-Anatase-(IV)p 500 °C | 2.40 ± 0.01 | 45 | 97.8 |

| TiO2-Anatase-(IV)p 600 °C | 3.10 ± 0.01 | 55 | 98.0 |

| TiO2-Mixture-(IV)p 700 °C | 0.20 ± 0.02 | 5 | 91.1 |

| TiO2-Mixture-(IV)p 800 °C | 4.00 ± 0.20 | 63 | 97.1 |

| TiO2-Anatase-(V)p 500 °C | 3.40 ± 0.10 | 59 | 99.1 |

| TiO2-Anatase-(V)p 600 °C | 1.30 ± 0.04 | 27 | 99.2 |

| TiO2-Mixture-(V)p 700 °C | 1.30 ± 0.09 | 27 | 96.4 |

| TiO2-Mixture-(V)p 800 °C | 0.60 ± 0.03 | 14 | 98.0 |

| TiO2-Anatase-(VI)p 500 °C | 1.70 ± 0.03 | 34 | 99.7 |

| TiO2-Mixture-(VI)p 600 °C | 2.40 ± 0.02 | 48 | 95.9 |

| TiO2-Mixture-(VI)p 700 °C | 2.60 ± 0.02 | 51 | 94.6 |

| TiO2-Rutile-(VI)p 800 °C | 0.50 ± 0.02 | 14 | 98.5 |

| Precursor | Eg (eV) |

|---|---|

| Chitosan(FeCl3) 1:1 | 1.83 |

| Chitosan(FeCl3) 1:5 | 2.15 |

| PS-co-4-PVP(FeCl3) 1:1 | 2.12 |

| Fe+3-PS-co-4-PVP(FeCl3) 1:5 | 2.12 |

| Chitosan(FeCl2) 1:1 | 2.15 |

| Chitosan(FeCl2) 1:5 | 2.15 |

| PS-co-4-PVP(FeCl2) 1:1 | 1.90 |

| PS-co-4-PVP(FeCl2) 1:5 | 2.09 |

| Photocatalyst | Apparent Photodegradation Rate Constant k (10−2 min−1) | Discoloration Rate η(%) at 60 min | Discoloration Rate η(%) at 150 min |

|---|---|---|---|

| α-Fe2O3 (PS-co-4-PVP) | 1.2 ± 0.04 | 62.6 | 86.9 |

| α-Fe2O3 (Chitosan) | 2.1 ± 0.1 | 73.4 | 94.6 |

| Photocatalyst | Apparent Photodegradation Rate Constant k (10−2 M·min−1) | Discoloration Rate (%) | R2 Linear Fit (%) |

|---|---|---|---|

| NiO-chitosan a | 2.4 | 71% | 0.998 |

| NiO-PS-4-PVP | 2.2 | 68% | 0.991 |

| NiO/SiO2-chitosan | 2.3 | 69% | 0.999 |

| NiO/SiO2-PS-4-PVP | 1.6 | 48% | 0.996 |

| NiO/TiO2-chitosan | 2.9 | 91% | 0.992 |

| NiO/TiO2-PS-4-PVP | 2.6 | 81% | 0.980 |

| NiO/Al2O3-chitosan | 1.5 | 45% | 0.990 |

| NiO/Na4.2Ca2.8(Si6O18) | 2.6 | 75% | 0.990 |

| Photocatalyst | Photodegradation Rate Constant k (10−3 M·min−1) | Discoloration Rate (%) | R2 Linear Fit (%) | Ref. |

|---|---|---|---|---|

| IrO2-PS-4-PVP | 1.7 | 53% | 0.995 | [55] |

| IrO2-chitosan | 2.4 | 38% | 0.991 | [55] |

| Rh/RhO2 | a | 78% | b | [56]] |

| Rh2O3 | a | 70% | b | [56] |

| ReO3-PS-4-PVP | 2.8 | 64% | 0.977 | [54] |

| ReO3-chitosan | 2.8 | 53% | 0.997 | [54] |

| Photocatalyst | Bandgap (eV) | Ref. |

|---|---|---|

| ReO3 | 4.36 | [54] |

| IrO2 | 2.4–2.6 | [55] |

| Rh/RhO2 | 3.7 | [56] |

| Rh2O3 | 3.0 | [56] |

| Photocatalyst | Eg (eV) | Apparent Photodegradation | Discoloration Rate (%) | R2 Linear Fit (%) |

|---|---|---|---|---|

| ThO2(chitosan precursor) | 5.66 | 3.7 × 10−3 | 67 | 0.992 |

| ThO2 (PS-4-PVP precursor) | 5.75 | 2.2 × 10−3 | 66 | 0.967 |

| ThO2/SiO2 (chitosan precursor) | 5.50 | 7.7 × 10−4 | 24 | 0.979 |

| ThO2/SiO2 (PS-4-PVP precursor) | 5.6 | 8.5 × 10−4 | 25 | 0.923 |

| ThO2/TiO2 (chitosan precursor) | 3.14 | 1.4 × 10−3 | 39 | 0.815 |

| ThO2/TiO2 (PS-4-PVP precursor) | 3.14 | 8.7 × 10−4 | 27 | 0.941 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz, C.; Segovia, M.; Valenzuela, M.L. Solid State Nanostructured Metal Oxides as Photocatalysts and Their Application in Pollutant Degradation: A Review. Photochem 2022, 2, 609-627. https://doi.org/10.3390/photochem2030041

Díaz C, Segovia M, Valenzuela ML. Solid State Nanostructured Metal Oxides as Photocatalysts and Their Application in Pollutant Degradation: A Review. Photochem. 2022; 2(3):609-627. https://doi.org/10.3390/photochem2030041

Chicago/Turabian StyleDíaz, Carlos, Marjorie Segovia, and Maria Luisa Valenzuela. 2022. "Solid State Nanostructured Metal Oxides as Photocatalysts and Their Application in Pollutant Degradation: A Review" Photochem 2, no. 3: 609-627. https://doi.org/10.3390/photochem2030041

APA StyleDíaz, C., Segovia, M., & Valenzuela, M. L. (2022). Solid State Nanostructured Metal Oxides as Photocatalysts and Their Application in Pollutant Degradation: A Review. Photochem, 2(3), 609-627. https://doi.org/10.3390/photochem2030041