A Review of Energy and Sustainability Management in the Fibre-Based Process Industry

Abstract

1. Introduction

1.1. Research Problem

1.2. Research Goal

1.3. Research Methodology

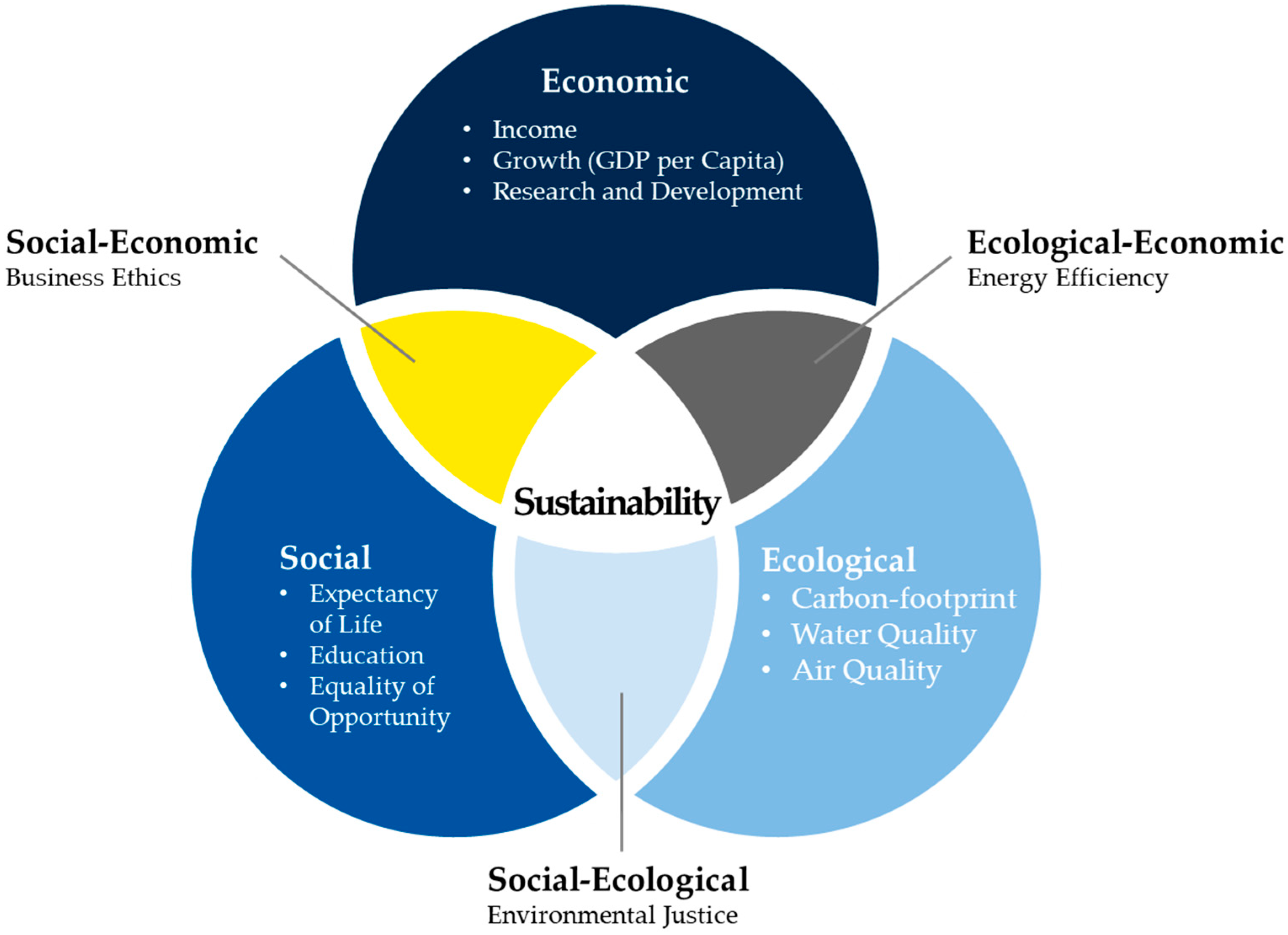

2. The Evolution and Importance of Sustainability Concepts

2.1. Historical Roots of Sustainability

2.2. Three Dimensions of Sustainability

3. Regulatory Frameworks for Sustainability in the EU

3.1. Foundations for Sustainability Frameworks

3.2. Frameworks by the European Union

3.3. Regulatory Framework and Standards for Energy Management in Germany

3.4. Corporate Sustainability Reporting and Ecodesign Regulation

3.5. Forecast and Sustainability Trends

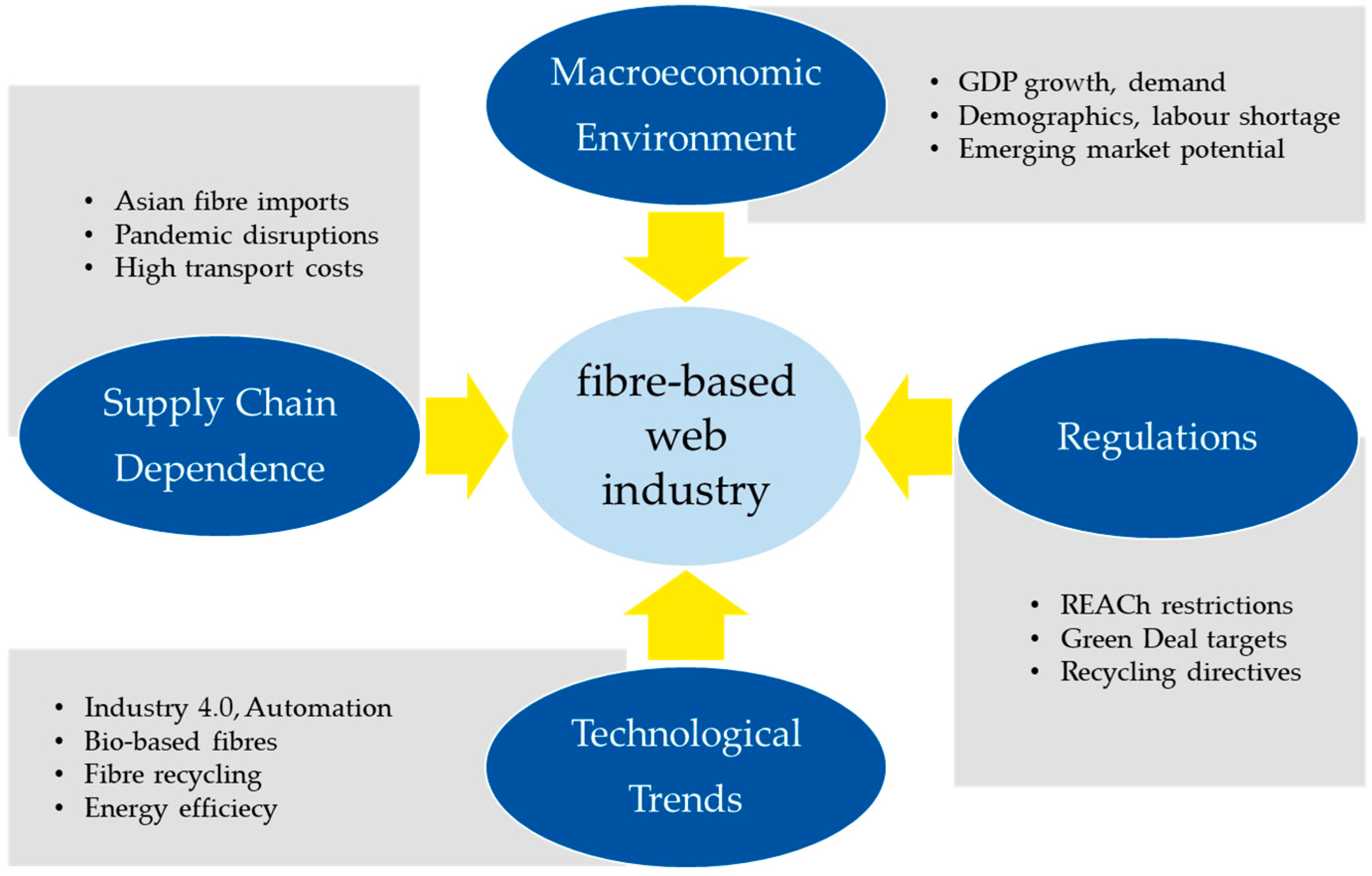

4. Market Forces

4.1. Macroeconomic Influences and Structural Challenges

4.2. Supply Chains, Regulations, and Bureaucracy

4.3. Productivity and Industry Outlook

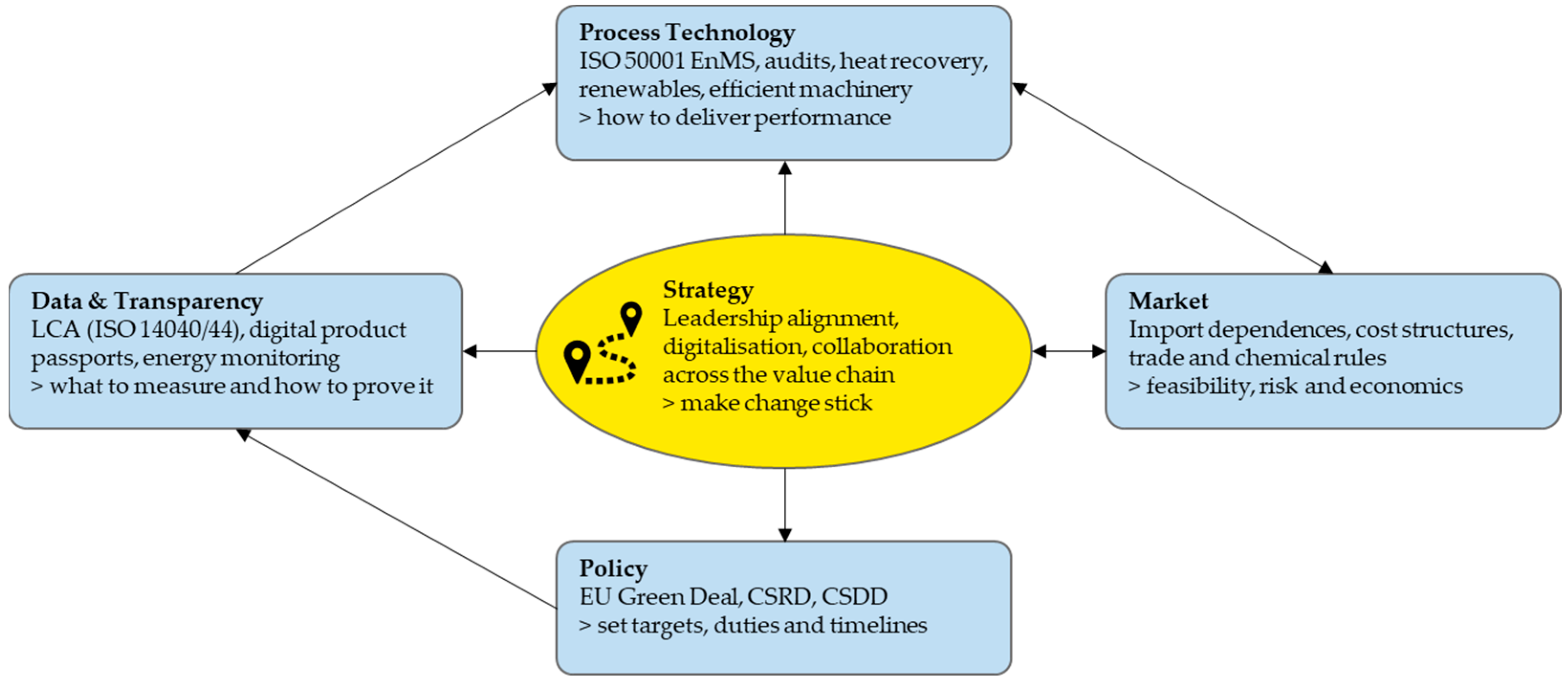

5. Significance for Companies

5.1. Sustainability in Business Strategy

5.2. Implementation Challenges

5.3. Standardization and Strategic Gaps

5.4. Core Topics in Energy Management

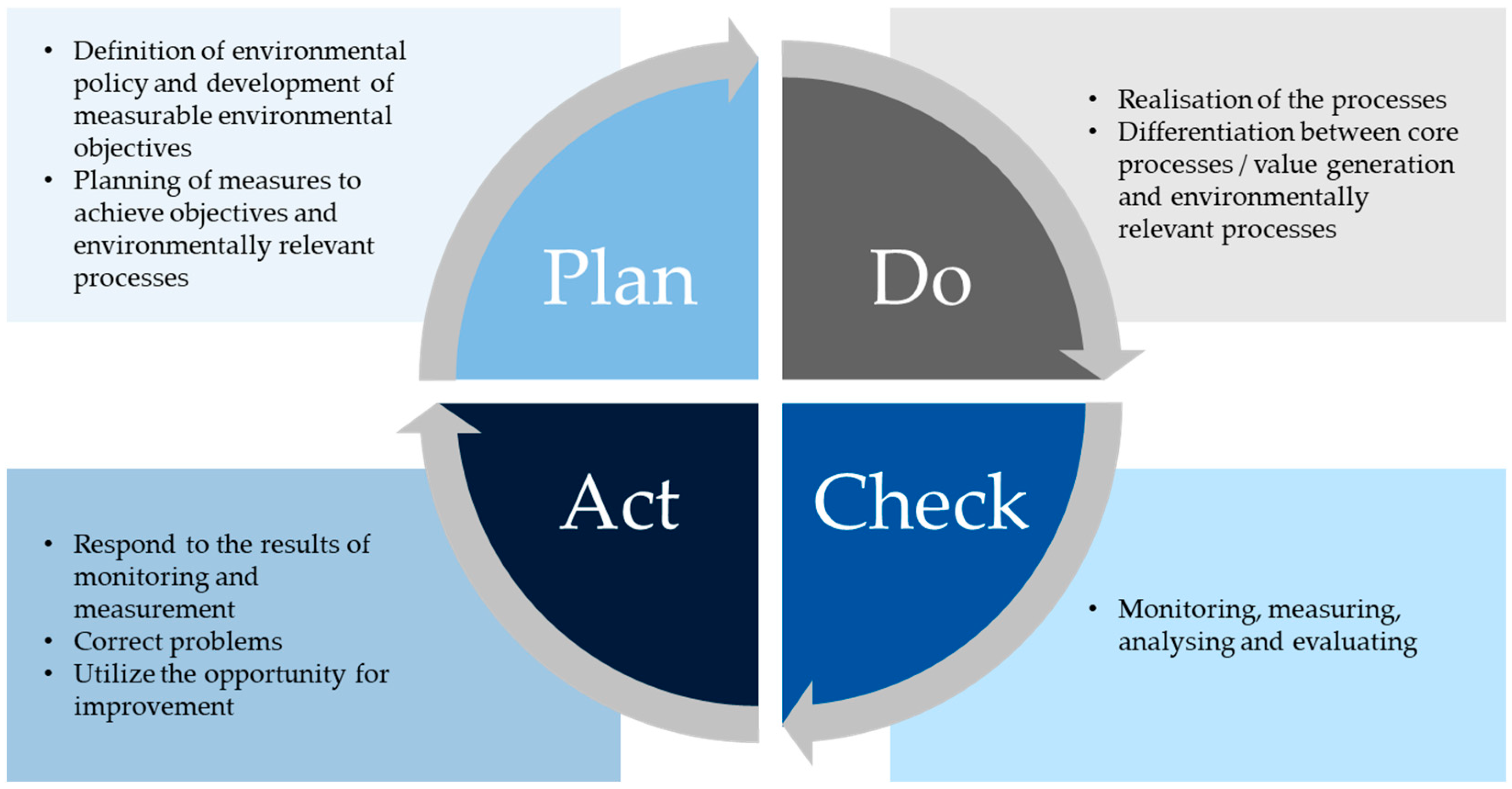

6. Methods and Evaluation Concepts

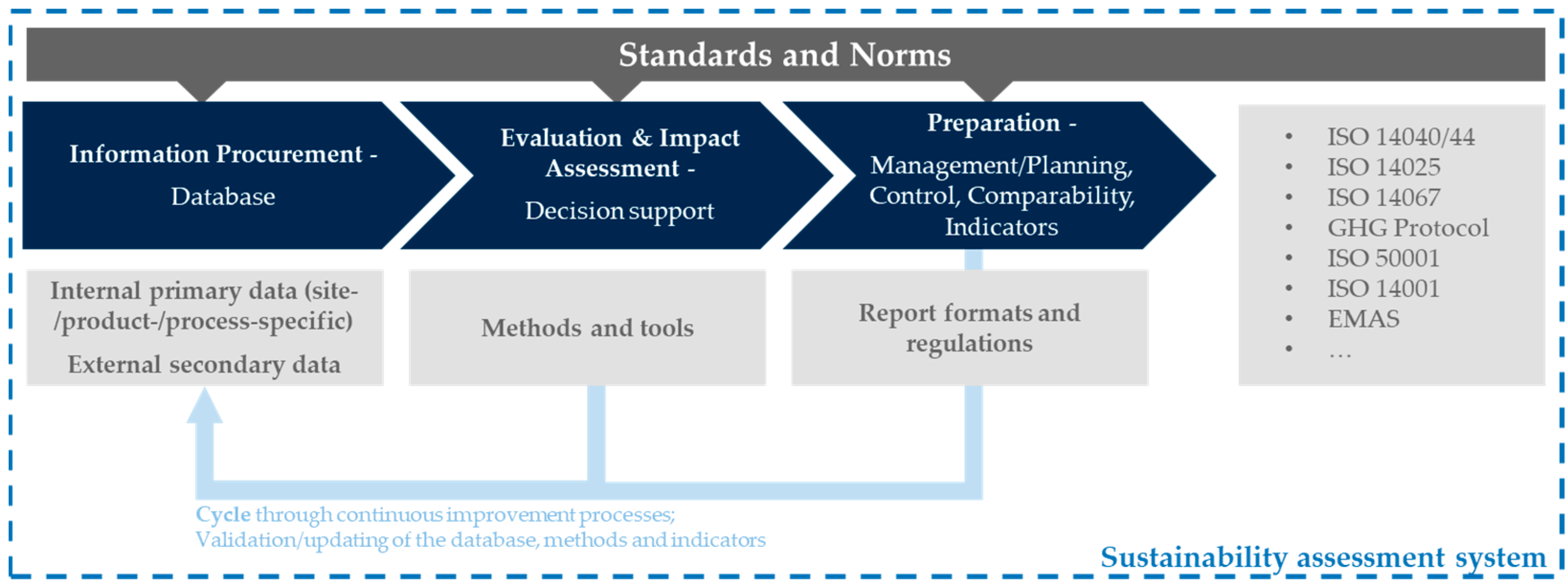

6.1. Sustainability Evaluation and Indicators

6.2. Life Cycle and Environmental Standards

- ISO 14001: Defines requirements for effective environmental management systems. Therefore it promotes continual improvement, efficient resource use and regulatory compliance (DIN Deutsches Institut für Normung e.V., 2015b).

- ISO 14060: Integrates environmental considerations into strategic planning (DIN Deutsches Institut für Normung e.V., 2019a).

- ISO 14067: Guides the quantification and communication of product carbon footprints by providing a consistent framework for carbon footprint accounting and reporting (DIN Deutsches Institut für Normung e.V., 2019a)

- establishing a framework for monitoring the implementation of existing Product Environmental Footprint Category Rules (PEFCRs) and Organisation Environmental Footprint Sector Rules (OEFSRs),

- developing new PEFCRs and OEFSRs and

- advancing methodological developments (Directorate-General for Communication of the European Comission, 2025).

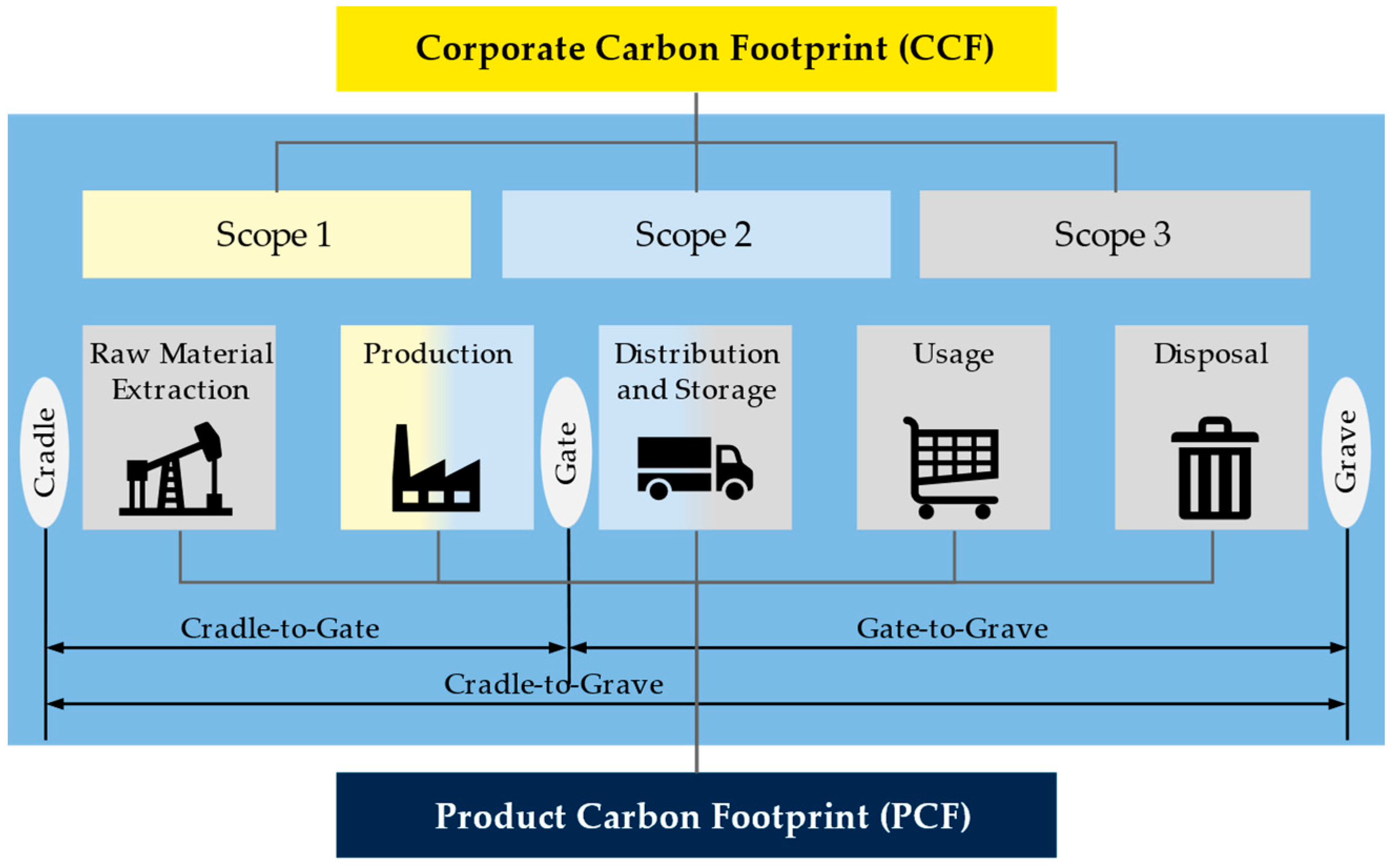

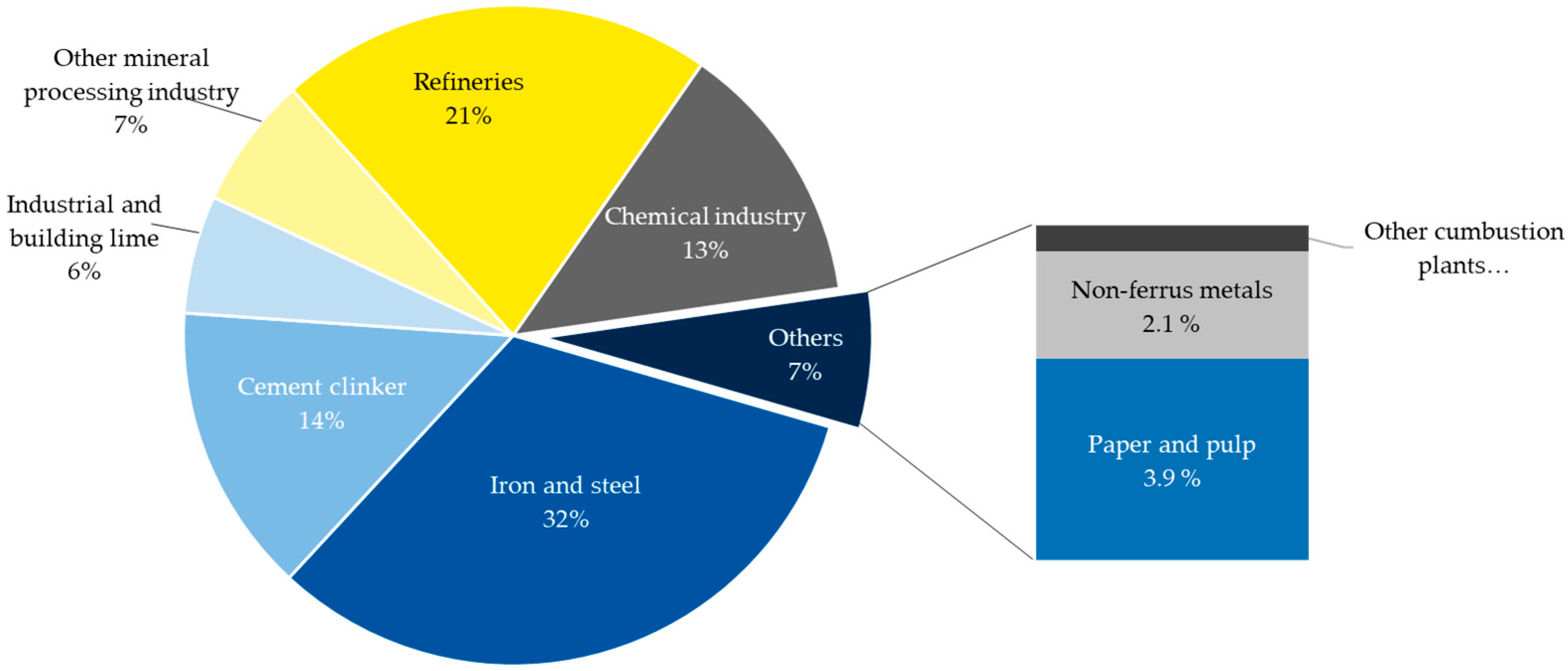

6.3. Greenhouse Gas Accounting

- Scope 1: Direct emissions from owned or controlled sources,

- Scope 2: Indirect emissions from purchased energy,

- Scope 3: Other indirect emissions, e.g., from travel, waste, or procurement (World Business Council for Sustainable Development & World Resources Institute, 2004).

7. Sustainability in the Nonwoven and Paper Industry

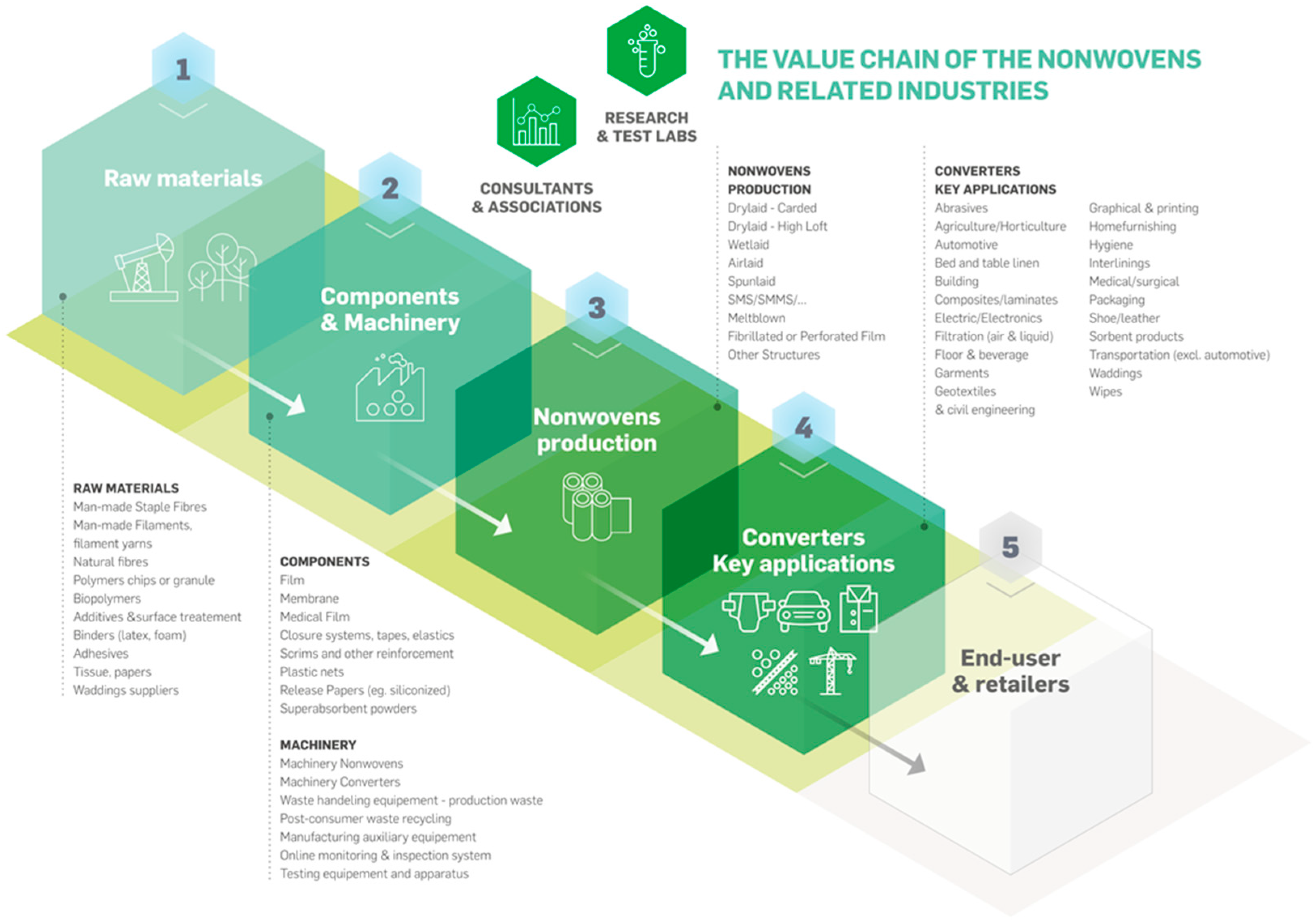

7.1. Nonwoven Products and Market Shares

- hygiene products (27%),

- wipes (20%),

- construction (16%),

- home and office (10%) and

- filtration (6%).

- natural fibres (e.g., cotton, flax),

- synthetic fibres (e.g., polyester, polypropylene),

- fluff pulp and

- polymer powders or granulates.

- raw material suppliers,

- machinery manufacturers,

- producers,

- converters,

- end users,

- research institutions and

- associations (Stevens & Tuncki, 2019).

- raw material preparation (fibre or granulate processing),

- web formation,

- web bonding and

- finishing (Schlichter et al., 2012; Wiertz & Fuchs, 2012).

7.2. Paper Products and Market Shares

7.3. Strategies and Challenges

7.4. Materials, Processes and End-of-Life

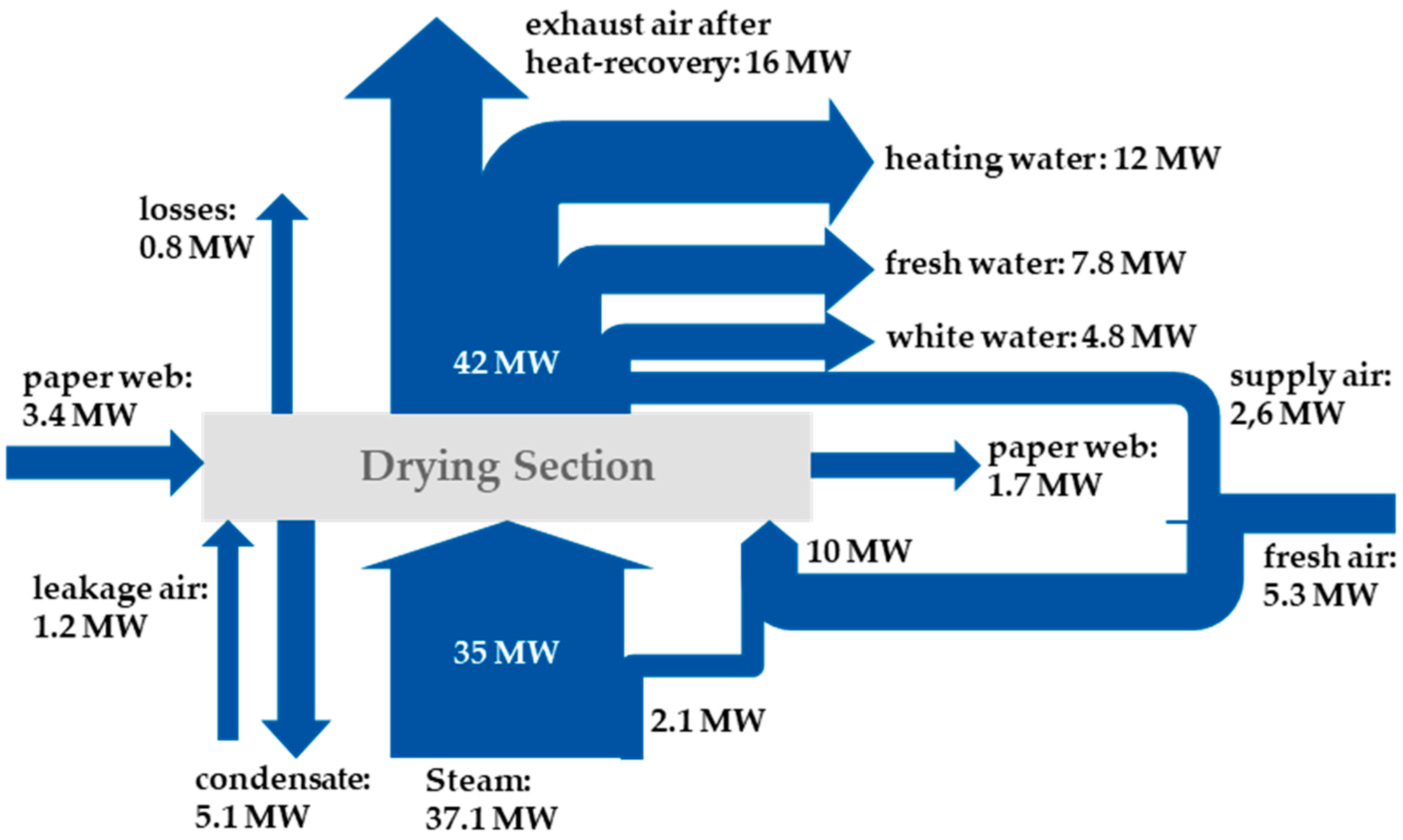

7.5. Paper Industry Energy Trends

- Advanced press section technologies (e.g., shoe press),

- Higher-efficiency machinery,

- Increased use of recycled paper.

8. Discussion and Outlook

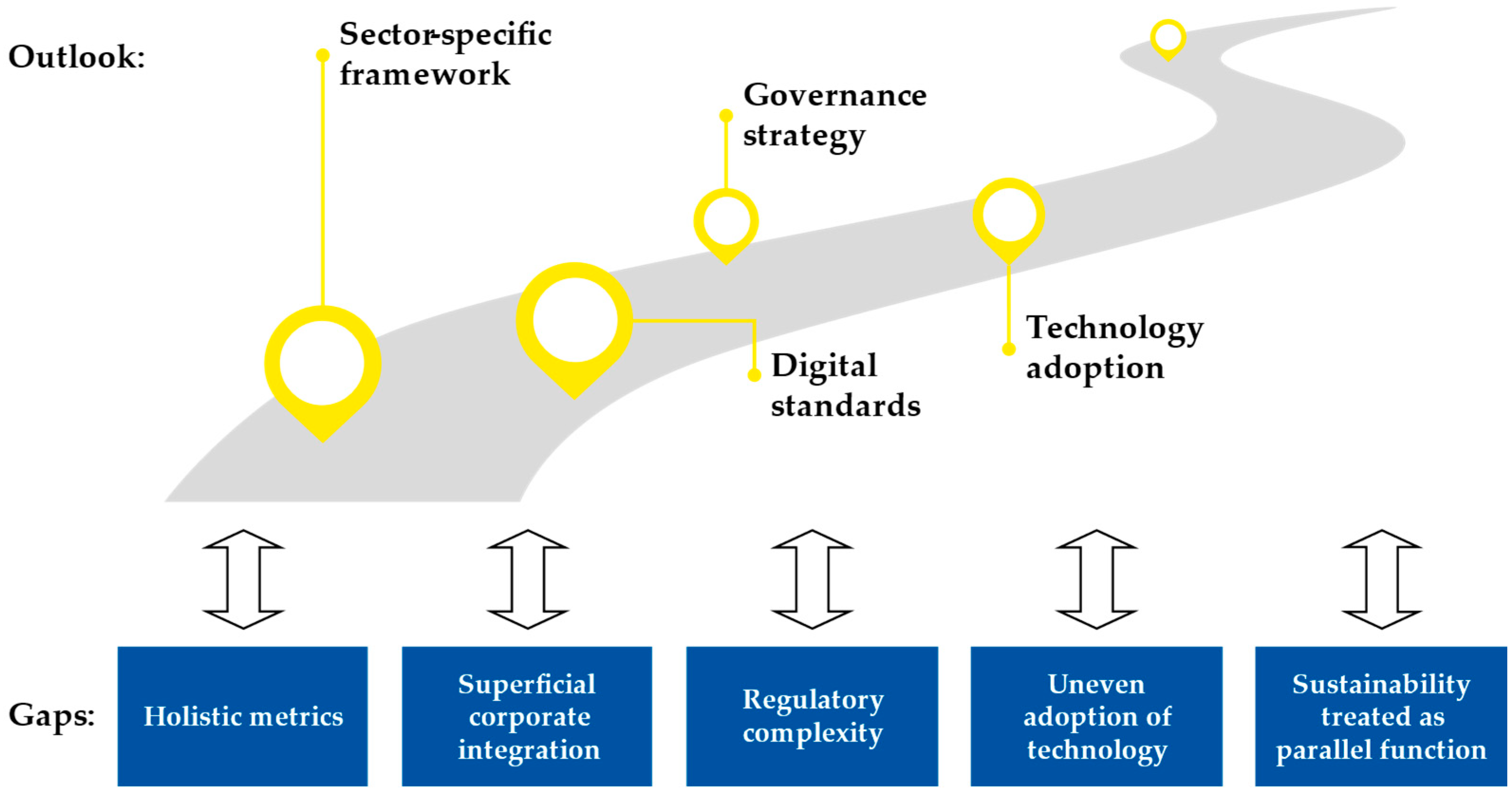

8.1. Gaps

8.2. Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alves, D. I., Barreiros, M., Fangueiro, R., & Ferreira, D. P. (2024). Valorization of textile waste: Non-woven structures and composites. Frontiers in Environmental Science, 12, 1365162. [Google Scholar] [CrossRef]

- Amt für Veröffentlichungen der Europäischen Union. (2023). Erweiterte Herstellerverantwortung für Textilien [Press release]. Available online: https://ec.europa.eu/commission/presscorner/api/files/attachment/875571/FS%20-%20Erweiterte%20Herstellerverantwortung%20f%C3%BCr%20Textilien.pdf (accessed on 26 May 2025).

- Axenbeck, J., Balduf, F., Dorsch, M., Eckert, C., Falk, S., Gesmann-Nuissl, D., Glück, K., Hoffmann, M. W., Klement, P., Köhler, C., Krohne, T., Kuttner, D., Madeja, N., Pollay, R., Reethen, L.-A., de Ritter, M., Seyfried, S., & Schuster, J. (2024). Nachhaltigkeit organisieren. ImpulspapierPlattform Industrie 4.0. [Google Scholar]

- Banks, I. (Ed.). (2017). A new textiles economy: Redesigning fashion’s future. Ellen MacArthur Foundation. [Google Scholar]

- Barahmand, Z., & Eikeland, M. S. (2022). Life Cycle Assessment under Uncertainty: A Scoping Review. World, 3, 692–717. [Google Scholar] [CrossRef]

- Bayerisches Landesamt für Umweltschutz. (2003). Klimaschutz durch effiziente energieverwendung in der Papierindustrie: Nutzung von niedertemperaturabwärme. Bayerisches Landesamt für Umweltschutz. [Google Scholar]

- Bertagnolli, F. (2020). Lean management. Springer Fachmedien Wiesbaden. [Google Scholar] [CrossRef]

- Blechschmidt, J. (Ed.). (2021). Taschenbuch der papiertechnik (3rd ed.). Hanser Verlag. [Google Scholar]

- Bundesfinanzministerium. (2017). Produktivität in Deutschland: Messbarkeit und entwicklung. Available online: https://www.bundesfinanzministerium.de/Monatsberichte/2017/10/Inhalte/Kapitel-3-Analysen/3-1-Produktivitaetsentwicklung-Deutschland.html (accessed on 26 May 2025).

- Bundesministerium für Umwelt, Naturschutz, nukleare Sicherheit und Verbraucherschutz (BMU). (2021). Die Klimakonferenz in Berlin. Available online: https://www.bmuv.de/themen/klimaschutz-anpassung/klimaschutz/internationale-klimapolitik/pariser-abkommen (accessed on 17 May 2022).

- Bundesministerium für Wirtschaft und Klimaschutz. (2024). Aktualisierung des integrierten nationalen Energie- und Klimaplans. Available online: https://www.bundeswirtschaftsministerium.de/Redaktion/DE/Textsammlungen/Energie/necp.html (accessed on 25 July 2025).

- Bundesministerium für Wirtschaft und Klimaschutz. (2025). Papier- und Druckindustrie—Branchenskizze. Available online: https://www.bundeswirtschaftsministerium.de/Redaktion/DE/Textsammlungen/Branchenfokus/Industrie/branchenfokus-papier-und-druckindustrie.html (accessed on 25 July 2025).

- Bundesministerium für Wirtschaft und Technologie. (2020). Spitzenausgleich- Effizienzsystemverordnung—SpaEfV. Available online: https://www.gesetze-im-internet.de/spaefv/index.html (accessed on 25 July 2025).

- Bundestag. (2023). Energieeffizienzgesetz (EnEfG). Available online: https://www.gesetze-im-internet.de/enefg/index.html (accessed on 25 July 2025).

- Ciatti, F., Vencovsky, D., Vencovska, J., & Postle, M. (2021). Development of REACH: Review of evidence on the benefits & costs of REACH (German Environment Agency Ed.). Available online: https://www.umweltbundesamt.de/publikationen/development-of-reach-review-of-evidence-on-the (accessed on 25 July 2025).

- Clift, R., & Druckman, A. (Eds.). (2016). Taking Stock of Industrial Ecology. Springer International Publishing. [Google Scholar] [CrossRef]

- Comoli, M., Tettamanzi, P., Bavagnoli, F., & Murgolo, M. (2023). Non-financial disclosure and sustainability regulation: Voluntary or mandatory effectiveness. In J. Dyczkowska (Ed.), Sustainable performance in business organisations and institutions: Measurement, reporting and management (pp. 15–40). Wroclaw University of Economics and Business. [Google Scholar] [CrossRef]

- Confederation of European Paper Industries (Ed.). (2020). 2030 industry manifesto: Our industry, our solutions, our future. Available online: https://www.cepi.org/2030-industry-manifesto/ (accessed on 29 October 2025).

- Confederation of European Paper Industries (Ed.). (2025). Key Statistics 2024: European pulp & paper industry. Confederation of European Paper Industries. [Google Scholar]

- Council for the Environment and Infrastructure (Ed.). (2015). Circular economy: From wish to practice. Available online: https://www.rli.nl/sites/default/files/advice_rli_circular_economy_interactive_def.pdf (accessed on 23 May 2025).

- Cramer, J. (2017). The raw materials transition in the Amsterdam metropolitan area: Added value for the economy, well-being, and the environment. Environment: Science and Policy for Sustainable Development, 59, 14–21. [Google Scholar] [CrossRef]

- Danel, R., Gajdzik, B., & Štverková, H. (2024). Risk factors in implementation of industry 4.0 for ERP/MES in small and medium enterprises. In P. Doucek, M. Sonntag, & L. Nedomova (Eds.), Schriftreihe Informatik (Vol. 53, pp. 231–240). Trauner Verlag. [Google Scholar] [CrossRef]

- Deutsche Emissionshandelsstelle im Umweltbundesamt (Ed.). (2021). Treibhausgasemissionen 2020 Emissionshandelspflichtige stationäre Anlagen und Luftverkehr in Deutschland (VET-Bericht 2020). Available online: https://www.dehst.de/SharedDocs/downloads/DE/publikationen/VET-Bericht-2020.pdf?__blob=publicationFile&v=4 (accessed on 7 March 2025).

- Deutsche Emissionshandelsstelle im Umweltbundesamt (Ed.). (2025). Emissionssituation 2024 im EU-ETS 1—Emissionshandelspflichtige stationäre Anlagen, Luft- und Seeverkehr in Deutschland: VET-Bericht 2024. Available online: https://www.dehst.de/SharedDocs/downloads/DE/publikationen/VET-Bericht-2024.pdf?__blob=publicationFile&v=8 (accessed on 18 August 2025).

- Diaconescu, I., Patrascu, R., & Minciuc, E. (Eds.). (2017, ). Energy efficiency study of the paper making drying process. International Conference on ENERGY and ENVIRONMENT (CIEM), Bucharest, Romania. Available online: https://ieeexplore.ieee.org/document/8120806 (accessed on 7 March 2025).

- Die Papierindustrie e.V. (2024). Leistungsbericht Papier 2024—Die Papierindustrie in Zahlen. Available online: https://www.papierindustrie.de/presse/pressedetails?tx_news_pi1%5Baction%5D=detail&tx_news_pi1%5Bcontroller%5D=News&tx_news_pi1%5Bnews%5D=5976&cHash=bb73c03f844decf7904df2c532e2e870 (accessed on 25 July 2025).

- Die Papierindustrie e.V (Ed.). (2025a). Leistungsbericht PAPIER 2025. Available online: https://www.papierindustrie.de/fileadmin/0002-PAPIERINDUSTRIE/07_Dateien/XX-LB/PAPIER_2025_Leistungsbericht_digital.pdf (accessed on 9 August 2025).

- Die Papierindustrie e.V. (2025b). Halbjahresbilanz 2024 der deutschen Papier- und Zellstoffindustrie. Available online: https://www.papierindustrie.de/presse/pressedetails?tx_news_pi1%5Baction%5D=detail&tx_news_pi1%5Bcontroller%5D=News&tx_news_pi1%5Bnews%5D=6106&cHash=3e9831f72965fd7dc830f91f7efbee7f (accessed on 25 July 2025).

- DIN Deutsches Institut für Normung e.V. (2015a). Qualitätsmanagementsysteme—Anforderungen (DIN EN ISO 9001). DIN Media GmbH.

- DIN Deutsches Institut für Normung e.V. (2015b). Umweltmanagementsysteme—Anforderungen mit Anleitung zur Anwendung (DIN EN ISO 14001). DIN Media GmbH.

- DIN Deutsches Institut für Normung e.V. (2018). Energiemanagementsysteme—Anforderungen mit Anleitung zur Anwendung (DIN EN ISO 50001). DIN Media GmbH.

- DIN Deutsches Institut für Normung e.V. (2019a). Treibhausgase—Carbon Footprint von Produkten—Anforderungen an und Leitlinien für Quantifizierung (ISO 14067). DIN Media GmbH.

- DIN Deutsches Institut für Normung e.V. (2019b). Treibhausgase—Teil 1: Spezifikation mit Anleitung zur quantitativen Bestimmung und Berichterstattung von Treibhausgasemissionen und Entzug von Treibhausgasen auf Organisationsebene (ISO 14064-1:2018); Deutsche und Englische Fassung EN ISO 14064-1:2018 (DIN EN ISO 14064-1). DIN Media GmbH.

- DIN Deutsches Institut für Normung e.V. (2019c). Vliesstoffe—Wörterbuch (DIN EN ISO 9092). DIN Media GmbH.

- DIN Deutsches Institut für Normung e.V. (2020a). Leitfaden zur gesellschaftlichen Verantwortung (DIN EN ISO 26000). DIN Media GmbH.

- DIN Deutsches Institut für Normung e.V. (2020b). Umweltmanagement—Ökobilanz—Anforderungen und Anleitungen (DIN EN ISO 14044). DIN Media GmbH.

- DIN Deutsches Institut für Normung e.V., DKE Deutsche Kommission Elektrotechnik Elektronik und Informationstechnik & VDI Verein Deutscher Ingenieure e.V. (Eds.). (2023). Deutsche Normungsroadmap Circular Economy. DKE. [Google Scholar]

- Directorate-General for Communication of the European Comission (Ed.). (2025). European platform on LCA. Available online: https://eplca.jrc.ec.europa.eu/EnvironmentalFootprint.html (accessed on 16 July 2025).

- Ellen MacArthur Foundation (Ed.). (2013). Towards the circular economy Vol. 1: An economic and business rationale for an accelerated transition. Available online: https://www.ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 23 May 2025).

- Ellen MacArthur Foundation (Ed.). (2017). A new textiles economy—Redesigning fashions future. Available online: https://www.ellenmacarthurfoundation.org/a-new-textiles-economy (accessed on 23 May 2025).

- Enit Energy IT Systems GmbH (Ed.). (2025). Was ist eine CO2-Bilanz? Wie läuft eine CO2-Bilanzierung konkret ab? Available online: https://enit.io/de/wissen/knowledgebase/co2-bilanz (accessed on 11 August 2025).

- Europäische Kommission. (2019). Der europäische Grüne deal. Mitteilung der Komission an das Europäische Parlament, den Europäischen Rat, den Rat, den Europäischen Wirtschafts- und Sozialausschuss und den Ausschuss der Regionen. [Google Scholar]

- European Commission. (2019). The European green deal. Available online: https://commission.europa.eu/document/daef3e5c-a456-4fbb-a067-8f1cbe8d9c78_de (accessed on 29 June 2025).

- European Commission (Ed.). (2020a). Eine neue Industriestrategie für Europa [Mitteilung der Komission an das europäische Parlament, den europäischen Rat, den europäischen Wirtschafts- und Sozialausschuss]. Europäische Kommission. Available online: https://eur-lex.europa.eu/legal-content/DE/TXT/PDF/?uri=CELEX:52020DC0102 (accessed on 24 July 2025).

- European Commission. (2020b). A new circular economy action plan. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0098 (accessed on 22 October 2025).

- European Commission. (2021). Communication from the commission to the European parliament, the council, the European econocmic and social committee and the committee of the regions: Updating the 2020 new industrial strategy: Building a sronger single market for Europe’s recovery. European Commission. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52021DC0350 (accessed on 29 October 2025).

- European Commission. (2022a). Der Grüne deal: Neue Vorschläge, um nachhaltige Produkte zur Norm zu [Press release]. Available online: https://ec.europa.eu/commission/presscorner/api/files/document/print/de/ip_22_2013/IP_22_2013_DE.pdf (accessed on 24 July 2025).

- European Commission. (2022b). Neue vorschläge, um nachhaltige Produkte zur Norm zu machen [Press release]. Available online: https://ec.europa.eu/commission/presscorner/detail/de/ip_22_2013 (accessed on 6 March 2025).

- European Commission. (2022c). EU strategy for sustainable and circular textiles [Press release]. Available online: https://environment.ec.europa.eu/document/download/74126c90-5cbf-46d0-ab6b-60878644b395_en?filename=COM_2022_141_1_EN_ACT_part1_v8.pdf (accessed on 24 July 2025).

- European Commission. (2023a). Transition pathway for the textiles ecosystem. Publications Office of the European Union. [Google Scholar] [CrossRef]

- European Commission. (2023b). Ergänzung der Richtlinie 2013/34/EU durch Standards für die Nachhaltigkeitsberichterstattung. Available online: http://data.europa.eu/eli/reg_del/2023/2772/oj (accessed on 18 September 2025).

- European Commission. (2024). Directive on corporate sustainability due diligence and amending directive and regulation (CSDDD). Available online: https://commission.europa.eu/business-economy-euro/doing-business-eu/sustainability-due-diligence-responsible-business/corporate-sustainability-due-diligence_en (accessed on 22 October 2025).

- European Parliament & Council of the European Union. (2009). On the voluntary participation by organisations in a community Eco-Management and Audit Scheme (EMAS): European parliament. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32009R1221 (accessed on 25 July 2025).

- European Parliament & Council of the European Union. (2022). Directives: Directive (EU) 2022/2464 of the European Parliament and of the Council. Official Journal of the European Union (L 322/15). Available online: https://eur-lex.europa.eu/legal-content/DE/TXT/?uri=uriserv:OJ.L_.2022.322.01.0015.01.DEU (accessed on 25 July 2025).

- Falck, O., Guo, Y. M., & Pfaffl, C. (2024). Lost Economic Output Due to High Bureaucratic Burden. EconPol Forum, 2024, 31–35. Available online: https://www.ifo.de/DocDL/econpol-forum-2024-6-falck-guo-pfaffl-eu-regulation.pdf (accessed on 26 May 2025).

- Francisco Bertinetti Lengler, J., João Bettencourt Gomes de Carvalho, M., & José dos Santos António, N. (2013). Integration of sustainable development in the strategy implementation process: Proposal of a model. Corporate Governance: The International Journal of Business in Society, 13, 511–526. [Google Scholar] [CrossRef]

- Fuchs, J., Söhnlein, D., & Weber, B. (2021). IAB-Kurzbericht—Aktuelle Analysen aus dem Institut für Arbeitsmarkt- und Berufsforschung (Institut für Arbeitsmarkt- und Berufsforschung (IAB) der Bundesagentur für Arbeit Ed.). [Google Scholar]

- Garz, H., Schnella, F., & Frank, R. (2010). Kpis for ESG: A guideline for the integration of ESG into financial analysis and corporate valuation, version 3.0. Key performance indicators for environmental, social & governance issues. DVFA; The European Federation of Financial Analysts Societies (EFFAS). [Google Scholar]

- Ghodbanan, S., Alizadeh, R., & Shafiei, S. (2015). Steady-state modeling of multi-cylinder dryers in a corrugating paper machine. Drying Technology, 33, 1474–1490. [Google Scholar] [CrossRef]

- Giungato, P., Moramarco, B., Rana, R. L., & Tricase, C. (2024). Carbon footprint of FFP2 protective facial masks against SARS-CoV-2 used in the food sector: Effect of materials and dry sanitisation. British Food Journal, 126, 33–47. [Google Scholar] [CrossRef]

- Global Reporting Initiative, United Nations Global Compact & World Business Council for Sustainable Development (Eds.). (2015). SDG Compass—Leitfaden für Unternehmensaktivitäten zu den SDGs. World Business Council for Sustainable Development (WBCSD). [Google Scholar]

- Goswami, P., & O’Haire, T. (2016). Developments in the use of green (biodegradable), recycled and biopolymer materials in technical nonwovens. In Advances in Technical Nonwovens (pp. 97–114). Elsevier. [Google Scholar] [CrossRef]

- Grebe. (2014). Technische Textilien—Branchenbericht (Commerzbank AG Ed.). [Google Scholar]

- Grober, U. (2007). Deep roots—A conceptual history of ‘sustainable development’ (Nachhaltigkeit). Available online: https://nbn-resolving.org/urn:nbn:de:0168-ssoar-110771 (accessed on 6 October 2025).

- Hauff, M. v. (2021). Nachhaltige entwicklung: Grundlagen und umsetzung (3., überarbeitete und erweiterte Auflage). De Gruyter Oldenbourg. [Google Scholar]

- Hinrichs, B. (2023). Nachhaltigkeit als unternehmensstrategie. Haufe. [Google Scholar] [CrossRef]

- Holik, H. (2013). Handbook of paper and board (2nd ed.). John Wiley & Sons Incorporated. [Google Scholar] [CrossRef]

- Holzbaur, U., & Fierke, M. (2022). Nachhaltige Entwicklung im Unternehmen. In U. Holzbaur, & M. Fierke (Eds.), Essentials. Nachhaltiges projektmanagement (pp. 7–12). Springer Fachmedien Wiesbaden. [Google Scholar] [CrossRef]

- ISO International Organization for Standardization. (2013). Treibhausgase—Quantifizierung und Berichterstattung von Treibhausgasemissionen für Organisationen—Leitfaden für die Anwendung der ISO 14064-1 (ISO/TR 14069). International Organization for Standardization.

- ISO International Organization for Standardization. (2023). Management des Klimawandels—Übergang zu Netto-Null—Teil 1: Treibhausgasneutralität (ISO 14068-1). International Organization for Standardization.

- Javied, T., Bakakeu, J., Gessinger, D., & Franke, J. (2018, April 23–26). Strategic energy management in industry 4.0 environment. 2018 Annual IEEE International Systems Conference (SysCon) (pp. 1–4), Vancouver, BC, Canada. [Google Scholar] [CrossRef]

- Jovanović, B., & Filipović, J. (2016). ISO 50001 standard-based energy management maturity model—Proposal and validation in industry. Journal of Cleaner Production, 112, 2744–2755. [Google Scholar] [CrossRef]

- Kadner, S., Kobus, J., Hansen, E. G., Akinci, S., Elsner, P., Hagelüken, C., Jaeger-Erben, M., Kick, M., Kwade, A., Müller-Kirschbaum, T., Kühl, C., Obeth, D., Schweitzer, K., Stuchtey, M., Vahle, T., Weber, T., Wiedemann, P., Wilts, H., & von Wittken, R. (2021). Circular economy Roadmap für Deutschlandacatech—Deutsche Akademie der Technikwissenschaften. SYSTEMIQ Ltd.; Circular Economy Initiative Deutschland. [Google Scholar] [CrossRef]

- Kır, A., Ozturk, E., Yetis, U., & Kitis, M. (2024). Resource utilization in the sub-sectors of the textile industry: Opportunities for sustainability. Environmental Science and Pollution Research International, 31, 25312–25328. [Google Scholar] [CrossRef]

- Kleinekorte, J., Fleitmann, L., Bachmann, M., Kätelhön, A., Barbosa-Póvoa, A., von der Assen, N., & Bardow, A. (2020). Life cycle assessment for the design of chemical processes, products, and supply chains. Annual Review of Chemical and Biomolecular Engineering, 11, 203–233. [Google Scholar] [CrossRef]

- Kurz, R., & Wild, W. (2015). Nachhaltigkeit und Unternehmen. Uwf UmweltWirtschaftsForum, 23, 323–328. [Google Scholar] [CrossRef]

- Laurijssen, J., de Gram, F. J., Worrell, E., & Faaij, A. (2010). Optimizing the energy efficiency of conventional multi-cylinder dryers in the paper industry. Energy, 35, 3738–3750. [Google Scholar] [CrossRef]

- Madreiter, T., & Ansari, F. (2024). From OEE to OSEE: How to reinforce production and maintenance management indicator systems for sustainability? IFAC-PapersOnLine, 58, 204–209. [Google Scholar] [CrossRef]

- Mann, C., Schäfer, M., & Rückert-John, J. (2017). Kernelemente einer Governance-Strategie für eine nachhaltige Gesellschaftstransformation. In J. Rückert-John, & M. Schäfer (Eds.), Innovation und Gesellschaft. Governance für eine Gesellschaftstransformation: Herausforderungen des Wandels in Richtung nachhaltige Entwicklung (pp. 45–67). Springer VS. [Google Scholar]

- McIntyre, K. (2021). Sustainability efforts continue: Throughout the supply chain nonwovens-related companies are working on making greener products. Nonwovens Industry, 52, 46–53. [Google Scholar]

- McIntyre, K. (2022). Sustainability report: Report suppliers to nonwovens producers continue to focus on ways to make their clients’ products more sustainable. Nonwovens Industry, 53, 28–36. [Google Scholar]

- McIntyre, K. (2024). Recycling report: Despite challenges, companies continue to look at viable end-of-life solutions for absorbent hygiene products. Nonwovens Industry, 55, 30–33. [Google Scholar]

- Meulen, P. a. d., Christiaans, T., Wilke, C. B., & Wohlmann, M. (2024). Volkswirtschaftslehre. Springer Fachmedien Wiesbaden. [Google Scholar] [CrossRef]

- Michael, C., & Safacas, A. (2003, June 9–11). Analysis of a drive system consisting of two DC motors driving the Yankee drying cylinder of a tissue paper machine. ISIE 2003: 2003 IEEE International Symposium on Industrial Electronics (pp. 1026–1031), Rio de Janeiro, Brasil. [Google Scholar] [CrossRef]

- Mieck, K.-P., Beckmann, E., Ortlepp, G., Albrecht, W., Fuchs, H., Guobiao, J., & Gulich, B. (2012). Faserstoffe. In H. Fuchs, & W. Albrecht (Eds.), Vliesstoffe: Rohstoffe, Herstellung, Anwendung, Eigenschaften, Prüfung (2nd ed., Vol. 1, pp. 21–60). Wiley-VCH. [Google Scholar]

- Moock, P. (2024). Nachhaltigkeit im Unternehmenskontext und die Relevanz für mittelständische Unternehmen. In P. Moock (Ed.), SDG—Forschung, Konzepte, Lösungsansätze zur Nachhaltigkeit. SDGs im Mittelstand (pp. 1–14). Springer. [Google Scholar] [CrossRef]

- Mordor Intelligence (Ed.). (2024). Marktgrößen- und Marktanteilsanalyse für Vliesstoffe—Wachstumstrends und Prognose (2024–2029). Available online: https://www.mordorintelligence.com/de/industry-reports/nonwoven-fabric-market (accessed on 26 May 2025).

- Nakajima, S. (1988). Introduction to TPM: Total productive maintenance. Productivity Press. [Google Scholar]

- Naujock, H.-J., & Blechschmidt, J. (Eds.). (2021). Taschenbuch der Papiertechnik (3., neu bearbeitete und erweiterte Auflage). Hanser. [Google Scholar]

- Osterwalder, A., & Pigneur, Y. (Eds.). (2010). Business model generation: A handbook for visionaries, game changers, and challengers. Wiley. [Google Scholar]

- Othen, R., Sejdija, J., Prinz, M., Zehnpfund, A., Schlake, J., Song, C., Schmeiser, A., Kayser, P., Möbitz, C., & Gries, T. (2023). Decarbonisation in the paper industry: A scalable digital approach for CO2eq transparency, energy efficiency, and flexibilisation. Atp Magazin, 67, 40–51. [Google Scholar] [CrossRef]

- Page, M. J., McKenzie, J. E., Bossuyt, P. M., Boutron, I., Hoffmann, T. C., Mulrow, C. D., Shamseer, L., Tetzlaff, J. M., Akl, E. A., Brennan, S. E., Chou, R., Glanville, J., Grimshaw, J. M., Hróbjartsson, A., Lalu, M. M., Li, T., Loder, E. W., Mayo-Wilson, E., McDonald, S., … Moher, D. (2021). The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Systemic Reviews, 10, 89. [Google Scholar] [CrossRef]

- Pathak, P., & Sharma, C. (2023). Processes and problems of pulp and paper industry: An overview. Physical Sciences Reviews, 8, 299–325. [Google Scholar] [CrossRef]

- Pinelli, M., & Maiolini, R. (2017). Strategies for sustainable development: Organizational motivations, stakeholders’ expectations and sustainability agendas. Sustainable Development, 25, 288–298. [Google Scholar] [CrossRef]

- Prigneaux, J. (2023). 2022 Nonwovens market insights: Production & deliveries in greater Europe. European Disposable and Nonwovens Association (EDANA). [Google Scholar]

- Prigneaux, J. (2024). 2023 Nonwovens market insights. European Disposable and Nonwovens Association (EDANA). [Google Scholar]

- Prigneaux, J. (2025). 2024 Nonwovens market insights. European Disposable and Nonwovens Association (EDANA). [Google Scholar]

- Rouhento, V. (2023). The oulook of current sustainable business models for single-use nonwovens. Tampere University of Applied Sciences. Available online: https://www.theseus.fi/handle/10024/791809 (accessed on 26 May 2025).

- Röhl, K.-H. (2020). Bürokratieabbau und bessere Rechtsetzung: Wer macht was in EU, bund und Ländern? Available online: https://www.econstor.eu/handle/10419/211477 (accessed on 26 May 2025).

- Russell, S. J. (Ed.). (2022). The textile institute book series handbook of nonwovens (2nd ed.). Woodhead Publishing an imprint of Elsevier. [Google Scholar] [CrossRef]

- Rüger, J., & Buchheim, A. (2021). Klimaschutz in Zahlen. Bundesminsterium für Umwelt Naturschutz Bau und Reaktorsicherheit. Available online: http://www.christianwillim.de/app/download/5824929296/klimaschutz_zahlen_2021_bf.pdf (accessed on 29 October 2025).

- Schaltegger, S. (2005, November). Nachhaltiges Wirtschaften aus Sicht des “business case of sustainability”: Ergebnispapier zum Fachdialog des Bundesumweltministeriums (BMU) am 17. November 2005. CSM. Available online: http://fox.leuphana.de/portal/de/publications/nachhaltiges-wirtschaften-aus-sicht-des-business-case-of-sustainability(fea1b766-1191-42cd-8485-cdb1b0dc5587).html (accessed on 29 October 2025).

- Schimmel. (2020). Energiewende in der Industrie: Potenziale und Wechselwirkungen mit dem Energiesektor (Branchensteckbrief der Papierindustrie Navigant Energy Germany GmbH Forschungsgesellschaft für Energiewirtschaft BBG und Partner & Universität Stuttgart Eds.). Available online: https://www.bundeswirtschaftsministerium.de/Redaktion/DE/Downloads/E/energiewende-in-der-industrie-ap2a-branchensteckbrief-papier.pdf?__blob=publicationFile&v=4 (accessed on 25 July 2025).

- Schlichter, S., Rübenach, B., Morgner, J., Bernhardt, S., Kittelmann, W., Schäffler, M., Gulich, B., Krčma, R., Macková, I., Erth, H., Schilde, W., Blechschmidt, D., Dauner, M., & Steinbach, U. (2012). Trockenverfahren. In H. Fuchs, & W. Albrecht (Eds.), Vliesstoffe: Rohstoffe, Herstellung, Anwendung, Eigenschaften, Prüfung (2nd ed., Vol. 4, pp. 123–228). Wiley-VCH. [Google Scholar]

- Schunz, S. (2022). The ‘European Green Deal’—A paradigm shift? Transformations in the European Union’s sustainability meta-discourse. Political Research Exchange, 4, 2085121. [Google Scholar] [CrossRef]

- Seller, & Upmeier. (2023). Das Lieferkettensorgfaltspflichtengesetz wirkt—Aber vielfach nicht, wie gewünscht (DIHK Ed.). Available online: https://www.dihk.de/de/aktuelles-und-presse/aktuelle-informationen/nachhaltigkeit-sollte-nicht-auf-kosten-der-diversifizierung-gehen-97880 (accessed on 29 October 2025).

- Sivill, L., & Ahtila, P. (2009). Energy efficiency improvement of dryer section heat recovery systems in paper machines—A case study. Applied Thermal Engineering, 29, 3663–3668. [Google Scholar] [CrossRef]

- Statista Market Insights. (2024). Windeln—Europa, Afrika, Nordamerika, Europa. Available online: https://de.statista.com/outlook/cmo/haushalts-hygienepapier/windeln/europa (accessed on 23 May 2025).

- Statistisches Bundesamt. (2022). Durchschnittlicher Bruttomonatsverdienst von vollzeitbeschäftigten Arbeitnehmern in Deutschland von 1991 bis 2021. Statista GmbH. Available online: https://de.statista.com/statistik/daten/studie/237674/umfrage/durchschnittlicher-bruttomonatsverdienst-eines-arbeitnehmers-in-deutschland/ (accessed on 25 January 2024).

- Statistisches Bundesamt. (2023). Durchschnittlicher Bruttomonatsverdienst in der deutschen Textilindustrie in den Jahren 1996 bis 2022 (in Euro). Statista GmbH. Available online: https://de.statista.com/statistik/daten/studie/253675/umfrage/durchschnittliche-monatsverdienste-in-der-deutschen-textilindustrie/ (accessed on 25 January 2024).

- Stevens, G. (2018). Environmental claims guidelines. European Disposable and Nonwovens Association (EDANA). Available online: https://www.edana.org/how-we-take-action/edana-sustainability-iniatives-faq/edana-environmental-claims (accessed on 23 May 2025).

- Stevens, G., & Tuncki, C. (2019). Sustainability report. European Disposable and Nonwovens Association (EDANA). [Google Scholar]

- Suhr, M., Klein, G., Kourti, I., Gonzalo, M. R., Santonja, G. G., Roudier, S., & Sancho, L. D. (2015). Best available techniques (BAT) reference document for the production of pulp, paper and board: Industrial emissions directive 2010/75/EU (integrated pollution prevention and control) (JRC science and policy reports JRC95678). Publications Office of the European Union. [Google Scholar] [CrossRef]

- Textile Exchange (Ed.). (2023). Materials market report 2023. Textile Exchange. [Google Scholar]

- The Fiber Year Consulting GmbH (Ed.). (2023). The fiber year 2023: World survey on textiles & nonwovens. Available online: https://www.ivc-ev.de/de/shop/fiber-year-20222023 (accessed on 23 May 2025).

- Treppe, K., Zelm, R., Schinke, L., Kuitunen, S., Pinnau, S., Kamischke, R., & Dixit, O. (2012). Energetische Optimierung der Trockenpartie: Wärmetechnische Bewertung zur Steigerung der Energieeffizienz. INFOR-Projekt Nr. 117. Technische Universität Dresden. Available online: https://tu-dresden.de/ing/maschinenwesen/ifvu/ressourcen/dateien/tvu/forschungsprojekte/forschung_alt/INFOR117/Bericht_INFOR117.pdf?lang=de (accessed on 25 July 2025).

- TWE GmbH & Co. KG (Ed.). (2023). GHG inventory TWE group SBTi data. Available online: https://www.twe-group.com/fileadmin/Downloads/White_Paper/TWE_SBTi_GHG_FINAL_V4_New_Data.pdf (accessed on 10 October 2024).

- Umwelt Bundesamt. (2000). Integrierte Vermeidung und Verminderung der Umweltverschmutzung (IVU): Referenzdokument über die Besten Verfügbaren Techniken in der Zellstoff- und Papierindustrie. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/419/dokumente/bvt_zellstoff-papierindustrie_vv.pdf (accessed on 25 July 2025).

- Umweltbundesamt & Bundesministerium für Umwelt, Naturschutz und nukleare Sicherheit (Eds.). (2019). Energiemanagementsysteme in der Praxis: Vom Energieaudit zum Managementsystem nach ISO 50001: Leitfaden für Unternehmen und Organisationen. Available online: https://www.umweltbundesamt.de/publikationen/energiemanagementsysteme-in-praxis (accessed on 25 July 2025).

- United Nations (Ed.). (2015, September). Transformation unserer Welt: Die Agenda 2030 für nachhaltige Entwicklung. Resolution der Generalversammlung, verabschiedet am 25. [Google Scholar]

- Veit, D. (2022). Fibers. Springer International Publishing. [Google Scholar] [CrossRef]

- Waddock, S. (2020). Achieving sustainability requires systemic business transformation. Global Sustainability, 3, e12. [Google Scholar] [CrossRef]

- Wiertz, P., & Fuchs, H. (2012). Einführung. In H. Fuchs, & W. Albrecht (Eds.), Vliesstoffe: Rohstoffe, herstellung, anwendung, eigenschaften, prüfung (2nd ed., pp. 1–17). Wiley-VCH. [Google Scholar]

- Wilson, A. (2022). Development of the nonwovens industry. In S. J. Russell (Ed.), The textile institute book series. Handbook of nonwovens (2nd ed., Vol. 1, pp. 1–11). Woodhead Publishing an imprint of Elsevier. [Google Scholar]

- World Business Council for Sustainable Development & World Resources Institute. (2004). The greenhouse gas protocol: A corporate accounting and reporting standard (revised ed.). World Resources Institute and World Business Council for Sustainable Development. [Google Scholar]

- Wühle, M. (2022). Nachhaltigkeit messbar machen. Springer. [Google Scholar] [CrossRef]

| Operational Optimization | Organizational Transformation | Systemic Building |

|---|---|---|

| Eco-efficiency | New market opportunities | Societal change |

|

|

|

| Standards | Content | |

|---|---|---|

| Overarching Standards | ESRS 1: General principles ESRS 2: General information | General requirements and regulatory obligations |

| Thematic Standards | Environment: E1: Climate change E2: Environmental pollution E3: Water and marine resources E4: Biodiversity and ecosystems E5: Resource use Social: S1: Own workforce S2: Employees in the value chain S3: Affected community S4: Consumers and end users Corporate governance: G1: Business conduct |

|

| Type of Product | Market Share 2024 [%] | Growth by Segment (2024 vs. 2023) [%] | ||

|---|---|---|---|---|

| By Weight | By Surface Area | By Weight | By Surface Area | |

| Hygiene products | 27.0 | 56.1 | 1.7 | 4.0 |

| Wipes | 20.4 | 15.2 | 3.4 | 1.6 |

| Construction | 15.8 | 6.0 | 9.5 | 24.4 |

| Home and office | 10.2 | 5.0 | −2.5 | −14.0 |

| Filtration | 6.3 | 4.8 | 1 | 0 |

| Transportation | 4.4 | 1.3 | −4.0 | −7.7 |

| Medical | 3.4 | 3.2 | −0.9 | 1.1 |

| Agriculture | 2.0 | 2.7 | 0.3 | −2.4 |

| Other | 10.5 | 5.7 | 15.5 | 42.0 |

| Type of Product | Production Share 2024 (by Weight) [%] | Growth by Segment (2024 vs. 2023) [%] |

|---|---|---|

| Containerboard | 41.1 | 4.5 |

| Packaging and wrapping | 21.8 | 11.2 |

| Printing and writing | 18.6 | 4.9 |

| Tissue | 10.5 | 5.6 |

| Newsprint | 3.5 | −1.8 |

| Other | 4.6 | 5.6 |

| Total | 78,742,000 t | 5.9 |

| Type of Pulp/Paper | Specific Energy Consumption | |

|---|---|---|

| Power [kWh/t] | Heat [kWh/t] | |

| wood-containing paper | 1200–2100 | 1000–2100 |

| coated wood-free paper | 600–1000 | 1200–2100 |

| wood-free speciality paper | 600–3000 | 1600–4500 |

| recycled packaging paper | 300–700 | 1100–1800 |

| recycled graphic paper | 900–1400 | 100–1600 |

| recycled tissue | 800–2000 | 1900–2800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pohlmeyer, F.; Othen, R.; Möbitz, C.; Gries, T. A Review of Energy and Sustainability Management in the Fibre-Based Process Industry. Businesses 2025, 5, 55. https://doi.org/10.3390/businesses5040055

Pohlmeyer F, Othen R, Möbitz C, Gries T. A Review of Energy and Sustainability Management in the Fibre-Based Process Industry. Businesses. 2025; 5(4):55. https://doi.org/10.3390/businesses5040055

Chicago/Turabian StylePohlmeyer, Florian, Rosario Othen, Christian Möbitz, and Thomas Gries. 2025. "A Review of Energy and Sustainability Management in the Fibre-Based Process Industry" Businesses 5, no. 4: 55. https://doi.org/10.3390/businesses5040055

APA StylePohlmeyer, F., Othen, R., Möbitz, C., & Gries, T. (2025). A Review of Energy and Sustainability Management in the Fibre-Based Process Industry. Businesses, 5(4), 55. https://doi.org/10.3390/businesses5040055