Abstract

Humans are in constant contact with clothing and textiles throughout their lives, which can expose them to chemicals present in these materials. Chemicals used in fiber production and in material processing can be absorbed through the skin, ingested, or inhaled, causing allergic reactions. Advancements in modern textiles have made them more versatile and functional for a variety of applications, resulting in the use of more chemicals. Regarding the textile industry, several studies have focused on the environmental impact of its effluents and dyes, and, more recently, several studies have focused on textile waste impact in general. Nevertheless, few studies have been carried out on human cytotoxicity, and very little is known about the dangers of long-term use of textiles. The aim of this work was to review the literature to understand what has been done in the field of textile cytotoxicity. In addition, this work also highlights the existing gap regarding regulation and standardized tests for the analysis of everyday clothing. There is an urgent need to establish regulations and standardize testing protocols to assess the potential cytotoxic effects that may arise from finished textile products before they are marketed, in order to guarantee consumer safety.

1. Introduction

Following fashion trends and fast fashion is tempting, but it is important to be aware of our choices, and that what we wear daily can pose significant risks, not only to the environment, but also to our health. When we wear a garment, we rarely consider the potential dangers associated with the material itself, but it can contain toxic chemicals. In the textile industry, various chemicals are used for fiber production and for the different processes and stages of material transformation to increase their quality (Figure 1).

Figure 1.

Key phases of the textile manufacturing process and some examples of chemicals used at each stage.

These substances can be absorbed through the skin or inhaled, posing health risks and potentially causing allergic reactions or skin irritations. There are regulations that define which chemical substances are allowed and that limit quantities applicable to fabrics. REACH (registration, evaluation, authorization and restriction of chemicals) is a European Union regulation that came into force in 2007 to improve the protection of human health and the environment from the risks that can result from chemical products, while helping to reinforce the competitiveness of the European Union’s chemical industry. It also promotes alternative methods for assessing the hazards of substances, with the aim of reducing the number of animal tests. This regulation applies to all chemical substances, not just those used in industrial processes, but also those that are part of our daily lives, such as those in cleaning products, inks, and articles like clothing, furniture and electrical appliances. REACH, therefore, has an impact on most companies in the European Union. Companies must identify and manage the risks associated with the substances they manufacture and place on the market in the EU in order to comply with the regulation [1]. However, it is not easy to find regulations regarding the toxicity or adverse effects of dyed and finished materials, since all the tests carried out according to the standards of the Organization for Economic Co-operation and Development (OECD) only contemplate textile chemicals [2]. The OECD Guidelines for the Testing of Chemicals are a collection of about 150 of the most relevant internationally agreed testing methods used by government, industry and independent laboratories to identify and characterize potential hazards of chemicals [2]. There are no tests for fabrics and textile fibers based on these standards.

In 1992, the Austrian Textile Research Institute and the German Hohenstein Research Institute founded the OEKO-TEX® Association, located in Zurich, Switzerland, to support consumers and companies in making responsible decisions with products that are safe, environmentally friendly and manufactured in a socially responsible way. The aim of this association is to use laboratory tests to ensure that textile products are harmless to human health. The association created the STANDARD 100 [3] certification that guarantees the legal compliance of tested textile products and certifies that a product has been tested for the presence of harmful substances. In 2015, the MADE IN GREEN label was launched, setting benchmarks regarding transparency; the manufacture of a textile can be tracked. Labelled textiles are tested for harmful substances, manufactured in an environmentally friendly way and produced under fair working conditions. Just one year later, OEKO-TEX offered a new certification for sustainable textile chemicals, the ECO PASSPORT, which is an independent certification system for chemicals used in the textile industry. This certification process involves multiple stages, and certified chemicals are recognized under global regulations, helping manufacturers to prove that their products meet the criteria for environmentally friendly textile production [4]. It is well known that textiles contain chemicals, and there is growing awareness of the need to comply with existing regulations. However, the overall toxic effects of the end products are often unknown. This information would be extremely important, especially for raising awareness among industry professionals and consumers. Biocompatibility is a crucial aspect to consider when studying the effects of certain substances on the skin and is a complex and multidisciplinary field that faces many challenges and offers many opportunities for improvement in the textile area. The lack of standardized and predictive methods for assessing biocompatibility, the variability and heterogeneity of the biological responses and their environment are some of the challenges. In addition, the ethical and regulatory issues involved in animal and human testing can sometimes present obstacles [5].

In a constantly evolving society, and with the growing need for creative solutions and materials in the face of new individual and social demands, multidisciplinary discussion is essential for the creation and development of standards that keep pace with recent technological advances in materials and biotechnological processes. Nowadays, more and more textiles are being developed to have different functionalities: protection, health, comfort and cosmetics, among many others, always with the aim of promoting well-being and improving the quality of user’s life [6]. These textiles may serve various functions, such as thermoregulation, moisture control, antimicrobial, antioxidant, healing, anti-odor, anti-ultraviolet (anti-UV), moisturizing or repellency against certain substances (water, oil, insects, etc.) [7,8,9]. At the end of the whole process, these textiles may contain a mixture of compounds that, in combination, can either produce toxic effects or none at all. The toxicity of all these chemicals and their combinations is not well known, especially when they are present in a finished product. Regarding textiles used as matrices for medical devices, there are regulatory standards that address their biocompatibility and the absence of adverse responses from the human body. The ISO 10993 “Biological Evaluation of Medical Devices” [10] is an international standard that identifies primary tests for the biological evaluation of these medical devices, considering the material nature, device type and contact duration. An important aspect in the initial assessment of these devices is cytotoxicity. Cytotoxicity is the ability of a substance to inhibit cell proliferation or cause damage and injury to cells, leading to cell death. Thus, toxic substances can impair a tissue’s ability to regenerate or cause its degeneration through cell death. Cytotoxicity can be endogenous (promoted by the immune system) or exogenous (caused by external factors such as toxic, poisonous or pollutant substances) [11]. The cytotoxicity test is conducted in vitro, as specified in ISO 10993-5:2009, and it can be evaluated through direct cell contact or in the form of extracts. Thus, it allows us to determine whether the material used in medical devices is toxic to cells, which is crucial to ensure the safety and efficacy of these products. Clinical use masks, composed of non-woven fabric materials (TNT), belong to the class of medical devices. They are designed to come into contact not only with skin but also with mucous membranes. Typically, these masks are worn for limited periods (less than 24 h), or in worst-case scenarios, for cumulative extended periods (from 1 to 30 days). As a result, the recommended biological tests for this type of material, according to the respective ISO standards, include cytotoxicity, skin irritation and sensitization tests. Due to the recent COVID-19 pandemic situation, numerous studies have been published in the field of the safe use of surgical masks [12,13].

In 2024, in a study carried out by Pereira Lobato and collaborators [14], suitable proportions of polylactic acid (PLA) and polycaprolactone (PCL) fibers were mixed to produce textile structures with properties for specific biomedical applications. The biocompatibility of these fabrics was evaluated following the ISO 10993-5:2009 standard, using both direct and indirect tests. Cell viability was evaluated by the [3-(4,5 dimethylthiazol-2-yl) 2,5-diphenyl tetrazolium bromide] MTT assay using pre-osteoblast cells from mouse calvarial MC3T3-E1 sub-clone 4. The material tested is considered non-cytotoxic, indicating that the fabric can be used in biomedical applications.

Kubíckova and co-workers [15] developed, in 2022, non-woven textiles from unmodified hyaluronan (HA) for applications in the field of wound healing. Among the various tests carried out to understand the mechanical and application properties of this new material, they also carried out cell viability tests using two cell lines (mouse fibroblasts—3T3, and human keratinocytes—HaCaT) in order to demonstrate that the textiles produced are not cytotoxic. The properties of these HA non-woven textiles make them promising for use in medicine, namely in wound healing applications.

As the skin is the main interface of the human body with the environment, it has the role of protecting us from the exogenous aspects. The skin protects the human body from water loss, harmful microorganisms, irritants and injuries, and is an important barrier against exposure to environmental contaminants. In our daily lives, we worry about our surroundings, about what we are exposed to or about what we touch (so we do not harm our health), but many times we forget the most important thing, which is in contact with us almost 24 h a day: what we wear. Textiles undoubtedly have an intimate connection with our skin, in such a way that we often refer to clothes as a “second skin”. The use of synthetic clothes and functionalized garments often may be responsible for irritation, sensitization, or even the penetration of hazardous chemicals into the body [16].

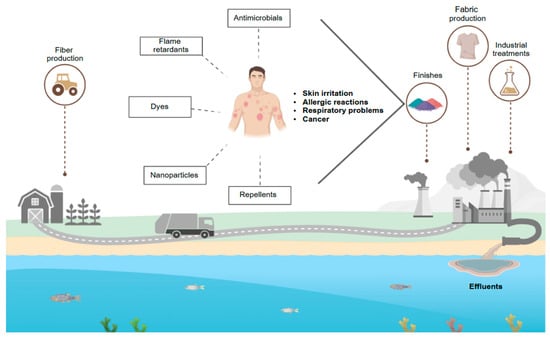

Considering the lack of standardized methods for assessing biocompatibility in textiles in general, the aim of this work is to review whether there is any progress on textiles cytotoxicity analyses. Thus, a literature review was carried out to investigate the cytotoxicity of textiles in their different stages of production, and the summary of the main conclusions are described below. The literature search was conducted by searching for keywords like “textiles cytotoxicity”; “the cytotoxicity potential of textile chemicals”; “textiles and skin irritation”; and “textile health’s risks” in the PubMed database, focusing on the last 5 years. The scientific papers were selected based on those that mentioned cytotoxicity tests carried out on textiles or materials applied to textiles. Figure 2 illustrates the comprehensive sequence of processes involved in the textile production chain, starting from the initial fiber production through to the final finishing stages. This illustration emphasizes the potential impacts that various finishing processes can have on both human health and the environment. These impacts may include the release of harmful chemicals, exposure to toxic substances and environmental pollution. By highlighting these impacts, the diagram reinforces the necessity of testing for skin cytotoxicity in the textile industry to prevent negative health effects.

Figure 2.

Illustration of the several processes in textile chain, from fiber production to finishing, and the potential impact of major finishes on human health and environment.

1.1. The Cytotoxicity of Dyes

Dyes are a common part of our everyday lives, especially in the fabrics of our clothing. Their use is expanding as industries look for new methods to improve the look and appeal of products. Producers and consumers of colorants are looking for solutions to improve the stability of these chemicals, which are consequently more difficult to degrade after application [17]. Humans may be exposed to textile dyes through various routes of exposure, with oral and dermal contact being the most frequent ones. For workers in the dye production industry, as well as for those handling freshly dyed products, inhalation is also a route of concern [18]. Colorants are highly soluble in water and difficult to remove from the environment, leading to a possible ingestion of polluted water containing dispersive dyes. Under conditions of intense perspiration, dyes can migrate from colored clothes and penetrate the human skin, compromising human health by inducing DNA (Deoxyribonucleic Acid) damage. Some dyes contain heavy metals like chromium and lead, which can cause skin irritation, allergic reactions and even cancer with prolonged exposure [19].

Since cotton fabrics are the most common clothing, the group of Daniela Leme [20] conducted a study aiming to identify safe textiles dyes for cotton fabrics. They used normal human dermal fibroblasts to assess the genotoxicity by Comet assay, and Salmonella for the mutagenicity. The dyes were tested in their formulated form and as extracts from cotton fibers, using different artificial sweat solutions. The main conclusion from this study was that besides that dyes could migrate from the cotton fibers to the artificial sweat, they did not show genotoxic/mutagenic effects. However, in the formulated form, a weak mutagenic potential was detected. The results obtained from this study demonstrate the importance of evaluating textile dyes under conditions that resemble real human exposure, in order to recognize any danger to which we may be exposed. Considering that cotton garments are also the most commonly used for baby’s and children’s clothing, these tests become even more important. Another study performed by Enzo Silva et al. in 2022 [21] investigated the organ-specific cytotoxicity and genotoxicity of five textile dyes. HaCaT (immortalized human keratinocyte cell line) and HepaRG (immortalized human hepatic cell line) cells were utilized as a representative model of dermal and oral routes of exposure. The authors concluded that the effects caused by the reactive dyes are specific to each organ, revealing that epidermal cells are more prone to the cytotoxic effects than hepatic cells. These results highlight the need for further research into the toxicity of textile dyes taking into account actual human exposure. Kaisa Klemola and co-workers [22] investigated the cytotoxicity of reactive dyes and dyed tissues, using HaCaT cells in culture. The HaCaT cells were exposed to three monochlorotriazinyl dyes, yellow, blue and red, in different concentrations. In addition, cells were also exposed to aqueous extracts of dyed fabrics. The results indicated that the dyes are toxic, while the dyed fabrics are not. This difference can be explained by the fact that pure reactive dye, in powder form, is highly active, but after the dyeing process, many of the reagents in the dye molecules participate in the formation of covalent bonds with the fiber molecules, resulting in a more stable product. The stability of these bonds is a key factor in explaining why the dyed fabric material does not exhibit toxicity. This study demonstrates that HaCaT cells are a valuable model for assessing the overall toxicity of textile chemicals and the fabrics that contain them [22]. In 2018, Morshed and co-workers studied the cytotoxicity of four active dyes, using the zoological organism Artemis salina, collected from pet shop. Using this method of evaluation, the four dyes showed similar cytotoxic potential, indicating that they might have a similar mechanism of cytotoxicity [18].

The constant evolution of the textile industry allows the production of safer materials for everyone, as well as more sustainable ones with less environmental impact, such as harmless textile dyes. Some examples are (1) natural dyes, extracted from plants, insects and minerals, which are biodegradable and generally less toxic; (2) reactive dyes that form covalent bonds with fibers, resulting in reduced release of unfixed dyes into the environment; (3) disperse dyes, used mainly on synthetic fibers and designed to be less soluble in water, reducing water pollution; and (4) water-based dyes that replace organic solvents with water, reducing the emission of volatile organic compounds and improving safety in the workplace. Additionally, beyond the different types of dyes, there are advanced dyeing technologies, such as dry dyeing and the use of enzymes, which can significantly reduce the use of water and harmful chemicals [23].

A study performed by Eduardo M. Costa et al. [24] in 2021 describes the hypothesis of obtaining an ecological, or more environmentally friendly, dyeing method based on chitosan nanoparticles. They produced nanoparticles containing yellow everzole and itosperse navy blue dye, showing high encapsulation efficiency (over 90%), and they achieved up to 17.60% dyeing capacity for a viscose/wool blend. Furthermore, although reactive dyes have high cytotoxicity, the nano-encapsulated dyes were not cytotoxic to HaCaT cells (as determined by the XTT assay). Although all these innovations are being studied, and everything possible is being done to implement them, it is well described in the literature that the dyes used in the textile industry present numerous dangers to the environment and human health [25]. However, little is known about their cytotoxic potential and long-term effects when they are used regularly in contact with the skin. This makes it extremely important to implement tests to evaluate these possible effects, so that the industry can evolve towards developing safer products.

1.2. The Potential Toxicity of Textile Effluents

The textile industry consumes a significant amount of water during the production processes, which consequently leads to a huge quantity of effluents containing a wide variety of chemicals, mostly dyes. Due to their toxic nature, these dyes are major contributors to industrial wastewater pollution, impacting the quality of water, air and soil [26]. During washing, textiles can release microfibers that carry toxic chemicals, including dyes, heavy metals and organic compounds, which are often non-biodegradable. These microfibers can be ingested by marine organisms and potentially enter the human food chain, posing health risks [27]. Effluent chemicals may pose health risks to people living near industrial areas, such as skin irritation, respiratory problems and serious effects such as mutagenicity and carcinogenicity [28].

Iqbal M and Nisar J. [29] hypothesized that gamma radiation in combination with hydrogen peroxide would be a promising approach to reduce the toxicity of textile wastewaters. They collected wastewater from three textile industries and concluded that textile effluents are cytotoxic and mutagenic. Nonetheless, they showed that these could be detoxified through degradation by the gamma radiation combined with hydrogen peroxide, indicating that this treatment might be an interesting alternative for effluents contaminated with toxic agents. Another common approach found in the literature is the use of microorganisms to remediate the damage that textile dyes cause to the environment, through the detoxification and disintegration of synthetic dyes [30]. In 2022, Rima et al. [31] performed a work in which two bacterial strains were isolated from textile waste to evaluate how successfully they degraded textile dyes. They also investigated the cytotoxicity of this wastewater on Artemia salina and phytotoxicity on Triticum aestivum, using brine shrimp lethality assay and plant growth analysis, respectively. Wastewater containing dyes negatively affects the germination of wheat seeds. However, when the isolated bacterial strains treated the wastewater, the germination improved. The dye degrading capacity of the bacteria was validated by HPLC (High-Performance Liquid Chromatography) analysis. The researchers concluded that the native bacterial community from textile effluents (in that case, Pseudomonas sp. and Bacillus sp.) could degrade several dyes, indicating that bacteria could be used as an efficient treatment of textile effluents. Textile effluents have a significant impact on both human health and the environment. Although studies and solutions are underway to treat and minimize these impacts, there is still a lot of work to be done.

1.3. The Cytotoxicity of Textile Functionalization

Textile functionalization refers to the process of enhancing the properties of textile materials to provide additional functionalities beyond their basic use. This can include a wide range of improvements, such as the following: (1) Smart textiles, which incorporate technology to interact with the environment or the wearer, like fabrics that can monitor health indicators, change color or adjust to temperature changes [32]. (2) Nanotechnology, from which, through nanomaterial application, textiles can acquire properties such as increased strength, stain resistance or antibacterial effects. Nano-coatings can also provide UV protection and water repellency to textiles [5]. (3) Microencapsulation, a technique that involves embedding tiny capsules within the fabric that can release substances like fragrances, moisturizes or insect repellents over time [33]. (4) Shape memory fabrics that can return to their original shape after being stretched or deformed, offering durability and maintaining their appearance over time [34]. (5) Protective textiles providing protection against various hazards, such as fire, chemicals or extreme weather conditions. This is particularly important for industrial, military and medical applications [35]. Functionalization of textiles offers numerous benefits but can also pose toxicity risks due to the chemicals and materials used in their production. Some of these chemicals, such as antimicrobial agents, nanoparticles, UV stabilizers and plasticizers can be cytotoxic, affecting cell viability and function [36].

Nanoparticles (NPs) and their oxides are increasingly being employed in textiles. Some studies show that the application of NPs and nanofibers in the textile structure can lead to stable modifications and enhanced durability [37]. NPs can pose significant toxicological risks, despite some evidence proving the safety of nano-structured material applications [38]. Thus, until the real facts are understood, which requires more time and further investigation, people should be cautious regarding the uncertain toxicities of nano-structured materials. The stability of nano-oxide particles in the materials’ interior is a persistent challenge due to their lack of functional groups for direct interaction with textiles. Consequently, in various finishing processes, certain components are added to NPs that can lead to toxicity and to the potential release of NPs during common laundering, physical stress and exposure to sweat [39]. The NPs used for textile coating come into contact with the epidermis, and then may reach the dermis through the hair follicle or by penetration through the several layers of the skin, or through small wounds [40].

In 2021, Tharwat Shaheen and collaborators biosynthesized CuO (copper oxide) nanoparticles to create antibacterial active textiles and evaluated their bactericidal activity and cytotoxicity. In order to estimate the safe dose of nanoparticles, they treated cotton fabrics with CuO NPs. These CuO-modified fabrics showed significant bactericidal activity against pathogenic bacteria while exhibiting low cytotoxicity. The in vitro cytotoxicity was evaluated by cell viability MTT assay, using the human colorectal adenocarcinoma epithelial cells (Caco-2) and normal lung fibroblast (Wi 38). This work indicates that these fabrics could be useful for medical applications and other textile products [41]. In the same year, Rossella Bengali’s research group [42] focused on the problem of nosocomial infections. Recognizing the urgent need to develop efficient nanomaterials with antibacterial properties, they developed and investigated the toxicological impact of CuO- and ZnO-NP-coated textiles. The researchers used 3D human reconstructed Epiderm™ and fibroblast monolayers as models for the epidermis and dermis, respectively. The textile extracts were obtained with different artificial sweat pH levels to better simulate physiological conditions. Among the various conclusions that the authors obtained, it was highlighted that sweat pH has a key role in the release of metal oxide ions by textiles. This can influence the epidermal tissue, which is not as tight a barrier to these ions. These results underscore the importance of investigating the potential hazards of NP-coated textiles, taking into consideration the integrity of the skin barrier. In addition to the standard cytotoxicity assays, investigations using more sensible biomarkers are of extreme importance to guarantee improved safety. Another work with CuO NPs was performed in 2024 by Ziba Najmi et al. [43], who coated different materials with CuO NPs and assessed the cytocompatibility, antibacterial activity and the effect of released Cu ions on human cells. This was the first time that extensive research was performed on the five different natural and synthetic materials: Lycra, neoprene, nylon, bamboo fibers and x-dry, which were coated by CuO nanoparticles. The cytocompatibility was evaluated through the metabolic activity of the surface-adhered human bone marrow mesenchymal stem cells (bMSCs), using the colorimetric/fluorometric assay Alamar blue. This test showed that fabrics coated with CuO were compatible with human cells.

In recent years, extensive research has been conducted on the preparation of antimicrobial cotton textiles by incorporating antimicrobial agents, which can efficiently inhibit the growth and spread of bacteria [44,45,46]. A variety of antimicrobial agents, such as antibiotics, metals, metals salts, and some specific molecules, have been applied in textiles in order to kill microorganisms upon contact [47,48,49]. Quaternary ammonium compounds (QACs) are widely used as antimicrobial disinfectants in both commercial and household settings. They are effective in cleaning and sanitizing surfaces to prevent the spread of harmful microorganisms. The use of QACs in a wide variety of applications, such as medical materials, water purification and food storage, has become increasingly common due to their recognized antimicrobial and broad-spectrum properties [50]. In 2014, Melin et al. [51] demonstrated that exposure to a common QAC disinfectant mixture significantly impaired reproductive health in mice. Another work performed by Christen and collaborators in 2017 [52] showed acute toxicity of QACs to various aquatic organisms. Although it has been shown that QACs present various dangers to the environment and also to human health, Zhaoshuang Li et al. [50] modified the surface of cotton textiles with antimicrobial agents, namely the maleopimaric acid quaternary ammonium cation (MPA-N+) based on rosin acid. They characterized the surface morphology and composition and the mechanical properties and thermal stability, among other characteristics, of this new modified cotton. These modified cotton textiles have the role of killing microbes and protecting normal cells at the same time. To study the biocompatibility, human aorta smooth muscle cells were placed directly in contact with the modified cotton, and the viability of the cells was investigated by MTT assay. It exhibited good hemocompatibility with no toxicity to cells. In 2017, the research group of Nela Maráková compared the antimicrobial activity of cotton fabrics coated with two conducting polymers (polyaniline and polypyrrole) alone or in combination with in situ deposited silver nanoparticles. The authors used mouse embryonic fibroblast cell line (NIH/3T3) and the MTT assay to evaluate the cytotoxicity, since it is an important parameter for the application of any material for industrial and medical purposes. They concluded that cotton coated with polypyrrole displayed antibacterial effects even without silver nanoparticles. However, antibacterial performance was improved after the deposition of silver, as expected. While the cytotoxicity of polypyrrole-coated cotton was low, even lower than cotton alone, the polyaniline coatings were significantly more cytotoxic. The cytotoxicity further increased after deposition of silver for both polymers [53].

One of the interests of sports medicine is to find solutions that can help optimize performance and recovery processes. In recent years, technical clothing has been very successful, with solutions that are able to modulate body temperature and humidity and promote better blood circulation and muscle contraction, thus improving both performance and recovery. In 2023, Alexander Bertuccioli and co-workers [54] published a work where a fabric (Accapì FIR) engineered to emit far infrared based on the applications of noble metals, when stimulated by body heat, was evaluated. The authors evaluated some parameters like variations in lactate and cortisol values and bio-impedance, among others. In the Materials and Methods section, the authors mentioned that the garment was produced in accordance with ISO 10993-1 and evaluated for cytotoxicity, skin irritation and allergic potential from contact dermatitis. However, it does not explain why these tests were chosen, nor does it discuss what other tests could be carried out on this type of garment in order to guarantee its safe use.

Protection against fire is a concern in textiles, and antimony compounds, mainly antimony trioxide, are used as a flame retardant for textiles, plastics, adhesives, paints, paper and rubber. Additionally, it can act as a catalyst in the production of polyethylene terephthalate, popularly known as PET, the most common type of polyester in textiles. However, despite its many applications, the antimony trioxide is known as potentially carcinogenic for humans [55]. In 2021, Marc Biver and his research group published a study of the antimony release from polyester textiles using artificial sweat solutions [56]. They reported that there is no regulatory limit for antimony concentrations in clothing or polyester textiles used in furniture, and there is a scarcity of information regarding its migration into human sweat and potential impacts of dermal exposure. The authors showed that when polyester samples produced to be in contact with human skin are placed in artificial sweat solution under default conditions they release up to 2% of total antimony. This study presents an example of a study in which it would be interesting to test the cytotoxicity of these extracts obtained in artificial sweat solutions, in order to understand their potential effect on skin toxicity, sensitization and irritation. Repellent textiles are a part of protective textiles that are typically treated with insect-repelling chemicals. These chemicals can be either embedded into the fibers during the manufacturing process or applied as a coating on the fabric. A recent work performed by Tariq et al. [57] describes the synthesis of microcapsules containing lavender oil, which were applied to cotton fabrics, with the objective to develop a long-lasting mosquito repellent textile. The biocompatibility of functionalized fabrics was assessed using L929 cells. The cytotoxicity results revealed that this functionalization is non-toxic to these cells, indicating a good biocompatibility.

Efforts are being made to develop safer functional textiles; however, it is crucial to monitor and regulate the use of potentially harmful substances in textile production, to minimize health and environmental risks.

1.4. The Potential Toxicity of End-of-Life Textile Residues

The predominant consumption of textile products, coupled with the rapid evolution of fashion trends observed in recent years, has led to a huge environmental impact, both during the manufacture of products and in the large volume of textile waste generated. Recently, a growing trend towards recycling textile waste has been observed, and recycling from textile to textile is a primary concern. Depending on the quality and composition of the waste, textile recycling can be carried out through mechanical or chemical treatments [58]. A study described by Lorena Villar and co-workers [59] shows the production of high-quality cellulosic fibers from cotton–elastane textile waste. In the same year, Osama M. Darwesh and his research group published a work [60] whose objective was the production of intelligent textiles from polyester/cotton waste using a green technique. They demonstrate the capacity of ZnO NPs to bind to these new smart textiles. In this study, the toxicity of ZnO NPs alone was assessed through MTT assay, but not in the finished product. The increasing focus on the circular economy using waste to produce new fibers could be a significant step towards minimizing the environmental impact caused by the textile industry and other sectors. However, assessing the cytotoxicity of these recycled textile materials and the challenges associated with reintroducing waste into new production should also be a concern, since the use of chemical treatments can introduce dangers that may be overlooked. An interesting discussion published by Agathe and colleagues in 2023 [61] highlights that many chemicals used in textiles are hazardous, and some present a risk for consumers. With this paper, the authors aimed to show the importance of knowing which hazardous substances can be found in recycled textiles and drew attention to the gaps in current regulations covering chemicals in textiles. They argue that implementing a safe circular textiles economy requires that chemicals of concern should be eliminated from the market. Their group also mentions the importance of creating a product passport, which will allow the traceability of the product throughout the value chain.

As has been discussed in previous topics of this review, it is well described that many chemicals are present in textiles in order to enhance properties like resistance and durability, among others, for a variety of functionalizations. This raises another essential point to consider and which should not be ignored by the regulatory authorities: the impact of prolonged use of textiles and the repeated exposure of users to these materials. It is known that chemical elements may pose health risks to humans when present in high concentrations or during prolonged exposure. They have the potential to accumulate in the body and interact with biological enzymes, forming complexes. When elements assume different chemical forms, their toxicity can change drastically. Although contaminants in textiles can potentially affect human health, research into how these substances penetrate and accumulate in the skin after extended contact has been limited. While clothing acts as a barrier, prolonged contact between the skin’s outer layer (stratum corneum) and textile materials, especially synthetic ones, can lead to irritation, sensitization or even the absorption of harmful chemicals into the body. Francesco Iadaresta and collaborators [62] studied the release of Benzothiazole (BT) by textile materials, their permeation through the skin and related accumulation. They used the data obtained to estimate the cutaneous exposure of BT and their correlated risk to human health. The results indicated that there are significant risks of transfer, penetration and accumulation of BT in human skin. Another recent work performed by Marta Herrero and co-workers [63] investigated the concentration of twenty trace elements in the clothing of pregnant women, newborns and toddlers sold in Spain and estimated the dermal absorption of these chemicals through direct-contact clothing. The authors concluded that aluminum, zinc and titanium showed the highest concentrations. High levels of chromium were found in black polyester, since it is employed as a metal complex dye in synthetic fibers. Titanium is a ubiquitous element in clothes made of synthetic fibers with a hazard quotient (HQ) threshold value (HQ > 1). Dermal exposure to titanium revealed HQ values of 1.13 for pregnant women and 1.22 for newborns. On the other hand, HQ values of other elements and cancer risks were lower than the recommended values. Evaluating exposure to toxic elements can help to find potential sources and mitigate or prevent human exposure, especially in vulnerable groups.

1.5. Micropollutants Released During Textile Supply Chain

As previously stated, the textile supply chain encompasses a wide range of industrial processes, many of which involve the use of chemical substances that can lead to the release of micropollutants. These contaminants, depending on their nature and concentration, may pose significant risks to human health. The following section outlines the most toxic processes in the textile chain, the associated micropollutants and their potential impacts on human health. Table 1 aims to succinctly highlight some critical stages of the textile production process, as well as some of the micropollutants most released at each stage. It also presents the potential adverse effects these substances may have on human health, which includes, for example, dermatological reactions, endocrine disruption, bioaccumulation, systemic toxicity and impacts on embryonic development, among others. The selected examples aim to provide a general overview of the most environmentally and toxicologically relevant compounds, to support a better understanding of the risks associated with textile production.

Table 1.

Main micropollutants released during the textile supply chain and their impact on human health.

2. Final Remarks

The future of textiles is very promising, as it will integrate advanced technology, sustainability and functionality to meet the demands of the next generations. The textile industry is on the brink of transformation, with innovations like smart textiles, nanotechnology, 3D printing, advanced dyeing methods, eco-friendly materials, shape-memory fabrics and biodegradable electronics set to revolutionize the field in the coming years. Long-term exposure to certain chemicals used in the functionalization of textiles can lead to serious health problems, including skin irritation, respiratory issues and even cancers and immune system disorders. Currently, there is still very limited information available about the exact methods or tests that should be used to assess the cytotoxicity of the functionalized textiles.

This review aimed to provide an overview of the assessment of cytotoxicity in the textile industry. It was observed that some studies have evaluated the cytotoxicity of finishes and additives that have been, or may be, used in textiles. Additionally, there are studies where the toxicity of the final product was assessed. However, the methods chosen are not always consistent, which may lead to disparities in the final results. With the emergent evolution of technical textiles and even the development of new textile fibers, it is imperative to create regulations for the tests that must be carried out on the finished product before it is marketed, similar to the current regulations for medical devices. Textiles are in constant contact with the skin, and it is known that some additives can be absorbed, so this is a matter that deserves our full attention. Little is known about the impact of such functional textile products on human skin, as well as their prolonged use, and this information is of huge importance for consumers. Future research should develop and implement standardized methods for assessing the cytotoxicity of functionalized textiles to ensure consistent and reliable results. Comprehensive studies are needed to better understand the long-term health impacts of exposure to chemicals in textiles, particularly regarding skin absorption and prolonged use. Regarding smart textiles, for example, the integration of them with health-monitoring capabilities should be explored to ensure they are safe for prolonged skin contact. The textile industry has been making efforts to challenge and create alternatives to harmful chemicals in textiles, poised for a transformative future. Increasing consumer awareness about the health and environmental impacts of textiles, and promoting the adoption of safer alternatives, should be prioritized. It is urgent to accelerate research and innovation to ensure a sustainable and healthy future for both consumers and the environment.

Author Contributions

Conceptualization, V.M., A.M. and P.V.d.C.; methodology, V.M. and A.M.; validation, V.M., A.M., P.V.d.C. and T.S.; formal analysis, V.M., A.M. and P.V.d.C.; investigation, V.M. and A.M.; writing—original draft preparation, V.M. and A.M.; writing—review and editing, V.M., A.M. and T.S.; visualization, P.V.d.C.; supervision, P.V.d.C.; project administration, P.V.d.C. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the financial support from the integrated project be@t—Textile Bioeconomy (TC-C12-i01, Sustainable Bioeconomy No. 02/C12-i01.01/2022), promoted by the Portuguese Recovery and Resilience Plan (RRP), Next Generation EU, for the period 2021–2026.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| BT | Benzothiazole |

| CuO | Copper Oxide |

| CuO NPs | Copper Oxide Nanoparticles |

| DNA | Deoxyribonucleic Acid |

| EU | European Union |

| HA | Hyaluronan |

| HPLC | High-Performance Liquid Chromatography |

| HQ | Hazard Quotient |

| ISO | International Organization for Standardization |

| MTT | [3-(4,5 dimethylthiazol-2-yl) 2,5-diphenyl tetrazolium bromide] |

| NPs | Nanoparticles |

| OECD | Organization for Economic Cooperation and Development |

| PCL | Polycaprolactone |

| PET | Polyethylene Terephthalate |

| PLA | Polylactic |

| QAC | Quaternary Ammonium Compounds |

| REACH | Registration, Evaluation, Authorization and Restriction of Chemicals |

| TNT | Non-woven Fabric |

| UV | Ultraviolet |

| ZnO NPs | Zinc Nanoparticles |

References

- Regulation (EC) No 1907/2006 of the European Parliament and of the Council. Off. J. Eur. Union 2006. Available online: https://eur-lex.europa.eu/eli/reg/2006/1907/oj/eng (accessed on 20 January 2025).

- OECD Guidelines. Available online: https://mneguidelines.oecd.org/mneguidelines (accessed on 25 October 2024).

- OEKO-TEX® STANDARD 100, 3rd ed.; OEKO-TEX Service GmbH: Zurich, Switzerland, 2025.

- OEKO-TEX® Standards Enable Everyone to Make Responsible Decisions and Protect Natural Resources. Available online: https://www.oeko-tex.com/en/our-standards (accessed on 25 October 2024).

- Klemola, K. Textile Toxicity Cytotoxicity and Spermatozoa Motility Inhibition Resulting from Reactive Dyes and Dyed Fabrics. Ph.D. Thesis, University of Kuopio, Kuopio, Finland, October 2008. [Google Scholar]

- Shah, M.A.; Pirzada, B.M.; Price, G.; Shibiru, A.L.; Qurashi, A. Applications of nanotechnology in smart textile industry: A critical review. J. Adv. Res. 2022, 38, 55–75. [Google Scholar] [CrossRef] [PubMed]

- Omerogullari, B.Z.; Coskun, H. Enhancing Antibacterial and Water-Repellent Properties for the Production of High-Performance Fabrics in Home Textiles. Fibers. Polym. 2024, 25, 1789–1804. [Google Scholar] [CrossRef]

- Pakdel, E.; Wang, X. Thermoregulating textiles and fibrous materials for passive radiative cooling functionality. Mater. Des. 2023, 231, 112006. [Google Scholar] [CrossRef]

- Wang, S.-M.; Wu, J.-X.; Gunawan, H.; Tu, R.-Q. Highly Specialized Textiles with Antimicrobial Functionality—Advances and Challenges. Textiles 2023, 3, 219–245. [Google Scholar] [CrossRef]

- ISO 10993; Biological Evaluation of Medical Devices—Part 5: Tests for in Vitro Cytotoxicity. International Organization for Standardization: Geneva, Switzerland, 2009.

- Zhang, Y. Cell toxicity mechanism and biomarker. Clin. Transl. Med. 2018, 7, 34. [Google Scholar] [CrossRef]

- Petrachi, T.; Ganzerli, F.; Cuoghi, A.; Ferrari, A.; Resca, E.; Bergamini, V.; Accorsi, L.; Burini, F.; Pasini, D.; Arnaud, G.F.; et al. Assessing biocompatibility of face mask materials during COVID-19 pandemic by a rapid multi-assays strategy. Int. J. Environ. Res. Public. Health 2021, 18, 5387. [Google Scholar] [CrossRef]

- Meier, P.; Zabara, M.; Hirsch, C.; Gogos, A.; Tscherrig, D.; Richner, G.; Nowack, B.; Wick, P. Evaluation of fiber and debris release from protective COVID-19 mask textiles and in vitro acute cytotoxicity effects. Environ. Int. 2022, 167, 107364. [Google Scholar] [CrossRef]

- Pereira-Lobato, C.; Echeverry-Rendón, M.; Fernández-Blázquez, J.; González, C.; Llorca, J. Mechanical properties, in vitro degradation and cytocompatibility of woven textiles manufactured from PLA/PCL commingled yarns. J. Mech. Behav. Biomed. Mater. 2024, 150, 106340. [Google Scholar] [CrossRef]

- Kubíčková, J.; Medek, T.; Husby, J.; Matonohová, J.; Vágnerová, H.; Marholdová, L.; Velebný, V.; Chmelař, J. Nonwoven textiles from hyaluronan for wound healing applications. Biomolecules 2022, 12, 16. [Google Scholar] [CrossRef]

- Zhong, W.; Xing, M.M.Q.; Pan, N.; Maibach, H.I. Textiles and human skin, microclimate, cutaneous reactions: An overview. Cutan. Ocul. Toxicol 2006, 25, 23–39. [Google Scholar] [CrossRef]

- Shen, D.; Fan, J.; Zhou, W.; Gao, B.; Yue, Q.; Kang, Q. Adsorption kinetics and isotherm of anionic dyes onto organo-bentonite from single and multisolute systems. J. Hazard Mater. 2009, 172, 99–107. [Google Scholar] [CrossRef] [PubMed]

- Morshed, M.H.; Das, P.K.; Roy, A.K.; Ibrahim, M. Cytotoxicity of Four Active Dyes Against Artemia Salina Leach. J. Eng. Sci. 2018, 9, 55–59. [Google Scholar]

- Domingues, G.; Düsman, E.; Vicentini, V.E.P. Cytotoxicity of Crude and Treated Liquid Effluents from Textile Industry Dyeing Using Bioindicator Allium cepa L. Water Air Soil Pollut. 2020, 231, 1–10. [Google Scholar] [CrossRef]

- Leme, D.M.; de Oliveira, G.A.R.; Meireles, G.; dos Santos, T.C.; Zanoni, M.V.B.; de Oliveira, D.P. Genotoxicological assessment of two reactive dyes extracted from cotton fibres using artificial sweat. Toxicol. Vitr. 2014, 28, 31–38. [Google Scholar] [CrossRef]

- Silva, E.Z.M.; Sehr, A.; Grummt, T.; de Oliveira, D.P.; Leme, D.M. The Evaluation of Reactive Textile Dyes Regarding their Potential to Cause Organ-Specific Cyto- and Geno-Toxicity. Ecotoxicol. Environ. Contam. 2022, 17, 60–66. [Google Scholar] [CrossRef]

- Klemola, K.; Pearson, J.; Lindstrom-Seppä, P. Evaluating the Toxicity of Reactive Dyes and Dyed Fabrics with the HaCaT Cytotoxicity Test. AUTEX Res. J. 2007, 7, 217–223. [Google Scholar] [CrossRef]

- Pizzicato, B.; Pacifico, S.; Cayuela, D.; Mijas, G.; Riba-Moliner, M. Advancements in Sustainable Natural Dyes for Textile Applications: A Review. Molecules 2023, 28, 5954. [Google Scholar] [CrossRef]

- Costa, E.M.; Silva, S.; Veiga, M.; Baptista, P.; Tavaria, F.K.; Pintado, M.E. Textile dyes loaded chitosan nanoparticles: Characterization, biocompatibility and staining capacity. Carbohydr. Polym. 2021, 251, 117120. [Google Scholar] [CrossRef]

- Lara, L.; Cabral, I.; Cunha, J. Ecological Approaches to Textile Dyeing: A Review. Sustainability 2022, 14, 8353. [Google Scholar] [CrossRef]

- Lellis, B.; Fávaro-Polonio, C.Z.; Pamphile, J.A.; Polonio, J.C. Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnol. Res. Innov. 2019, 3, 275–290. [Google Scholar] [CrossRef]

- Periyasamy, A.P. Microfiber Emissions from Functionalized Textiles: Potential Threat for Human Health and Environmental Risks. Toxics 2023, 11, 406. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Malik, A. Environmental and health effects of textile industry wastewater. In Environmental Deterioration and Human Health Natural and Anthropogenic Determinants; Malik, A., Grohmann, E., Akhtar, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 55–71. [Google Scholar]

- Iqbal, M.; Nisar, J. Cytotoxicity and mutagenicity evaluation of gamma radiation and hydrogen peroxide treated textile effluents using bioassays. J. Environ. Chem. Eng. 2015, 3, 1912–1917. [Google Scholar] [CrossRef]

- Jamee, R.; Siddique, R. Biodegradation of synthetic dyes of textile effluent by microorganisms: An environmentally and economically sustainable approach. Eur. J. Microbiol. Immunol. 2019, 9, 114–118. [Google Scholar] [CrossRef]

- Rima, S.A.J.; Paul, G.K.; Islam, S.; Ekram, A.E.; Zaman, S.; Saleh, A.; Uddin, S. Efficacy of Pseudomonas sp. and Bacillus sp. in textile dye degradation: A combined study on molecular identification, growth optimization, and comparative degradation. J. Hazard. Mater. Lett. 2022, 3, 100068. [Google Scholar] [CrossRef]

- Júnior, H.L.O.; Neves, R.M.; Monticeli, F.M.; Dall Agnol, L. Smart Fabric Textiles: Recent Advances and Challenges. Textiles 2022, 2, 582–605. [Google Scholar] [CrossRef]

- Cheng, S.Y.; Yuen, C.W.M.; Kan, C.W.; Cheuk, K.K.L. Development of Cosmetic Textiles Using Microencapsulation Technology. Res. J. Text. Appar. 2008, 12, 41–51. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Bianchi, O. Temperature-Dependent Shape-Memory Textiles: Physical Principles and Applications. Textiles 2023, 3, 257–274. [Google Scholar] [CrossRef]

- Singha, K.; Maity, S.; Pandit, P.; Mondal, M.I.H. Introduction to protective textiles. In Protective Textiles from Natural Resources; Elsevier: Amsterdam, The Netherlands, 2022; pp. 3–38. [Google Scholar]

- Kumar, S.M. Textiles Functionalization—A Review of Materials, Processes, and Assessment. In Textiles for Functional Applications; Kumar, B., Ed.; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Becheri, A.; Dürr, M.; Lo Nostro, P.; Baglioni, P. Synthesis and characterization of zinc oxide nanoparticles: Application to textiles as UV-absorbers. J. Nanopart. Res. 2008, 10, 679–689. [Google Scholar] [CrossRef]

- Dastjerdi, R.; Montazer, M. A review on the application of inorganic nano-structured materials in the modification of textiles: Focus on anti-microbial properties. Colloids Surf. B Biointerfaces 2010, 79, 5–18. [Google Scholar] [CrossRef]

- Khandual, A.; Rout, N.; Verma, S.K.; Patel, P.; Pattanaik, P.; Luximon, Y.; Suar, M. Controlled nano-particle dyeing of cotton can ensure low cytotoxicity risk with multi-functional property enhancement. Mater. Today Chem. 2020, 17, 100345. [Google Scholar] [CrossRef]

- Fiandra, L.; Bonfanti, P.; Piunno, Y.; Nagvenkar, A.P.; Perlesthein, I.; Gedanken, A.; Saibene, M.; Colombo, A.; Mantecca, P. Hazard assessment of polymer-capped CuO and ZnO nanocolloids: A contribution to the safe-by-design implementation of biocidal agents. NanoImpact 2020, 17, 100195. [Google Scholar] [CrossRef]

- Shaheen, T.I.; Fouda, A.; Salem, S.S. Integration of Cotton Fabrics with Biosynthesized CuO Nanoparticles for Bactericidal Activity in the Terms of Their Cytotoxicity Assessment. Ind. Eng. Chem. Res. 2021, 60, 1553–1563. [Google Scholar] [CrossRef]

- Bengalli, R.; Colantuoni, A.; Perelshtein, I.; Gedanken, A.; Collini, M.; Mantecca, P.; Fiandra, L. In vitro skin toxicity of CuO and ZnO nanoparticles: Application in the safety assessment of antimicrobial coated textiles. NanoImpact 2021, 21, 100282. [Google Scholar] [CrossRef]

- Najmi, Z.; Mlinarić, N.M.; Scalia, A.C.; Cochis, A.; Selmani, A.; Učakar, A.; Abram, A.; Zore, A.; Delač, I.; Jerman, I.; et al. Antibacterial evaluation of different prosthetic liner textiles coated by CuO nanoparticles. Heliyon 2024, 10, e23849. [Google Scholar] [CrossRef] [PubMed]

- Gulati, R.; Sharma, S.; Sharma, R.K. Antimicrobial textile: Recent developments and functional perspective. Polymer. Bull. 2022, 79, 5747–5771. [Google Scholar] [CrossRef]

- Granados, A.; Pleixats, R.; Vallribera, A. Recent advances on antimicrobial and anti-inflammatory cotton fabrics containing nanostructures. Molecules 2021, 26, 3008. [Google Scholar] [CrossRef]

- Hussein, U.A.-R.; Mahmoud, Z.H.; Alaziz, K.M.A.; Alid, M.L.; Yasin, Y.; Ali, F.K.; Faisal, A.N.; Abd, A.N.; Kianfar, E. Antimicrobial finishing of textiles using nanomaterials. Braz. J. Biol. 2023, 84, e264947. [Google Scholar] [CrossRef]

- Rabel, A.M.; Namasivayam, S.K.R.; Prasanna, M.; Bharani, R.S.A. A green chemistry to produce iron oxide—Chitosan nanocomposite (CS-IONC) for the upgraded bio-restorative and pharmacotherapeutic activities—Supra molecular nanoformulation against drug-resistant pathogens and malignant growth. Int. J. Biol. Macromol. 2019, 138, 1109–1129. [Google Scholar] [CrossRef]

- Zhou, C.; Wu, Y.; Thappeta, K.R.V.; Subramanian, J.T.L.; Pranantyo, D.; Kang, E.-T.; Duan, H.; Kline, K.; Chan-Park, M.B. In Vivo Anti-Biofilm and Anti-Bacterial Non-Leachable Coating Thermally Polymerized on Cylindrical Catheter. ACS Appl. Mater. Interfaces 2017, 9, 36269–36280. [Google Scholar] [CrossRef]

- Cai, Q.; Yang, S.; Zhang, C.; Li, Z.; Li, X.; Shen, Z.; Zhu, W. Facile and Versatile Modification of Cotton Fibers for Persistent Antibacterial Activity and Enhanced Hygroscopicity. ACS Appl. Mater. Interfaces 2018, 10, 38506–38516. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, J.; Yang, X.; Liu, H.; Xu, X.; Ma, L.; Shang, S.; Song, Z. Construction of antimicrobial and biocompatible cotton textile based on quaternary ammonium salt from rosin acid. Int. J. Biol. Macromol. 2020, 150, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Melin, V.; Potineni, H.; Hunt, P.; Griswold, J.; Siems, B.; Werre, S.; Hrubec, T. Exposure to common quaternary ammonium disinfectants decreases fertility in mice. Reprod. Toxicol. 2014, 50, 163–170. [Google Scholar] [CrossRef] [PubMed]

- Christen, V.; Faltermann, S.; Brun, N.R.; Kunz, P.Y.; Fent, K. Cytotoxicity and molecular effects of biocidal disinfectants (Quaternary ammonia, glutaraldehyde, poly (Hexamethylene biguanide) hydrochloride PHMB) and their mixtures in vitro and in zebrafish eleuthero-embryos. Sci. Total Environ. 2017, 586, 1204–1218. [Google Scholar] [CrossRef]

- Maráková, N.; Humpolíček, P.; Kašpárková, V.; Capáková, Z.; Martinková, L.; Bober, P.; Trchová, M.; Stejskal, J. Antimicrobial activity and cytotoxicity of cotton fabric coated with conducting polymers, polyaniline or polypyrrole, and with deposited silver nanoparticles. Appl. Surf. Sci. 2017, 396, 169–176. [Google Scholar] [CrossRef]

- Bertuccioli, A.; Cannataro, R.; Gervasi, M.; Benelli, P.; Gregoretti, A.; Ragazzini, M.; Neri, M.; Palazzi, C.M.; Cardinali, M.; Zonzini, G. Preliminary Assessment of the Acute Effects of Far Infrared-Emitting Garments: What Are the Possible Implications for Recovery and Performance? Life 2023, 13, 1998. [Google Scholar] [CrossRef]

- Wang, H.S.A.; Ewens, D.A.; Garner, S.C.; Lunn, R.M.; Mehta, S.S.; Peters, A.F.; Trgovcich, J.; Witt, K.L. Report on Carcinogens Monograph on Antimony Trioxide; National Toxicology Program: Research Triangle Park, NC, USA, 2018. [Google Scholar] [CrossRef]

- Biver, M.; Turner, A.; Filella, M. Antimony release from polyester textiles by artificial sweat solutions: A call for a standardized procedure. Regul. Toxicol. Pharmacol. 2021, 119, 104824. [Google Scholar] [CrossRef] [PubMed]

- Tariq, Z.; Zhang, H.-T.; Wang, R.-Q.; Zeng, Q.; Wang, X.; Wang, X.; Deng, S.-Q.; Wang, X. Enhancing the durability of mosquito repellent textiles through microencapsulation of lavender oil. J. Pest. Sci. 2024, 98, 477–492. [Google Scholar] [CrossRef]

- Sathasivam, T.; Sugiarto, S.; Yew, M.P.Y.; Oh, X.Y.; Chan, S.Y.; Chan, B.Q.Y.; Tim, M.J.; Kai, D. Transforming textile waste into nanocellulose for a circular future. Nanoscale 2024, 16, 14168–14194. [Google Scholar] [CrossRef]

- Villar, L.; Schlapp-Hackl, I.; Sánchez, P.B.; Hummel, M. High-Quality Cellulosic Fibers Engineered from Cotton-Elastane Textile Waste. Biomacromolecules 2024, 25, 1942–1949. [Google Scholar] [CrossRef]

- Darwesh, O.M.; Matter, I.A.; Al-Balakocy, N.G.; Abo-Alkasem, M.I. Circular economy reinforcement through molecular fabrication of textile wastes with microbial synthesized ZnO nanoparticles to have multifunctional properties. Sci. Rep. 2024, 14, 16660. [Google Scholar] [CrossRef]

- Bour, A.; Christensen, T.B.; Hunka, A.D.; Palmqvist, A.; Skjold, E.; Syberg, K. Implications of circular textile policies for the future regulation of hazardous substances in textiles in the European Union. Sci. Total Environ. 2023, 896, 165153. [Google Scholar] [CrossRef] [PubMed]

- Iadaresta, F.; Manniello, M.D.; Östman, C.; Crescenzi, C.; Holmbäck, J.; Russo, P. Chemicals from textiles to skin: An in vitro permeation study of benzothiazole. Environ. Sci. Pollut. Res. 2018, 25, 24629–24638. [Google Scholar] [CrossRef] [PubMed]

- Herrero, M.; Rovira, J.; González, N.; Marquès, M.; Barbosa, F.; Sierra, J.; Domingo, J.L.; Nadal, M.; Souza, M.C.O. Clothing as a potential exposure source of trace elements during early life. Environ. Res. 2023, 233, 116479. [Google Scholar] [CrossRef]

- Lopes-Ferreira, M.; Farinha, L.; Costa, Y.; Pinto, F.; Disner, G.; Rosa, J.; Lima, C. Pesticide-Induced Inflammation at a Glance. Toxics 2023, 11, 896. [Google Scholar] [CrossRef] [PubMed]

- Hwang, J.; Jeong, H.; Jung, Y.; Nam, K.; Lim, K. Skin irritation and inhalation toxicity of biocides evaluated with reconstructed human epidermis and airway model. Food Chem. Toxicol. 2021, 150, 112064. [Google Scholar] [CrossRef]

- Seidu, R.; Ofori, E.; Eghan, B.; Fobiri, G.; Afriyie, A.; Acquaye, R. A systematic review of work-related health problems of factory workers in the textile and fashion industry. J. Occup. Health 2024, 66, uiae007. [Google Scholar] [CrossRef]

- Maceira, A.; Marcé, R.; Borrull, F. Occurrence of benzothiazole, benzotriazole and benzenesulfonamide derivates in outdoor air particulate matter samples and human exposure assessment. Chemosphere 2018, 193, 557–566. [Google Scholar] [CrossRef]

- Rovira, J.; Domingo, J. Human health risks due to exposure to inorganic and organic chemicals from textiles: A review. Environ. Res. 2018, 168, 62–69. [Google Scholar] [CrossRef]

- Mekala, K.; Malki, A.; Amarasinghe, D.; Ishara, G. Occupational Health and Safety in the textile industry. J. Res. Technol. Eng. 2023, 4, 127–140. [Google Scholar] [CrossRef]

- Badmus, S.; Amusa, H.; Oyehan, T.; Saleh, T. Environmental risks and toxicity of surfactants: Overview of analysis, assessment, and remediation technique. Environ. Sci. Pollut. Res. 2021, 28, 62085–62104. [Google Scholar] [CrossRef]

- Frantz, A. Chronic quaternary ammonium compound exposure during the COVID-19 pandemic and the impact on human health. Toxicol. Environ. Health Sci. 2023, 15, 199–206. [Google Scholar] [CrossRef]

- Papavasilopoulos, R.; Kang, S. Bibliometric Analysis: The Effects of Triclosan on Human Health. Toxics 2022, 10, 523. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).