The Role of Human Resource Practices for the Development of Operator 4.0 in Industry 4.0 Organisations: A Literature Review and a Research Agenda

Abstract

:1. Introduction

2. Theoretical Framework

2.1. Operator 4.0

- Augmented reality is a technology enriching the real-world factory environment with digital information and media overlaid in real-time in her field of view by head-gear.

- Virtual reality creates a computer-simulated word replicating a manufacturing environment with virtual objects.

- Enterprise social networks, embedded in mobile devices, allow communicating with operators and share real-time information regarding the production status and knowledge about production activities.

- Intelligent personal assistance, a software agent or artificial intelligence, facilitates the interaction with the human-machine interface of I40 technologies, computers, and information systems.

- Big Data refers to a mix of technologies that analyse unstructured or semi-structured data extracted from I40 technologies to discover information about the production process.

- The enabling technologies for physical interactions are [30]

- The smart exoskeleton is a wearable mobile machine that facilitates limb movement with increased strength and endurance through electric motors, pneumatics, and lever.

- Cobots are robots designed to collaborate with humans in safety. Cobots perform various hard muscular, repetitive, and non-ergonomic activities related to the movement and manipulations of objects faster than workers.

2.2. Human Resource Management

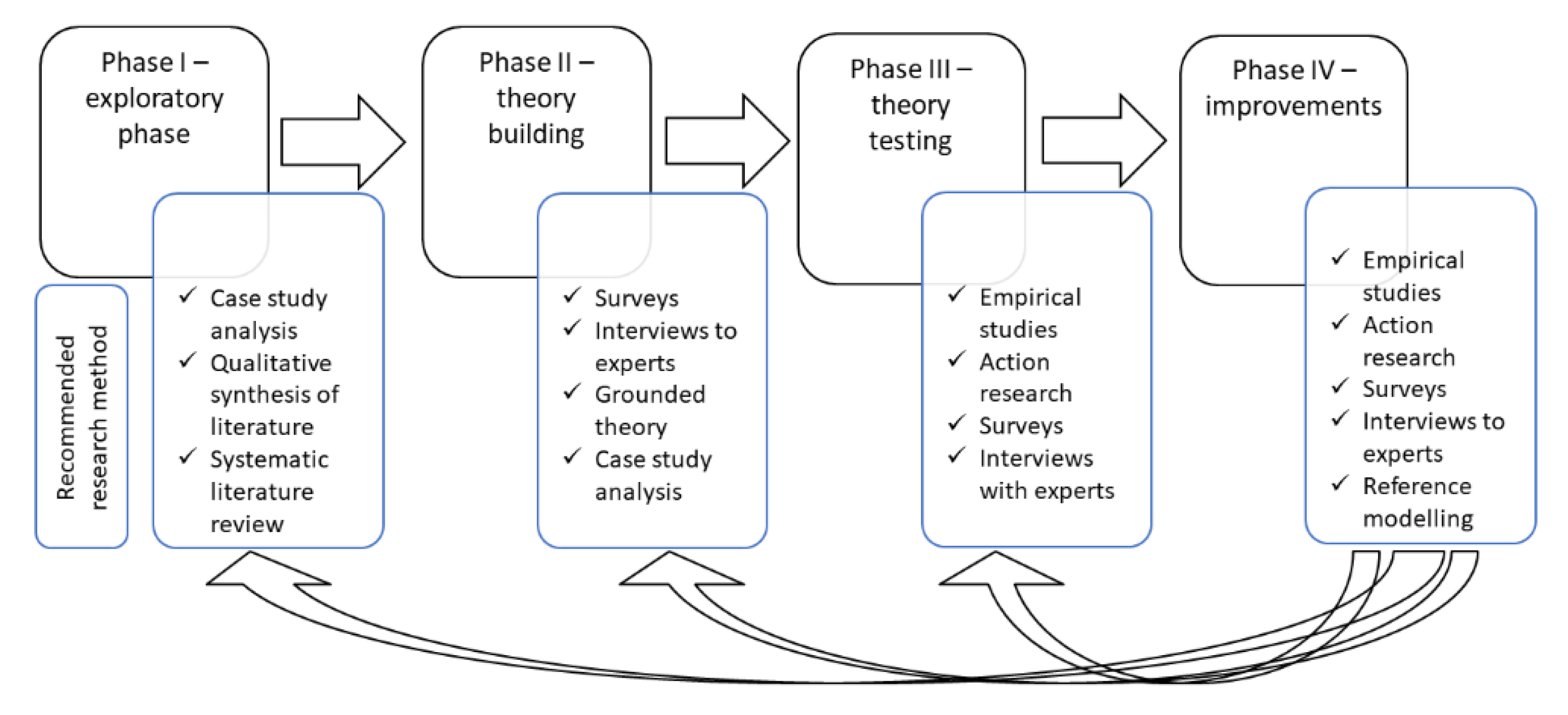

3. Research Design

4. Findings

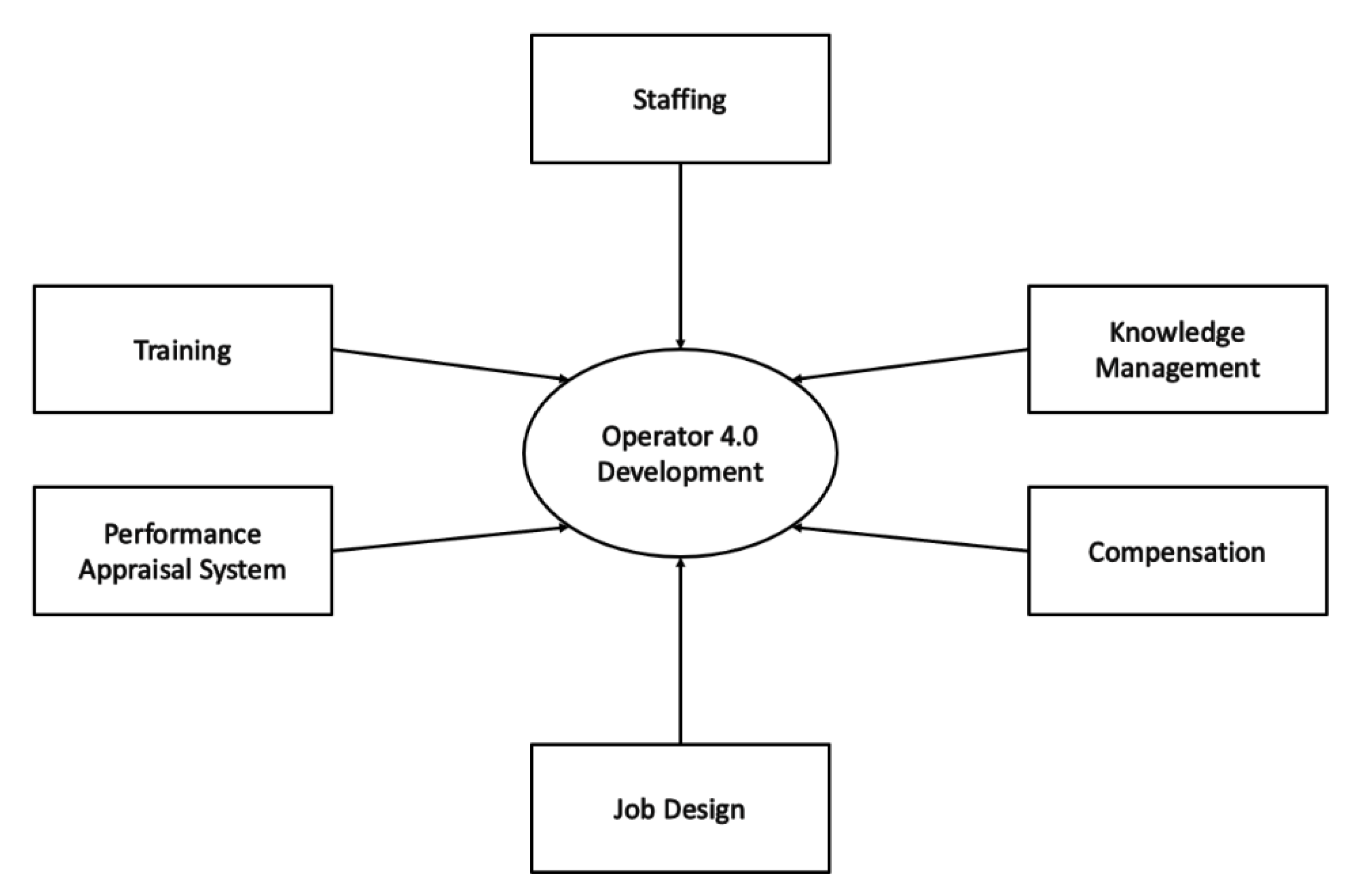

Human Resource Practices for the Development of Operator 4.0

- The super-strength operator is an OP40 who conducts manual tasks—such as handling heavy products—equipped with a smart exoskeleton that reduces worker fatigue and increases operators’ productivity [7].

- The smarter operator is an OP40 in charge of managing I40 technologies with an intelligent personal assistant that facilitates the interaction with the I40 technology interfaces and information systems.

- Augmented and virtual operators are OP40s that conduct manual, mental, and maintenance tasks with augmented reality or virtual reality that provides visual guidance for their tasks and reduces mental and physical effort [23].

- The collaborative operator is in charge of working with I40 technologies along the assembly line—such as cobots of robotised arms—to maintain constant and efficient organisation’s production.

- The analytical operator is the OP40 that examines Big Data extracted from I40 technologies. This operator is in charge of predicting and preventing potential critical events along the assembly line, such as the breaks of machinery pieces or lack of lubrication of the conveyor belt.

5. Discussion

A research Agenda to Advance the Topic of Human Resources Practices for Operator 4.0 Development and Implications for Practitioners

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Birkel, H.; Müller, J.M. Potentials of Industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2021, 289, 125612. [Google Scholar] [CrossRef]

- Margherita, E.G.; Braccini, A.M. Organizational impacts on sustainability of Industry 4.0: A systematic literature review from empirical case studies. In Lecture Notes in Information Systems and Organisation; Springer: Cham, Germany, 2020; pp. 173–186. [Google Scholar]

- Kagermann, H.; Wolfgang, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0. Working Group; Acatech: Frankfurt Am Main, Germany, 2013. [Google Scholar]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Breque, M.; Lars, D.N.; Athanasios, P. Industry 5.0. Available online: https://doi.org/10.2777/308407 (accessed on 15 April 2021).

- Romero, D.; Stahre, J.; Taisch, M. The Operator 4.0: Towards socially sustainable factories of the future. Comput. Ind. Eng. 2020, 139, 106128. [Google Scholar] [CrossRef]

- Li, D.; Fast-Berglund, Å.; Paulin, D. Current and future Industry 4.0 capabilities for information and knowledge sharing. Int. J. Adv. Manuf. Technol. 2019, 105, 3951–3963. [Google Scholar] [CrossRef] [Green Version]

- Margherita, E.G.; Braccini, A.M. Exploring the socio-technical interplay of Industry 4.0: A single case study of an Italian manufacturing organisation. In CEUR Workshop, Proceedings of the 6th International Workshop on Socio-Technical Perspective in IS Development (STPIS 2020), Grenoble, France, 8–9 June 2020; CEUR-WS: Aachen, Germany, 2020. [Google Scholar]

- Romero, D.; Stahre, J.; Wuest, T.; Noran, O.; Bernus, P.; Fast-Berglund, Å.; Gorecky, D. Towards an Operator 4.0 typology: A human-centric perspective on the fourth industrial revolution technologie. In Proceedings of the 46th International Conference on Computers & Industrial Engineering (CIE46), Tianjin, China, 29–31 October 2016. [Google Scholar]

- Mikalef, P.; Pappas, I.O.; Krogstie, J.; Giannakos, M. Big data analytics capabilities: A systematic literature review and research agenda. Inf. Syst. E Bus. Manag. 2018, 16, 547–578. [Google Scholar] [CrossRef]

- Kaasinen, E.; Schmalfuß, F.; Özturk, C.; Aromaa, S.; Boubekeur, M.; Heilala, J.; Heikkilä, P.; Kuula, T.; Liinasuo, M.; Mach, S.; et al. Empowering and engaging industrial workers with Operator 4.0 solutions. Comput. Ind. Eng. 2020, 139, 105678. [Google Scholar] [CrossRef]

- Shamim, S.; Cang, S.; Yu, H.; Li, Y. Management approaches for Industry 4.0. In Proceedings of the IEEE Congress on Evolutionary Computation, CEC 2016, Vancouver, BC, Canada, 24–29 July 2016. [Google Scholar]

- Braccini, A.; Margherita, E. Exploring organizational sustainability of Industry 4.0 under the triple bottom line: The case of a manufacturing company. Sustainability 2019, 11, 36. [Google Scholar] [CrossRef] [Green Version]

- Segura, Á.; Diez, H.V. Barandiaran, I.; Arbelaiz, A.; Álvarez, H.; Simões, B.; Posada, J.; García-Alonso, A.; Ugarte, R. Visual computing technologies to support the Operator 4.0. Comput. Ind. Eng. 2020, 139, 105550. [Google Scholar] [CrossRef]

- Frey, C.B.; Osborne, M.A. The future of employment: How susceptible are jobs to computerisation? Technol. Forecast. Soc. Chang. 2017, 114, 254–280. [Google Scholar] [CrossRef]

- Bonekamp, L.; Sure, M. Consequences of Industry 4.0 on human labour and work organisation. J. Bus. Media Psychol. 2015, 6, 33–40. [Google Scholar]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Analysis of the driving and dependence power of barriers to adopt industry 4.0 in Indian manufacturing industry. Comput. Ind. 2018, 101, 107–119. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.D.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Prause, G.; Atari, S. On sustainable production networks for Industry 4.0. Entrep. Sustain. Issues 2017, 4, 421–431. [Google Scholar] [CrossRef]

- Imperatori, B.; Bissola, R.; Butera, F.; Bodega, D. Work and HRM in the 4.0 era: Insights and research directions. Studi Organ. 2020, 2, 9–26. [Google Scholar] [CrossRef]

- Bulte, A. What is Industry 4.0 and what are its implications on HRM practices? In Proceedings of the 11th IBA Bachelor Thesis Conference, Enschede, The Netherlands, 10 July 2018; pp. 1–23. [Google Scholar]

- Sivathanu, B.; Pillai, R. Smart HR 4.0—How industry 4.0 is disrupting HR. Hum. Resour. Manag. Int. Dig. 2018, 26, 7–11. [Google Scholar] [CrossRef]

- Prieto, I.M.; Pérez-Santana, M.P. Managing innovative work behavior: The role of human resource practices. Pers. Rev. 2014, 43, 184–208. [Google Scholar] [CrossRef]

- Zolotová, I.; Papcun, P.; Kajáti, E.; Miškuf, M.; Mocnej, J. Smart and cognitive solutions for Operator 4.0: Laboratory H-CPPS case studies. Comput. Ind. Eng. 2020, 139, 105471. [Google Scholar] [CrossRef]

- Ruppert, T.; Jaskó, S.; Holczinger, T.; Abonyi, J. Enabling technologies for Operator 4.0: A survey. Appl. Sci. 2018, 8, 1650. [Google Scholar] [CrossRef] [Green Version]

- Romero, D.; Bernus, P.; Noran, O.; Stahre, J.; Berglund, Å.F. The operator 4.0: Human cyber-physical systems & adaptive automation towards human-automation symbiosis work systems. In IFIP Advances in Information and Communication Technology; Springer: New York, NY, USA, 2016; Volume 488, pp. 677–686. [Google Scholar]

- Stern, H.; Becker, T. Concept and evaluation of a method for the integration of human factors into human-oriented work design in cyber-physical production systems. Sustainability 2019, 11, 4508. [Google Scholar] [CrossRef] [Green Version]

- Sorge, A.; Streeck, W. Industrial relations and technical change: The case for an extended perspective. In New Technology and Industrial Relations; Hyman, R., Streeck, W., Eds.; Basil Blackwell: Oxford, UK, 1988; pp. 19–57. [Google Scholar]

- Romero, D.; Wuest, T.; Stahre, J.; Gorecky, D. Social factory architecture: Social networking services and production scenarios through the social internet of things, services and people for the social Operator 4.0. IFIP Adv. Inf. Commun. Technol. 2017, 513, 265–273. [Google Scholar] [CrossRef] [Green Version]

- Tarrar, M.; Thorvald, P.; Fasth-berglund, Å.; Romero, D. Challenges for the Operator 3.0 addressed through the enabling technologies of the Operator 4.0. In Advances in Production Management Systems. Towards Smart and Digital Manufacturing; Proceedings of the APMS 2020 IFIP Advances in Information and Communication Technology, Novi Sad, Serbia, 30 August–3 September 2020; Lalic, B., Majstorovic, V., Marjanovic, U., von Cieminski, G., Eds.; Springer: Cham, Germany, 2020; Volume 592, pp. 1–8. [Google Scholar]

- Romero, D.; Mattsson, S.; Fast-Berglund, Åsa; Wuest, T.; Gorecky, D.; Stahre, J. Digitalizing occupational health, safety and productivity for the Operator 4.0. Secur. Educ. Crit. Infrastruct. 2018, 536, 473–481. [Google Scholar] [CrossRef]

- Gan, J.L.; Yusof, H.M. Industrial revolution 4.0: The human resource practices. Int. J. Recent Technol. Eng. 2019, 8, 620–624. [Google Scholar]

- Margherita, E.G.; Braccini, A.M. Industry 4.0 Technologies in Flexible Manufacturing for Sustainable Organisational Value: Reflections from a Multiple Case Study of Italian Manufacturers. Inf. Syst. Front. 2020. [Google Scholar] [CrossRef]

- Margherita, E.G.; Braccini, A.M. Managing the fourth industrial revolution: A competence framework for smart factory. In Recent Advances in Computational Optimization; Springer: Cham, Germany, 2021; pp. 389–402. [Google Scholar]

- Wuest, T.; Romero, D.; Cavuoto, L.A.; Megahed, F.M. Empowering the workforce in Post–COVID-19 smart manufacturing systems. Smart Sustain. Manuf. Syst. 2020, 4, 5. [Google Scholar] [CrossRef]

- Papcun, P.; Kajati, E.; Koziorek, J. Human machine interface in concept of Industry 4.0. In Proceedings of the 2018 World Symposium on Digital Intelligence for Systems and Machines (DISA), Kosice, Slovakia, 23–25 August 2018; pp. 289–296. [Google Scholar] [CrossRef]

- Ras, E.; Wild, F.; Stahl, C.; Baudet, A. Bridging the skills gap of workers in Industry 4.0 by human performance augmentation tools. In Proceedings of the 10th International Conference on Predictive Models in Software Engineering, Turin, Italy, 17 September 2014; ACM: New York, NY, USA, 2017; Volume Part F128530, pp. 428–432. [Google Scholar]

- Quint, F.; Sebastian, K.; Gorecky, D. A Mixed-reality learning environment. Procedia Comput. Sci. 2015, 75, 43–48. [Google Scholar] [CrossRef] [Green Version]

- Schneider, P. Managerial challenges of Industry 4.0: An empirically backed research agenda for a nascent field. Rev. Manag. Sci. 2018, 12, 803–848. [Google Scholar] [CrossRef]

- Webster, J.; Watson, R.T. Analysing the past to prepare for the future: Writing a literature review. MIS Q. 2002, 26, 129–147. [Google Scholar]

- Scott-Findlay, S.; Estabrooks, C.A. Mapping the organizational culture research in nursing: A literature review. J. Adv. Nurs. 2006, 56, 498–513. [Google Scholar] [CrossRef] [PubMed]

- Flick, U. Introducing Research Methodology: A Beginner’s Guide to Doing a Research Project; SAGE Publications: Thousand Oaks, CA, USA, 2015. [Google Scholar]

- Okoli, C.; Schabram, K. A guide to conducting a systematic literature review of information systems research. SSRN Electron. J. 2010, 10, 2. [Google Scholar] [CrossRef] [Green Version]

- Marvel, M.R.; Davis, J.L.; Sproul, C.R. Human capital and entrepreneurship research: A critical review and future directions. Entrep. Theory Pr. 2014, 40, 599–626. [Google Scholar] [CrossRef]

- Onik, M.; Miraz, M.; Kim, C.-S. A recruitment and human resource management technique using blockchain technology for Industry 4.0. In Proceedings of the Smart Cities Symposium 2018, Chicago, IL, USA, 17–18 January 2018; p. 3. [Google Scholar]

- Waschull, S.; Bokhorst, J.A.C.; Wortmann, J.C. Impact of technology on work: Technical functionalities that give rise to new job designs in Industry 4.0. In Lecture Notes in Control and Information Sciences; Springer: Cham, Germany, 2017; pp. 274–281. [Google Scholar]

- Vrchota, J.; Mařiková, M.; Řehoř, P.; Rolínek, L.; Toušek, R. Human resources readiness for Industry 4.0. J. Open Innov. Technol. Mark. Complex. 2019, 6, 3. [Google Scholar] [CrossRef] [Green Version]

- Alhajjar, A.A.; Muhammed Kassim, R.; Raju, E.; Alnachef, T. Driving Industry 4.0 business through talent man-agement of human resource system: The conceptual framework for banking industry. World J. Res. Rev. 2018, 7, 53–57. [Google Scholar]

- Kadir, B.A.; Broberg, O. Human-centered design of work systems in the transition to industry 4.0. Appl. Ergon. 2021, 92, 103334. [Google Scholar] [CrossRef] [PubMed]

- Gabriel, M.; Pessel, E. Industry 4.0 and sustainability impacts: Critical discussion of sustainability aspects with a special focus on future of work and ecological consequences. Ann. Fac. Eng. Hunedoara 2016, 14, 131–136. [Google Scholar]

- Kraiger, K.; McLinden, D.; Casper, W.J. Collaborative planning for training impact. Hum. Resour. Manag. 2004, 43, 337–351. [Google Scholar] [CrossRef]

- Santhanam, R.; Sasidharan, S.; Webster, J. Using self-regulatory learning to enhance e-learning-based information technology training. Inf. Syst. Res. 2008, 19, 26–47. [Google Scholar] [CrossRef]

- Hecklau, F.; Galeitzke, M.; Flachs, S.; Kohl, H. Holistic approach for human resource management in Industry 4.0. Procedia CIRP 2016, 54, 1–6. [Google Scholar] [CrossRef]

- Van Der Sluis, L.E. Designing the workplace for learning and innovation. Dev. Learn. Organ. Int. J. 2004, 18, 10–13. [Google Scholar] [CrossRef]

- Fettig, K.; Gacic, T.; Koskal, A.; Kuhn, A.; Stuber, F. Impact of Industry 4.0 on organizational structures. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–8. [Google Scholar]

- Chen, C.-J.; Huang, J.-W. Strategic human resource practices and innovation performance—The mediating role of knowledge management capacity. J. Bus. Res. 2009, 62, 104–114. [Google Scholar] [CrossRef]

- Benešová, A.; Tupa, J. Requirements for education and qualification of people in Industry 4.0. Procedia Manuf. 2017, 11, 2195–2202. [Google Scholar] [CrossRef]

- Gehrke, L.; Kühn, A.T.; Rule, D.; Moore, P.; Bellmann, C.; Siemes, S.; Dawood, D.; Lakshmi, S.; Kulik, J.; Standley, M. A discussion of qualifications and skills in the factory of the future: A German and American perspective. VDI ASME Ind. 2015, 4, 1–28. [Google Scholar]

- Rada, M. Industry 5.0—From Virtual to Physical. Available online: https://www.linkedin.com/pulse/industry-50-from-virtual-physical-michael-rada/ (accessed on 11 September 2017).

- Tisch, M.; Hertle, C.; Cachay, J.; Abele, E.; Metternich, J.; Tenberg, R. A systematic approach on developing action-oriented, competency-based learning factories. Procedia CIRP 2013, 7, 580–585. [Google Scholar] [CrossRef] [Green Version]

- Peruzzini, M.; Grandi, F.; Pellicciari, M. Exploring the potential of Operator 4.0 interface and monitoring. Comput. Ind. Eng. 2020, 139, 105600. [Google Scholar] [CrossRef]

- Mavrikios, D.; Papakostas, N.; Mourtzis, D.; Chryssolouris, G. On industrial learning and training for the factories of the future: A conceptual, cognitive and technology framework. J. Intell. Manuf. 2011, 24, 473–485. [Google Scholar] [CrossRef]

- Fletcher, C. Performance appraisal and management: The developing research agenda. J. Occup. Organ. Psychol. 2001, 74, 473–487. [Google Scholar] [CrossRef] [Green Version]

- Denisi, A.S.; Pritchard, R.D. Performance appraisal, performance management and improving individual performance: A motivational framework. Manag. Organ. Rev. 2006, 2, 253–277. [Google Scholar] [CrossRef]

- Militello, L.G.; Hutton, R.J.B. Applied cognitive task analysis (ACTA): A practitioner’s toolkit for understanding cognitive task demands. Ergonomics 1998, 41, 1618–1641. [Google Scholar] [CrossRef]

- Woźniak, M.; Graña, M.; Corchado, E. A survey of multiple classifier systems as hybrid systems. Inf. Fusion 2014, 16, 3–17. [Google Scholar] [CrossRef] [Green Version]

- Davenport, T.H.; Prusak, L. Working Knowledge: How Organisations Manage What They Know; Harvard Business School Press: Boston, MA, USA, 1998. [Google Scholar]

- Pinzone, M.; Albè, F.; Orlandelli, D.; Barletta, I.; Berlin, C.; Johansson, B.; Taisch, M. A framework for operative and social sustainability functionalities in human-centric cyber-physical production systems. Comput. Ind. Eng. 2020, 139, 105132. [Google Scholar] [CrossRef]

- Roblek, V.; Meško, M.; Krapež, A. A complex view of Industry 4.0. SAGE Open 2016, 6, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Gerdin, M.B.; Fast-Berglund, L.D.; Palmquist, A. Knowledge strategies for organization 4.0—A workforce centric approach. In Advances in Production Management Systems. Towards Smart and Digital Manufacturing, Proceedings of the APMS 2020, IFIP Advances in Information and Communication Technology, Novi Sad, Serbia, 30 August–3 September 2020; Lalic, B., Majstorovic, V., Marjanovic, U., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Germany, 2020; Volume 592, pp. 31–36. [Google Scholar]

- Wolf, M.; Kleindienst, M.; Ramsauer, C.; Zierler, C.; Winter, E. Current and future industrial challenges: Demo-graphic change and measures for elderly workers in industry 4.0. Ann. Fac. Eng. Hunedoara Int. J. Eng. 2018, 16, 67–76. [Google Scholar]

- Johnson, R.D.; Stone, D.L.; Lukaszewski, K.M. The evolution of the field of human resource information systems: Co-evolution of technology and hr processes. Commun. Assoc. Inf. Syst. 2016, 38, 533–553. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

| Item | Description |

|---|---|

| Source | Scopus, Google Scholar, and Science Direct |

| Query | TOPIC: “Industry 4.0” OR “Operator 4.0” “AND Human Resourc *” OR “Human Resource Management” OR “Human Resource Practic *”. Refined by: LANGUAGES: (ENGLISH), Subject Area: Business, Management and Accounting, Source Type: Journals |

| Hits | 250 |

Papers retained after:

| 85 30 43 |

| Article | Year | Source Type | HR Practices for OP40 Development | |||||

|---|---|---|---|---|---|---|---|---|

| Staffing | Job Design | Training | Performance AppraisalSystem | Knowledge Management | Compensation | |||

| Romero et al. | 2016 | C. Proc. | √ | |||||

| Marvel et al. | 2016 | Journal | √ | |||||

| Onik et al. | 2018 | C. Proc. | √ | |||||

| Waschull et al. | 2017 | C. Proc. | √ | |||||

| Vrchota et al. | 2020 | Journal | √ | |||||

| Sivathanu and Pillai | 2018 | Journal | √ | √ | √ | |||

| Alhajjar et al. | 2018 | Journal | √ | √ | ||||

| Shamim et al. | 2016 | C. Proc. | √ | √ | √ | √ | √ | |

| Kadir and Broberg | 2021 | Journal | √ | |||||

| Gan and Yusof | 2019 | Journal | √ | √ | ||||

| Gabriel and Pessel | 2016 | Journal | √ | |||||

| Romero et al. | 2018 | C. Proc. | √ | |||||

| Zolotová et al. | 2020 | Journal | √ | |||||

| Braccini and Margherita | 2019 | Journal | √ | |||||

| Kraiger et al. | 2004 | Journal | √ | |||||

| Santhanam et al. | 2008 | Journal | √ | |||||

| Margherita and Braccini | 2021 | Journal | √ | |||||

| Hecklau et al. | 2016 | C. Proc. | √ | |||||

| Van Der Sluis | 2004 | Journal | √ | |||||

| Fettig et al. | 2018 | C. Proc. | √ | |||||

| Chen and Huang | 2009 | Journal | √ | √ | ||||

| Prieto and Pérez-Santana | 2014 | Journal | √ | |||||

| Benešová and Tupa | 2017 | C. Proc. | √ | |||||

| Gehrke | 2015 | Journal | √ | |||||

| Rada | 2015 | Web Article | √ | |||||

| Tisch et al. | 2013 | C. Proc. | √ | |||||

| Peruzzini et al. | 2020 | Journal | √ | |||||

| Mavrikios et al. | 2013 | Journal | √ | |||||

| Fletcher | 2001 | Journal | √ | |||||

| Kaasinen et al. | 2020 | Journal | √ | √ | ||||

| DeNisi and Pritchard | 2006 | Journal | √ | |||||

| Margherita and Braccini | 2020b | Journal | √ | |||||

| Li et al. | 2019 | Journal | √ | √ | ||||

| Militello and Hutton | 1998 | Journal | √ | |||||

| Woźniak et al. | 2014 | Journal | √ | |||||

| Ruppert et al. | 2018 | Journal | √ | |||||

| Davenport and Prusak | 1998 | Journal | √ | |||||

| Pinzone et al. | 2020 | Journal | √ | |||||

| Roblek et al. | 2016 | Journal | √ | |||||

| Gerdin et al. | 2020 | C. Proc. | √ | |||||

| Romero et al. | 2016 | C. Proc. | √ | |||||

| Wolf et al. | 2018 | Journal | √ | |||||

| Johnson et al. | 2016 | Journal | √ | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Margherita, E.G.; Bua, I. The Role of Human Resource Practices for the Development of Operator 4.0 in Industry 4.0 Organisations: A Literature Review and a Research Agenda. Businesses 2021, 1, 18-33. https://doi.org/10.3390/businesses1010002

Margherita EG, Bua I. The Role of Human Resource Practices for the Development of Operator 4.0 in Industry 4.0 Organisations: A Literature Review and a Research Agenda. Businesses. 2021; 1(1):18-33. https://doi.org/10.3390/businesses1010002

Chicago/Turabian StyleMargherita, Emanuele Gabriel, and Ilenia Bua. 2021. "The Role of Human Resource Practices for the Development of Operator 4.0 in Industry 4.0 Organisations: A Literature Review and a Research Agenda" Businesses 1, no. 1: 18-33. https://doi.org/10.3390/businesses1010002

APA StyleMargherita, E. G., & Bua, I. (2021). The Role of Human Resource Practices for the Development of Operator 4.0 in Industry 4.0 Organisations: A Literature Review and a Research Agenda. Businesses, 1(1), 18-33. https://doi.org/10.3390/businesses1010002