Artificial-Neural-Network-Based Predicted Model for Seam Strength of Five-Pocket Denim Jeans: A Review

Abstract

:1. Introduction

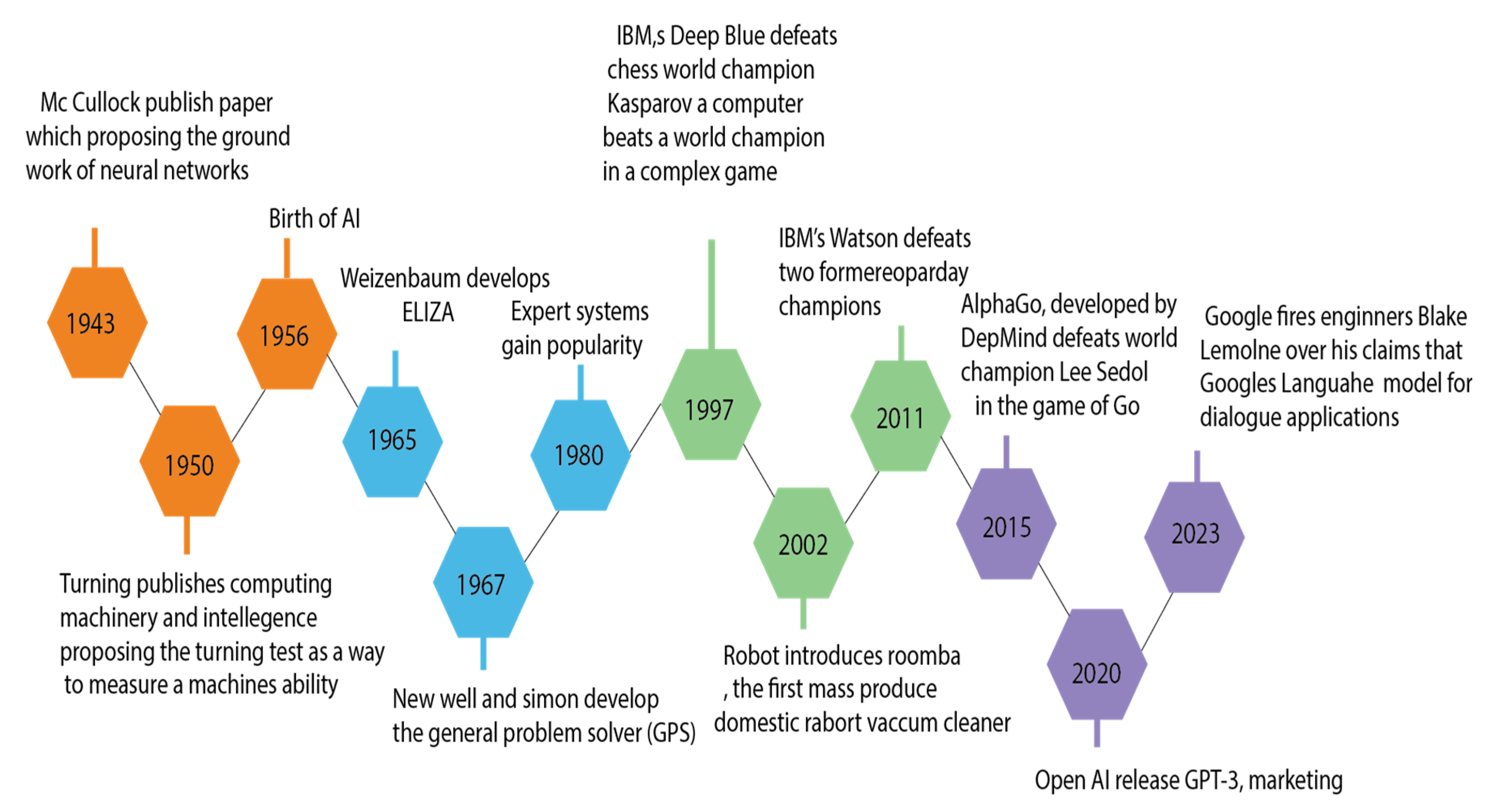

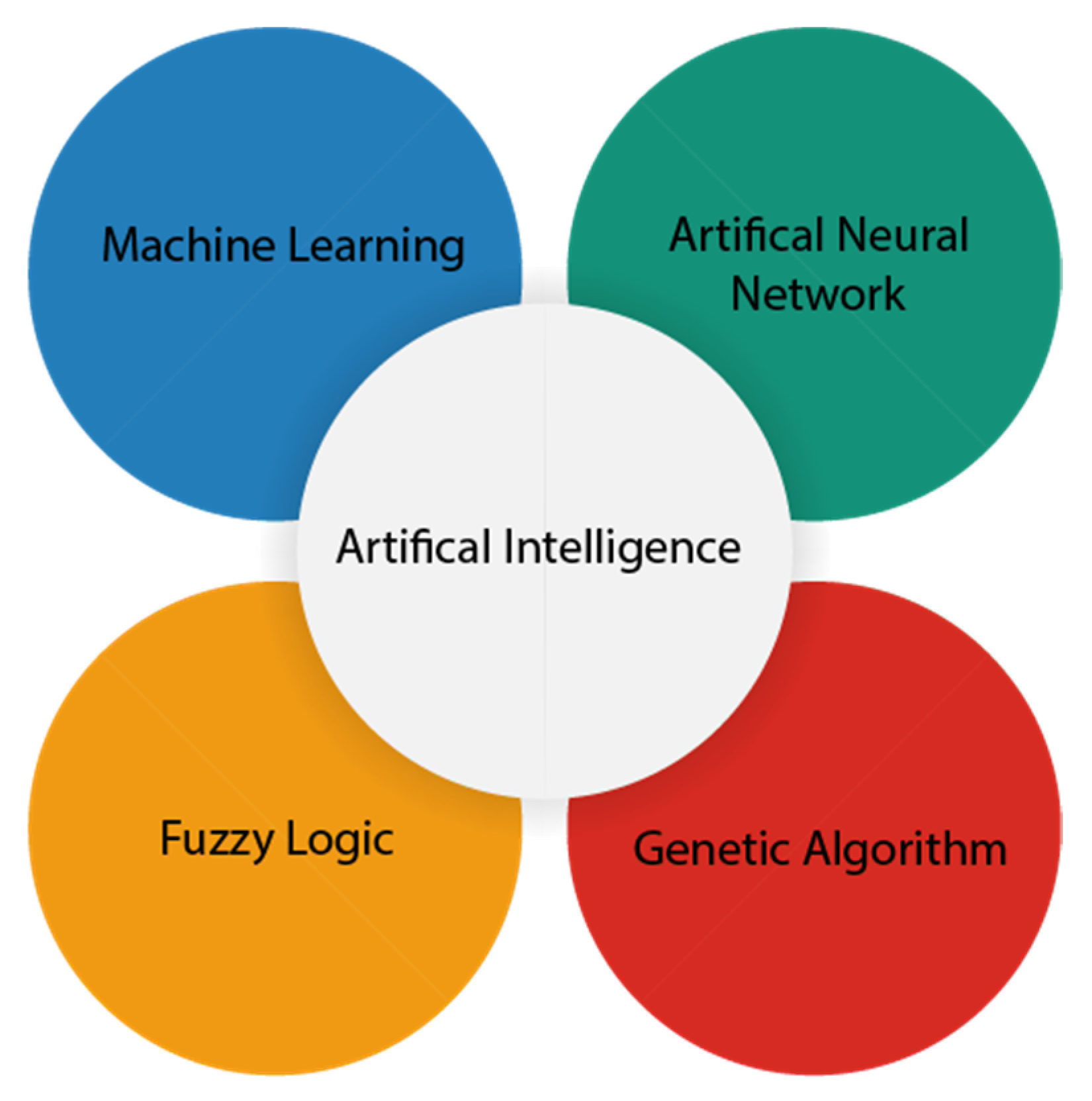

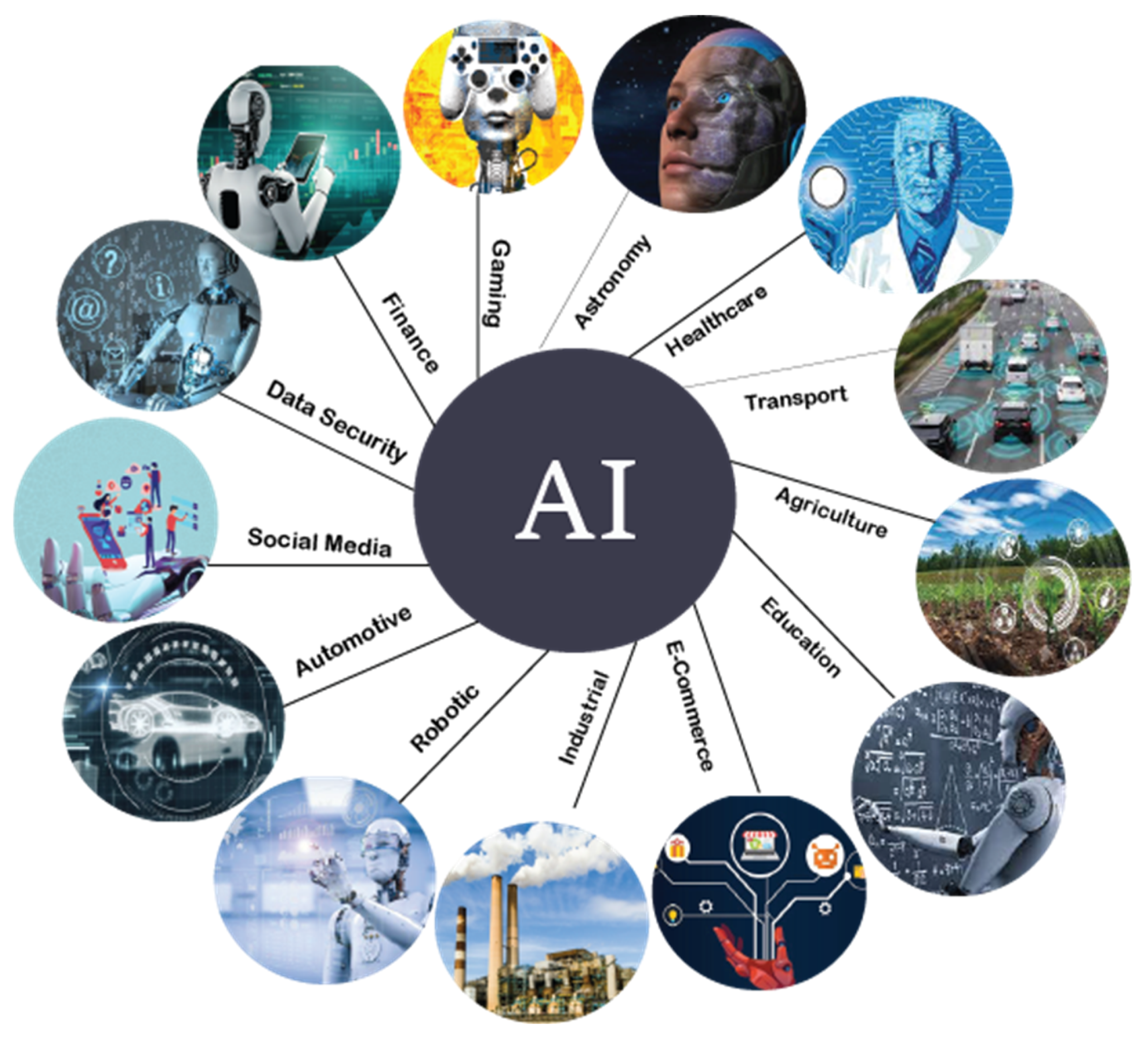

1.1. Artificial Intelligence in Different Fields of Life

1.1.1. In the Medical Field

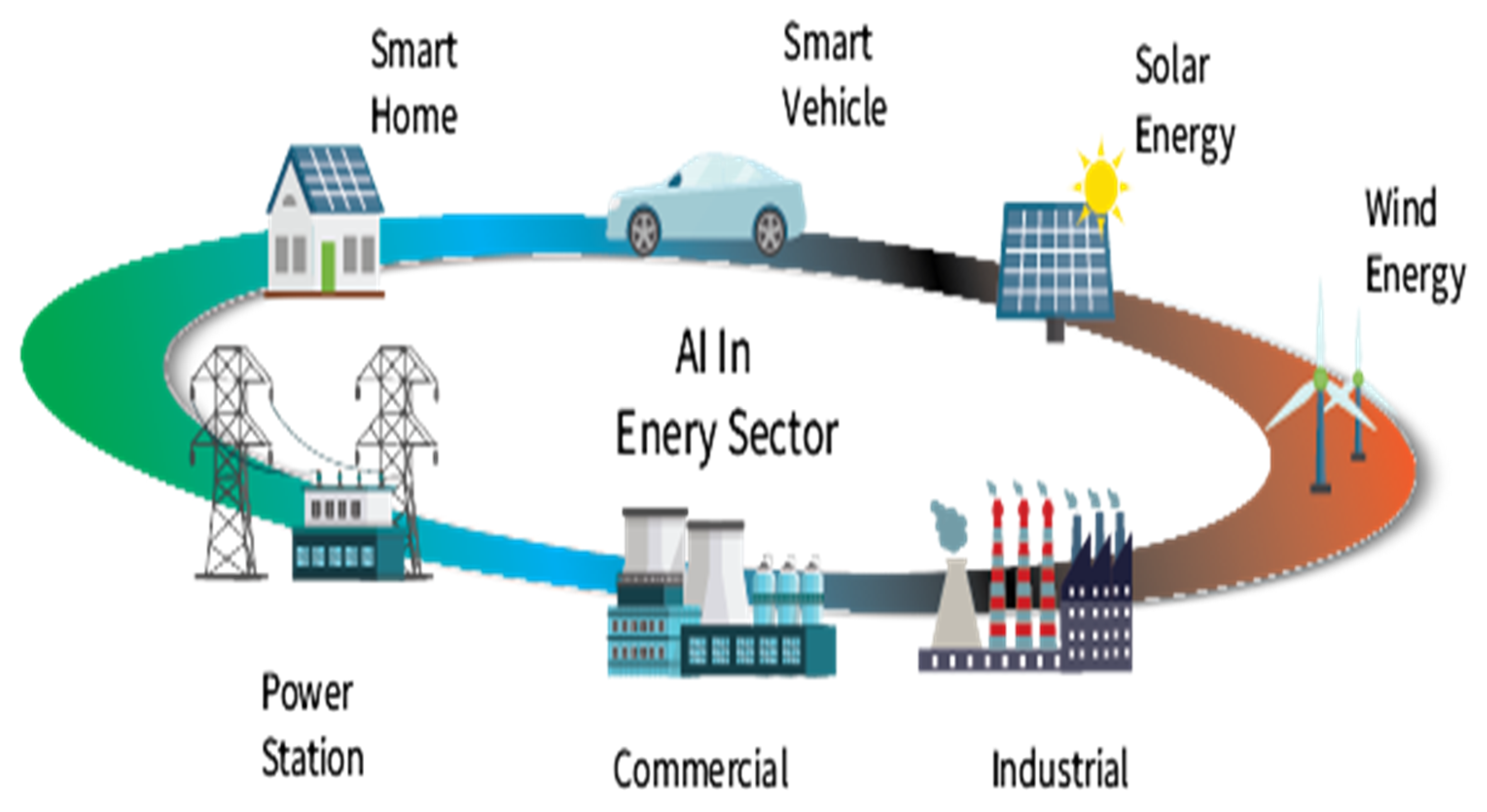

1.1.2. In the Energy Sector

1.1.3. AI in the Industrial Sector

1.1.4. In Power System Stabilizers

1.1.5. AI in Robotics

1.1.6. In the Education Field

1.1.7. In the Fashion Industry

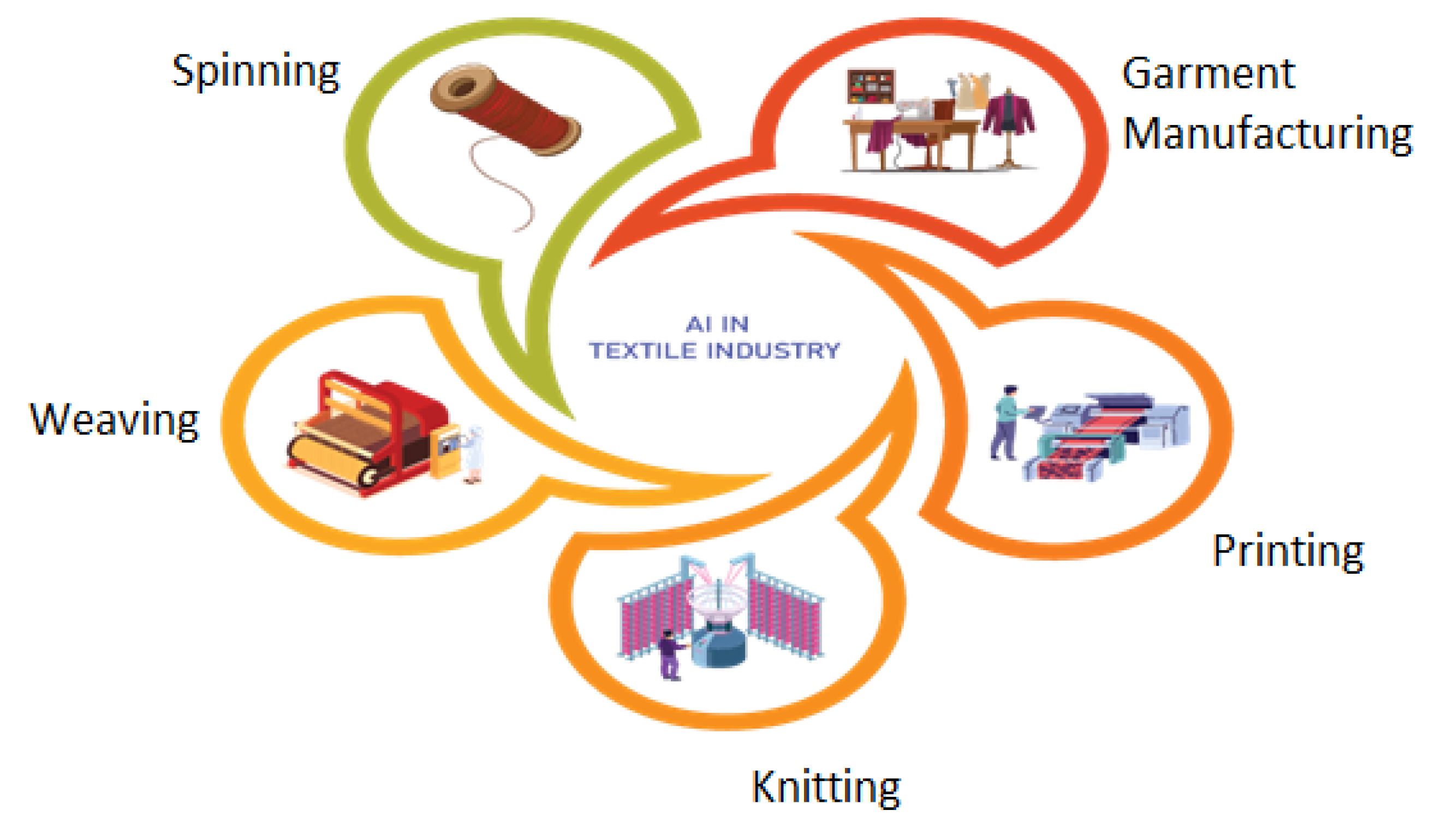

2. Artificial Intelligence in the Textile Industry

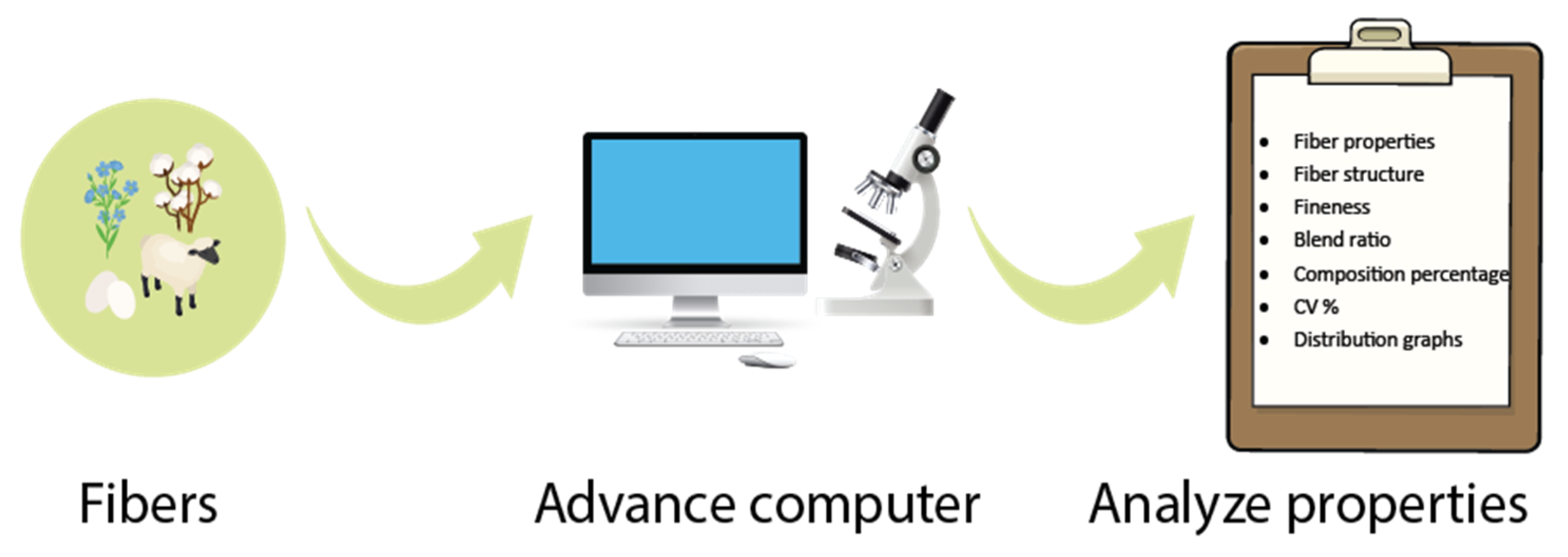

2.1. AI in Analyzing Fiber Characteristics

2.2. AI in Spinning

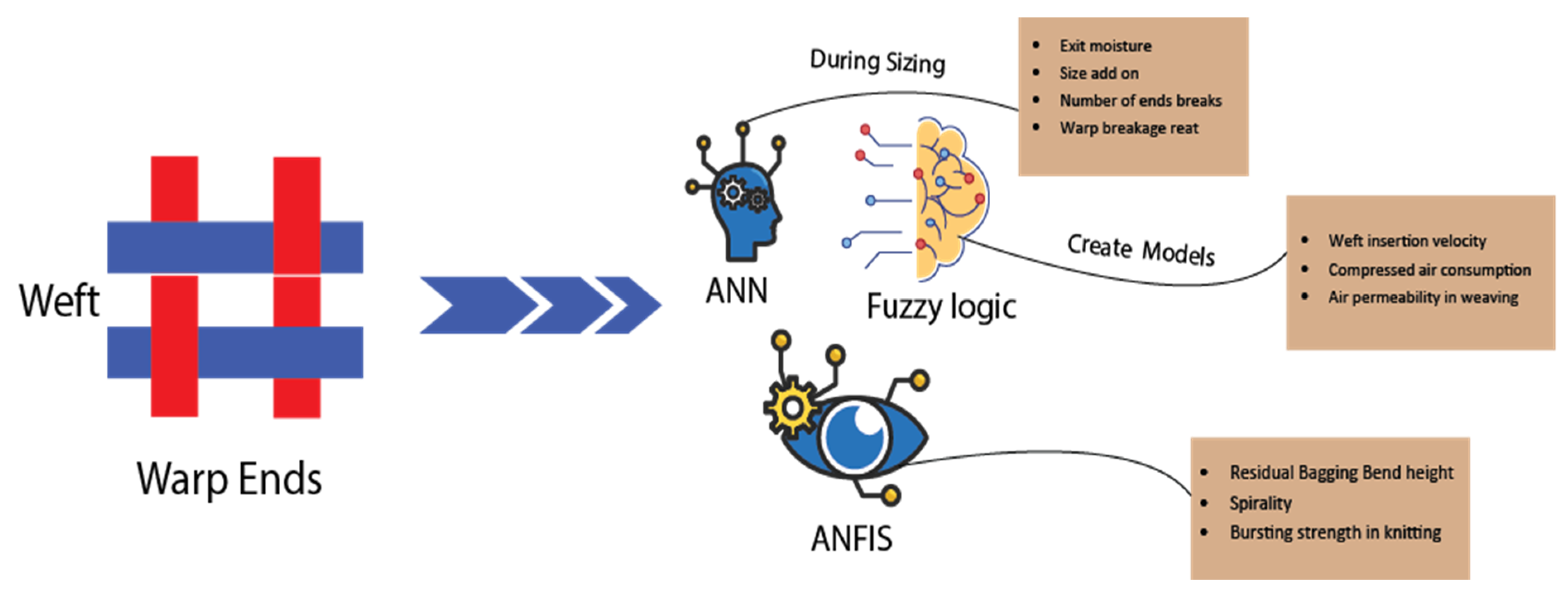

2.3. AI in Fabric Manufacturing

2.4. AI in Dyeing, Finishing, and Printing

3. Artificial Intelligence in Textile Testing

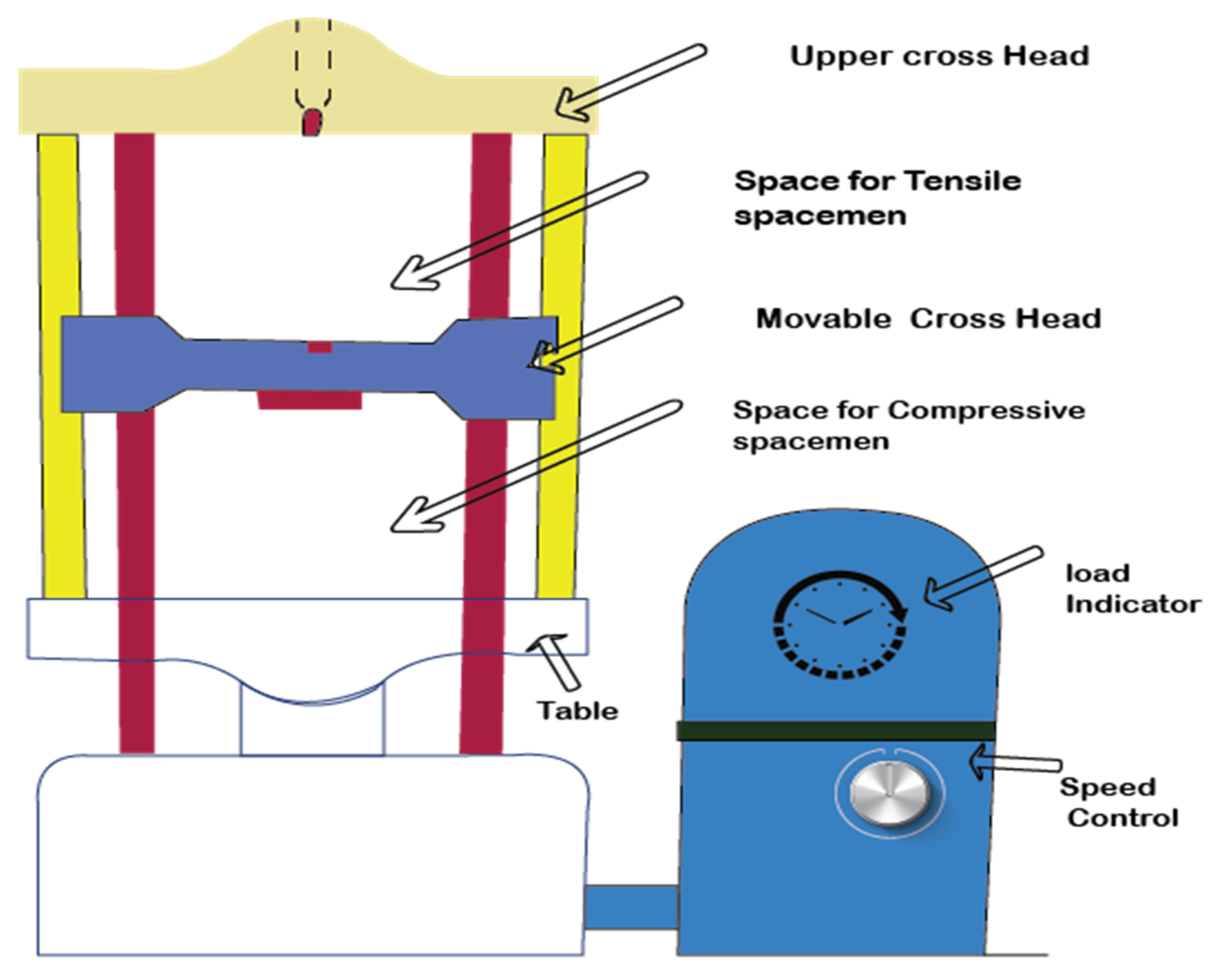

3.1. Tensile Strength Tests

3.2. Tear Strength Tests

3.3. Stiffness Tests

3.4. Abrasion Resistance Tests

3.5. Pilling Resistance Tests

3.6. Shrinkage Tests

3.7. Crease Recovery Tests

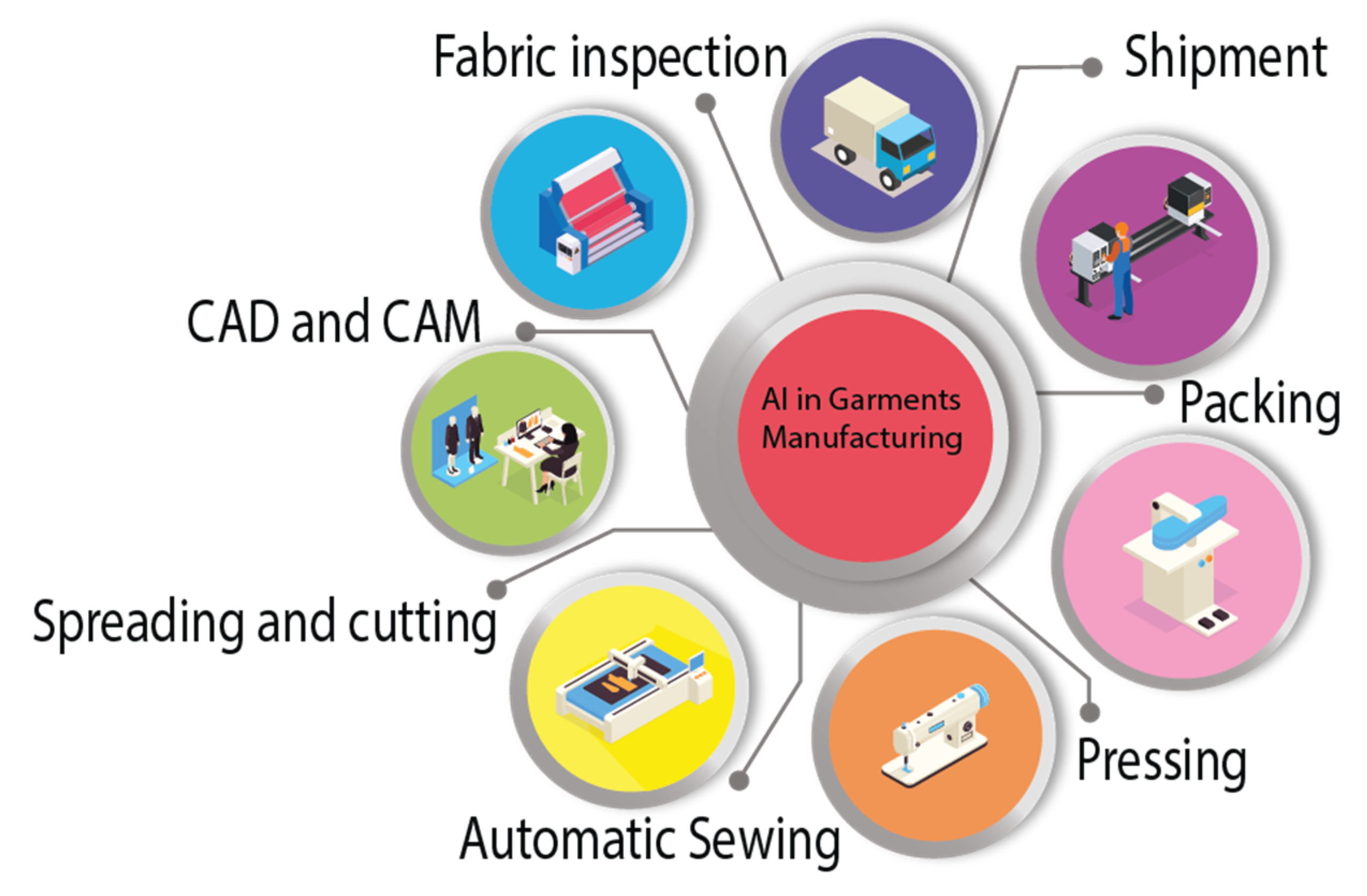

4. Artificial Intelligence in Garment Manufacturing

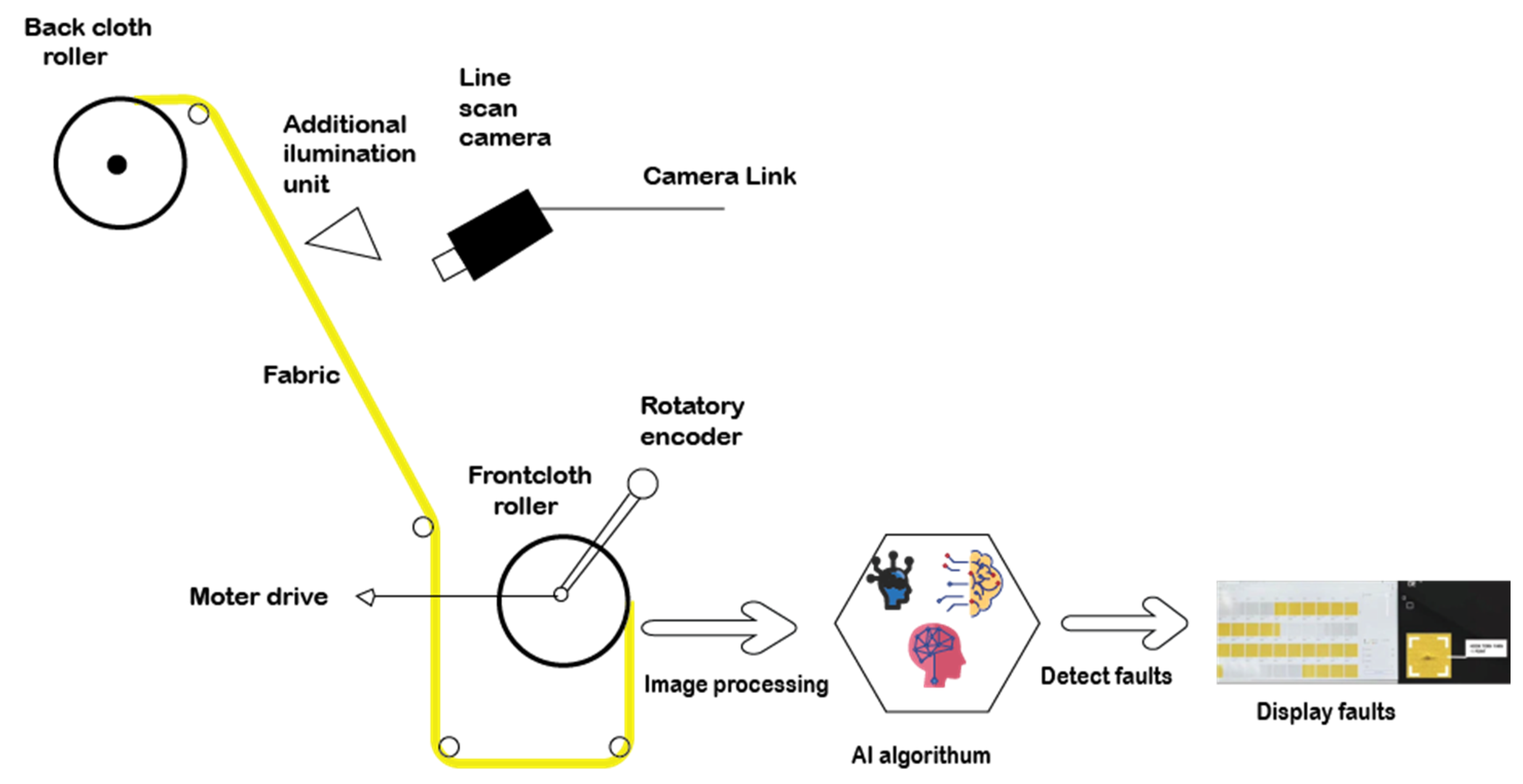

4.1. In Fabric Inspection

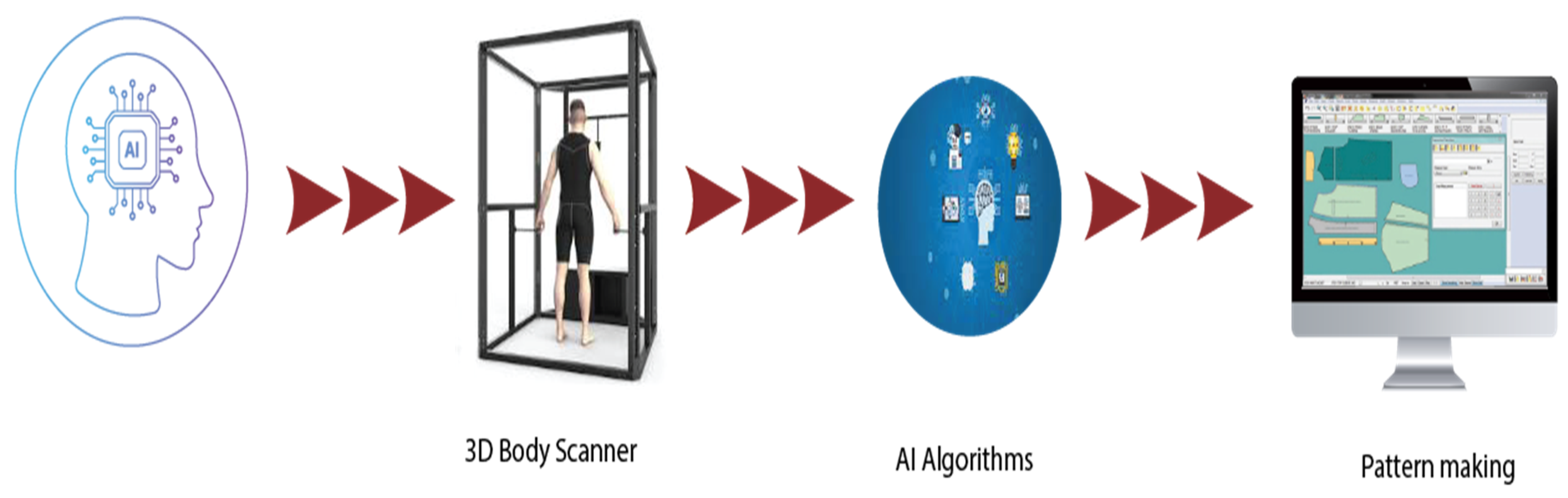

4.2. In Computer-Aided Design and Manufacturing Systems

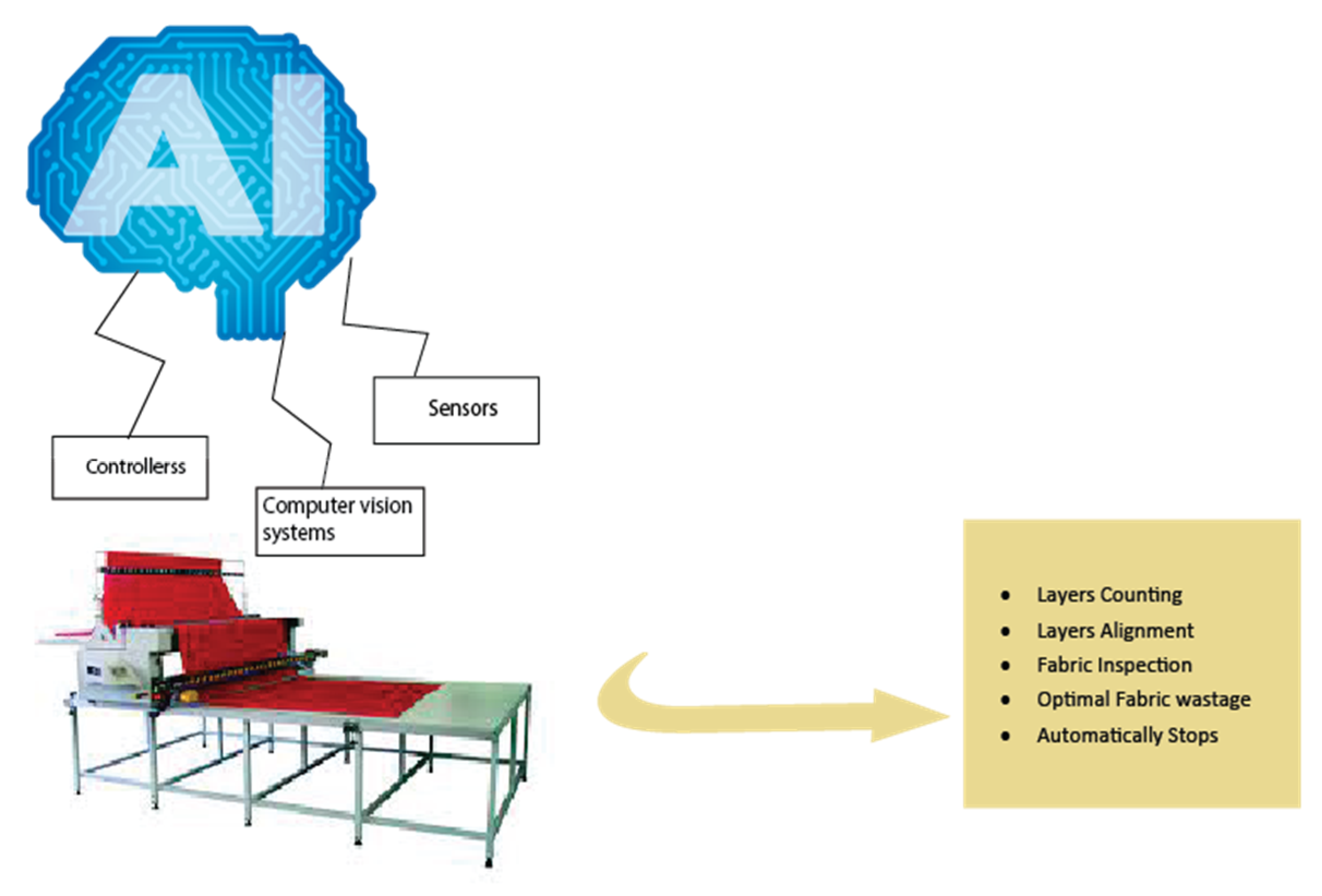

4.3. In the Spreading and Cutting of Fabrics

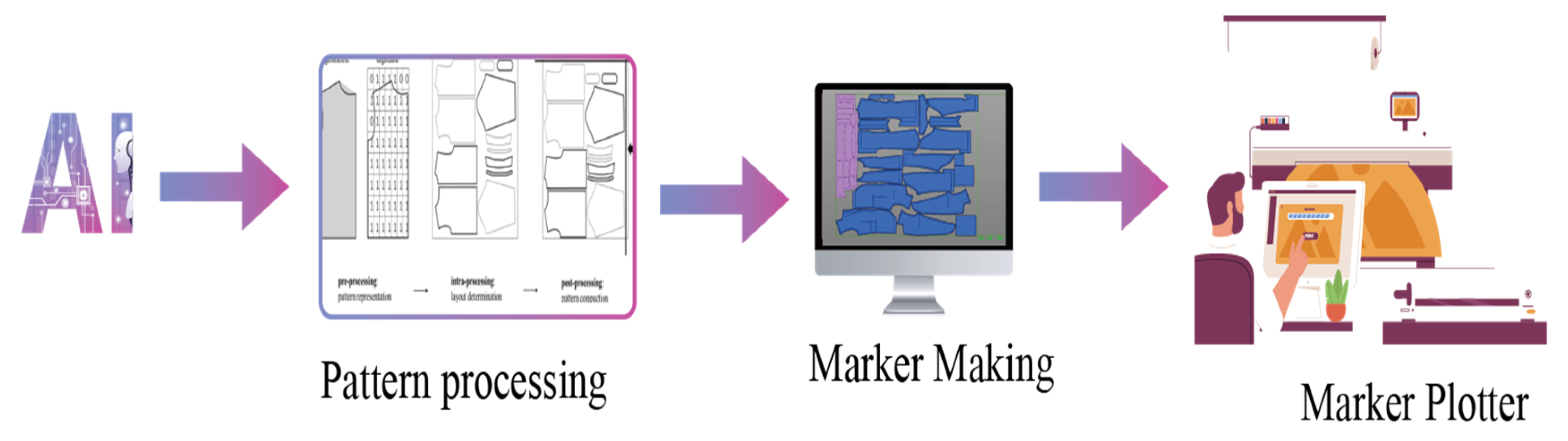

4.4. In Marker Making

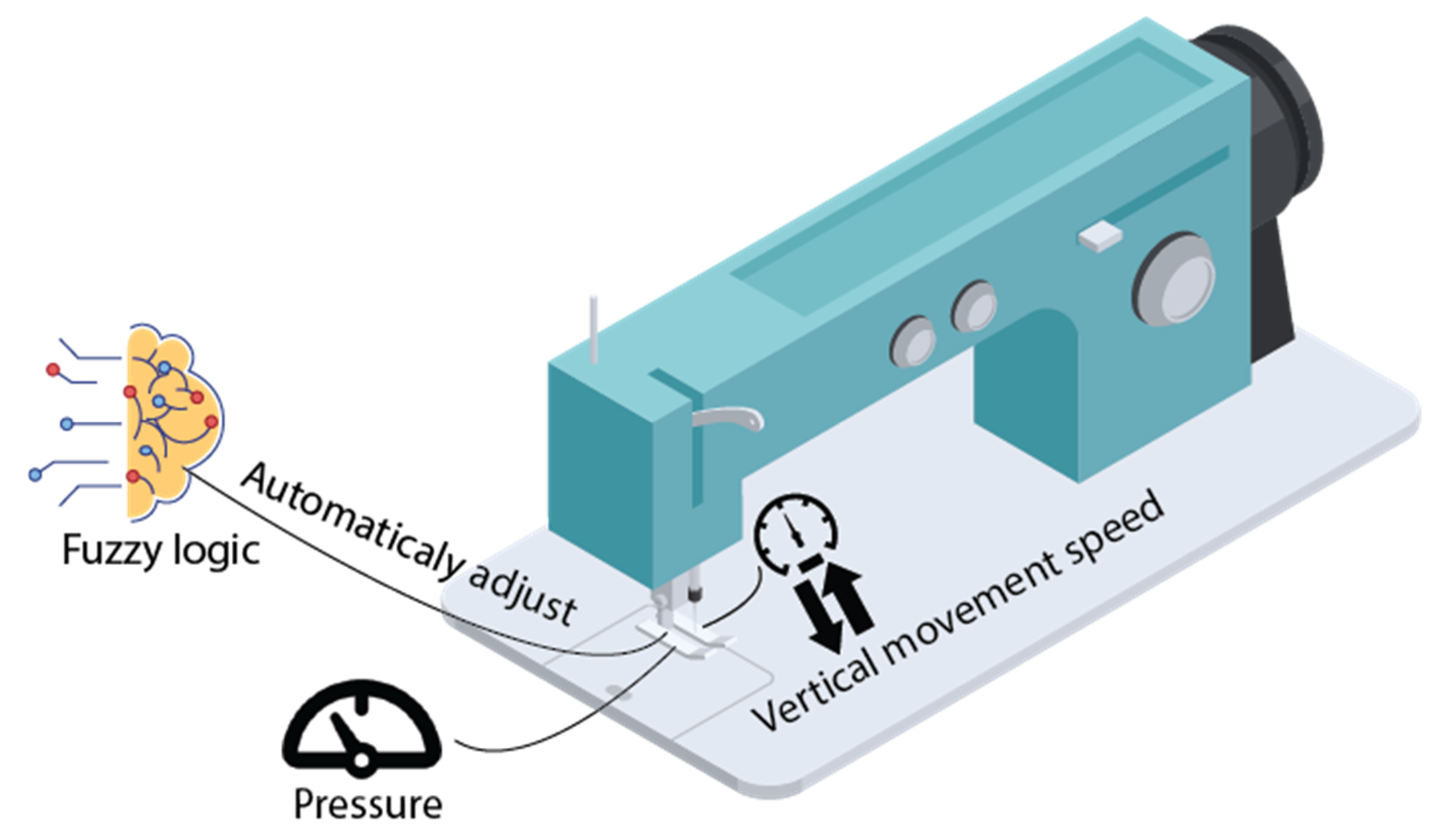

4.5. In Sewing Automation Equipment

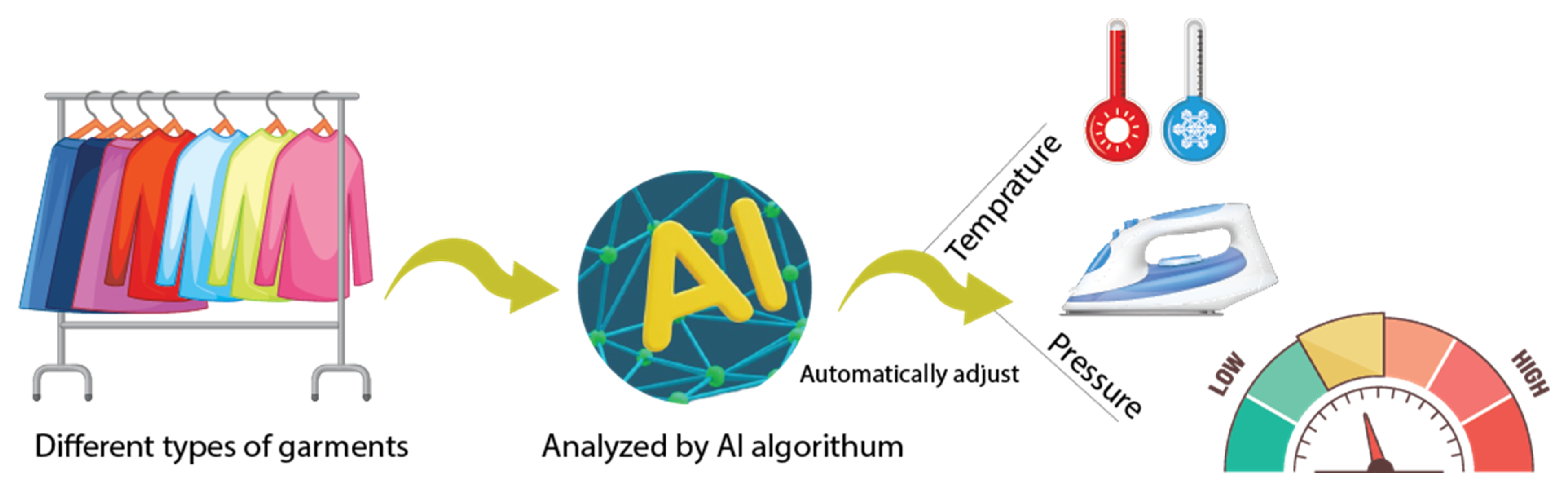

4.6. In Pressing

4.7. In Garment Packing

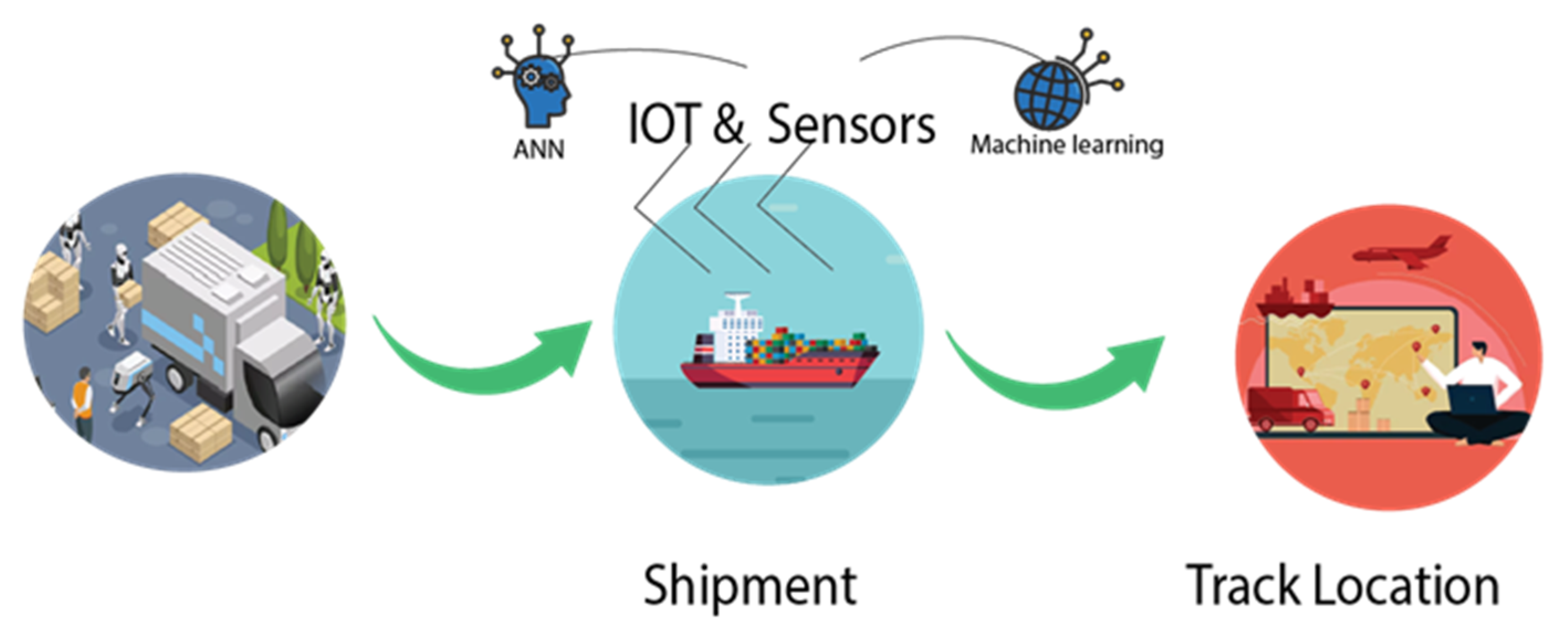

4.8. In Garment Shipment

4.9. AI for Garment Properties

4.10. AI in Industrial Engineering

4.11. AI for Optimizing Production Processes

4.12. AI for Detection of Fabric and Production Defects

4.13. AI for Seam Strength Assessment

4.13.1. Mathematical Model for Prediction of Seam Strength

4.13.2. Logic Expert System for Prediction of Seam Strength

5. Future Trends

- Data Collection and Preprocessing

- 2.

- Feature Selection and Engineering

- 3.

- Model Selection

- 4.

- Training and Validation

- 5.

- Model Evaluation

- 6.

- Deployment and Integration

- 7.

- Continuous Improvement

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mittal, U.; Sharma, D.M. Artificial Intelligence and its Application in Different Areas of Indian Economy. Int. J. Adv. Res. Sci. Commun. Technol. 2021, 4, 160–163. [Google Scholar] [CrossRef]

- Verma, M. Artificial intelligence and its scope in different areas with special reference to the field of education. Int. J. Adv. Educ. Res. 2018, 3, 2455–6157. [Google Scholar]

- Jin, D.; Ocone, R.; Jiao, K.; Xuan, J. Energy and AI. Energy AI 2020, 1, 100002. [Google Scholar] [CrossRef]

- McCarthy, J. Problems and projections in CS for the next 49 years. J. ACM 2003, 50, 73–79. [Google Scholar] [CrossRef]

- Machinery, C. Mind Association. Mind 1937, XLVI, 131–136. [Google Scholar] [CrossRef]

- Chauhan, N.; Nirmal, Y.; Nisha, A. Applications of Artificial Neural Network in Textile Engineering. Textileblog 2003, 7, 3134–3143. [Google Scholar]

- Mahesh, B. Machine Learning Algorithms—A Review. Int. J. Sci. Res. 2018, 9, 381–386. [Google Scholar]

- Shamey, R.; Hussain, T. Artificial intelligence in the colour and textile industry. Rev. Prog. Color. Relat. Top. 2003, 33, 33–45. [Google Scholar] [CrossRef]

- Lambora, A.; Gupta, K.; Chopra, K. Genetic Algorithm—A Literature Review. In Proceedings of the International Conference on Machine Learning, Big Data, Cloud and Parallel Computing: Trends, Prespectives and Prospects, COMITCon 2019, Faridabad, India, 14–16 February 2019; pp. 380–384. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; IEEE: Piscataway, NJ, USA, 1995; pp. 1942–1948. [Google Scholar] [CrossRef]

- Dorigo, M.; Birattari, M.; Stutzle, T. Ant colony optimization. IEEE Comput. Intell. Mag. 2006, 1, 28–39. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by Simulated Annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Gupta, M.M. Forty-five years of fuzzy sets and fuzzy logic—A tribute to professor Lotfi A. Zadeh (the father of fuzzy logic). Sci. Iran. 2011, 18, 685–690. [Google Scholar] [CrossRef]

- Neill, D.B. Using artificial intelligence to improve hospital inpatient care. IEEE Intell. Syst. 2013, 28, 92–95. [Google Scholar] [CrossRef]

- Deepa, S.N.; Devi, B.A. A survey on artificial intelligence approaches for medical image classification. Indian J. Sci. Technol. 2011, 4, 1583–1595. [Google Scholar] [CrossRef]

- Desbiens, A.B.; Bigué, J.P.L.; Véronneau, C.; Masson, P.; Iagnemma, K.; Plante, J.S. On the Potential of Hydrogen-Powered Hydraulic Pumps for Soft Robotics. Soft Robot. 2017, 4, 367–378. [Google Scholar] [CrossRef] [PubMed]

- Mathew, P.A.; Dunn, L.N.; Sohn, M.D.; Mercado, A.; Custudio, C.; Walter, T. Big-data for building energy performance: Lessons from assembling a very large national database of building energy use. Appl. Energy 2015, 140, 85–93. [Google Scholar] [CrossRef]

- Raza, M.Q.; Khosravi, A. A review on artificial intelligence based load demand forecasting techniques for smart grid and buildings. Renew. Sustain. Energy Rev. 2015, 50, 1352–1372. [Google Scholar] [CrossRef]

- Gu, G.H.; Noh, J.; Kim, I.; Jung, Y. Machine learning for renewable energy materials. J. Mater. Chem. A Mater. 2019, 7, 17096–17117. [Google Scholar] [CrossRef]

- Fox, M.S. Industrial Applications of Artificial Intelligence. Robotics 1986, 2, 301–311. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, G.P.; Hope, G.S. An Artificial Neural Network Based Adaptive power system stabilizer. IEEE Trans. Energy Convers. 1993, 8, 71–77. [Google Scholar] [CrossRef]

- Shubhendu, S.S.; Vijay, J. Applicability of Artificial Intelligence in Different Fields of Life. Int. J. Sci. Eng. Res. 2013, 1, 28–35. [Google Scholar]

- Mihm, B. Fast Fashion in A Flat World: Global Sourcing Strategies. Int. Bus. Econ. Res. J. 2010, 9, 55–64. [Google Scholar] [CrossRef]

- Giri, C.; Jain, S.; Zeng, X.; Bruniaux, P. A Detailed Review of Artificial Intelligence Applied in the Fashion and Apparel Industry. IEEE Access 2019, 7, 95376–95396. [Google Scholar] [CrossRef]

- Pérez, J.B.; Arrieta, A.G.; Hernández, A. Manufacturing processes in the textile industry. Expert Systems for fabrics production. Adv. Distrib. Comput. Artif. Intell. J. 2017, 6, 17–23. [Google Scholar]

- Nord, H.K. The Global Textile and Clothing Industry Post the Agreement on Textiles and Clothing; Discussion Paper No. 5; World Trade Organization: Geneva, Switzerland, 2004. [Google Scholar]

- Robotics, S. Application of Artificial Intelligence in Textile Industry. Int. J. Text. Eng. Process. 2021, 8, 49–64. [Google Scholar]

- Majumdar, A.; Ghosh, A. Yarn Strength Modelling Using Fuzzy Expert System. J. Eng. Fibers Fabr. 2008, 3, 62–69. [Google Scholar] [CrossRef]

- Agrawal, M. Automation in Textile Industry. Int. J. Text. Eng. Process. 2016, 2, 30–33. [Google Scholar]

- Sikka, M.P.; Sarkar, A.; Garg, S. Artificial intelligence (AI) in textile industry operational modernization. Res. J. Text. Appar. 2022, 28, 67–83. [Google Scholar] [CrossRef]

- Shamey, R.; Shim, W.; Joines, J.A. Development and Application of Expert Systems in the Textile Industry; Woodhead Publishing Limited: Sawston, UK, 2009. [Google Scholar] [CrossRef]

- Majumdar, A.; Ghosh, A.; Saha, S.S.; Roy, A.; Barman, S.; Panigrahi, D.; Biswas, A. Empirical modelling of tensile strength of woven fabrics. Fibers Polym. 2008, 9, 240–245. [Google Scholar] [CrossRef]

- Eltayib, H.E.; Ali, A.H.M.; Ishag, I.A. The Prediction of Tear Strength of plain weave fabric Using Linear Regression Models. Int. J. Adv. Eng. Res. Sci. 2016, 3, 151–154. [Google Scholar] [CrossRef]

- Erenler, A.; Oğulata, R.T. Prediction of Fabric Stiffness. J. Mater. Sci. Eng. A 2018, 8, 70–75. [Google Scholar] [CrossRef]

- Çeven, E.K.; Tokat, S.; Özdemir, Ö. Prediction of chenille yarn and fabric abrasion resistance using radial basis function neural network models. Neural Comput. Appl. 2007, 16, 139–145. [Google Scholar] [CrossRef]

- Beltran, R.; Wang, L.; Wang, X. Predicting the Pilling Propensity of Fabrics through Artificial Neural Network Modeling. Text. Res. J. 2005, 75, 557–561. [Google Scholar] [CrossRef]

- Dhouib, S.; Khedher, F.; Sakli, F. A new approach to predict the fabric shrinkage in denim garments after finishing treatments. J. Text. Inst. 2016, 107, 364–375. [Google Scholar] [CrossRef]

- Shi, F.; Wang, Y. Modelling crease recovery behaviour of woven fabrics. J. Text. Inst. 2009, 100, 218–222. [Google Scholar] [CrossRef]

- Ghani, S.A.; Yahya, M.F.; Gong, H. Structural equation modeling of seam failures analysis. In Proceedings of the 2012 IEEE Colloquium on Humanities, Science and Engineering (CHUSER), Kota Kinabalu, Malaysia, 3–4 December 2012; pp. 735–738. [Google Scholar] [CrossRef]

- Islam, A.; Akhter, S.; Mursalin, T.E.; Amin, M.A. Automated System to Detect Textile Defects. Statistics 2019, 50, 100. [Google Scholar]

- Fabijańska, A.; Jackowska-Strumillo, L. Image processing and analysis algorithms for yarn hairiness determination. Mach. Vis. Appl. 2012, 23, 527–540. [Google Scholar] [CrossRef]

- Golob, D.; Osterman, D.P.; Zupan, J. Determination of pigment combinations for textile printing using artificial neural networks. Fibres Text. East. Eur. 2008, 16, 93–98. [Google Scholar]

- Almodarresi, E.S.Y.; Mokhtari, J.; Almodarresi, S.M.T.; Nouri, M.; Nateri, A.S. A scanner based neural network technique for color matching of dyed cotton with reactive dye. Fibers Polym. 2013, 14, 1196–1202. [Google Scholar] [CrossRef]

- Carvalho, V.; Soares, F.; Vasconcelos, R. Artificial intelligence and image processing based techniques: A tool for yarns parameterization and fabrics prediction. In Proceedings of the 2009 IEEE Conference on Emerging Technologies and Factory Automation, Palma de Mallorca, Spain, 22–25 September 2009. [Google Scholar] [CrossRef]

- Carvalho, V.; Soares, F.; Vasconcelos, R.; Belsley, M.; Gonçalves, N. Yarn hairiness determination using image processing techniques. In ETFA2011; IEEE: New York, NY, USA, 2011; pp. 1–4. [Google Scholar]

- Chen, P.W.; Liang, T.-C.; Yau, H.-F.; Sun, W.-L.; Wang, N.-C.; Lin, H.C.; Lien, R.C. Classifying Textile Faults with a Back-Propagation Neural Network Using Power Spectra. Text. Res. J. 1998, 68, 121–126. [Google Scholar] [CrossRef]

- Ribolzi, S.; Mercklé, J.; Gresser, J.; Exbrayat, P.E. Real-Time Fault Detection on Textiles Using Opto-electronic Processing. Text. Res. J. 1993, 63, 61–71. [Google Scholar] [CrossRef]

- Nateri, A.S.; Ebrahimi, F.; Sadeghzade, N. Evaluation of yarn defects by image processing technique. Optik 2014, 125, 5998–6002. [Google Scholar] [CrossRef]

- Yao, G.; Guo, J.; Zhou, Y. Predicting the Warp Breakage Rate in Weaving by Neural Network Techniques. Text. Res. J. 2005, 75, 274–278. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Wu, J.; Xiao, C. Dyeing recipe prediction of cotton fabric based on hyperspectral colour measurement and an improved recurrent neural network. Color. Technol. 2021, 137, 166–180. [Google Scholar] [CrossRef]

- Sentilkumar, M.; Selvakumar, N. Achieving expected depth of shade in reactive dye application using artificial neural network technique. Dye. Pigment. 2006, 68, 89–94. [Google Scholar] [CrossRef]

- Cybulska, M. Assessing Yarn Structure with Image Analysis Methods1. Text. Res. J. 1999, 69, 369–373. [Google Scholar] [CrossRef]

- Das, P.P.; Chakraborty, S. Adaptive Neuro-fuzzy Inference System-based Modelling of Cotton Yarn Properties. J. Inst. Eng. India Ser. E 2021, 102, 257–272. [Google Scholar] [CrossRef]

- Jiang, H.Y.; Dong, M.; Li, W. Predicting K/S value of the reactive dyes based on RBF neural network. In Proceedings of the 2009 Asia-Pacific Conference on Information Processing, APCIP 2009, Shenzhen, China, 18–19 July 2009; Volume 1, pp. 91–93. [Google Scholar] [CrossRef]

- Hongyang, M.; Bingquan, C. Quantum network based on multiparty quantum secret sharing. In Proceedings of the SNPD 2007: Eighth ACIS International Conference on Software Engineering, Artificial Intelligence, Networking, and Parallel/Distributed Computing, Qingdao, China, 30 July–1 August 2007; Volume 2, pp. 347–351. [Google Scholar] [CrossRef]

- Kinoshita, M.; Hashimoto, Y.; Akiyama, R.; Uchiyama, S. Determination of weave type in woven fabric by digital image processing. J. Text. Mach. Soc. Jpn. 1989, 35, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Ozkaya, Y.A.; Acar, M.; Jackson, M.R. Yarn twist measurement using digital imaging. J. Text. Inst. 2010, 101, 91–100. [Google Scholar] [CrossRef]

- Carfagni, M.; Furferi, R.; Governi, L. A real-time machine-vision system for monitoring the textile raising process. Comput. Ind. 2005, 56, 831–842. [Google Scholar] [CrossRef]

- Semnani, D.; Latifi, M.; Tehran, M.A.; Pourdeyhimi, B.; Merati, A.A. Grading of Yarn Appearance Using Image Analysis and an Artificial Intelligence Technique. Text. Res. J. 2006, 76, 187–196. [Google Scholar] [CrossRef]

- Nayak, R.; Padhye, R. Introduction to Automation in Garment Manufacturing; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Zhang, Y. Development of an Intelligent Inspection System for Detecting and Classifying Garment Defects. Ph.D. Thesis, Hong Kong Polytechnic University, Hong Kong, 2013. Volume 1, pp. 1–14. Available online: https://theses.lib.polyu.edu.hk/bitstream/200/7399/1/b26818164.pdf (accessed on 5 January 2024).

- Nayak, R.; Padhye, R. Artificial Intelligence and Its Application in the Apparel Industry; Woodhead Publishing: Amsterdam, The Netherlands, 2017; pp. 109–138. [Google Scholar] [CrossRef]

- Daanen, H.A.M.; Psikuta, A. 3D Body Scanning; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 1. [Google Scholar] [CrossRef]

- Nayak, R.; Padhye, R. Automation in Garment Manufacturing; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar] [CrossRef]

- Noor, A.; Saeed, M.A.; Ullah, T.; Uddin, Z.; Khan, R.M.W.U. A review of artificial intelligence applications in apparel industry. J. Text. Inst. 2022, 113, 505–514. [Google Scholar] [CrossRef]

- Palmer, R.N. Review of Artificial Intelligence. Int. J. Sci. Res. Sci. Eng. Technol. 2020, 7, 143–171. [Google Scholar] [CrossRef]

- Islam, M.M.; Hossain, M.T.; Repon, M.R.; Islam, T.; Kibria, G.; Jalil, M.A. Seam Strength Prediction for Different Stitch Types Considering Stitch Density of Cotton Woven Fabrics. Text. Leather Rev. 2022, 5, 53–69. [Google Scholar] [CrossRef]

- Yildiz, Z.; Dal, V.; Ünal, M.; Yildiz, K. Use of artificial neural networks for modelling of seam strength and elongation at break. Fibres Text. East. Eur. 2013, 101, 117–123. [Google Scholar]

- Kim, H.; Jung, W.K.; Park, Y.C.; Lee, J.W.; Ahn, S.H. Broken stitch detection method for sewing operation using CNN feature map and image-processing techniques. Expert. Syst. Appl. 2022, 188, 116014. [Google Scholar] [CrossRef]

- Mariem, B.; Wissal, M.; Faouzi, K.; Boubaker, J.; Adolphe, D. A Study of the Consumption of Sewing Threads for Women’s Underwear: Bras and Panties. Autex Res. J. 2020, 20, 299–311. [Google Scholar] [CrossRef]

- Sarah, M.; Adolphe, D.C.; Boubaker, J. Prediction of Sewing Thread Consumption for Over-Edge Stitches Class 500 Using Geometrical and Multi-Linear Regression Models. Autex Res. J. 2019, 21, 2019. [Google Scholar] [CrossRef]

- Sarah, M.; Boubaker, J.; Dominique, A.C. Determination of Sewing Thread Consumption for 602, 605, and 607 Cover Stitches Using Geometrical and Multi-Linear Regression Models. Autex Res. J. 2022, 22, 497–508. [Google Scholar] [CrossRef]

- Jaouachi, B.; Khedher, F.; Adolphe, D. Compared basic stitch’s consumptions using image analysis, geometrical modelling and statistical techniques. J. Text. Inst. 2019, 110, 1280–1292. [Google Scholar] [CrossRef]

- Javed, Z.; Ahmad, F.; Khan, Q.; Naeem, M.S.; Javaid, M.U.; Jabbar, A.; Hassan, Z.; Karahan, M. Modeling the consumption of sewing thread for stitch class 301 through image analysis by using Fourier series. Text. Res. J. 2022, 92, 2792–2799. [Google Scholar] [CrossRef]

- Lee, C.K.H.; Choy, K.L.; Ho, G.T.S.; Lam, C.H.Y. A slippery genetic algorithm-based process mining system for achieving better quality assurance in the garment industry. Expert. Syst. Appl. 2016, 46, 236–248. [Google Scholar] [CrossRef]

- Chen, J.C.; Hsaio, M.H.; Chen, C.C.; Sun, C.J. A grouping genetic algorithm for the assembly line balancing problem of sewing lines in garment industry. In Proceedings of the 2009 International Conference on Machine Learning and Cybernetics, Baoding, China, 12–15 July 2009; Volume 5, pp. 2811–2816. [Google Scholar] [CrossRef]

- Babu, M.M.; Akter, S.; Rahman, M.; Billah, M.M.; Hack-Polay, D. The role of artificial intelligence in shaping the future of Agile fashion industry. Prod. Plan. Control 2022, 1–15. [Google Scholar] [CrossRef]

- Ghani, S.A. Seam Performance: Analysis and Modelling; The University of Manchester: Manchester, UK, 2011. [Google Scholar]

- Hui, P.C.L.; Chan, K.C.C.; Yeung, K.W.; Ng, F.S.F. Application of artificial neural networks to the prediction of sewing performance of fabrics. Int. J. Cloth. Sci. Technol. 2007, 19, 291–318. [Google Scholar] [CrossRef]

- Xu, Y.; Thomassey, S.; Zeng, X. AI for Apparel Manufacturing in Big Data Era: A Focus on Cutting and Sewing. Artif. Intell. Fash. Ind. Big Data Era 2018, 7, 125–151. [Google Scholar] [CrossRef]

- Rolich, T.; Šajatović, A.H.; Pavlinić, D.Z. Application of artificial neural network (ANN) for prediction of fabrics’ extensibility. Fibers Polym. 2010, 11, 917–923. [Google Scholar] [CrossRef]

- Gong, R.H.; Chen, Y. Predicting the Performance of Fabrics in Garment Manufacturing with Artificial Neural Networks. Text. Res. J. 1999, 69, 477–482. [Google Scholar] [CrossRef]

- Cao, H.; Ji, X. Prediction of garment production cycle time based on a neural network. Fibres Text. East. Eur. 2021, 29, 8–12. [Google Scholar] [CrossRef]

- Shao, Y.; Ji, X.; Zheng, M.; Chen, C. Prediction of Standard Time of the Sewing Process using a Support Vector Machine with Particle Swarm Optimization. Autex Res. J. 2022, 22, 290–297. [Google Scholar] [CrossRef]

- Xu, Y.; Thomassey, S.; Zeng, X. An Application of Machine Learning to Marker Prediction in Garment Industry. In Proceedings of the 3rd International Conference on Applications of Intelligent Systems, Las Palmas de Gran Canaria, Spain, 7–12 January 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Abeysooriya, R.P.; Wickramasinghe, G.L.D. Regression model to predict thread consumption incorporating thread-tension constraint: Study on lock-stitch 301 and chain-stitch 401. Fash. Text. 2014, 1, 14. [Google Scholar] [CrossRef]

- Ersöz, T.; Zahoor, H.; Ersöz, F. Fabric and Production Defect Detection in the Apparel Industry Using Data Mining Algorithms. Int. J. 3D Print. Technol. Digit. Ind. 2021, 5, 742–757. [Google Scholar] [CrossRef]

- Akter, M.; Khan, M.M.R. The effect of stitch types and sewing thread types on seam strength for cotton apparel. Int. J. Sci. Eng. Res. 2015, 6, 198–205. [Google Scholar]

- Hu, J. Structure and Mechanics of Woven Fabrics; Woodhead Publishing in Textiles; Woodhead Publishing: Cambridge, UK, 2004. [Google Scholar]

- Hasan, M.Z. Comparative Study on the Effect of Sewing Thread Count for Different Types of Seam Strength. Eur. J. Adv. Eng. Technol. 2016, 3, 1–7. [Google Scholar]

- Shishoo, L.R. International journal of clothing science and technology—Editorial. Int. J. Cloth. Sci. Technol. 2006, 18, 220–224. [Google Scholar]

- Carr, H.; Latham, B. The Technology of Clothing Manufacture; Wiley-Blackwell: Hoboken, NJ, USA, 1988. [Google Scholar]

- Hossain, A.; Moshwan, M.; Asif, A.K.M.A.H. Analysis of Seam Strength on Denim Fabric by Employing Different Sewing Parameters through Chain Stitch. IOSR J. Polym. Text. Eng. 2023, 10, 11–16. [Google Scholar]

- Mehta, P.V.; Bhardwaj, S.K. National Institute of Fashion Technology (New Delhi). In Managing Quality in the Apparel Industry; H.S. Poplai for New Age International (P) Ltd.: New Delhi, India, 1998. [Google Scholar]

- de Fi, E.S.M.; Corona, J.E.; Oliva, A.I.; Avilés, F.; González-Hernández, J. Revista mexicana de física. Rev. Mex. Física 2010, 56, 317–322. [Google Scholar]

- Crouse, C.R.U.E. Application of Value Engineering. Pacer 1969, 1, 17–45. [Google Scholar]

- Ali, N.; Rehan, A.M.; Ahmed, Z.; Memon, H.; Hussain, A. BUITEMS Quality & Excellence in Education Effect of Different Types of Seam, Stitch Class and Stitch Density on Seam Performance. J. Appl. Emerg. Sci. 2014, 5, 32–43. [Google Scholar]

- Efird, A. Stitches per Inch—What You Should Know; American & Efird, Inc.: Mount Holly, NC, USA, 2016; pp. 7–10. [Google Scholar]

- Buykin, A.I.; Verkhovsky, A.B.; Asavin, A.M.; Kogarko, L.N. Ar and N Isotopic Composition and Elemental Ratios of Ar, N, He, and C in Fluid Inclusions in Ultramafic Rocks of the Guli Massif (Polar Siberia). Geochem. Int. 2020, 58, 1199–1207. [Google Scholar] [CrossRef]

- Nayak, R.; Padhye, R.; Dhamija, S.; Kumar, V. Sewability of air-jet textured sewing threads in denim. J. Text. Appar. Technol. Manag. 2013, 8, 1–11. [Google Scholar]

- Ferreira, F.B.N.; Harlock, S.C.; Grosbera, P. A Study of Thread Tensions on a Lockstitch Sewing Machine (Part III) Further Stitch Formation Analysis. Int. J. Cloth. Sci. Technol. 1994, 6, 39–42. [Google Scholar] [CrossRef]

- Kakde, M. Effect of Sewing Parameters on Seam Strength and Seam Efficiency. Trends Text. Eng. Fash. Technol. 2018, 4, 398–402. [Google Scholar] [CrossRef]

- Sarhan, T.M.A.L. Interaction between sewing thread size and stitch density and its effect on the seam. J. Appl. Sci. Res. 2013, 9, 4548–4557. [Google Scholar]

- Jiang, J.; Trundle, P.; Ren, J.; Cheng, Y.L.; Lee, C.Y.; Huang, Y.L.; Buckner, C.A.; Lafrenie, R.M.; Dénommée, J.A.; Caswell, J.M.; et al. An Introduction to Actinobacteria. Intech 2010, 34, 57–67. [Google Scholar]

- Tsui, W.C. Aspects of Seam Strength Prediction. Ph.D. Thesis, University of Huddersfield, Huddersfield, UK, 1982. [Google Scholar]

- Ünal, B.Z. The prediction of seam strength of denim fabrics with mathematical equations. J. Text. Inst. 2012, 103, 744–751. [Google Scholar] [CrossRef]

- Sarkar, J.; Al Faruque, M.A.; Mondal, M.S. Modeling the seam strength of denim garments by using fuzzy expert system. J. Eng. Fiber. Fabr. 2021, 16, 1558925021988976. [Google Scholar] [CrossRef]

- Kusiak, A. Convolutional and generative adversarial neural networks in manufacturing. Int. J. Prod. Res. 2020, 58, 1594–1604. [Google Scholar] [CrossRef]

- Anantrasirichai, N.; Bull, D. Artificial intelligence in the creative industries: A review. Artif. Intell. Rev. 2022, 55, 589–656. [Google Scholar] [CrossRef]

- Yang, Y. Current Trends in Deep Learning. Adv. Eng. Technol. Res. 2023, 5, 422. [Google Scholar] [CrossRef]

- Duan, G.; Lin, M.; Wang, H.; Xu, Z. Deep Neural Networks for Stock Price Prediction. In Proceedings of the 2022 14th International Conference on Computer Research and Development (ICCRD), Shenzhen, China, 7–9 January 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 65–68. [Google Scholar] [CrossRef]

- Ahmadi, A.; Tani, J. A Novel Predictive-Coding-Inspired Variational RNN Model for Online Prediction and Recognition. Neural Comput. 2019, 31, 2025–2074. [Google Scholar] [CrossRef] [PubMed]

- Soloviev, V.; Chernyshenko, V.; Feklin, V.; Zolotareva, E.; Titov, N. Generative Adversarial Neural Networking of Agents; IGI Global: Hershey, PA, USA, 2020; pp. 107–120. [Google Scholar] [CrossRef]

- Cai, X.; Lan, Y.; Zhang, Z.; Wen, J.; Cui, Z.; Zhang, W. A Many-Objective Optimization Based Federal Deep Generation Model for Enhancing Data Processing Capability in IoT. IEEE Trans. Ind. Inform. 2023, 19, 561–569. [Google Scholar] [CrossRef]

- Polamuri, S.R.; Srinivas, D.K.; Mohan, D.A.K. Multi-model generative adversarial network hybrid prediction algorithm (MMGAN-HPA) for stock market prices prediction. J. King Saud Univ. Comput. Inf. Sci. 2022, 34, 7433–7444. [Google Scholar] [CrossRef]

- Tovar, W. Deep Learning Based on Generative Adversarial and Convolutional Neural Networks for Financial Time Series Predictions. arXiv 2020, arXiv:2008.08041. [Google Scholar]

- Śmietanka, M.; Koshiyama, A.; Treleaven, P. Algorithms in future insurance markets. Int. J. Data Sci. Big Data Anal. 2021, 1, 1–19. [Google Scholar] [CrossRef]

| Sr. | AI Type | Method | Application | Ref. |

|---|---|---|---|---|

| 1. | Structural Equation Modeling | Mathematical analysis, finite element analysis, and ANN software, Python 3.12.0. | The mechanical properties of thread and fabric that influence seam strength in apparel manufacturing were identified with this technique. | [39] |

| 2. | Artificial Neural Network | Digital fabric images, fully connected multi-layered ANN | Most common textile defects were identified using this technique. | [40] |

| 3. | Image Processing | Image quantitative analysis, analysis algorithms | This technique was used to develop a more universal and accurate method for measuring yarn hairiness. | [41] |

| 4. | Artificial Neural Network | Counter-propagation neural networks | This was used to identify the combinations of dyes and to determine the appropriate dyes for achieving a required color in textile printing. | [42] |

| 5. | Artificial Neural Network | Multi-layered perception neural network model, scanner-based NN technique | This technique was used for the prediction of color on cotton fabric using different dyes. | [43] |

| 6. | Artificial Neural Networks and Genetic Algorithms | Image processing algorithms | This was used for characterizing yarn properties accurately and to predict the visual appearance of fabrics. | [44] |

| 7. | Image Processing | Algorithms and computational methods to analyze and manipulate images | Using this technique, the coefficient of yarn hairiness was determined automatically. | [45] |

| 8. | Artificial Neural Network | Fourier transform analysis and back propagation neural network | This was used to detect and classify different textile defects. | [46] |

| 9. | Opto-electronic Processing Technique | Computational modeling, MATLAB software | This technique was used to detect faults in fabric during the process of weaving. | [47] |

| 10. | Image Processing | Image acquisition and mathematical analysis | This was used to identify and classify different types of yarn defects, such as neps, snarls, thick and thin places, and slubs. | [48] |

| 11. | Artificial Neural Network | Back propagation algorithm and multi-layer perception neural network | Evaluation of warp breakage rates was undertaken using this technique in textile weaving. | [49] |

| 12. | Artificial Neural Network | Recurrent neural network, long short-term memory | This technique was used to improve the accuracy of dyeing recipe prediction and to avoid the metamerism phenomenon. | [50] |

| 13. | Artificial Neural Network | Feed forward back propagation network | This was used to estimate the necessary dyeing time for achieving the desired color intensity for reactive HE dyes on cotton fabric. | [51] |

| 14. | Image Analysis | Image processing algorithm and mathematical analysis | This technique was used to estimate the fundamental structural characteristics of yarn thickness, hairiness, and twist. | [52] |

| 15. | Artificial Neural Network | Neuro-fuzzy inference system and computational modeling | This technique was used to predict the yarn strength, concerning fiber strength, elongation, uniformity index, short fiber content, fineness, and upper half mean length. | [53] |

| 16. | Artificial Neural Network | Radial basis neural network modeling | This was used to predict the K/S value of reactive dyes used in fabric dyeing. | [54] |

| 17. | Artificial Neural Network and Genetic Algorithms | Radial basis neural network modeling | Using this technique, an optimal formula for color coordination was developed by using the nonlinear correlation between dye concentration and textile reflectivity. | [55] |

| 18. | Digital Image Processing | Two-dimensional Fourier transformation patterns | This was used to determine weave types and to detect the characteristic patterns of woven fabrics. | [56] |

| 19. | Image Analysis | Image processing algorithm | This technique was used to measure the yarn twist. | [57] |

| 20. | Image Analysis | Image acquisition and image processing | This was used to monitor the textile raising process, i.e., assessment of the elevation and density of fibers protruding from an elevated fabric surface (pile). | [58] |

| 21. | Artificial Neural Network | Perceptron artificial neural network and image processing | This was used to detect and classify the yarn faults and to grade them based on appearance. | [59] |

| Sr. | AI Type | Method | Application | Ref. |

|---|---|---|---|---|

| 1. | Artificial Neural Network | Statistical analysis, prediction model | This technique was used to predict the seam strength for various stitch types in cotton plain woven fabric, concerning stitch density. | [67] |

| 2. | Artificial Neural Network | ANN parallel computational models(radial-based function and multi-layered perception neural network modeling) | A model based on ANN was developed using this technique; it can accurately predict the values of seam elongation and seam strength. | [68] |

| 3. | Image Processing | Deep learning method, convolutional neural network | This was used for the detection of some sewing defects, like broken stitches. | [69] |

| 4. | Regression Analysis | Statistical multi-linear regression method | The quantity of the sewing thread required for women’s undergarments was predicted using this technique. | [70] |

| 5. | Regression Analysis | Geometrical and statistical multi-linear regression method | The quantity of the sewing thread required for over-edge stitch class 500 was predicted using this technique. | [71] |

| 6. | Regression Analysis | Geometrical and statistical multi-linear regression method | The quantity of the sewing thread required for cover stitches class 602, 605, and 607 was predicted using this technique. | [72] |

| 7. | Image Analysis | Geometrical modeling and statistical technique | This was used to analyze the consumption of sewing thread for lockstitches and chain stitches of different classes. | [73] |

| 8. | Image Analysis | Fourier series | This was used to develop a mathematical model for the consumption of sewing thread required for stitch class 301. | [74] |

| 9. | Genetic Algorithms | Data mining technique (fuzzy association rule mining technique) | Using this technique, a genetic-algorithm-based process mining system was developed to improve the level of quality assurance in the garment industry. | [75] |

| 10. | Grouping Genetic Algorithm | GGA-based computational model | This technique was used to solve the line balancing problem by allocating the tasks to each workstation in a way that minimizes the workload imbalance. | [76] |

| 11. | Machine Learning and Deep Learning | QSR NVivo 11 software (11.0) for analyzing the data | This was used to implement AI in the textile and apparel industry, specifically in agile manufacturing. | [77] |

| 12. | Regression Analysis | Statistical regression method | This was used to predict the tendency of a fabric to pucker, concerning fabric thickness, compressibility, shear and bending properties, tear strength, and air permeability. | [78] |

| 13. | Artificial Neural Network | Back propagation neural network model with 21 input units and 16 output units | This technique was used to predict the sewing performance of apparel, concerning fabric weave structure, yarn count, fabric weight, formability, and extensibility. | [79] |

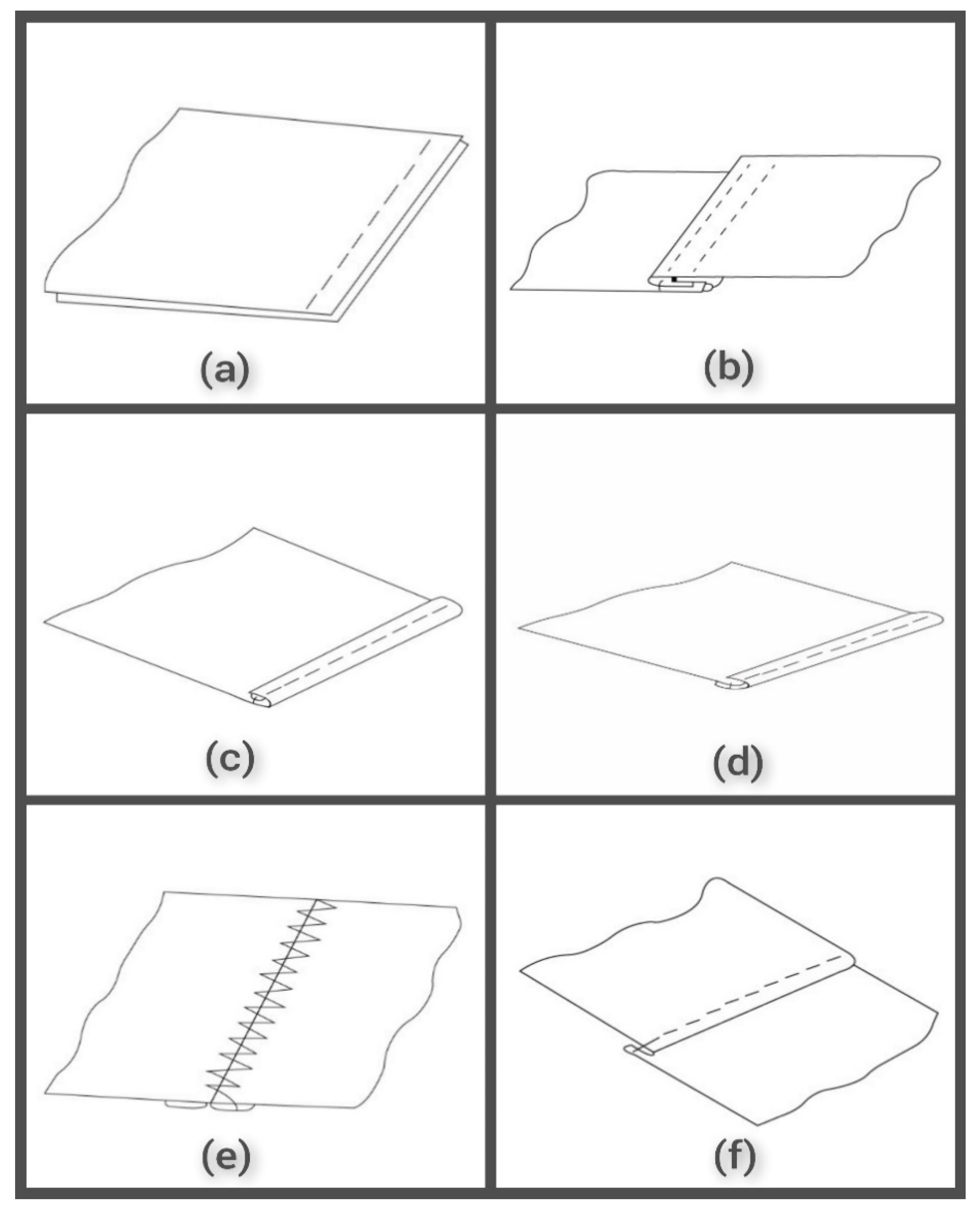

| Seam Class | Seam Type | Subgroup No. of Seam Type |

|---|---|---|

| SS | Superimposed seam | 55 |

| LS | Lapped seam | 101 |

| BS | Bound seam | 18 |

| FS | Flat seam | 6 |

| EF | Edge finishing | 32 |

| OS | Ornamental finishing | 8 |

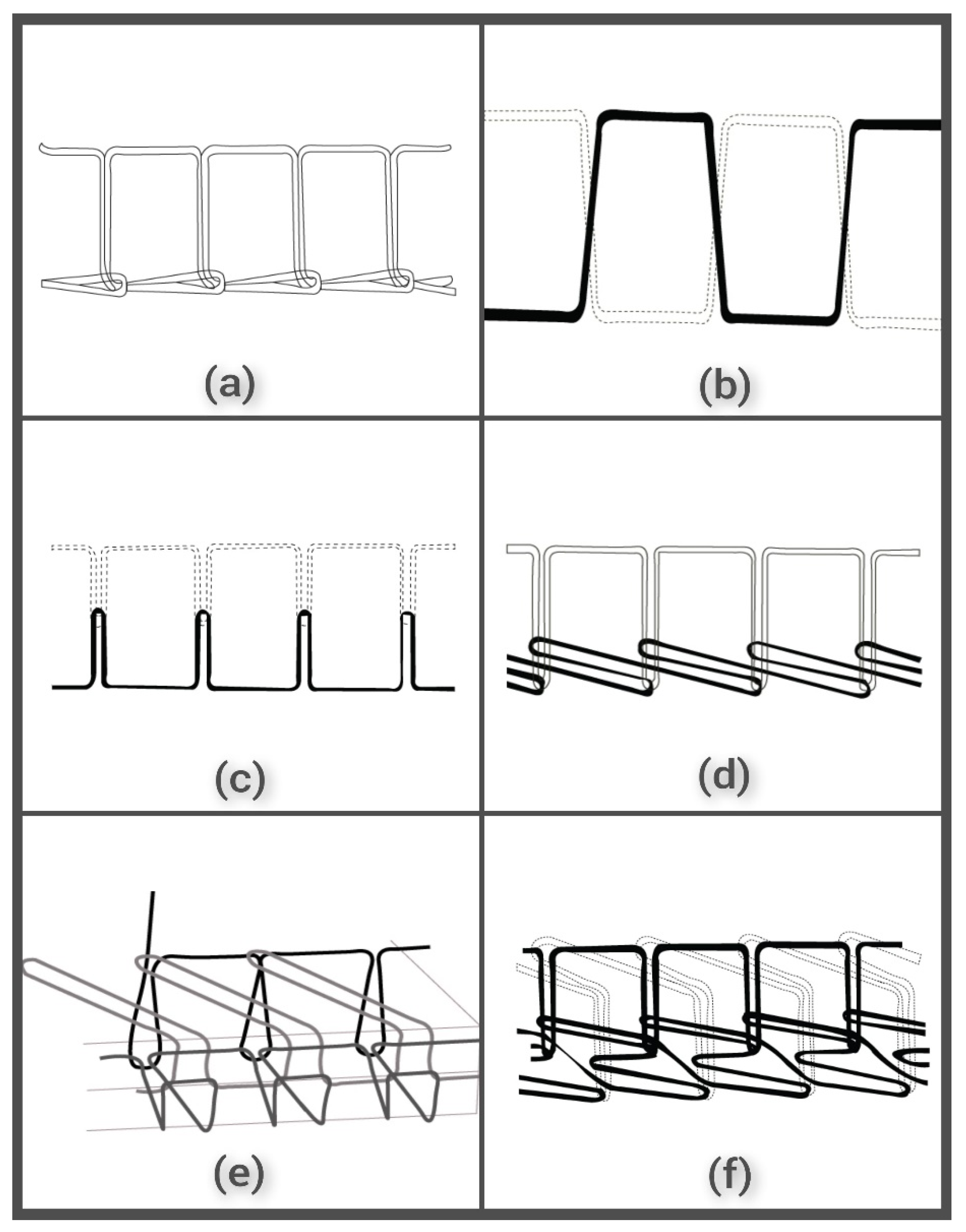

| Stitch Class | Stitch Type | Subgroup Numbers of Seam Types | Subgroups of Stitch Types |

|---|---|---|---|

| 100 | Chain Stitch with one needle thread | 5 | 101–105 |

| 200 | Hand Stitch | 5 | 201–205 |

| 300 | Lock Stitch | 16 | 301–316 |

| 400 | Multi-Thread Chain Stitch | 11 | 401–411 |

| 500 | Overlock Stitch | 22 | 501–522 |

| 600 | Covering Chain Stitch | 10 | 601–622 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zulfiqar, A.; Manzoor, T.; Ijaz, M.B.; Nawaz, H.H.; Ahmed, F.; Akhtar, S.; Iftikhar, F.; Nawab, Y.; Khan, M.Q.; Umar, M. Artificial-Neural-Network-Based Predicted Model for Seam Strength of Five-Pocket Denim Jeans: A Review. Textiles 2024, 4, 183-217. https://doi.org/10.3390/textiles4020012

Zulfiqar A, Manzoor T, Ijaz MB, Nawaz HH, Ahmed F, Akhtar S, Iftikhar F, Nawab Y, Khan MQ, Umar M. Artificial-Neural-Network-Based Predicted Model for Seam Strength of Five-Pocket Denim Jeans: A Review. Textiles. 2024; 4(2):183-217. https://doi.org/10.3390/textiles4020012

Chicago/Turabian StyleZulfiqar, Aqsa, Talha Manzoor, Muhammad Bilal Ijaz, Hafiza Hifza Nawaz, Fayyaz Ahmed, Saeed Akhtar, Fatima Iftikhar, Yasir Nawab, Muhammad Qamar Khan, and Muhammad Umar. 2024. "Artificial-Neural-Network-Based Predicted Model for Seam Strength of Five-Pocket Denim Jeans: A Review" Textiles 4, no. 2: 183-217. https://doi.org/10.3390/textiles4020012

APA StyleZulfiqar, A., Manzoor, T., Ijaz, M. B., Nawaz, H. H., Ahmed, F., Akhtar, S., Iftikhar, F., Nawab, Y., Khan, M. Q., & Umar, M. (2024). Artificial-Neural-Network-Based Predicted Model for Seam Strength of Five-Pocket Denim Jeans: A Review. Textiles, 4(2), 183-217. https://doi.org/10.3390/textiles4020012