Effect of Number of Layers on Tensile and Flexural Behavior of Cementitious Composites Reinforced with a New Sisal Fabric

Abstract

1. Introduction

2. Materials and Methods

2.1. Cement Matrix

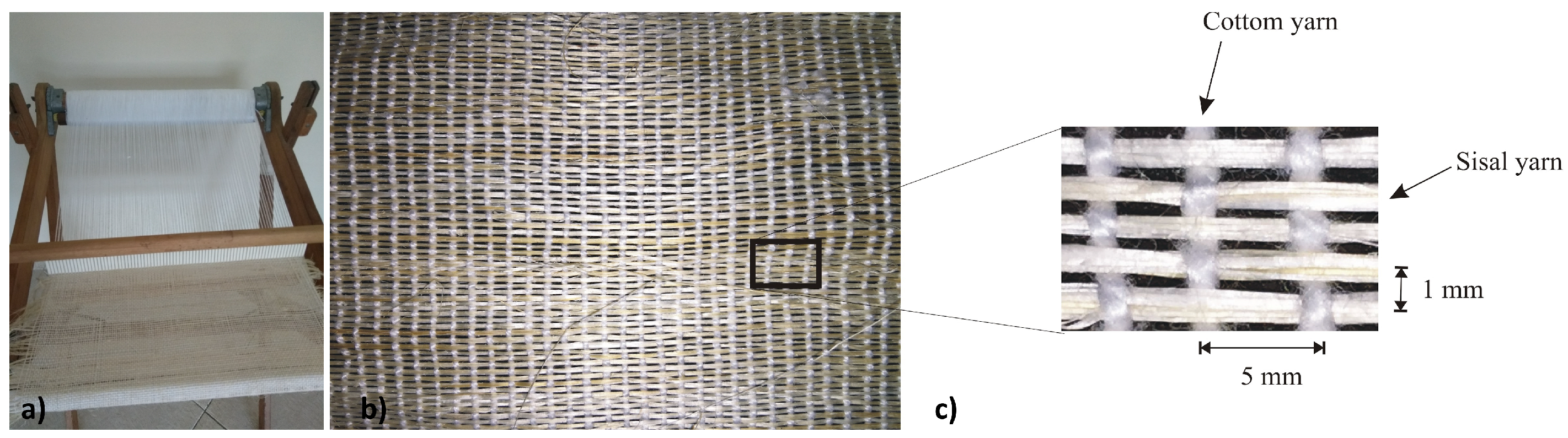

2.2. Natural Reinforcement

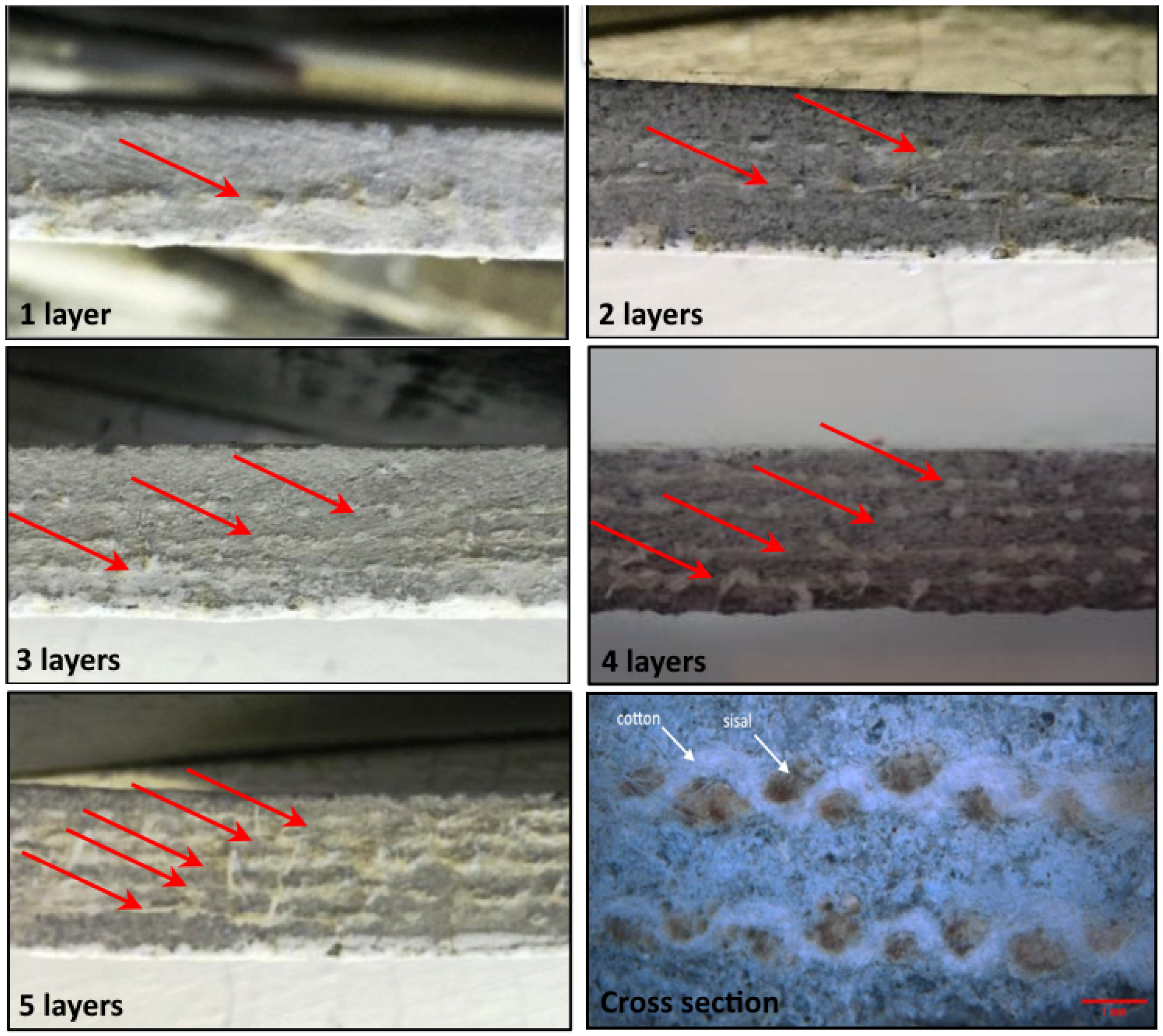

2.3. Production Method

2.4. Test Method

3. Results

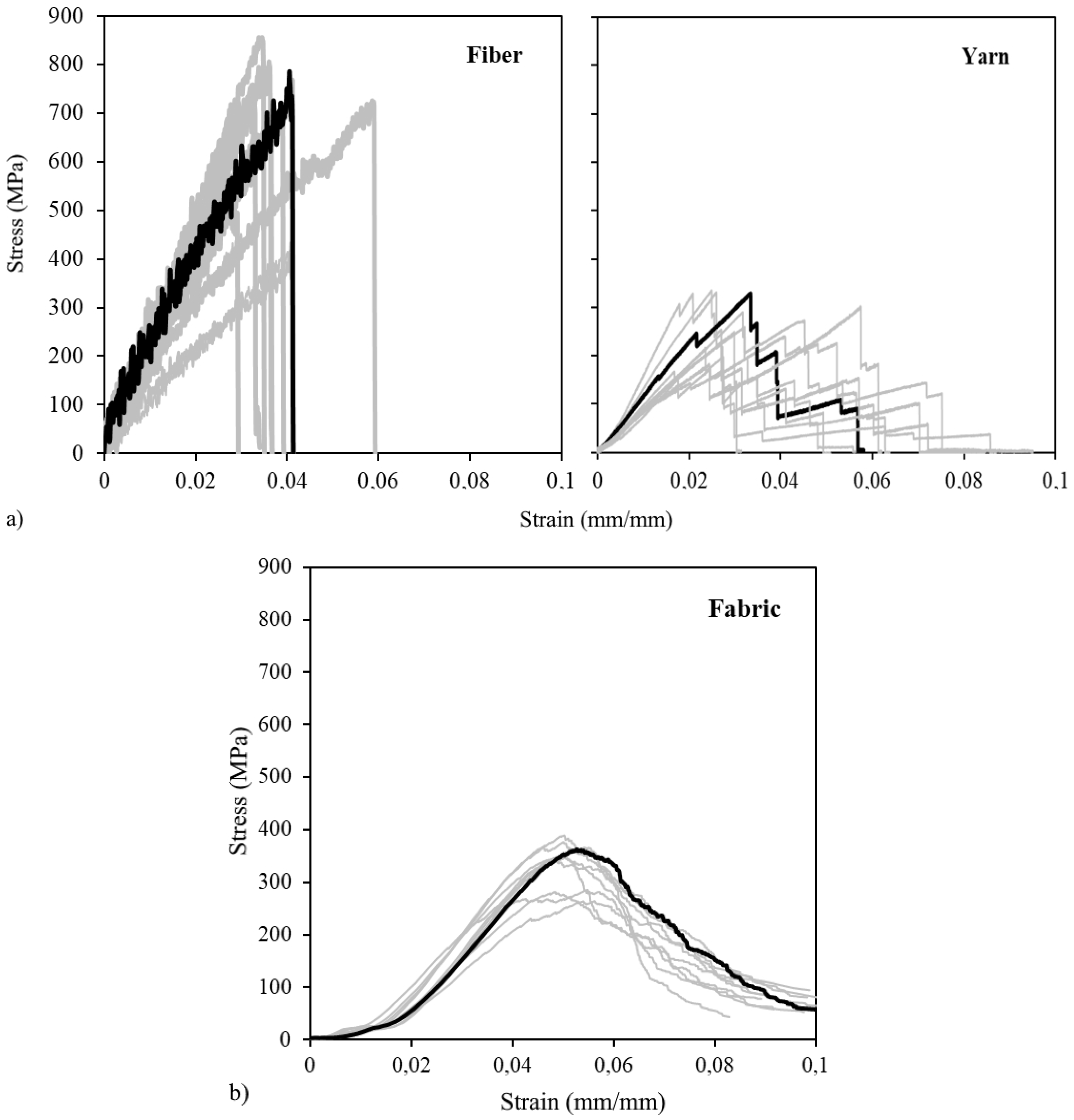

3.1. Tensile Behavior of Reinforcement

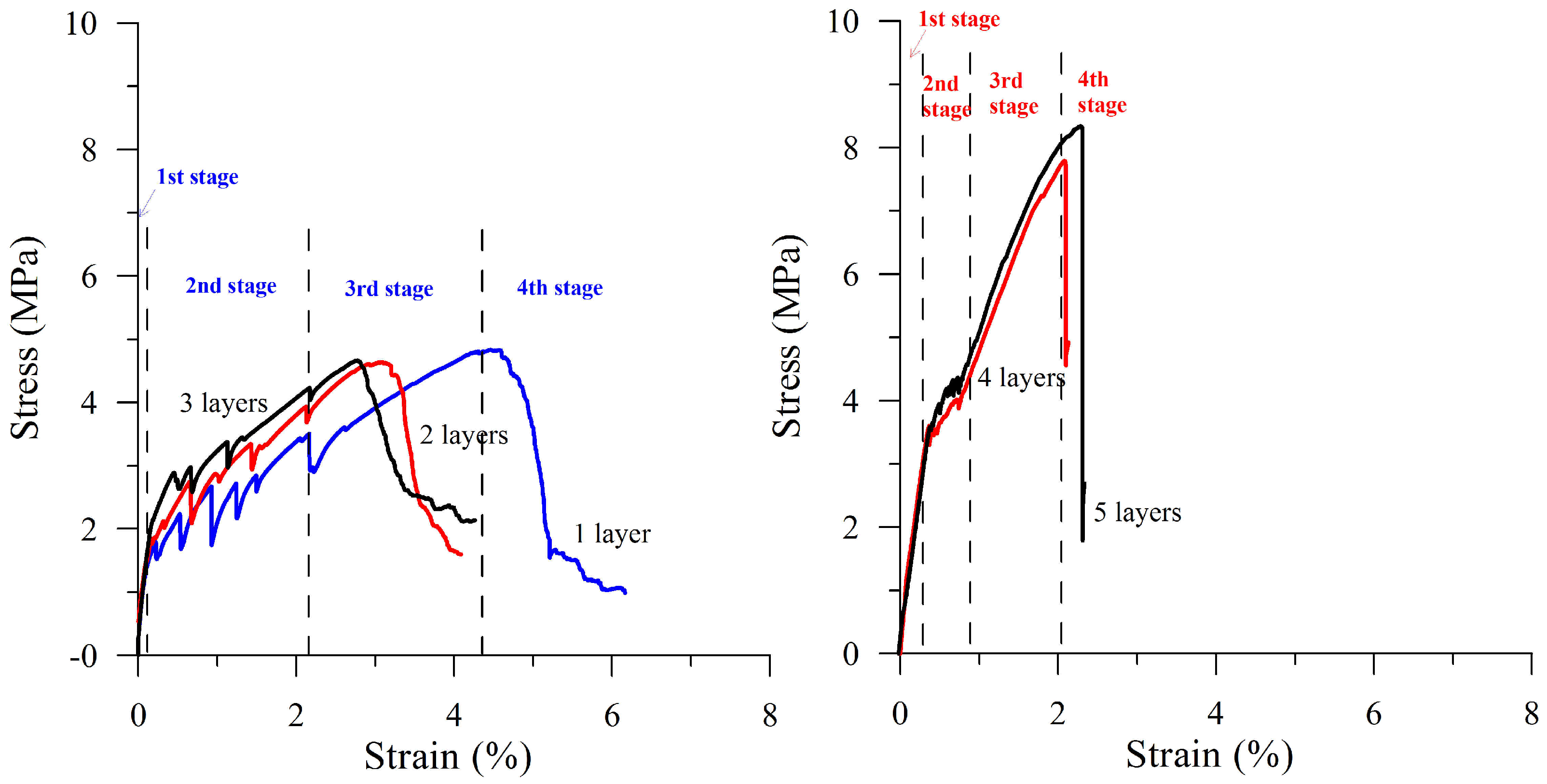

3.2. Tensile Stress-Strain Behaviour of Composite

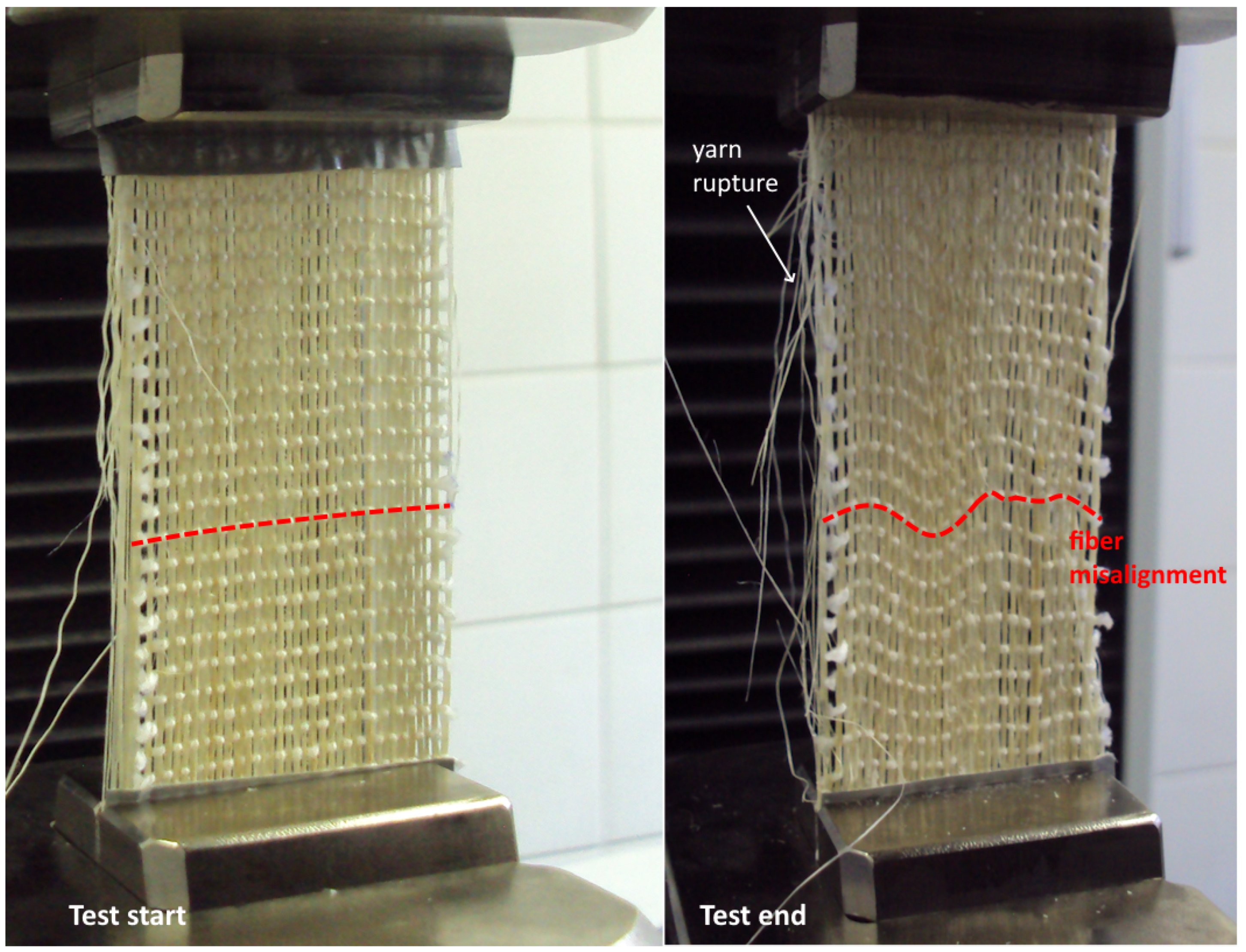

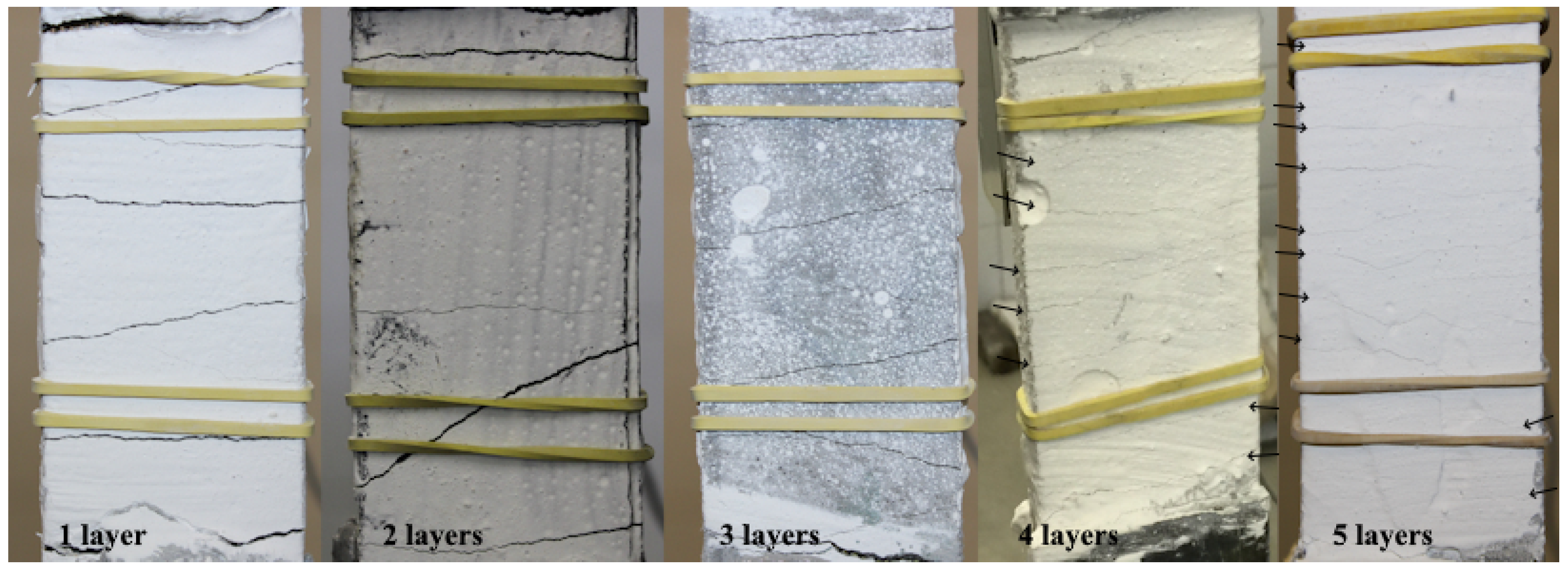

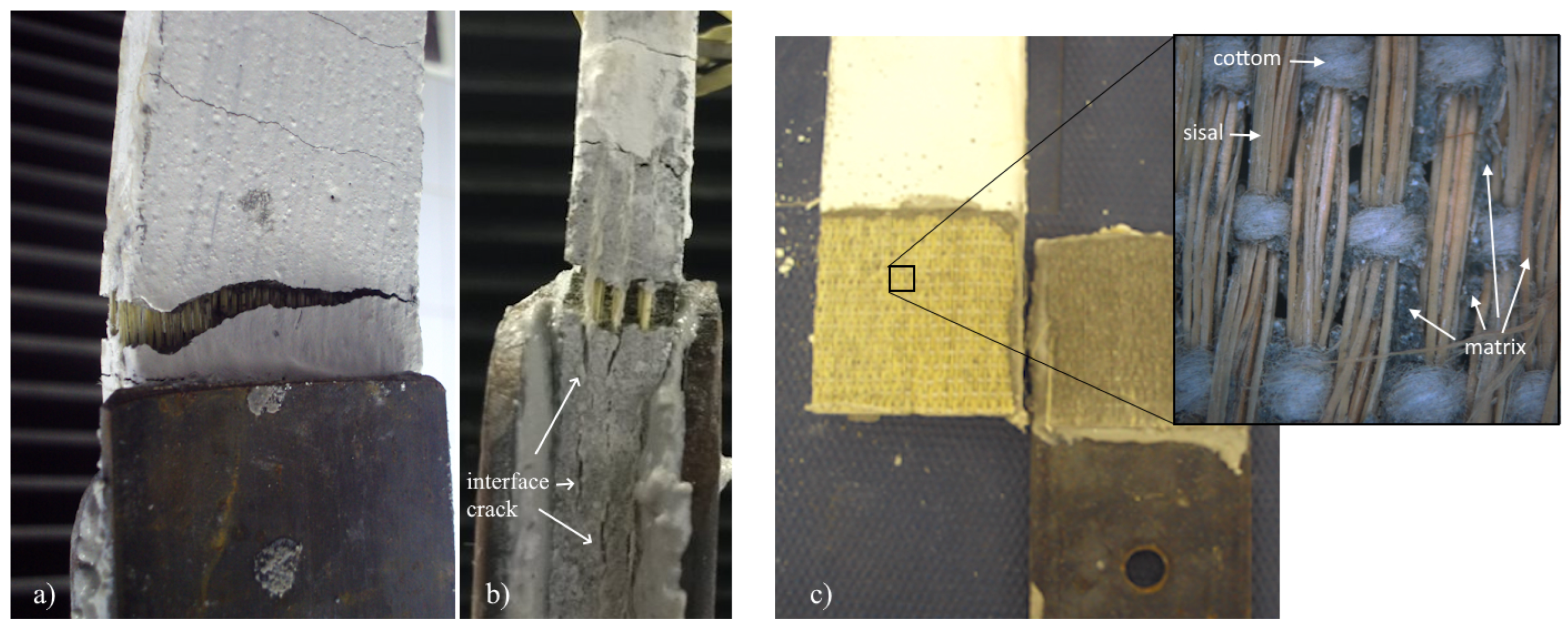

3.2.1. Mechanical Behaviour and Failure Mode

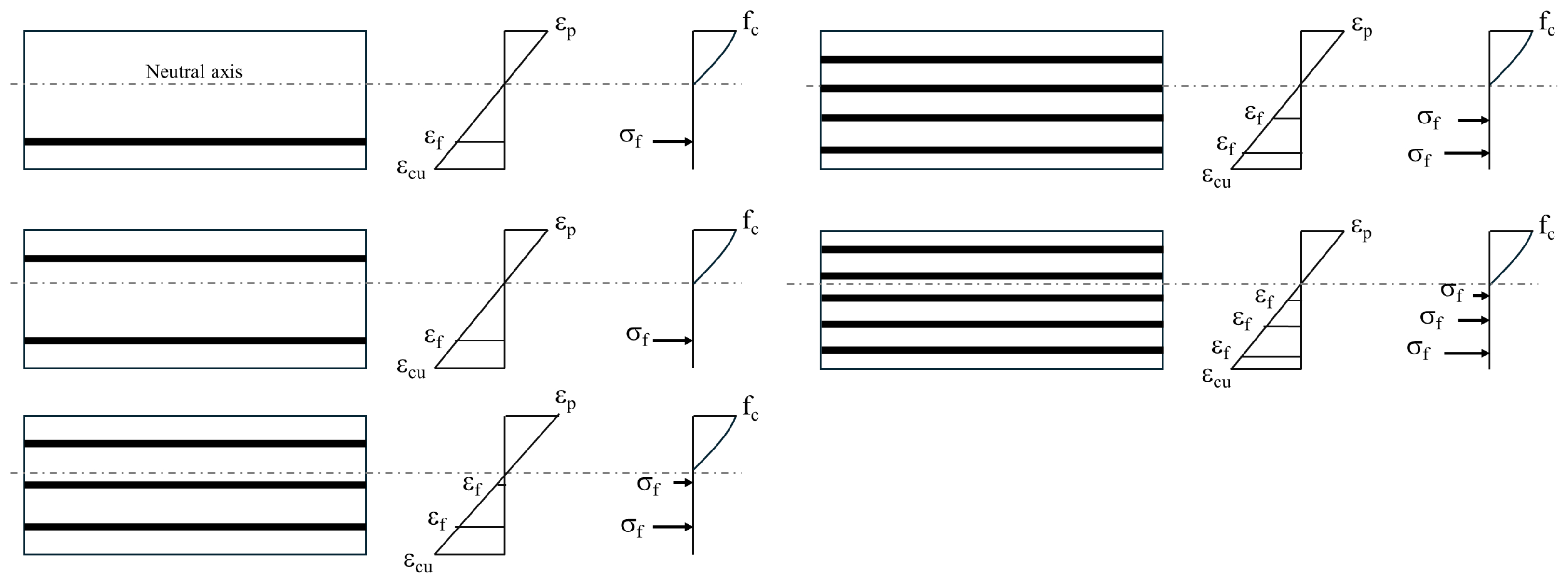

3.2.2. Modelling of Tensile Behaviour of Composites

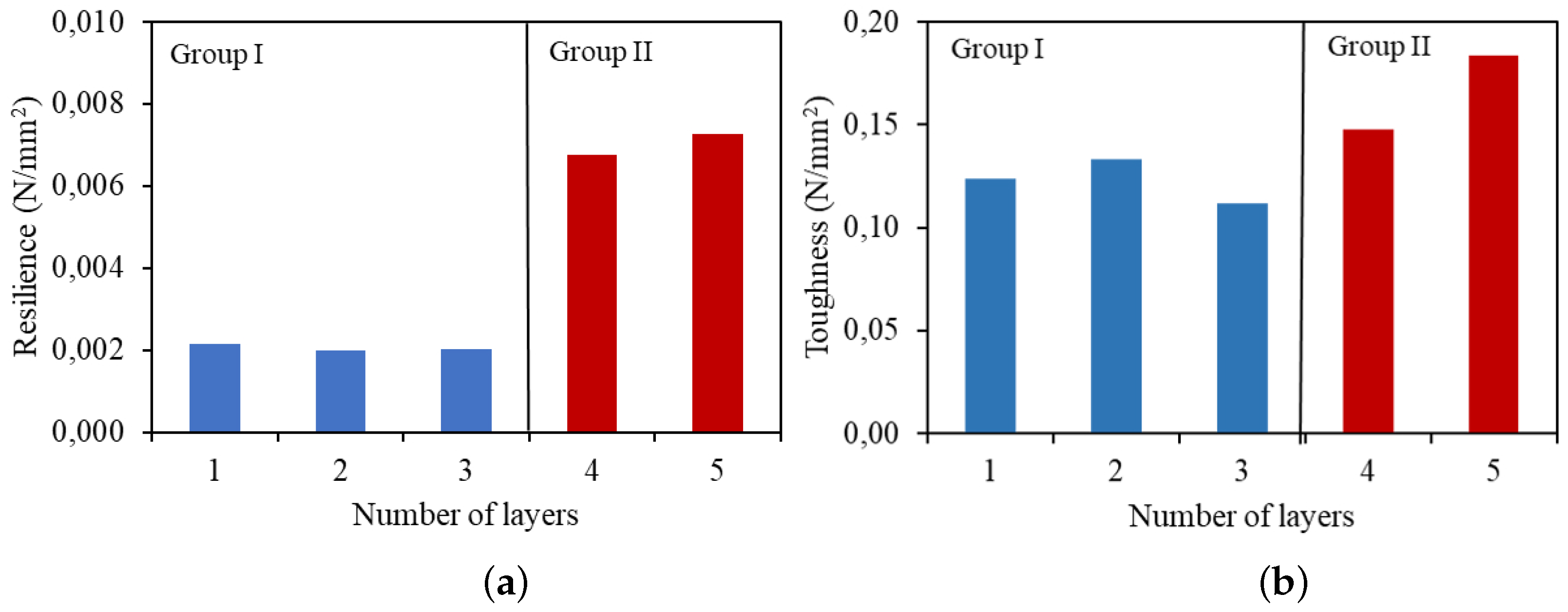

3.2.3. Tensile Resilience and Toughness

3.3. Flexural Behaviour of Composite

3.3.1. Mechanical Behaviour

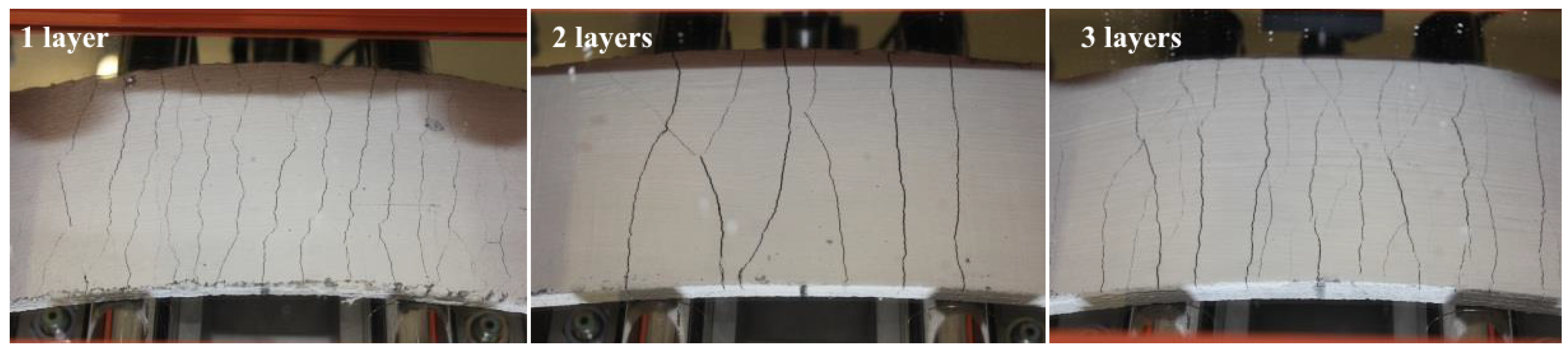

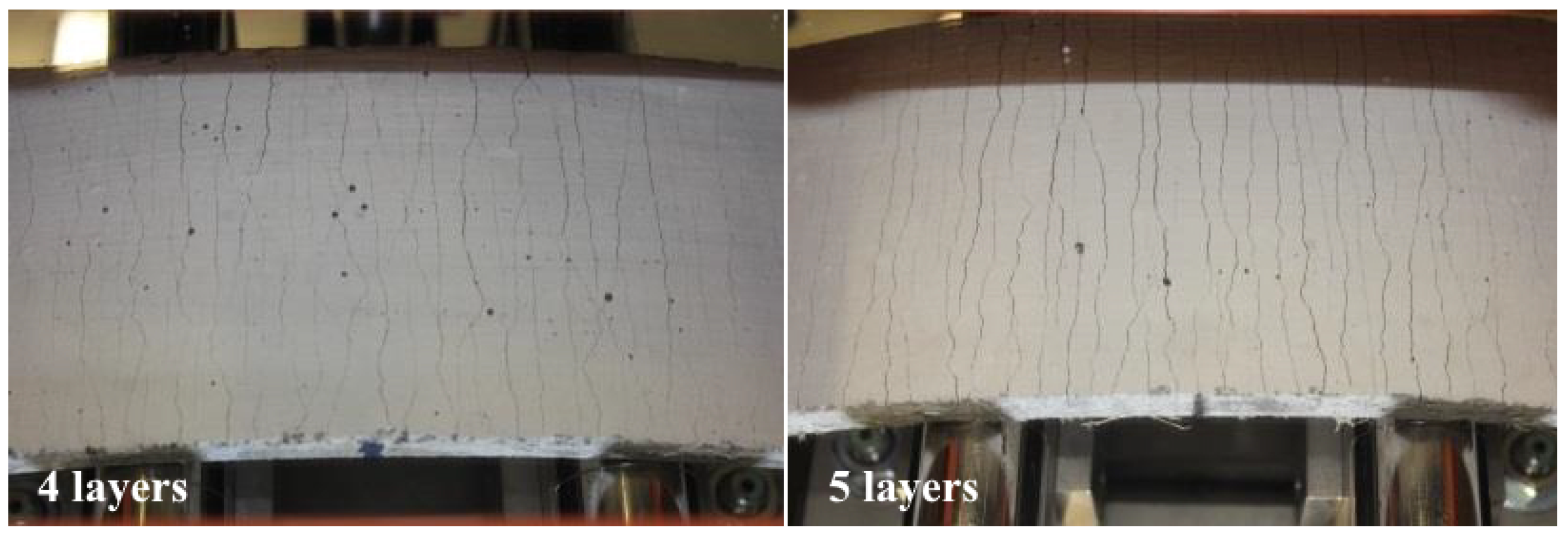

3.3.2. Cracking and Failure Mode

4. Conclusions

- Yarns exhibited linear behavior under direct tension, displaying a rapid tension increase post-loading and a ductile rupture due to gradual individual fiber fracture. The fabric also demonstrated ductile rupture, contrary to the individual fiber’s brittle rupture, and exhibited sufficient tensile strength suitable for composite reinforcement.

- Composites displayed strain-hardening behavior under direct tension, manifesting multiple cracking and increased stiffness pre-rupture. Greater layering in composites resulted in increased stiffness and post-cracking resistance. Rupture forms varied from crack coalescence and reinforcement pullout in composites with one to three layers, to rupture of the matrix covering layer in composites with four and five layers.

- Stress–strain behavior under direct tension of the composites was modeled using the Pseudo Strain-Hardening Model, enabling determination of resilience and toughness. Composites with five layers demonstrated higher resilience and toughness, although the effect of layering on the latter property was less pronounced.

- Flexural tests on the composites showed deflection-hardening behavior, with increased flexural resistance correlating with the number of reinforcement layers. Composite rupture occurred post multiple cracks and substantial deformation, characterized by crack propagation from the bottom face to the top of the plate.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Flansbjer, M.; Williams Portal, N.; Vennetti, D.; Mueller, U. Composite behavior of textile reinforced reactive powder concrete sandwich façade elements. Int. J. Concr. Struct. Mater. 2018, 12, 1–17. [Google Scholar] [CrossRef]

- Brückner, A.; Ortlepp, R.; Curbach, M. Textile reinforced concrete for strengthening in bending and shear. Mater. Struct. 2006, 39, 741–748. [Google Scholar] [CrossRef]

- Orlowsky, J.; Beßling, M.; Kryzhanovskyi, V. Prospects for the Use of Textile-Reinforced Concrete in Buildings and Structures Maintenance. Buildings 2023, 13, 189. [Google Scholar] [CrossRef]

- Sen, T.; Paul, A. Confining concrete with sisal and jute FRP as alternatives for CFRP and GFRP. Int. J. Sustain. Built Environ. 2015, 4, 248–264. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Characteristics of hemp fabric reinforced nanoclay–cement nanocomposites. Cem. Concr. Compos. 2014, 50, 27–354. [Google Scholar] [CrossRef]

- Guimarães, T.C.; Gomes, O.D.F.M.; Araújo, O.M.O.; Tadeu Lopes, R.; da-Gloria, M.H.Y.R.; Toledo Filho, R.D.; Koenders, E.; Caggiano, A.; Mankel, C.; Sam, M.N.; et al. PCM-Impregnated Textile-Reinforced Cementitious Composite for Thermal Energy Storage. Textiles 2023, 3, 98–114. [Google Scholar] [CrossRef]

- Mawlood, B.O. Flexural behavior of structure of laminated cementitious composites with different types of mesh reinforcements. Constr. Build. Mater. 2023, 389, 131732. [Google Scholar] [CrossRef]

- Claramunt, J.; Ventura, H.; Fernández-Carrasco, L.J.; Ardanuy, M. Tensile and flexural properties of cement composites reinforced with flax nonwoven fabrics. Materials 2017, 10, 215. [Google Scholar] [CrossRef]

- Olivito, R.S.; Cevallos, O.A.; Carrozzini, A. Development of durable cementitious composites using sisal and flax fabrics for reinforcement of masonry structures. Mater. Des. 2014, 57, 258–268. [Google Scholar] [CrossRef]

- Peled, A.; Sueki, S.; Mobasher, B. Bonding in fabric–cement systems: Effects of fabrication methods. Cem. Concr. Res. 2006, 36, 1661–1667. [Google Scholar] [CrossRef]

- Mercedes, L.; Gil, L.; Bernat-Maso, E. Mechanical performance of vegetal fabric reinforced cementitious matrix (FRCM) composites. Constr. Build. Mater. 2018, 175, 161–173. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, H.C. Pseudo strain-hardening design in cementitious composites. In Proceedings of the High Performance Fiber Reinforced Cement Composites, Mainz, Germany, 23–26 June 1991; Reinhardt, H.W., Naaman., E.A.E., Spon, F.N., Eds.; 1992. [Google Scholar]

- Zhakatayevl, A.; Kappassov, Z.; Varol, H.A. Analytical modeling and design of negative stiffness honeycombs. Smart Mater. Struct. 2020, 29, 045024. [Google Scholar] [CrossRef]

- Pokhrel, M.; Bandelt, M.J. Material properties and structural characteristics influencing deformation capacity and plasticity in reinforced ductile cement-based composite structural components. Compos. Struct. 2019, 224, 111013. [Google Scholar] [CrossRef]

- Lima, P.R.L.; Barros, J.A.; Roque, A.B.; Fontes, C.M.; Lima, J.M. Short sisal fiber reinforced recycled concrete block for one-way precast concrete slabs. Constr. Build. Mater. 2018, 187, 620–634. [Google Scholar] [CrossRef]

- Cerchiaro, J.R. Comportamento Mecânico de Compósitos com Poliéster e Tecidos de Sisal por Moldagem Manual. Master Thesis, Federal University of Bahia, Salvador, Brazil, 2010. [Google Scholar]

- Ferreira, S.R.; de Andrade Silva, F.; Lima, P.R.L.; Toledo Filho, R.D. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curauá fiber cement based composite systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Gahgah, M.; Belaadi, A.; Boumaaza, M.; Alshahrani, H.; Khan, M.K. Effect of Number of Tests on the Mechanical Characteristics of Agave sisalana Yarns for Composites Structures: Statistical Approach. Polymers 2023, 15, 2885. [Google Scholar] [CrossRef] [PubMed]

- Badawi, S.S. Geometrical and Mathematical Analysis of the Elongation of Woven Fabric Structures. Int. Des. J. 2023, 13, 411–422. [Google Scholar] [CrossRef]

- Ferrara, G.; Coppola, B.; Di Maio, L.; Incarnato, L.; Martinelli, E. Tensile strength of flax fabrics to be used as reinforcement in cement-based composites: Experimental tests under different environmental exposures. Compos. Part B Eng. 2019, 168, 511–523. [Google Scholar] [CrossRef]

- Allen, H.G. Stiffness and Strength of two glass fibre reinforced cement laminates. J. Compos. Mater. 1971, 3, 151–158. [Google Scholar]

- Bertolesi, E.; Carozzi, F.G.; Milani, G.; Poggi, C. Numerical modeling of Fabric Reinforce Cementitious Matrix composites (FRCM) in tension. Constr. Build. Mater. 2014, 70, 531–548. [Google Scholar] [CrossRef]

- Aveston, J.; Cooper, G.A.; Kelly, A. Single and multiple fracture. In Properties Of Fibre Composites; IPC Science and Technology Press: Guildford, UK, 1971; pp. 15–26. [Google Scholar]

- Carreira, D.J.; Chu, K.H. Stress-strain Relationship for Reinforced Concrete in Tension. ACI J. 1986, 83, 21–28. [Google Scholar]

- Nagahama, K.J.; Gadéa, A.D.S.M.; Lima, P.R.L. Finite strip modeling of cementitious laminates reinforced with sisal fibers. Cem. Concr. Compos. 2015, 63, 8–16. [Google Scholar] [CrossRef]

- da Gloria, M.H.Y.R.; Toledo Filho, R.D. Innovative sandwich panels made of wood bio-concrete and sisal fiber reinforced cement composites. Constr. Build. Mater. 2021, 27, 121636. [Google Scholar] [CrossRef]

| Characteristics | Cement | Fly Ash | Silica Fume | |

|---|---|---|---|---|

| CaO | 69.77 | 2.06 | 0.17 | |

| SiO2 | 15.89 | 53.33 | 95.3 | |

| Major chemical | SO3 | 4.76 | 1.51 | – |

| component (%) | Al2O3 | 4.35 | 33.23 | 0.04 |

| K2O | 1.07 | 3.44 | 1.33 | |

| Fe2O3 | 3.66 | 4.96 | 0.35 | |

| Specific gravity (g/cm3) | 3.06 | 2.01 | 2.65 |

| Property | Water Absorption (%) | Density (g/cm3) | Compressive Strength (MPa) | Splitting Strength (MPa) |

|---|---|---|---|---|

| Value | 4.12 ± 1.10 | 2.09 ± 0.01 | 47.78 ± 0.4 | 3.53 ± 0.20 |

| Group | Sample | Fabric Weight (g/mm2) | Number of Layers | Vf (%) |

|---|---|---|---|---|

| SFRCC1 | 0.025 | 1 | 2.91 | |

| I | SFRCC2 | 0.022 | 2 | 4.11 |

| SFRCC3 | 0.021 | 3 | 5.48 | |

| II | SFRCC4 | 0.024 | 4 | 9.30 |

| SFRCC5 | 0.024 | 5 | 10.46 |

| Reinforcement | Rupture Strain (mm/mm) | Tensile Strength (MPa) | Stiffness (GPa) |

|---|---|---|---|

| Fiber | 0.0375 ± 0.0060 | 722.11 ± 89.49 | 18.99 ± 1.77 |

| Yarn | 0.0598 ± 0.0073 | 276.50 ± 37.45 | 9.35 ± 1.42 |

| Fabric | 0.1062 ± 0.0118 | 335.77 ± 26.09 | 8.32 ± 0.78 |

| Sample | First Crack | End Multiple Crack | Maximum | |||

|---|---|---|---|---|---|---|

| Stress (MPa) | Deflection (mm) | Stress (MPa) | Deflection (mm) | Stress (MPa) | Deflection (mm) | |

| SFRCC1 | 2.4 ± 0.0 | 0.4 ± 0.1 | 4.8 ± 0.9 | 8.3 ± 1.8 | 10.0 ± 0.9 | 24.3 ± 1.2 |

| SFRCC2 | 2.6 ± 0.0 | 0.7 ± 0.1 | 5.9 ± 1.5 | 11.6 ± 2.4 | 8.3 ± 0.2 | 26.5 ± 8.6 |

| SFRCC3 | 2.8 ± 0.3 | 0.4 ± 0.1 | 8.3 ± 0.1 | 25.8 ± 1.2 | 14.4 ± 0.8 | 31.9 ± 0.1 |

| SFRCC4 | 3.9 ± 0.0 | 0.3 ± 0.0 | 10.5 ± 0.5 | 5.9 ± 1.5 | 25.9 ± 0.5 | 17.0 ± 3.5 |

| SFRCC5 | 4.7 ± 0.3 | 0.4 ± 0.0 | 10.8 ± 1.0 | 5.6 ± 0.9 | 18.3 ± 0.1 | 16.1 ± 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arruda Filho, A.B.d.; Lima, P.R.L.; Carvalho, R.F.; Gomes, O.d.F.M.; Filho, R.D.T. Effect of Number of Layers on Tensile and Flexural Behavior of Cementitious Composites Reinforced with a New Sisal Fabric. Textiles 2024, 4, 40-56. https://doi.org/10.3390/textiles4010004

Arruda Filho ABd, Lima PRL, Carvalho RF, Gomes OdFM, Filho RDT. Effect of Number of Layers on Tensile and Flexural Behavior of Cementitious Composites Reinforced with a New Sisal Fabric. Textiles. 2024; 4(1):40-56. https://doi.org/10.3390/textiles4010004

Chicago/Turabian StyleArruda Filho, Adilson Brito de, Paulo Roberto Lopes Lima, Ricardo Fernandes Carvalho, Otavio da Fonseca Martins Gomes, and Romildo Dias Toledo Filho. 2024. "Effect of Number of Layers on Tensile and Flexural Behavior of Cementitious Composites Reinforced with a New Sisal Fabric" Textiles 4, no. 1: 40-56. https://doi.org/10.3390/textiles4010004

APA StyleArruda Filho, A. B. d., Lima, P. R. L., Carvalho, R. F., Gomes, O. d. F. M., & Filho, R. D. T. (2024). Effect of Number of Layers on Tensile and Flexural Behavior of Cementitious Composites Reinforced with a New Sisal Fabric. Textiles, 4(1), 40-56. https://doi.org/10.3390/textiles4010004